Abstract

This paper endeavors to construct an evaluative framework to assess the level of development in advanced manufacturing across the 31 provinces in China from 2003 to 2021. Additionally, it aims to investigate the impact of industrial synergy agglomeration on the development of advanced manufacturing by employing a moderated mediation model and the Spatial Durbin Model (SDM). The research results demonstrate that industrial synergy agglomeration facilitates the development of advanced manufacturing, with particularly pronounced effects in the eastern region of China and the 18 provinces that already possess national advanced manufacturing clusters. Urban innovation capacity plays an intermediary role, and both manufacturing intelligence and international capacity cooperation exhibit positive moderating effects in the direct and indirect pathways through which industrial synergy agglomeration influences the development of advanced manufacturing. Furthermore, industrial synergy agglomeration exhibits strong spillover effects on the development of advanced manufacturing. To boost the development of the advanced manufacturing industry, it is imperative to expedite the establishment of an industrial synergy spatial layout, foster a culture of enterprise innovation and intelligent transformation, emphasize inter-provincial communication and cooperation, and facilitate cross-border resource integration.

1. Introduction

In 2022, the added value of China’s manufacturing industry accounted for 27.7% of GDP, and the scale of the manufacturing industry continued to maintain a world-leading position. Nevertheless, there still exists a gap between China’s manufacturing industry and the world’s advanced level in terms of independent innovation capability, resource-utilization efficiency, and the quality of benefits, among other aspects. Compared with traditional manufacturing, advanced manufacturing is located in the high-end part of the global production system, with high added value and technological content as its prominent features. Its strong innovation in technology and research and development keeps it highly competitive in the market (Peng et al. 2019, 2020; Zhao et al. 2020). Accelerating the development of advanced manufacturing is a key measure for China’s manufacturing industry to achieve high-quality development.

How can the level of advanced manufacturing development across different provinces in China be evaluated? How can the further growth of China’s advanced manufacturing industry be promoted? To answer these questions, it is crucial to first define the concept of “advanced manufacturing”; then, we must select appropriate indicators to scientifically measure the level of development in provincial regions. In academic research, “advanced manufacturing” is mainly defined in two forms. Some researchers have identified specific sub-sectors within manufacturing that exhibit a high application rate of advanced technologies, designating them as “advanced manufacturing”, which is distinguished from “traditional manufacturing” sectors (Feng et al. 2022). This study, like the research conducted by Hu and Zhang (2011), considers “advanced manufacturing” to be a holistic concept that reflects its advancement in terms of indicator selection. There are also two ways to measure advanced manufacturing. It can be measured through some single indicators such as the proportion of employees (Feng et al. 2020). Moreover, multiple indicators can be selected to comprehensively evaluate its level of development. When selecting multiple indicators, one can adopt a single-dimensional approach, such as using the 10Rs of advanced manufacturing capabilities to measure its development (Bag et al. 2021). Alternatively, one can follow the principles of scientific, systematic, and operational criteria to construct a multidimensional indicator system (Huang and Zhang 2021). Among these dimensions, technology, economy, and environmental considerations are fundamental aspects that can evaluate the research and utilization capabilities of advanced manufacturing technologies, the economic performance and profitability of manufacturing enterprises, and their sustainable development capabilities (Hu and Zhang 2011). The assessment of management level and social benefits are also reflected in relevant studies (Xu and Xie 2013). Compared to single indicators, a comprehensive indicator system allows for a multidimensional evaluation of advanced manufacturing development, yielding more scientifically grounded results. However, research on measuring the level of advanced manufacturing development using multidimensional indicator systems is still in the theoretical stage, with limited quantitative analysis conducted using provincial panel data. Additionally, there is a gap in empirical examinations that utilize comprehensive indicators to measure the level of advanced manufacturing.

In recent years, with the transition from an “industrial economy” to a “service-oriented economy” (Zhang et al. 2023), the global industrial layout has gradually shifted towards spatial diversification, and the coordinated development and efficient interactions between manufacturing and productive service industries have become a trend (Tu et al. 2019; Zheng et al. 2020). The productive service industry improves the production efficiency of manufacturing through industrial linkage effects, technology spillover effects, and other means, transforming the manufacturing industry into a “production + service” pattern (Ke et al. 2014). Regarding the issue of advanced manufacturing development, previous studies have acknowledged the role of industrial synergy agglomeration (Qiu and Gong 2021). Under the “collaborative agglomeration pattern”, the productive service industry runs through the entire process of advanced manufacturing, providing warehousing, logistics, design, financing, and other services. Compared with the previous “separation agglomeration pattern”, the production efficiency of manufacturing industry enterprises has significantly improved. At the same time, industrial collaborative agglomeration accelerates the decomposition, extension, and restructuring of the value chain, and endows the new value chain with a higher level of utility (Gao et al. 2020). How can industrial synergy agglomeration promote the development of advanced manufacturing? A few studies have delved into the influencing mechanisms from a singular perspective. When measuring the development of advanced manufacturing using green and environmentally friendly indicators, studies have found that industrial synergy agglomeration can reduce ecological pollution through the mediating effect of technological innovation (Zhuang et al. 2021; Yang et al. 2021). However, academic research on the question remains insufficient. To explore the pathways through which industrial synergy agglomeration influences the development of advanced manufacturing, it is necessary to build upon the scientific measurement of the development level of advanced manufacturing as a foundation. Subsequently, we will be equipped to explain the economic logic through which mechanism variables exert their influence on the development of advanced manufacturing. These variables should be incorporated into the same analytical framework for a comprehensive empirical examination.

Our study has two specific objectives: Firstly, we aim to construct an evaluative framework to gauge the level of development in advanced manufacturing. Secondly, we aim to determine whether industrial synergy agglomeration has a positive and significant impact on the development of advanced manufacturing, and to explore the mechanisms behind this influence. In order to address the existing research gaps in the measurements and determinants of advanced manufacturing, this paper selects secondary indicators from five dimensions of advanced manufacturing technology: advanced manufacturing management, advanced manufacturing workforce, green advanced manufacturing, and advanced manufacturing efficiency. Then Then, calculating the development level of advanced manufacturing in 31 provinces1 of China from 2003 to 2021, a comprehensive indicator is applied for empirical analysis. The findings reveal that industrial synergy agglomeration facilitates the development of advanced manufacturing. Urban innovation capacity plays a mediating role, while manufacturing intelligence and international capacity cooperation exhibit positive moderating effects in the direct and indirect pathways through which industrial synergy agglomeration influences the development of advanced manufacturing.

This paper makes two significant contributions. Firstly, we refine the evaluation index system for advanced manufacturing and quantitatively measure the development level of advanced manufacturing in different provinces of China using provincial panel data. Compared to previous research relying on single indicators, this research provides a more scientific measurement of advanced manufacturing development. Secondly, we employ a moderated mediation model that incorporates urban innovation, manufacturing intelligence, and international capacity cooperation into a unified analytical framework to investigate the mechanisms through which industrial synergy agglomeration influences advanced manufacturing.

The remainder of this paper is organized as follows: Section 2 conducts a comprehensive review of the relevant studies. Section 3 establishes a theoretical analytical framework and presents three research hypotheses. Section 4 provides an introduction to the model employed in the study, along with explanations regarding the selection of variables and measurement methods. Section 5 presents empirical findings, delving into the implications of the results and validating the hypotheses proposed in Section 3. Section 6 provides a summary of the research conclusions. Lastly, our conclusions are presented in Section 7.

2. Literature Review

Regarding the definition of advanced manufacturing, the academic community predominantly adopts two approaches. The first regards advanced manufacturing as a collection of several high-technology, high-value-added sub-industries. For instance, Zhu et al. (2020) compare manufacturing industries involved in the National Bureau of Statistics with the KLEMS industry standards and classify them into “high-tech manufacturing”, encompassing nine sectors such as “computer, communication, and other electronic equipment manufacturing”, “instrument and apparatus manufacturing”, and “pharmaceutical manufacturing”. The second perspective posits that advanced manufacturing is a comprehensive term encompassing industries that continuously absorb high-tech advancements in information, machinery, materials, and modern management. It represents the manufacturing sector’s pursuit of superior, efficient, low-consumption, clean, and flexible production. In other words, advanced manufacturing comprises manufacturing industries that showcase advancement in technology, management, environmental sustainability, and other aspects (Hu and Zhang 2011). Presently, articles studying the evaluation index system of advanced manufacturing often adopt the second definition, considering “advanced manufacturing” to be a holistic concept. They select indicators from different dimensions to reflect the advancement of the manufacturing industry (Xu and Xie 2013; Huang and Zhang 2021).

Regarding the driving forces behind the development of advanced manufacturing, Ocampo et al. (2017) construct a competitiveness evaluation index system for the manufacturing industry based on dimensions such as cost, quality, production flexibility, transportation time, and environmental protection. Their findings reveal that the utilization of advanced manufacturing tools enhances the competitiveness of the industry. Feng et al. (2020) discover that foreign direct investment promotes the development of advanced manufacturing, albeit with dual thresholds. Bag et al. (2021) point out that Industry 4.0 technologies provide digital solutions for manufacturing automation, significantly impacting the enhancement of advanced manufacturing capabilities in the resource “10R” cycle process and sustainable development. Feng et al. (2022) found that the establishment of national manufacturing innovation centers can facilitate the development of advanced manufacturing, with an intermediate effect of innovation input expansion. Following the introduction of the “Carbon Peaking and Carbon Neutrality Goals”, the green transformation of the manufacturing industry has become a research hotspot. Scholars have empirically analyzed the efficiency of green growth in the manufacturing industry, highlighting the significant influence of industrial clustering (Lv and Lu 2022; Zhu et al. 2022).

The concept of industrial synergy agglomeration was initially proposed by Ellison and Glaeser (1997), referring to the phenomenon of manufacturing enterprises and upstream/downstream companies that produce accessory products agglomerating together in space. As research deepened, the spatial phenomenon of industrial synergy agglomeration was further confirmed, and the conceptual definition gradually improved. Andersson (2004) found that the location of productive service industries is a function of the location of the manufacturing industry, indicating the inevitability of their spatial agglomeration. Helsley and Strange (2014) point out that industrial synergy represents a transitional state from a single-industry pattern to a diverse and integrated economic structure, where multiple associated industries are heavily concentrated within a certain geographic area. With the improvement and upgrading of industrial structures, social division of labor tends towards specialization and refinement, and the dominance of the “industrial economy” is gradually being replaced by the emergence of the “service economy”. The trend of collaborative development between productive service industries and the manufacturing industry becomes increasingly evident (Ke et al. 2014).

In recent years, the academic community has linked industrial synergy agglomeration with the development of advanced manufacturing. However, due to the imperfect evaluation index system, existing studies mainly analyze certain prominent characteristics of advanced manufacturing. From the perspective of production efficiency and economic benefits, industrial synergy agglomeration enhances the overall factor efficiency of the manufacturing industry through green technological innovation (Yang et al. 2022). It also exerts a significant positive impact on China’s Green Economic Efficiency (GEE) through firm-level innovation and entrepreneurial innovation (Zhu et al. 2022). Expanding the perspective to the manufacturing industry’s value chain, research has found that industrial synergy agglomeration strengthens the resilience of the manufacturing industry’s value chain through technological innovation. This enhances the industry’s flexibility and adaptability in response to external environments, thereby creating a stable space for improving economic performance.

With the deepening of green and environmental concepts, several scholars have conducted research on the relationship between industrial synergy agglomeration and green sustainable development. Industrial synergy agglomeration can significantly improve energy efficiency (Liu et al. 2017), increase carbon productivity, and reduce carbon intensity. However, the effectiveness of carbon emissions reduction is constrained by the rational allocation of resources, which acts as a dual threshold (Li et al. 2019). Yang et al. (2021) utilize a Spatial Durbin Model and find that industrial synergy agglomeration effectively controls environmental pollution through technological innovation, particularly in reducing emissions of air pollutants such as SO2, PM2.5, and NOx (Ye et al. 2022; L. Gao et al. 2023). Chang and Zheng (2023) discover that industrial synergy agglomeration significantly enhances green innovation efficiency within both the local region and in neighboring areas, but spatial spillover effects exhibit geographic decay.

3. Research Hypothesis

The impact of industrial synergy agglomeration on the development of advanced manufacturing manifests in various aspects. Firstly, industrial synergy agglomeration swiftly elevates the level of advanced technology within manufacturing enterprises. During the initial phase of industrial synergy agglomeration, manufacturing plays a dominant role, while productive services act as auxiliary support (Yang et al. 2021). As the productive service system gradually matures, the deepening of regional industrial synergy and the integration of upstream and downstream cooperation mechanisms facilitate efficient division of labor and matching between the two industries. Through this enduring collaboration, information barriers between companies diminish, reducing search time, transaction costs, and simplifying transaction procedures. Consequently, this provides convenience for the extensive flow of manufacturing talents, information, and technology within the local region, leading to a rapid overall advancement in manufacturing technologies (Pandit et al. 2001).

Moreover, industrial synergy agglomeration contributes to green and sustainable development of the manufacturing industry. The spatial synergy and linkage between manufacturing and productive services optimize resource allocation between industries, generating economies of scale and centralized governance effects. This approach reduces raw material consumption and transport losses in intermediate product processing, lowers energy consumption per unit, enhances resource-utilization efficiency (Zeng and Zhao 2009; Wang et al. 2020), improves overall factor energy efficiency (Yang et al. 2020), and plays a positive role in achieving carbon reduction and pollution control (Zhuang et al. 2021; Wang et al. 2022).

Additionally, industrial synergy agglomeration enhances the management level of manufacturing enterprises. The synergy between manufacturing and productive services reduces the costs of information dissemination and learning. In high-synergy regions, advanced management techniques are rapidly shared, strengthening cost-control and risk-management capabilities, thereby demonstrating the positive external influence of synergy agglomeration (Fan and Scott 2003). Furthermore, industrial synergy agglomeration lowers the cost of information sharing among companies and drives technological innovation through knowledge spillover effects. To some extent, this fosters healthy market competition, improves production efficiency, and overall capacity levels of manufacturing enterprises, thereby promoting economic growth and capital expansion (Klein and Crafts 2020).

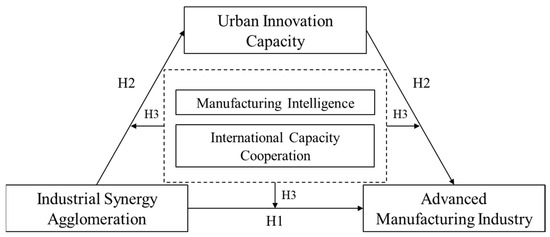

The promoting effect of industrial synergy agglomeration on the development of advanced manufacturing varies among different provinces. Taking the collaboration between the pharmaceutical manufacturing industry and medical services as an example, Hu et al. (2021) utilize a threshold regression model and find that the enhancement of coupling coordination between the two sectors can effectively promote further development, only when the pharmaceutical manufacturing industry reaches a relatively advanced level. We have listed the above literature in Table 1. Based on the discussion, we propose a research hypothesis, which is illustrated in Figure 1.

Table 1.

Summary of studies on the impact of industrial synergy agglomeration on the development of advanced manufacturing.

Figure 1.

Mechanism of influence diagram.

H1.

Industrial synergy agglomeration promotes the development of advanced manufacturing, and this promoting effect is more pronounced in provinces with a solid foundation for advanced manufacturing development.

Marshall advances four pivotal factors in the context of industrial synergy agglomeration, namely the relationships between intermediate inputs and final product suppliers, the sharing of labor markets, increased information exchange, and innovation opportunities, thereby linking the concepts of industrial synergy agglomeration with innovation efficiency (Howard et al. 2016). As the spatial layout of industrial synergy takes shape, the integrated development of core industries with peripheral industries and the external economic effects stemming from specialized division of labor become evident, leading to enhanced innovation efficiency among regional manufacturing enterprises (Shen et al. 2019; Wang et al. 2019; Zhong et al. 2021; Peng et al. 2023). Notably, the impact of industrial synergy agglomeration on innovation performance is particularly prominent in high-tech manufacturing industries (Wu et al. 2021; Peng et al. 2022). For instance, the synergy between transportation and warehousing services and manufacturing industries reduces the time costs associated with information acquisition, while the financial sector provides services such as capital management and employee incentives to manufacturing enterprises. The synergy between these two sectors contributes to the improvement of regional innovation efficiency.

Innovation serves as a crucial driving force for sustainable industrial development in a region, embodying the pulse and wellspring of urban economic progress (Wang and Deng 2022). The essence of the urban innovation chain lies in the openness of innovative elements, the synergistic operation of the entire system, and the value-added nature of innovation (Ambos et al. 2021). The concentration of innovation leads to a transformation in the hierarchical structure of urban innovation, rationalizing the allocation of innovative elements and consequently propelling the positive development of various industries within the region (Fan et al. 2021). Active innovation activities in a region yield abundant patent outputs, which, when implemented in the production processes of enterprises, translate into advanced technological achievements. Entrepreneurs often encourage socially responsible actions among enterprises, particularly those with strong innovation capabilities (Wei et al. 2021; Ahmad et al. 2022), addressing employment issues. Moreover, effective utilization of capital by enterprise management facilitates the establishment of a social network, leveraging internal and external employees, thereby enhancing productivity and generating economic benefits (Lafuente et al. 2020; Becerra-Vicario et al. 2023). The urban innovation chain can be divided into three stages: primordial, technological, and transformative. Zhang et al. (2022) construct a three-dimensional indicator system for urban innovation capabilities and measured innovation performance based on the development level of strategic emerging industries, revealing that urban innovation promotes the development of strategic emerging industries in the short term. Urban innovation optimizes industrial structures, realizing efficient resource allocation, thereby accelerating the concentration of high-tech industries and enhancing economic efficiency. In recent years, academia has confirmed a symbiotic relationship between urban innovation and green development. In low-carbon pilot cities (LCPCs), green innovation has led to reduced energy consumption in industrial enterprises and improved resource-utilization efficiency (Tian et al. 2021).

The innovation in cities propels the upgrading of industrial technologies and facilitates advanced transformations, simultaneously expanding the scale of industrial personnel while enhancing production efficiency. Moreover, this influence encompasses sustainable development implications, extending its impact to advanced manufacturing. On the basis of Hypothesis 1, we further propose another hypothesis:

H2.

Industrial synergy agglomeration enhances urban innovation capabilities, thereby promoting the development of advanced manufacturing.

Intelligent manufacturing stands as a crucial pathway for the ascent of China’s manufacturing industry along the value chain. The development of intelligence, encompassing technological innovation, production efficiency, and economic benefits, exerts a profound influence on the level of advanced manufacturing. Industrial intelligence enhances corporate profits, expedites the transition towards sustainability, and ultimately elevates the overall production efficiency of the supply chain (Mahalakshmi et al. 2019). In manufacturing enterprises employing robots, human labor is supplanted, leading to substantial enhancements in production efficiency, as well as a noticeable increase in the value-added aspects of their products (Acemoglu et al. 2020). There exists a substitutive effect between industrial robots and the labor force, whereby the scarcity of labor supply compels manufacturing enterprises to engage in technological innovation, thus further enhancing labor productivity (Song and Zuo 2019). The proliferation of industrial robots also contributes to the reduction in industrial carbon emissions and promotes sustainable development (Wu 2023).

In recent years, with the development of the digital economy and the widespread adoption of artificial intelligence technologies, researchers have begun to focus on the specific pathways through which intelligent manufacturing influences the development of advanced manufacturing. Artificial intelligence enables enterprises to substitute low-end labor, thereby reducing costs, improving productivity, and enhancing their competitiveness—an endeavor that assists them in engaging more effectively in the division of labor within the global value chain. Intelligence significantly boosts the total-factor productivity of the manufacturing industry, with the objective of achieving carbon neutrality (Wang et al. 2023), thereby promoting the high-quality development of the manufacturing sector. In regions where the level of intelligent manufacturing is relatively high, there is greater efficiency in information exchange and resource allocation between industries, and the positive effects of industrial synergy on the development of advanced manufacturing become more pronounced, as is the capacity for urban innovation. Furthermore, technological innovation and the development of intelligent cities are mutually complementary (Cugurullo 2020), as the widespread adoption of artificial intelligence enhances urban innovation capabilities, thereby driving the construction of smart cities (Yigitcanlar et al. 2020). In regions with a solid foundation in intelligent development, the utilization of advanced technologies and the provision of well-equipped facilities are favorable, attracting a strong pool of talent, making the role of industrial synergy agglomeration in enhancing urban innovation capacity more apparent.

International capacity cooperation encompasses forms such as foreign trade, foreign direct investment, and overseas engineering contracts, with foreign direct investment occupying a predominant position. International capacity cooperation provides a platform foundation for enterprise technological upgrading, directly propelling the development of advanced manufacturing. From the perspective of foreign trade analysis, international trade contributes to the transformation and upgrading of the manufacturing industry, and the improvement of total-factor productivity in manufacturing relies on technological progress. From the perspective of foreign direct investment analysis, multinational corporations can assist domestic enterprises in acquiring advanced technologies (Chen et al. 2012). From the perspective of overseas engineering contracts, on one hand, the contracting party can absorb advanced knowledge and technology from the contracting party and enhance their own production efficiency through the process of “learning by doing” (Lo 2014). On the other hand, in order to gain recognition during the project implementation process, the contracting party must actively improve their technological and service levels (Martinez-Noya et al. 2012), thereby creating a virtuous cycle. In regions with a high level of international capacity cooperation, there is frequent exchange and interaction between domestic and foreign entities, making it easier for Chinese manufacturing enterprises to access advanced foreign knowledge, technology, and management experience. With the strengthening of industrial synergy, the development of advanced manufacturing accelerates. Similarly, international capacity cooperation provides favorable support for enterprise innovation and research development—as the collaboration between manufacturing and productive service industries deepens, the improvement of urban innovation levels becomes more pronounced. Combined with the aforementioned two hypothesis, we come up with the last hypothesis:

H3.

Both manufacturing intelligence and international capacity cooperation exert positive regulatory effects in the direct and indirect pathways of industrial synergy on the development of advanced manufacturing.

4. Methodology

4.1. Model

4.1.1. Two-Way Fixed-Effects Model

The primary focus of this study lies in ascertaining whether industrial synergy agglomeration has a positive and significant impact on the development of advanced manufacturing, while also delving into the underlying mechanisms of this influence. The baseline regression model is presented below:

In Equation (1), p denotes provinces and t represents years. The dependent variable is the level of development in the advanced manufacturing industry denoted as . The core explanatory variable is the level of industrial synergy agglomeration, denoted as . represents a set of control variables. and represent province fixed effects and time fixed effects, respectively. denotes the error term. If is significantly positive, then Hypothesis 1 is confirmed.

4.1.2. Mediation Effect Model

The mediation effect is examined using a stepwise regression approach. The constructed model is as follows:

where the mediating variable is urban innovation capacity denoted as . Equation (2) tests the direct effect of urban innovation capacity on the development of advanced manufacturing. Equations (3) and (4) examine the mediating role of urban innovation capacity in the process of industrial synergy promoting the development of advanced manufacturing. If , , and are all significantly positive, then Hypothesis 2 is confirmed.

4.1.3. Moderated Mediation Effect Model

The effect of the moderating variable on both the direct and indirect effects is examined using hierarchical multiple regression (Baron and Kenny 1986; Sun et al. 2020). The constructed model is as follows:

where the moderating variables are manufacturing intelligence () and international capacity cooperation (), represented as for simplicity. If , , and are all significantly positive, then Hypothesis 3 is confirmed.

4.1.4. Spatial Durbin Model (SDM)

In order to examine the spatial spillover effects of industrial synergy agglomeration on the development of advanced manufacturing at the provincial level, this study constructs an SDM model to further investigate their spatial relationship:

In Equation (10) and represent the spatial lag coefficients for advanced manufacturing and industrial synergy agglomeration, respectively. denotes the spatial weight matrix. If is significantly positive, then the presence of spatial spillover effects in the development of advanced manufacturing itself is indicated. If both and are significantly positive, then it suggests that industrial synergy agglomeration has a positive spatial spillover effect on the development of advanced manufacturing at the provincial level.

4.2. Variable and Data

4.2.1. Explained Variable

The level of development in advanced manufacturing, which is the overall level of development in the manufacturing industry, is derived through a comprehensive calculation of multiple indicators that reflect advanced manufacturing capabilities. In this study, we construct an evaluation index system for advanced manufacturing from five perspectives: advanced manufacturing technology, advanced manufacturing management, advanced manufacturing workforce, green advanced manufacturing, and advanced manufacturing efficiency. A total of 21 secondary indicators are included, and the development level of advanced manufacturing in 31 provincial regions in China from 2003 to 2021 is calculated. Commonly used multivariate weighting methods include the entropy method and principal component analysis (PCA). In this study, we not only calculate the overall development level of advanced manufacturing but also separately calculate the development levels of the five sub-dimensions for robustness testing. Due to the limited number of secondary indicators in the sub-dimensions (around four to five indicators each), PCA is deemed unsuitable. Therefore, the entropy method is chosen. The specific calculation process refers to the study conducted by Yu and Fan (2022). represents the original value of indicator m at time t, represents the minimum value of the indicator, and represents the maximum value of the indicator. represents the standardized value. Equation (11) is used to handle positive indicators, while Equation (12) is used to handle negative indicators:

Next, the weights and information entropy values for each indicator are determined using the following calculation method (where n represents the total number of years):

Finally, the information utility value for each indicator m and the weights for each indicator are calculated, as shown in Table 2. These values are then used to calculate the level of development in advanced manufacturing (AMI) for the 31 provinces in China, as well as the values for the five primary indicators. These values will be used in the baseline regression. The specific calculation process is as follows:

Table 2.

Evaluation indicator system for advanced manufacturing.

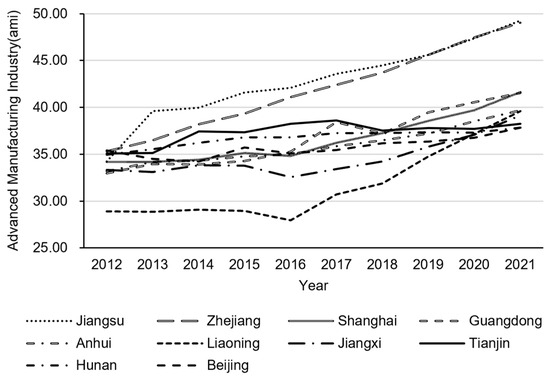

Based on the calculations, the top-ten provinces in China for advanced manufacturing in 2021 are Jiangsu Province, Zhejiang Province, Shanghai Municipality, Guangdong Province, Anhui Province, Liaoning Province, Jiangxi Province, Tianjin Municipality, Hunan Province, and Beijing Municipality. The development trends of advanced manufacturing in these provinces from 2012 to 2021 are illustrated in Figure 2.

Figure 2.

Development level of advanced manufacturing in provinces.

4.2.2. Explaining Variable

In the present study, an initial assessment is conducted to determine the level of industrial synergy agglomeration, referred to as “coagglo”. To define the productive service sector, existing research is taken into account, encompassing the amalgamation of five industries: “transportation, warehousing, and postal services”, “leasing and business services”, “information transmission, computer services, and software industry”, “financial industry”, and “scientific research, technical services, and geophysical prospecting”. The specific methodology employed for computation is outlined as follows:

In Equation (18), represents the number of manufacturing industry employees in province p during period t, denotes the total employment in province p during period t, represents the national manufacturing industry employment during period t, and represents the national employment during period t. By utilizing these variables, the level of manufacturing industry agglomeration can be computed. Similarly, in Equation (19), the meanings of the respective indicators remain consistent, allowing for the computation of the level of agglomeration in the productive service sector . Finally, Equation (20) yields the annual average level of industrial synergy agglomeration for each province over the years.

4.2.3. Control Variables

The following reasons justify the selection of provincial economic development, foreign direct investment, human capital level, government support intensity, fixed investment level, industrial structure, and informatization level as control variables:

Economic Development (pdgp): A vibrant regional economy fosters a conducive social environment and injects impetus into industrial development, enhancing the innovation capacity of the manufacturing industry.

Foreign Direct Investment (fdi): Inflows of FDI lead to reduced domestic market share and intensified competition, creating a mechanism of natural selection that compels domestic firms to upgrade their technology to adapt to the new market environment. Additionally, foreign-funded enterprises possess advanced research and management capabilities, and the flow of personnel between domestic and foreign-funded enterprises can accelerate the formation of a comprehensive industry radiation effect in the region, promoting advanced manufacturing development in various aspects such as technology, management, and human capital.

Human Capital Level (hcl): The educational attainment of the regional population directly influences the quality of talent reserves. The longer the average years of education per person, the richer the reservoir of knowledge and skills, which are ultimately reflected in work capacity and efficiency.

Government Support Intensity (gov): Government actions have a significant impact on regional industrial development. On one hand, the government can promote industrial development through funding, tax incentives, and other means. On the other hand, improper government intervention can hinder regional industrial development and increase policy burdens on local enterprises.

Fixed Investment Level (inv): Economic growth hinges on fixed asset investment. However, excessive investment can increase enterprise investment costs, burden cash flow, and impede long-term development.

Industrial Structure (str): Industrial structure directly influences the level of innovation and research and development in enterprises. A rational industrial structure reduces the cost of cross-industry resource allocation and provides advanced production factors for enterprises to carry out research and innovation activities and achieve technological innovation.

Informatization Level (inf): With the evolution of economic structure towards informatization, factor markets provide ample knowledge information for the development of advanced manufacturing. Information resources are extensively shared, and new knowledge and technologies quickly disseminate across the industry, with advanced enterprises playing a more prominent role. In this study, the level of informatization is measured using the volume of postal and telecommunications services in the region.

4.2.4. Mechanism Variables

Urban innovation capacity (uic) is gauged through the prism of patent indicators (Huang et al. 2022), taking into account the technological content and research and development costs. Thus, the quantity of granted patents for inventions serves as a quantifiable measure (Jin et al. 2019).

Manufacturing intelligence (mi) is assessed based on the import data of three categories of industrial robots, classified by their HS eight-digit codes: 84795010 (multi-functional industrial robots), 84795090 (industrial robots excluding multi-functional ones), and 84864031 (IC factory-specific automated handling robots) (Li et al. 2021).

International capacity cooperation (icc) encompasses various forms such as foreign trade, foreign direct investment, and contracted projects (Wang and Hui 2019). Thus, this study measures the level of international capacity cooperation by examining the proportion of total imports and exports, foreign direct investment, and contracted project amounts in the manufacturing industry to each province’s GDP.

4.2.5. Data Sources

Advanced manufacturing indicators data are derived from publications such as The China Statistical Yearbook, The China Industrial Statistical Yearbook, The China Science and Technology Statistical Yearbook, and The China Environmental Statistical Yearbook. Industry synergy aggregation data are sourced from The China Labor Statistical Yearbook. Control variables, urban innovation capacity, and manufacturing intelligence data are obtained from the EPS database. International capacity cooperation data is sourced from The China Foreign Economic Statistical Yearbook (2003–2005) and The China Trade and Economic Statistical Yearbook (2006–2021).

To address missing values, linear interpolation is employed to construct panel data for the 31 provinces spanning from 2003 to 2021. The selection of substitute variables for each indicator and descriptive statistical results are presented in Table 3.

Table 3.

The descriptive statistical analysis of the variables.

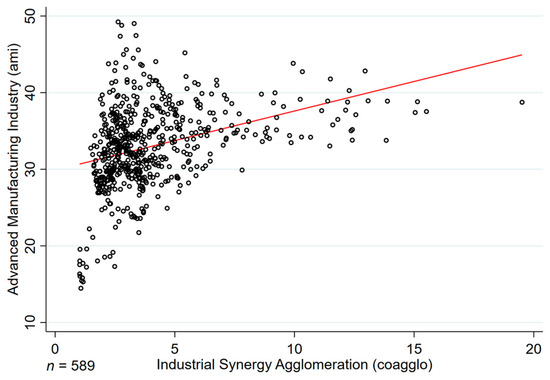

Figure 3 illustrates the scatter plot and fitted line depicting the relationship between industrial synergy agglomeration and the development of advanced manufacturing. The plot clearly demonstrates a positive correlation between the two variables, providing a solid foundation for the empirical research that follows.

Figure 3.

Correlation between industrial synergy agglomeration and the development of advanced manufacturing.

5. Results

5.1. Baseline Regression

The p-value of the Hausman test is less than 0.05, indicating the adoption of a two-way fixed-effects (two-way FE) model. The regression results, presented in Table 4, column (1), reveal that the coefficient of industrial synergy agglomeration level is significantly positive, suggesting its promotion effect on the development of advanced manufacturing, and thus supporting H1. The levels of regional economic development, foreign direct investment, and informatization exhibit significant positive impacts on the development of advanced manufacturing. The government support intensity and fixed investment level demonstrate significant negative effects, aligning with the earlier description of control variables. The coefficient of human capital level is not significant, potentially due to the gradual accumulation of the positive impact of improved educational attainment among regional personnel on firm performance and industrial development, which may exhibit certain time-lag effects.

Table 4.

Baseline regression and robustness testing.

5.2. Robustness Testing

5.2.1. Addressing Endogeneity Issues

This empirical study may potentially face two sources of endogeneity issues. Firstly, there is the concern of bidirectional causality, whereby the development of advanced manufacturing stimulates the demand for the integration of manufacturing with upstream and downstream industries, thereby promoting the synergistic development of manufacturing and productive service sectors. Secondly, there is the issue of omitted variables, wherein certain variables that have an impact on the development of advanced manufacturing are not included in the model.

To tackle these concerns, we draw upon existing research and employ a two-stage least squares estimation (FE2SLS) with a lagged one-period industrial synergy agglomeration as the instrumental variable. The results of the first-stage regression, presented in Table 4, column (2), indicate that the coefficient of the instrumental variable is positive and statistically significant at the 1% level. Additionally, the first-stage F-statistic of 47.850 passes the weak instrument test. Moving to the second stage, the regression results in Table 4, column (3), reveal that the coefficient of industrial synergy agglomeration remains statistically significant and positive, providing support for H1. Furthermore, the instruments pass the tests for instrument validity and endogeneity.

5.2.2. Alternate Explaining ()Variable

Ellison and Glaeser (1997) develop the EG correction index based on the EG index, which is used to examine the level of industrial synergy agglomeration. Devereux et al. (2004) simplify this index, reducing data requirements, and it has been widely adopted in current research. In this study, the EG index is recalculated to measure the level of industrial synergy agglomeration for robustness testing. The calculation process of this index is as follows:

In Equation (21), variables and represent the proportions of employees in the manufacturing and productive service sectors, respectively, in relation to the total number of employees in both sectors. , , and , on the other hand, describe the overall geographic concentration of the two sectors as well as the individual concentration levels of the manufacturing and productive service sectors. The calculation methods for these variables are as follows:

where represents the proportion of employees in the manufacturing, productive service, or both sectors in a given province k relative to the total number of employees in the corresponding (sub-)sector nationwide. The value of EG index reflects the degree of industrial synergy agglomeration in the provincial region, with higher values indicating a higher level of agglomeration. As an alternative indicator for the level of industrial synergy agglomeration, we utilize the EG index as the core explanatory variable. The regression results, presented in Table 4, column (4), demonstrate that the coefficient of the EG index is statistically significant and positive. This finding suggests that industrial synergy agglomeration can indeed promote the development of advanced manufacturing, aligning with the conclusions drawn from the baseline regression.

5.2.3. Alternate Explained Variable

Starting from 2016, China began to establish regional manufacturing innovation platforms, with the first batch of national manufacturing innovation centers being established and expanded to 26 centers by the end of 2022. These centers are distributed across 17 provinces, including Guangdong, Beijing, and Shanghai. In recent years, a series of policies have been implemented to indicate the key directions for the development of advanced manufacturing. Measuring and considering relevant indicators can reflect the development status of advanced manufacturing in different provinces.

In this study, we select the number of national manufacturing innovation centers in the 31 provinces of China from 2016 to 2021, as an alternative indicator for the level of advanced manufacturing development, and conduct robustness testing. The results, presented in Table 4, column (5), demonstrate that industrial synergy agglomeration has a significant positive impact on the development of advanced manufacturing, which is consistent with the conclusions drawn from the baseline regression. Therefore, we can conclude that the findings regarding the positive influence of industrial synergy agglomeration on the development of advanced manufacturing remain robust, even when using the number of national manufacturing innovation centers as an alternative indicator for advanced manufacturing development.

5.2.4. Subdivision Evaluation Indicators

By building upon the regression analysis with the comprehensive index of advanced manufacturing development as the dependent variable, this study further examines the impact of industrial synergy agglomeration on five specific indicators: advanced manufacturing technology, advanced manufacturing management, advanced manufacturing workforce, green advanced manufacturing, and advanced manufacturing efficiency.

The results, presented in Table 5, columns (1) to (5), reveal that the coefficients of industrial synergy agglomeration are all statistically significant and positive. This signifies that the positive influence of synergy between the manufacturing and productive service sectors on advanced manufacturing development permeates across various aspects. Strengthening the collaborative development between these two sectors not only enhances the independent research and innovation capabilities of manufacturing enterprises, leading to greater economic benefits, but also improves the overall quality of industry personnel, optimizes management models, and promotes sustainable development with a green and environmentally friendly approach.

Table 5.

Subdivision advanced manufacturing evaluation indicators.

5.3. Heterogeneity Analysis

5.3.1. Based on Regional Divisions

By stratifying the geographical regions into four sub-samples, namely the Eastern, Central, Western, and Northeastern regions2, a regression analysis is conducted, and the results are presented in columns (1) to (4) of Table 6. It is discerned that industrial synergy agglomeration significantly stimulates the development of advanced manufacturing in the eastern provinces and exerts a positive influence on the northeastern region. However, in the central and western regions, this impact is not statistically significant. An analysis of these disparities reveals that industrial synergy agglomeration has a positive impact on the development of advanced manufacturing, with industry development foundations serving as a threshold. The eastern region, boasting a generally favorable state of advanced manufacturing development, effectively showcases the promotional role of industrial synergy agglomeration. As a longstanding industrial powerhouse, the northeastern region possesses a solid industrial development foundation, thereby enabling industrial synergy agglomeration to facilitate manufacturing transformation and propel the advancement of advanced manufacturing. In contrast, the central region exhibits significant disparities in the level of advanced manufacturing development, rendering the overall impact of industrial synergy agglomeration on advanced manufacturing development inconclusive. The western region lags behind in advanced manufacturing development, where, relative to factors such as absolute input magnitude, the impact of industrial synergy agglomeration is relatively modest. Hence, the region urgently requires an uplift in the level of advanced manufacturing, supporting H1.

Table 6.

Heterogeneity analysis.

5.3.2. Based on the Presence of National Advanced Manufacturing Clusters

In November 2022, the Ministry of Industry and Information Technology released a list of 45 national advanced manufacturing clusters, with 18 provinces having national advanced manufacturing clusters3. Among them, Jiangsu Province topped the list with 11 clusters, followed by Guangdong Province with 7 clusters. Hunan Province and Zhejiang Province both had four clusters, ranking third nationwide. The remaining 13 provinces currently do not have national advanced manufacturing clusters. Based on this criterion, two sub-samples are formed, one with provinces that have national advanced manufacturing clusters and the other without. Separate regressions are conducted for each sub-sample, and the results are presented in Table 6, columns (4) and (5). It is observed that, in provinces with advanced manufacturing clusters, industrial synergy agglomeration significantly promotes the development of advanced manufacturing. However, in provinces without advanced manufacturing clusters, this positive influence is not significant. This result is similar to the findings of the regional heterogeneity analysis. The underlying reason is that the promotion of advanced manufacturing through the synergy between the manufacturing and productive service sectors requires a solid industrial development foundation in the region.

5.4. Intermediate Effect Test

The mediational analysis results can be found in Table 7, encompassing columns (1) through (4). The initial regression findings unveil a remarkable positive impact of industrial synergy agglomeration on the development of advanced manufacturing. Subsequently, in the second regression, the coefficient of the core explanatory variable exhibits a significant positive value, implying that industrial synergy agglomeration enhances urban innovative capabilities. Furthermore, upon integrating industrial synergy agglomeration and urban innovative capabilities into the equation in the third step, their combined influence on the development of advanced manufacturing remains significantly positive. Hence, it can be inferred that industrial synergy agglomeration enhances urban innovative capabilities, thereby fostering the advancement of advanced manufacturing, thereby lending support to H2. Moreover, it is worth noting that, in column (2), the coefficient for urban innovative capabilities exhibits a significant positive value, thus confirming H2.

Table 7.

Intermediate effect test.

The implementation of the bootstrap method, renowned for its scientific rigor and accuracy, is employed in this study to examine the robustness of the mediating effects. As per the findings in Table 8, within a 95% error-corrected confidence interval, it is observed that the indirect effect of industrial synergy agglomeration on the development of advanced manufacturing, mediated through the enhancement of urban innovative capabilities, amounts to 0.367 (CI = [0.202, 0.591]). The confidence interval, devoid of the inclusion of zero, attests to the presence of a mediating effect. Furthermore, the direct effect of industrial synergy agglomeration on the development of advanced manufacturing is estimated at 0.400 (CI = [0.161, 0.602]) within the same confidence interval, signifying a positive and significant impact even when controlling for the mediating variable of urban innovative capabilities. Thus, urban innovative capabilities play a partial mediating role in the process of industrial synergy agglomeration fostering the advancement of advanced manufacturing. The results of the bootstrap test likewise provide support for H2.

Table 8.

The results of the bootstrap mediation analysis.

5.5. Moderated Mediating Effect Test

5.5.1. The Regulating Effect of Manufacturing Intelligence

Columns (1) to (5) in Table 9 present the moderating effect of manufacturing intelligence on the relationship between industrial synergy agglomeration and advanced manufacturing development. Column (1) indicates that the coefficient of the interaction term between industrial synergy agglomeration and manufacturing intelligence is significantly positive, suggesting that manufacturing intelligence plays a positive moderating role in the direct path through which industrial synergy agglomeration promotes advanced manufacturing development. Furthermore, in columns (3) and (5), the coefficients of the interaction term between industrial synergy agglomeration and manufacturing intelligence, as well as the coefficients of urban innovative capabilities and the interaction term between manufacturing intelligence, are all significantly positive. This indicates that manufacturing intelligence exerts a positive moderating effect in both of the two-step indirect paths through which industrial synergy agglomeration fosters advanced manufacturing development, thereby supporting H3.

Table 9.

The regulating effect of manufacturing intelligence.

5.5.2. The Regulating Effect of International Capacity Cooperation

The results of the moderation analysis, examining the moderating effect of international capacity cooperation on the relationship between industrial synergy agglomeration and advanced manufacturing development, are presented in Table 10, spanning columns (1) to (5). Column (1) reveals that the moderating factor exhibits a positive moderating effect in the relationship between industrial synergy agglomeration and advanced manufacturing development. Further investigation of the moderated mediation effects within the indirect paths reveals that international capacity cooperation plays a positive moderating role in both the relationship between industrial synergy agglomeration and urban innovative capabilities, as well as the relationship between urban innovative capabilities and advanced manufacturing development. These findings support H3, indicating that international capacity cooperation positively moderates the indirect effects within the mediation process.

Table 10.

The regulating effect of international capacity cooperation.

5.6. Spatial Spillover Effect Test

Based on the GDP and the latitude–longitude of each province, an economic, geographic, nested matrix is constructed. The global Moran’s I index is computed for the levels of industrial synergy agglomeration and advanced manufacturing development from 2003 to 2021, accompanied by the creation of a scatter plot. The core variable Moran’s I indices all exhibit significant positive values, indicating the presence of spatial positive autocorrelation.

Initially, an LM test is conducted, encompassing the LM (lag) test (183.745 ***), the R-LM (lag) test (9.030 ***), the LM (error) test (198.843 ***), and the R-LM (error) test (24.128 ***). The results of all these tests are significant, suggesting the adoption of the Spatial Durbin Model (SDM). Subsequently, Wald and LR tests are performed. The Wald (SAR) test (32.42 ***) and Wald (SEM) test (32.45 ***) reject the null hypothesis that the SDM model can be degraded to either SAR or SEM models, thus passing the test. Similarly, the LR (SAR) test (31.56 ***) and LR (SEM) test (31.64 ***) also support the aforementioned conclusion. Finally, the Hausman test yielded a p-value below 0.05, leading to the adoption of the fixed-effects SDM model.

The regression results are presented in Table 11. From column (1), it can be observed that the main effect is significantly positive, indicating a positive influence of industrial synergy agglomeration on the development of advanced manufacturing within the province, aligning with the baseline regression results. In column (2), the coefficient of the core explanatory variable is significantly positive, suggesting a preliminary promotion effect of increased levels of industrial synergy agglomeration within the province on the development of advanced manufacturing in other provinces. However, the presence of spatial spillover effects still needs to be examined through the coefficients of the indirect effects. Columns (3) to (5) reflect the spatial spillover effects of various variables on the development of provincial advanced manufacturing. It can be observed that both the direct and indirect effects of industrial synergy agglomeration are significantly positive, indicating the existence of positive spatial spillover effects. Even when the economic geographic nested matrix is replaced by an economic distance matrix, the aforementioned conclusions remain valid.

Table 11.

Spatial spillover effect test.

6. Discussion

The synergistic agglomeration of manufacturing and productive service industries infuses the development of advanced manufacturing with a wellspring of vitality (Qiu and Gong 2021; Song et al. 2023). In this study, we construct an indicator system to assess the level of development of advanced manufacturing in Chinese provinces. Subsequently, empirical analysis is conducted to examine the direction and mechanisms through which industrial synergy agglomeration influences the development of advanced manufacturing. Furthermore, we examine the spatial spillover effects of industrial synergy agglomeration.

In line with previous research (Gao et al. 2020), our findings confirm that industrial synergy agglomeration promotes the development of advanced manufacturing. As manufacturing and service industries deepen their collaboration within regions, the costs of factor mobility and information sharing decrease, facilitating the dissemination of advanced manufacturing technology (Pandit et al. 2001), significantly improving the management capabilities of manufacturing enterprises. Consequently, this leads to increased economic benefits (Klein and Crafts 2020). The optimization of spatial layout in these two industries engenders the effects of concentrated governance and economies of scale, curbing carbon emissions and environmental pollution (Wang et al. 2022), thereby enhancing the green growth efficiency of the manufacturing sector (Lv and Lu 2022; Zhu et al. 2022). In comparison to the above-mentioned existing studies that focus on the effects of industrial synergy agglomeration on advanced manufacturing development from singular perspectives such as technology, management, or environmental sustainability, this study employs a comprehensive index to measure the level of advanced manufacturing development, ensuring a more scientific and comprehensive approach. Furthermore, our research reveals that the promoting effect of industrial synergy agglomeration on advanced manufacturing development is more pronounced in the eastern regions of China and in 18 provinces with national advanced manufacturing clusters. This finding indicates that the process through which industrial synergy agglomeration exerts its influence is influenced by the heterogeneity of the regional foundation for advanced manufacturing development, aligning with the research results that focused on the pharmaceutical manufacturing industry (Hu et al. 2021). However, some earlier studies have raised objections to the results of our research. Wang and Wang (2023) find that the impact of industrial synergy agglomeration on regional economic growth exhibits scale effects and congestion effects, with a “U-shaped” relationship curve present in both the local region and neighboring areas.

This study enriches the research on the drivers of advanced manufacturing by incorporating innovation as a mediating factor into the regression equation (Zhuang et al. 2021; Yang et al. 2021). It reveals that industrial synergy agglomeration enhances urban innovation capabilities, thereby promoting the development of advanced manufacturing. As the spatial layout of industrial synergy agglomeration takes shape, the external economic effects generated by specialized division of labor become evident, leading to improved innovation efficiency among regional manufacturing firms (Shen et al. 2019; Wang et al. 2019; Peng et al. 2023). The enhancement of innovation capabilities, coupled with rationalized factor allocation, drives the positive development of various industries within the region (Fan et al. 2021). The output of innovation activities, when integrated into the production process of enterprises, transforms into advanced technological achievements, with positive and long-term effects on economic benefits (Lafuente et al. 2020; Becerra-Vicario et al. 2023). However, Zhang et al. (2022) argue in their research that the impact of urban innovation on the development level of emerging industries follows an inverted “U-shaped” curve, contradicting the findings of this study.

We further examine the mechanisms through which industrial synergy agglomeration impacts advanced manufacturing development and reveal that manufacturing intelligence and international capacity cooperation, as moderating factors, play a positive role in both the direct and indirect pathways of industrial synergy agglomeration’s impact. In regions with higher levels of manufacturing intelligence, there is a better utilization of advanced technologies, improved facility conditions (Yigitcanlar et al. 2020), stronger talent attraction, and higher efficiency in information exchange and resource allocation among industries (Song and Zuo 2019). International capacity cooperation provides favorable support for enterprise innovation and research and development by facilitating the flow of mobile factors (Chen et al. 2012). In regions with higher levels of international capacity cooperation, there is frequent exchange of learning and communication between domestic and foreign entities, enabling Chinese manufacturing enterprises to access advanced knowledge, technology, and management experience from abroad more easily (Martinez-Noya et al. 2012). As the synergistic effect of industry agglomeration strengthens, the improvement in urban innovation levels becomes more evident, leading to the more rapid development of advanced manufacturing.

Lastly, research from the perspective of green development in the manufacturing industry indicates that the synergistic collaboration between manufacturing and productive service industries has a spatial spillover effect in suppressing atmospheric pollution (Zhuang et al. 2021). This study further deepens the spatial-level research and utilizes the Spatial Durbin Model (SDM) to verify the positive spatial spillover effects of industrial synergy agglomeration on the comprehensive development of advanced manufacturing at the provincial level. As the development of productive service industries becomes more refined, the supporting services provided to advanced manufacturing enterprises become increasingly specialized (Ke et al. 2014). When the demands of advanced manufacturing enterprises in a province are met, upstream and downstream service enterprises, in search of new business opportunities, actively engage in cross-provincial cooperation, thereby providing support for the development of advanced manufacturing in neighboring provinces.

7. Conclusions

This study formulates a comprehensive indicator system for evaluating the advancement of the manufacturing industry and proceeds to quantitatively assess the development level of advanced manufacturing across 31 provinces in China. Expanding upon this, the study delves into the pathways through which industrial synergy agglomeration promotes the development of advanced manufacturing at the provincial level. Notably, it unveils the partial mediating role played by urban innovation capabilities, while highlighting the positive moderating effects of manufacturing intelligence and international capacity cooperation.

At the academic level, this paper makes two significant contributions. Firstly, it enhances the evaluation indicator system for advanced manufacturing and employs panel data at the provincial level to quantitatively assess the development level of advanced manufacturing across various provinces in China. In comparison to previous studies that relied on single indicators, this paper’s measurement of advanced manufacturing development is more scientifically rigorous, filling the gap in comprehensive indicators for assessing advanced manufacturing. Secondly, this paper employs a moderated mediation model (Baron and Kenny 1986; Sun et al. 2020) that incorporates urban innovation, manufacturing intelligence, and international capacity cooperation into a unified analytical framework. By delving into the mechanisms through which industrial synergy agglomeration influences advanced manufacturing, this study goes beyond existing research that solely focuses on mediating effects. It also takes into account the role of moderating variables, thereby deepening the understanding of the drivers behind advanced manufacturing development.

Furthermore, this study holds valuable implications for the formulation of China’s manufacturing development policies. Specifically, provincial regions should focus on the synergistic development of manufacturing and productive service industries and seek optimal solutions for industrial synergy agglomeration based on their own industrial development foundations. Additionally, provinces should strengthen the cultivation of enterprise innovation capabilities, optimize the layout of innovation chains, and establish city-based manufacturing innovation centers. Moreover, in the current complex and ever-changing international landscape, provinces should focus on localized research and development of intelligent manufacturing technologies, fostering a comprehensive industry layout for manufacturing intelligence. Lastly, provinces should actively promote international capacity cooperation to catalyze the development of advanced manufacturing.

This study may have certain limitations in examining the spatial spillover effects. Currently, the study has examined the direct impact of industrial synergy agglomeration on the development of advanced manufacturing, but has not examined the indirect pathway of urban innovation. It would be beneficial to investigate whether the positive regulatory effects of manufacturing intelligence and international capacity cooperation exhibit significant spatial spillover characteristics among provinces.

Author Contributions

Conceptualization, H.Y. and W.S.; methodology, H.Y.; software, W.S.; validation, H.Y. and W.S.; formal analysis, H.Y. and W.S.; investigation, H.Y. and W.S.; resources, H.Y.; data curation, W.S.; writing—original draft preparation, H.Y. and W.S.; writing—review and editing, H.Y. and W.S.; visualization, W.S.; supervision, H.Y.; project administration, H.Y.; funding acquisition, H.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Hunan Office for Philosophy and Social Sciences, China, grant number 22JD002; National Office for Philosophy and Social Sciences of China, grant number 16BJY079.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data has been generated.

Conflicts of Interest

The authors declare no conflicts of interest.

Notes

| 1 | Our sample does not include data from Hong Kong, Macau, and Taiwan. |

| 2 | The Eastern region comprises ten provinces and municipalities, namely Beijing, Tianjin, Hebei, Shanghai, Jiangsu, Zhejiang, Fujian, Shandong, Guangdong, and Hainan. The Central region encompasses six provinces, namely Shanxi, Anhui, Jiangxi, Henan, Hubei, and Hunan. The Western region includes twelve provinces, regions, and municipalities, namely Inner Mongolia, Guangxi, Chongqing, Sichuan, Guizhou, Yunnan, Tibet, Shaanxi, Gansu, Qinghai, Ningxia, and Xinjiang. Lastly, the Northeastern region consists of three provinces, namely Liaoning, Jilin, and Heilongjiang. |

| 3 | Apologies for the previous incorrect information. The 18 provinces with national advanced manufacturing clusters are as follows: Beijing, Tianjin, Hebei, Inner Mongolia, Liaoning, Jilin, Shanghai, Jiangsu, Zhejiang, Anhui, Fujian, Shandong, Hubei, Hunan, Guangdong, Chongqing, Sichuan, and Shaanxi. |

References

- Acemoglu, Daron, Claire Lelarge, and Pascual Restrepo. 2020. Competing with Robots: Firm-Level Evidence from France. AEA Papers and Proceedings 110: 383–88. [Google Scholar] [CrossRef]

- Ahmad, Zafran, Liu Chao, Wang Chao, Wasim Iqbal, Sulaman Muhammad, and Shujaat Ahmed. 2022. Assessing the Performance of Sustainable Entrepreneurship and Environmental Corporate Social Responsibility: Revisited Environmental Nexus from Business Firms. Environmental Science and Pollution Research 29: 21426–39. [Google Scholar] [CrossRef]

- Ambos, Björn, Kristin Brandl, Alessandra Perri, Vittoria G. Scalera, and Ari Van Assche. 2021. The Nature of Innovation in Global Value Chains. Journal of World Business 56: 101221. [Google Scholar] [CrossRef]

- Andersson, Martin. 2004. Co-Location of Manufacturing & Producer Services—A Simultaneous Equation Approach. Working Paper Series in Economics and Institutions of Innovation; Stockholm: Royal Institute of Technology, CESIS, pp. 1–24. [Google Scholar]

- Bag, Surajit, Shivam Gupta, and Sameer Kumar. 2021. Industry 4.0 Adoption and 10R Advance Manufacturing Capabilities for Sustainable Development. International Journal of Production Economics 231: 107844. [Google Scholar] [CrossRef]

- Baron, Reuben M., and David A. Kenny. 1986. The Moderator–Mediator Variable Distinction in Social Psychological Research: Conceptual, Strategic, and Statistical Considerations. Journal of Personality and Social Psychology 51: 1173–82. [Google Scholar] [CrossRef] [PubMed]

- Becerra-Vicario, Rafael, Daniel Ruiz-Palomo, Ana León-Gómez, and José Manuel Santos-Jaén. 2023. The Relationship Between Innovation and the Performance of Small and Medium-Sized Businesses in the Industrial Sector: The Mediating Role of CSR. Economies 11: 92. [Google Scholar] [CrossRef]

- Chang, Zheren, and Meng Zheng. 2023. Impact of Collaborative Industrial Agglomeration on Green Innovation Efficiency from Perspective of Spatial Spillover. Research on Financial and Economic Issues 10: 53–67. [Google Scholar] [CrossRef]

- Chen, Victor Zitian, Jing Li, and Daniel M. Shapiro. 2012. International Reverse Spillover Effects on Parent Firms: Evidences from Emerging-Market MNEs in Developed Markets. European Management Journal 30: 204–18. [Google Scholar] [CrossRef]

- Cugurullo, Federico. 2020. Urban Artificial Intelligence: From Automation to Autonomy in the Smart City. Frontiers in Sustainable Cities 2: 1–14. [Google Scholar] [CrossRef]

- Devereux, Michael P., Rachel Griffith, and Helen Simpson. 2004. The Geographic Distribution of Production Activity in the UK. Regional Science and Urban Economics 34: 533–64. [Google Scholar] [CrossRef]

- Ellison, Glenn, and Edward L. Glaeser. 1997. Geographic Concentration in U.S. Manufacturing Industries: A Dartboard Approach. Journal of Political Economy 105: 889–927. [Google Scholar] [CrossRef]

- Fan, C. Cindy, and Allen J. Scott. 2003. Industrial Agglomeration and Development: A Survey of Spatial Economic Issues in East Asia and a Statistical Analysis of Chinese Regions. Economic Geography 79: 295–319. [Google Scholar] [CrossRef]

- Fan, Fei, Shangze Dai, Keke Zhang, and Haiqian Ke. 2021. Innovation Agglomeration and Urban Hierarchy: Evidence from Chinese Cities. Applied Economics 53: 6300–18. [Google Scholar] [CrossRef]

- Feng, Delian, Jin Wang, and Ruomei Wang. 2020. Openness Threshold Effect of OFDI on Advanced Manufacturing Development in Yangtze River Economic Belt. Finance and Trade Research 31: 1–13. [Google Scholar] [CrossRef]

- Feng, Luanye, Chunying Cui, Yucen Zhou, and Xiaolin Xu. 2022. Can the National Manufacturing Innovation Center Boost Advanced Manufacturing: A Quasi-Natural Experiment in Hubei Province. Science & Technology Progress and Policy 39: 62–71. [Google Scholar]

- Gao, Lei, Jingran Zhang, Yu Tian, Xinyu Liu, Shuxin Guan, and Yuhong Wu. 2023. Study on the Impact of Collaborative Agglomeration of Manufacturing and Producer Services on PM2.5 Pollution: Evidence from Urban Agglomerations in the Middle Reaches of the Yangtze River in China. International Journal of Environmental Research and Public Health 20: 3216. [Google Scholar] [CrossRef]

- Gao, Xinyu, Chengpeng Lu, and Jinhuang Mao. 2020. Effects of Urban Producer Service Industry Agglomeration on Export Technological Complexity of Manufacturing in China. Entropy 22: 1108. [Google Scholar] [CrossRef]

- Helsley, Robert W., and William C. Strange. 2014. Coagglomeration, Clusters, and the Scale and Composition of Cities. Journal of Political Economy 122: 1064–93. [Google Scholar] [CrossRef]

- Howard, Emma, Carol Newman, and Finn Tarp. 2016. Measuring Industry Coagglomeration and Identifying the Driving Forces. Journal of Economic Geography 16: 1055–78. [Google Scholar] [CrossRef]

- Hu, Die, and Xiangqian Zhang. 2011. An Analysis on the Development of Advanced Manufacturing Base in the Economic Zone on the West Side of the Straits. Economic Geography 31: 961–67. [Google Scholar] [CrossRef]

- Hu, Meng, Chunhai Tao, and Hao Zhou. 2021. The Influence of Industrial Structure Upgrade on Coupling and Coordinated Development—Empirical Analysis from Chinese Pharmaceutical Manufacturing and Pharmaceutical Service Industries. Frontiers in Public Health 9: 1–16. [Google Scholar] [CrossRef] [PubMed]

- Huang, Shunchun, and Shuqi Zhang. 2021. Research Review on the Evaluation Index System of High-Quality Development in China’s Manufacturing Industry. Statistics & Decision 37: 5–9. [Google Scholar] [CrossRef]

- Huang, Xiaocheng, Jianjun Zhou, and Yake Zhou. 2022. Digital Economy’s Spatial Implications on Urban Innovation and Its Threshold: Evidence from China. Complexity 2022: e3436741. [Google Scholar] [CrossRef]

- Jin, Peizhen, Desheng Ying, and Zhuang Jin. 2019. Urban Heterogeneity, Institution Supply and Innovation Quality. The Journal of World Economy 42: 99–123. [Google Scholar] [CrossRef]

- Ke, Shanzi, Ming He, and Chenhua Yuan. 2014. Synergy and Co-Agglomeration of Producer Services and Manufacturing: A Panel Data Analysis of Chinese Cities. Regional Studies 48: 1829–41. [Google Scholar] [CrossRef]

- Klein, Alexander, and Nicholas Crafts. 2020. Agglomeration Externalities and Productivity Growth: US Cities, 1880–1930. The Economic History Review 73: 209–32. [Google Scholar] [CrossRef]

- Lafuente, Esteban, Zoltan J. Acs, Mark Sanders, and László Szerb. 2020. The Global Technology Frontier: Productivity Growth and the Relevance of Kirznerian and Schumpeterian Entrepreneurship. Small Business Economics 55: 153–78. [Google Scholar] [CrossRef]

- Li, Lei, Xiaoxia Wang, and Qun Bao. 2021. The Employment Effect of Robots: Mechanism and Evidence from China. Management World 37: 104–19. [Google Scholar] [CrossRef]

- Li, Tuochen, Dongri Han, Shaosong Feng, and Lei Liang. 2019. Can Industrial Co-Agglomeration Between Producer Services and Manufacturing Reduce Carbon Intensity in China? Sustainability 11: 4024. [Google Scholar] [CrossRef]

- Liu, Jun, Zhonghua Cheng, and Huiming Zhang. 2017. Does Industrial Agglomeration Promote the Increase of Energy Efficiency in China? Journal of Cleaner Production 164: 30–37. [Google Scholar] [CrossRef]

- Lo, Chu-Ping. 2014. International Outsourcing, Wage Gap, and Welfare. Economic Modelling 43: 168–72. [Google Scholar] [CrossRef]

- Lv, Xiaofei, and Xiaoli Lu. 2022. Green Growth or Gray Growth: Measuring Green Growth Efficiency of the Manufacturing Industry in China. Systems 10: 255. [Google Scholar] [CrossRef]

- Mahalakshmi, S., A. Arokiasamy, and J. Fakrudeen Ali Ahamed. 2019. Productivity Improvement of an Eco Friendly Warehouse Using Multi Objective Optimal Robot Trajectory Planning. International Journal of Productivity and Quality Management 27: 305–28. [Google Scholar] [CrossRef]

- Martinez-Noya, Andrea, Esteban Garcia-Canal, and Mauro F. Guillen. 2012. International R&D Service Outsourcing by Technology-Intensive Firms: Whether and Where? Journal of International Management 18: 18–37. [Google Scholar] [CrossRef]

- Ocampo, Jared R., Juan Carlos Hernández-Matías, and Antonio Vizán. 2017. A Method for Estimating the Influence of Advanced Manufacturing Tools on the Manufacturing Competitiveness of Maquiladoras in the Apparel Industry in Central America. Computers in Industry 87: 31–51. [Google Scholar] [CrossRef]

- Pandit, Naresh R., Gary A.S. Cook, and Peter G.M. Swann. 2001. The Dynamics of Industrial Clustering in British Financial Services. The Service Industries Journal 21: 33–61. [Google Scholar] [CrossRef]

- Peng, Benhong, Hong Chen, Ehsan Elahi, and Guo Wei. 2020. Study on the Spatial Differentiation of Environmental Governance Performance of Yangtze River Urban Agglomeration in Jiangsu Province of China. Land Use Policy 99: 105063. [Google Scholar] [CrossRef]