1. Introduction

Control charts are a statistical process control (SPC) tool used to monitor a process over time and determine whether a manufacturing or business process is in control or out of control. An in-control process refers to a process that is stable, predictable, and exhibits only random cause variations [

1]. Conversely, an out-of-control process may display various nonrandom patterns on the control chart, indicating the presence of assignable causes that are responsible for variations in process performance [

1]. By understanding the underlying causes, organizations can make informed decisions to improve processes, reduce variation, and enhance product or service quality.

Generally, control charts can be divided into two types: variables control charts and attribute control charts [

1]. The specific type of control chart used depends on the nature of the data being monitored. A variable control chart is used to monitor and control process variability when the data being measured are quantitative and continuous. On the other hand, an attribute control chart is a tool used to monitor and control process quality characteristics that are discrete or qualitative in nature. In SPC, the

control chart is an attribute control chart used to monitor the fraction of nonconforming items in a sample [

1]. The sample fraction nonconforming (also known as nonconforming rate) is defined as the ratio of the number of nonconforming units in a sample (denoted as

) to the sample size (denoted as

). The

control charts have been widely used in monitoring manufacturing processes. Recently, the use of

control charts is increasing in the healthcare industry [

2,

3,

4,

5].

This section provides a brief overview of the

chart. For more details, please refer to Montgomery [

1]. The development of the

chart requires estimating the process fraction nonconforming,

, from a set of historical data because the value of

is typically unknown. This estimation is carried out by selecting

preliminary samples (also known as subgroups), each with a size of

. Denote

as the average of these sample fractions nonconforming. The statistic

is then used to estimate the unknown fraction nonconforming,

. Based on this estimation, the parameters of the

control chart can be expressed as follows:

If the true fraction nonconforming in the production process is known or is a specified standard value, , then the value in Equations (1)–(3) can be replaced with .

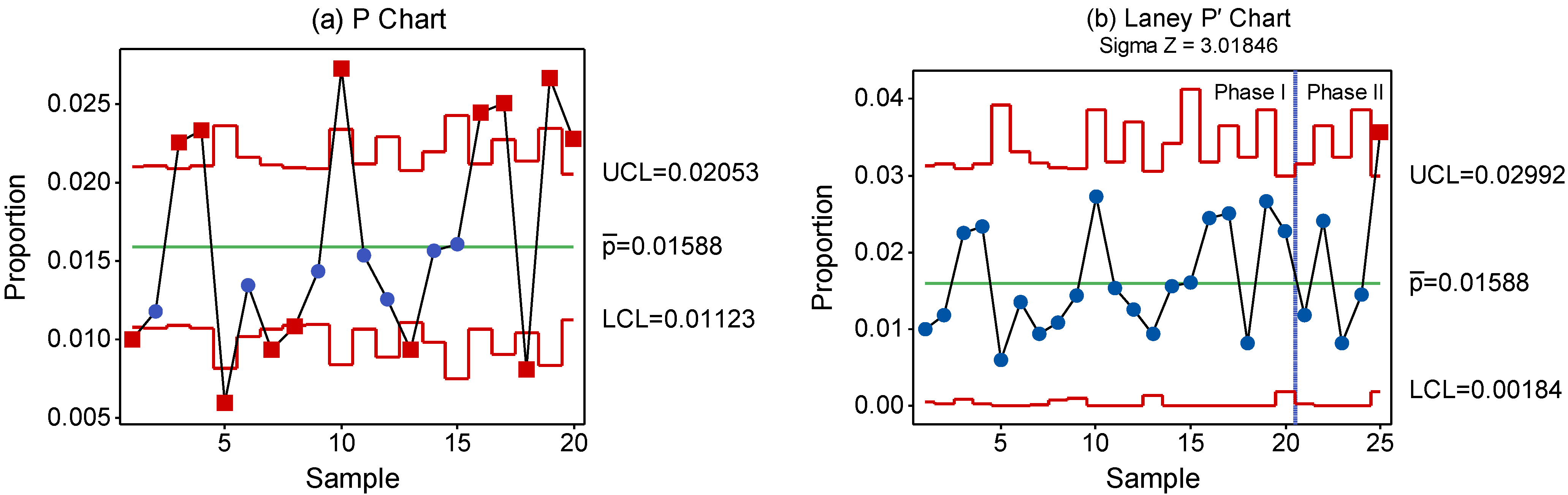

The above description represents the two-phase implementation of control charts. In Phase I, a set of process data is collected and used to estimate the unknown parameters when the process is in control. These estimates are then used to construct the Phase II chart, which monitors the process by plotting the chart statistics and comparing their values to the control limits. It is well known that the more accurate the estimates of the control chart parameters in Phase I, the better the Phase II control chart will perform.

In certain cases where the control chart is used to monitor the fraction of nonconforming items, the sample consists of a complete inspection of the process output during a specific timeframe. Due to variations in the number of units produced during each period, this leads to variable control limits on the chart.

In the past, numerous studies have been conducted to enhance the traditional

control chart. One area of research involves exploring different control charts, such as MA [

6], EWMA [

7], and CUSUM [

8], to improve the ability to detect changes in the nonconforming rate. Another line of research aims to address the issue of ARL-biased characteristics that emerge when using traditional

control charts to detect changes in the nonconforming rate [

9,

10,

11]. A third category of research focuses on employing supplementary rules to enhance the detection capability of traditional

control charts [

9,

12,

13]. The final research direction aims to modify the traditional

control chart to address the issue of variation in nonconforming rates between samples. This aspect is also the primary focus of our study.

It is important to note that the traditional control chart assumes that the samples are independent and that the probability of nonconforming is constant over time. If these assumptions are not met, it may be necessary to consider alternative control charts. For instance, in the healthcare application of SPC methods, one issue that raises concern is that of overdispersion. Overdispersion commonly arises in the cases when sample sizes are very large and the parameter (event probability) is not constant but changes over time.

The Laney

chart [

14] is a new type of attribute control chart that is particularly useful in scenarios where there are large sample sizes and the data exhibit overdispersion. Overdispersion can lead to false indications of out-of-control points on a traditional

chart. The Laney

chart incorporates both the variation within samples and the variation between consecutive samples in its definition of common cause variation. When there is overdispersion, the control limits on a Laney

chart are wider in comparison to those of a traditional

chart. The wider control limits mean that only significant deviations in the process are identified as out of control.

The Laney chart is also useful in the situation when data exhibit underdispersion. Underdispersion, which can occur with samples of any size, is often caused by a lack of randomness. Underdispersion can result in control limits that are too wide for the data. The Laney chart corrects for underdispersion by calculating narrower control limits.

The calculations for the Laney

chart include

, which is an adjustment for overdispersion or underdispersion. In order to compute

, the sample statistic

is first standardized using Equation (4):

where

The value of

can be estimated as

where

if a moving range of two observations is used.

The average of the moving range of

can be obtained by

where

is the number of samples. The parameters for the Laney

chart are

A value of 1 indicates that no adjustment is necessary and that the Laney control chart is the same as a traditional chart.

Equations (8) and (10) reveal that the utilization of a chart incorporates an extra variance component resulting from the variability in parameter over time, in addition to the conventional calculation of binomial sampling variance.

After conducting a comprehensive literature review, it is evident that a research gap exists regarding the impact of parameter estimation on the performance of the

control chart. Previous studies have primarily focused on evaluating performance solely based on the average run length (ARL). However, when parameters are estimated, the ARL becomes a random variable, necessitating the consideration of both the average value of the average run length (AARL) and the standard deviation of the average run length (SDARL) for performance evaluation [

15,

16]. This is crucial because different practitioners may obtain varying estimates of the process parameters, leading to different ARL values. Consequently, practitioner-to-practitioner variability introduces randomness into the ARL.

The main objective of this study is to evaluate the performance of the chart with estimated parameters based on the AARL and SDARL metrics. We also investigate how the number of samples in Phase I influences the performance of the control chart when the parameters are unknown. Furthermore, we evaluate the performance of the chart when the values of sample size and nonconforming rate are allowed to vary from sample to sample.

The rest of the paper is organized as follows.

Section 2 provides a review of previous studies on the Laney attribute control charts, as well as studies on the performance evaluation of the Laney

control charts, where the parameters are estimated from historical data.

Section 3 outlines the experimental setup and simulation procedure employed in this study.

Section 4 presents the experimental results. In

Section 5, we utilize real data to explain the applications of the Laney

control chart in the PCB and IC substrate industries. Finally,

Section 6 summarizes the findings and proposes potential avenues for future research.

2. Related Work

This section presents a literature review on topics that are relevant to this study, which includes the application of Laney control charts, as well as the research on evaluating the performance of the control chart.

In the past, many researchers have studied the impact of overdispersion or underdispersion on data and proposed solutions. Jones and Govindaraju [

17] pointed out that overdispersion refers to the variability in data exceeding the variability assumed by their probability distribution. They proposed a simple graphical method to verify the distributional assumption of attribute control charts. This method can also indicate whether there is excessive dispersion or underdispersion in the data. They also briefly reviewed the literature on handling process attributes that do not follow the binomial or Poisson distribution.

Laney [

14] introduced the

control chart as a means to prevent negative outcomes resulting from overdispersion in process data. This new type of attribute control chart can also be utilized in cases where a process exhibits insufficient dispersion. Laney demonstrated the application of the

control chart using examples from Heimann [

18] but did not conduct performance testing on this chart. Since its introduction, the Laney

control chart has been widely used in healthcare quality monitoring, particularly in cases with large sample sizes. Mohammed and Laney [

19] further applied the

control chart to monitor overdispersion in healthcare performance data, highlighting its relevance in healthcare quality monitoring.

Sellers [

20] proposed a generalized statistical control chart that can be used to monitor count data for overdispersion or underdispersion. The distributions considered in this study include the binomial, Poisson, and negative binomial distributions.

Vidmara and Blagus [

21] pointed out that the identification of outliers in overdispersed proportion data is crucial for effective healthcare quality monitoring. Their study found that the Laney method produces the lowest rate of false alarms. However, in situations where the sample size is small and the proportion is very low, it is difficult to detect outliers, or when the proportion value is very high, outliers are difficult to detect irrespective of sample size.

Evaluating the microbiological quality of pharmaceutical products is an important criterion for determining whether they can be safely released into the drug market. Eissa [

22] stated that since the data of the total viable count (TVC) in pharmaceuticals do not follow any specific distribution type, the Laney

control chart is suitable for application in such cases. Eissa [

22] believes that when there is significant overdispersion or underdispersion in the data distribution, the Laney

control chart pattern is highly appropriate for monitoring the microbiological characteristics of pharmaceutical products.

Moon [

23] applied the Laney

control chart to schedule performance management. In this study, planned value costs were considered as the sample size, and each dollar was assumed to represent an attribute (inspection) unit. Earned value cost, which represents the value of work completed to date, was treated as a variable. By dividing the earned value cost by the planned value cost, a schedule performance index (SPI) was obtained. The study treated SPI as a sample statistic and monitored its variation using the Laney

control chart.

Arafah [

24] utilized the Laney

control chart to monitor the variations in the COVID-19 cases in Jordan. The study defined the infection rate (IR) as the number of confirmed cases divided by the number of polymerase chain reaction (PCR) tests conducted. The objective of the research was to understand the effectiveness of the government’s restrictive measures in controlling the infection rate during the COVID-19 pandemic, which included restrictions on population movement and activities. The study results demonstrated that implementing restrictive measures effectively reduced the infection rate, while relaxing these measures had the opposite effect.

Valdés-Manuel and Cogollo-Flórez [

25] pointed out that overdispersion is a phenomenon that frequently occurs in large-sample data analysis. In the analysis of discrete data, it refers to a higher level of variation in the data than what is implied by the reference binomial or Poisson distribution. In clinical laboratories, there is often high variability in the proportion of nonconforming units, leading to the occurrence of overdispersion. Therefore, it is necessary to analyze and identify the most suitable control chart to overcome the limitations of traditional control charts when dealing with overdispersed data.

With the introduction and application of the Laney

control chart, some researchers have recently begun to investigate its performance. Ahsan et al. [

26] used simulation to evaluate and compare the in-control and out-of-control average run lengths for the

and Laney

control charts. Their study aimed to determine whether the performance of the Laney

control chart is superior to that of the

control chart.

Hagan and Li [

27] evaluated the Phase II performance of the Laney

control chart using a simulation approach. Their study allowed for variation in the sample size (

) and process nonconforming rate (

) between samples. The study assumed that

and

followed truncated normal distributions with a mean of

and a standard deviation of

(or

). When

was allowed to vary across subgroups, its simulated value of

was either 0.1 or 0.5. When

was allowed to vary, its simulated value of

μ varied from 10 to 2000. The performance metric was ARL.

The studies of [

26,

27] assumed that the process parameters are known and evaluated the performance of the control chart in Phase II. In other words, these studies did not take into account the impact of parameter estimation errors on the performance of the control chart. Furthermore, it is worth noting that the study conducted by Ahsan et al. [

26] did not consider the variation in the fraction of nonconforming items between samples.

Recently, Goedhart and Woodall [

28] proposed a new method for calculating the control limits of the

chart. They demonstrated that the Laney

chart does not perform well when there are significant variations in subgroup sizes. Laney’s method [

14] only yields appropriate limits when there is no intersubgroup variation. Additionally, they pointed out that the estimated control limits for the

chart are excessively wide for smaller sample sizes and too narrow for larger sample sizes. They showed that their method is able to handle situations involving varying subgroup sizes and intersubgroup variation.

4. Results and Discussion

The aim of this study is to assess the performance of the Laney control chart through various experiments. In this section, we present the results obtained from the simulation experiments. We investigate the effect of between-sample variation on the ARL performance.

Firstly, we consider the performance of the traditional control chart and the Laney control chart under different sample sizes () when the nonconforming rate varies between samples. In this experiment, we assume , which means the average is 0.05. When the sample sizes are 100, 150, 225, 300, and 350, the theoretical values of the chart are 233.96, 277.54, 422.76, 365.86, and 279.28, respectively.

The results of the

chart are presented in

Table 1, while

Table 2 displays the results of the Laney

chart. In general, as the number of Phase I samples increases, the SDARL becomes smaller. The results show that the use of a small number of Phase I samples to estimate the unknown parameters leads to a huge variability in the ARL values, resulting in a very poor chart performance. In this specific case, the variation in the nonconforming rate 𝑝 is not considered significant. It can be observed that the in-control AARL of the 𝑝 control chart and Laney

control chart does not differ significantly when the number of samples 𝑚 is equal to or greater than 1000. However, when the number of samples 𝑚 is small, both the AARL and SDARL of the Laney

control chart will be higher compared to those of the traditional 𝑝 control chart.

When the sample size 𝑛 is large, even if there is not much variation in the nonconforming rate 𝑝, the Laney

control chart will still exhibit higher AARL and SDARL values compared to the traditional 𝑝 control chart. This is evident by comparing column (e) of

Table 1 to column (e) of

Table 2.

The results from

Table 2 also highlight that when the sample size (

) is small (

), the AARL of the Laney

control chart does not reach the

value of the traditional control chart. This observation further illustrates that the Laney

control chart may not adequately widen the control limits when the sample size is relatively small. However, when the sample size (

) is increased to 350, the AARL of the Laney

control chart exceeds the theoretical

value when the number of samples

is 10,000. This indicates that the control limits are excessively widened in this scenario.

Finally, there are some unusual phenomena observed in column (c) of

Table 1 and

Table 2 that need to be explained. By observing

Table 1 and

Table 2, it can be seen that under the combination of

and

in column (c) of

Table 1, the SDARL is noticeably larger than other combinations. Furthermore, column (c) of

Table 2 shows that the SDARL for the Laney

control chart is smaller than the traditional

control chart. After conducting an in-depth investigation, we found that in column (c), under the combination of

and

, there may or may not be a lower control limit. This causes an increase in the variability in in-control ARL, resulting in an increase in SDARL. For columns (a) and (b) of

Table 1, there are no lower control limits under the combination of

and

. Furthermore, for columns (d) and (e) of

Table 1, both combinations of

and

have lower control limits. These phenomena result in smaller variations in ARL for columns (a), (b), (d), and (e), indicating smaller values of SDARL.

Next, we consider the impact on the performance of traditional

control charts and Laney

control charts when the sample size

is fixed, and the nonconforming rate varies within different ranges. We consider the case where the true fraction nonconforming

and sample size

. In this case, the

.

Table 3 presents the in-control AARLs and SDARLs of the

control chart when the process parameters are estimated. On the other hand,

Table 4 shows the in-control AARLs and SDARLs for the Laney

chart.

From panel (a) of

Table 3, when the number of samples,

, exceeds 3000, the AARL of the

control chart approaches the theoretical

value of 365.86. This demonstrates the high accuracy of the simulation program developed in this study.

Although the Laney

control chart is suitable for situations where the nonconforming rate of the process is excessively dispersed, one may be interested in investigating its performance when there is no variation in sample size

and process

. If

is small, one can see from panel (a) of

Table 4 that the

chart may tend to overadjust the control limits, leading to the AARLs higher than the

when the fraction nonconforming remains constant. When

is greater than 2000, the AARL is close to the true ARL value. This can be explained by the fact that the estimate of

is more accurate when

increases. When there is neither overdispersion nor underdispersion in the nonconforming rate, and if the number of Phase I samples (

) is large, the AARL of the

control chart (panel (a) of

Table 4) is close to that of the

control chart (panel (a) of

Table 3). However, the

control chart exhibits a higher SDARL. This is because the

control chart requires an additional estimation of

, leading to greater variability in its performance.

When the control chart parameters are estimated from Phase I samples, it is important to investigate the influence of the number of samples,

, on the size of the SDARL. When using control charts, it is generally recommended to have at least 20 or 25 Phase I samples to estimate the unknown parameters [

1]. However, in this particular case, even with a significantly larger number of samples exceeding 20, the desired performance is not achieved. For instance, when using 50 samples, the AARL of the

chart is 335.73, which corresponds to approximately 91% of the desired

. Additionally, the SDARL is 128.22, approximately 35% of the

. To attain satisfactory performance, it is necessary to utilize 1000 samples, as this yields an AARL of 362.66 (around 99% of the desired

) and an SDARL of 24.61 (approximately 7% of the desired

). In the case of the Laney

control chart, utilizing 5000 samples is recommended, as it produces an AARL of 358.30 (about 98% of the desired

) and an SDARL of 34.91 (approximately 9.5% of the desired

). It is evident that when using the Laney

control chart, we require a larger number of samples to meet the recommended requirements of Zhang et al. [

32].

Next, we investigate the impact of overdispersion in the process fraction nonconforming on the control chart. Overdispersion refers to the variation in data that exceeds the assumed probability distribution. In this experiment, we assume that the average of the fraction nonconforming is fixed, but the variability in the fraction nonconforming is uniformly distributed.

From the results in

Table 3, it can be observed that when the sample size

is fixed, the AARL of the

control chart decreases as the variation in the nonconforming rate increases. From

Table 4, it can be seen that the AARL of the

control chart increases as the variability in nonconforming rate increases. The AARL value has exceeded the case when the nonconforming rate follows a binomial distribution (i.e., no overdispersion or underdispersion), indicating that the control limits are excessively widened.

The above results also show that when there is overdispersion in 𝑝, even if the sample size 𝑛 is not very large, it will result in a much lower in-control ARL than the in-control ARL value of the traditional 𝑝 control chart. In other words, using a traditional 𝑝 control chart in this scenario would lead to an elevation in Type I error.

We will now examine situations where the sample sizes differ from those in the previous experiment, while ensuring that the product of sample size and nonconforming rate remains constant.

Table 5 and

Table 6 display the AARLs and SDARLs of the

chart and Laney

chart with a sample size of 3000 and an average fraction nonconforming of 0.005, respectively. In this scenario, the ARL₀ of the

chart is 290.73.

Furthermore,

Table 7 and

Table 8 present the AARLs and SDARLs of the

chart and Laney

chart, respectively, with a larger sample size of

and an average fraction nonconforming of

. In this case, the ARL₀ of the

chart is 284.51.

Upon comparing

Table 3,

Table 4,

Table 5,

Table 6,

Table 7 and

Table 8, we observe that the conclusions drawn from

Table 3 and

Table 4 are also applicable to

Table 5 and

Table 6, as well as

Table 7 and

Table 8. That is, when the sample size remains constant and the variability in the process nonconforming rate increases, the in-control AARLs of the traditional

control charts decrease. The

chart can address the between-sample variation. The in-control AARLs are close to the advertised values. In some cases, the AARLs may exceed the advertised value.

Next, we consider the scenario where both the sample size,

, and the nonconforming rate,

, are allowed to vary between samples.

Table 9 shows the results of the traditional

control chart, while

Table 10 presents the results of the Laney

control chart. By comparing

Table 5 with

Table 9 and

Table 6 with

Table 10, we can observe that the variation in sample size (

) does not have a significant impact on the AARL performance of both the traditional

control chart and the Laney

control chart. However, it is worth noting that when both

and

vary, it can lead to an increased variability in parameter estimation, as evidenced by the increase in SDARL.

Next, we set a fixed number of samples for the Phase I dataset and examine the influence of sample size on the in-control AARL and SDARL for the

control chart. In this experiment, we consider a wider range of variations in the sample size. Based on previous experiments, it has been found that when the number of samples is 1000 or more, the AARL and SDARL of the

control chart yield better results. Therefore, we fix the number of samples at 1000 and investigate the impact of sample size on AARL and SDARL when there are variations in the nonconforming rate between samples.

Table 11 summarizes the results of the experiment.

From the table, we can observe that the in-control AARL of the traditional control chart is very small, far below the theoretical values of the 3-sigma control chart. This is due to the impact of overdispersion. As the sample size increases, the influence of overdispersion on the in-control AARL becomes more significant. In other words, when there is a high degree of variation in the fraction nonconforming between samples, the reduction in AARL for the control chart becomes more substantial as increases.

Finally, we compare the out-of-control AARL and SDARL of the

chart and Laney

chart. The magnitude of shift considered is represented by a multiple

of

. If the in-control nonconforming rate varies between U(

), the range of variation for the out-of-control mean is U(

) +

. After estimating the control limits using a set of Phase I data, the estimation of the out-of-control ARL is performed. The AARL and SDARL performance of the traditional

chart and the Laney

chart are summarized in

Table 12 and

Table 13, respectively. In this comparison, the number of Phase I samples (

) for the traditional

chart and the Laney

chart is 1000 and 3000, respectively, with a fixed sample size of 3000. The selection of

values for the

chart and the Laney

chart is based on the following rationale. According to

Table 5, it is evident that when the value of 𝑚 is 1000 or higher, the SDARL for the 𝑝 control chart stays within 10% of the expected in-control ARL. Similarly,

Table 6 shows that the Laney

control chart exhibits a similar behavior when the 𝑚 value is 3000 or above.

Table 12 and

Table 13 also include the in-control AARL and SDARL values for ease of comparison.

From

Table 12 and

Table 13, it is observed that both the

chart and Laney

chart exhibit a decrease in AARL as the magnitude of shift increases. When the nonconforming rate is kept fixed among samples, from column (a) of

Table 12 and

Table 13, we can see that the AARLs of the traditional

control chart and the Laney

p′ control chart are very close, but the SDARLs of the Laney

chart are still greater than those of the

chart. As explained earlier, this is because the Laney

p′ control chart requires an additional estimation of

, resulting in an increased variability in ARL. By comparing columns (b) and (c) of

Table 12 and

Table 13, we can observe significant differences in the in-control and out-of-control performance between the traditional

control chart and the Laney

p′ control chart. This is due to variations in the nonconforming rates among different samples, indicating excessive process dispersion. The datasets generated based on the scenarios described in columns (b) and (c) of

Table 12 have been checked using Minitab statistical software (Version 19, Minitab LLC, State College, PA, USA) and the diagnostic method described in [

17]. This confirms the presence of overdispersion. Additionally, comparing column (d) of

Table 12 and

Table 13, we can notice that the in-control and out-of-control performance of the two control charts are very similar. The diagnostic method described in [

17] confirms that overdispersion does not exist.

Based on the above comparison, this study summarizes the advantages and disadvantages of the 𝑝 control chart and the Laney p′ control chart as follows. While the calculation of the 𝑝 control chart is relatively simple, it tends to have a higher Type I error when the nonconforming rate varies between samples. On the other hand, the Laney p′ control chart has the disadvantage of requiring an estimation of the variation in the nonconforming rate between samples. This typically requires a larger number of samples to achieve an accurate parameter estimation. When the number of samples 𝑚 is small, the SDARL for the Laney p′ control chart is higher compared to the traditional 𝑝 control chart. If there is minimal variation in the nonconforming rate between samples, the control limits of the Laney p′ control chart closely resemble those of the traditional 𝑝 control chart. However, due to the need for estimating between-sample variation, the variability in its performance also increases. Additionally, the Laney p′ control chart addresses the issue of overdispersion by widening the control limits. This study found that the Laney p′ control chart can indeed reduce Type I errors caused by overdispersion. However, in some cases, this approach may result in excessively wide control limits, thereby reducing its ability to detect changes in the nonconforming rate.