Abstract

Increasing energy demand and the detrimental environmental impacts of fossil fuels have led to the development of renewable energy sources. Rapid demand growth for wood pellets over the last decade has established wood pellets as a potential renewable energy source in a globally competitive energy market. Integrated decision making including all stakeholders in the wood pellet supply chain (WPSC) is essential for a smooth transition to commercially viable wood pellet production. In this aspect, this study aims to suggest a decision support system for optimizing biomass-based wood pellet production supply chain network design (WPP-SCND). The WPP-SCND decision system minimizes the total supply chain (SC) cost of the system while also reducing carbon emissions associated with wood pellet SC activities. All objective parameters, including biomass availability at the supply terminals, market demand, and biomass production, are considered fuzzy to account for epistemic uncertainty. A fuzzy flexible robust possibilistic programming (fuzzy-FRPP) technique is developed for solving the suggested uncertain WPP-SCND model. The case findings show that the imprecise nature of the parameters has a significant impact on the strategic and tactical decisions in the wood pellet SC. By investing almost 10% of the total cost, robust decisions within the wood pellet SC can be obtained. It is established that the fuzzy-FRPP technique successfully provides robust decisions and achieves a balance between transportation costs, emissions costs, and economies of scale when making capacity decisions. Although the suggested decision support system is used to manage the production and distribution of wood pellets, the insights and solution methodology may be extended to the production of other biofuels. The proposed research may be valuable to authorities involved in planning large-scale wood pellet-related production-distribution projects.

Keywords:

fuzzy optimization techniques; wood pellet supply chain; flexible programming; linear programming MSC:

90C05; 90C08; 90C11

1. Introduction

Major worldwide issues include the energy crisis, population growth, food scarcity, resource depletion, and global warming [1,2]. Given these conditions, recovering resources from waste is essential for reducing dependence on nonrenewable energy sources [3]. A circular economy (CE) plays a crucial role in this regard since it supports the transition from a linear to a circular framework defined by return operations of waste resources. CE seeks to make all operations circular, where no “disposable trash” is produced, and all outputs are inputs for other systems [4,5]. However, a CE alone may not be sustainable. Switching to a bioeconomy (BE) based on renewable resources in conjunction with circular economy (CE) will not only reduce environmental stress but also make CE feasible, resulting in a circular bioeconomy (CRBE) [6]. CRBE entails converting waste materials into products with added value, such as food, biomass, and bioenergy, in order to conserve virgin natural resources. CRBE has both economic and environmental benefits, as recovery of bio-based wastes or byproducts encourages potential reutilization, transforming wastes into marketable goods with added value and enabling economic growth [6,7].

Multiple studies have emphasized the potential importance of biomass in meeting the world energy need through CRBE [8,9,10]. The promotion of CRBE in the context of energy production is supported by the valorization of accessible biomass through biofuel production. Biofuels are carbon-neutral fuels that are more environmentally friendly than fossil fuels [11,12]. Governments throughout the world, however, are taking initiatives to reduce fossil fuel utilization and greenhouse gas (GHG) emissions [13]. In this context, wood pellets are considered a viable energy source due to their multiple advantages, including their high heat value, low moisture content, and portability [14]. Wood pellets are equivalent to other biofuels such as biodiesel and bioethanol in terms of traded volume and are one of the most commonly traded commodities in the world [10]. The market outlook for wood pellets is relatively optimistic: the worldwide pellet market is projected to reach 54 million tons by 2025 [13].

Historically, forest companies were able to profit from their massive harvesting operations, which pushed resources to wood pellet processing plants and then to other markets following a push production system. Now, the push production business strategy is economically unsustainable for both the industry and the forest-dependent communities in light of the current extremely volatile global economy [15]. In addition, sawmill waste, which is often used to manufacture wood pellets, is desired biomass for a range of processes and hence insufficient for meeting demand [13]. Therefore, manufacturers have had to discover new sources of biomass for the manufacturing of wood pellets. In this context, following the CRBE, biomass such as forest harvesting byproducts and agricultural leftovers (wheat straw, rice husk, and bagasse) has tremendous potential to replace sawmill waste. To compete in the market, these feedstock sources are often geographically distributed and must be supplied to wood pellet production facilities cost-effectively, since high production costs are the major barrier to the commercialization of wood pellets [16]. Furthermore, the transportation of biomass and wood pellets in a wood pellet supply chain (WPSC) contributes significantly to carbon emissions. As a result, effective WPSC network design is essential for a quick transition to a circular bioeconomy.

Additionally, wood pellet production SCs are more susceptible to parameter uncertainty than commercial SCs due to highly volatile business dynamics: Wood pellet feedstocks are dependent on primary goods that are largely seasonal, whereas biomass pricing, and logistics costs, are influenced by international variations in fossil fuel prices [17]. Most prior studies do not include the integration of uncertainties associated with biomass supply and transportation, wood pellet manufacturing, and market demand in the optimal design of WPSC. In contrast, most of the previous WPSC design literature has used deterministic methodologies (see: Boukherroub et al. [13], Méndez-Vázquez et al. [16], Mansuy et al. [18], Shabani et al. [19], Kanzian et al. [20], etc.). Failure to account for the uncertain environment during the planning phase may result in a WPSC design that is less than optimal or impractical. Effective uncertainty management related to the materials and operations utilized in the manufacture of wood pellets throughout the whole supply chain allows all stakeholders to enjoy additional economic advantages, which strengthens the operations’ sustainability.

Keeping in mind the abovementioned challenges for a successful transition to a circular bioeconomy, this study addresses the following questions:

- Research question 1: How can an integrated decision support system that efficiently collects, transports, and converts massive quantities of various biomasses into wood pellets be developed in a sustainable manner to support the transition to a circular bioeconomy?

- Research question 2: How can robust decisions for strategic and tactical levels in a wood pellet SC be acquired in a highly uncertain environment?

To answer these research questions, a multi-period wood pellet production supply chain network design (WPP-SCND) model employing a linear programming approach is proposed. The purpose of the suggested optimization model is to minimize the value of the economic objective while taking into account the associated environmental impact costs. The suggested WPP-SCND model decreases the environmental effect and total cost of wood pellet production and distribution while fulfilling demand, resulting in a low-carbon bioeconomy.

2. Research Context

Researchers and practitioners are focusing their attention on renewable energy generation because of the global energy crisis. As a result, there has been increased interest in incorporating circular bioeconomy principles into the development of wood waste-to-energy chains.

Given this context, several researchers have used mathematical modeling-based methods to apply principles of circular bioeconomy considering various types of wood waste. Méndez-Vázquez et al. [16] proposed a nonlinear mixed integer programming (MIP) model to efficiently locate biofuel pellet processing plants in a circular bioeconomy setting. The objectives of overall systems cost reduction and GHG emissions minimization were considered in designing a low-carbon WPSC network. The principles of circular bioeconomy were employed by Mansuy et al. [18] in using fire-killed forest trees in two Canadian forest management units to develop and optimize supply scenarios to meet different pellet plant capacities under multiple operational, ecological, and economic constraints. The authors provided their findings using a deterministic mixed-integer linear programming (MILP) model. Shabani et al. [19] examined various optimization methods for reducing total wood pellet production system costs, as well as conducting a comprehensive analysis of various wood pellet SC-related decisions such as location-allocation and capacity of wood pellet processing facilities, transportation modes, and optimal biomass mix. Kanzian et al. [20] developed a deterministic MILP model for minimizing total wood biomass supply costs to heating plants by considering transportation, processing, and storage costs. The optimization model provided decisions for allocating wood chips to the selected terminals and plants. An et al. [21] devised a strategic and tactical decision-making mathematical model for the design of the lignocellulosic biofuel supply chain, taking into account different types of wood waste as biomass. This study highlights the most economically significant aspects at all levels of the circular bioeconomy. Vasković et al. [22] used the VIKOR multi-criteria decision technique to rank the energy chain of wooden biomass supply and select the best variant in a circular bioeconomy. Cambero and Sowlati [23] proposed a deterministic multi-objective MILP forest-based biomass SC model that takes into account all three dimensions of sustainability to maximize net present value, CO2 emissions savings, and societal welfare. Trochu et al. [24] address the circular bioeconomy under environmental policies by targeting recycled wood materials from the construction and demolition of buildings. The proposed MILP model minimizes the cost of the wood recycling SC by deciding the optimal locations and capacities of wood processing facilities. All aforementioned research addressing the circular bioeconomy by considering different types of wood waste-to-energy generation settings has presented solutions in a deterministic environment while neglecting the related uncertainties.

A few researchers have integrated uncertainty in the planning phase of designing a wood pellet supply chain. In this domain, Mobini et al. [25] developed a simulation model that takes into account the stochastic uncertainty of the environment to assist SC managers in planning a wood pellet SC by encompassing the entire echelon from biomass collection to wood pellet delivery to clients. Akhtari and Sowlati [26] also considered stochastic uncertainties in the wood pellet SC by proposing a hybrid simulation–optimization technique named recursive optimization-simulation. Using this solution approach, the authors integrated strategic, tactical, and operational plans for the wood pellet SC. Boukherroub et al. [13] adopted a generic approach using LogiLab simulation software to choose the best raw material, optimal quantity allocations, and most optimal locations of wood pellet production facilities in order to design a profitable wood pellet SC taking into account economies of scale. Yılmaz Balaman et al. [27] proposed a fuzzy approach-based framework for strategic and tactical level planning in waste biomass-based energy production investments that optimizes several forms of waste, including numerous types of production technologies, in consideration of circular economy principles. A summary of research related to WPSC network design is provided in Table 1.

Investigating wood pellet production-related studies demonstrates that these studies offer comprehensive systems for the wood pellet supply chain but that only a few of them have taken into account the uncertainties associated with biomass availability, transportation, production, and market demand. Because of these uncertainties, some of the supply chain configurations may be impractical or less than optimal. According to Pishvaee et al. [28], there are two types of uncertainties: stochastic and epistemic. Stochastic uncertainty is appropriate for instances when historical data on an uncertain parameter are available for accurately estimating probability distribution, which is not the case in the majority of cases involving wood waste management. As a result, the stochastic method is inappropriate for the considered problem. According to Torabi et al. [29], fuzzy programming is the most effective technique for dealing with imprecise parameters for which stochastic approaches are inapplicable. Keeping this in view, in this study, fuzzy possibilistic programming (FPP) is employed to manage the uncertain parameters of the WPP-SCND model. The FPP approach does not need historic information on ambiguous parameters; rather, a probability distribution for the uncertain parameter is built based on the experience of experts. Moreover, the concept of flexible programming is incorporated into FPP to relax the WPP-SCND model’s uncertain constraints, such as biomass-to-pellet conversion, biomass availability, and wood pellet demand. Since the robustness of the strategic and tactical decisions of the WPP-SCND model is essential, fuzzy flexible robust possibilistic programming (fuzzy-FRPP) is proposed by combining the robust programming (RP) technique with flexible FPP.

To the best of the author’s knowledge, Yılmaz Balaman et al. [27] are the only researchers to use a fuzzy solution approach to design a wood pellet SC network considering circular bioeconomy principles. Although epistemic uncertainty is adequately addressed in that research using a fuzzy technique, it does not claim to offer robust solutions in an uncertain environment, which is essential for the sustainability of the wood pellet SC. To bridge this research gap, this study presents a decision support system for a wood pellet production SC in an unpredictable environment and adds to the existing literature on the design of WPSC networks in the following ways:

- Proposing a multi-period WPP-SCND optimization model that takes into account epistemic uncertainty in input parameters to obtain reliable integrated strategic and tactical decisions that take into account the effects of WPSC activities on the environment and the economy.

- Proposing a fuzzy-FRPP solution to tackle the uncertain environment and obtain robust WPSC decisions by taking advantage of both flexible and robust programming techniques under a highly uncertain environment.

Providing a solution that allows for wood pellet SC management to quantify the economic impacts of carbon emissions associated with wood pellet SC activities in order to design policies accordingly.

Table 1.

Summary of the research related to WPSC network design.

Table 1.

Summary of the research related to WPSC network design.

| Author | Source | Type of Feedstock | Decision Levels | Method/Analysis | Uncertainty Handling Approach | Environmental Aspect | Economic Aspect | Supply Chain Decisions Considered | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stochastic | Fuzzy | LA | CP | FM | UN | |||||||

| Boukherroub et al. [13] | Forest and agriculture biomass | Wood chips | Strategic, tactical, operational | LogiLab simulation package | ✓ | ✓ | ✓ | ✓ | ||||

| Méndez-Vázquez et al. [16] | Residual biomass | Agriculture waste | Strategic, tactical, operational | Deterministic mixed-integer non-linear programming | ✓ | ✓ | ✓ | ✓ | ✓ | |||

| Mansuy et al. [18] | Forest biomass | Fire killed trees | Strategic | Deterministic linear mathematical modeling | ✓ | ✓ | ✓ | ✓ | ||||

| Shabani et al. [19] | Forest and agriculture biomass | Wood chips | Strategic, tactical | Comparative analysis of techniques | ✓ | ✓ | ✓ | ✓ | ✓ | |||

| Kanzian et al. [20] | Forest biomass | Wood chips | Strategic, operational | Deterministic linear mathematical modeling | ✓ | ✓ | ||||||

| Vasković et al. [22] | Agricultural biomass | Wood chips | Prioritization | VIKOR multi-criteria decision-making technique | ✓ | |||||||

| Cambero and Sowlati [23] | Forest biomass | Wood chips | Strategic, tactical, operational | Multi-objective deterministic linear mathematical modeling | ✓ | ✓ | ✓ | ✓ | ✓ | |||

| Trochu et al. [24] | Household wood waste | Construction and demolition of wood waste | Strategic, tactical, operational | Linear mathematical modeling | ✓ | ✓ | ✓ | ✓ | ✓ | |||

| Mobini et al. [25] | Agricultural biomass | Sawmill wood waste | Strategic | Discrete event simulation for modeling of SC for planning and analysis of SC model | ✓ | ✓ | ✓ | ✓ | ✓ | |||

| Akhtari and Sowlati [26] | Forest biomass | Forest waste and sawmills dust | Strategic, tactical operational | Recursive optimization-simulation approach | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Yılmaz Balaman et al. [27] | Forest and agriculture | Mix wastes | Strategic, tactical, | Fuzzy multi-objective | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ||

| Van Dyken et al. [30] | Forest biomass | Wood chips | Strategic, operational | Deterministic linear mathematical modeling | ✓ | ✓ | ✓ | ✓ | ✓ | |||

| Vitale et al. [31] | Forest biomass | Sawdust, shaving, wood chip | Operational | Column generation method | ✓ | ✓ | ✓ | |||||

| De Laporte et al. [32] | Agriculture biomass | Switchgrass and miscanthus | Strategic | GIS-based empirical study | ✓ | |||||||

| This study | Agricultural biomass | Sawdust, wheat straw, bagasse, Rice husk | Operational, strategic, tactical | Fuzzy flexible robust possibilistic programming approach | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | |

LA—location allocation, CP—capacity planning, FM—flow of materials, UN—uncertainty.

3. Research Methodology

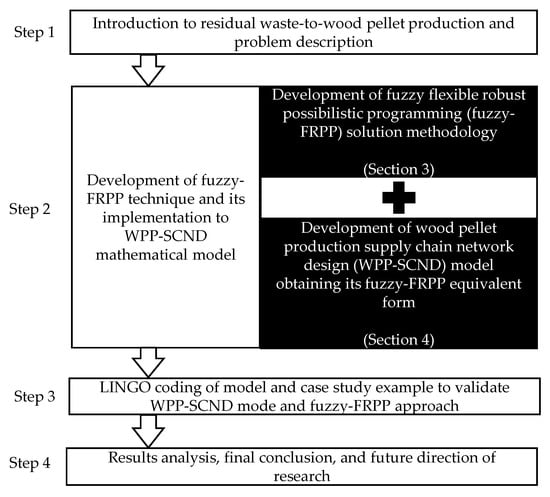

As discussed in the above section, this study aims to provide a decision support system for wood pellet production managers by integrating economic and environmental aspects in the background of a circular bioeconomy. That implies that the study should provide a comprehensive overview of SC performance in an uncertain environment for the optimization model objectives. The research methodology used in this study is provided in Figure 1.

Figure 1.

Research methodology employed for the study.

In the first step, the theoretical foundation for the investigation is established. This section provides a comprehensive explanation of essential principles and issues in a wood pellet manufacturing and distribution system, as well as determines the study’s goals, which are described explicitly and simply in a problem statement. In light of the mentioned issues, the research questions are developed. The second step involves developing a mathematical model in line with the problem statement and research questions. The WPP-SCND model is designed in this stage to reduce the cost of wood pellet manufacturing as well as the environmental impact of the related operations. To handle the uncertainty in the WPP-SCND model, a fuzzy-FRPP solution combining FPP, flexible programming, and robust programming is proposed. After that, the fuzzy-FRPP equivalent form of the WPP-SCND model is coded in LINGO optimization software. In the third stage, to answer the research questions and validate the proposed mathematical model and solution approach, a comprehensive quantitative analysis is undertaken using a case study. Finally, at the last stage, the conclusion and limitations of the study, as well as future research directions, are provided.

3.1. Why Are Linear Programming and Fuzzy-FRPP the Most Appropriate Solution Strategies for the Proposed WPP-SCND Model?

In the first part of this study, a linear programming approach is used to achieve the aims of cost and carbon emissions reduction in a wood pellet SC in a circular bioeconomy scenario. The benefit of the linear programming approach is that it is based on simple algebraic formulations and provides better insights into complex systems by always guaranteeing global optimal solutions.

In the second part, to address the problem of an uncertain environment associated with the WPP-SCND model parameters, this study integrates FPP, RP, and flexible programming to develop fuzzy-FRPP. Each technique offers the following distinct advantages to deal with uncertainty:

- FPP is the best choice when there is epistemic uncertainty in the collected data and stochastic methodologies cannot be used because there are no previous data [33]. Epistemic uncertainty affects WPP-SCND model elements such as biomass-to-wood-pellet conversion, production costs, wood pellet demand, and biomass availability. To nullify the effect of uncertainty, FPP is best suited. However, FPP simply gives the average value of the unknown parameter and cannot account for fluctuations [28]. This drawback can be overcome by merging RP with FPP to form fuzzy robust possibilistic programming (fuzzy-RPP).

- Robust programming makes the WPP-SCND model objective independent of average value and also integrates feasibility and optimality robustness. Hence, the incorporation of FP within robust programming will form fuzzy-FRPP.

- Flexible programming enables managers to integrate flexibility into uncertain constraint goals. The level of flexibility in these soft constraints can be decided by the manager.

Hence, the fuzzy-FRPP approach can efficiently minimize the risk due to operational uncertainty/epistemic uncertainty.

3.2. Generic Formulation of Fuzzy-FRPP Solution Approach

To address the challenge of uncertainty linked with WPP-SCND model parameters, a solution called fuzzy-FRPP is proposed here. Generic form of fuzzy-FRPP approach is provided below:

3.2.1. Fuzzy Possibilistic Programming

A generalized version of an optimization model containing imprecise parameters is presented in Equation (1) to understand the composition of possibilistic programming:

In Equation (1), F, H, V, and T are the parameters tainted with epistemic uncertainty and follow the trapezoidal fuzzy number (TFN). The membership function of can be developed as follows:

- (a)

- Expected value (ExV)

Under the FPP technique, uncertain parameters of the objective are transformed into the crisp form using the ExV operator [34] as follows:

- (b)

- Me-measure

Me-measure, proposed by Xu and Zhou [35], was applied to translate uncertain constraints into crisp form. Using Me, SC managers can interactively incorporate their preferences in the range of pessimistic and optimistic approaches as below:

In Equation (5), represents the preference of SC managers on the spectrum of pessimistic-optimistic. The Me for and is obtained as follows:

Using Me, the ExV of is obtained as:

Using Equations (6)–(9), Me for and is obtained as:

Using the ExV and Me provided in Equations (4), (12) and (13), the uncertain parameters of Equation (1) are transformed into a certain form as below:

3.2.2. Fuzzy Flexible Possibilistic Programming

In the next stage, the FPP equivalent form presented in Equation (14) is modified by integrating flexibility in its constraint. The modified FPP form is as below:

where is the pessimistic–optimistic parameter, J1 and J2 depict SC manager level of confidence, and integrates flexibility in the uncertain constraints target.

Equation (16) is the equivalent form of the FPP approach for the uncertain model provided in Equation (1). The constraint target uncertainty sign is substituted with and terms. In these terms, and are TFN for and , respectively, and represent constraint flexibility margins. Further, and represent the level of confidence of the SC manager specifically for uncertain constraint flexibility margin parameters and . The FPP formulation provided in Equation (16) perfectly tackles the operational uncertainty. Nevertheless, there are two drawbacks of the FPP method. First, the deviation of the objective from ExV of uncertain parameters cannot be controlled. Second, it will take longer to achieve global optimal as the number of flexible equations in the optimization model increases. A modified method called fuzzy RPP is suggested to address these problems.

3.2.3. Flexible Robust Possibilistic Programming (FRPP)

To address the shortcomings of flexible FPP, the RPP-II formulation developed by Pishvaee et al. [28] is further integrated into the flexible FPP formulation provided in Equation (16) as follows:

In Equation (17), represents the worst-case value of the objective, while the second term of the objective minimizes deviation for the worst case scenario, thus providing optimality robustness; is the scaling factor of optimality robustness, which can range between 0 and 1. The disparity between the worst possible value and the value utilized within uncertain constraints is minimized by the third and fourth terms, which incorporate feasibility robustness into the results. Finally, the fifth and sixth terms are the penalties for deviating from the soft constraint’s target value.

4. Mathematical Model and Case Results

4.1. Working Framework of the WPP-SCND Model

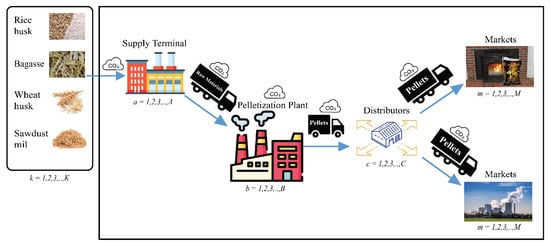

The mathematical model of the wood pellet supply chain is described in this section. The WPP-SCND model reduces the overall system cost by first choosing the best locations for biomass processing facilities and then allocating the optimal amounts to facilities during each planning period. Biomass in the form of sawdust and agricultural waste is delivered from supply terminal a to pelletization plant b, where it is converted into wood pellets. Following that, wood pellets are provided from pelletization facility b to distribution center c, whence they are transferred to market m to meet energy demands. This model not only reduces the system cost but also accounts for the carbon emissions related to raw material collection, transportation to pelletization facilities, and transportation of wood pellets from pelletization plants to market centers in terms of carbon penalty.

Figure 2 illustrates the structure of the WPP-SCND model.

Figure 2.

Working framework of WPP-SCND optimization model.

4.1.1. Notations

In this section, the notations used in the WPP-SCND model are presented.

Indices

| k | Index for raw material types |

| a | Index for raw material collection points |

| b | Index for pelletization plant |

| c | Index for distribution center |

| m | Index for marketplace |

| q | Index for the capacity level of pelletization plant |

| r | Index for the capacity level of the distribution center |

| t | Index for the period |

Decision Variables

| Amount of raw material type (k) transported from collection point (a) to pelletization plant (b) in time (t) | |

| Amount of pellets transported from pelletization plant (b) to distributor (c) in the time period (t) | |

| Quantity of pellet supplied from the distributor (c) to marketplace (m) during the time (t) | |

| 0 if supply terminal (a) is not selected, 1 if supply terminal (a) is selected | |

| 0 if the plant (b) with capacity (q) is not selected, 1 if the plant (b) with capacity (q) is selected | |

| 0 if distribution center (c) with capacity (r) is not selected, 1 if distribution center (c) with capacity (r) is selected |

Parameters

| Cost of constructing (a) biomass supply terminal (a) | |

| Cost of constructing pelletizing facility (b) with capacity (q) | |

| Cost of constructing distribution center (c) with capacity (r) | |

| The purchasing cost of biomass (k) at supply terminal (a) in time (t) | |

| Quantity of CO2 emissions during raw material handling at biomass supply terminal (a) | |

| Cost of biomass handling at biomass supply terminal (a) | |

| Quantity of CO2 emissions during raw pellet production at location (b) | |

| Carbon emission tax | |

| The available quantity of raw material type (k) at the collection point (a) in time (t) | |

| Pellets demand in market m during the period (t) | |

| Production capacity of the pellets plant with level (q) | |

| Storage capacity of the distribution center c with level (r) | |

| The conversion factor for biomass to pellets | |

| Wood pellets production cost at pelletization plant (b) | |

| The shipping cost of supplying raw material from the supply terminal (a) to the pelletization plant (b) | |

| Transportation cost of moving pellets from pelletization plant (b) to distribution center (c) | |

| Transportation cost of moving pellets from the distribution center (c) to market (m) | |

| Quantity of carbon emissions during raw material transportation from supply terminal (a) to pelletization plant (b) | |

| Quantity of carbon emissions during transportation of pellets from pelletization plant (b) to distribution center (c) | |

| Quantity of carbon emissions during transportation of pellets from the distribution center (c) to market (m) |

4.1.2. Assumptions

- The homogenous fleet of vehicles is assumed to be available at all echelons of the supply chain.

- Allowable cargo is less than one truckload.

- The regional collection of biomass is assumed to be available at potential locations of supply terminals.

- The distances between the collecting points and the pelletization plants, as well as between the pelletization plants and the demand zones, are known.

- A CO2 emission tax is imposed under local government policy for all stakeholders.

- I.

- Objectives functions of the WPP-SCND model:

- (a)

- Total supply chain cost objective

The first, second, and third terms of the objective function represent the costs of establishing a supply terminal, pelletization plant, and distribution center:

The fourth term of the objective function illustrates the cost of purchasing biomass, handling costs, and handling-related emissions penalties:

The fifth term shows the total wood pellet production cost and the CO2 emissions tax imposed during pellet production:

The sixth, seventh, and eighth terms illustrate the total SC transportation cost in the WPP-SCND model:

The total carbon emissions tax that is incurred during the transportation of raw material and wood pellets among processing facilities of the WPP-SCND model is provided in the ninth, tenth, and eleventh terms of the objective function:

- II.

- Constraints of the WPP-SCND model

The biomass supply constraint is provided by Equation (23). It represents that the amount of biomass type ‘b’ at a supply terminal should be greater than the amount of biomass carried from the supply terminal to pelletization facilities:

Equation (24) represents the biomass-to-wood pellet conversion constraints, which also limit the system in that the amount of wood pellets delivered to distributors should not exceed the total amount manufactured at a pelletization facility:

Equation (25) depicts demand constraints, which bound the system to fulfill the demand of all markets:

Equation (26) requires that the total amount of wood pellets provided to market from a distribution center not exceed the entire amount of wood pellets supplied from a palletization factory to that distribution center:

Equations (27) and (28) represent the processing capacity and storage capacity restrictions of pelletization plants and distribution centers, respectively:

Equations (29) and (30), respectively, limit the system to a single capacity level for all operational pelletization plants and distribution centers:

Equations (31) and (32) are the non-negativity and binary constraints, respectively:

4.1.3. Equivalent Fuzzy-FRPP Form of WPP-SCND Model

Using the systematic conversions of the uncertain model provided in Section 3.2.1, Section 3.2.2, and Section 3.2.3, the equivalent fuzzy-FRPP form of the WPP-SCND model is provided below:

and constraints (26)–(32).

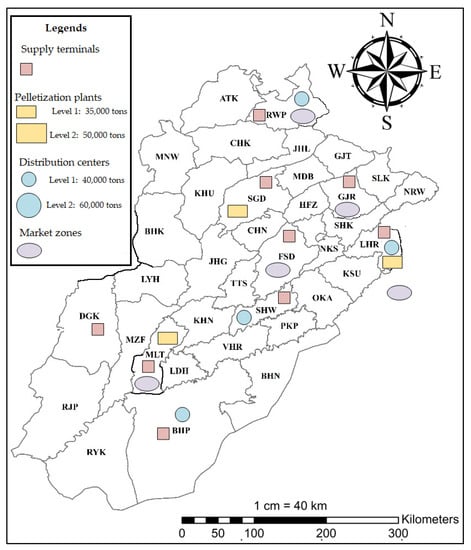

4.2. Case Study to Validate Fuzzy-FRPP-Based WPP-SCND Model

To assess the efficacy of the WPP-SCND model and fuzzy-FRPP solution approach, a Pakistan-specific case study is presented in this section. Pakistan’s economy is suffering as a result of a serious energy crisis. Utilities’ electricity supply falls well short of demand. The current shortage surpasses 6000 megawatts. Natural gas, the country’s second-largest fuel source after biofuels, is also becoming increasingly scarce. Generally, the shortage imposes substantial costs on the economy, estimated at around 2% of GDP each year, through reduced productivity, exports, and jobs. In this grim situation, using locally accessible second-generation biomass to generate energy can support the shrinking economy of the country. In this context, four types of locally available biomass are utilized to manufacture wood pellets that may be used to generate energy in a variety of ways. These biomasses include sawmill dust, rice husk, wheat straw, and bagasse. The Punjab province is chosen for this case because it is the most fertile region in Pakistan and meets the majority of the country’s agricultural needs. For the given case, nine potential locations for biomass supply terminals, four possible sites for pelletization plants, and three potential sites for distribution hubs are considered to meet the energy demands of five major markets of the province. Furthermore, 2 capacity levels are considered for each pelletization plant, 35 and 50 thousand tons, while 2 capacity levels are evaluated for each distribution center, 40 and 60 thousand tons. The following are the key tactical and strategic decisions provided by the WPP-SCND model: minimum number of operational supply terminals, pelletization plants, and distribution hubs; capacity levels of operational pelletization plants and distribution hubs; and optimal quantities of allocated biomass from supply terminals to pelletization plants, wood pellets to be supplied from plants to distribution hubs, and pellets transported to demand zones from distribution hubs.

The WPP-SCND model efficiently provides answers to the following questions while designing the wood pellet supply chain:

- Which supply terminals should be selected to purchase biomass?

- What are the optimal quantities and mix of biomass (sawmill waste, wheat straw, rice husk, and bagasse) to supply to the production plant in each planning period?

- Where should wood production plants and distribution centers be located considering the economies of scale?

- What quantity is produced/processed at each operational facility in each planning period?

Figure 3 shows all potential wood pellet production SC sites for the given case study.

Figure 3.

Potential wood pellet production SC sites for the given case.

4.2.1. Data Collection and Analysis for the WPP-SCND Model

For the proposed WPP-SCND model, datasets are mostly collected from regional government departments. The availability of rice husk, wheat straw, and bagasse biomass in each division of the province is acquired from the federal agriculture marketing department (http://www.amis.pk/, accessed on 10 May 2021) Pakistan. The potential of sawdust production is estimated after analyzing the reports provided by the provincial agriculture department (https://agripunjab.gov.pk/, accessed on 10 May 2021) and the forest, wildlife, and fisheries department (https://fwf.punjab.gov.pk/, accessed on 10 May 2021). The purchase cost of biomass and its handling costs are decided based on the locally collected information. Further, input parameters such as the construction cost of the pelletization plant and distribution hub were decided after analyzing published articles and regional industries [36,37]. Since railways infrastructure is not very reliable, only the roadway mode of transportation is assumed for the given case. The transportation matrix for each tier is obtained from Google Maps and is also considered an imprecise parameter in the computational analysis. Transportation costs among wood pellet processing facilities were decided in consultation with local logistics companies. The considered wood pellet SC comprises the shipping of biomass among supply terminals and pelletization plants and the handling of supplied biomass at each pelletization plant. It also entails the transportation of wood pellets from production plants to the distribution hub and then from the distribution hub to the wood pellet markets. Further, a homogenous fleet of vehicles with 45 tons of load-carrying capacity is considered. Emissions during transportation between wood pellet production sites are adapted from Gonela et al. [38]. A government tax of USD 10/ton is assumed following a report by the World Bank [39].

In this research, all objective parameters, including biomass availability at the supply terminals, market demand, and biomass production, are considered fuzzy to account for epistemic uncertainty. For each uncertain parameter, a TFN is developed. In order to obtain a TFN for each uncertain parameter, 4 random numbers (a1, a2, a3, a4) between 0.25 and 0.75 following uniform distribution are generated. Using these random numbers, the TFN of an uncertain parameter is obtained according to Equations (39)–(42). For instance, if is a parameter having trapezoidal distribution, four points TFN of are obtained using the following set of Equations (39)–(42) [40,41]:

Appendix A includes the most likely datasets utilized for the computational analysis of the WPP-SCND optimization model.

4.2.2. Results and Discussion on Research Questions

- (a)

- Research question 1: How can an integrated decision support system that efficiently collects, transports, and converts massive quantities of various biomasses into wood pellets be developed in a sustainable manner to support the transition to a circular bioeconomy?

The first research question, which aims to provide a decision support system for the efficient design of WPSC, is discussed here. To answer this research question, first, a WPP-SCND optimization model is proposed, and then, a fuzzy-FRPP solution is suggested. After that, the collected datasets and corresponding fuzzy-FRPP form of the WPP-SCND model given in Equations (26)–(38) are solved using the LINGO optimization solver. As previously stated, the fuzzy-FRPP approach comprises several interactive parameters such as (scaling multiplier for optimality robustness), (constraints optimistic-pessimistic factor), (objective optimistic-pessimistic factor), (confidence level for constraint parameters), (soft constrain margins), and (penalties for violating uncertain constraints). All of these parameters’ values are defined following the real-time environment. The value of the scaling multiplier for optimality robustness (χ) controls the deviation over and above the ExV of the WPP-SCND model and may vary between 0 and 1. Further, the value of the optimistic–pessimistic parameter (λ) decides the inclination of the manager between the two extremes of the worst-case scenario and best-case scenario. If λ = 0, then the approach of the manager is pessimistic, and Me becomes equal to Nec. If λ = 0.5, then the attitude of the manager is compromising, and Me becomes equal to Cr. Lastly, if λ = 1, then the manager is more inclined toward the optimistic side, and Me becomes equal to Pos. Finally, the values of the target violation penalties () are decided based on real-time information. Considering a scaling multiplier for optimality robustness of 0.5 and a confidence interval of 0.75 for uncertain constraints and objective parameters, and adopting an optimistic approach, results of the WPP-SCND model are obtained to answer the following research questions:

For the given values of the parameters, a minimum total cost of USD 113,137,700 for both planning periods is obtained. For the given set of parameters, ExV cost of USD 102,773,900 is attained. However, ExV cost only computes results based on the average value of an imprecise parameter, which is not reliable. Therefore, the fuzzy-FRPP method given in Equation (33) is utilized to obtain robust results. According to this methodology, the robustness of results is enhanced by adding penalties for the violation of the target value due to uncertainty. For the given case, USD 6,909,209 is incurred as a penalty to increase the optimality, while a penalty of USD 3,454,605 is imposed to enhance the feasibility of the WPP-SCND model. The analysis of the total cost of the considered wood pellet supply chain system is shown in Table 2.

Table 2.

Breakdown of the total cost of the wood pellet SC according to the fuzzy-FRPP approach.

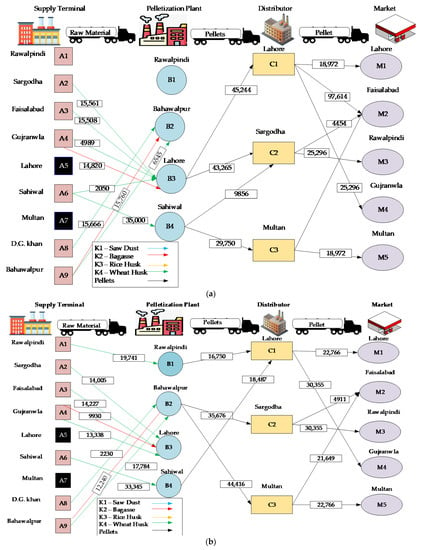

Comprehensive results for the specified settings of parameters depicting all strategic and tactical level decisions are illustrated in Figure 4. The obtained findings show that seven potential biomass supply terminals have been chosen out of nine. Because the supply terminals in Lahore and Multan have the greatest facility installation costs of all, they are not operational. The Rawalpindi supply terminal gathers biomass from the southern districts of the Punjab, whilst Sargodha and Faisalabad cover the center and western portions. Gujranwala mostly serves the western portions of Punjab, whereas DG Khan and Bahawalpur serve the southern regions. It is also found that to reduce the SC cost in terms of transportation and emissions due to transportation, supply terminals having the maximum potential of biomass are made operational.

Figure 4.

WPP-SCND model decisions using fuzzy-FRPP during (a) first time period t1 (b) second time period t2.

All four of the pelletization facilities in Rawalpindi, Bahawalpur, Lahore, and Sahiwal are chosen for the second echelon of the wood pellet SC. One of these, the Lahore plant, was put into operation with a 50,000-ton processing capacity. The other plants were all installed with a 30,000-ton processing capacity. The Rawalpindi supply terminal supplies all biomass to its pelletization plant. Because the Lahore pelletization plant is designed to operate with the maximum pelletization capacity/period biomass, supplies from the biomass supply terminals in Sargodha, Faisalabad, and Gujranwala are sent to Lahore during both planning periods. The Sahiwal biomass terminal also supplies all of its biomass to its pelletization plant. Lastly, supplies from the DG Khan and Bahawalpur supply points also send their biomass to the pelletization plant located in Bahawalpur. Decisions made in the second tier of the supply chain show that to reduce the cost associated with emissions and transportation, the optimization model preferably chose all the pelletization plants located closest to their supply locations. It is also noticed that among the four types of available biomass, sawmill dust was the least preferred due to its high purchase cost.

In the third tier, the Rawalpindi pelletization facility sent its wood pellets to the Multan distribution center in the first planning period and the Lahore distribution center in the second planning period. Further, in the first planning period, Bahawalpur did not manufacture any pellets, but in the second period, it delivered pellets to the distribution centers in Sargodha and Multan. Lahore only produced wood pellets during the first planned period, sending them to its own distribution facility and the Sargodha distribution center. During the first planning period, the Sahiwal pelletization facility delivered its pellets to Sargodha and Lahore, whereas during the second, it sent all of its pellets to the Lahore distribution center. For the final echelon of WPSC, the distribution facilities in Lahore and Sargodha were made operational with higher capacity levels, while Multan’s facility was chosen with a lower capacity level. Wood pellets from the Lahore distribution center met the energy needs of its market zone as well as the Gujranwala market. The Sargodha distribution facility sent wood pellets to the market zones of Faisalabad and Rawalpindi. Finally, Multan’s distribution hub meets the energy demands of its market zone as well as the market in Faisalabad.

- (b)

- Research question 2: How can robust decisions for strategic and tactical levels in a wood pellet SC be acquired in a highly uncertain environment?

Herein, the second research question aims to deal with an uncertain environment and provide robust decisions for strategic and tactical planning for a WPSC network design. To attain this goal, the fuzzy-FRPP approach is proposed that provides not only robust but also cost-efficient optimal solutions under uncertain environments. To evaluate the quality of the results provided by the fuzzy-FRPP approach, its results are compared with a counterpart solution methodology named FRPP. Further, an explanation of how a subjective approach to dealing with risk impacts the results of the fuzzy-FRPP technique is also provided in this section.

- I.

- Comparative analysis of FPP and fuzzy-FRPP approach to analyze the impact of robustness

In this part, a comparison of the FPP and fuzzy-FRPP approaches is presented for evaluating the impact of robustness. As described in Section 3.2, the FPP approach makes decisions based on the ExV of imprecise parameters of the objective, but fuzzy-FRPP considers costs of flexibility margins in constraints, as well as feasibility and optimality robustness. A comparison of the two methodologies demonstrates that high-cost location decisions, such as pelletization plant installation and distribution hubs, do not vary. However, in terms of capacity decisions, the decisions regarding the two approaches differ. This is because fuzzy-FRPP adds resilience to model decisions by selecting wood pellet production facilities with larger aggregate capacities. In order to achieve the goal of a higher aggregate capacity, either small-capacity facilities in several locations or larger-capacity facilities in fewer sites are chosen. Additionally, it was demonstrated that when making capacity decisions, the fuzzy-FRPP approach successfully strikes an equilibrium between transportation costs, emissions costs, and economies of scale.

A detailed analysis of the results shows that the majority of the location decisions made by the two methodologies are similar. In the first echelon, instead of Multan, the Rawalpindi biomass supply terminal is made operational in FPP. Further, the Rawalpindi pelletization facility was not chosen for the second tier of the WPP-SCND model; instead, the Bahawalpur pelletization facility was placed into operation with a greater capacity level. Finally, in the last tier of FPP decisions, all three distribution centers were chosen, with the Multan distribution center becoming operational with a lower processing capacity. The FPP technique operates with lower aggregate capacity, and therefore, the total cost is lower than the fuzzy-FRPP approach.

- II.

- Impact of change in objective and constraint pessimistic–optimistic (λ) factor on the total cost of the WPP-SCND model

Since the values of the interactive parameters are decided based on real-time dynamics, therefore, a sensitivity analysis for multiple scenarios is provided to establish the effectiveness of provided model and solution technique. For this purpose, a comprehensive analysis is provided to examine the impact of combined variation in the objective pessimistic-optimistic factor () and constraints pessimistic–optimistic (λ) factor on the total cost of the WPP-SCND model. Using various combinations of these interactive parameters multiple global optimal solutions are provided in Table 3. Pessimistic–optimistic factor (λ) is one of the key parameters that provide information about the attitude of the decision maker in an uncertain environment. If the value of λ = 0, then the decision maker has adopted a risk aversion approach and they are planning for the best-case scenario, and if λ = 0.99, then the decision makers are planning by keeping the best-case scenario; λ = 0.5 provides a compromise between the two extremes. The results provided in Table 3 are in line with this proposition. Analysis of the results shows that as λ increases from 0.1 to 0.9 for each value of the confidence level of the decision maker, the overall system cost of the WPP-SCND model decreases. This is because higher values of λ provide an optimistic approach as a results model provides the minimum possible cost. It is also seen that as the value of the objective pessimistic–optimistic factor () increases, the total SC cost also increases.

Table 3.

Effect of variation in objective pessimistic–optimistic factor () and constraint pessimistic-optimistic (λ) factor on the objective of the WPP-SCND model.

- III.

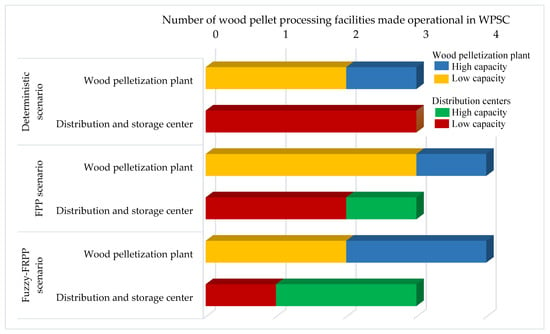

- Impact of uncertainty handling technique on the WPP-SCND model facilities capacity level decision and scalability aspect

Strategic planning decisions regarding facility placement and capacity are crucial for determining the performance of the system. Therefore, the WPP-SCND model considers the capacity level decisions in the wood pelletization plant echelon and distribution and storage echelon of the WPSC. The suggested model aims to find the optimal tradeoff between the capacity levels and the total number of facilities in each supply chain tier. In addition, it is also important to strike a balance between logistics costs and economies of scale to make WPSC decisions that are both cost-effective and environmentally sustainable. For instance, increasing the number of low-capacity facilities (wood pelletization plant and distribution and storage center) can lower transportation costs, but ignoring economies of scale may raise total system costs. On the contrary, economies of scale will be more advantageous if fewer facilities with more capacity are placed into operation. In this instance, nevertheless, longer distances between facilities may result in higher system costs overall.

Herein, the impact of a specific type of uncertainty handling of the WPP-SCND model facility capacity level decision is observed. Each solution provides capacity decisions by striking a balance between the robustness of the solutions and the objective value of the WPP-SCND model. In this background, a comparative analysis of WPP-SCND model capacity decisions for the following three solution approaches is provided: (i) deterministic approach, (ii) FPP approach, and (iii) fuzzy-FRPP approach. Figure 5 shows the operational number and capacity levels of wood pelletization plants and distribution and storage facilities against each solution. The results indicate that the WPP-SCND model with a deterministic approach chooses the fewest number of facilities and the lowest capacity levels in each wood pellet SC tier. This is because neither penalties for constraint violation nor a flexibility margin is included in the deterministic method, and the model only attempts to find an efficient balance between economies of scale and transportation costs; the deterministic approach thus has the lowest overall WPSC costs. For the second solution, FPP, the WPP-SCND approach yields greater overall costs than the deterministic method. This is because the FPP approach acknowledges epistemic uncertainty by using a possibilistic distribution for each uncertain parameter that may vary within a certain range, but it does not also include the constraint violation penalty factor. As a consequence, the overall WPSC cost is more than that of the deterministic approach but lower than that of the fuzzy-FRPP approach. Finally, the fuzzy-FRPP methodology has the greatest overall cost of all available solution approaches. This is because fuzzy-FRPP takes into consideration not just the epistemic uncertainty in the WPP-SCN D model’s uncertain parameters but also the constraints violation penalties. In order to decrease the surge in overall WPSC costs, the model chooses wood pellet processing facilities with greater capacities. This approach not only allows the WPP-SCND model to avoid constraint violation penalties but also minimizes the system’s overall logistics cost.

Figure 5.

Impact of specific uncertainty handling technique on the WPP-SCND model’s facility capacity level decision.

The uncertainty associated with critical WPP-SCND model parameters further hampers the scalability of wood pellet production. Analyses of the results indicate that the scalability of wood pellet production is significantly dependent on biomass type, biomass cost, biomass availability, biomass yield, and scalable wood pellet production method. For instance, the production yield of wood pellets is highly dependent on the kind of biomass and its manufacturing process. In this context, the suggested WPP-SCND model accounts for the uncertainty regarding biomass supply and biomass production. In line with this, the fuzzy-FRPP technique provides efficient solutions by including the biomass supply and yields penalty violations into the objective function of the optimization model. In addition to the previously indicated critical factor for the scalability of wood pellet manufacturing, the robust design of the logistics network is a crucial aspect in the biofuels sector. The disruption of the logistics network may be caused by both natural and man-made disasters. Wood pellet biomass supply disruptions may impact biomass production (e.g., natural disasters), material processing capacity (e.g., underinvestment), transportation network (e.g., damaged roads), and biomass demand for competing sectors (e.g., increased demand due to material competition).

5. Conclusions, Limitations, and Future Research Directions

This research proposed a multi-period wood pellet production distribution using residual wastes as biomass. The provided optimization model aims to minimize the environmental effect and total cost of wood pellet collection, manufacturing, and supply while satisfying the target market’s need for wood pellets for the sustainable growth of a wood waste-based bioeconomy. Because biomass used for wood pellets is a residual product that is primarily seasonal, and because biomass purchasing and transportation costs are related to fossil fuels, a very dynamic environment exists. To deal with this uncertain environment, a fuzzy-FRPP technique is developed. The fuzzy-FRPP technique not only permits flexibility in the target of constraints with imprecise parameters but also incorporates resilience into the WPP-SCND model results. Fuzzy-FRPP is an interactive solution that contains 12 parameters. The scope of the suggested approach is significantly expanded since choosing the values of the parameters would allow decision makers to make decisions in line with their preferences. Although the proposed decision support system is employed to manage wood pellet production and distribution, the results and solution may be used for the synthesis of other biofuels (bioethanol, biodiesel, biomethane, etc.). The most important findings of this study are as follows:

- It is observed that for situations where epistemic uncertainty is largely associated with the collected dataset, the fuzzy-FRPP approach will always provide robust decisions with a slight increase in overall system cost. According to the computational analysis of the case study, the outcomes may be protected against uncertainty by spending an additional 10%.

- Comparing the results of the FPP and fuzzy-FRPP approaches shows that the latter favors adopting a centralized SC structure by making fewer facilities with a greater capacity level operational, while the former favors decentralizing the wood pellet SC structure.

- It was also discovered that the two largest expenses associated with WPSC were the installation of the wood pellet plant and the cost of producing wood pellets. This demonstrates that by exploring alternative, cost-effective wood pellet manufacturing processes, wood pellet fuels may be made more economically competitive with fossil fuels.

This study also has some limitations that give a roadmap for future research in this field. This study does not explore any form of contract mechanism that may play a key role in overcoming uncertainty among WPSC stakeholders. The consideration of a contract mechanism between suppliers of wood-based biomass and wood pellet-manufacturing plants is therefore another way to broaden the scope of this research. Additionally, cooperation across WPSC stakeholders is essential for reducing the uncertainty associated with biomass supply and enhancing the economic viability of wood pellets in comparison with fossil fuels, and extending this research by employing LCA-based environmental impact assessment could be valuable. In addition, for the scalable production of wood pellets, it is essential to address the uncertainties associated with biomass supply, biomass yields, and wood pellet production technology. However, the uncertainty associated with pellet production technology is not addressed in this study. This investigation may be expanded by addressing the scalability of cost-effective wood pellet production technologies. Further, this research does not consider the risk associated with the disruption perspective. The integration of SC disruption within the proposed model will also enhance the utilization of this research in practical scenarios. Furthermore, the utilization of this research can be enhanced by considering sustainability.

Author Contributions

Z.A.: Conceptualization, Writing—original draft, Methodology, Investigation, Funding. M.S.H.: Conceptualization, Writing—original draft, Writing—revised draft, Investigation, Software, Supervision. A.S.: Software and Investigation, Data collection. M.K.: Conceptualization, Writing—original draft, Supervision, Project administration, Funding. R.A.: Software and Investigation. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1, Table A2, Table A3, Table A4, Table A5, Table A6 and Table A7 provide the most likely values of the input parameters of the WPP-SCND model. Due to space limitations, only information about key parameters is provided.

Table A1.

Quantity of raw material available at each supply terminal in period t (tons).

Table A1.

Quantity of raw material available at each supply terminal in period t (tons).

| K1 (Straw Mil) | K2 (Bagasse) | K3 (Rice Husk) | K4 (Wheat Husk) | |||||

|---|---|---|---|---|---|---|---|---|

| T1 | T2 | T1 | T2 | T1 | T2 | T1 | T2 | |

| A1 | 7800 | 7540 | 9230 | 17,260 | 21,190 | 29,878 | 35,880 | 32,292 |

| A2 | 7800 | 7280 | 6760 | 12,641 | 42,900 | 60,489 | 16,380 | 14,742 |

| A3 | 5200 | 5720 | 5252 | 9821 | 20,020 | 28,228 | 16,640 | 14,976 |

| A4 | 4160 | 3900 | 5252 | 9821 | 24,700 | 34,827 | 15,600 | 14,040 |

| A5 | 7800 | 8320 | 10,400 | 19,448 | 26,000 | 36,660 | 10,400 | 9360 |

| A6 | 5200 | 5850 | 7280 | 13,614 | 33,800 | 47,658 | 39,000 | 35,100 |

| A7 | 10,400 | 10,400 | 9880 | 18,476 | 7800 | 10,998 | 41,600 | 37,440 |

| A8 | 5200 | 6500 | 6760 | 12,641 | 35,100 | 49,491 | 26,000 | 23,400 |

| A9 | 5200 | 6240 | 6890 | 12,884 | 39,000 | 54,990 | 20,800 | 18,720 |

Table A2.

Pelletization capacity of the plant (tons/period).

Table A2.

Pelletization capacity of the plant (tons/period).

| Q1 | Q2 | |

|---|---|---|

| B1 | 35,000 | 50,000 |

| B2 | 35,000 | 50,000 |

| B3 | 35,000 | 50,000 |

| B4 | 35,000 | 50,000 |

Table A3.

Distribution center storage capacity (tons/period).

Table A3.

Distribution center storage capacity (tons/period).

| R1 | R2 | |

|---|---|---|

| C1 | 40,000 | 60,000 |

| C2 | 40,000 | 60,000 |

| C3 | 40,000 | 60,000 |

Table A4.

Pellet demand in each market zone (tons).

Table A4.

Pellet demand in each market zone (tons).

| T1 | T2 | |

|---|---|---|

| M1 | 12,000 | 14,400 |

| M2 | 14,000 | 16,800 |

| M3 | 16,000 | 19,200 |

| M4 | 16,000 | 19,200 |

| M5 | 12,000 | 14,400 |

Table A5.

Transportation cost of biomass between biomass supply terminal and pelletization plants (USD/ton-km).

Table A5.

Transportation cost of biomass between biomass supply terminal and pelletization plants (USD/ton-km).

| B1 (Pelletization Plant) | B2 (Pelletization Plant) | B3 (Pelletization Plant) | B4 (Pelletization Plant) | ||

|---|---|---|---|---|---|

| RAWALPINDI | A1 | 6 | 574 | 359 | 401 |

| SARGODHA | A2 | 232 | 370 | 188 | 186 |

| FAISALABAD | A3 | 301 | 321 | 181 | 102 |

| GUJRANWALA | A4 | 212 | 474 | 92 | 363 |

| LAHORE | A5 | 359 | 413 | 10 | 171 |

| SAHIWAL | A6 | 401 | 243 | 171 | 5 |

| MULTAN | A7 | 520 | 100 | 338 | 180 |

| D.G. KHAN | A8 | 615 | 183 | 438 | 279 |

| BAHAWALPUR | A9 | 599 | 8 | 430 | 244 |

Table A6.

Transportation cost of wood pellets between pelletization plants and distribution centers (USD/ton-km).

Table A6.

Transportation cost of wood pellets between pelletization plants and distribution centers (USD/ton-km).

| C1 | C2 | C3 | ||

|---|---|---|---|---|

| RAWALPINDI | B1 | 332 | 218 | 517 |

| BAHAWALPUR | B2 | 427 | 381 | 100 |

| LAHORE | B3 | 10 | 188 | 338 |

| SAHIWAL | B4 | 171 | 230 | 181 |

Table A7.

Transportation cost of wood pellets between pelletization plants and distribution centers (USD/ton-km).

Table A7.

Transportation cost of wood pellets between pelletization plants and distribution centers (USD/ton-km).

| M1 | M2 | M3 | M4 | M5 | ||

|---|---|---|---|---|---|---|

| LAHORE | C1 | 10 | 181 | 331 | 92 | 338 |

| SARGODHA | C2 | 187 | 91 | 232 | 221 | 291 |

| MULTAN | C3 | 338 | 242 | 520 | 395 | 8 |

References

- Habib, M.S.; Tayyab, M.; Zahoor, S.; Sarkar, B. Management of animal fat-based biodiesel supply chain under the paradigm of sustainability. Energy Convers. Manag. 2020, 225, 113345. [Google Scholar] [CrossRef]

- Munir, M.A.; Habib, M.S.; Hussain, A.; Shahbaz, M.A.; Qamar, A.; Masood, T.; Sultan, M.; Abbas, M.M.; Imran, S.; Hasan, M. Blockchain adoption for sustainable supply chain management: An economic, environmental, and social perspective. Front. Energy Res. 2022, 613, 899632. [Google Scholar] [CrossRef]

- Habib, M.S.; Omair, M.; Ramzan, M.B.; Chaudhary, T.N.; Farooq, M.; Sarkar, B. A robust possibilistic flexible programming approach toward a resilient and cost-efficient biodiesel supply chain network. J. Clean. Prod. 2022, 366, 132752. [Google Scholar] [CrossRef]

- D’adamo, I.; Sassanelli, C. Biomethane Community: A Research Agenda towards Sustainability. Sustainability 2022, 14, 4735. [Google Scholar] [CrossRef]

- Taddei, E.; Sassanelli, C.; Rosa, P.; Terzi, S. Circular supply chains in the era of industry 4.0: A systematic literature review. Comput. Ind. Eng. 2022, 170, 108268. [Google Scholar] [CrossRef]

- Salvador, R.; Puglieri, F.N.; Halog, A.; Andrade, F.G.D.; Piekarski, C.M.; De Francisco, A.C. Key aspects for designing business models for a circular bioeconomy. J. Clean. Prod. 2021, 278, 124341. [Google Scholar] [CrossRef]

- D’Adamo, I.; Gastaldi, M.; Morone, P.; Rosa, P.; Sassanelli, C.; Settembre-Blundo, D.; Shen, Y. Bioeconomy of Sustainability: Drivers, Opportunities and Policy Implications. Sustainability 2022, 14, 200. [Google Scholar] [CrossRef]

- Kanan, M.; Habib, M.S.; Habib, T.; Zahoor, S.; Gulzar, A.; Raza, H.; Abusaq, Z. A Flexible Robust Possibilistic Programming Approach for Sustainable Second-Generation Biogas Supply Chain Design under Multiple Uncertainties. Sustainability 2022, 14, 11597. [Google Scholar] [CrossRef]

- Raimondo, M.; Caracciolo, F.; Cembalo, L.; Chinnici, G.; Pappalardo, G.; D’Amico, M. Moving towards circular bioeconomy: Managing olive cake supply chain through contracts. Sustain. Prod. Consum. 2021, 28, 180–191. [Google Scholar] [CrossRef]

- Yun, H.; Wang, H.; Clift, R.; Bi, X. The role of torrefied wood pellets in the bio-economy: A case study from Western Canada. Biomass Bioenergy 2022, 163, 106523. [Google Scholar] [CrossRef]

- Habib, M.S.; Asghar, O.; Hussain, A.; Imran, M.; Mughal, M.P.; Sarkar, B. A robust possibilistic programming approach toward animal fat-based biodiesel supply chain network design under uncertain environment. J. Clean. Prod. 2021, 278, 122403. [Google Scholar] [CrossRef]

- Kanan, M.; Habib, M.S.; Shahbaz, A.; Hussain, A.; Habib, T.; Raza, H.; Abusaq, Z.; Assaf, R. A Grey-Fuzzy Programming Approach towards Socio-Economic Optimization of Second-Generation Biodiesel Supply Chains. Sustainability 2022, 14, 10169. [Google Scholar] [CrossRef]

- Boukherroub, T.; LeBel, L.; Lemieux, S. An integrated wood pellet supply chain development: Selecting among feedstock sources and a range of operating scales. Appl. Energy 2017, 198, 385–400. [Google Scholar] [CrossRef]

- Hughes, N.M.; Shahi, C.; Pulkki, R. A Review of the Wood Pellet Value Chain, Modern Value/Supply Chain Management Approaches, and Value/Supply Chain Models. J. Renew. Energy 2014, 2014, 654158. [Google Scholar] [CrossRef]

- Mobtaker, A.; Ouhimmou, M.; Audy, J.F.; Rönnqvist, M. A review on decision support systems for tactical logistics planning in the context of forest bioeconomy. Renew. Sustain. Energy Rev. 2021, 148, 111250. [Google Scholar] [CrossRef]

- Méndez-Vázquez, M.A.; Gómez-Castro, F.I.; Ponce-Ortega, J.M.; Serafín-Muñoz, A.H.; Santibañez-Aguilar, J.E.; El-Halwagi, M.M. Mathematical optimization of a supply chain for the production of fuel pellets from residual biomass. Clean Technol. Environ. Policy 2017, 19, 721–734. [Google Scholar] [CrossRef]

- Ghaderi, H.; Moini, A.; Pishvaee, M.S. A multi-objective robust possibilistic programming approach to sustainable switchgrass-based bioethanol supply chain network design. J. Clean. Prod. 2018, 179, 368–406. [Google Scholar] [CrossRef]

- Mansuy, N.; Thiffault, E.; Lemieux, S.; Manka, F.; Paré, D.; Lebel, L. Sustainable biomass supply chains from salvage logging of fire-killed stands: A case study for wood pellet production in eastern Canada. Appl. Energy 2015, 154, 62–73. [Google Scholar] [CrossRef]

- Shabani, N.; Akhtari, S.; Sowlati, T. Value chain optimization of forest biomass for bioenergy production: A review. Renew. Sustain. Energy Rev. 2013, 23, 299–311. [Google Scholar] [CrossRef]

- Kanzian, C.; Holzleitner, F.; Stampfer, K.; Ashton, S. Regional energy wood logistics–optimizing local fuel supply. Silva Fenn. 2009, 43, 113–128. [Google Scholar] [CrossRef]

- An, H.; Wilhelm, W.E.; Searcy, S.W. A mathematical model to design a lignocellulosic biofuel supply chain system with a case study based on a region in Central Texas. Bioresour. Technol. 2011, 102, 7860–7870. [Google Scholar] [CrossRef]

- Vasković, S.; Halilović, V.; Gvero, P.; Medaković, V.; Musić, J. Multi-criteria optimization concept for the selection of optimal solid fuels supply chain from wooden biomass. Croat. J. For. Eng. J. Theory Appl. For. Eng. 2015, 36, 109–123. [Google Scholar]

- Cambero, C.; Sowlati, T. Incorporating social benefits in multi-objective optimization of forest-based bioenergy and biofuel supply chains. Appl. Energy 2016, 178, 721–735. [Google Scholar] [CrossRef]

- Trochu, J.; Chaabane, A.; Ouhimmou, M. Reverse logistics network redesign under uncertainty for wood waste in the CRD industry. Resour. Conserv. Recycl. 2018, 128, 32–47. [Google Scholar] [CrossRef]

- Mobini, M.; Sowlati, T.; Sokhansanj, S. A simulation model for the design and analysis of wood pellet supply chains. Appl. Energy 2013, 111, 1239–1249. [Google Scholar] [CrossRef]

- Akhtari, S.; Sowlati, T. Hybrid optimization-simulation for integrated planning of bioenergy and biofuel supply chains. Appl. Energy 2020, 259, 114124. [Google Scholar] [CrossRef]

- Yılmaz Balaman, Ş.; Wright, D.G.; Scott, J.; Matopoulos, A. Network design and technology management for waste to energy production: An integrated optimization framework under the principles of circular economy. Energy 2018, 143, 911–933. [Google Scholar] [CrossRef]

- Pishvaee; Razmi, J.; Torabi, S.A. Robust possibilistic programming for socially responsible supply chain network design: A new approach. Fuzzy Sets Syst. 2012, 206, 1–20. [Google Scholar] [CrossRef]

- Torabi; Namdar, J.; Hatefi, S.; Jolai, F. An enhanced possibilistic programming approach for reliable closed-loop supply chain network design. Int. J. Prod. Res. 2016, 54, 1358–1387. [Google Scholar] [CrossRef]

- Van Dyken, S.; Bakken, B.H.; Skjelbred, H.I. Linear mixed-integer models for biomass supply chains with transport, storage and processing. Energy 2010, 35, 1338–1350. [Google Scholar] [CrossRef]

- Vitale, I.; Dondo, R.G.; González, M.; Cóccola, M.E. Modelling and optimization of material flows in the wood pellet supply chain. Appl. Energy 2022, 313, 118776. [Google Scholar] [CrossRef]

- De Laporte, A.V.; Weersink, A.J.; McKenney, D.W. Effects of supply chain structure and biomass prices on bioenergy feedstock supply. Appl. Energy 2016, 183, 1053–1064. [Google Scholar] [CrossRef]

- Pishvaee; Torabi, S.A. A possibilistic programming approach for closed-loop supply chain network design under uncertainty. Fuzzy Sets Syst. 2010, 161, 2668–2683. [Google Scholar] [CrossRef]

- Habib, M.S.; Sarkar, B. A multi-objective approach to sustainable disaster waste management. In Proceedings of the International Conference on Industrial Engineering and Operations Management, Paris, France, 26–27 July 2018; pp. 1072–1083. [Google Scholar]

- Xu, J.; Zhou, X. Approximation based fuzzy multi-objective models with expected objectives and chance constraints: Application to earth-rock work allocation. Inf. Sci. 2013, 238, 75–95. [Google Scholar] [CrossRef]

- Visser, L.; Hoefnagels, R.; Junginger, M. Wood pellet supply chain costs—A review and cost optimization analysis. Renew. Sustain. Energy Rev. 2020, 118, 109506. [Google Scholar] [CrossRef]

- Pirraglia, A.; Gonzalez, R.; Saloni, D. Techno-economical analysis of wood pellets production for US manufacturers. BioResources 2010, 5, 2374–2390. [Google Scholar]

- Gonela, V.; Zhang, J.; Osmani, A.; Onyeaghala, R. Stochastic optimization of sustainable hybrid generation bioethanol supply chains. Transp. Res. Part E Logist. Transp. Rev. 2015, 77, 1–28. [Google Scholar] [CrossRef]

- World Bank. Carbon Tax Guide: A Handbook for Policy Makers; World Bank Open Knowledge: Washington, DC, USA, 2017. [Google Scholar]

- Habib, M.S. Robust Optimization for Post-Disaster Debris Management in Humanitarian Supply Chain: A Sustainable Recovery Approach. Ph.D. Thesis, Hanyang University, Seoul, Korea, 2018. [Google Scholar]

- Habib, M.S.; Maqsood, M.H.; Ahmed, N.; Tayyab, M.; Omair, M. A multi-objective robust possibilistic programming approach for sustainable disaster waste management under disruptions and uncertainties. Int. J. Disaster Risk Reduct. 2022, 75, 102967. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).