Vibration Analysis for Diagnosis of Diesel Engines with Air Flow Sensor Failure †

Abstract

1. Introduction

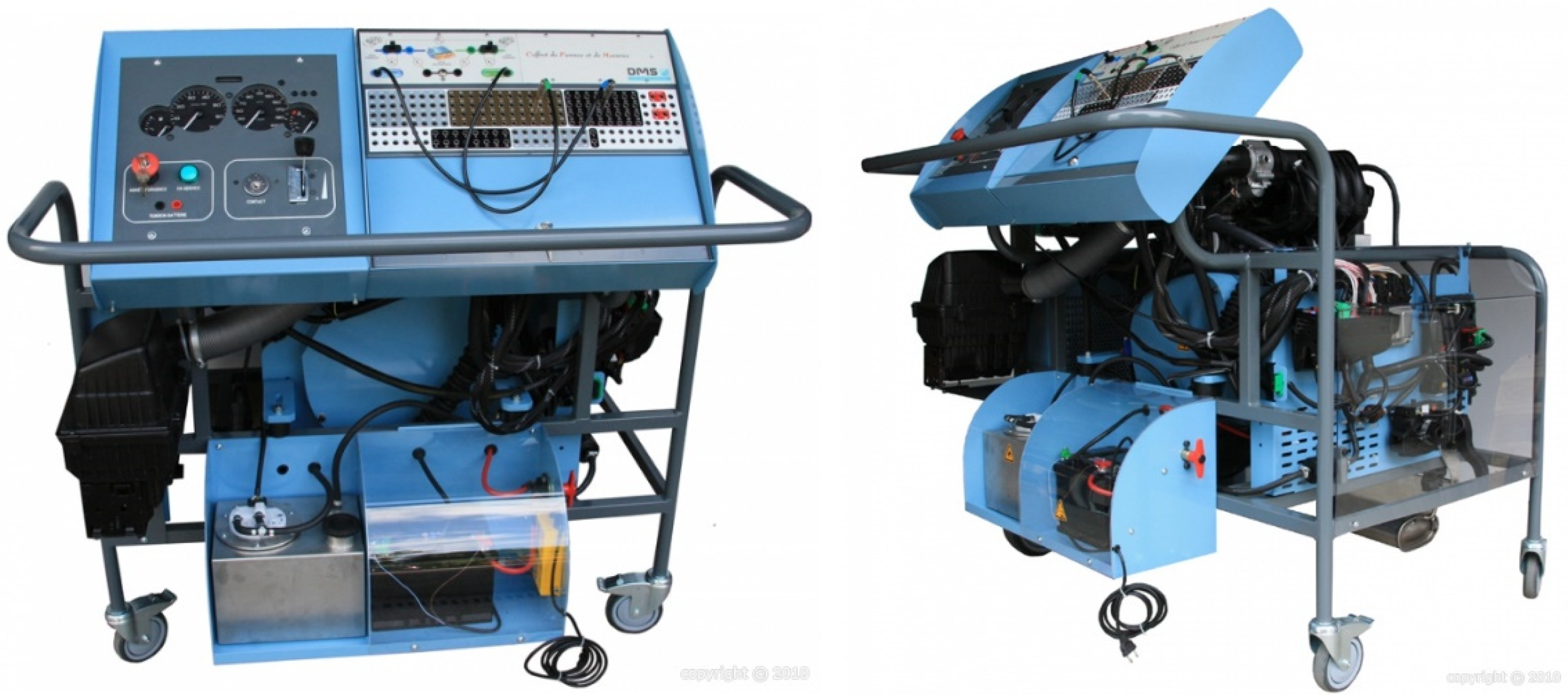

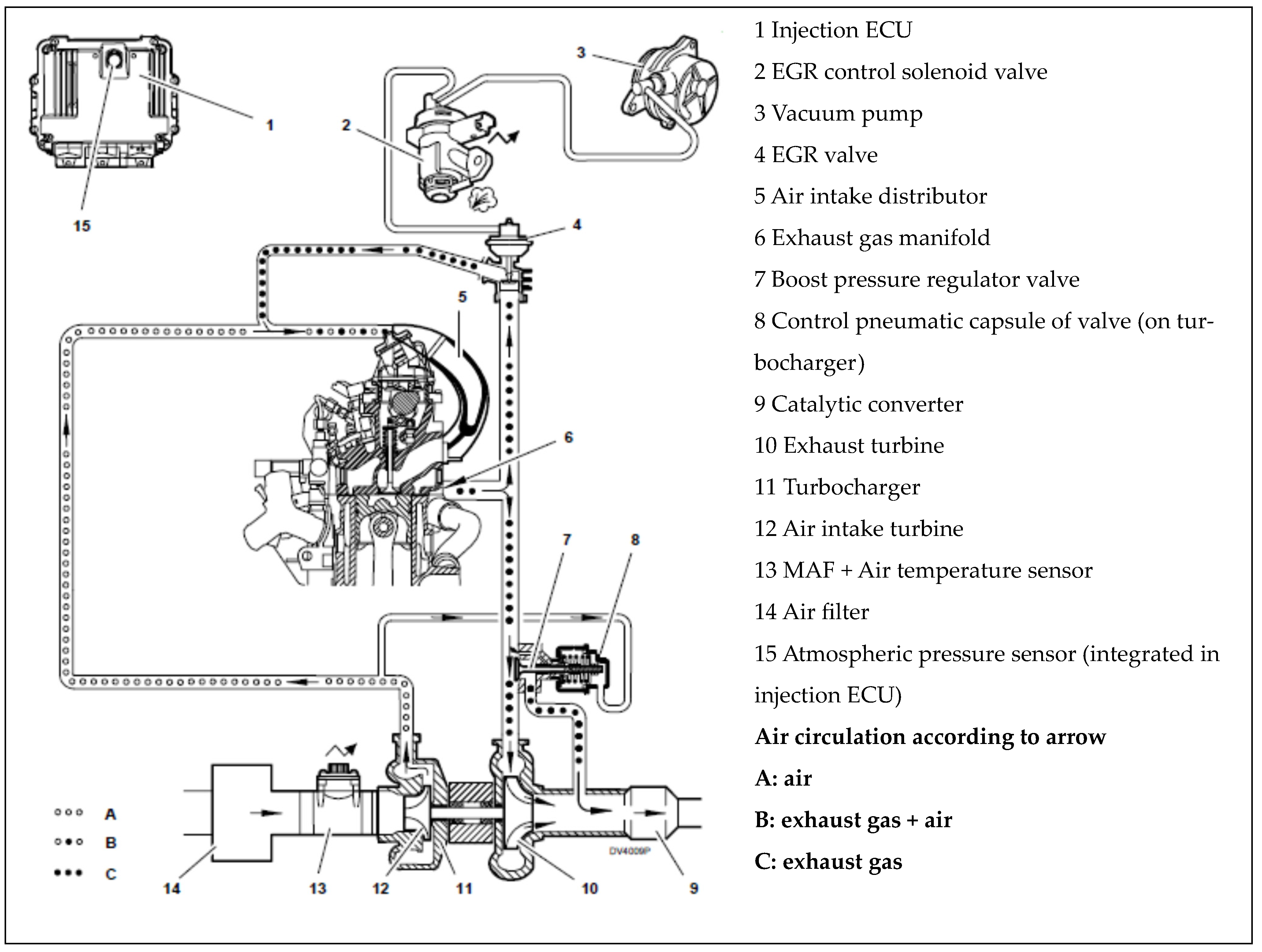

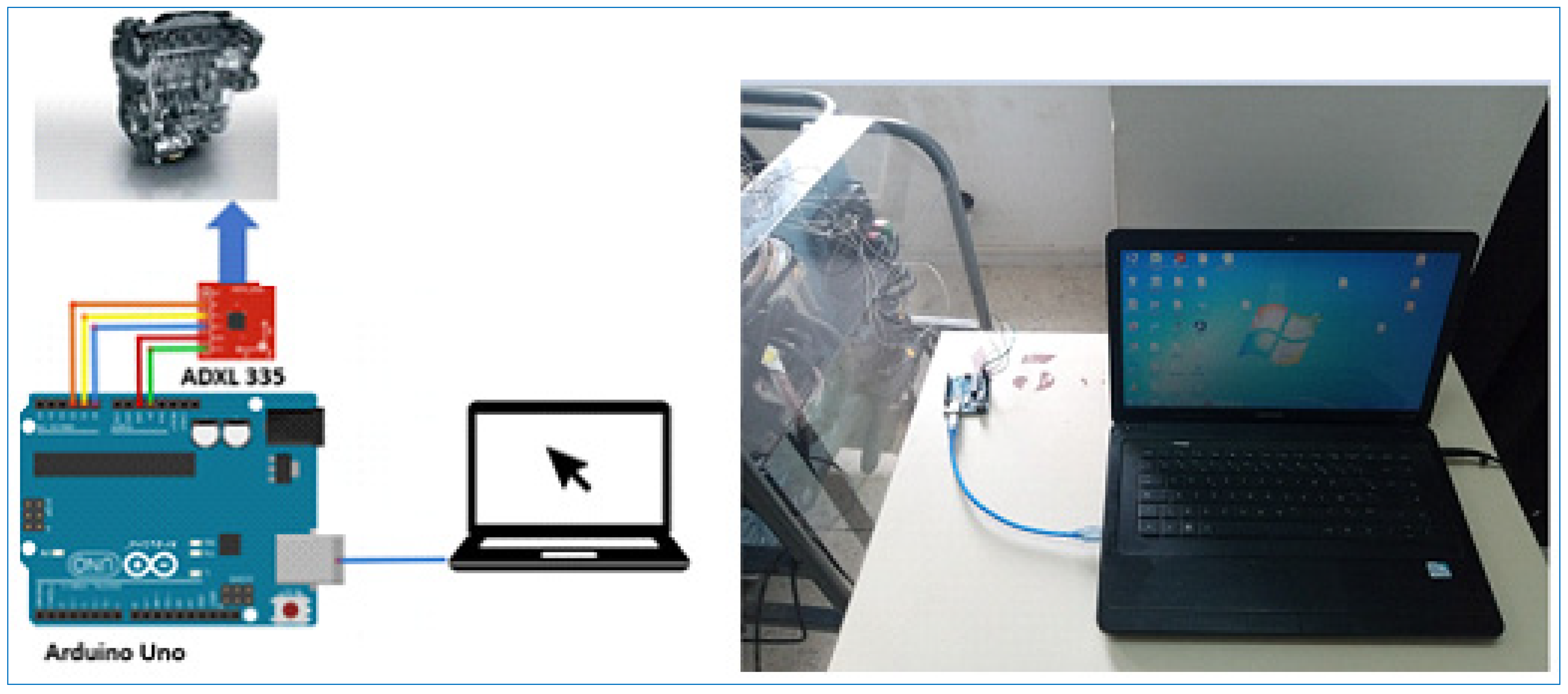

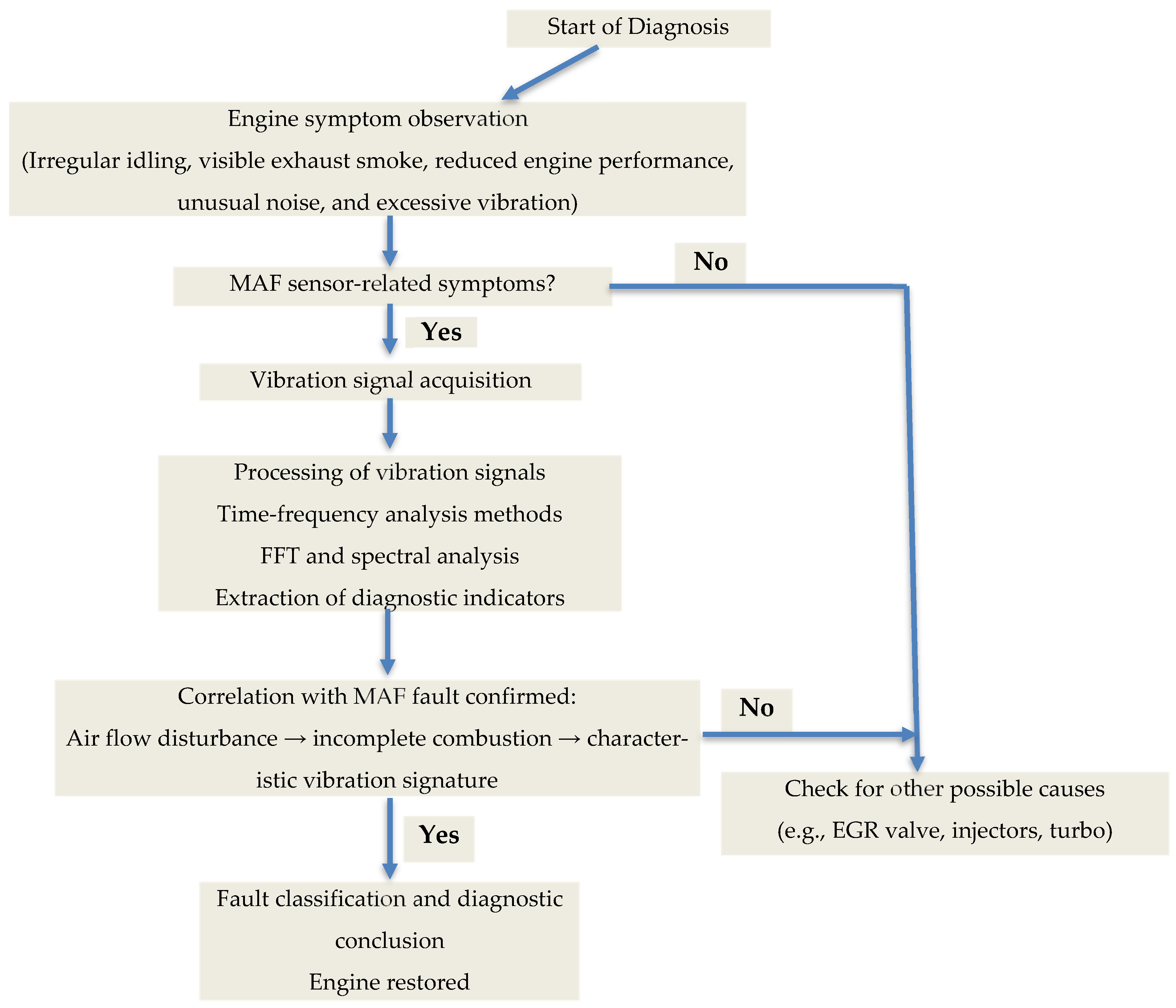

2. Materials and Methods

2.1. Materials

2.2. Methods

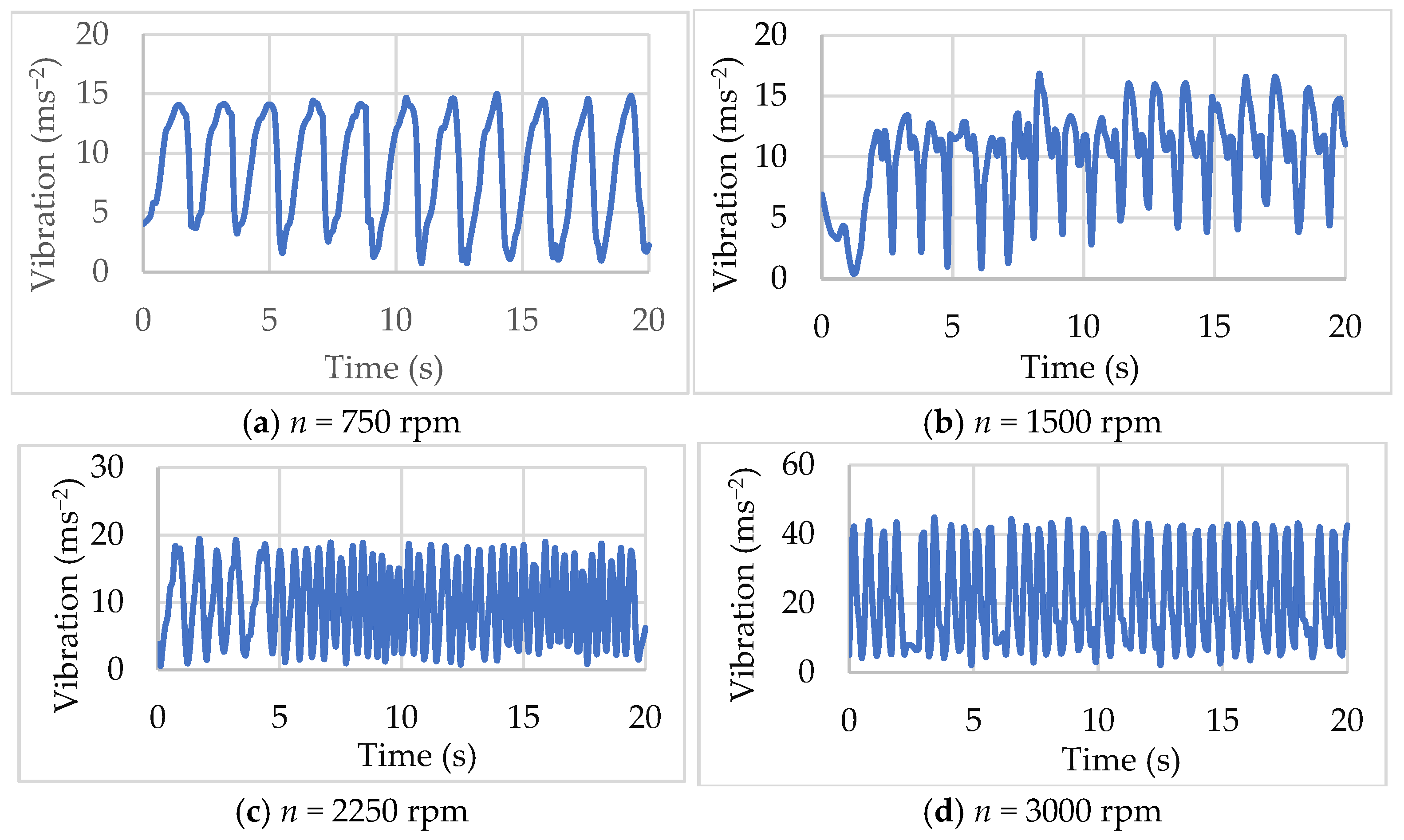

- Temporal Analysis: An analysis was made in the time domain to observe how the vibrating amplitude varies with time, representing engine operating condition information in different states.

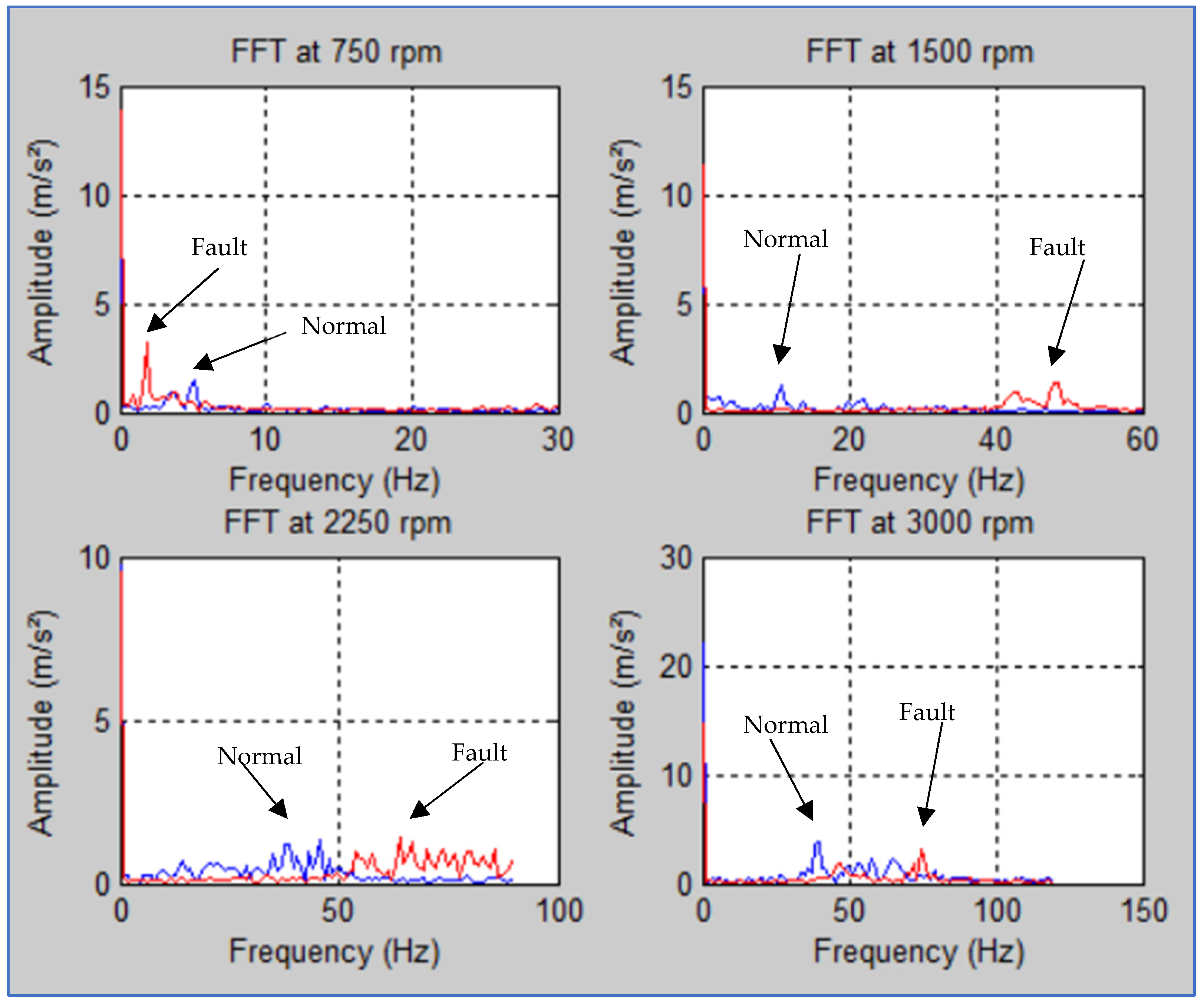

- Frequency Analysis: Frequency spectral-domain analysis was employed for identification of characteristic frequencies associated with a particular engine component and fault. The short-time Fourier transform (STFT) was utilized as a non-stationary signal processing technique, giving a time-frequency view of vibration signals [18].

3. Results

3.1. Temporal Analysis

- Average

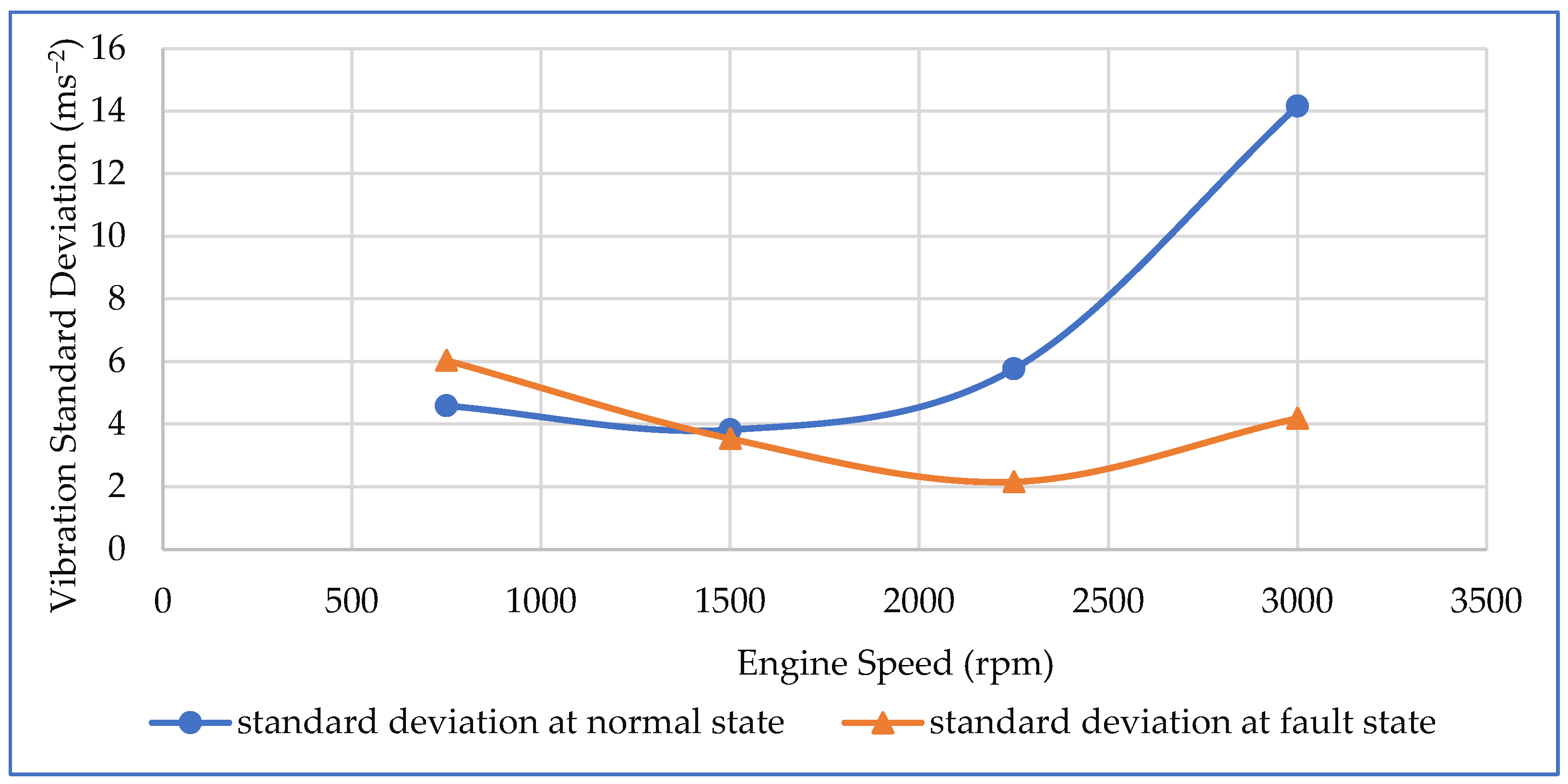

- Standard deviation

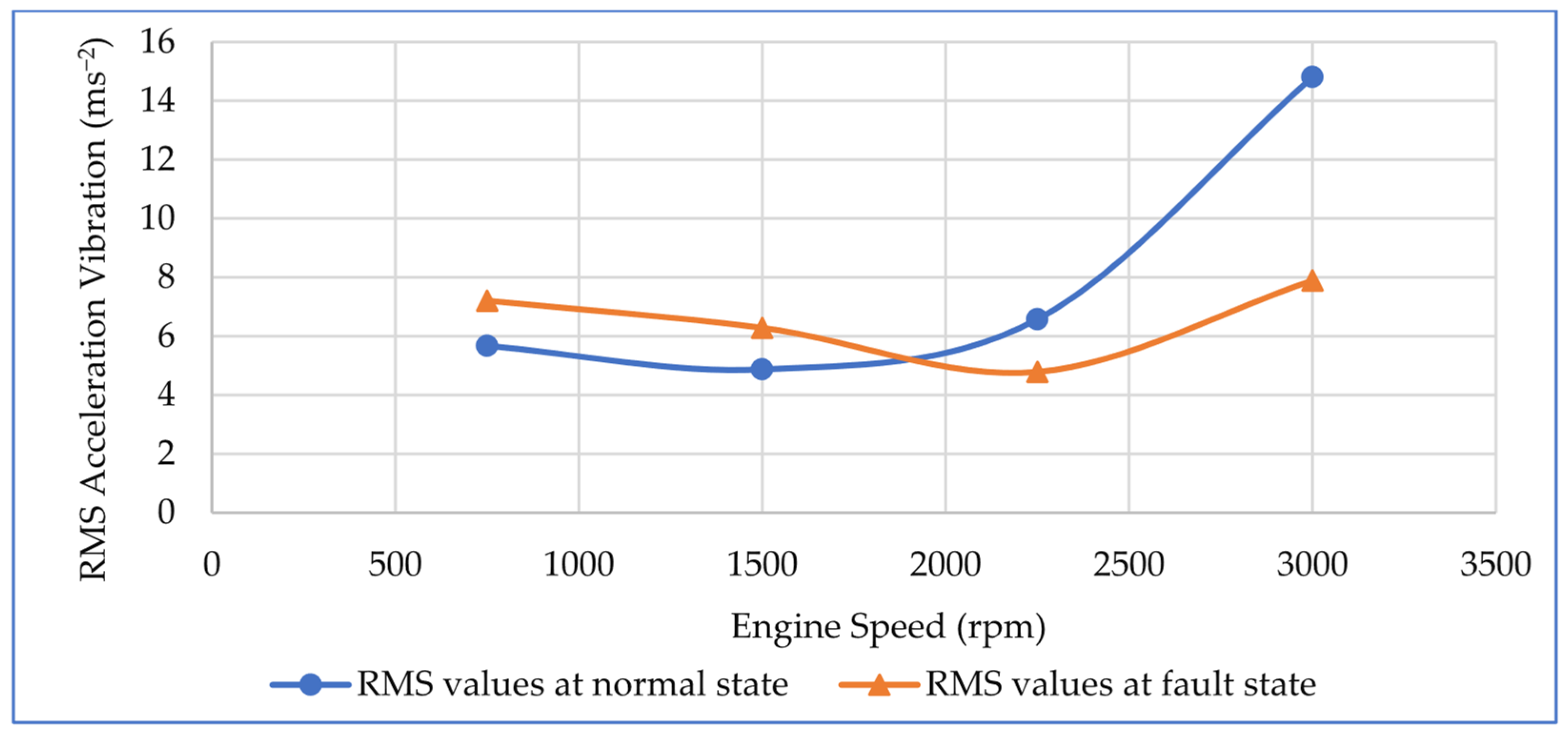

- RMS

- Kurtosis

- Clearance Factor

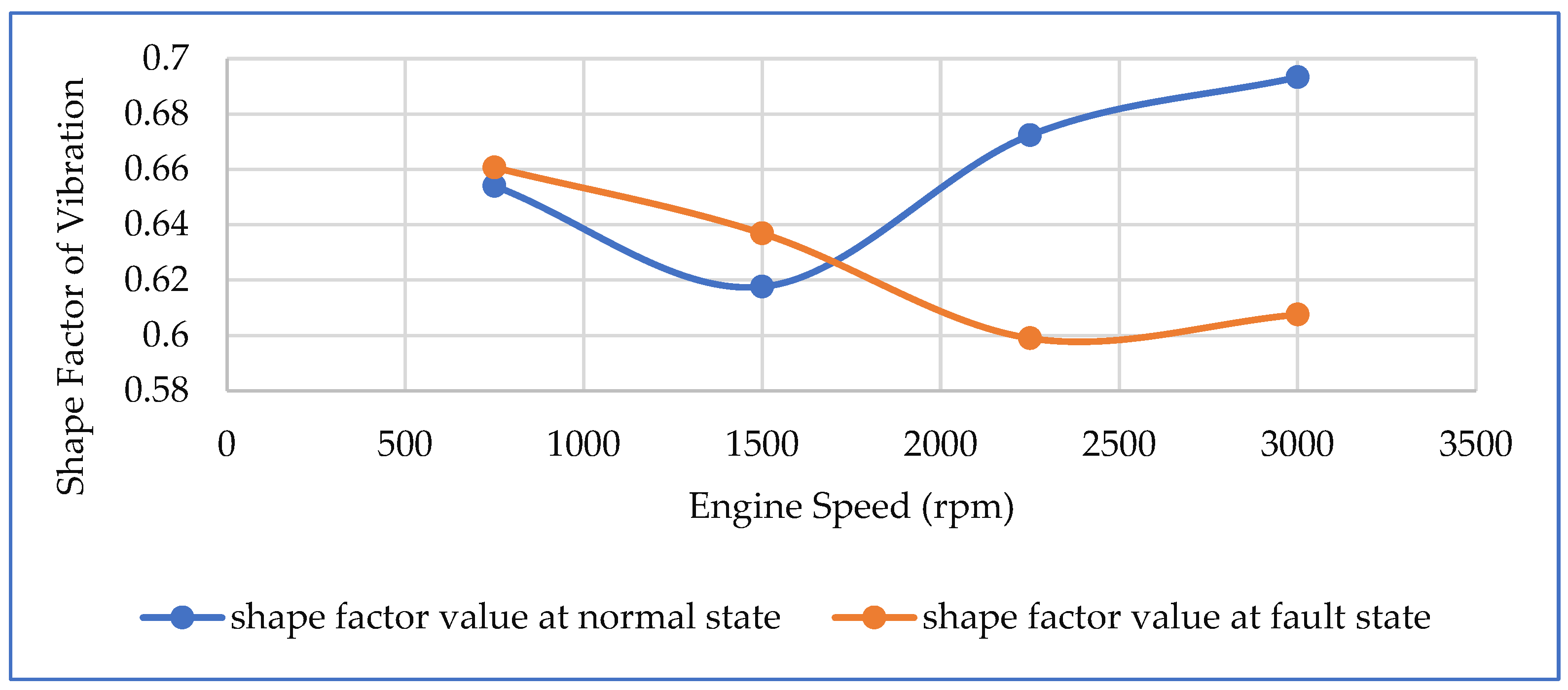

- Shape Factor

3.2. Temporal Indicators Evolution

3.3. Frequency (Spectral) Analysis

4. Discussion

- Time-Domain Analysis

- Frequency (spectral) domain analysis

5. Conclusions

- Demonstrating diagnostic practicability of MAF sensor fault vibration signatures.

- Associating the frequency range with faulty conditions of engine components.

- Depicting vibration analysis as an economic, scalable, real-time diesel engine condition monitoring technique.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mafla-Yépez, C.; Castejon, C.; Rubio, H.; Morales, C. A Vibration Analysis for the Evaluation of Fuel Rail Pressure and Mass Air Flow Sensors on a Diesel Engine: Strategies for Predictive Maintenance. Sensors 2024, 24, 1551. [Google Scholar] [CrossRef] [PubMed]

- Ward, T.; Jenab, K.; Ortega-Moody, J.; Staub, S. A Comprehensive Review of Machine Learning Techniques for Condition-Based Maintenance. Int. J. Progn. Health Manag. 2024, 15. [Google Scholar] [CrossRef]

- Gangsar, P.; Bajpei, A.R.; Porwal, R. A Review on Deep Learning Based Condition Monitoring and Fault Diagnosis of Rotating Machinery. Noise Vib. Worldw. 2022, 53, 550–578. [Google Scholar] [CrossRef]

- Li, Y.; Peng, S.; Li, Y.; Jiang, W. A Review of Condition-Based Maintenance: Its Prognostic and Operational Aspects. Front. Eng. Manag. 2020, 7, 323–334. [Google Scholar] [CrossRef]

- Karabacak, Y.E. Condition Monitoring of Internal Combustion Engines with Vibration Signals and Fault Detection by Using Machine Learning Techniques. Int. J. Automot. Eng. Technol. 2024, 13, 191–200. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, C. Sequential Multi-Objective Multi-Agent Reinforcement Learning Approach for System Predictive Maintenance of Turbofan Engine. Adv. Eng. Inform. 2025, 67, 103553. [Google Scholar] [CrossRef]

- ElAraby, W.S.; Madian, A.H.; Saad, M.H. Fault Diagnosis for Rotating Machinery Based on Deep Learning. Noise Vib. Worldw. 2025, 56, 400–421. [Google Scholar] [CrossRef]

- Zonta, T.; Da Costa, C.A.; Righi, R.d.R.; de Lima, M.J.; Da Trindade, E.S.; Li, G.P. Predictive Maintenance in the Industry 4.0: A Systematic Literature Review. Computers 2020, 150, 106889. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, J.; Jiang, Z.; Wei, D.; Zhang, X.; Mao, Z. A New Fault Diagnosis Method for a Diesel Engine Based on an Optimized Vibration Mel Frequency Under Multiple Operation Conditions. Sensors 2019, 19, 2590. [Google Scholar] [CrossRef]

- Kim, B.; Yang, Y.; Park, J.S.; Jang, H.-J. Machine Learning Based Representative Spatio-Temporal Event Documents Classification. Appl. Sci. 2023, 13, 4230. [Google Scholar] [CrossRef]

- Abdullah, N.R.; Shahruddin, N.S.; Mamat, R.; Mamat, A.M.I.; Zulkifli, A. Effects of Air Intake Pressure on the Engine Performance, Fuel Economy and Exhaust Emissions of a Small Gasoline Engine. J. Mech. Eng. Sci. 2014, 6, 949–958. [Google Scholar] [CrossRef]

- Mukhopadhyay, A.; Sen, S. Fundamentals of Combustion Engineering; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar] [CrossRef]

- Smail, B.; AKM, M. Combustion Chamber Design Effect on the Rotary Engine Performance—A Review. Int. J. Automot. Eng. 2020, 11, 200–212. [Google Scholar] [CrossRef]

- Sujesh, G.; Ramesh, S. Modeling and Control of Diesel Engines: A Systematic Review. Alex. Eng. J. 2018, 57, 4033–4048. [Google Scholar] [CrossRef]

- Komorska, I.; Wołczyński, Z.; Borczuch, A. Fault Diagnostics in Air Intake System of Combustion Engine Using Virtual Sensors. Diagnostyka 2018, 19, 5–10. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, H.; Yue, Z.; Li, Y.; Liang, H. Effects of Intake High-Pressure Compressed Air on Thermal-Work Conversion in a Stationary Diesel Engine. Int. J. Green Energy 2023, 20, 338–351. [Google Scholar] [CrossRef]

- Herpel, T.; Koerber, H.; Rasshofer, R.H.; Spies, M. Multi-Sensor Data Fusion in Automotive Applications. In Proceedings of the 3rd International Conference on Sensing Technology (ICST 2008), Tainan, Taiwan, 30 November–3 December 2008; pp. 100–105. [Google Scholar]

- Taghizadeh-Alisaraei, A.; Mahdavian, A. Fault Detection of Injectors in Diesel Engines Using Vibration Time-Frequency Analysis. Appl. Acoust. 2019, 143, 48–58. [Google Scholar] [CrossRef]

- Qian, J.; Zhang, Y.; Liu, X.; Chen, H.; Wang, T. Improved Sensor System Detecting via Joint Transfer Learning and Array Optimization Design Based on Multiple Phase Feature Extraction. IEEE Trans. Instrum. Meas. 2024, 74, 1–11. [Google Scholar] [CrossRef]

- Jin, C.; Sun, J.; Sun, H.; Li, B. A Vibration-Based Approach for Diesel Engine Fault Diagnosis. In Proceedings of the 2014 International Conference on Prognostics and Health Management (ICPHM), Chengdu, China, 12–14 June 2014; pp. 1–6. [Google Scholar]

- Khalifa, R.M.; Yacout, S.; Bassetto, S.; Shaban, Y. Experimental vibration data collected for a belt drive system under different operating conditions. Data Brief 2023, 48, 109175. [Google Scholar] [CrossRef]

- Mohd Ghazali, M.H.; Rahiman, W. Vibration Analysis for Machine Monitoring and Diagnosis: A Systematic Review. Shock Vib. 2021, 2021, 9469318. [Google Scholar] [CrossRef]

- Renwick, J.T.; Babson, P.E. Vibration Analysis—A Proven Technique as a Predictive Maintenance Tool. IEEE Trans. Ind. Appl. 1985, IA-21, 324–332. [Google Scholar] [CrossRef]

- Tran, B.; Nguyen, D. Acoustic Emission Monitoring for Early Detection of Faults in Automotive Engines. Appl. Acoust. 2023, 210, 119876. [Google Scholar]

- Ramteke, S.M.; Chelladurai, H.; Amarnath, M. Diagnosis of Liner Scuffing Fault of a Diesel Engine via Vibration and Acoustic Emission Analysis. J. Vib. Eng. Technol. 2020, 8, 815–833. [Google Scholar] [CrossRef]

- Allam, S.; Abdo, M.; Rabie, M. Diesel Engine Fault Detection Using Vibration and Acoustic Emission Signals. IJASRE 2018, 4, 86–93. [Google Scholar] [CrossRef]

- Ma, X.; Li, Y.; Wang, Z.; Zhang, L. Combined Frequency Domain Analysis and Fuzzy Logic for Engine Misfire Diagnosis. SAE Tech. Pap. 2015-01-0207 2015. [Google Scholar] [CrossRef]

- Helali, A.; Belkacem, I.; Abdellaoui, J.; Zegnani, A. Vibration Diagnosis of Diesel Engines with Air Flow Sensor Failure. In Proceedings of the International Conference on Advances in Mechanical Engineering and Mechanics, Sousse, Tunisia, 28–30 June 2024; pp. 90–98. [Google Scholar]

- Taghizadeh-Alisaraei, A.; Mahdavian, A.; Tavakoli, H.R.; Farid, M. Characterization of Engine’s Combustion-Vibration Using Diesel and Biodiesel Fuel Blends by Time-Frequency Methods: A Case Study. Renew. Energy 2016, 95, 422–432. [Google Scholar] [CrossRef]

- Galiullin, L.A.; Valiev, R.A. Developing Technical Diagnostic Systems for Internal Combustion Engines. In Advances in Automation, Proceedings of the International Russian Automation Conference, RusAutoCon 2019, Sochi, Russia, 8–14 September 2019; Springer: Cham, Switzerland, 2020; pp. 123–130. [Google Scholar]

- Ramteke, S.M.; Chelladurai, H.; Amarnath, M. Diagnosis and Classification of Diesel Engine Components Faults Using Time–Frequency and Machine Learning Approach. J. Vib. Eng. Technol. 2022, 10, 175–192. [Google Scholar] [CrossRef]

- Yao, Z.T.; Pan, H.X. The Engine Fault Diagnosis Based on Time Domain and Frequency Domain. Adv. Mater. Res. 2014, 936, 2243–2246. [Google Scholar] [CrossRef]

- Elamin, F. Fault Detection and Diagnosis in Heavy Duty Diesel Engines Using Acoustic Emission. Ph.D. Thesis, University of Huddersfield, Huddersfield, UK, 2013. [Google Scholar]

- Tsallis, C.; Papadopoulos, S.; Georgiadis, M.; Iliadis, L. Application-Wise Review of Machine Learning-Based Predictive Maintenance: Trends, Challenges, and Future Directions. Appl. Sci. 2025, 15, 4898. [Google Scholar] [CrossRef]

- Kanevski, H.; Lyubomirov, S.; Asenov, S. Simulation of Engine Malfunctions and Their Impact on Emissions with an Emphasis on Engineering Education. In Proceedings of the 15th International Conference of Education, Research and Innovation (ICERI 2022), Seville, Spain, 7–9 November 2022. [Google Scholar]

- Zhang, C.; Zhou, J.; Wang, Y.; Li, H.; Zhang, W. Vibration Feature Extraction Using Signal Processing Techniques for Structural Health Monitoring: A Review. Mech. Syst. Signal Process. 2022, 177, 109175. [Google Scholar] [CrossRef]

- Nithin, S.K.; Hemanth, K.; Shamanth, V. A Review on Combustion and Vibration Condition Monitoring of IC Engine. Mater. Today Proc. 2021, 45, 65–70. [Google Scholar] [CrossRef]

- Pacella, M.; Papadia, G. Fault Diagnosis by Multisensor Data: A Data-Driven Approach Based on Spectral Clustering and Pairwise Constraints. Sensors 2020, 20, 7065. [Google Scholar] [CrossRef]

- Mohammadpour, J.; Franchek, M.; Grigoriadis, K. A Survey on Diagnostic Methods for Automotive Engines. Int. J. Engine Res. 2012, 13, 41–64. [Google Scholar] [CrossRef]

- Miller, T.; Nowak, P.; Kowalski, M.; Zieliński, A. Artificial Intelligence in Maritime Cybersecurity: A Systematic Review of AI-Driven Threat Detection and Risk Mitigation Strategies. Electronics 2025, 14, 1844. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, H. A Review on Predictive Maintenance Strategies for Modern Vehicles. J. Intell. Transp. Syst. 2023, 28, 123–136. [Google Scholar]

- O’Connor, P.; Evans, D. Integration of Real-Time Monitoring with Predictive Analytics for Automotive Diagnostics. IEEE Trans. Ind. Inform. 2024, 20, 567–579. [Google Scholar]

- Injection BOSCh HDI Moteur DV4TD. Centre International de Formation Commerce Edition Janvier 2003. Available online: https://fr.scribd.com/doc/45751402/Injection-BOSCh-HDI-Moteur-DV4TD (accessed on 1 April 2025).

- Shaobo, J.; Cheng, Y.; Wanyou, H.; Minli, H. Comparison of the Vibration Sensors Used in the Estimation of the Combustion Process in a Diesel Engine. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2014, 228, 1210–1219. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, Y. Vibration Signal Analysis of Cylinder Head During Engine Combustion Process. J. Vib. Shock 2021, 40, 210–215. [Google Scholar]

- Goyal, D.; Pabla, B.S. The Vibration Monitoring Methods and Signal Processing Techniques for Structural Health Monitoring: A Review. Arch Comput. Methods Eng. 2016, 23, 585–594. [Google Scholar] [CrossRef]

- Arnone, L.; Boni, M.; Manelli, S.; Morselli, M. Diesel Engine Combustion Monitoring Through Block Vibration Signal Analysis. SAE Tech. Pap. 2009-01-0765 2009. [Google Scholar] [CrossRef]

- Narayan, S.; Milojevic, S.; Gupta, V. Combustion Monitoring in Engines Using Accelerometer Signals. J. Vibroeng. 2019, 21, 1552–1563. [Google Scholar] [CrossRef]

- Randall, R.B. Vibration-Based Condition Monitoring: Industrial, Aerospace and Automotive Applications; Wiley: Chichester, UK, 2011. [Google Scholar] [CrossRef]

- Zabihi-Hesari, A.; Ansari-Rad, S.; Shirazi, F.A.; Ayati, M. Fault detection and diagnosis of a 12-cylinder trainset diesel engine based on vibration signature analysis and neural network. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2018, 233, 1910–1923. [Google Scholar] [CrossRef]

- Heywood, J.B. Combustion engine fundamentals. 1a Edição. Estados Unidos 1988, 25, 1117–1128. [Google Scholar]

- Zeng, R.; Zhang, L.; Xiao, Y.; Mei, J.; Zhou, B.; Zhao, H.; Jia, J. An approach on fault detection in diesel engine by using symmetrical polar coordinates and image recognition. Adv. Mech. Eng. 2014, 6, 273929. [Google Scholar] [CrossRef]

- Grega, R.; Czech, P. Non-invasive vibroacoustic diagnostics of car internal combustion engines. Zesz. Naukowe. Transp. Politech. Śląska 2024, 125, 69–87. [Google Scholar] [CrossRef]

- Li, S.; Liu, Z.; Yan, Y.; Wang, R.; Dong, E.; Cheng, Z. Research on Diesel Engine Fault Status Identification Method Based on Synchro Squeezing S-Transform and Vision Transformer. Sensors 2023, 23, 6447. [Google Scholar] [CrossRef]

- Freire Moraes, G.H.; Ribeiro Junior, R.F.; Gomes, G.F. Fault Classification in Diesel Engines Based on Time-Domain Responses Through Signal Processing and Convolutional Neural Network. Vibration 2024, 7, 863–893. [Google Scholar] [CrossRef]

- Gupta, H.N. Fundamentals of Internal Combustion Engines; PHI Learning Pvt. Ltd.: New Delhi, India, 2012. [Google Scholar]

- Ramachandran, T.; Padmanaban, K.P. Review on Internal Combustion Engine Vibrations and Mountings. Int. J. Eng. Sci. Emerg. Technol. 2012, 3, 63–73. [Google Scholar]

- Stone, R. Introduction to Internal Combustion Engines, 3rd ed.; Palgrave Macmillan: London, UK, 1999. [Google Scholar]

- Tandon, N.; Choudhury, A. A Review of Vibration and Acoustic Measurement Methods for the Detection of Defects in Rolling Element Bearings. Tribol. Int. 1999, 32, 469–470. [Google Scholar] [CrossRef]

- Tao, J.; Wang, S.; Zhang, Y.; Li, H.; Zhou, W. Intelligent fault diagnosis of diesel engines via extreme gradient boosting and high-accuracy time–frequency information of vibration signals. Sensors 2019, 19, 3280. [Google Scholar] [CrossRef]

- Alharbi, F.; Luo, S.; Zhang, H.; Shaukat, K.; Yang, G.; Wheeler, C.A.; Chen, Z. A Brief Review of Acoustic and Vibration Signal-Based Fault Detection for Belt Conveyor Idlers Using Machine Learning Models. Sensors 2023, 23, 1902. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Pang, Y.; Lodewijks, G.; He, D. Experimental research on condition monitoring of belt conveyor idlers. Measurement 2018, 127, 277–282. [Google Scholar] [CrossRef]

- Ewert, P.; Kowalski, C.T.; Jaworski, M. Comparison of the Effectiveness of Selected Vibration Signal Analysis Methods in the Rotor Unbalance Detection of PMSM Drive System. Electronics 2022, 11, 1748. [Google Scholar] [CrossRef]

- Bagri, I.; Tahiry, K.; Hraiba, A.; Touil, A.; Mousrij, A. Vibration Signal Analysis for Intelligent Rotating Machinery Diagnosis and Prognosis: A Comprehensive Systematic Literature Review. Vibration 2024, 7, 1013–1062. [Google Scholar] [CrossRef]

- Gougam, F.; Rahmoune, C.; Benazzouz, D.; Afia, A.; Zair, M. Bearing Faults Classification Under Various Operation Modes Using Time Domain Features, Singular Value Decomposition, and Fuzzy Logic System. Adv. Mech. Eng. 2014, 12, 1687814020967874. [Google Scholar] [CrossRef]

- Yan, H.; Bai, H.; Zhan, X.; Wu, Z.; Wen, L.; Jia, X. Combination of VMD Mapping MFCC and LSTM: A New Acoustic Fault Diagnosis Method of Diesel Engine. Sensors 2022, 22, 8325. [Google Scholar] [CrossRef]

- Bi, X.; Li, Y.; Wang, Z.; Chen, J. VMD-KFCM algorithm for the fault diagnosis of diesel engine vibration signals. Energies 2020, 13, 228. [Google Scholar] [CrossRef]

- Ahmadian, H.; Shafiei, M.; Mirzaei, M.; Ebrahimzadeh, E. Evaluation of the combustion-induced noise and vibration using coherence and wavelet coherence estimates in a diesel engine. Int. J. Engine Res. 2021, 22, 827–846. [Google Scholar] [CrossRef]

- Abdeltwab, M.M.; Ghazaly, N.M. A review on engine fault diagnosis through vibration analysis. Int. J. Recent Technol. Mech. Electr. Eng. 2022, 9, 1–6. [Google Scholar] [CrossRef]

- Yang, Q.; Liu, Y.; Chen, H.; Wang, X.; Li, J. Gear backlash detection and evaluation based on current characteristic extraction and selection. IEEE Access 2020, 8, 107161–107176. [Google Scholar] [CrossRef]

- Hunicz, J.; Szkoda, M.; Jakubik, M.; Moskal, D.; Stępniowski, M. An analytical approach to converting vibration signal to combustion characteristics of homogeneous charge compression ignition engines. Energy Convers. Manag. 2023, 294, 117564. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, Y.; Wang, H.; Chen, J.; Li, X. Harmonic Measurement Method and System Design Based on Self-Compensating FFT. IEEE Sens. J. 2025, 25, 24588–24597. [Google Scholar] [CrossRef]

- Jayasooriya, P.V.; Siriwardana, G.C.; Bandara, T.R. Vibration Analysis to Detect and Locate Engine Misfires. In Proceedings of the 2021 International Research Conference on Smart Computing and Systems Engineering (SCSE), Colombo, Sri Lanka, 29 September 2021; Volume 4. [Google Scholar]

| Criteria | Vibration-Based Diagnosis | Conventional Diagnostic Methods |

|---|---|---|

| Detection Accuracy | High sensitivity to early-stage faults and subtle anomalies in engine behavior | Often miss minor or intermittent electronic faults that do not exceed diagnostic thresholds or trigger ECU alerts |

| Sensor Requirements | Requires accelerometers only (non-intrusive) | Relies on multiple engine sensors (MAF, O2, EGR) |

| Cost Efficiency | Cost-effective (uses fewer and more affordable sensors) | Expensive (multiple sensors and diagnostic tools required) |

| Response Time | Rapid fault detection through real-time vibration analysis | Typically slower; depends on ECU fault code generation |

| Ability to Detect MAF Sensor Fault | Capable of identifying indirect signs of air flow sensor failure through vibration signatures | May not detect degraded or partially faulty MAF sensors |

| Data Interpretation Complexity | Requires signal processing and spectral analysis (FFT, STFT, etc.) | Often plug-and-play with straightforward code readings |

| Adaptability to Other Faults | Applicable to a wide range of mechanical and combustion faults | Limited to predefined sensor-based errors |

| Non-intrusive Monitoring | No engine disassembly or alteration needed | Often requires physical inspection or sensor replacement |

| Training and Expertise | Requires expertise in vibration analysis | More accessible by using diagnostic scanners |

| 750 RPM (12.5 Hz) | 1500 RPM (25 Hz) | 2250 RPM (37.5 Hz) | 3000 RPM (50 Hz) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NC | FC | RE % | NC | FC | RE % | NC | FC | RE % | NC | FC | RE % | |

| Peak | 14.95 | 24.77 | 65.64 | 16.79 | 15.86 | 5.52 | 19.46 | 14.27 | 26.65 | 44.10 | 21.40 | 51.47 |

| K | 4.85 | 6.2 | 27.77 | 4.01 | 4.86 | 21.24 | 5.50 | 3.76 | 31.62 | 6.33 | 4.08 | 35.43 |

| RMS | 5.67 | 7.20 | 27.01 | 4.87 | 6.28 | 28.97 | 6.57 | 4.78 | 27.17 | 14.80 | 7.88 | 46.72 |

| Av | 8.67 | 10.90 | 25.72 | 10.17 | 7.64 | 24.81 | 9.70 | 7.98 | 17.69 | 21.35 | 12.98 | 39.20 |

| SF | 0.65 | 0.66 | 1.03 | 0.61 | 0.63 | 3.12 | 0.67 | 0.59 | 10.91 | 0.69 | 0.60 | 12.36 |

| CF | 2.50 | 2.87 | 14.59 | 2.60 | 3.05 | 17.34 | 2.89 | 2.54 | 12.07 | 2.83 | 2.54 | 10.34 |

| SD | 4.59 | 6.04 | 31.56 | 3.82 | 6.04 | 57.96 | 5.77 | 2.16 | 62.55 | 14.15 | 4.19 | 70.38 |

| Engine RPM | 750 | 1500 | 2250 | 3000 | Explanation |

|---|---|---|---|---|---|

| Crankshaft | 6.25 Hz | 12.5 Hz | 25 Hz | 50 Hz | Direct rotational frequency |

| Pistons and Connecting Rods | 6.25 Hz | 12.5 Hz | 12.5 Hz | 25 Hz/cylinder | Combustion, 1 cycle every 2 rotations |

| Camshaft | 3.125 Hz | 6.25 Hz | 12.5 Hz | 25 Hz | 1 rotation for every 2 engine rotations |

| Valves | 3.125 Hz | 6.25 Hz | 12.5 Hz | 25 Hz/cylinder | Driven by the camshaft |

| Injectors | 3.125 Hz | 6.25 Hz | 12.5 Hz | 25 Hz/cylinder | 1 injection per engine cycle |

| Timing Chain | 6.25 Hz | 12.5 Hz | 25 Hz | 50 Hz | Linked to the crankshaft |

| Crankshaft Bearings | 6.25 Hz | 12.5 Hz | 25 Hz | 50 Hz + harmonics | Dependent on design; high-frequency harmonics |

| Camshaft Bearings | 3.125 Hz | 6.25 Hz | 12.5 Hz | 25 Hz + harmonics | As they rotate at 25 Hz |

| Parasitic Noises/Imbalances | 3.125 Hz | 6.25 Hz | 12.5 Hz | 2 × 25 Hz or 2 × 50 Hz | Mechanical vibrations and defects |

| Speed (RPM) | Peak Frequencies (Hz) | Amplitude Characteristics | Likely Source (s) | Condition |

|---|---|---|---|---|

| 750 | 3.125–5.0 | Low, structured | Crankshaft, camshaft, timing gear | Healthy |

| 3.25 | High, isolated | Irregular combustion | Faulty | |

| 1500 | 10.0 | Medium | Combustion cycle, injectors, pistons | Healthy |

| 43–50 | Broader, erratic | Combustion anomalies, valve misalign. | Faulty | |

| 2250 | 37.5–50 | High, harmonic | Injectors, valvetrain, timing chain | Healthy |

| 55–75 | Spread, high amplitude | Misfire, delayed combustion, resonance | Faulty | |

| 3000 | 75.0 | Sharp, dominant | Crankshaft harmonics, combustion sync | Healthy |

| >75 | Dense harmonics, unstable | Resonance, air–fuel imbalance | Faulty |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Helali, A.; Belkacem, I.; Abdellaoui, J.; Zegnani, A. Vibration Analysis for Diagnosis of Diesel Engines with Air Flow Sensor Failure. Technologies 2025, 13, 380. https://doi.org/10.3390/technologies13090380

Helali A, Belkacem I, Abdellaoui J, Zegnani A. Vibration Analysis for Diagnosis of Diesel Engines with Air Flow Sensor Failure. Technologies. 2025; 13(9):380. https://doi.org/10.3390/technologies13090380

Chicago/Turabian StyleHelali, Ali, Ines Belkacem, Jamila Abdellaoui, and Achraf Zegnani. 2025. "Vibration Analysis for Diagnosis of Diesel Engines with Air Flow Sensor Failure" Technologies 13, no. 9: 380. https://doi.org/10.3390/technologies13090380

APA StyleHelali, A., Belkacem, I., Abdellaoui, J., & Zegnani, A. (2025). Vibration Analysis for Diagnosis of Diesel Engines with Air Flow Sensor Failure. Technologies, 13(9), 380. https://doi.org/10.3390/technologies13090380