Toward Sustainability or Efficiency: The Case of Smallholder Coffee Farmers in Vietnam

Abstract

1. Introduction

2. Materials and Methods

2.1. Theoretical Framework

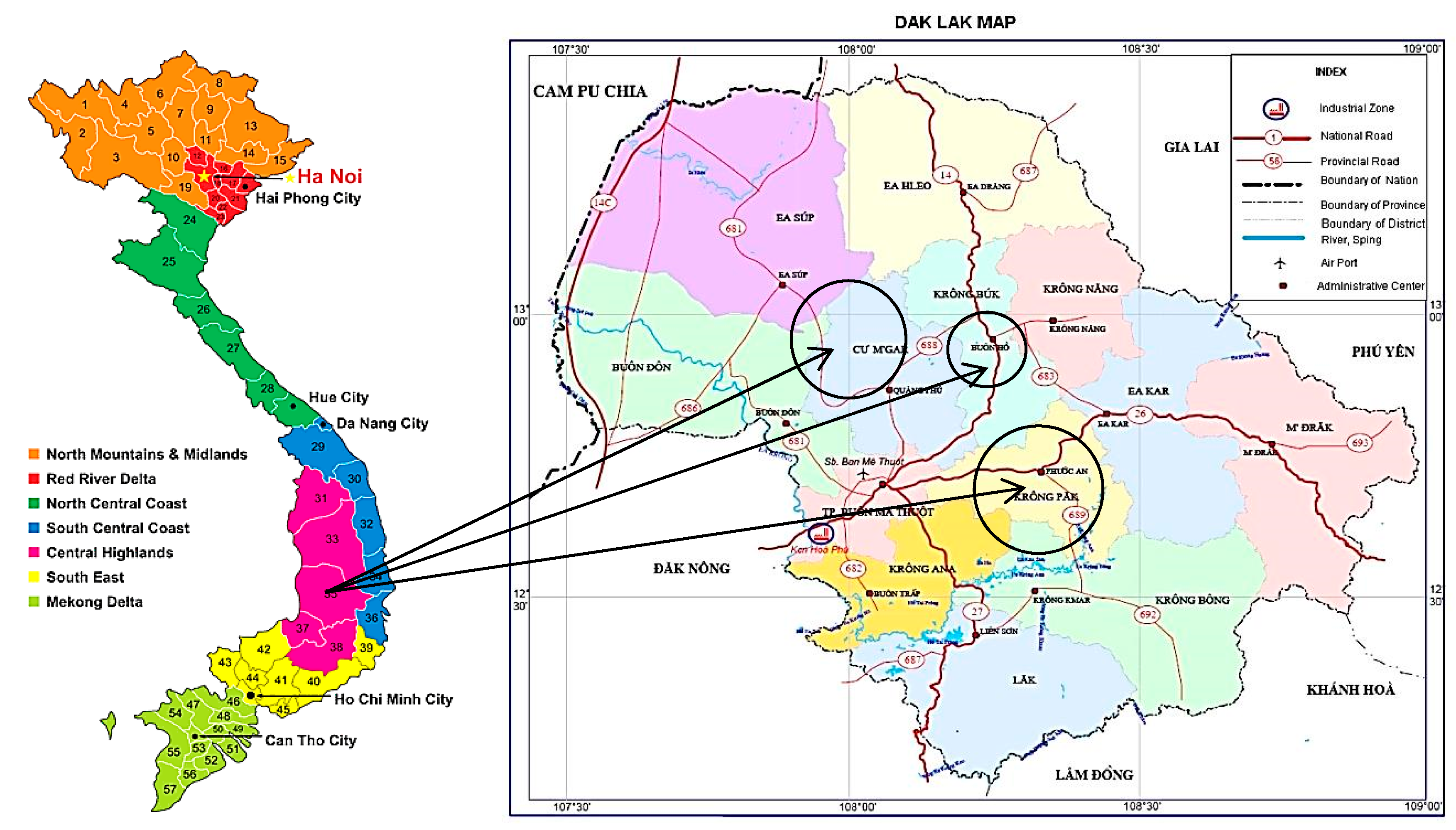

2.2. Research Area

2.3. Data Source and Sampling

2.4. Data Analysis and Model Specification

3. Results

3.1. Socioeconomic Characteristics of Coffee Farmer

3.2. Coffee Farming Practices

3.2.1. Replantation

3.2.2. Coffee Varieties

3.2.3. Fertilizer

3.2.4. Irrigation

3.2.5. Pruning

3.2.6. Pest and Disease Management

3.2.7. Shade Trees

3.3. Factors of Production

3.4. Coffee Yield

3.5. Maximum Likelihood Estimates

3.5.1. Stochastic Frontier Production Model

3.5.2. The Inefficiency Effects Model

3.6. Technical Efficiency

3.7. Cost-Benefit Analysis

4. Discussion

4.1. Determinants of Technical Efficiency

4.2. Factors Influencing Coffee Output

4.3. Challenges Facing Sustainable Coffee Production

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Variables | Parameter | SCP | Non-SCP | ||

|---|---|---|---|---|---|

| Tolerance | VIF | Tolerance | VIF | ||

| NPK fertilizer | β1 | 0.663 | 1.509 | 0.520 | 1.923 |

| Organic fertilizer | β2 | 0.630 | 1.588 | 0.633 | 1.579 |

| Manure | β3 | 0.825 | 1.212 | 0.784 | 1.276 |

| Pesticide | β4 | 0.785 | 1.274 | 0.756 | 1.323 |

| Water | β5 | 0.639 | 1.565 | 0.535 | 1.869 |

| Hired labor | β6 | 0.580 | 1.724 | 0.572 | 1.749 |

| Family labor | β7 | 0.685 | 1.460 | 0.434 | 2.303 |

| Depreciation | β8 | 0.582 | 1.719 | 0.422 | 2.371 |

| Other cost | β9 | 0.759 | 1.318 | 0.810 | 1.235 |

| Constant/intercept | δ0 | 0.438 | 2.284 | 0.598 | 1.671 |

| Age of farmer | δ1 | 0.806 | 1.240 | 0.741 | 1.350 |

| Gender | δ2 | 0.686 | 1.458 | 0.623 | 1.604 |

| Education level | δ3 | 0.522 | 1.918 | 0.361 | 2.770 |

| Ethnic | δ4 | 0.386 | 2.594 | 0.181 | 5.528 |

| Farming experience | δ5 | 0.742 | 1.347 | 0.542 | 1.846 |

| Household size | δ6 | 0.376 | 2.659 | 0.341 | 2.934 |

| Farm size | δ7 | 0.532 | 1.880 | 0.328 | 3.052 |

| Labor to land ratio | δ8 | 0.693 | 1.443 | 0.245 | 4.088 |

| Coop. membership | δ9 | 0.619 | 1.615 | 0.572 | 1.748 |

| Extension | δ10 | 0.441 | 2.268 | 0.359 | 2.789 |

| Formal credit | δ11 | 0.663 | 1.509 | 0.520 | 1.923 |

| Source | Sum of Squares | df | Mean Square | F | Sig. |

|---|---|---|---|---|---|

| Contrast | 0.702 | 10 | 0.070 | 2.304 | 0.013 |

| Error | 9.025 | 296 | 0.030 |

References

- Ahmad, Alia. 2001. An Institutional Analysis of Changes in Land Use Pattern and Water Scarcity in Dak Lak Province, Vietnam. Copenhagen: NIAS Press. Available online: http://dlc.dlib.indiana.edu/dlc/bitstream/handle/10535/7903/ahmadviet.pdf?sequence=1 (accessed on 20 January 2019).

- Aigner, Dennis, C. A. Knox Lovell, and Peter Schmidt. 1977. Formulation and estimation of stochastic frontier production function models. Journal of Econometrics 6: 21–37. [Google Scholar] [CrossRef]

- Amarasinghe, Upali A., Chu Thai Hoanh, Dave D’Haeze, and Tran Quoc Hung. 2015. Toward sustainable coffee production in Vietnam: More coffee with less water. Agricultural Systems 136: 96–105. [Google Scholar] [CrossRef]

- Amarasinghe, Upali, Lal Muthuwatta, and Ramaswamy Sakthivadivel. 2019. Water Scarcity Variations within a Country: A Case Study of Sri Lanka. Colombo: International Water Management Institute. Available online: https://EconPapers.repec.org/RePEc:iwt:rerpts:h024897 (accessed on 23 January 2019).

- Ateka, Josiah, A. Onono, and Perez Martin Etyang. 2018. Technical Efficiency and its Determinants in Smallholder Tea Production: Evidence from Nyamira and Bomet Counties in Kenya. Global Journal of Science Frontier Research: D Agriculture and Veterinary 18: 43–54. [Google Scholar]

- Bacon, Christopher. 2005. Confronting the Coffee Crisis: Can Fair Trade, Organic, and Specialty Coffees Reduce Small-Scale Farmer Vulnerability in Northern Nicaragua? World Development 33: 497–511. [Google Scholar] [CrossRef]

- Bardhan, Pranab K. 1973. Size, Productivity, and Returns to Scale: An Analysis of Farm-Level Data in Indian Agriculture. Journal of Political Economy 81: 1370–86. [Google Scholar] [CrossRef]

- Bati Mustefa, Alemu Ayele, Mulugeta Tilahun, and Raja Kumar Parabathina. 2017. Studies on Economic Efficiency of Coffee Production in Ilu Abbabor Zone, Oromia Region, Ethiopia. Journal of Agricultural Economics and Rural Development 3: 293–306. [Google Scholar]

- Battese, George E., and Timothy Coelli. 1988. Prediction of firm-level technical efficiencies with a generalized frontier production function and panel data. Journal of Econometrics 38: 387–99. [Google Scholar] [CrossRef]

- Bau, Le Ngoc. 2015. Ứng dụng tiến bộ kỹ thuật để phát triển bền vững ngành cà phê Việt Nam. Institute of Agricultural Science for Southern Vietnam. Available online: http://iasvn.org/homepage/Ung-dung-tien-bo-ky-thuat-de-phat-trien-ben-vung-nganh-ca-phe-Viet-Nam-7133.html (accessed on 3 March 2019).

- Bauer, Paul W. 1990. Recent developments in the econometric estimation of frontiers. Journal of Econometrics 46: 39–56. [Google Scholar] [CrossRef]

- Bich Hong, Nguyen, and Mitsuyasu Yabe. 2015. Technical Efficiency Analysis of Tea Production in the Northern Mountainous Region of Vietnam. Global Journal of Science Frontier Research: D Agriculture and Veterinary 15: 31–42. Available online: https://pdfs.semanticscholar.org/96b3/f6649f94d6c6be2d4c7459a7939df21ec00b.pdf (accessed on 23 January 2019).

- Binam, Joachim Nyemeck, Jean Tonyè, Njankoua wandji, Gwendoline Nyambi, and Mireille Akoa. 2004. Factor affecting the technical efficiency among smallholder farmers in the slash and burn agriculture zone of Cameron. Food Policy 29: 531–45. [Google Scholar] [CrossRef]

- Borbor-Cordova, Mercy J., Elizabeth Boyer, William McDowell, and Charles Hall. 2006. Nitrogen and phosphorus budgets for a tropical watershed impacted by agricultural land use: Guayas, Ecuador. Biogeochemistry 79: 135–61. [Google Scholar] [CrossRef]

- Bravo-Monroy, Simon Potts, and Joseph Tzanopoulos. 2016. Drivers influencing farmer decisions for adopting organic or conventional coffee management practices. Food Policy 58: 49–61. Available online: http://www.sciencedirect.com/science/article/pii/S0306919215001359 (accessed on 2 March 2019). [CrossRef]

- Brombini Santos, Adriana, and Paulo Mazzafera. 2012. Dehydrins Are Highly Expressed in Water-Stressed Plants of Two Coffee Species. Tropical Plant Biology 5: 218–32. [Google Scholar] [CrossRef]

- Capa Mora, Edwin Daniel, Javier Pérez-Esteban, and Alberto Masaguer. 2015. Unsustainability of recommended fertilization rates for coffee monoculture due to high N2O emissions. Agronomy for Sustainable Development 35: 1551–59. [Google Scholar] [CrossRef]

- Castro-Tanzi, Sebastian, Thomas Dietsch, Natalia Urena, Lucia Vindas, and Mark Chandler. 2012. Analysis of management and site factors to improve the sustainability of smallholder coffee production in Tarrazú, Costa Rica. Agriculture, Ecosystems & Environment 155: 172–81. [Google Scholar]

- Charnes, A., W. W. Cooper, and E. Rhodes. 1978. Measuring the efficiency of decision making units. European Journal of Operational Research 2: 429–44. [Google Scholar] [CrossRef]

- Coelli, Timothy. 1995. Recent developments in Frontier modelling and efficiency measurement. Australian Journal of Agricultural Economics 39: 219–45. [Google Scholar] [CrossRef]

- Coelli, Tim J. 1996. A Guide to FRONTIER Version 4.1: A Computer Program for Stochastic Frontier Production and Cost Function Estimation. CEPA Working Paper 96/7. Armidale, Australia: University of New England. [Google Scholar]

- Coelli, Timothy, and George Battese. 1995. A Model For Technical Inefficiency Effects in a Stochastic Frontier Production Function for Panel Data. Empirical Economics 20: 325–32. [Google Scholar]

- Coelli, Timothy, D. S. Rao, Christopher O’Donnell, and George Battese. 2005. An Introduction to Efficiency and Productivity Analysis. Berlin/Heidelberg: Springer Science & Business Media. [Google Scholar]

- Cong Thang, Tran, Michael P. Burton, and Donna C. Brennan. 2009. Optimal replanting and cutting rule for coffee farmers in Vietnam. Paper presented at the 2009 Conference (53rd), Cairns, Australia, February 11–13; Available online: https://ideas.repec.org/p/ags/aare09/47638.html (accessed on 1 March 2019).

- Crisosto, Carlos H., David A. Grantz, and F. C. Meinzer. 1992. Effects of water deficit on flower opening in coffee (Coffea arabica L.). Tree Physiology 10: 127–39. [Google Scholar] [CrossRef]

- D’Haeze Dave, Jozef Deckers, Dirk Raes, Tran An Phong, and Nguyen Dang Minh Chanh. 2003. Over-irrigation of Coffea canephora in the Central Highlands of Vietnam revisited: Simulation of soil moisture dynamics in Rhodic Ferralsols. Agricultural Water Management 63: 185–202. [Google Scholar] [CrossRef]

- D’haeze Dave, Jozef Deckers, Dirk Raes, Tran An Phong, and Hugo Loi. 2005. Environmental and socio-economic impacts of institutional reforms on the agricultural sector of Vietnam: Land suitability assessment for Robusta coffee in the Dak Gan region. Agriculture, Ecosystems & Environment 105: 59–76. [Google Scholar]

- DakLakDARD. 2016. Dak Laks’ Sustainable Coffee Plan Till 2020 and Vision to 2030. Buon Ma Thuot: Dak Lak Peoples’ Committee. [Google Scholar]

- Daviron Benoit and Stefano Ponte. 2005. The Coffee Paradox: Global Markets, Commodity Trade and the Elusive Promise of Development. London: Technical Centre for Agricultural Rural Cooperation, Zed Books. [Google Scholar]

- De Beenhouwer, Matthias, Diriba Muleta, Bram Peeters, Maarten Van Geel, Bart Lievens, and Olivier Honnay. 2014. DNA pyrosequencing evidence for large diversity differences between natural and managed coffee mycorrhizal communities. Agronomy for Sustainable Development 35: 241–49. [Google Scholar] [CrossRef]

- Dessale, Moges. 2018. Measurement of Technical Efficiency and Its Determinants in Wheat Production: The Case of Smallholder Farmers in Wogidi District, South Wollo Zone Ethiopia. Food Science and Quality Management 81: 86–93. [Google Scholar]

- Dessale, Moges. 2019. Analysis of technical efciency of small holder wheat-growing farmers of Jamma district, Ethiopia. Agriculture and Food Security 8: 1–8. [Google Scholar] [CrossRef]

- Dietsch, Thomas V., Stacy M. Philpott, Robert A. Rice, Russell Greenberg, Peter Bichier, Timothy G. O’Brien, and Margaret F. Kinnaird. 2004. Conservation Policy in Coffee Landscapes. Science 303: 625–26. [Google Scholar] [CrossRef] [PubMed]

- FAO. 2003. World Agriculture: Towards 2015/2030: An FAO Perspective. London: Earthscan Publications Ltd. Available online: http://www.fao.org/3/a-y4252e.pdf (accessed on 1 March 2019).

- Farrell, Michaeal James. 1957. The Measurement of Productive Efficiency. Journal of the Royal Statistical Society. Series A (General) 120: 253–90. [Google Scholar] [CrossRef]

- Førsund Finn, Knox Lovell, and Peter Schmidt. 1980. A survey of frontier production functions and of their relationship to efficiency measurement. Journal of Econometrics 13: 5–25. [Google Scholar] [CrossRef]

- Gaitán Cremaschi, Daniel, Frits van Evert, Don Jansen, Miranda Meuwissen, and Alfons Oude Lansink. 2018. Assessing the Sustainability Performance of Coffee Farms in Vietnam: A Social Profit Inefficiency Approach. Sustainability 10: 4227. [Google Scholar] [CrossRef]

- Giovannucci, Daniele, and Stefano Ponte. 2005. Standards as a new form of social contract? Sustainability initiatives in the coffee industry. Food Policy 30: 284–301. [Google Scholar] [CrossRef]

- Glaser, Barney. G., and Anselm. L. Strauss. 1967. The Discovery of Grounded Theory: Strategies for Qualitative Research. Venice: Aldine. [Google Scholar]

- Greene, William. 1980. Maximum likelihood estimation of econometric frontier functions. Journal of Econometrics 13: 27–56. [Google Scholar] [CrossRef]

- Greene, William H. 1990. A Gamma-distributed stochastic frontier model. Journal of Econometrics 46: 141–63. [Google Scholar] [CrossRef]

- Greene, William. 1993. The Econometric Approach to Efficiency Analysis. In The Measurement of Productive Efficiency: Techniques and Applications. Edited by Harold. O. Fried and Shelton. S. Schmidt. Oxford: Oxford University Press. [Google Scholar]

- Greene, William. 2010. Testing hypotheses about interaction terms in nonlinear models. Economics Letters 107: 291–96. [Google Scholar] [CrossRef]

- Haggar, Jeremy, Gabriela Soto, Fernando Casanoves, and Elias de Melo Virginio. 2017. Environmental-economic benefits and trade-offs on sustainably certified coffee farms. Ecological Indicators 79: 330–37. [Google Scholar] [CrossRef]

- Hajjar Reem, Peter Newton, Daniel Adshead, Meghan Bogaerts, Victoria Maguire-Rajpaul, Louis F. G. Pinto, Constance McDermott, Jeffrey Milder, Eva Wollenberg, and Arun Agrawal. 2019. Scaling up sustainability in commodity agriculture: Transferability of governance mechanisms across the coffee and cattle sectors in Brazil. Journal of Cleaner Production 206: 124–32. [Google Scholar] [CrossRef]

- Ho, Thong, and Hoa Niekdam. 2016. Labor Dependence, Income Diversification, Rural Credit, and Technical Efficiency ofSmall-Holder Coffee Farms: A Case Study of Cu M’gar District, Dak Lak Province, Vietnam. Journal of Economics Development 23: 22–41. [Google Scholar]

- Ho, Thong, Prabodh Illukpitiya, and John F. Yanagida. 2014. Factors Affecting Technical Efficiency of Small-holder Coffee Farming in the Krong Ana Watershed, Vietnam. Asian Journal of Agricultural Extension, Economics & Sociology 3: 37–49. [Google Scholar]

- Huang, Clief J., and Jin Tan Liu. 1994. Estimation of a Non-Neutral Stochastic Frontier Production Function. Journal of Productivity Analysis 5: 171–80. [Google Scholar] [CrossRef]

- Huynh, Viet, Huynh Khai, and Mitsuyasu Yabe. 2011. Technical efficiency analysis of rice production in Vietnam. Journal of ISSAAS 17: 135–46. [Google Scholar]

- Islam, Gazi, Shzee Yew Tai, and Mohd Noh Kusairi. 2016. A stochastic frontier analysis of technical efficiency of fish cage culture in Peninsular Malaysia. SpringerPlus 5: 1127. [Google Scholar] [CrossRef]

- Jha, Shalene, Christopher Bacon, Stacy Philpott, V. Méndez, Robert Rice, and Peter Laderach. 2014. Shade Coffee: Update on a Disappearing Refuge for Biodiversity. Bioscience 64: 416–28. [Google Scholar] [CrossRef]

- Jondrow, James, C. Lovell, Ivan S. Materov, and Peter Schmidt. 1982. On the estimation of technical inefficiency in the stochastic frontier production function model. Journal of Econometrics 19: 233–38. [Google Scholar] [CrossRef]

- Kamau, Victor, Josiah Ateka, Robert Mbeche, and Kavoi M. Muendo. 2017. Assesment of technical efficiency of smallholder coffee farming enterprises in Muranga, Kenya. Journal of Agriculture Science and Technology 18: 12–23. [Google Scholar]

- Kirkley, James E., Dale Squires, and Ivar E. Strand. 1995. Assessing Technical Efficiency in Commercial Fisheries: The Mid-Atlantic Sea Scallop Fishery. American Journal of Agricultural Economics 77: 686–97. [Google Scholar] [CrossRef]

- Kumbhakar, Subal, Soumendra Ghosh, and J. Thomas McGuckin. 1991. A Generalized Production Frontier Approach for Estimating Determinants of Inefficiency in U.S. Dairy Farms. Journal of Business & Economic Statistics 9: 279–86. [Google Scholar]

- Luong, Quoc V., and Loren Tauer. 2006. A real options analysis of coffee planting in Vietnam. Agricultural Economics 35: 49–57. [Google Scholar] [CrossRef]

- Mango, Nelson, Clifton Makate, Benjamin Hanyani-Mlambo, Shephard Siziba, and Mark Lundy. 2015. A stochastic frontier analysis of technical efficiency in smallholder maize production in Zimbabwe: The post-fast-track land reform outlook. Cogent Economics & Finance 3: 1117189. [Google Scholar]

- Meeusen, Wim, and Julien van den Broeck. 1977. Efficiency Estimation from Cobb-Douglas Production Functions with Composed Error. International Economic Review 18: 435–44. [Google Scholar] [CrossRef]

- Milder, J. C., and D. Newsom. 2015. SAN/Rainforest Alliance Impacts Report: Evaluating the Effects of the SAN/Rainforest Alliance Certification Systems on Farms, People, and the Environment. New York: SAN/Rainforest Alliance, p. 115. [Google Scholar]

- Mistiaen, V. 2012. A Better Future Is Percolating for Vietnam’s Coffee. The Guardian. March 26. Available online: www.theguardian.com/global-development/poverty-matters/2012/mar/26/better-future-vietnam-coffee-growth (accessed on 23 January 2019).

- Moguel, Patricia, and Víctor Toledo. 1999. Biodiversity Conservation in Traditional Coffee Systems of Mexico. Conservation Biology 13: 11–21. [Google Scholar] [CrossRef]

- Nchare, Amadou. 2007. Analysis of Factors Affecting the Technical Efficiency of Arabica Coffee Producers in Cameroon. African Economic Research Consortium, Research Papers. Available online: https://www.semanticscholar.org/paper/Analysis-of-Factors-Affecting-the-Technical-of-inNchare/5b15916f558900da4da97a5354533d8cc573e802 (accessed on 12 March 2019).

- Nguyen, Giang N. T., and Tapan Sarker. 2018. Sustainable coffee supply chain management: A case study in Buon Me Thuot City, Daklak, Vietnam. International Journal of Corporate Social Responsibility 3: 1. [Google Scholar] [CrossRef]

- Nyagaka Daniel, Gideon Obare, and Wilson Nguyo. 2009. Economic Efficiency of Smallholder Irish Potato Producers in Kenya: A Case of Nyandarua North District. Paper presented at the 27th Conference of the International Association of Agricultural Economists (IAAE), on The New Landscape of Global Agriculture, Beijing, China, August 16–22. [Google Scholar]

- Okoruwa, Victor O., Olorunfemi O. Ogundele, and B. O. Oyewusi. 2006. Efficiency and Productivity of Farmers in Nigeria: A Study of Rice Farmers in North Central Nigeria. Paper presented at the 2006 Annual Meeting, Queensland, Australia, August 12–18; Available online: https://ageconsearch.umn.edu/record/25248 (accessed on 3 March 2019).

- Parmeter, Christopher F., and Subal C. Kumbhakar. 2014. Efficiency Analysis: A Primer on Recent Advances. Foundations and Trends® in Econometrics 7: 191–385. [Google Scholar] [CrossRef]

- Perfecto, Ivette, Robert Rice, Russell Greenberg, and Martha Van der Voort. 1996. Shade Coffee: A Disappearing Refuge for Biodiversity. BioScience 46: 598–608. [Google Scholar] [CrossRef]

- Pindyck, Robert S., and Daniel L. Rubinfeld. 1981. Econometric Models and Economic Forecasts. New York: McGraw-Hill. [Google Scholar]

- Pitt, Mark, and Lung-Fei Lee. 1981. The measurement and sources of technical inefficiency in the Indonesian weaving industry. Journal of Development Economics 9: 43–64. [Google Scholar] [CrossRef]

- Ponte, Stefano. 2002. The ‘Latte Revolution’? Regulation, Markets and Consumption in the Global Coffee Chain. World Development 30: 1099–122. [Google Scholar] [CrossRef]

- Poudel, Krishna Lal, Thomas G. Johnson, Naoyuki Yamamoto, Shriniwas Gautam, and Bhawani Mishra. 2015. Comparing technical efficiency of organic and conventional coffee farms in rural hill region of Nepal using data envelopment analysis (DEA) approach. Organic Agriculture 5: 263–75. [Google Scholar] [CrossRef]

- Poungchompu, Supaporn, and Supawadee Chantanop. 2015. Factor affecting technical efficiency of smallholder rubber farming in Northeast Thailand. American Journal of Agricultural and Biological Science 10: 83–90. [Google Scholar] [CrossRef]

- Ravallion, Martin. 2008. Evaluating Anti-Poverty Programs. Edited by T. Paul Schultz and John A. Strauss. Amsterdam: Elsevier, pp. 3787–846. [Google Scholar]

- Raynolds, Laura T., Douglas Murray, and Andrew Heller. 2007. Regulating sustainability in the coffee sector: A comparative analysis of third-party environmental and social certification initiatives. Agriculture and Human Values 24: 147. [Google Scholar] [CrossRef]

- Reifschneider, David, and Rodney Stevenson. 1991. Systematic Departures from the Frontier: A Framework for the Analysis of Firm Inefficiency. International Economic Review 32: 715–23. [Google Scholar] [CrossRef]

- Robson, Colin. 2002. Real World Research: A Resource for Social Scientists and Practitioner-Researchers, 2nd ed. Oxford: Blackwell Publishers Ltd. [Google Scholar]

- Sharma, Khem R. 1999. Technical efficiency of carp production in Pakistan. Aquaculture Economics & Management 3: 131–41. [Google Scholar] [CrossRef]

- Soto-Pinto, Lorena, Ivette Perfecto, and Javier Caballero. 2002. Soto-Pinto, Lorena, Ivette Perfecto, and Javier Caballero. 2002. Shade over coffee: Its effects on berry borer, leaf rust and spontaneous herbs in Chiapas, Mexico. Agroforestry Systems 55: 37–45. [Google Scholar] [CrossRef]

- Sriboonchitta, Songsak, and Aree Wiboonpongse. 2004. The Effects of Production Inputs, Technical Efficiency and Other Factors on Jasmine and Non-jasmine Rice Yields in Thailanda. Asia-Pacific Productivity Conference 5: 14–16. [Google Scholar]

- Staver, Charles, Falguni Guharay, D. Monterroso, and Reinhold Muschler. 2001. Designing pest-suppressive multistrata perennial crop systems: Shade-grown coffee in Central America. Agroforestry Systems 53: 151–70. [Google Scholar] [CrossRef]

- Stevenson, Rodney E. 1980. Likelihood functions for generalized stochastic frontier estimation. Journal of Econometrics 13: 57–66. [Google Scholar] [CrossRef]

- Suranjan Priyanath, Hunuwala Malawarage, S. P. Premaratne, Amina Yoosuf, and D. Maurice. 2018. Technical Efficiency for Tea Smallholder Farmers under UTZ Certification System in Sri Lanka: A Stochastic Frontier Approach. SEISENSE Journal of Management 2: 1–19. [Google Scholar] [CrossRef]

- Swain, Braja. 2016. Does Technological Linkage in Contract Farming Increase Farm Productivity and Efficiency? The Case of Hybrid Paddy Seed Cultivation in Undivided Andhra Pradesh. Agricultural Economics Research Review 29: 211. [Google Scholar] [CrossRef]

- Tadesse, Getachew, Erika Zavaleta, and Carol Shennan. 2014. Coffee landscapes as refugia for native woody biodiversity as forest loss continues in southwest Ethiopia. Biological Conservation 169: 384–91. [Google Scholar] [CrossRef]

- Technoserve. 2013. Vietnam: A Business Case For Sustainable Coffee Production. Available online: www.sustainablecoffeeprogram.com/site/getfile.php?id=211 (accessed on 20 January 2019).

- Tingley, Diana, Sean Pascoe, and Louisa Coglan. 2005. Factors affecting technical efficiency in fisheries: Stochastic production frontier versus data envelopment analysis approaches. Fisheries Research 73: 363–76. [Google Scholar] [CrossRef]

- Tun, YuYu, and Hye-Jung Kang. 2015. An Analysis on the Factors Affecting Rice Production Efficiency in Myanmar. Journal of East Asian Economic Integration 19: 167–88. [Google Scholar] [CrossRef]

- Van Der Vossen, H. A. M. 2005. A critical analysis of the agronomic and economic sustainability of organic coffee production. Experimental Agriculture 41: 449–73. [Google Scholar] [CrossRef]

- Van Long, Nguyen, Nguyen Quang Ngoc, Nguyen Ngoc Dung, Paul Kristiansen, Isa Yunusa, and Christine Fyfe. 2015. The Effects of Shade Tree Types on Light Variation and Robusta Coffee Production in Vietnam. Engineering 7: 742–53. [Google Scholar] [CrossRef]

- Widjaya, Dani, Yuli Hariyati, and Djoko Soejono. 2017. Technical and Economic Efficiency of Smallholder Arabica Coffee Farming in Panti Sub-district, Jember. Pelita Perkebunan (a Coffee and Cocoa Research Journal) 33: 51. [Google Scholar] [CrossRef][Green Version]

- Wollni, Meike, and Bernhard Brümmer. 2009. Productive Efficiency of Specialty and Conventional Coffee Farmers in Costa Rica: Accounting for Technological Heterogeneity and Self-Selection. Göttingen: Universität Göttingen. [Google Scholar]

- Wunderle, Joseph, Jr., and Steven Latta. 1996. Avian abundance in sun and shade coffee plantations and remnant pine forest in the Cordillera Central, Dominican Republic. Ornitologia Neotropical 7: 19–34. [Google Scholar]

- Wurst, John, John Neter, and James Godfrey. 1989. Efficiency of Sieve Sampling in Auditing. Journal of Business & Economic Statistics 7: 199–205. [Google Scholar] [CrossRef]

| Variables | Definition | SC | Non-SC | Chi-Square | ||

|---|---|---|---|---|---|---|

| Value 0 | Value 1 | Value 0 | Value 1 | |||

| Gender | 1 = male; 0 = female | 61 (33.3) | 122 (66.7) | 40 (30.1) | 93 (69.9) | 0.38 |

| Ethnic | 1 = Kinh; 0 = others | 44 (20.0) | 139 (80.0) | 49 (36.8) | 84 (63.2) | 6.07 * |

| Coop. membership | 1= member of cooperative; 0 = otherwise | 123 (67.2) | 60 (32.8) | 64 (48.1) | 69 (51.9) | 11.62 * |

| Extension | 1 = access to extension service; 0 = otherwise | 79 (43.2) | 104 (56.8) | 95 (71.4) | 38 (28.6) | 24.86 * |

| Variables | SC | Non-SC | t-Ratio | ||

|---|---|---|---|---|---|

| Mean | Std. Deviation | Mean | Std. Deviation | ||

| Yield | 3215.77 | 805.10 | 2933.25 | 905.95 | 2.9206 * |

| NPK fertilizer | 14,612.24 | 4159.10 | 16,632.28 | 5260.66 | −3.6722 * |

| Organic fertilizer | 6510.76 | 2358.90 | 3289.20 | 2285.84 | 12.1424 * |

| Manure | 5762.84 | 2500.14 | 3983.07 | 2669.15 | 6.0717 * |

| Pesticide | 1788.13 | 1204.13 | 1282.48 | 1310.16 | 3.5507 * |

| Water | 3946.67 | 2313.61 | 4556.26 | 4190.37 | −1.5180 |

| Hired labor | 10,135.25 | 5111.64 | 6612.93 | 6018.77 | 5.6091 * |

| Family labor | 108.91 | 37.00 | 146.24 | 29.80 | −9.9213 * |

| Depreciation | 2070.82 | 1282.15 | 1520.35 | 1609.33 | 3.3811 * |

| Other costs | 1225.90 | 837.74 | 4110.14 | 2986.90 | −10.8309 * |

| Age | 44.60 | 10.03 | 43.08 | 11.70 | 1.2380 |

| Education | 9.66 | 2.45 | 9.17 | 3.07 | 1.5164 |

| Farming experience | 8.74 | 4.18 | 16.21 | 8.05 | −9.7791 * |

| Household size | 4.70 | 1.19 | 4.63 | 1.37 | 0.4705 |

| Farm size | 1.40 | 0.65 | 1.61 | 1.02 | −2.0529 * |

| Labor/land ratio | 2.26 | 1.54 | 2.47 | 2.22 | −0.9384 |

| Credit | 51,923.77 | 23,080.82 | 59,887.22 | 41,428.41 | −2.0024 * |

| Yield | SC | Non-SC | Total | |

|---|---|---|---|---|

| <2 ton/ha | 8 (2.5) | 18 (5.7) | 26 (8.2) | |

| 2–3 ton/ha | 60 (19.0) | 39 (12.3) | 99 (31.3) | |

| 3–4 ton/ha | 75 (23.7) | 57 (18.0) | 132 (41.8) | |

| 4–5 ton/ha | 35 (11.1) | 16 (5.1) | 51 (16.1) | |

| >5 ton/ha | 5 (1.6) | 3 (0.9) | 8 (2.5) | |

| Total | 183 (57.9) | 133 (42.1) | 316 (100.0) | |

| Mean | 3.216 | 2.933 | 3.097 | |

| Minimum | 1.200 | 0.867 | 0.867 | |

| Maximum | 5.400 | 5.915 | 5.915 | |

| Standard Deviation | 0.805 | 0.906 | 0.859 | |

| Chi-Square Tests | Value | df | Asymp. Sig. (2-sided) | Exact Sig. (2-sided) |

| Pearson Chi-Square | 10.690 a | 4 | 0.030 | 0.028 |

| Likelihood Ratio | 10.710 | 4 | 0.030 | 0.036 |

| Fisher’s Exact Test | 10.509 | 0.030 | ||

| N of Valid Cases | 316 |

| Variables | Parameter | SC | Non-SC | ||||

|---|---|---|---|---|---|---|---|

| Coef. | SE | t-Ratio | Coef. | SE | t-Ratio | ||

| Production frontier | |||||||

| Constant/intercept | β0 | 1.6208 | 0.4035 | 4.0174 * | 1.7320 | 0.5521 | 3.1370 * |

| NPK fertilizer | β1 | 0.4092 | 0.0342 | 11.9549 * | 0.4564 | 0.0530 | 8.6130 * |

| Organic fertilizer | β2 | 0.0757 | 0.0237 | 3.1968 * | 0.1332 | 0.0264 | 5.0484 * |

| Manure | β3 | 0.0716 | 0.0165 | 4.3527 * | 0.0324 | 0.0267 | 1.2104 |

| Pesticide | β4 | 0.0038 | 0.0105 | 0.3650 | −0.0134 | 0.0256 | −0.5225 |

| Water | β5 | 0.0799 | 0.0156 | 5.1305 * | 0.0000 | 0.0232 | 0.0016 |

| Hired labor | β6 | 0.0003 | 0.0163 | 0.0202 | 0.0491 | 0.0235 | 2.0925 * |

| Family labor | β7 | 0.1053 | 0.0276 | 3.8133 * | 0.0567 | 0.0752 | 0.7551 |

| Depreciation | β8 | 0.0152 | 0.0150 | 1.0124 | 0.0018 | 0.0234 | 0.0788 |

| Other cost | β9 | 0.0073 | 0.0156 | 0.4687 | −0.0002 | 0.0207 | −0.0106 |

| Technical inefficiency model | |||||||

| Constant/intercept | δ0 | 0.8404 | 0.2344 | 3.5857 * | 0.1468 | 0.3877 | 0.3787 |

| Age | δ1 | −0.0002 | 0.0027 | −0.0606 | 0.0274 | 0.0139 | 1.9701 * |

| Gender | δ2 | 0.0492 | 0.0731 | 0.6722 | −0.0097 | 0.0912 | −0.1064 |

| Education level | δ3 | −0.0348 | 0.0145 | −2.4029 * | −0.0294 | 0.0207 | −1.4236 |

| Ethnic | δ4 | 0.0882 | 0.0699 | 1.2619 | −0.2834 | 0.1212 | −2.3370 * |

| Farming experience | δ5 | −0.0222 | 0.0130 | −1.7124 | −0.0328 | 0.0181 | −1.8058 |

| Household size | δ6 | −0.0731 | 0.0275 | −2.6579 * | −0.0364 | 0.0337 | −1.0785 |

| Farm size | δ7 | 0.1557 | 0.0880 | 1.7695 | 0.1471 | 0.0893 | 1.6469 |

| Labor/land ratio | δ8 | 0.0442 | 0.0260 | 1.7009 | −0.0543 | 0.0351 | −1.5477 |

| Coop. membership | δ9 | −0.3842 | 0.1892 | −2.0309 * | 0.0023 | 0.0995 | 0.0233 |

| Extension | δ10 | −0.0088 | 0.0522 | −0.1684 | 0.1054 | 0.1340 | 0.7865 |

| Credit | δ11 | −8.96 × 10−6 | 3.60 × 10−6 | −2.4845 * | −9.69 × 10−6 | 4.59 × 10−6 | −2.1109 * |

| Variance of parameters | |||||||

| Sigma-squared | σ2 | 0.0491 | 0.0192 | 2.5556 * | 0.0679 | 0.0171 | 3.9794* |

| Gamma | γ | 0.9179 | 0.0408 | 22.4995 * | 0.7168 | 0.1146 | 6.2565* |

| Log likelihood function | 140.0706 | 41.0813 | |||||

| LR test of one side error | 93.6163 | 27.4995 | |||||

| Mean of exp (Ui) | 88.2458 | 87.6944 | |||||

| Categories | SC | Non-SC | ||

|---|---|---|---|---|

| Farmer | Percentage | Farmer | Percentage | |

| TE < 40 | 0 | 0 | 0 | 0 |

| 40 ≤ TE < 50 | 1 | 0.546 | 1 | 0.752 |

| 50 ≤ TE < 60 | 4 | 2.186 | 2 | 1.504 |

| 60 ≤ TE < 70 | 8 | 4.372 | 5 | 3.759 |

| 70 ≤ TE < 80 | 17 | 9.290 | 16 | 12.030 |

| 80 ≤ TE < 90 | 45 | 24.590 | 30 | 22.556 |

| 90 ≤ TE | 108 | 59.016 | 79 | 59.398 |

| Total | 183 | 100.000 | 133 | 100.000 |

| Min | 45.4635 | 49.1096 | ||

| Max | 98.0241 | 97.2277 | ||

| Mean | 88.245762 | 87.694357 | ||

| SD | 9.8345411 | 9.8835196 | ||

| Farm Size | SC | Non-SC |

|---|---|---|

| <1 ha (Small) | 82.11 | 87.38 |

| 1–2 ha (Medium) | 89.43 | 86.90 |

| >2 ha (Large) | 90.81 | 91.12 |

| Total | 88.25 | 87.69 |

| Variables | SC | Non-SC | t-Ratio | ||

|---|---|---|---|---|---|

| Mean | Std. Deviation | Mean | Std. Deviation | ||

| Yield/hectare | 3215.77 | 805.10 | 2933.25 | 905.95 | 2.921 * |

| Coffee price | 34.82 | 2.18 | 33.14 | 0.96 | 9.236 * |

| Input cost | 63,066.83 | 36,162.48 | 58,156.88 | 42,804.93 | 1.102 |

| Input cost/hectare | 43,981.78 | 9550.28 | 40,466.37 | 13,093.32 | 2.629 * |

| Gross output | 161,710.84 | 98,951.60 | 140,635.11 | 97,817.81 | 1.878 |

| Gross output/hectare | 112,347.36 | 30,503.97 | 97,229.38 | 30,176.49 | 4.369 * |

| Gross margin | 68,365.58 | 25,058.52 | 56,763.02 | 22,819.66 | 4.218 * |

| Rate of return | 1.575 | 0.538 | 1.484 | 0.666 | 1.343 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hung Anh, N.; Bokelmann, W.; Thi Nga, D.; Van Minh, N. Toward Sustainability or Efficiency: The Case of Smallholder Coffee Farmers in Vietnam. Economies 2019, 7, 66. https://doi.org/10.3390/economies7030066

Hung Anh N, Bokelmann W, Thi Nga D, Van Minh N. Toward Sustainability or Efficiency: The Case of Smallholder Coffee Farmers in Vietnam. Economies. 2019; 7(3):66. https://doi.org/10.3390/economies7030066

Chicago/Turabian StyleHung Anh, Nguyen, Wolfgang Bokelmann, Do Thi Nga, and Nguyen Van Minh. 2019. "Toward Sustainability or Efficiency: The Case of Smallholder Coffee Farmers in Vietnam" Economies 7, no. 3: 66. https://doi.org/10.3390/economies7030066

APA StyleHung Anh, N., Bokelmann, W., Thi Nga, D., & Van Minh, N. (2019). Toward Sustainability or Efficiency: The Case of Smallholder Coffee Farmers in Vietnam. Economies, 7(3), 66. https://doi.org/10.3390/economies7030066