Abstract

To ensure development sustainability, the linear economic approach is being transformed into a cyclical model. For the pulp and paper industry (PPI), which occupies a significant place in the Russian economy, the shift of circular principles to the field of bioeconomics is becoming more important. This requires the development of basic biotechnological approaches implemented in closed cycles (biorefining). The aim of this study was to develop the biotechnological foundations of the circular economic system of the pulp and paper industry. To achieve the goal, the factors for the implementation of the circular mechanism in the pulp and paper industry were established. The composition of pulp and paper waste was systematized, taking into account the places of their occurrence; the directions and forms of the biorefining of pulp and paper secondary renewable resources were determined; and the principal possibility of obtaining bioethanol, based on the whole complex of sugars from cellulose production wastes, is shown. A wide range of general scientific methods was involved (analysis, synthesis, classification, modeling, etc.). Statistical methods were used to process experimental results in the field of pulp and paper waste bioconversion. The biotechnologies involved included methods of destruction, detoxification, and conversion of useful resources into secondary raw materials and final products. From the standpoint of the environmental approach, there are serious efficiency imbalances in the pulp and paper industry, which justify the implementation of circular mechanisms for organizing economic systems. The overall efficiency is ensured by the use of renewable resources and obtaining environmental effects. Algorithms and parameters of green biotechnological regulations for pulp and paper industry waste recycling provide the possibility of microbiological production of a complex of products: biocomposites, bioplastics, medical products, fertilizers, feed additives, vitamin supplements, and bioenergy resources. A strategy for the efficient biochemical processing of pulp and paper waste into green ethanol was determined. The possibility of increasing the efficiency of alcoholic fermentation using various biocatalysts was experimentally confirmed. The technological features of this method, associated with the need for microaerobic fermentation modes, were determined.

1. Introduction

At present, the priority global concept is the sustainable development of modern society without prejudice to future generations (Kvasha and Malevskaya-Malevich 2022; Babkin et al. 2021). The concept of sustainable development as one of the main components of the overall economic development strategy arose back in 1972 at the UN conference in Stockholm. Sustainable Development Goals (SDGs) aim to achieve economic growth without harming the environment or society. They are achieved through lean, environmentally friendly production. Our research aimed to achieve SDGs 6, 9, 11, 14, 15, and 17 in the pulp and paper industry. The concept of a circular economy arose in the context of the need to increase resource efficiency, due to the limitations of many resources, especially natural, material resources. Researchers agree that in order to ensure sustainable development, the linear economic approach that dominated the industrial period needs to be transformed into a cyclical model that provides a focus on the circular economy (Kvasha et al. 2021; Ghosh 2020; Geng et al. 2019; Bobylev 2021; Lacy and Rutqvist 2016). A significant number of scientific works are devoted to the study of the entire set of issues of the circular economy. Review materials testify to the exponential growth of publications on the problems of the circular economy (Suchek et al. 2021). First, it should be noted the works of Kamenik (Kamenik 2020) established that the basis for the sustainable development of industrial production is the formation of a unified ecological and economic system. Webster introduced the concept of a circular economy, believing that such a model, among other things, requires the transformation of the public administration system (Webster 2017), which we definitely agree with. Vitunskienė (Vitunskienė et al. 2017) noted that long-term forecasts show the need for radical institutional changes, since current trends in global economic growth and development are already having a serious impact on natural resources and the global ecosystem. The green growth theory states that the compatibility of economic growth with the ecology of the planet should be provided by innovative technologies, models, and mechanisms to completely separate GDP growth from resource use and carbon emissions (Hickel and Kallis 2020). The development of these innovative mechanisms, in our opinion, can also be considered as one of the possible solutions to accelerate the process of transition to circular economic systems.

The pulp and paper industry (PPI) in Russia occupies a significant place in the global production of the corresponding products, which is explained by an interconnected set of historical and geographical reasons. In terms of the scale of the raw material base for the pulp and paper industry, Russia ranks first in the world, possessing, according to estimates, more than 20% of the world’s forests more than 20% forest’s stock in the world (Dubovy et al. 2022). The pulp and paper industry in Russia is highly consolidated: the five largest pulp and paper mills (PPMs) owned by three timber holdings cover more than 60% of the industry’s total output. Taking into account the availability of forest, water, and energy resources (for example, more than 17% of the forest fund of Russia is concentrated in the Northwestern Federal District, with a predominance of more valuable coniferous wood), the main enterprises of the industry are located in the northwest of Russia (in the republics of Karelia and Komi and Arkhangelsk, Vologda, and Leningrad regions). In 2022, the northwest of Russia accounted for more than half of the volume of pulp and paper production (Order of the Government of the Russian Federation dated 2 November 2021 N 312-r). Under these conditions, a significant share of the industrial problems of the northwest region, largely related to the scale of industrial pollution, traditionally consists of waste from pulp and paper mills (many of which are toxic) (Kvasha et al. 2021). These issues certainly need to be addressed.

Currently, the pulp and paper industry is mainly associated with various methods of biochemical processing of cellulose-containing raw materials. In addition, a significant proportion of waste that can become sources of secondary raw materials are bioresources (bark, sawdust, etc.) and various organic compounds (lignin, hemicellulose, etc.). Thus, for the pulp and paper industry, the shift of circular principles to the field of biotechnology is being updated. This, in turn, determines the transition to a circular bioeconomy, which also requires the development of basic biotechnological approaches implemented in closed cycles. By focusing more on research and innovation, new biomass products and new services needed to develop the bioeconomy can be created, helping to reduce negative environmental impacts (including climate change), reduce waste, and create new jobs. The typology of biotechnologies, including Russian peculiarities, is being developed; for example, see the study of (Kudryavtseva et al. 2014).

The organization of recycling processes in the economy based on biotechnologies bears the general name of biorefining. There are already sufficiently deep studies of the fundamental issues of biorefining, as well as some practical aspects of this model (Akim 2017; Ivanova and Moiseeva 2021; Maity 2015; Awasthi et al. 2022). However, the scientific literature lacks a sufficient number of theoretical, methodological, and practical developments aimed at establishing the directions and forms of biorefining of secondary renewable resources released in the pulp and paper industries. Among individual works in the field of microbiological conversion of waste from wood-processing enterprises of various profiles, one can single out the studies of Cheng and Wang (Cheng and Wang 2013).

Bioethanol is currently the most significant secondary resource released during the technological processes of pulp and paper mills. Research in the field of green ethanol production from both pulp and paper mill waste and, in principle, from wood and plant biomass is being carried out quite widely (Moldazhanov 2018; Raj et al. 2022; Joshi et al. 2021). At the same time, the requirements of resource saving and ensuring efficiency require a deeper study of some issues. Thus, the composition of organic waste depends mainly on the type of wood; the proportion of monosaccharides utilized in ethanol in hardwood can be 1.5–2 times higher than that of coniferous wood. At the same time, 90% of sugars during the cooking of hardwood are pentose (Dubovy et al. 2022), which is not assimilated by industrial strains of microorganisms. The involvement of this secondary resource in the circular ecosystems of the pulp and paper industry requires the search for new biocatalysts.

Thus, the purpose of this work was to develop the biotechnological foundations of the circular ecosystem of the pulp and paper industry (in particular, the northwestern region of Russia). To achieve this goal, the following tasks were solved during the study:

- identifying the factors that determine the need for the implementation of a circular mechanism in the pulp and paper industry, focused on the closed-cycle model;

- forming a systematized composition of pulp and paper waste, taking into account the places of their occurrence;

- determining directions and forms of biorefining of secondary resources released in the pulp and paper industries as an adequate circular mechanism for closing their economic systems;

- establishing the fundamental possibility of obtaining the most promising bioresource—bioethanol, based on the entire complex of sugars from the organic waste of pulp production.

2. Methodology

To solve the tasks set, a wide range of general scientific methods was used, such as analysis (comparative, logical, structural, systemic, and factorial), as well as synthesis, classification methods and various approaches to descriptive modeling. To process experimental results in the field of pulp and paper waste bioconversion, statistical methods were used at a significance level of α = 0.05. Thus, the results are considered reliable, with no more than a 5% deviation of experimental data from the theoretically expected ones.

Circular economic systems were considered to ensure national economic efficiency by cycling, slowing down and narrowing resource and consumer flows while maintaining the initial level of the final product. The transformation of flows in a circular economy is achieved through the formation of production–consumer circular economic systems (CES), which shifts the minimum object unit toward the meso level (Kvasha et al. 2021). In this case, the circular mechanism includes such tools as the cluster approach (Kudryashov et al. 2023), the principles of industrial symbiosis (Mironova et al. 2022), and biorefining models (Akim 2017).

The nature of resource and consumer flows within the pulp and paper industry determines the direction of the field of special methods of bioeconomics, the core of which is biotechnology, which is one of the main scientific and practical directions in the formation of a new economic development model. At the same time, the implementation of innovative methods—not only in the field of biotechnology—is a catalyst for the process of transition to circular economic systems, which makes it possible to create new products from biomass. Thus, for pulp and paper it is advisable to form a circular mechanism using the biorefining model, which in a broad sense is the use of any recycling processes based on biotechnologies. In a more specific sense, biorefining means the production of science-intensive products with high added value, based on the complex deep processing of bioresources directly in the territory of origin. Biorefining involves the creation of related biotechnological complexes at the places of use and disposal of bioresources, focusing on the use of secondary raw materials that are obtained to produce a number of products intended for further industrial usage and, in some cases, final consumption (biofuels, preparations from lignin (in particular, biocomposites and lignosulfonates), platform chemicals (in particular furfural, ethanol, and lactic acid), feed additives, vitamin D, etc.) (Vakkilainen 2016; Yang et al. 2019; Singhvi et al. 2019; Moldazhanov 2018; Hakeem et al. 2023), which ensures the cycling of resources and product flows of timber processing in the pulp and paper industry, necessary for the formation of the CES.

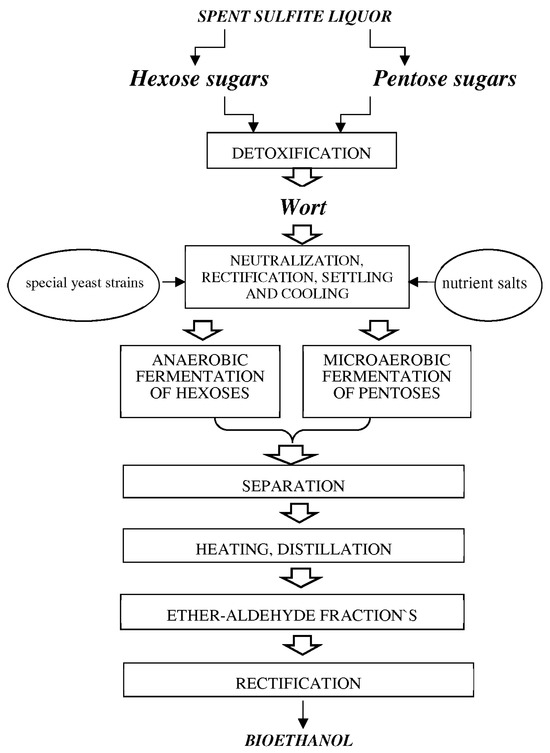

The biotechnologies involved include methods of destruction, detoxification, and conversion of useful resources into secondary raw materials and final products. To establish the fundamental possibility of obtaining bioethanol (the technology is shown in Figure 1), strains of xylose-assimilating yeast P. tannophilus Y-1532, Y-1533 and Y-1534 were used, based on the entire complex of sugars from cellulose production’s organic waste. Samples of sulfite liquor containing hexose and pentose sugars in various concentrations (depending on the feedstock) were obtained at the Svetogorsk pulp and paper mill. Sulfite liquors were subjected to selective extraction of toxic impurities to final concentrations: 0.002% (furfural), 0.01% (hydroxymethylfurfural), 0.10 g/L (volatile organic acids) and 0.8% (substances of the lignofuran complex), enriched with ammonium sulfate (0.05%) and superphosphate (0.03%). The resulting wort was subjected to alcoholic fermentation by the yeast P. tannophilus. Samples to analyze the depth of sugar utilization and bioethanol accumulation dynamics were taken, on average, during every 3 h of fermentation.

Figure 1.

Technological scheme of microbiological production of ethanol based on sulfite liquor.

3. Results

3.1. From the Standpoint of the Technogenic Approach, the Pulp and Paper Industry Demonstrates Profitability, although Lower than the Average for the Russian Economy (Kostenko 2019)

From the perspective of a sustainable approach, the pulp and paper industry can be characterized as unbalanced. Despite their significant positions and their strategic importance, in the total volume of industrial production in Russia (valuation of the volume of final products), pulp and paper occupy less than 1.5% (Kostenko 2019). At the same time, the pulp and paper industry has the following synergistic set of characteristics:

- -

- High resource intensity, including significant material consumption (according to estimates, 2–2.5 times more wood is required per ton of pulp); significant water intensity (according to estimates, about 350 m3 of water is required per ton of pulp); and energy intensity (estimated at about 2000 kWh per ton of pulp) (Faizullin 2018).

- -

- High capital intensity and a long investment cycle (measured in tens of years). The machines and equipment used in the pulp and paper industry are mostly complex and expensive. Production of technological equipment for the pulp and paper industry is highly consolidated and is mainly concentrated within three Austrian, German, and Finnish concerns (Akim 2017).

- -

- A high level of production waste. According to available data, pulp and paper waste accounts for about 17% of the total industrial waste (Kostenko 2019), most of which is in the form of potentially significant secondary raw materials.

- -

- A significant level of impact on the environment and public health. The pulp and paper industry distinguishes complex organic, inorganic, and gaseous pollutants from all components of the geosystem. In Russia, paper and cardboard make up about 30% of municipal solid waste (MSW). The index of total pulp and paper industry waste is approximately 1:5 (State Report on the State and Protection of the Russian Environment in 2021). In the absence of recycling or elimination, all components of the geosphere are exposed to pollution: the lithosphere, the atmosphere, the hydrosphere, and the biosphere. During the sulfate pulping process, sulfur compounds and nitrogen oxides enter the atmosphere, and dioxins are released during the bleaching process. Emissions have health effects that manifest themselves in the form of respiratory disorders and skin irritation, and they have neurotoxic effects. Epidemiological studies in the pulp and forestry areas of Karelia (in northwest Russia) have established a direct relationship between the level of environmental pollution and respiratory diseases (Bolotnikova et al. 2020). Some pollutants contain substances that disrupt the endocrine system (Haile et al. 2021). Waste from sulfite pulping at a pulp and paper mill is more detrimental to the lithospheric and hydrospheric regions. Soil pollution, in combination with pollution of water bodies, poses a threat to both the flora and fauna of the region, including aquatic ones. In soils, some undesirable elements, such as heavy metals, can disrupt nutrient dynamics. The high content of extraneous organic substances in wastewater can increase the level of biochemical oxygen demand in water, causing eutrophication of lakes, ponds, and other water systems (Simão et al. 2018).

Thus, when the efficiency analysis includes not only the internal results of individual economic units of the pulp and paper industry, but also the emerging significant externalities and the costs of conditionally free natural and ecosystem services, an imbalance of positive and negative effects is observed. This is, of course, a factor that determines the need for special theoretical and methodological approaches and practical balancing tools to ensure the overall efficiency of the economic systems of the pulp and paper industry. To some extent, the introduction of certain already-developed approaches of “clean”, resource-saving production can reduce the cost of production by optimizing resource consumption, as well as by increasing the capitalization of enterprises by increasing the overall ESG effects. At the same time, point methods are not able to ensure the overall efficiency of the economic system.

The solution to this problem is provided by the implementation of a circular mechanism oriented toward closed-cycle models. The closure of the CEC is achieved through the formation of production-consumer ecosystems, collaborations and intersectoral integration. A single mesoeconomic circular economic system involves the inclusion in its elemental composition of many initially weakly affiliated entities which, under the conditions of a linear model, are focused on ensuring private commercial efficiency. When interacting between subjects within the CES, multiple mutual effects arise when the costs of one element provide results on another (Kinnaman and Yamamoto 2023; Yamamoto and Kinnaman 2022). For example, the supply of raw materials and materials with maximum green characteristics demonstrates the main effect in production links. The principles of the circular economy significantly expand the range of effects included in the analysis. The cumulative efficiency is provided not only by the partial results of the subjects of the individual elements of the system. The functioning of the CES also determines the formation of social effects, defined as the net results of activities for a social group or society as a whole.

3.2. To Determine the Directions and Forms of Recycling of Secondary Resources Released in the Pulp and Paper Industry, It Is Necessary to Identify and Describe the Typology of Pulp and Paper Waste in Order to Systematize It by Place of Origin

The main factors determining the type and amount of waste (of various forms and aggregate states) are the following:

- -

- The pulping technology (in particular, sulfate or sulfite). The sulfate method, also called the kraft process, involves treatment of wood chips with a hot mixture of water, sodium hydroxide (NaOH), and -Na2S -(Grigorai 2012; Carrillo-Varela et al. 2022). The sulfite method includes the processing of wood with a cooking solution containing sulfur dioxide (SO2) and sulfurous acid salts (sulfites and hydrosulfites of sodium, potassium, ammonium, calcium, or magnesium) at elevated temperatures and pressures (Dubovy et al. 2022).

- -

- The type of raw material used (wood of different species and places of growth, forestry and wood processing industry waste, municipal waste, agricultural waste).

- -

- Purification technologies (mainly water).

- -

- Nomenclature of manufactured products.

Wastes generated at pulp and paper mills are classified, among other things, by the stages of the production process, which fix the places of their occurrence. Despite the variability of the possible composition at a particular pulp and paper mill, a generalized list of waste can be formed in accordance with the places of their occurrence in the production of pulp and paper products (Table 1).

Table 1.

Generalized composition of pulp and paper mill waste in correlation with the places of their occurrence.

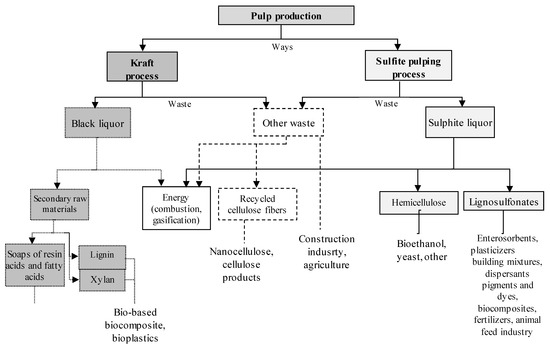

3.3. As Part of Determining the Directions and Forms of Biorefining, a Model of Secondary Resources and Secondary Raw Materials of the Pulp and Paper Industry Has Been Developed (Figure 2)

As shown, the main part of the waste generated at a pulp and paper mill is organic residues, since wood, in addition to cellulose (the share of which varies between 35 and 51% for different species and places of growth), contains other polymers, in particular hemicellulose and lignin. Depending on the method of pulping, organic waste is present as either black liquor from sulfate pulping (estimated, on average, to be 7 tons per ton of pulp, Grigorai 2012) or as sulfite liquors from sulfite pulping (estimated at 6–8 cubic meters per ton of pulp, Bolotnikova et al. 2019a, 2019b).

Figure 2.

Model of secondary resources and secondary raw materials of the pulp and paper industry.

The most common method of pulp production is the sulfate method. In the northwestern region of Russia, it is used, for example, by the Arkhangelsk and Segezha pulp and paper mills. The main way to dispose of black liquor is to burn it in waste heat boilers and use it as an additional source of energy, since it provides steam. A modern alternative reuse technology is black liquor gasification (Haile et al. 2021). At the same time, the use of biotechnologies makes it possible to process the organic components of black liquor into useful secondary bio-raw materials, since it has been repeatedly shown that waste-energy utilization is not the most effective recycling method (Kinnaman and Yamamoto 2023; Yamamoto and Kinnaman 2022; Jaswal et al. 2022).

One of the significant bioresources is lignin (450–500 kg of lignin is allocated for each ton of cellulose), which is characterized by a high strength-to-weight ratio, which makes it an ideal structural material for a carrier element in lightweight high-performance biocomposites. The specified direction of lignin utilization allows for solving the problem of the non-renewability of hydrocarbon composites, providing sustainable and environmentally friendly solutions (Vakkilainen 2016).

In addition to lignin, black liquors contain hemicellulose, which consists of various polysaccharides (xylose, arabinose, glucose, mannose, and galactose), which are conventionally divided into pentoses and hexoses. The biotechnological method allows one to isolate, for example, xylan, which serves as a source of various types of secondary bio-raw materials (Yang et al. 2019; Zarubina et al. 2019). Xylan can be biorefined into lactic acid, which is a source of important renewable ingredients for bioplastic synthesis. The lactic acid polymer (polylactide, or PLA) has a high melting point and impressive technical characteristics (Singhvi et al. 2019), which makes it possible to obtain biodegradable raw materials for packaging, disposable tableware, materials for additive technologies, and medical materials (surgical sutures and pins). The main problems associated with the production and use of secondary raw materials from xylan are associated, first, with the difficulties of biorefining to the extent necessary for the production of polymers and, second, the lower melting point of PLA produced based on existing technologies for the polycondensation of lactic acid and polymerization lactide. Further research is being conducted to improve existing biotechnologies (Haile et al. 2021).

When the black liquor is cooled, sodium salts float to the surface, the mixture of which is called crude sulfate soap (soaps of resin acids and fatty acids). This secondary resource is used to produce tall oil. The maximum yield of sulfate soap is from pinewood, which is an order of magnitude greater than that from spruce wood. Tall oil is a raw material in the production of varnishes, drying oils, lubricating oils, laundry soap, etc.

The sulfite method for producing pulp is less common in the world, although in Russia, the northwest region is characterized by the presence of large sulfite production. These areas are, in particular, Kondopoga PPM (the Republic of Karelia) and Svetogorsk PPM (the Leningrad Region). This is explained by the availability of the necessary raw materials in the region, since for the acid method it is preferable to use raw materials from spruce wood species. For sulfite processing, the high content of resins in pinewood and the unacceptably short length of hardwood fibers for this technology create difficulties. Sulfite pulping has lost ground to the sulfate method, mainly due to the high physical and chemical characteristics of cellulose and the lower toxicity of the latter’s waste (which, however, cannot be said about the toxicity of atmospheric emissions). At the same time, the sulfite method has the advantages of higher yield and initial pulp whiteness. Accordingly, solving the problem of toxic waste significantly increases the overall efficiency of the acid method in the pulp and paper mill process.

The specific volume of formation of sulfite liquors depends on the enterprise’s productivity and averages 6–8 m3 per ton of cellulose (Dubovy et al. 2022). The composition of sulfite liquors includes biotechnologically utilizable hemicellulose and lignosulfonates and their derivatives that are difficult to decompose, the share of which in liquors is 30–37% when using hardwood and 55–60% when using coniferous wood (Zhulanova 2022). When using the sulfite method of cellulose production, objects of the hydrosphere and lithosphere, as well as the representatives of flora and fauna associated with them, are primarily polluted (the sulfite method is mainly characterized by atmospheric pollution).

The use of lignosulfonates as secondary resources is accompanied by complex processing technologies, which are not effective in a linear model that takes into account only the internal commercial effects of the economic system. The main method of disposal of spent liquors is their evaporation and drying to obtain industrial lignosulfonates (LSTs). LSTs are used as foundry binders in clay solutions when drilling oil wells, as plasticizers for building mixtures, as dispersants of pigments and dyes, etc., as well as in the production of feed and fertilizers and carbon sorbents. In addition, there are examples of the use of LSTs as binders in the production of composite materials (chipboard and fiberboard), instead of phenol-formaldehyde and urea-formaldehyde resins characterized by toxic emissions of phenol and formaldehyde into the environment. The development of methods for producing composite materials based on lignosulfonates (in particular, epoxy resins) ensures an increase in the volume of waste disposal as a result of secondary bio-raw materials, as well as the creation of environmentally neutral building materials. Currently, research in the field of developing technologies for obtaining composite bioresistant building materials based on lignosulfonates is being carried out quite actively (Zhulanova 2022; Ryłko-Polak et al. 2022). In particular, the study of additive manufacturing of fully recyclable walls in wood construction, made of a composite of renewable secondary resources, aroused interest (Kromoser et al. 2022), as did work devoted to production issues of eco-friendly, zero-formaldehyde fiberboard panels, bonded with calcium lignosulfonate (CLS) as a lignin-based (Antov et al. 2021).

The utilization of monosaccharides, which are part of sulfite liquor hemicellulose, is mainly aimed at obtaining such secondary raw materials as feed additives for livestock and poultry farming, as well as an important secondary energy resource—bioethanol. Bioethanol is the dominant type of both primary and secondary bioenergy resources in the world. The global biofuel market is growing by 20–25% annually. Brazil is a leader in the use of bioethanol as a green fuel, not only for cars but also for aviation. It is used as an additive to gasoline in Europe and the USA. The use of bioethanol as a fuel leads to such positive effects as the reduction of carbon monoxide emissions, the reduction of the “greenhouse effect”, the reduction of urban smog, etc. (Moldazhanov 2018). The expansion of the use of recycled bioethanol adds to the listed environmental benefits of the circular effects of closed economies. The complexity of the technology for processing hemicellulose into bioethanol lies, first, in the requirement for the resistance of yeast Candida shehatae and Pichia stipities producers to the influence of toxicants contained in the initial solution and, second, in the inability of most Saccharomyces strains to alcohol conversion of pentoses of hemicellulose, along with hexoses (Bolotnikova et al. 2019a, 2019b). The composition of sugars also mainly depends on the wood species.

3.4. The Fundamental Possibility of Obtaining Bioethanol from Sulfite Liquor Sugars Based on the Xylose-Assimilating Yeast P. tannophilus Was Evaluated

The existing developments of complex methods for preliminary detoxification of sulfite liquor substrates provide a depth of selective extraction sufficient to maintain the alcohol-forming activity of xylose-assimilating yeast P. tannophilus on sulfite–alkali wort (Bolotnikova et al. 2019a, 2019b). A strain of P. tannophilus Y-1533 has been identified, which has biotechnological prospects for the alcohol conversion of hexoses and pentoses of sulfite liquor, and the results obtained can serve as initial parameters for its laboratory regulations. According to calculations, the productivity of obtaining bioethanol during this process increases by 2.4–2.9 times, due to the utilization of D-xylose. The inclusion of a new biocatalyst in the standard technological scheme for the disposal of pulp production waste does not require fundamental changes. However, the microaerobic conditions are necessary for pentose fermentation by xylose-assimilating yeasts Pachysolen tannophilus. So, the rate control should be especially needed in the case of the oxygen supply to the fermentation medium (Bolotnikova et al. 2019a, 2019b).

4. Discussion

Thus, as a result of the study, a complex biotechnological basis was formed that ensures the construction of circular economic systems with anchor pulp and paper production.

4.1. In the Technogenic Coordinate System That Dominated in the Era of Industrialization and Is Inertial Used Now in the Process of Analyzing the Effectiveness of Economic Activity, the Pulp and Paper Industry Demonstrates Profitability

At the same time, from the standpoint of an environmental approach, when external effects are included in the analysis, as well as the costs of conditionally free natural resources and ecosystem services, serious imbalances are observed in sectoral efficiency. The introduction of individual approaches to resource-saving production can ensure the overall efficiency of the economic system. The need for circular mechanisms for the organization of economic systems within the framework of the pulp and paper industry, focused on the closed-cycle model, is substantiated. The introduction of the CES model based on biotechnology in the practice of the pulp and paper industry covers the need to transform the existing economic system into a structure that meets the principles of efficiency and sustainable development. Further research is required regarding the elaboration of specific mechanisms (market, network, and organizational) that ensure the economic integration of individual elements into a single circular economic system.

4.2. The Tools of the Circular Mechanism Include Such Well-Developed Tools as the Cluster Approach, the Principles of Industrial Symbiosis, and Biorefining Models

Based on the analysis of the nature of resource and consumer flows of pulp industries, it was concluded that it is advisable to form a circular mechanism for pulp and paper using the biorefining model, which, in a broad sense, is the involvement of any recycling processes based on biotechnologies. Biorefining involves the creation of adjacent biotechnological complexes in place of the use and disposal of PPM bioresources. These complexes are focused on the use of previously unclaimed renewable sources of secondary raw materials to obtain a number of products, which ensures the cycle of resource and product flows of timber processing and the pulp and paper industry necessary for the formation of the CES. Taking into account the additional effects of using secondary resources, as well as the environmental effects of neutralizing hazardous impacts on the environment and human health, biorefining can ensure the overall efficiency of the circular economic system, even from the standpoint of a sustainable approach.

4.3. The Generalized Composition of Pulp and Paper Mill Waste in Correlation with Their Places of Origin Made It Possible to Establish Common Ways and Forms of Biorefining within the Pulp and Paper Industry

Generalized methods, algorithms, and parameters of green biotechnological regulations for the recycling of waste from the pulp and paper industry provide the possibility of microbiological production of a complex of products: biocomposites, bioplastics, medical products, fertilizers, feed additives, vitamin supplements, and bioenergy resources. Deepening research should take place in the direction of specifying circular tools, depending on the type of technologies used, the types of raw materials, the cleaning technologies used, and the composition of the products produced.

4.4. The Expansion of the Recycled Bioethanol Usage from the Pulp and Paper Industry, in Addition to the Benefits of Sustainability, Provides Circular Effects of Circular Economies

However, the strategy for efficient biochemical processing of pulp and paper waste into green ethanol has not yet been determined. Experimental data have shown the fundamental possibility of increasing the efficiency of alcohol fermentation using various biocatalysts, which ensures the alcohol conversion of both hexose and pentose fractions that are not assimilated by traditional strains. The technological feature of this method is the need for alcoholic fermentation of pentose sugars in a microaerobic conditions, that is, the “respiratory type” of pentose catabolism, which requires further research in the development of industrial conditions for controlling low rates of oxygen supply to the fermentation medium.

5. Conclusions

Based on the results of this study, the authors substantiated the need to increase the sustainability of the pulp and paper industry. As a method for solving this problem, the authors propose the integration of individual enterprises in the pulp and paper industry into a circular economic system of the region. Such integration will improve the sustainability of the industry as a whole, as it will ensure the circularity of many production processes. The implementation of the proposed concept determines the need for special theoretical and methodological approaches and practical balancing tools to ensure the overall efficiency of economic systems of the pulp and paper industry. To some extent, the introduction of individual already developed approaches to “clean”, resource-saving production can ensure a reduction in production costs by reducing costs by optimizing resource consumption, as well as increasing the capitalization of enterprises by increasing the overall ESG effects. The solution to this problem is provided by the implementation of a circular mechanism focused on closed-loop models. Closing the central economic system is achieved through the formation of production and consumption ecosystems, collaborations, and cross-sectoral integration.

Author Contributions

Conceptualization, N.K.; methodology, O.B.; software, O.B.; validation, N.K., E.M.-M.; formal analysis, N.K.; investigation, O.B.; resources, O.B.; data curation, N.K.; writing—original draft preparation, E.M.-M.; writing—review and editing, O.B.; visualization, N.K.; supervision, E.M.-M.; project administration, E.M.-M.; funding acquisition, E.M.-M. All authors have read and agreed to the published version of the manuscript.

Funding

The study was funded by the Russian Science Foundation grant No. 23-28-00619: «Methodology for ensuring the efficiency of circular economic systems in the region (on the example of the North-West of Russia), https://rscf.ru/project/23-28-00619/ 1 August 2023.

Data Availability Statement

Publicly available datasets were analyzed in this study.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Akim, E. L. 2017. Pulp and paper industry (PP) in the world and in Russia. Paper presented at the Forests of Russia: Politics, Industry, Science, Education: Materials of the Second International Scientific and Technical Conference, St. Petersburg, Russia, May 24–26; St. Petersburg: St. Petersburg State Forestry University named after C.M. Kirova, vol. 3, pp. 198–202. [Google Scholar]

- Antov, Petar, Roman Réh, Viktor Savov, and Antonios N. Papadopoulos. 2021. Eco-friendly fiberboard panels from recycled fibers bonded with calcium lignosulfonate. Polymers 13: 639. [Google Scholar] [CrossRef] [PubMed]

- Awasthi, Mukesh Kumar, Raveendran Sindhu, Ranjna Sirohi, Vinod Kumar, Vivek Ahluwalia, Parameswaran Binod, Ankita Juneja, Deepak Kumar, Binghua Yan, Surendra Sarsaiya, and et al. 2022. Agricultural waste biorefinery development towards circular bioeconomy. Renewable and Sustainable Energy Reviews 158: 112122. [Google Scholar] [CrossRef]

- Babkin, A., E. Malevskaia-Malevich, N. Kvasha, and E. Eliseev. 2021. The relationship between socially responsible investment and the market value of an enterprise. Paper presented at the E3S Web of Conferences: IV International Scientific and Practical Conference “Sustainable Development and Green Growth on the Innovation Management Platform” (SDGG 2021), Kaliningrad, Russia, May 27–28; Kaliningrad: EDP Sciences, vol. 291, p. 01002. [Google Scholar]

- Bobylev, S. N. 2021. Economics of Sustainable Development: Textbook. Moscow: KNORUS. 672p, ISBN 978-5-406-01850-7. [Google Scholar]

- Bolotnikova, O. I., N. P. Mikhailova, and Yu. G. Bazarnova. 2019a. Problems and prospects for the use of microorganisms for the disposal of lignocellulose waste. News of universities. Applied Chemistry and Biotechnology 9: 679–93. [Google Scholar] [CrossRef]

- Bolotnikova, O. I., J. Bazarnova, and E. Aronova. 2019b. Spent sulphite liquor utilization by xylose-assimilating yeast pachysolen tannophilus, capable of bioethanol producing. Paper presented at the E3S Web of Conferences: International Scientific Conference on Energy, Environmental and Construction Engineering, EECE 2019, Saint-Petersburg, Russia, November 19–20; Saint-Petersburg: EDP Sciences, vol. 140, p. 02008. [Google Scholar]

- Bolotnikova, O. I., T. N. Khilkov, and T. B. Marataeva. 2020. Use of the catalytic potential of xylose-assimilating yeast Pachysolen tannophilus for the utilization of industrial wastewater as a means of preventing morbidity among the population of the Republic of Karelia. In Medical Institute of PETRSU—Flagship University of Russia: An Institute Looking to the Future: Collection of Articles of the North-Western Scientific and Practical Conference with International Participation, Petrozavodsk, Russia, September 9–10. Petrozavodsk: Petrozavodsk State University, pp. 17–20. [Google Scholar]

- Carrillo-Varela, Isabel, Claudia Vidal, Sebastián Vidaurre, Carolina Parra, Ángela Machuca, Rodrigo Briones, and Regis Teixeira Mendonça. 2022. Alkalization of kraft pulps from pine and eucalyptus and its effect on enzymatic saccharification and viscosity control of cellulose. Polymers 14: 3127. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Hongbin, and Lei Wang. 2013. Lignocelluloses feedstock biorefinery as petrorefinery substitutes. In Biomass Now—Sustainable Growth and Use. Edited by M. D. Matovic. Rijeka: InTech, pp. 347–88. [Google Scholar]

- Dubovy, V. K., A. S. Smolin, E. G. Smirnova, and P. M. Keizer. 2022. Technological Processes and Equipment of Pulp and Paper Industry: Textbook. St. Petersburg: HSE SPbGUPTD. 91p, ISBN 978-5-91646-311-8. [Google Scholar]

- Faizullin, I. 2018. Pulp and Paper Mills of Russia: List, Features of the Production Process, Review of Products. Electronic Resource. Available online: https://pc-des.ru/proizvodstvo-bumagi-a4.html (accessed on 1 August 2023).

- Geng, Yong, Joseph Sarkis, and Raimund Bleischwitz. 2019. How to globalize the circular economy. Nature 565: 153–55. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, Sadhan Kumar, ed. 2020. Circular Economy: Global Perspective. Singapore: Springer. [Google Scholar]

- Grigorai, O. B. 2012. Processing of Black Liquors from Sulfate Production. Edited by O. B. Grigorai, Yu. S. Ivanov, A. A. Komissarenkov and A. S. Smolin. St. Petersburg: SPbGTURP. 106p. [Google Scholar]

- Haile, Adane, Gemeda Gebino Gelebo, Tamrat Tesfaye, Wassie Mengie, Million Ayele Mebrate, Amare Abuhay, and Derseh Yilie Limeneh. 2021. Pulp and paper mill wastes: Utilizations and prospects for high value-added biomaterials. Bioresources and Bioprocessing 8: 35. [Google Scholar] [CrossRef]

- Hakeem, Ibrahim Gbolahan, Anita Sharma, Tanima Sharma, Abhishek Sharma, Jyeshtharaj B. Joshi, Kalpit Shah, Andrew S. Ball, and Aravind Surapaneni. 2023. Techno-economic analysis of biochemical conversion of biomass to biofuels and platform chemicals. Biofuels, Bioproducts and Biorefining 17: 718–50. [Google Scholar] [CrossRef]

- Hickel, J., and G. Kallis. 2020. Is green growth possible? New Political Economy 25: 469–86. [Google Scholar] [CrossRef]

- Ivanova, T. O., and E. E. Moiseeva. 2021. Biorefining as a strategic direction for the development of the timber industry complex of the Krasnoyarsk Territory. Paper Presented at the Innovations in the Chemical Forestry Complex: Trends and Development Prospects: Collection of Materials of the All-Russian Scientific and Practical Conference, Krasnoyarsk, Russia, June 2–4; Krasnoyarsk: Federal State Budgetary Educational Institution of Higher Education “Siberian State University of Science and Technology named after Academician M.F. Reshetnev”, pp. 194–97. [Google Scholar]

- Jaswal, Anurag, Piyush Pratap Singh, and Tarak Mondal. 2022. Furfural—A versatile, biomass-derived platform chemical for the production of renewable chemicals. Green Chemistry 24: 510–51. [Google Scholar] [CrossRef]

- Joshi, Abhishek, Bhanupriya Kanthaliya, Supriya Meena, Farhana Khan, and Jaya Arora. 2021. Process consolidation approaches for cellulosic ethanol production. In Sustainable Biofuels. Cambridge: Academic Press, pp. 43–72. [Google Scholar]

- Kamenik, L. L. 2020. Ecological-resource balance—A new approach in the study of the bio-environment. Paper Presented at the XXV International Bios Forum and Youth Bios Olympiad 2020: Collection of Materials, St. Petersburg, Russia, October 1–5; St. Petersburg: St. Petersburg Scientific Center of the Russian Academy of Sciences, Volume Book 2, pp. 42–50. [Google Scholar]

- Kinnaman, Thomas C., and Masashi Yamamoto. 2023. Has Incineration Replaced Recycling? Evidence from OECD Countries. Sustainability 15: 3234. [Google Scholar] [CrossRef]

- Kostenko, O. V. 2019. Pulp and paper industry in Russia: Main trends and directions of innovative development. Fundamental Research 9: 38–43. [Google Scholar] [CrossRef]

- Kromoser, B., S. Reichenbach, R. Hellmayr, R. Myna, and R. Wimmer. 2022. Circular economy in wood construction–Additive manufacturing of fully recyclable walls made from renewables: Proof of concept and preliminary data. Construction and Building Materials 344: 128219. [Google Scholar] [CrossRef]

- Kudryashov, V. S., N. V. Kvasha, and E. D. Malevskaya-Malevich. 2023. Efficiency of development of circular economic systems of the region based on the cluster approach. In Paper Presented at the Intelligent Engineering Economics and Industry 5.0 (INPROM): Collection of Proceedings of the VIII International Scientific and Practical Conference, St. Petersburg, Russia, April 27–30; St. Petersburg: Polytech-Press, pp. 251–53. [Google Scholar]

- Kudryavtseva, O. V., E. Yu Yakovleva, and M. V. Vilt. 2014. Typology of biotechnologies and the place of the Russian bioenergy industry in it. Bulletin of the University 13: 123–132. [Google Scholar]

- Kvasha, Nadezhda, Ekaterina Malevskaya-Malevich, and Svetlana Kornilova. 2021. Information Modeling Technology as the Integrating Basis of the Development Investment Process. Communications in Computer and Information Science 1445: 59–72. [Google Scholar] [CrossRef]

- Kvasha, N. V., and E. D. Malevskaya-Malevich. 2022. The problem of ensuring the efficiency of circular economic systems of the North-West region. Economy of the North-West: Problems and Development Prospects 3: 54–60. [Google Scholar] [CrossRef]

- Lacy, Peter, and Jakob Rutqvist. 2016. Waste to Wealth: The Circular Economy Advantage. Berlin: Springer. [Google Scholar]

- Maity, Sunil K. 2015. Opportunities, recent trends and challenges of integrated biorefinery: Part I. Renewable and Sustainable Energy Reviews 43: 1427–45. [Google Scholar] [CrossRef]

- Mironova, D. Yu, I. V. Timakhovich, E. E. Pomazkova, and Yu. V. Zharkova. 2022. The concept of industrial symbiosis: Experience of application in various countries and prospects for implementation in Russia using the example of the Pskov region. Scientific Journal of NRU ITMO. Series: Economics and Environmental Management 2: 49. [Google Scholar] [CrossRef]

- Moldazhanov, B. K. 2018. Bioethanol: Reality and forecasts. World Science 11: 20. [Google Scholar]

- Order of the Government of the Russian Federation Dated 2 November 2021 N 312-r “On approval of the Strategy for the Development of the Forestry Complex of the Russian Federation until 2030”. Available online: https://www.consultant.ru/document/cons_doc_LAW_377162/ (accessed on 12 November 2022). (In Russian).

- Raj, Tirath, K. Chandrasekhar, A. Naresh Kumar, J. Rajesh Banu, Jeong-Jun Yoon, Shashi Kant Bhatia, Yung-Hun Yang, Sunita Varjani, and Sang-Hyoun Kim. 2022. Recent advances in commercial biorefineries for lignocellulosic ethanol production: Current status, challenges and future perspectives. Bioresource Technology 344: 126292. [Google Scholar] [CrossRef]

- Ryłko-Polak, I., W. Komala, and A. Białowiec. 2022. The Reuse of Biomass and Industrial Waste in Biocomposite Construction Materials for Decreasing Natural Resource Use and Mitigating the Environmental Impact of the Construction Industry: A Review. Materials 15: 4078. [Google Scholar] [CrossRef]

- Simão, L., D. Hotza, F. Raupp-Pereira, J. A. Labrincha, and O. R. K. Montedo. 2018. Wastes from pulp and paper mills—A review of generation and recycling alternatives. Cerâmica 64: 443–53. [Google Scholar] [CrossRef]

- Singhvi, M. S., S. S. Zinjarde, and D. V. Gokhale. 2019. Polylactic acid: Synthesis and biomedical applications. Journal of Applied Microbiology 127: 1612–26. [Google Scholar] [CrossRef] [PubMed]

- State Report on the State and Protection of the Russian Environment in 2021. Available online: https://2021.ecology-gosdoklad.ru/doklad/o-doklade/ (accessed on 21 July 2022).

- Suchek, Nathalia, Cristina I. Fernandes, Sascha Kraus, Matthias Filser, and Helena Sjögrén. 2021. Innovation and the circular economy: A systematic literature review. Business Strategy and the Environment 30: 3686–702. [Google Scholar] [CrossRef]

- Vakkilainen, E. K. 2016. Steam Generation from Biomass: Construction and Design of Large Boilers. Oxford: Butterworth-Heinemann. [Google Scholar]

- Vitunskienė, V., V. Aleknevičienė, N. Ramanauskė, A. Miceikienė, J. Čaplikas, V. Kargytė, D. MAKUTĖNIENĖ, and D. Jazepčikas. 2017. Global, European and national drivers of Lithuanian bioeconomy strategy. Paper Presented at the International Scientific Conference Rural Development 2017, Kaunas, Lithuania, November 23–24; pp. 1391–99. [Google Scholar]

- Webster, K. 2017. The Circular Economy: A Wealth of Flows. The Isle of Wight: Ellen MacArthur Foundation Publishing. Available online: https://www.greenbiz.com/article/origins-circular-economy (accessed on 15 August 2021).

- Yamamoto, Masashi, and Thomas C. Kinnaman. 2022. Is incineration repressing recycling? Journal of Environmental Economics and Management 111: 102593. [Google Scholar] [CrossRef]

- Yang, Jianlei, Yern Chee Ching, and Cheng Hock Chuah. 2019. Applications of lignocellulosic fibers and lignin in bioplastics: A review. Polymers 11: 751. [Google Scholar] [CrossRef]

- Zarubina, A. N., A. N. Ivankin, A. S. Kuleznev, and V. A. Kochetkov. 2019. Cellulose and nano-cellulose. Review. Forestry Bulletin 23: 116–25. [Google Scholar] [CrossRef]

- Zhulanova, A. E. 2022. Utilization of lignosulfonates to produce composite building materials. Theoretical and Applied Ecology, 134–39. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).