Shape-Memory Properties of 3D Printed Cubes from Diverse PLA Materials with Different Post-Treatments

Abstract

:1. Introduction

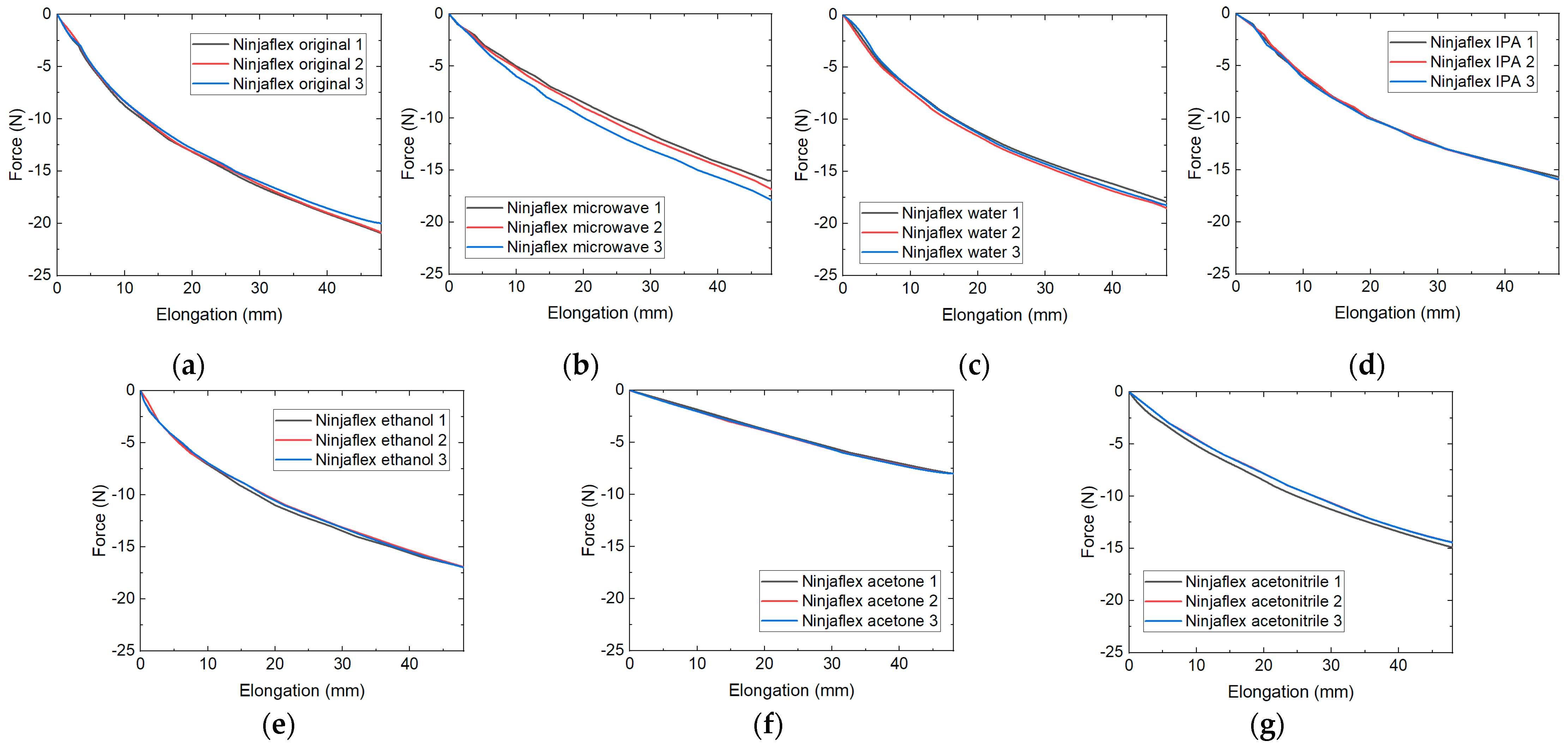

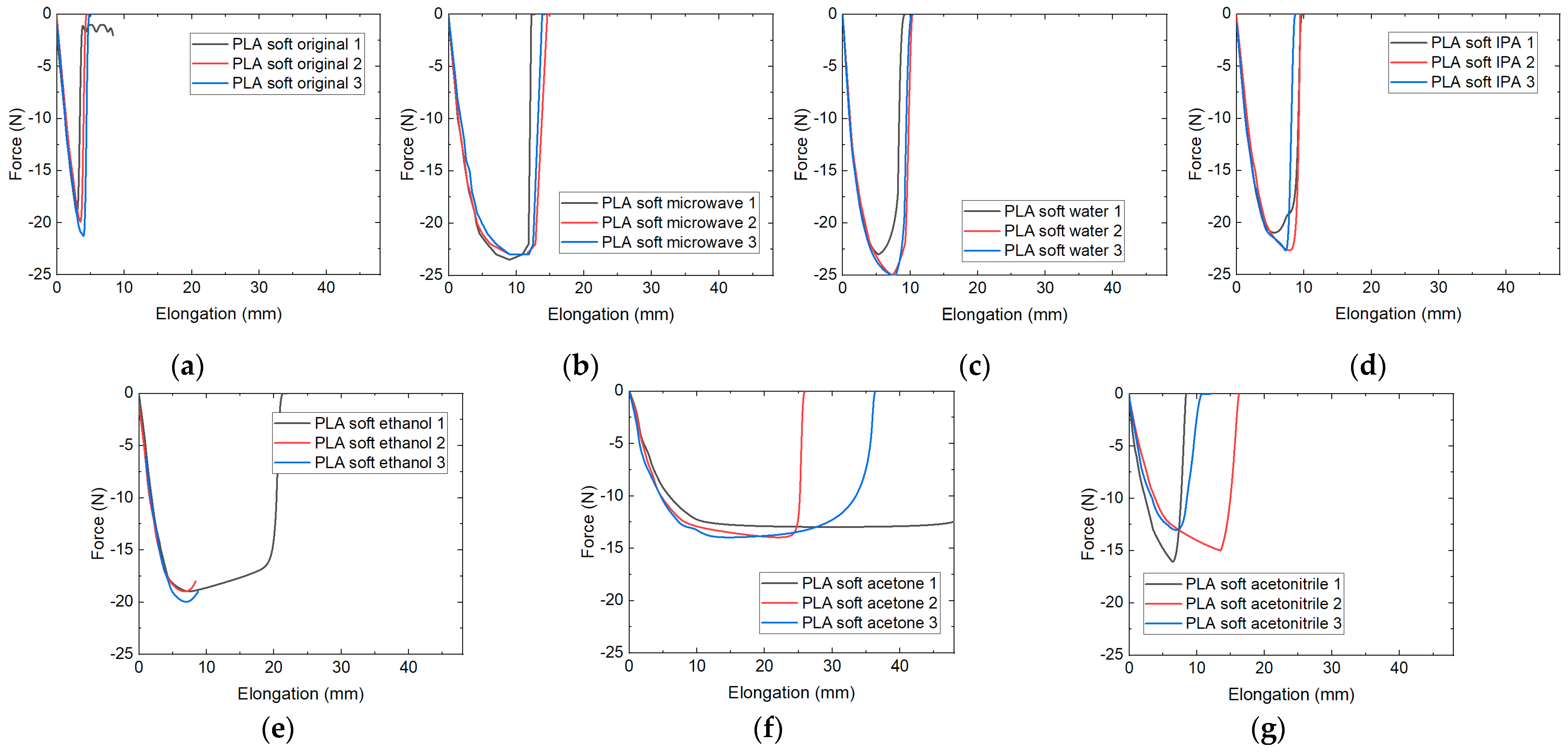

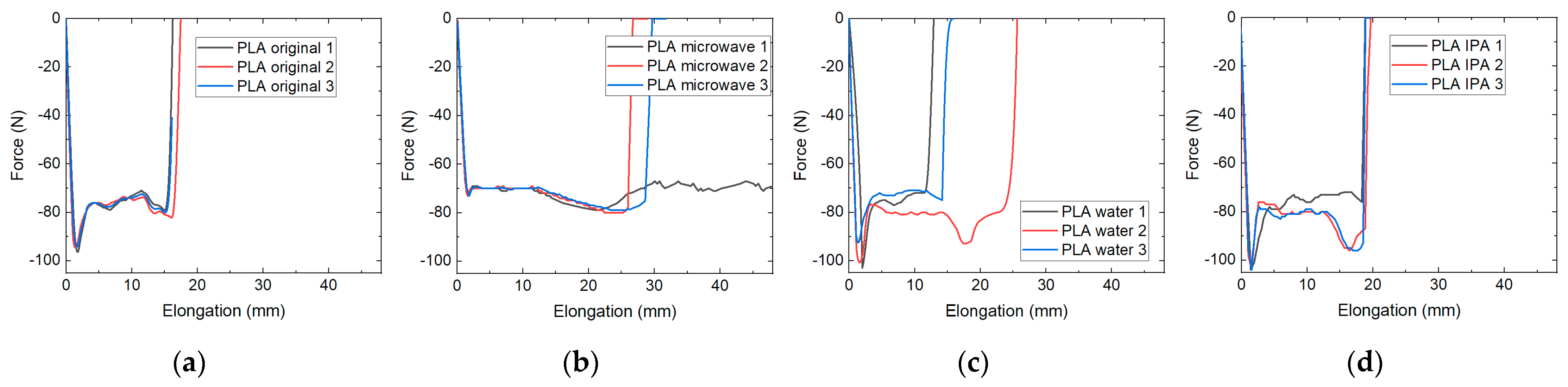

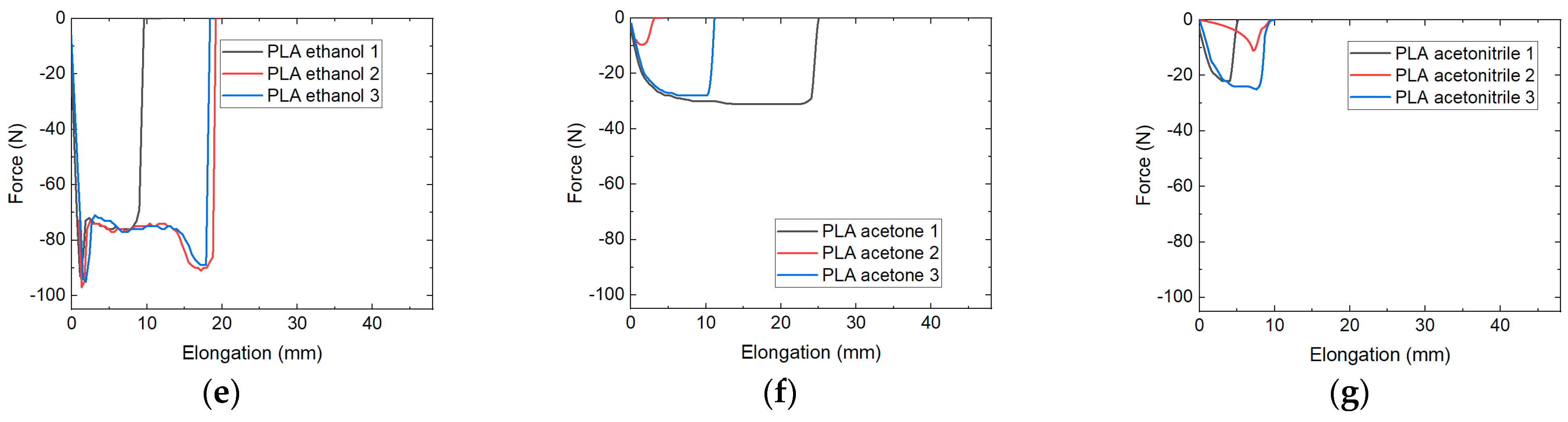

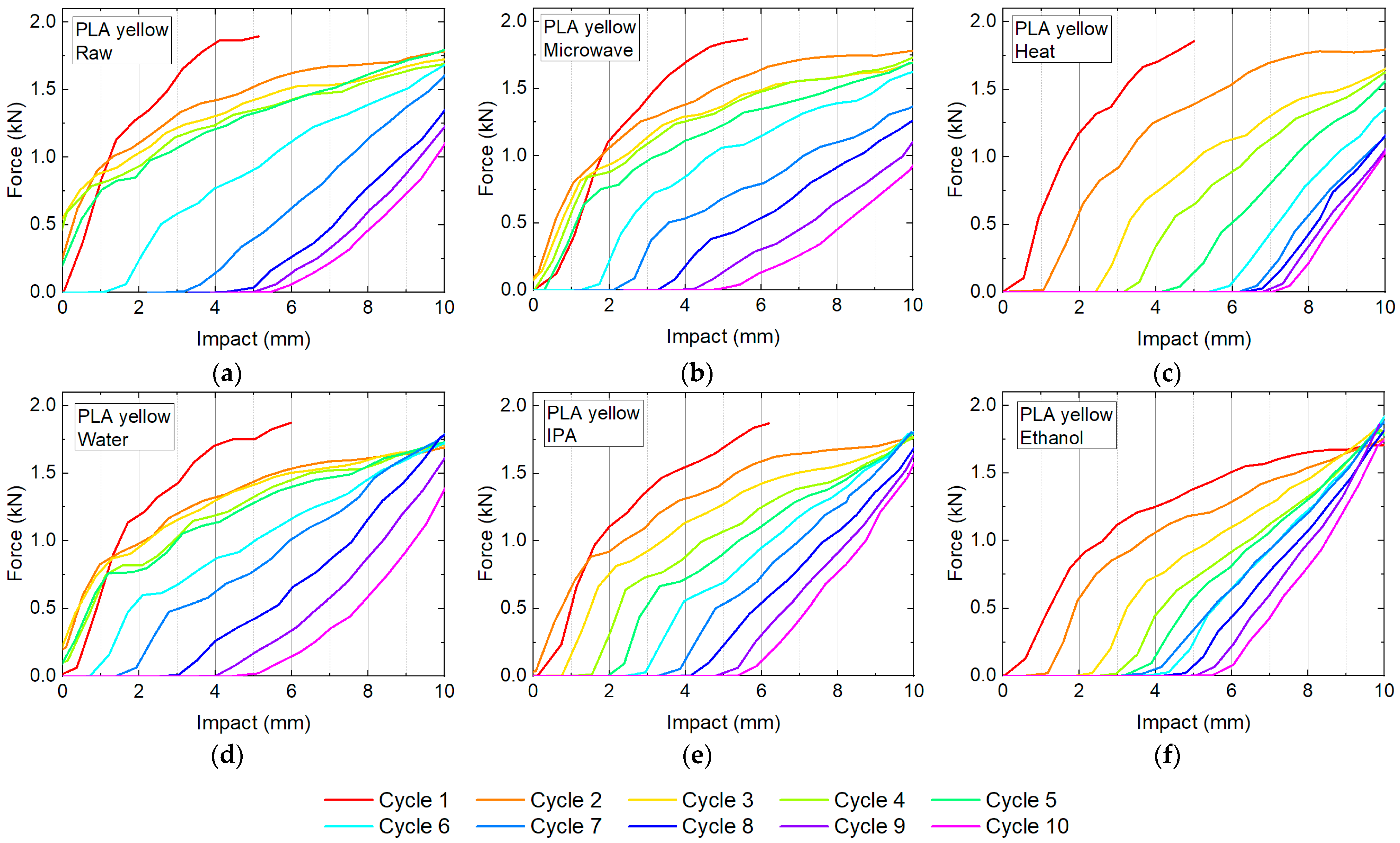

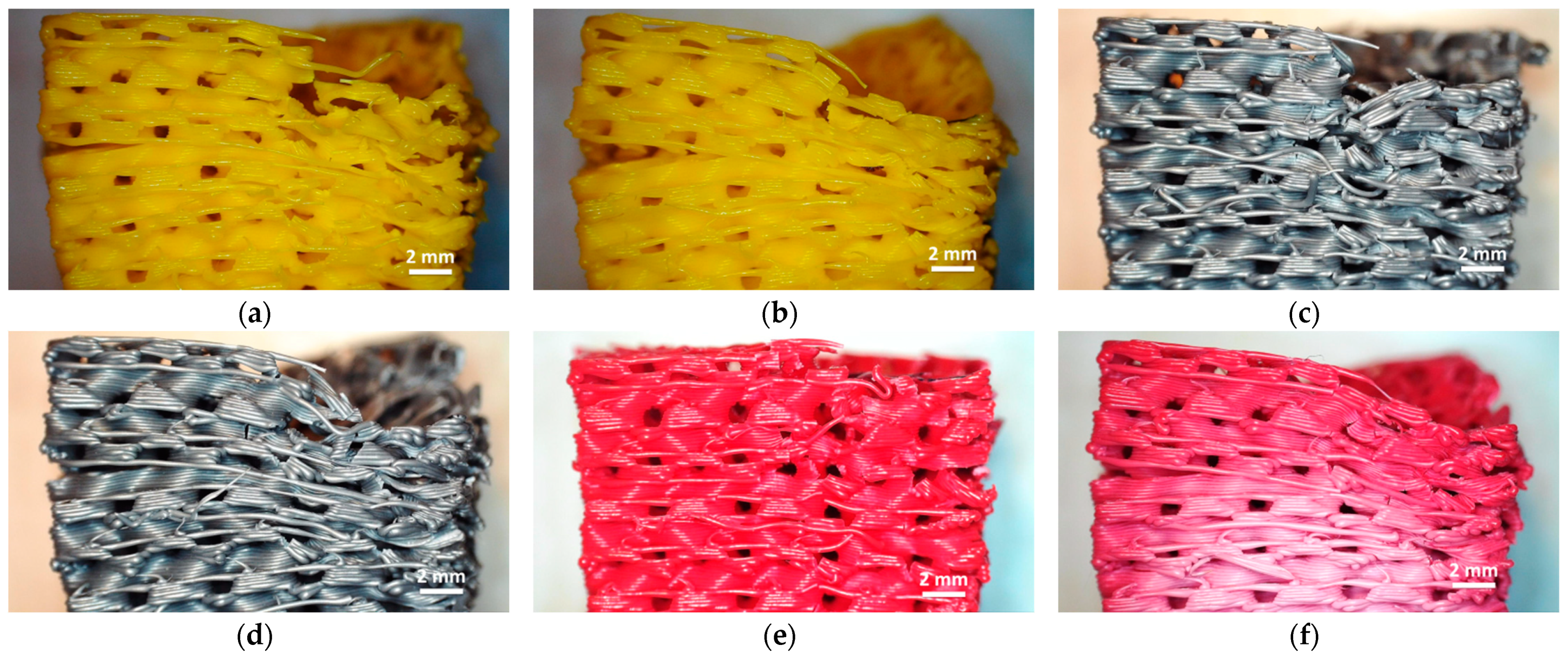

2. Materials and Methods

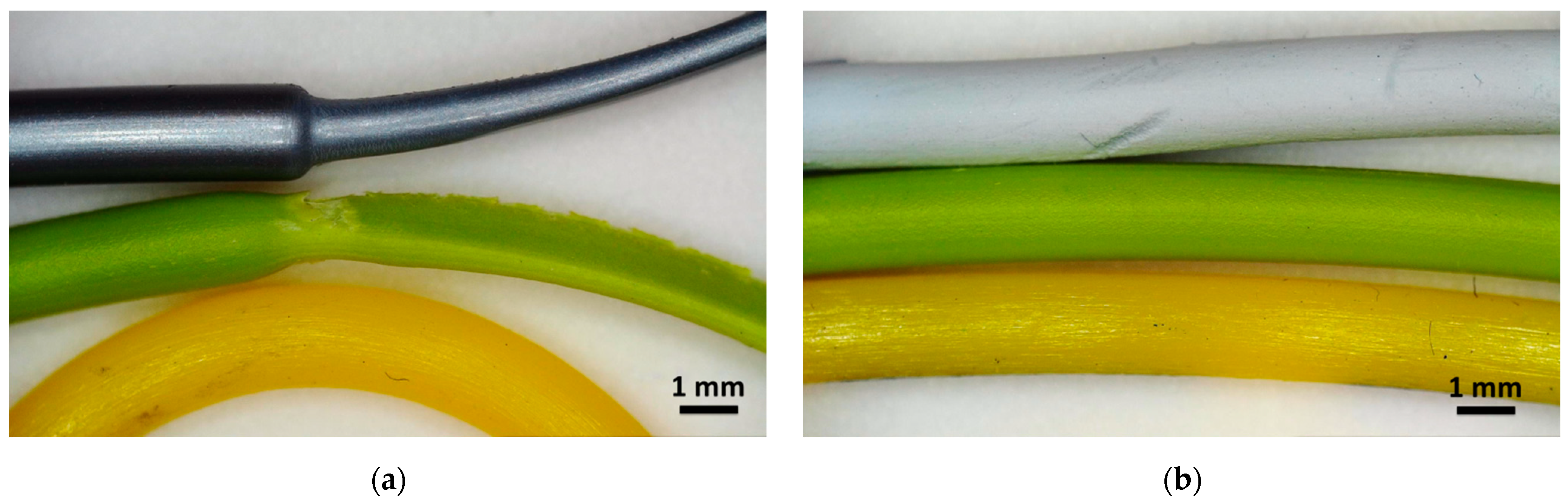

- Silver–grey filament produced by Prusa Research A.S. (shore (78 ± 2)D)

- Yellow filament produced by Filamentworld (Neu-Ulm, Germany) (shore (80 ± 2)D)

- Red filament Fil-A-Gehr produced by Gehr (Mannheim, Germany) (shore (75 ± 2)D)

- No treatment (original filament/raw specimen)

- Placing in water at room temperature for 4 h

- Placing in ethanol at room temperature for 4 h

- Placing in isopropyl alcohol (IPA) at room temperature for 4 h

- Placing in acetone at room temperature for 4 h (Ninjaflex and PLA soft) or 1 h (PLA), respectively

- Placing in acetonitrile at room temperature for 4 h (Ninjaflex and PLA soft) or 1 h (PLA), respectively

- Placing in a microwave oven at 600 W for 3 min

- Placing in an oven at 70 °C for 4 h

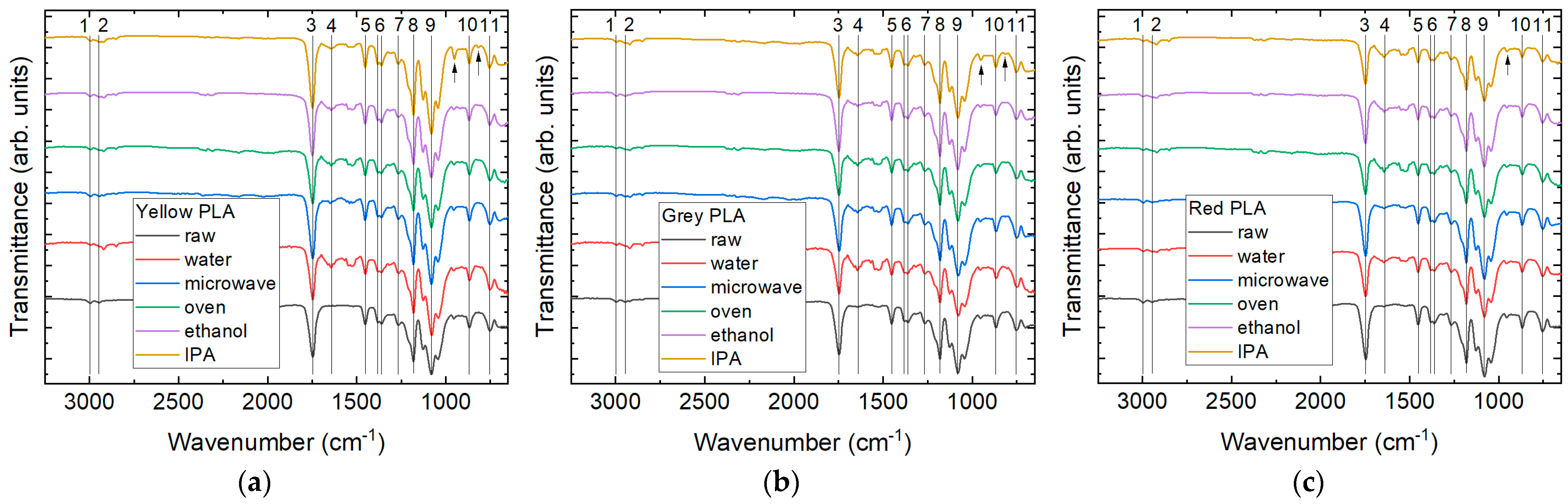

3. Results

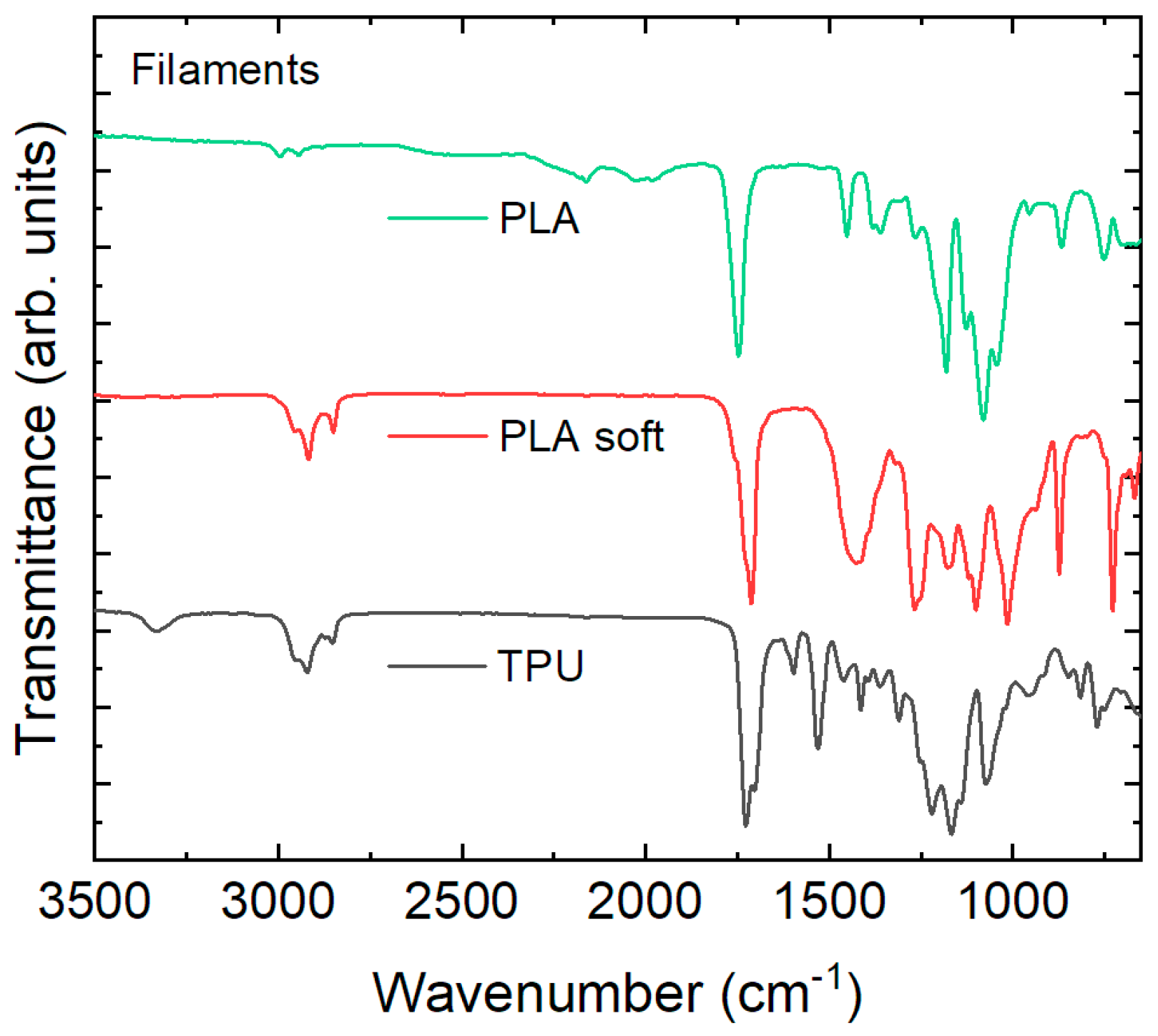

- 815 cm−1—deforming vibrations of the CH and CH2 in ketones (RCOCH=CH2) and/or vinyl ethers (ROCH=CH2) [33]

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Blachowicz, T.; Ehrmann, G.; Ehrmann, A. Optical elements from 3D printed polymers. e-Polymers 2021, 21, 549–565. [Google Scholar] [CrossRef]

- Duarte, L.C.; Chagas, C.; Ribeiro, L.E.B.; Coltro Tomazelli, W.K. 3D printing of microfluidic devices with embedded sensing electrodes for generating and measuring the size of microdroplets based on contactless conductivity detection. Sens. Actuators B Chem. 2017, 251, 427–432. [Google Scholar] [CrossRef]

- Noorani, R. Rapid Prototyping: Principles and Applications; John Wiley & Sons: New York, NY, USA, 2005. [Google Scholar]

- Wan, M.L.; Liu, S.F.; Huang, D.; Qu, Y.; Hu, Y.; Su, Q.S.; Zheng, W.X.; Dong, X.M.; Zhang, H.W.; Wei, Y.; et al. Biocompatible heterogeneous bone incorporated with polymeric biocomposites for human bone repair by 3D printing technology. J. Appl. Polym. Sci. 2020, 138, e50114. [Google Scholar] [CrossRef]

- Sölmann, S.; Rattenholl, A.; Blattner, H.; Ehrmann, G.; Gudermann, F.; Lütkemeyer, D.; Ehrmann, A. Mammalian cell adhesion on different 3D printed polymers with varying sterilization methods and acidic treatment. AIMS Bioeng. 2021, 8, 25–35. [Google Scholar]

- Han, S.H.; Cha, M.; Jin, Y.Z.; Lee, K.M.; Lee, J.H. BMP-2 and hMSC dual delivery onto 3D printed PLA-Biogel scaffold for critical-size bone defect regeneration in rabbit tibia. Biomed. Mater. 2021, 16, 015019. [Google Scholar] [CrossRef] [PubMed]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-based 3D printing of polymer and associated composite: A review on mechanical properties, defects and treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef] [PubMed]

- Ivanov, E.; Kotsilkova, R.; Xia, H.S.; Chen, Y.H.; Donato, R.K.; Donato, K.; Godoy, A.P.; di Maio, R.; Silvestre, C.; Cimmino, S.; et al. PLA/Graphene/MWCNT composites with improved electrical and thermal properties suitable for FDM 3D printing applications. Appl. Sci. 2019, 9, 1209. [Google Scholar] [CrossRef] [Green Version]

- Le Duigou, A.; Chabaud, G.; Matsuzaki, R.; Castro, M. Tailoring the mechanical properties of 3D-printed continuous flax/PLA biocomposites by controlling the slicing parameters. Compos. B Eng. 2020, 203, 108474. [Google Scholar] [CrossRef]

- Senatov, F.S.; Zadorozhnyy, M.Y.; Niaza, K.V.; Medvedev, V.V.; Kaloshkin, S.D.; Anisimova, N.Y.; Kiselevskiy, M.V.; Yang, K.-C. Shape memory effect in 3D-printed scaffolds for self-fitting implants. Eur. Polym. J. 2017, 93, 222–231. [Google Scholar] [CrossRef]

- Langford, T.; Mohammed, A.; Essa, K.; Elshaer, A.; Hassanin, H. 4D printing of origami structures for minimally invasive surgeries using functional scaffold. Appl. Sci. 2021, 11, 332. [Google Scholar] [CrossRef]

- Ehrmann, G.; Ehrmann, A. 3D printing of shape memory properties. J. Appl. Polym. Sci. 2021, 138, 50847. [Google Scholar] [CrossRef]

- Wu, W.Z.; Ye, W.L.; Wu, Z.C.; Geng, P.; Wang, Y.L.; Zhao, J. Influence of layer thickness, raster angle, deformation temperature and recovery temperature on the shape-memory effect of 3D-printed polylactic acid samples. Materials 2017, 10, 970. [Google Scholar] [CrossRef] [Green Version]

- Senatov, F.S.; Niaza, N.K.; Zadorozhnyy, M.Y.; Maksimkin, A.V.; Kaloshkin, S.D.; Estrin, Y.Z. Mechanical properties and shape memory effect of 3D-printed PLA-based porous scaffolds. J. Mech. Behav. Biomed. Mater. 2016, 57, 139–148. [Google Scholar] [CrossRef]

- Lendlein, A.; Langer, R. Biodegradable, elastic shape-memory polymers for potential biomedical applications. Science 2002, 296, 1673–1676. [Google Scholar] [CrossRef]

- Ehrmann, G.; Ehrmann, A. Investigation of the shape-memory properties of 3D printed PLA structures with different infills. Polymers 2021, 13, 164. [Google Scholar] [CrossRef]

- Ehrmann, G.; Ehrmann, A. Pressure orientation dependent recovery of 3D-printed PLA objects with varying infill degree. Polymers 2021, 13, 1275. [Google Scholar] [CrossRef] [PubMed]

- Koske, D.; Ehrmann, A. Infill design for 3D-printed shape memory objects. Technologies 2021, 9, 29. [Google Scholar] [CrossRef]

- Srithep, Y.; Nealey, P.; Turng, L. Effects of annealing time and temperature on the crystallinity and heat resistance behavior of injection-molded poly(lactic acid). Polym. Eng. Sci. 2013, 53, 580–588. [Google Scholar] [CrossRef]

- Jayanth, N.; Jaswanthraj, K.; Sandeep, S.; Mallaya, N.H.; Siddhartz, S.R. Effect of heat treatment on mechanical properties of 3D printed PLA. J. Mech. Beh. Biomed. Mater. 2021, 123, 104764. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Liu, Z.G.; Gu, H.W.; Cui, C.Z.; Hao, J.B. Improved mechanical properties of 3D-printed SiC/PLA composite parts by microwave heating. J. Mater. Res. 2019, 34, 3412–3419. [Google Scholar] [CrossRef]

- Lavecchia, F.; Guerra, M.G.; Galantucci, L.M. Chemical vapor treatment to improve surface finish of 3D printed polylactic acid (PLA) parts realized by fused filament fabrication. Prog. Addit. Manuf. 2021. early access. [Google Scholar] [CrossRef]

- Valerga, A.P.; Batista, M.; Fernandez-Vidal, S.R.; Gamez, A.J. Impact of chemical post-processing in fused deposition modelling (FDM) on polylactic acid (PLA) surface quality and structure. Polymers 2019, 11, 566. [Google Scholar] [CrossRef] [Green Version]

- Panda, S.S.; Chabra, R.; Kapil, S.; Patel, V. Chemical vapour treatment for enhancing the surface finish of PLA object produced by fused deposition method using the Taguchi optimization method. SN Appl. Sci. 2020, 2, 1–13. [Google Scholar] [CrossRef]

- Villani, M.; Consonni, R.; Canetti, M.; Bertoglio, F.; Iervese, S.; Bruni, G.; Visai, L.; Iannace, S.; Bertini, F. Polyurethane-based composites: Effects of antibacterial fillers on the physical-mechanical behavior of thermoplastic polyurethanes. Polymers 2020, 12, 362. [Google Scholar] [CrossRef] [Green Version]

- Shankar, S.; Rhim, J.-W. Tocopherol-mediated synthesis of silver nanoparticles and preparation of antimicrobial PBAT/silver nanoparticles composite films. LWT-Food Sci. Technol. 2016, 72, 149–156. [Google Scholar] [CrossRef]

- Franca, D.C.; Almeida, T.G.; Abels, G.; Canedo, E.L.; Carvalho, L.H.; Wellen, R.M.R.; Haag, K.; Koschek, K. Tailoring PBAT/PLA/Babassu films for suitability of agriculture mulch application. J. Nat. Fibers 2019, 16, 933–943. [Google Scholar] [CrossRef]

- Siyamak, S.; Ibrahim, N.A.; Abdolmohammadi, S.; Yunus, W.M.Z.W.; Rahman, M.Z.A.B. Effect of fiber esterification on fundamental properties of oil palm empty fruit bunch fiber/poly(butylene adipate-co-terephthalate) biocomposites. Int. J. Mol. Sci. 2012, 13, 1327–1346. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, P.; Liu, W.Q.; Wu, Q.S.; Ren, J. Preparation, mechanical, and thermal properties of biodegradable polyesters/poly(lactic acid) blends. J. Nanomater. 2010, 2010, 287082. [Google Scholar] [CrossRef] [Green Version]

- Pop, M.A.; Croitoru, C.; Bedo, T.; Geaman, V.; Radomir, I.; Cosnita, M.; Zaharia, S.M.; Chicos, L.A.; Milosan, I. Structural changes during 3D printing of bioderived and synthetic thermoplastic materials. J. Appl. Polym. 2019, 136, 47382. [Google Scholar] [CrossRef]

- Garlotta, D. A literature review of poly(lactic acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- Jia, W.; Luo, Y.M.; Yu, J.; Liu, B.W.; Hu, M.L.; Chai, L.; Wang, C.Y. Effects of high-repetition-rate femtosecond laser micromachining on the physical and chemical properties of polylactide (PLA). Opt. Express 2015, 23, 26934. [Google Scholar] [CrossRef] [PubMed]

- Stepak, B.D.; Antonczak, A.J.; Szustakiewicz, K.; Koziol, P.E.; Abramski, K.M. Degradation of poly(L-lactide) under KrF excimer laser treatment. Polym. Degrad. Stab. 2014, 110, 156–164. [Google Scholar] [CrossRef]

- Shen, W.; Zhang, G.H.; Ge, X.M.; Li, Y.L.; Fan, G.D. Effect of electrospun fibres by synthesis of high branching polylactic acid. R. Soc. Open Sci. 2018, 5, 180134. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Marra, A.; Cimmino, S.; Silvestre, C. Effect of TiO2 and ZnO on PLA degradation in various media. Adv. Mater. Sci. 2017, 2, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Xu, R.J.; Xie, J.Y.; Lei, C.H. Influence of melt-draw ratio on the crystalline behavior of a polylactic acid cast film with a chi structure. RSC Adv. 2017, 7, 39914–39921. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ehrmann, G.; Brockhagen, B.; Ehrmann, A. Shape-Memory Properties of 3D Printed Cubes from Diverse PLA Materials with Different Post-Treatments. Technologies 2021, 9, 71. https://doi.org/10.3390/technologies9040071

Ehrmann G, Brockhagen B, Ehrmann A. Shape-Memory Properties of 3D Printed Cubes from Diverse PLA Materials with Different Post-Treatments. Technologies. 2021; 9(4):71. https://doi.org/10.3390/technologies9040071

Chicago/Turabian StyleEhrmann, Guido, Bennet Brockhagen, and Andrea Ehrmann. 2021. "Shape-Memory Properties of 3D Printed Cubes from Diverse PLA Materials with Different Post-Treatments" Technologies 9, no. 4: 71. https://doi.org/10.3390/technologies9040071

APA StyleEhrmann, G., Brockhagen, B., & Ehrmann, A. (2021). Shape-Memory Properties of 3D Printed Cubes from Diverse PLA Materials with Different Post-Treatments. Technologies, 9(4), 71. https://doi.org/10.3390/technologies9040071