Experimental Tests on Steel Plate-to-Plate Splices Bonded by C-FRPS Laminas with and without Wrapping

Abstract

:1. Introduction

2. Experimental Program

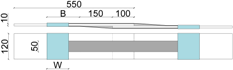

2.1. Investigated Parameters and Experimental Program

- (1)

- Bonding length: This parameter may noticeably affect the failure load [18]. Therefore, different strip lengths were examined in order to verify the effectiveness of the strengthening in accordance with Italian code provisions [15], in particular 150 mm, 200 mm (value recommended by the Italian code [15]) and 250 mm.

- (2)

- Wrapping sheet: The effects of the anchored jacketing by wrapping composite sheets were analysed considering, alternatively, 100 mm and 150 mm widths of wrapping sheets.

- (3)

- Load eccentricity: Both butt and lapped plates were considered in order to analyse the effects of secondary bending moments induced by load eccentricity on adhesive deformation and strength.

- C is the splice configuration (e.g., B: Butt; U: Unsymmetrical lapped);

- B is the bonding length (e.g., 150, 200, 250 mm);

- W is the wrapping depth (e.g., 100, 150 mm);

| Specimen Tag | Butt | Unsymmetrical | B (mm) | W (mm) | Test No. |

|---|---|---|---|---|---|

| Unwrapped | |||||

| B150 | √ | 150 | 3 (a, b, c) | ||

| B200 | √ | 200 | 3 (a, b, c) | ||

| B250 | √ | 250 | 3 (a, b, c) | ||

| U-B150 | √ | 150 | 3 (a, b, c) | ||

| U-B200 | √ | 200 | 3 (a, b, c) | ||

| U-B250 | √ | 250 | 3 (a, b, c) | ||

| Wrapped | |||||

| B150W100 | √ | 150 | 100 | 3 (a, b, c) | |

| B150W150 | √ | 150 | 150 | 3 (a, b, c) | |

| U-B150W100 | √ | 150 | 100 | 3 (a, b, c) | |

| U-B150W150 | √ | 150 | 150 | 3 (a, b, c) | |

| Total test 30 | |||||

| Butt | Lapped | |

|---|---|---|

| Unwrapped |  |  |

| Wrapped |  |  |

2.2. Experimental Set-Up and Monitored Parameters

- -

- δ = (δLVDT1 + δLVDT2)/2: Average displacement (being δLVDTi the displacement recorded by the ith LVDT);

- -

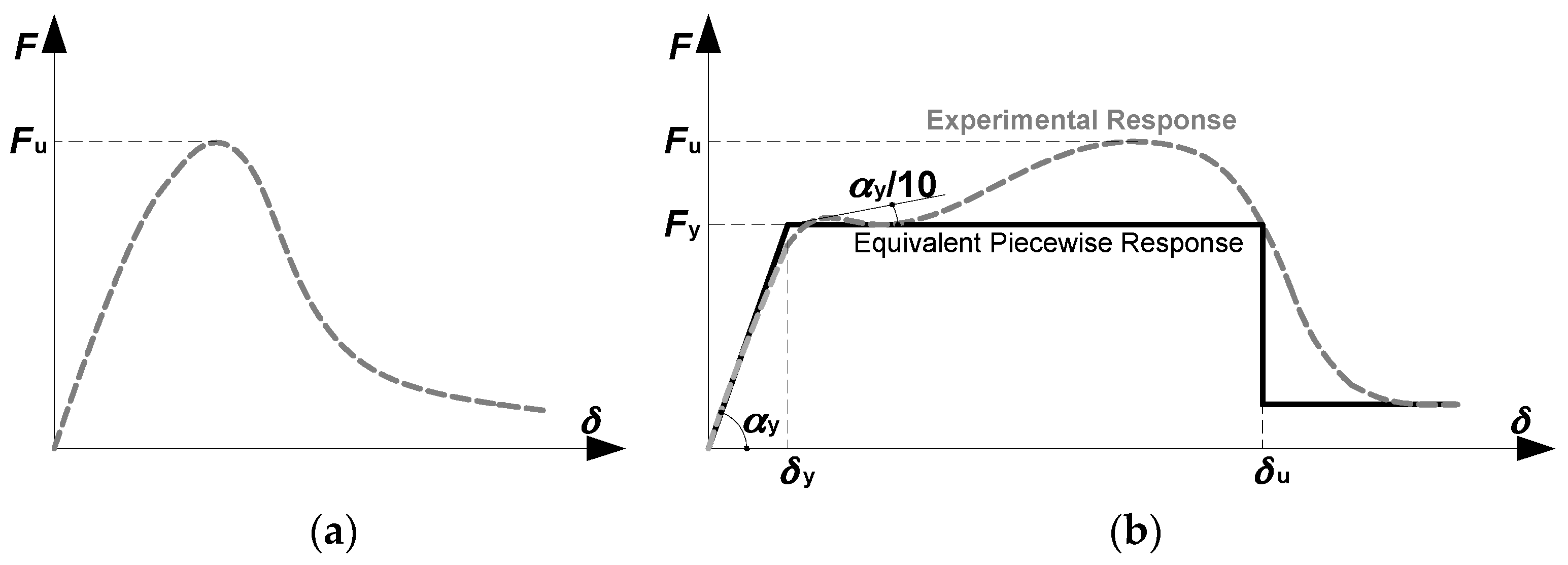

- Fy: Conventional elastic strength determined according to European recommendations for testing steel elements developed by European Convention for Constructional Steelwork (ECCS), i.e., ECCS-45 [19]. In particular, this approach requires the following steps: (1) evaluating the tangent line at the origin of the force-displacement, it gives a slope equal to αy (see Figure 2b); (2) locating a tangent line tilt of αy/10 on the experimental response (see Figure 2b); (3) the intersection of the two tangents defines the level of Fy;

- -

- Fu: Ultimate strength, which is the maximum recorded average load;

- -

- δy: Slip corresponding to Fy;

- -

- δu: Displacement corresponding to a load equal to Fy on the post-peak branch of the response curve

- -

- μ = δu/δy: Displacement capacity.

3. Experimental Results

3.1. Unwrapped Specimens

| Specimen | ta * (mm) | Fu (kN) | Failure Mechanism | |||||

|---|---|---|---|---|---|---|---|---|

| Mean | SD | CV | Test Value | Mean | SD | CV | ||

| B150 a | 0.49 | 0.09 | 0.18 | 70.37 | 71.00 | 0.77 | 0.01 | Delamination |

| B150 b | 0.56 | 0.08 | 0.14 | 71.86 | Delamination | |||

| B150 c | 0.54 | 0.11 | 0.21 | 70.76 | Delamination | |||

| B200 a | 0.41 | 0.08 | 0.19 | 73.22 | 73.78 | 0.67 | 0.01 | C-FRP to adhesive interface + Delamination |

| B200 b | 0.40 | 0.09 | 0.22 | 74.53 | Adhesive/Delamination | |||

| B200 c | 0.41 | 0.10 | 0.24 | 73.60 | Adhesive/Delamination | |||

| B250 a | 0.38 | 0.07 | 0.18 | 76.59 | 74.71 | 1.80 | 0.02 | Adhesive/Delamination |

| B250 b | 0.39 | 0.09 | 0.23 | 73.01 | Adhesive/Delamination | |||

| B250 c | 0.41 | 0.09 | 0.22 | 74.53 | C-FRP to adhesive interface | |||

| L150 a | 0.38 | 0.09 | 0.24 | 63.03 | 63.08 | 0.09 | 0.00 | Adhesive/Delamination |

| L150 b | 0.36 | 0.08 | 0.22 | 63.18 | Adhesive/Delamination | |||

| L150 c | 0.39 | 0.11 | 0.28 | 63.01 | Adhesive/Delamination | |||

| L200 a | 0.40 | 0.08 | 0.20 | 60.61 | 63.15 | 2.26 | 0.04 | C-FRP to adhesive interface |

| L200 b | 0.38 | 0.09 | 0.24 | 63.89 | C-FRP to adhesive interface | |||

| L200 c | 0.37 | 0.10 | 0.27 | 64.94 | C-FRP to adhesive interface + Adhesive/Delamination | |||

| L250 a | 0.41 | 0.07 | 0.17 | 63.89 | 67.18 | 3.05 | 0.05 | C-FRP to adhesive interface |

| L250 b | 0.39 | 0.09 | 0.23 | 69.91 | Adhesive/Delamination | |||

| L250 c | 0.39 | 0.09 | 0.23 | 67.73 | Adhesive/Delamination | |||

| Specimen | ta * (mm) | Fy (kN) | Fu (kN) | μ = δu/δy | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | SD | CV | Test Value | Mean | SD | CV | Test Value | Mean | SD | CV | Test Value | Mean | SD | CV | (-) | (-) | |

| B150 W100 a | 0.38 | 0.09 | 0.23 | 76.60 | 77.32 | 1.15 | 0.01 | 84.49 | 81.62 | 2.62 | 0.03 | 6.12 | 3.83 | 2.42 | 0.63 | 1.09 | 1.15 |

| B150 W100 b | 0.35 | 0.10 | 0.28 | 78.36 | 79.36 | 1.29 | |||||||||||

| B150 W100 c | 0.37 | 0.11 | 0.30 | 77.00 | 81.01 | 4.07 | |||||||||||

| B150 W150 a | 0.39 | 0.08 | 0.20 | 78.20 | 77.78 | 1.32 | 0.02 | 91.96 | 93.92 | 1.70 | 0.02 | 6.38 | 5.68 | 1.23 | 0.22 | 1.10 | 1.32 |

| B150 W150 b | 0.38 | 0.10 | 0.26 | 76.34 | 94.75 | 4.26 | |||||||||||

| B150 W150 c | 0.36 | 0.10 | 0.28 | 78.80 | 95.05 | 6.41 | |||||||||||

| L150 W100 a | 0.37 | 0.10 | 0.27 | 80.08 | 78.29 | 1.33 | 0.03 | 85.60 | 83.97 | 1.59 | 0.02 | 4.64 | 4.92 | 0.43 | 0.09 | 1.24 | 1.33 |

| L150 W100 b | 0.41 | 0.09 | 0.21 | 76.02 | 83.90 | 5.42 | |||||||||||

| L150 W100 c | 0.36 | 0.12 | 0.34 | 78.78 | 82.42 | 4.71 | |||||||||||

| L150 W150 a | 0.38 | 0.09 | 0.23 | 78.76 | 78.85 | 1.71 | 0.01 | 104.95 | 107.85 | 3.41 | 0.03 | 8.26 | 7.61 | 1.18 | 0.15 | 1.25 | 1.71 |

| L150 W150 b | 0.40 | 0.10 | 0.25 | 78.20 | 107.00 | 6.25 | |||||||||||

| L150 W150 c | 0.39 | 0.11 | 0.28 | 79.60 | 111.60 | 8.33 | |||||||||||

3.2. Wrapped Specimens

4. Conclusions

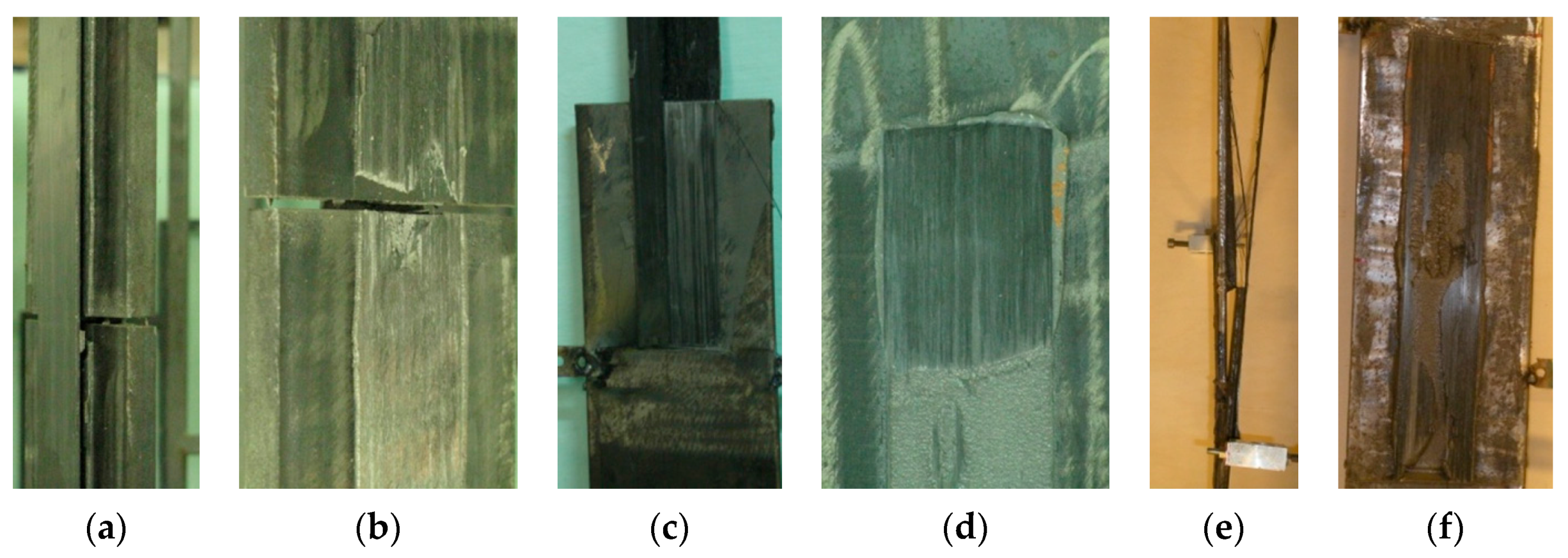

- The failure modes exhibited by both butt and lapped bonded splices were similar, characterized by a non-ductile response with a clear post-peak softening behaviour. The lapped specimens experienced a peak strength lesser than those of butt splices of about 11.2%.

- Tests on unwrapped bonded splices showed that the ultimate bonding strength is practically insensitive to the bonding length of the strips in the range of 150 mm–250 mm. Hence, the limit of 200 mm proposed by the Italian code [15] is conservative.

- Tests of wrapped splices highlighted the beneficial role of anchoring externally bonded FRP laminas in order to achieve larger deformations prior to failure, even though a more timely installation process is necessary.

- The anchorage with wrapped C-FRP fabrics modified the post-elastic response of the splices by providing a pseudo-ductile behaviour, thus allowing a non-negligible ductility.

- Similarly to the bonded specimens, the failure modes exhibited by both butt and lapped wrapped splices were substantially similar. As a consequence, it was not possible to observe a strict dependence of the failure mechanism on the splice geometry.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- D’Aniello, M.; Portioli, F.; Fiorino, L.; Landolfo, R. Experimental investigation on shear behaviour of riveted connections in steel structures. Eng. Struct. 2011, 33, 516–531. [Google Scholar] [CrossRef]

- Sustainable bridges—European Research Project under the EU 6th Framework Programme, 2006. Available online: http://www.sustainablebridges.net/ (accessed on 4 February 2016).

- British Standards Institution (BSI). Hot Rolled Products of Non-Alloy Structural Steels. Technical Delivery Conditions for Non-Alloy Structural Steels; BS EN 10025-2:2004; BSI: London, UK, 2004. [Google Scholar]

- Zhao, X.; Zhang, L. State-of-the-art review on FRP strengthened steel structures. Eng. Struct. 2007, 29, 1808–1823. [Google Scholar] [CrossRef]

- Hollaway, L.C.; Cadei, J. Progress in the technique of upgrading metallic structures with advanced polymer composites. Prog. Struct. Eng. Mater. 2002, 4, 131–148. [Google Scholar] [CrossRef]

- Hollaway, L.C. Polymers, Fibres, Composites and the Civil Engineering Environment: A Personal Experience. Adv. Struct. Eng. 2010, 13, 927–960. [Google Scholar] [CrossRef]

- Song, K.; Zhang, Y.; Meng, J.; Green, E.C.; Tajaddod, N.; Li, H.; Minus, M.L. Structural Polymer-Based Carbon Nanotube Composite Fibers: Understanding the Processing–Structure–Performance Relationship. Materials 2013, 6, 2543–2577. [Google Scholar] [CrossRef]

- Guades, E.; Aravinthan, T.; Islam, M.; Manalo, A. A review on the driving performance of FRP composite piles. Compos. Struct. 2012, 94, 1932–1942. [Google Scholar] [CrossRef]

- Deng, J.; Lee, M.M.K. Adhesive bonding in steel beams strengthened with CFRP. Proc. Inst. Civ. Eng. Struct. Build. 2009, 162, 241–249. [Google Scholar] [CrossRef]

- Stratford, T.J.; Chen, J.F. Designing for tapers and defects in FRP-strengthened metallic structures. In Proceedings of the Designing for Tapers and Defects in Frp-Strengthened Metallic Structures, BBFS2005, Hong Kong, China, 7–9 December 2005.

- Kim, Y.J.; Brunell, G. Interaction between CFRP-repair and initial damage of wide flange steel beams subjected to three-point bending. Compos. Struct. 2011, 93, 1986–1996. [Google Scholar] [CrossRef]

- Bassetti, A.; Nussbaumer, A.; Hirt, M.A. Crack repair and fatigue life extension of riveted bridge members using composite materials. In Proceedings of the Crack Repair and Fatigue Life Extension of Riveted Bridge Members Using Composite Materials, ESE-IABSE-FIB, Sharm El Sheikh, Egypt, 26–30 March 2000.

- Xia, S.H.; Teng, J.G. Behaviour of FRP-to-steel bonded joints. In Proceedings of the International Symposium on Bond Behaviour of FRP in Structures, BBFS2005, Hong Kong, China, 7–9 December 2005.

- Teng, J.G.; Yu, T.; Fernando, D. Strengthening of steel structures with fiber reinforced polymer composites. J. Constr. Steel Res. 2012, 78, 131–143. [Google Scholar] [CrossRef]

- Istruzioni per la Progettazione, l’Esecuzione ed il Controllo di Interventi di Consolidamento Statico Mediante l’utilizzo di Compositi Fibrorinforzati. Available online: http://www.cnr.it/documenti/norme/IstruzioniCNR_DT200_2004.pdf (accessed on 4 February 2016).

- Cadei, J.M.C.; Stratford, T.J.; Hollaway, L.C.; Duckett, W.G. Strengthening Metallic Structures Using Externally Bonded Fibre-Reinforced Polymers; Publication C595, Construction Industry Research and Information Association (CIRIA): London, UK, 2004. [Google Scholar]

- Yang, Y.; Yue, Q.; Peng, F. Experimental research on bond behaviour of CFRP to steel. In Proceedings of the Experimental Study on Bond Behaviour between UHM CFRP Laminate and Steel, BBFS2005, Hong Kong, China, 7–9 December 2005.

- Mancusi, G.; Ascione, F. Performance at collapse of adhesive bonding. Compos. Struct. 2013, 96, 256–261. [Google Scholar] [CrossRef]

- ECCS-45. Recommended Testing Procedure for Assessing the Behaviour of Steel Elements under Cyclic Loads; European Convention for Constructional Steelwork: Brussels, Belgium, 1986. [Google Scholar]

- D’Aniello, M.; Portioli, F.; Landolfo, R. Lap shear tests on hot-driven steel riveted connections strengthened by means of C-FRPs. Compos. Part B Eng. 2014, 59, 140–152. [Google Scholar] [CrossRef]

- Fawzia, S.; Zhao, X.L.; Al-Mahaidi, R. Bond-slip models for double strap joints strengthened by CFRP. Compos. Struct. 2009, 92, 2137–2145. [Google Scholar] [CrossRef]

- Da Silva Lucas, F.M.; Rodriguesa, T.N.S.S.; Figueiredoa, M.A.V.; de Mouraa, M.F.S.F.; Chousal, J.A.G. Effect of adhesive type and thickness on the lap shear strength. J. Adhes. 2006, 82, 1091–1115. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

D’Aniello, M.; Portioli, F.; Landolfo, R. Experimental Tests on Steel Plate-to-Plate Splices Bonded by C-FRPS Laminas with and without Wrapping. Technologies 2016, 4, 5. https://doi.org/10.3390/technologies4010005

D’Aniello M, Portioli F, Landolfo R. Experimental Tests on Steel Plate-to-Plate Splices Bonded by C-FRPS Laminas with and without Wrapping. Technologies. 2016; 4(1):5. https://doi.org/10.3390/technologies4010005

Chicago/Turabian StyleD’Aniello, Mario, Francesco Portioli, and Raffaele Landolfo. 2016. "Experimental Tests on Steel Plate-to-Plate Splices Bonded by C-FRPS Laminas with and without Wrapping" Technologies 4, no. 1: 5. https://doi.org/10.3390/technologies4010005

APA StyleD’Aniello, M., Portioli, F., & Landolfo, R. (2016). Experimental Tests on Steel Plate-to-Plate Splices Bonded by C-FRPS Laminas with and without Wrapping. Technologies, 4(1), 5. https://doi.org/10.3390/technologies4010005