Comprehensive Identification of Surface Subsidence Evaluation Grades of Mines in Southwest China

Abstract

:1. Introduction

2. Methods

2.1. Southwest Mine Surface Subsidence Grade Evaluation System

2.2. AHP Determines the Weight of Each Index of Surface Subsidence

2.2.1. Constructing the Judgement Matrix and Calculating the Indicator Weights

- (1)

- Judgement matrix southwest mine surface subsidence evaluation system

- (2)

- Judgement matrix mining disturbance

- (3)

- Judgement matrix geological structure

2.2.2. Formatting of Mathematical Components

2.3. Construction of Extension Evaluation Model of Surface Subsidence

2.3.1. Establishment of the Classical Domain, Section Domain and Matter–Element to Be Evaluated

- (1)

- Classical domain matter–elementwhere represents the matter-element of the classical domain, and is the range of the index.

- (2)

- Segmental matter–elementwhere represents the matter–element of the node domain, and is the range of the index feature quantity, p represents the totality of the evaluation grades in the entire matter–element system, and .

- (3)

- Judgement matrix geological structure MB2where is the event to be evaluated, and is the specific value of the influencing factor .

2.3.2. Determination of the Correlation Function

- (1)

- Correlation of the evaluation index to the evaluation level

- (2)

- Comprehensive correlation degree for the event to be evaluated to the evaluation level

- (3)

- Judgement of the level of the event to be evaluated

3. Result

3.1. Cloud Model Theory

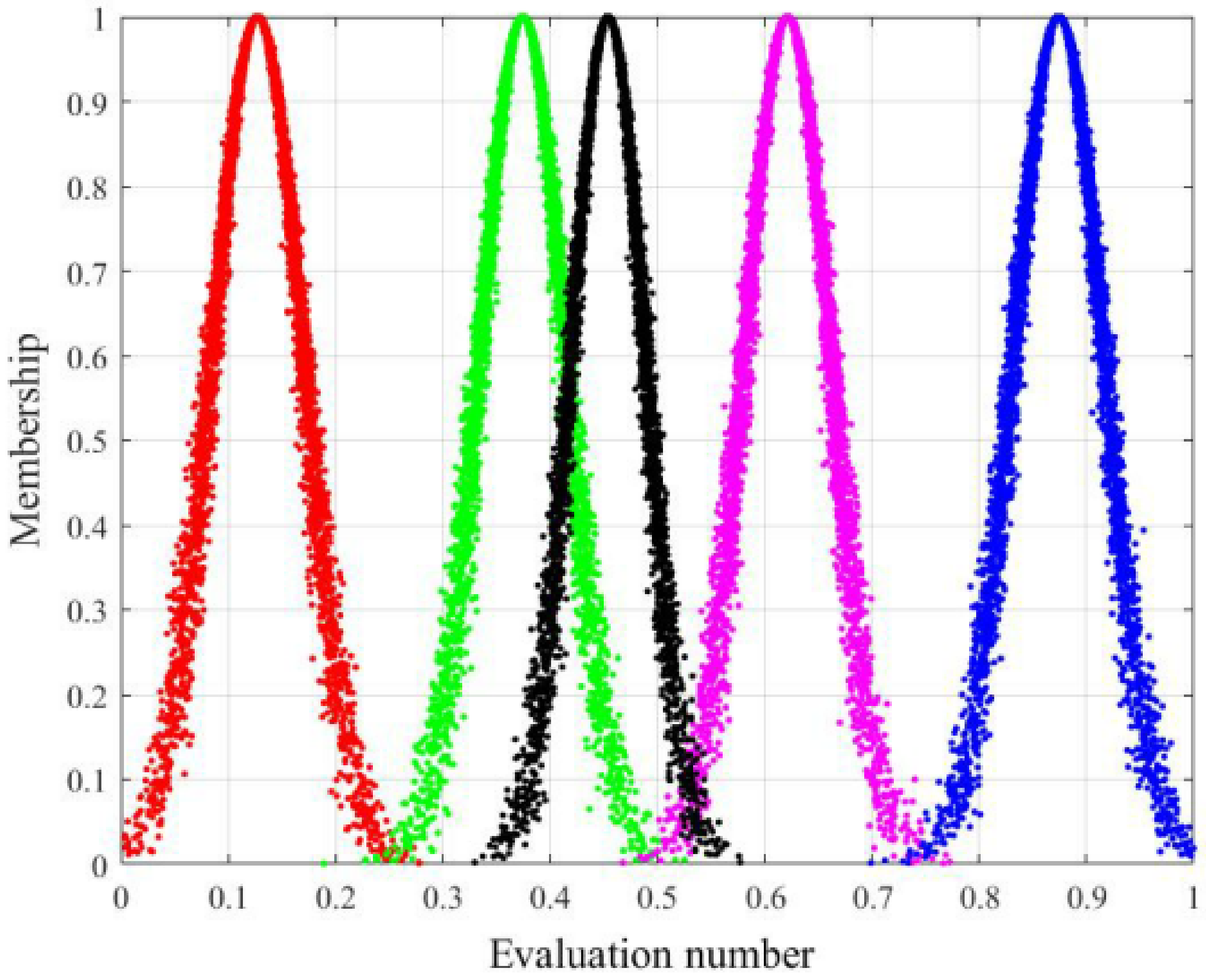

Building a Standard Cloud Model

3.2. Case Analysis

3.2.1. Construction of Extension Model

- Calculation of Matter–Element Correlation Degree to Be Evaluated

- 2.

- Level of the Event to be Evaluated is Determined

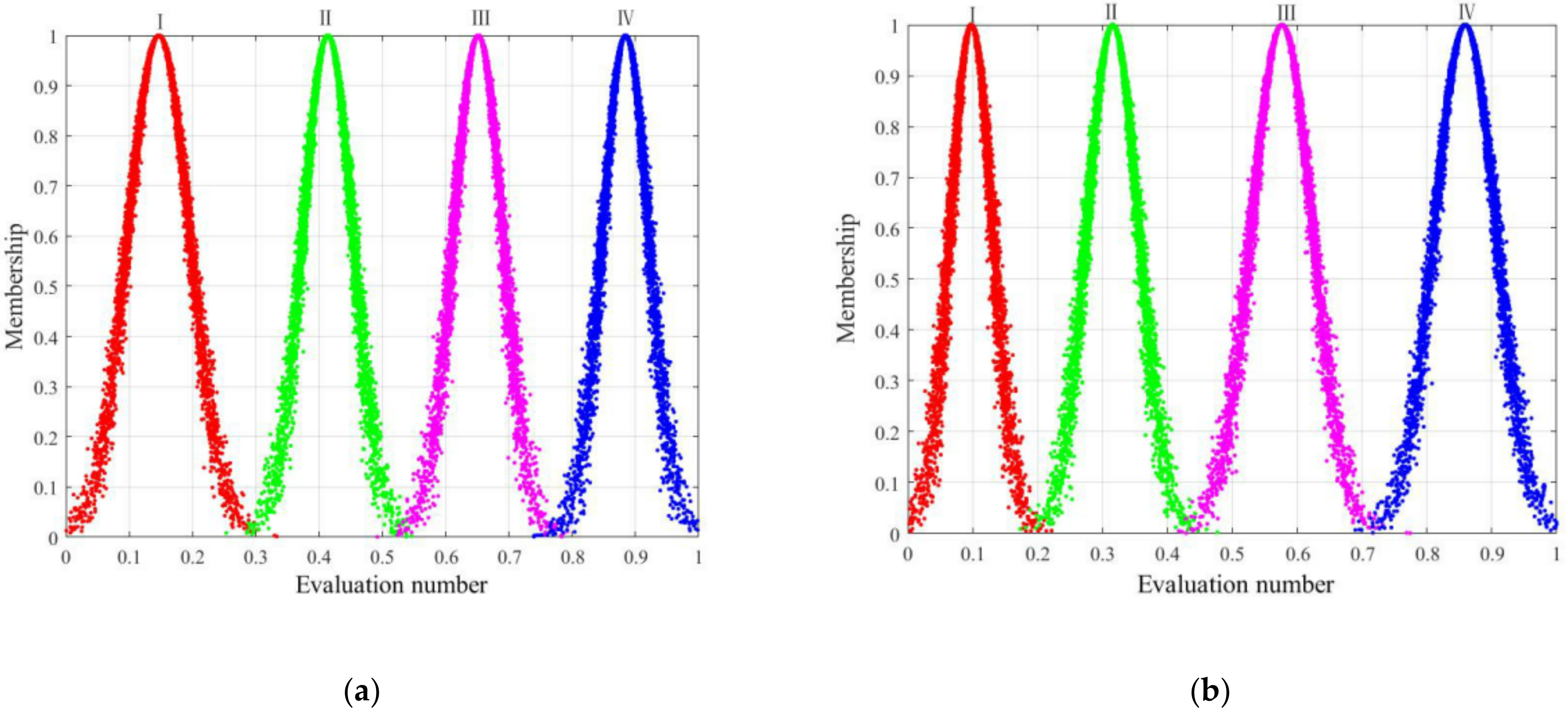

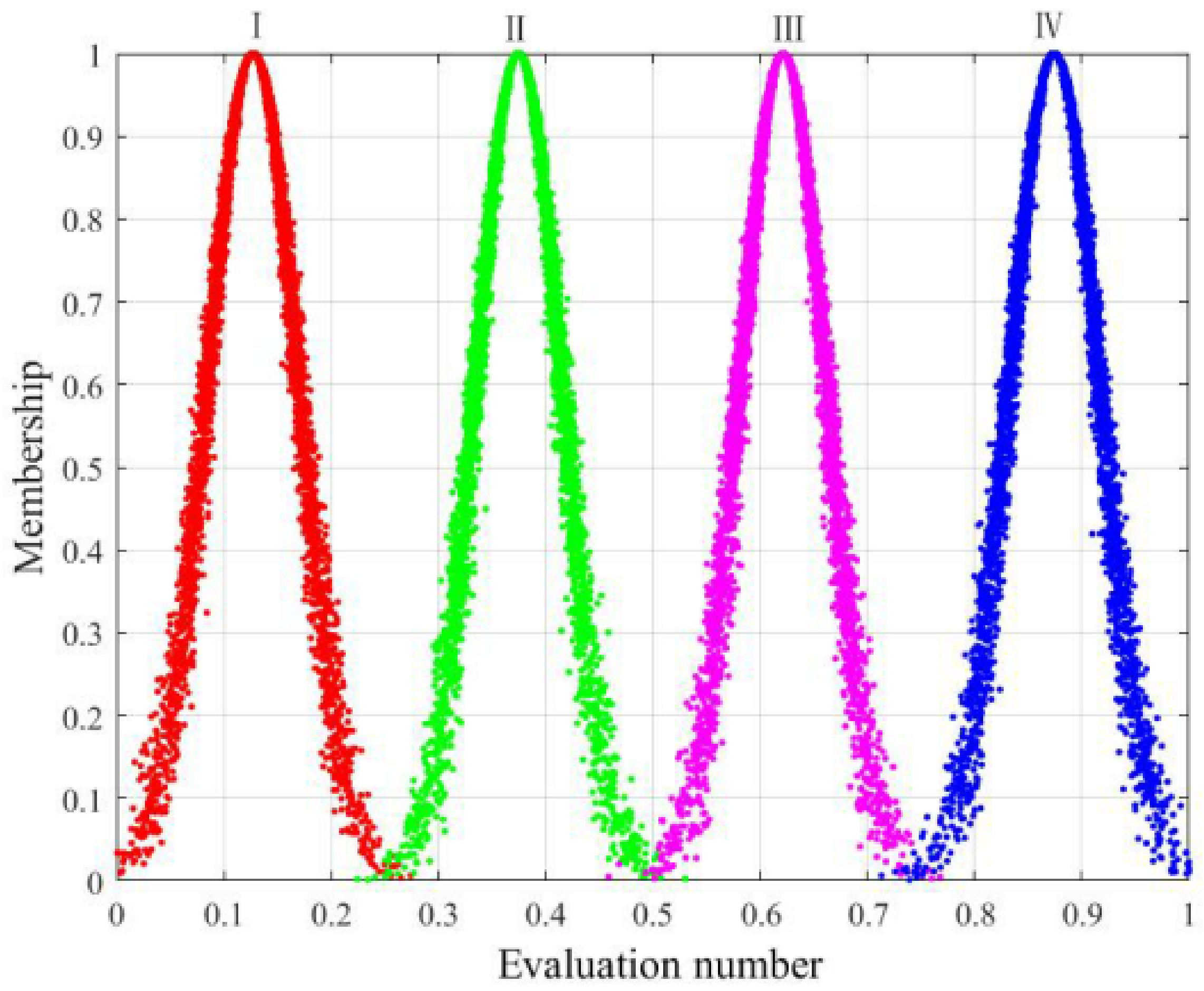

3.2.2. Construction of the Cloud Model

3.2.3. Cloud Map for Comprehensive Evaluation of Surface Subsidence Grades

4. Discussion

5. Conclusions

- (1)

- With the use of AHP, ten evaluation indicators were established from the perspectives of mining disturbance and geological structure. Similar to the northern plain coal mines, the main factors that affect the surface subsidence of southwest mines are: the number of coal seams, mining height and comprehensive Platt hardness of the overlying rock, as well as the surface slope, subsidence area rate, and other important factors.

- (2)

- An extension matter–element model was constructed, and the correlation degree was calculated according to the surface subsidence index of the southwest mines. The surface subsidence level of the mines can therefore be obtained directly. With a coal mine in Anshun used as an example, the comprehensive correlation degree of 4 levels was obtained. The comprehensive correlation degree of each level of the coal mine is −0.29836, 0.192232, −0.1093 and 0.46531, respectively. Therefore, the surface subsidence level of the coal mine is level Q2, which is a relatively safe level and is in line with actual engineering.

- (3)

- A cloud model for the comprehensive evaluation of the coal mine surface subsidence was established. Findings show that the similarity between the cloud map of the total index evaluation and each standard grade is 0, 0.3453, 0.7872 and 0, respectively. This result indicates that the surface subsidence of the coal mine is in a relatively safe state, which is consistent with the calculation results of the extension model, thereby showing that the two evaluation methods can verify each other to a certain extent. Moreover, both methods have certain feasibility and scientificity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cui, X.M.; Zhao, Y.L.; Wang, G.R.; Zhang, B.; Li, C.Y. Calculation of Residual Surface Subsidence Above Abandoned Longwall Coal Mining. Sustainability 2020, 12, 1528. [Google Scholar] [CrossRef] [Green Version]

- Han, H.L.; Hu, N.L.; Cui, B. Dynamic Modeling of Surface Subsidence Induced by Underground Mining. Adv. Mater. Res. 2012, 382, 323–327. [Google Scholar] [CrossRef]

- Yu, X.J. Coal mining and environmental development in southwest China. Environ. Dev. 2017, 21, 77–86. [Google Scholar] [CrossRef]

- Yang, M.G.H.; Hu, Z.Q.; Li, Y.J.; Li, X.J. Analysis of Reclamation for Coal Mining Subsidence Land in Chongqing. AASRI-AIT 2011 2011, 3, 291–294. [Google Scholar]

- Wang, S.Y.; Zhang, G.; Chen, Z.W.; Cui, H.; Zheng, Y.Z.; Xu, Z.X.; Li, Q.H. Surface deformation extraction from small baseline subset synthetic aperture radar interferometry (SBAS-InSAR) using coherence-optimized baseline combinations. GISci. Remote Sens. 2022, 59, 295–309. [Google Scholar] [CrossRef]

- Guo, Y.Q.; Zhao, Y.L.; Yan, H.Y. Disturbed boundaries extraction in coal-grain overlap areas with high groundwater levels using UAV-based visible and multispectral imagery. Environ. Sci. Pollut. Res. 2022. [Google Scholar] [CrossRef] [PubMed]

- Kong, D.Z.; Li, Q.; Wu, G.Y.; Song, G.F. Characteristics and control technology of face-end roof leaks subjected to repeated mining in close-distance coal seams. Bull. Eng. Geol. Environ. 2021, 80, 8363–8383. [Google Scholar] [CrossRef]

- Li, Q.; Wu, G.Y.; Kong, D.Z.; Han, S.; Ma, Z.Q. Study on Mechanism of End Face Roof Leaks Based on Stope Roof Structure Movement under Repeated Mining. Eng. Fail. Anal. 2022, 135, 106162. [Google Scholar] [CrossRef]

- Xiong, Y.; Kong, D.Z.; Cheng, Z.B.; Wu, G.Y.; Zhang, Q. The Comprehensive Identification of Roof Risk in a Fully Mechanized Working Face Using the Cloud Model. Mathematics 2021, 9, 2072. [Google Scholar] [CrossRef]

- Kong, D.Z.; Xiong, Y.; Cheng, Z.B. Stability analysis of coal face based on coal face-support-roof system in steeply inclined coal seam. Geomech. Eng. 2021, 25, 233–243. [Google Scholar] [CrossRef]

- Li, L.; Wu, G.Y.; Liu, Q.Z. Study on Overburden Movement and Fissure Evolution Law of Protective Layer Mining in Shallow Coal Seam. Energies 2022, 15, 1831. [Google Scholar] [CrossRef]

- Pathak, P.; Ghosh, P.; Banerjee, S.; Chatterjee, R.S.; Muzakkira, N.; Sikdar, P.K.; Ghosal, U.; Liang, M.C.; Meeran, K. Relic surface water (clay-pore water) input triggers arsenic release into the shallow groundwater of Bengal aquifers. J. Earth Syst. Sci. 2022, 131, 80. [Google Scholar] [CrossRef]

- Jirankova, E.; Waclawik, P.; Nemcik, J. Assessment of models to predict surface subsidence in the czech part of the upper silesian coal basin-case study. Acta Geodyn. Geomater. 2020, 17, 469–484. [Google Scholar] [CrossRef]

- Yan, W.T.; Chen, J.J.; Yan, Y.G. A new model for predicting surface mining subsidence: The improved lognormal function model. Geosci. J. 2019, 23, 165–174. [Google Scholar] [CrossRef]

- Han, H.K.; Xu, J.L.; Wang, X.Z.; Xie, J.L.; Xing, Y.T. Surface Subsidence Prediction Method for Coal Mines with Ultrathick and Hard Stratum. Adv. Civ. Eng. 2019, 2019, 3714381. [Google Scholar] [CrossRef]

- Vyazmensky, A.; Elmo, D.; Stead, D. Role of Rock Mass Fabric and Faulting in the Development of Block Caving Induced Surface Subsidence. Rock Mech. Rock Eng. 2010, 43, 533–556. [Google Scholar] [CrossRef]

- Bazaluk, O.; Rysbekov, K.; Nurpeisova, M.; Lozynskyi, V.; Kyrgizbayeva, G.; Turumbetov, T. Integrated monitoring for the rock mass state during large-scale subsoil development. Front. Environ. Sci. 2022, 10, 852591. [Google Scholar] [CrossRef]

- Petlovanyi, M.; Malashkevych, D.; Sai, K.; Zubko, S. Research into balance of rocks and underground cavities formation in the coal mine flowsheet when mining thin seams. Min. Miner. Depos. 2020, 14, 66–81. [Google Scholar] [CrossRef]

- Vynnykov, Y.; Kharchenko, M.; Dmytrenko, V.; Manhura, A. Probabilistic calculation in terms of deformations of the formations consisting of compacted overburden of Quarternary rocks. Min. Miner. Depos. 2020, 14, 122–129. [Google Scholar] [CrossRef]

- Field, E.H. Overview of the Working Group for the Development of Regional Earthquake Likelihood Models (RELM). Seismol. Res. Lett. 2007, 78, 7–16. [Google Scholar] [CrossRef]

- Fleurisson, J.-A. Slope Design and Implementation in Open Pit Mines: Geological and Geomechanical Approach. Procedia Eng. 2012, 46, 27–38. [Google Scholar] [CrossRef]

- Gerasymenko, O.; Shumlyanska, L.; Nadezhka, L.; Pivovarov, S.; Ganiev, O.; Ostapchuk, N.; Shipko, N. Neural Network Modeling in the Problem of Localization Earthquake of Ukraine. Geofiz. Zhurnal 2020, 42, 86–98. [Google Scholar] [CrossRef]

- Golik, V.I.; Komashchenko, V.I.; Morkun, V.S.; Morkun, N.V.; Hryshchenko, S.M. Energy Saving in Mining Production. Sci. Innov. 2018, 14, 29–39. [Google Scholar] [CrossRef]

- Haiko, H.; Saik, P.; Lozynskyi, V. The Philosophy of Mining: Historical Aspect and Future Prospect. Philos. Cosmol. 2019, 22, 76–90. [Google Scholar] [CrossRef]

- Kong, D.Z.; Pu, S.J.; Cheng, Z.H.; Wu, G.Y.; Liu, Y. Coordinated Deformation Mechanism of the Top Coal and Filling Body of Gob-Side Entry Retaining in a Fully Mechanized Caving Face. Int. J. Geomech. 2021, 21, 04021030. [Google Scholar] [CrossRef]

- Diaz, H.; Teixeira, A.P.; Soares, C.G. Application of Monte Carlo and Fuzzy Analytic Hierarchy Processes for ranking floating wind farm locations. Ocean Eng. 2022, 245, 110453. [Google Scholar] [CrossRef]

- Fedrizzi, M.; Krejci, J. A Note on the Paper “Fuzzy Analytic Hierarchy Process: Fallacy of the Popular Methods”. Int. J. Uncertain. Fuzziness Knowl.-Based Syst. 2015, 23, 965–970. [Google Scholar] [CrossRef]

- Wang, F.; Lu, Y.; Li, J.; Ni, J. Evaluating Environmentally Sustainable Development Based on the PSR Framework and Variable Weigh Analytic Hierarchy Process. Int. J. Environ. Res. Public Health 2021, 18, 2836. [Google Scholar] [CrossRef]

- Hadi-Vencheh, A.; Niazi-Motlagh, M. An improved voting analytic hierarchy process-data envelopment analysis methodology for suppliers selection. Int. J. Comput. Integr. Manuf. 2011, 24, 189–197. [Google Scholar] [CrossRef]

- Fan, Y.; Fang, Z.G.; Liu, S.F.; Liu, J. A grey approach to site selection for nursing homes: An extension of the fuzzy analytic hierarchy process. J. Intell. Fuzzy Syst. 2021, 40, 8807–8818. [Google Scholar] [CrossRef]

- Yuen, K.K.F. The primitive cognitive network process: Comparisons with the analytic hierarchy process. Int. J. Inf. Technol. Decis. Mak. 2011, 10, 659–680. [Google Scholar] [CrossRef]

- Naghashzargar, E.; Ghiasi, M.; Semnani, D. Using analytical hierarchy process to optimize mechanical properties of multi-twisted buckled silk yarn as a collagenous tissue scaffold. J. Text. Inst. 2022, 113, 460–466. [Google Scholar] [CrossRef]

- Sherin, S.; Rehman, Z.; Hussain, S.; Mohammad, N.; Raza, S. Hazards identification and risk analysis in surface mines of Pakistan using fault tree analysis technique. Min. Miner. Depos. 2021, 15, 119–126. [Google Scholar] [CrossRef]

- Cox, M.A.A. Which is the appropriate triangular distribution to employ in the modified analytic hierarchy process? IMA J. Manag. Math. 2012, 23, 227–239. [Google Scholar] [CrossRef]

- Li, S.Q.; Li, R.R. Energy Sustainability Evaluation Model Based on the Matter-Element Extension Method: A Case Study of Shandong Province, China. Sustainability 2017, 9, 2128. [Google Scholar] [CrossRef] [Green Version]

- Jin, J.; Qian, H.; Chen, Y.F.; Xi, W.J. Assessment of Groundwater Quality Based on Matter Element Extension Model. J. Chem. 2013, 2013, 715647. [Google Scholar] [CrossRef]

- Liu, J.C.; Lu, Y.Y. Research on the evaluation of China’s photovoltaic policy driving ability under the background of carbon neutrality. Energy 2022, 250, 123809. [Google Scholar] [CrossRef]

- Li, X.J.; Zhang, Z.; Jim, C.Y.; Lai, J.Y.; Chen, X.Q. Owner-based benefit evaluation of BIM applications in China’s engineering projects. Eng. Constr. Archit. Manag. 2022. [Google Scholar] [CrossRef]

- Yang, S.; Xu, Z.T.; Su, K.J. Variable Weight Matter-Element Extension Model for the Stability Classification of Slope Rock Mass. Mathematics 2021, 9, 2807. [Google Scholar] [CrossRef]

- Zhang, K.; Yu, X.D.; Liu, S.L.; Dong, X.; Li, D.Q.; Zang, H.Z.; Xu, R. Wind power interval prediction based on hybrid semi-cloud model and nonparametric kernel density estimation. Energy Rep. 2022, 8, 1068–1078. [Google Scholar] [CrossRef]

- Xu, Q.W.; Xu, K.L. Evaluation of ambient air quality based on synthetic cloud model. Fresenius Environ. Bull. 2018, 27, 141–146. [Google Scholar]

- Davies, H.J.; Bachtiger, P.; Williams, I.; Molyneaux, P.L.; Peters, N.S.; Mandic, D.P. Wearable In-Ear PPG: Detailed Respiratory Variations Enable Classification of COPD. IEEE Trans. Biomed. Eng. 2022, 69, 2390–2400. [Google Scholar] [CrossRef]

- Yang, D.J.; Bian, Z.F. Comparison of the disturbance of soil physical quality indices between different underground mining stages in semi-arid regions of Western China. Environ. Earth Sci. 2022, 81, 354. [Google Scholar] [CrossRef]

- Wang, E.; Xie, S.R. Determination of coal pillar width for gob-side entry driving in isolated coal face and its control in deep soft-broken coal seam: A case study. Energy Sci. Eng. 2022, 10, 2305–2316. [Google Scholar] [CrossRef]

- Rastegarmanesh, A.; Mirzaghorbanali, A.; McDougall, K.; Aziz, N.; Anzanpour, S.; Nourizadeh, H.; Moosavi, M. Axial Performance of Cementitious Grouted Cable Bolts Under Rotation Constraint Scenarios. Rock Mech. Rock Eng. 2022. [Google Scholar] [CrossRef]

- Yan, W.T.; Chen, J.J.; Yang, W.F.; Liu, X.S.; Wang, W.W.; Zhang, W.K. On-Site Measurement on Surface Disturbance Law of Repeated Mining with High Relief Terrain. Sustainability 2022, 14, 3166. [Google Scholar] [CrossRef]

- Liu, P.Z.; Gao, L.; Zhang, P.D.; Wu, G.Y.; Wang, C.; Ma, Z.Q.; Kong, D.Z.; Kang, X.T.; Han, S. A Case Study on Surrounding Rock Deformation Control Technology of Gob-Side Coal-Rock Roadway in Inclined Coal Seam of a Mine in Guizhou, China. Processes 2022, 10, 863. [Google Scholar] [CrossRef]

- Shang, Y.; Kong, D.; Pu, S.; Xiong, Y.; Li, Q.; Cheng, Z. Study on Failure Characteristics and Control Technology of Roadway Surrounding Rock under Repeated Mining in Close-Distance Coal Seam. Mathematics 2022, 10, 2166. [Google Scholar] [CrossRef]

- Wang, G.Y.; Xu, C.L.; Li, D.Y. Generic normal cloud model. Inf. Sci. 2014, 280, 1–15. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, S.H.; Han, J.T.; Zhao, Y.; Han, Q.; Wu, L.Y.; Wang, X.; Qiu, Z.Y.; Zou, T.Q.; Fan, C. A study of the temporal and spatial variations in the suitability of the environment in Chinese cities for tourism and in strategies for optimizing the environment. Int. J. Digit. Earth. 2022, 15, 527–552. [Google Scholar] [CrossRef]

- Zhu, X.J.; Guo, G.L.; Liu, H.; Yang, X.Y. Surface subsidence prediction method of backfill-strip mining in coal mining. Bull. Eng. Geol. Environ. 2019, 78, 6235–6248. [Google Scholar] [CrossRef]

- Ju, J.F.; Xu, J.L. Surface stepped subsidence related to top-coal caving longwall mining of extremely thick coal seam under shallow cover. Int. J. Rock Mech. Min. Sci. 2015, 78, 27–35. [Google Scholar] [CrossRef]

| Influencing Factors | Evaluation Level | ||||

|---|---|---|---|---|---|

| Level 4 (Q4) | Level 3 (Q3) | Level 2 (Q2) | Level 1 (Q1) | ||

| Mining Disturbance | Mining depth (m) | >1000 | 800–1000 | 600–800 | <600 |

| Mining height (m) | >3 | 2–3 | 1–2 | 0–1 | |

| Mining width (m) | 250–300 | 200–250 | 150–200 | 100–150 | |

| Stent resistance (KN) | 0–6000 | 6000–8000 | 8000–10,000 | 10,000–12,000 | |

| Mining coal seams (layer) | 4 | 3 | 2 | 1 | |

| Working face advancing speed | 85–100 | 65–85 | 40–65 | <40 | |

| Geological structure | Surface slope (°) | >45 | 30–45 | 15–30 | 0–15 |

| Comprehensive Platts Hardness (KN) | 0–3 | 3–6 | 6~9 | >9 | |

| Fault density (strip × km−2) | >4 | 2.5–4 | 1–2.5 | 0–1 | |

| Subsidence area rate (%) | >70 | 30–70 | 10–30 | 0–10 | |

| Matrix Order | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| RI | 0 | 0 | 0.58 | 0.9 | 1.12 | 1.24 |

| Judgement Matrix | Judgement Matrix Maximum Eigenvalue | Eigenvector | Vector of Index Weight | CI | RI | Consistency Check |

|---|---|---|---|---|---|---|

| MA | 2 | (0.6, 0.4) | 0.6, 0.4 | 0 | 0 | pass |

| MB1 | 6.2518 | (0.2360, 0.1293, 0.0894, 0.1199, 0.3340, 0.0914) | 0.2360, 0.1293, 0.0894, 0.1199, 0.3340, 0.0914 | 0.050 | 0.040 | pass |

| MB2 | 4.2193 | (0.2252, 0.2894, 0.2694, 0.2161) | 0.2252, 0.2894, 0.2694, 0.2161 | 0.073 | 0.081 | pass |

| 0.0776 | 0.1416 | 0.0536 | 0.0719 | 0.2004 | 0.0548 | 0.0901 | 0.1157 | 0.1078 | 0.0864 |

| Evaluation Indicators | Evaluation Index Level | |||

|---|---|---|---|---|

| Q1 | Q2 | Q3 | Q4 | |

| B1 | (0.1468, 0.0490, 0.004) | (0.4139, 0.0400, 0.004) | (0.6514, 0.0391, 0.004) | (0.8844, 0.0386, 0.004) |

| B2 | (0.0980, 0.0327, 0.004) | (0.3157, 0.0399, 0.004) | (0.5765, 0.0471, 0.004) | (0.8589, 0.0471, 0.004) |

| Overall indicator | (0.1273, 0.0425, 0.004) | (0.3746, 0.0400, 0.004) | (0.6214, 0.0401, 0.004) | (0.8742, 0.0420, 0.004) |

| Level | ||||||||||

| Q1 | −0.300 | −0.143 | −0.333 | −0.500 | −0.250 | −0.500 | −0.256 | −0.445 | −0.187 | −0.333 |

| Q2 | 0.100 | 0.200 | 0 | −0.250 | 0.500 | −0.143 | 0.333 | 0.333 | −0.278 | 0.500 |

| Q3 | −0.005 | −0.400 | 0 | 0.500 | −0.250 | 0.500 | −0.167 | −0.250 | 0.067 | −0.333 |

| Q4 | −0.525 | −0.600 | −0.333 | −0.250 | −0.500 | −0.333 | −0.444 | −0.286 | −0.469 | −0.714 |

| Comprehensive Correlation Degree | Q1 | Q2 | Q3 | Q4 |

|---|---|---|---|---|

| −0.29836 | 0.192232 | −0.1093 | −0.46531 |

| Index | Ex | En | He |

|---|---|---|---|

| C1 | 0.4688 | 0.0104 | 0.0010 |

| C2 | 0.3000 | 0.0250 | 0.0025 |

| C3 | 0.4000 | 0.0667 | 0.0067 |

| C4 | 0.7375 | 0.0097 | 0.0009 |

| C5 | 0.5000 | 0.0833 | 0.0083 |

| C6 | 0.6750 | 0.0117 | 0.0012 |

| C7 | 0.4250 | 0.0194 | 0.0019 |

| C8 | 0.4583 | 0.0417 | 0.0042 |

| C9 | 0.4000 | 0.0167 | 0.0017 |

| C10 | 0.2100 | 0.0133 | 0.0013 |

| B1 | 0.5023 | 0.0417 | 0.0042 |

| B2 | 0.3814 | 0.0238 | 0.0024 |

| Comprehensive Evaluation Index | Evaluation Level | |||

|---|---|---|---|---|

| Q1 | Q2 | Q3 | Q4 | |

| B1 | 0 | 0.7576 | 0.4579 | 0 |

| B2 | 0 | 0.6519 | 0.1401 | 0 |

| overall indicator | 0 | 0.6658 | 0.348 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Kong, D.; Liu, Q.; Xiong, Y.; Chen, F.; Zhang, H.; Chu, Y. Comprehensive Identification of Surface Subsidence Evaluation Grades of Mines in Southwest China. Mathematics 2022, 10, 2664. https://doi.org/10.3390/math10152664

Li L, Kong D, Liu Q, Xiong Y, Chen F, Zhang H, Chu Y. Comprehensive Identification of Surface Subsidence Evaluation Grades of Mines in Southwest China. Mathematics. 2022; 10(15):2664. https://doi.org/10.3390/math10152664

Chicago/Turabian StyleLi, Li, Dezhong Kong, Qinzhi Liu, Yu Xiong, Fei Chen, Haibing Zhang, and Yunyun Chu. 2022. "Comprehensive Identification of Surface Subsidence Evaluation Grades of Mines in Southwest China" Mathematics 10, no. 15: 2664. https://doi.org/10.3390/math10152664

APA StyleLi, L., Kong, D., Liu, Q., Xiong, Y., Chen, F., Zhang, H., & Chu, Y. (2022). Comprehensive Identification of Surface Subsidence Evaluation Grades of Mines in Southwest China. Mathematics, 10(15), 2664. https://doi.org/10.3390/math10152664