Advanced HVOF-Sprayed Carbide Cermet Coatings as Environmentally Friendly Solutions for Tribological Applications: Research Progress and Current Limitations

Abstract

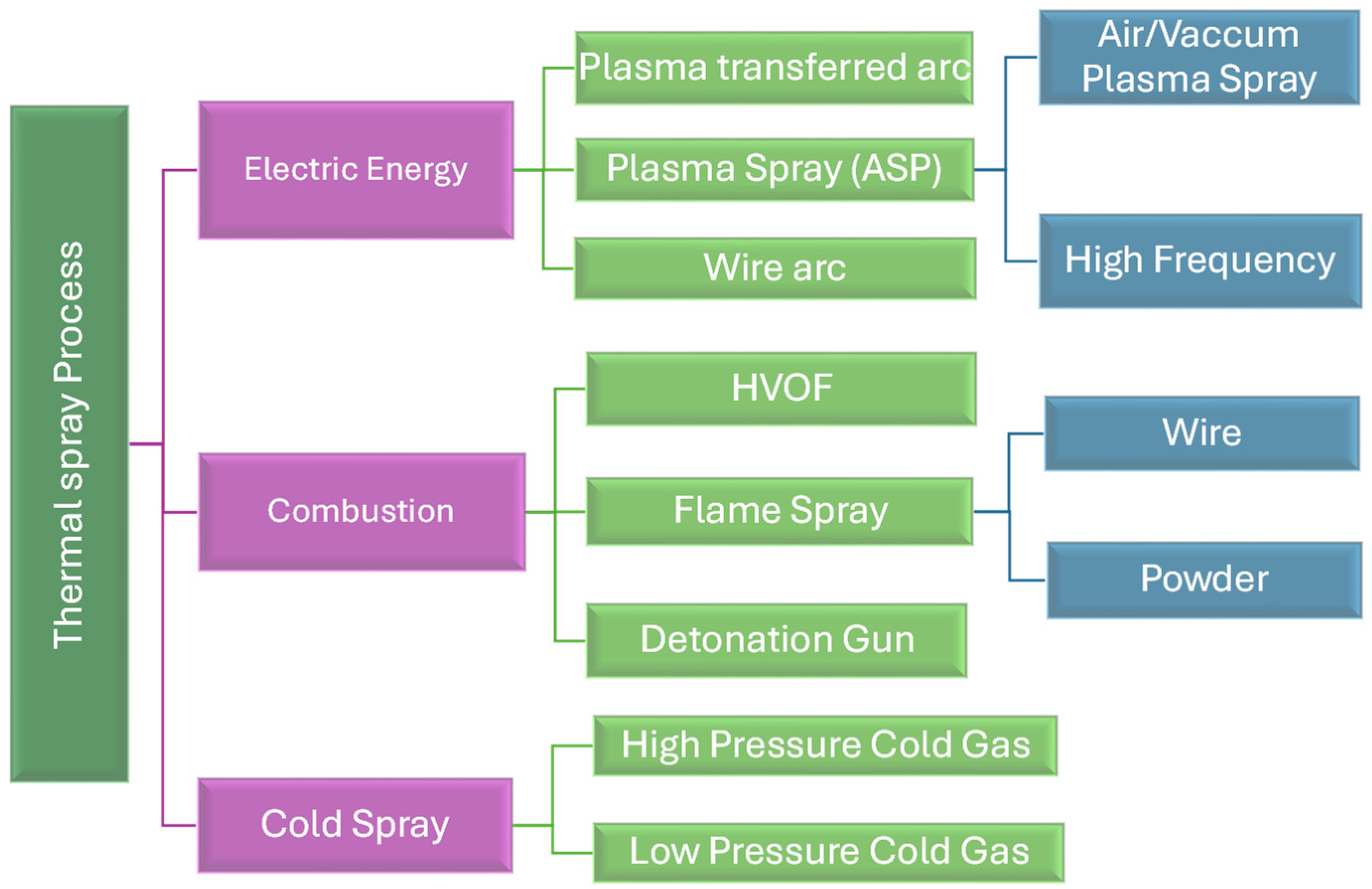

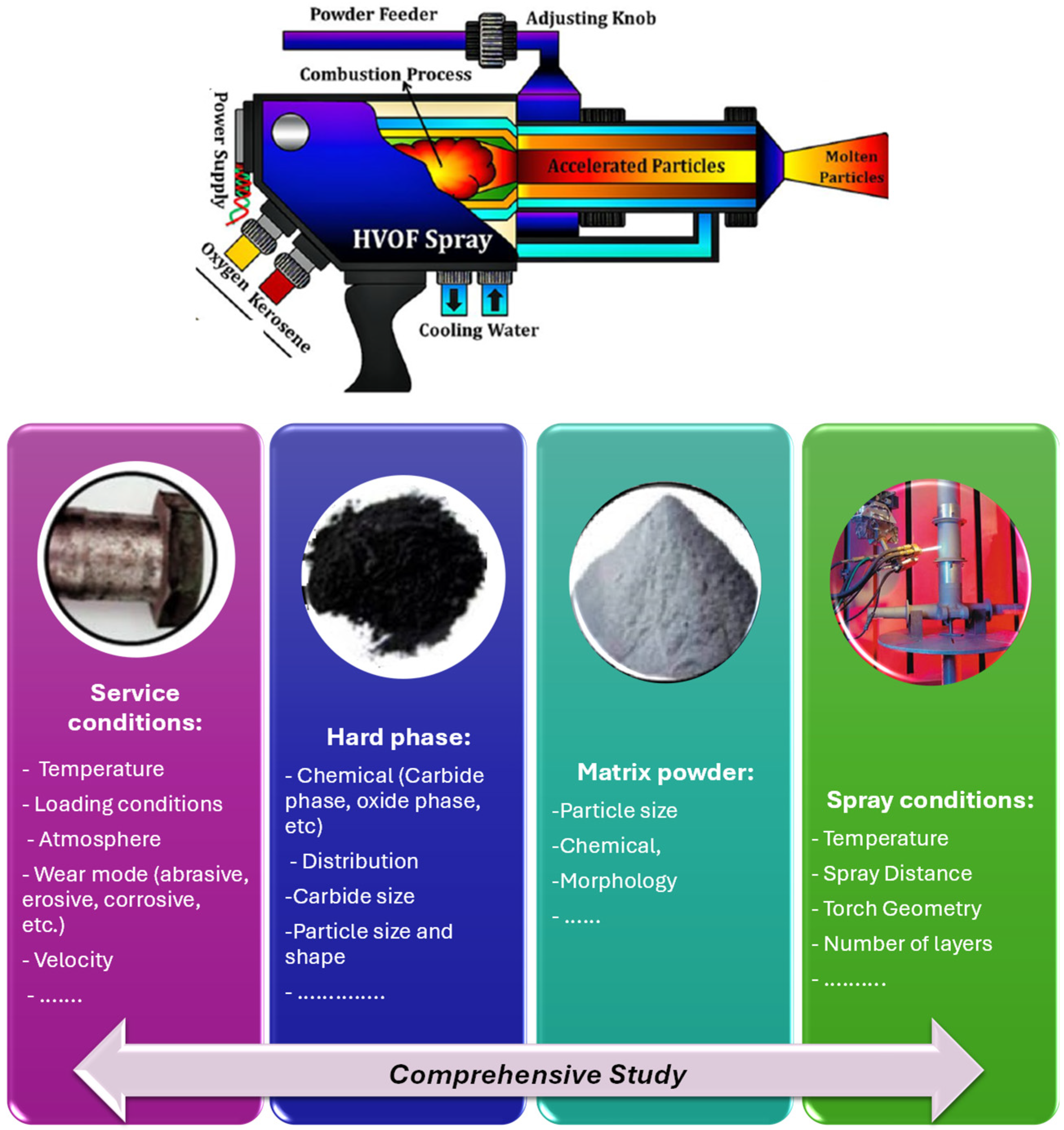

1. Introduction

2. Historical Overview and Performance Standards for HVOF Cermet Coatings

3. Advanced HVOF-Sprayed Coatings for the Automotive Sector

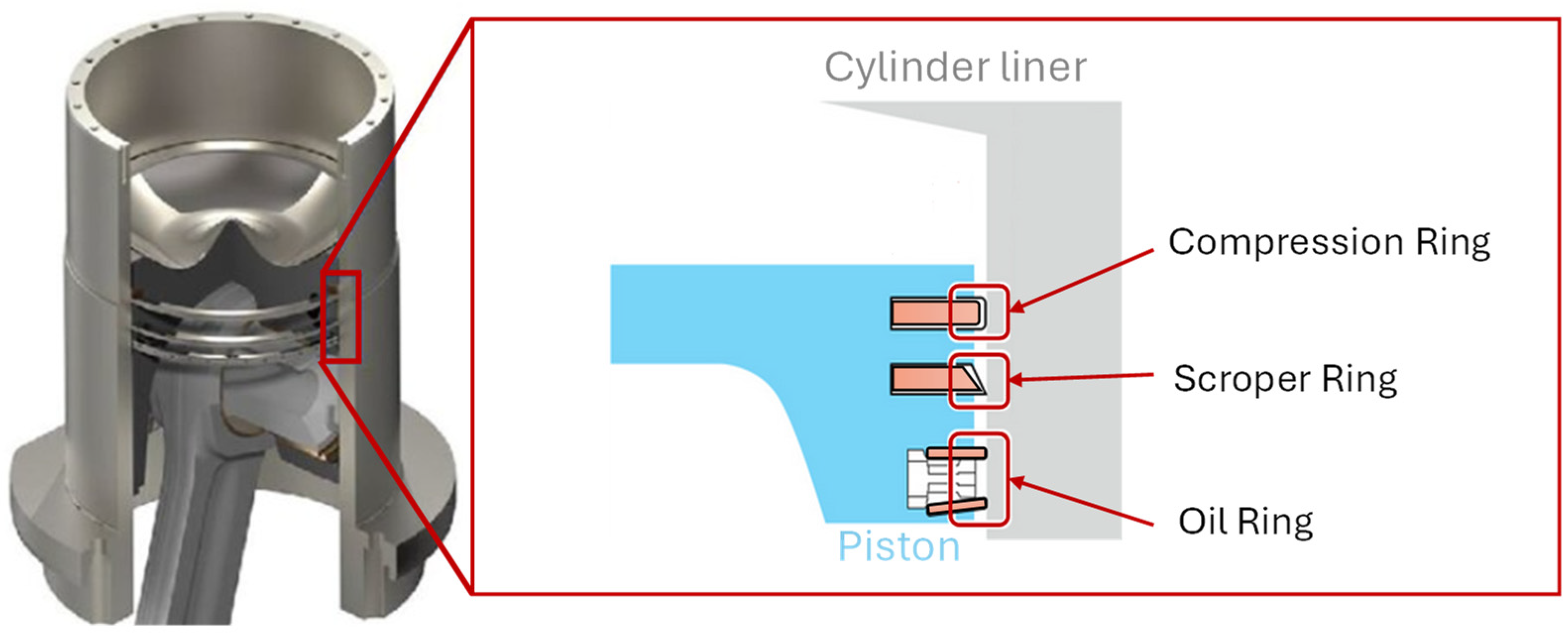

3.1. Internal Combustion Engine

3.2. Brake Assemblies

3.3. Rolling Stock Parts

4. Tribological Performances of Carbide-Alloy Cermet Coatings

4.1. Service Conditions

4.2. Feedstock Powders

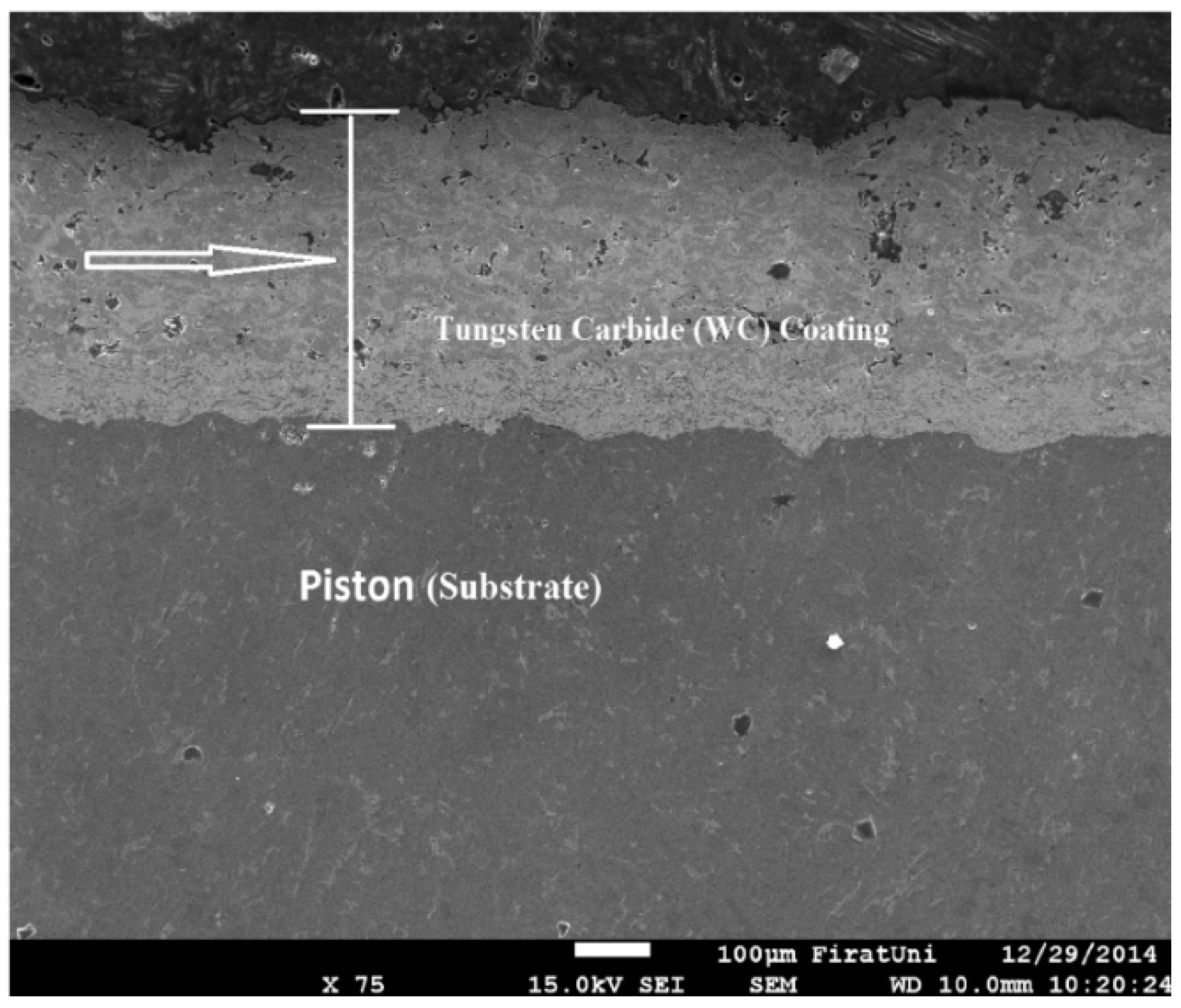

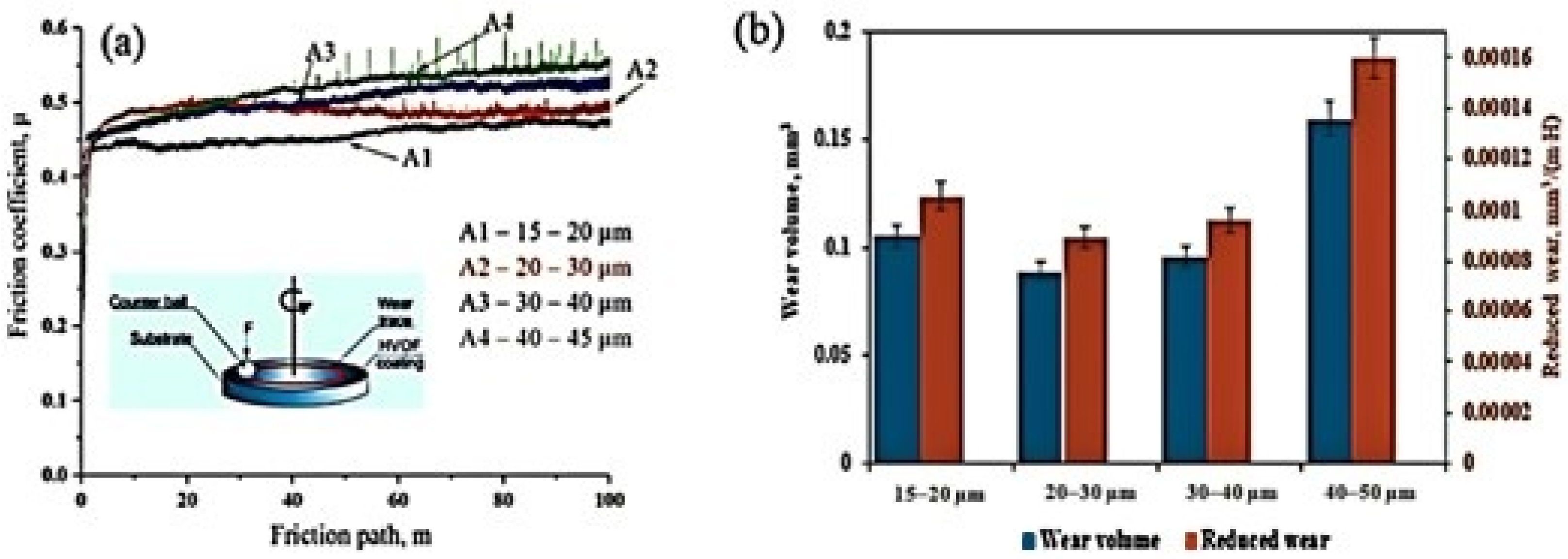

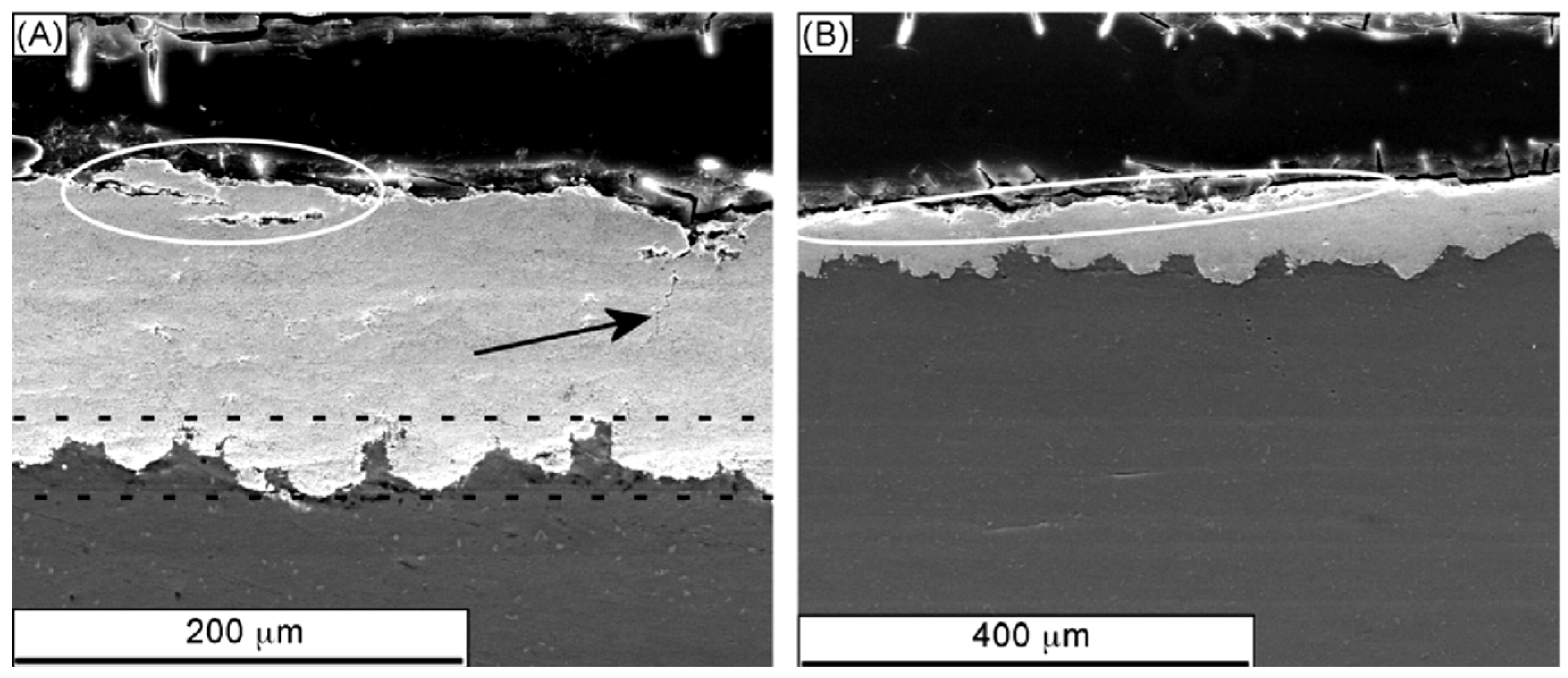

4.3. Thickness Characteristics of Protective Coatings

5. Challenges and Future Scope of HVOF Carbide Cermet Coatings

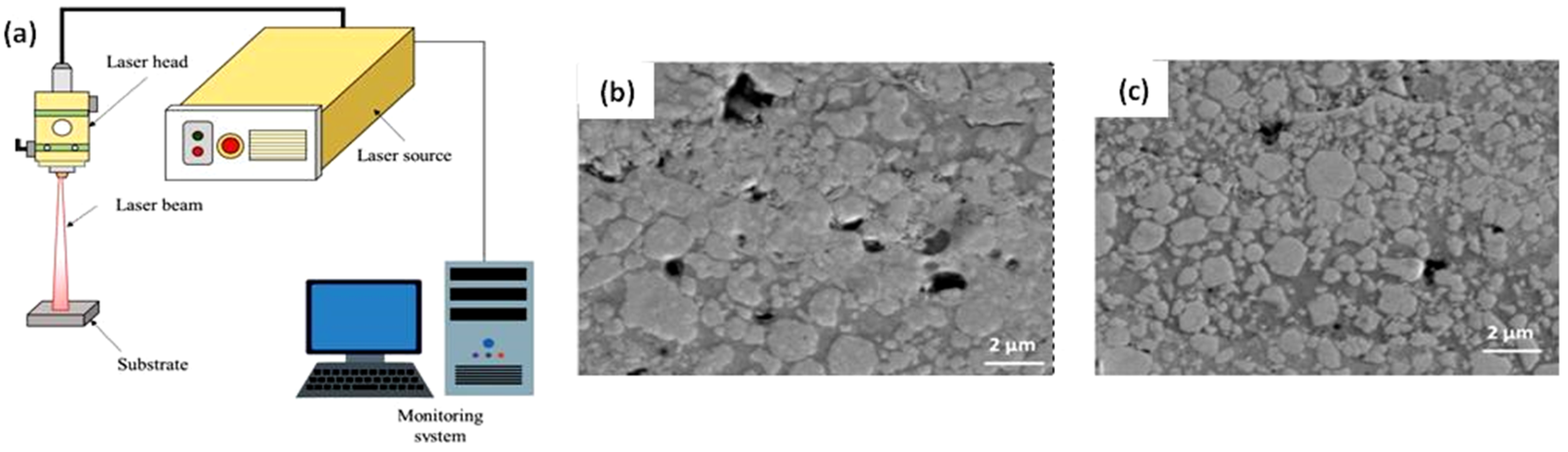

5.1. Fine-Grained Microstructures

5.2. Advances in Multi-Element Alloying

5.2.1. Incorporation of Earth Elements

5.2.2. Incorporation of Transition Metals

5.3. New Techniques for HVOF Spraying

5.3.1. Mixing Methods for Feedstock Powders

5.3.2. Heat Treatment of HVOF-Sprayed Carbide Cermet Coatings

5.3.3. Deep-Learning-Based Prediction of the HVOF Process and Coating Performances

6. Sustainability Considerations in HVOF Coating Processes

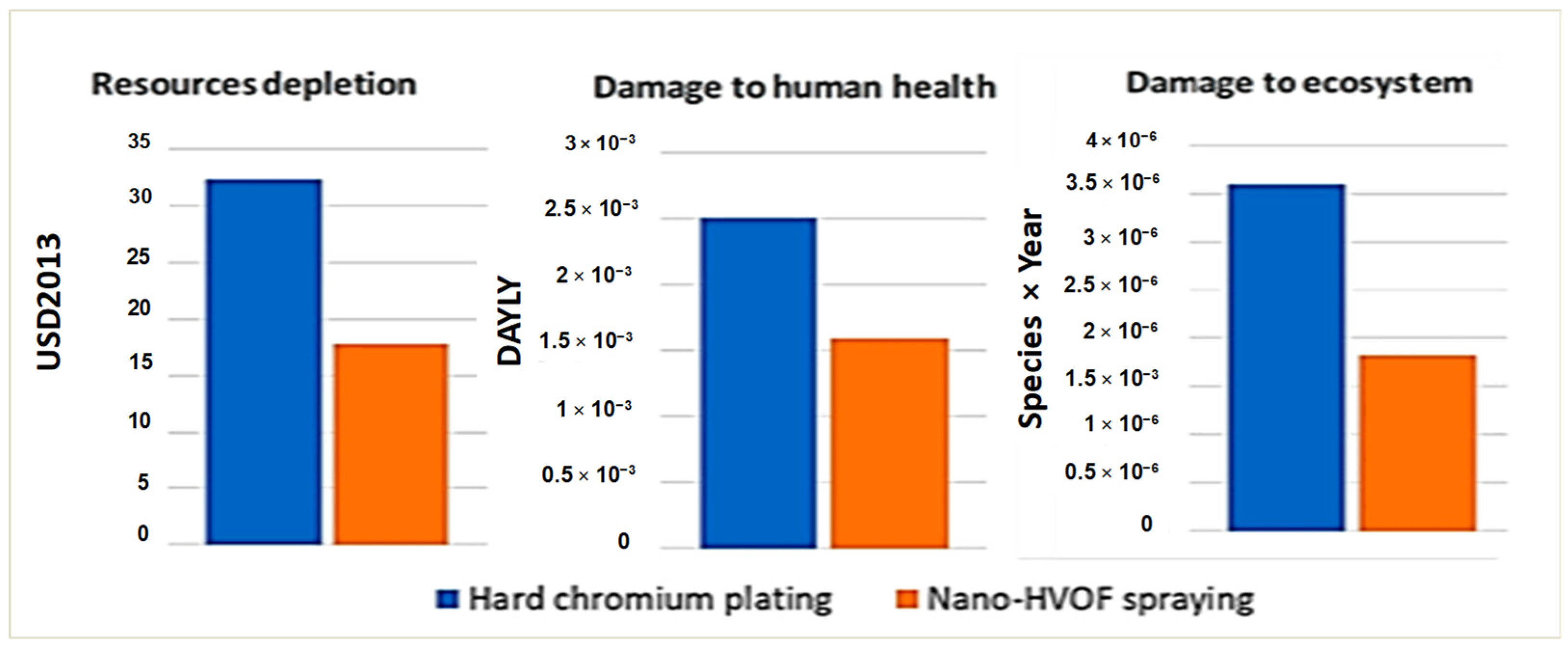

6.1. Process Limitations and Possible Solutions

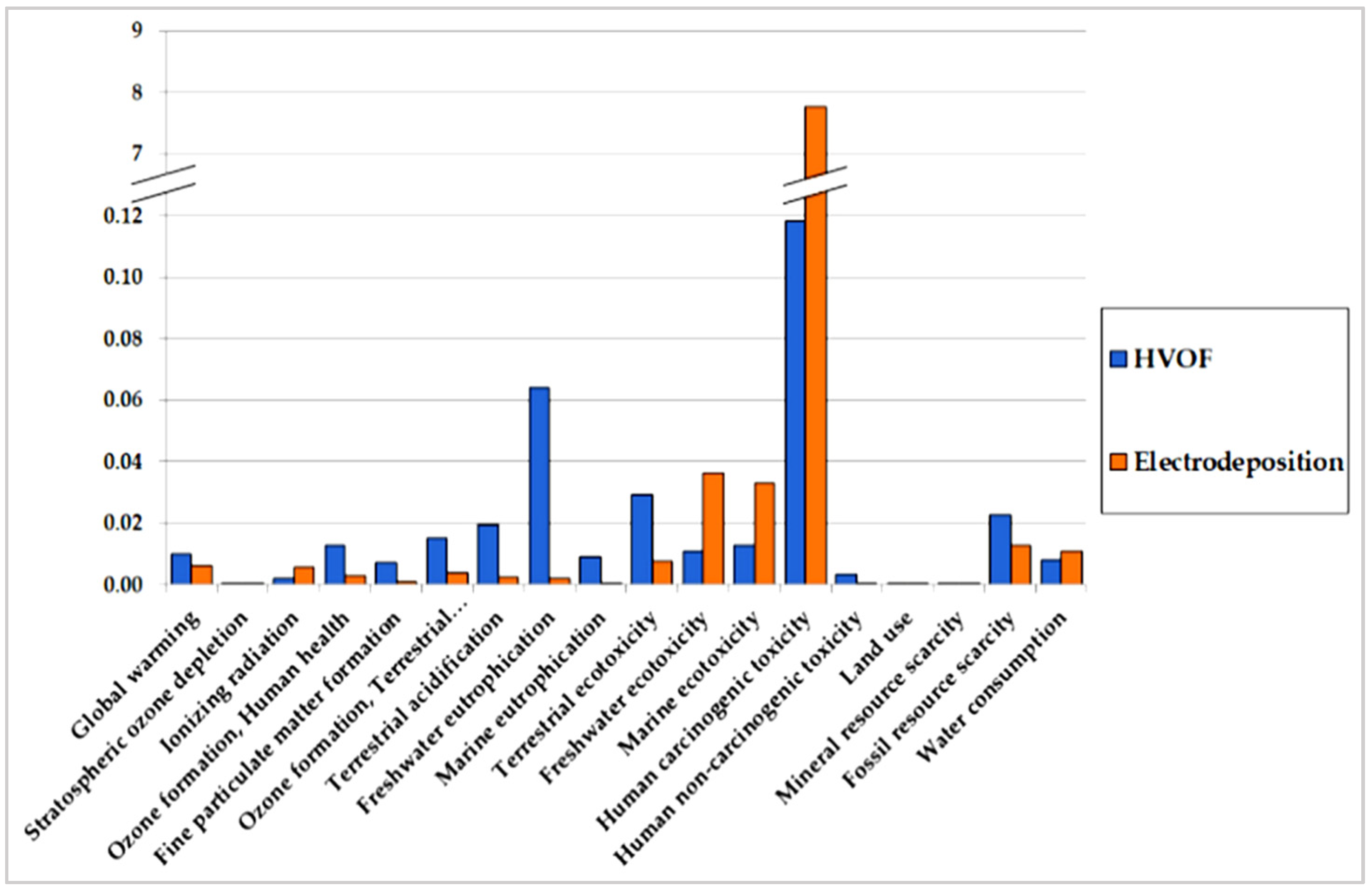

6.2. Environmental Impact Evaluation via Life Cycle Assessment

6.3. Ecological and Health Challenges: Future Directions

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Kumar, S.S.; Prasad, C.D.; Hanumanthappa, H. Role of thermal spray coatings on erosion, corrosion, and oxidation in various applications: A review. J. Bio-Tribo-Corros. 2024, 10, 22. [Google Scholar] [CrossRef]

- Kay, C.M. Thermal spray applications in the steel industry. In ASM Handbook, Volume 5A: Thermal Spray Technology; Tucker, R.C., Ed.; ASM International: Materials Park, OH, USA, 2013; pp. 324–327. [Google Scholar]

- Suresh Babu, P.; Madhavi, Y.; Rama Krishna, L.; Sivakumar, G.; Srinivasa Rao, D.; Padmanabham, G. Thermal spray coatings for erosion–corrosion resistant applications. Trans. Indian Inst. Met. 2020, 73, 2141–2159. [Google Scholar] [CrossRef]

- Azzoug, R.; Mebdoua, Y.; Hellal, F.; Marra, F. Analysis of microstructure, mechanical indentation and corrosive behavior of a thermally sprayed NiFeCrBSi-WC composite coating. J. Alloys Compd. 2021, 900, 163505. [Google Scholar] [CrossRef]

- Ben Difallah, B.; Bouaziz, A.; Horovistiz, A.; Kharrat, M.; Dammak, M.; Cardoso, C.; Pereira, A. Microstructural, mechanical and tribological behaviors of Cu/LLDPE-based composite coatings for lightweight applications. Lubricants 2024, 12, 231. [Google Scholar] [CrossRef]

- Ben Difallah, B.; Bouaziz, A.; Pereira, A.; Kharrat, M.; Cardoso, C.; Dammak, M.; Horovistiz, A. The development of wear-resistant composite coatings onto LLDPE substrate for tribological purposes. J. Coat. Technol. Res. 2025, 22, 1331–1348. [Google Scholar] [CrossRef]

- Hebbale, A.M.; Ramesh, M.R.; Petru, J.; Chandramouli, T.V.; Srinath, M.S.; Shetty, R.K. A Microstructural Study and High-Temperature Oxidation Behaviour of Plasma Sprayed NiCrAlY Based Composite Coatings. Results Eng. 2025, 25, 103926. [Google Scholar] [CrossRef]

- Gafsi, N.; Verdejo, R.; Kharrat, M.; Barletta, M.; López-Manchado, M.Á.; Dammak, M. Effect of filler content on scratch behavior and tribological performance of polyester/graphene oxide nanocomposite coating. J. Coat. Technol. Res. 2021, 18, 1269–1280. [Google Scholar] [CrossRef]

- Richert, M. Thermally sprayed coatings for the protection of industrial fan blades. Materials 2024, 17, 3903. [Google Scholar] [CrossRef]

- Lebedev, A.S.; Kostennikov, S.V. Trends in increasing gas-turbine units efficiency. Therm. Eng. 2008, 55, 461–468. [Google Scholar] [CrossRef]

- Vishnoi, M.; Kumar, P.; Murtaza, Q. A review on coating for hydro-turbine application by HVOF process. In Advances in Materials Engineering and Manufacturing Processes; Springer: Singapore, 2020; pp. 79–103. [Google Scholar] [CrossRef]

- Pulci, G.; Tului, M.; Tirillo, J.; Marra, F.; Lionetti, S.; Valente, T. High temperature mechanical behavior of UHTC coatings for thermal protection of re-entry vehicles. J. Therm. Spray Technol. 2011, 20, 139–144. [Google Scholar] [CrossRef]

- Javed, M.A.; Ang, A.S.M.; Bhadra, C.M.; Piola, R.; Neil, W.C.; Berndt, C.C.; Leigh, M.; Howse, H.; Wade, S.A. Corrosion and mechanical performance of HVOF WC-based coatings with alloyed nickel binder for use in marine hydraulic applications. Surf. Coat. Technol. 2021, 418, 127195. [Google Scholar] [CrossRef]

- Crawmer, D.E. Thermal Spray Processes. In ASM Handbook, Volume 5A: Thermal Spray Technology; Tucker, R.C., Ed.; ASM International: Materials Park, OH, USA, 2013; pp. 33–35. [Google Scholar] [CrossRef]

- Horizon Databook. Thermal Spray Coatings Market Size, Share & Trends Analysis Report By Material (Metal, Ceramics, Abradable), by Technology (Plasma Spray, HVOF), by Application, by Region, and Segment Forecasts, 2024–2030; Report ID 978-1-68038-514-4; Horizon Databook: San Francisco, CA, USA, 2024. [Google Scholar]

- Harabi, F.; Ben Difallah, B.; Kharrat, M.; Aversa, C.; Barletta, M.; El Sayed, Y.M.; Fortunato, M.; Lionetti, S.; Valle, R. Preparation and Characterizations of NiCrFeSiAlBC Coatings via a HVOF Process. In Design and Modeling of Mechanical Systems—VI; Chouchane, M., Abdennadher, M., Aifaoui, N., Chaari, F., Bouaziz, S., Affi, Z., Haddar, M., Romdhane, L., Benamara, A., Eds.; Springer Nature: Cham, Switzerland, 2024; pp. 360–367. [Google Scholar] [CrossRef]

- Gehlen, L.R.; Bolelli, G.; Puddu, P.; Forlin, E.; Colella, A.; Pintaude, G.; Lusvarghi, L. Tribological and electrochemical performances of HVOF sprayed NbC-NiCr coatings. Surf. Coat. Technol. 2023, 474, 130098. [Google Scholar] [CrossRef]

- Berger, L.-M. Application of hardmetals as thermal spray coatings. Int. J. Refract. Met. Hard Mater. 2015, 49, 350–364. [Google Scholar] [CrossRef]

- Cizek, J.; Matejicek, J. Medicine meets thermal spray technology: A review of patents. J. Therm. Spray Technol. 2018, 27, 1251–1279. [Google Scholar] [CrossRef]

- Sadeghi, E.; Markocsan, N.; Joshi, S. Advances in corrosion-resistant thermal spray coatings for renewable energy power plants. Part I: Effect of composition and microstructure. J. Therm. Spray Technol. 2019, 28, 1749–1788. [Google Scholar] [CrossRef]

- Sundararajan, G.; Chavan, N.M.; Sivakumar, G.; Phani, P.S. Evaluation of parameters for assessment of inter-splat bond strength in cold-sprayed coatings. J. Therm. Spray Technol. 2010, 19, 1255–1266. [Google Scholar] [CrossRef]

- Sidhu, T.S.; Prakash, S.; Agrawal, R.D. Studies on the properties of high-velocity oxy-fuel thermal spray coatings for higher temperature applications. Mater. Sci. 2005, 41, 600–606. [Google Scholar] [CrossRef]

- Song, B.; Murray, J.W.; Wellman, R.G.; Pala, Z.; Hussain, T. Dry sliding wear behaviour of HVOF thermal sprayed WC-Co-Cr and WC-CrxCy-Ni coatings. Wear 2020, 442–443, 203114. [Google Scholar] [CrossRef]

- Abhijith, N.V.; Kumar, D.; Kalyansundaram, D. Development of single-stage TiNbMoMnFe high-entropy alloy coating on 304L stainless steel using HVOF thermal spray. J. Therm. Spray Technol. 2022, 31, 1032–1044. [Google Scholar] [CrossRef]

- Ashokkumar, M.; Thirumalaikumarasamy, D.; Thirumal, P.; Barathiraja, R. Influences of mechanical, corrosion, erosion and tribological performance of cold sprayed coatings: A review. Mater. Today Proc. 2021, 46, 7581–7587. [Google Scholar] [CrossRef]

- Yin, S.; Cavaliere, P.; Aldwell, B.; Jenkins, R.; Liao, H.; Li, W.; Lupoi, R. Cold spray additive manufacturing and repair: Fundamentals and applications. Addit. Manuf. 2018, 21, 650–662. [Google Scholar] [CrossRef]

- Joshi, S.; Nylen, P. Advanced coatings by thermal spray processes. Technologies 2019, 7, 79. [Google Scholar] [CrossRef]

- Younus, S.; Arshad, M. Thermal Spray Coating: A Brief Understanding. Int. J. Adv. Res. 2019, 7, 919–928. [Google Scholar] [CrossRef] [PubMed]

- Szeri, A.Z. Tribology: Friction, Lubrication, and Wear; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Belém, M.J.X.; Junior, M.V.; Piran, F.A.S. Eco-efficiency Evaluation of Thermal Spraying Processes Using Data Envelopment Analysis. Process Integr. Optim. Sustain. 2023, 8, 655–668. [Google Scholar] [CrossRef]

- Faisal, N.F.; Prathuru, A. Sustainable Development Goals and Circularity in Thermal Spray Coating Manufacturing and Value Chain. Spraytoday 2024, 4, 8–11. [Google Scholar]

- Barbezat, G. Application of Thermal Spraying in the Automobile Industry. Surf. Coat. Technol. 2006, 201, 2028–2031. [Google Scholar] [CrossRef]

- Ben Difallah, B.; Kharrat, M.; Mebdoua, Y.; Dammak, M. Challenges in Thermal Spray to Design Engineering Coatings and Associated Environmental Concerns. In Advances in Mechanical Engineering, Materials and Mechanics II, ICAMEM 2024; Elleuch, R., Ben Difallah, B., Mnif, R., Baklouti, M., Abdelkefi, A., Kharrat, M., Eds.; Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2025; pp. 168–178. [Google Scholar] [CrossRef]

- Ettmayer, P.; Lengauer, W. The Story of Cermets. Powder Metall. Int. 1989, 21, 37–38. [Google Scholar]

- Schroter. Gesinterte harte Metallegierung und Verfahren zu ihrer Herstellung. German Patent No. 420689, 30 March 1923. [Google Scholar]

- Schwarzkopf, P.; Hirshl, I. Carbide Containing Several Metal Carbides, in Particular for Moldings or Tool Parts. Austrian Patent No. 160172, 1931. [Google Scholar]

- Jose, S.A.; John, M.; Menezes, P.L. Cermet Systems: Synthesis, Properties, and Applications. Ceramics 2022, 5, 210–236. [Google Scholar] [CrossRef]

- Aramian, A.; Sadeghian, Z.; Prashanth, K.G.; Berto, F. In situ fabrication of TiC-NiCr cermets by selective laser melting. Int. J. Refract. Met. Hard Mater. 2020, 87, 105171. [Google Scholar] [CrossRef]

- Elgazzar, A.; Zhou, S.-J.; Ouyang, J.-H.; Liu, Z.-G.; Wang, Y.-J.; Wang, Y.-M. A Critical Review of High-Temperature Tribology and Cutting Performance of Cermet and Ceramic Tool Materials. Lubricants 2023, 11, 122. [Google Scholar] [CrossRef]

- Huo, S.; Wang, Y.; Yao, M.; Zhang, Z.; Chen, L.; Gu, H.; Ouyang, J.; Zhou, Y. Novel TiC-based composites with enhanced mechanical properties. J. Eur. Ceram. Soc. 2021, 41, 5466–5473. [Google Scholar] [CrossRef]

- Zou, B.; Ji, W.; Huang, C.; Wang, J.; Li, S.; Xu, K. Effects of superfine refractory carbide additives on microstructure and mechanical properties of TiB2–TiC+Al2O3 composite ceramic cutting tool materials. J. Alloys Compd. 2014, 585, 192–202. [Google Scholar] [CrossRef]

- Kresse, T.; Meinhard, D.; Bernthaler, T.; Schneider, G. Hardness of WC-Co Hard Metals: Preparation, Quantitative Microstructure Analysis, Structure-Property Relationship and Modelling. Int. J. Refract. Met. Hard Mater. 2018, 75, 287–293. [Google Scholar] [CrossRef]

- Jonda, E.; Łatka, L.; Pakieła, W. Comparison of Different Cermet Coatings Sprayed on Magnesium Alloy by HVOF. Materials 2021, 14, 1594. [Google Scholar] [CrossRef]

- Zamora, R.S.; Sánchez-Orozco, M. A comparative study on slurry erosion behavior of HVOF sprayed coatings. Dyna 2017, 84, 239–246. [Google Scholar] [CrossRef]

- Moskowitz, L.; Trelewicz, K. HVOF Coatings for Heavy-Wear, High-Impact Applications. J. Therm. Spray Technol. 1997, 6, 294–298. [Google Scholar] [CrossRef]

- Wang, Q.; Luo, S.; Wang, S.; Wang, H.; Ramachandran, C.S. Wear, erosion and corrosion resistance of HVOF-sprayed WC and Cr3C2 based coatings for electrolytic hard chrome replacement. Int. J. Refract. Met. Hard Mater. 2019, 81, 242–252. [Google Scholar] [CrossRef]

- Ozkan, D. Structural characteristics and wear, oxidation, hot corrosion behaviors of HVOF sprayed Cr3C2-NiCr hardmetal coatings. Surf. Coat. Technol. 2023, 457, 129319. [Google Scholar] [CrossRef]

- Verstak, A.; Baranovski, V. AC-HVAF Sprayed Tungsten Carbide: Properties and Applications. In Proceedings of the International Thermal Spray Conference (ITSC 2006), Seattle, WA, USA, 15–17 May 2006; pp. 643–648. [Google Scholar] [CrossRef]

- Lakhdari, R.; Fernandes, F.; Antunes, P.V.; Mebdoua, Y.; Cavaleiro, A. Fe-based (W,Ti)C EAS and WC-12Co HVOF sprayed coatings: Microstructure, mechanical properties, and micro-scale abrasion performance. Mater. Res. Express 2019, 6, 096580. [Google Scholar] [CrossRef]

- Berghaus, J.O.; Marple, B.; Moreau, C. Suspension Plasma Spraying of Nanostructured WC-12Co Coatings. J. Therm. Spray Technol. 2006, 15, 676–681. [Google Scholar] [CrossRef]

- Kapsiz, M.; Durat, M.; Ficici, F. Friction and wear studies between cylinder liner and piston ring pair using Taguchi design method. Adv. Eng. Softw. 2011, 42, 595–603. [Google Scholar] [CrossRef]

- Gangopadhyay, A. A Review of Automotive Engine Friction Reduction Opportunities Through Technologies Related to Tribology. Trans. Indian Inst. Met. 2017, 70, 527–535. [Google Scholar] [CrossRef]

- Uzun, A.; Altuncu, E.; Ustel, F.; Turk, A.; Ozturk, S. Investigation of wear behaviour of HVOF sprayed WC-Co coatings for automotive parts in different working conditions. Int. J. Surf. Sci. Eng. 2011, 5, 180–192. [Google Scholar] [CrossRef]

- Asgari, H.; Saha, G.; Mohammadi, M. Tribological behavior of nanostructured high velocity oxy-fuel (HVOF) thermal sprayed WC-17NiCr coatings. Ceram. Int. 2017, 43, 2123–2135. [Google Scholar] [CrossRef]

- Holmberg, K.; Andersson, P.; Nylund, N.-O.; Mäkelä, K.; Erdemir, A. Global energy consumption due to friction in trucks and buses. Tribol. Int. 2014, 78, 94–114. [Google Scholar] [CrossRef]

- Singh, D.; Subramanian, K.A.; Singal, S.K. Emissions and fuel consumption characteristics of a heavy-duty diesel engine fueled with Hydroprocessed Renewable Diesel and Biodiesel. Appl. Energy 2015, 155, 440–446. [Google Scholar] [CrossRef]

- Söderfjäll, M.; Herbst, H.M.; Larsson, R.; Almqvist, A. Influence on friction from piston ring design, cylinder liner roughness and lubricant properties. Tribol. Int. 2017, 116, 272–284. [Google Scholar] [CrossRef]

- Pandey, S.M.; Murtaza, Q.; Walia, R.S. Study of dry wear behavior and morphological characteristic of 60%Mo-20%NiCr-10%CrC-10%Mo+Fe based alloy coating by atmospheric plasma spray technique. Adv. Mater. Process. Technol. 2017, 3, 393–406. [Google Scholar] [CrossRef]

- Baker, A.; Gazzard, S. Developments in materials for pistons. Mater. Des. 1988, 9, 28–33. [Google Scholar] [CrossRef]

- Mishra, P.C.; Roychoudhury, A.; Banerjee, A.; Saha, N.; Das, S.R.; Das, A. Coated piston ring pack and cylinder liner elastodynamics in correlation to piston subsystem elastohydrodynamic: Through FEA modelling. Lubricants 2023, 11, 192. [Google Scholar] [CrossRef]

- Ferreira, R.; Martins, J.; Carvalho, Ó.; Sobral, L.; Carvalho, S.; Silva, F. Tribological solutions for engine piston ring surfaces: An overview on the materials and manufacturing. Mater. Manuf. Process. 2019, 34, 498–520. [Google Scholar] [CrossRef]

- Abdelbary, A.; Chang, L. Practical Applications of Tribology. In Principles and Applications of Tribology, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar] [CrossRef]

- Scott, D.; Smith, A.I.; Tait, J.; Tremain, G.R. Materials and metallurgical aspects of piston ring scuffing—A literature survey. Wear 1975, 33, 293–315. [Google Scholar] [CrossRef]

- Shen, Y.; Ye, B.; Yu, B.; Liu, Z.; Huang, R.; Xu, J. Enhancement of heavy-duty friction and wear characteristics of cast-iron surface by electrolytic micro-textures filled with MoS2. Surf. Coat. Technol. 2021, 408, 126806. [Google Scholar] [CrossRef]

- Arsha, A.; Jayakumar, E.; Rajan, T.; Antony, V.; Pai, B. Design and fabrication of functionally graded in-situ aluminium composites for automotive pistons. Mater. Des. 2015, 88, 1201–1209. [Google Scholar] [CrossRef]

- Carvalho, O.; Buciumeanu, M.; Madeira, S.; Soares, D.; Silva, F.; Miranda, G. Optimization of AlSi–CNTs functionally graded material composites for engine piston rings. Mater. Des. 2015, 80, 163–173. [Google Scholar] [CrossRef]

- Holmberg, K.; Andersson, P.; Erdemir, A. Global energy consumption due to friction in passenger cars. Tribol. Int. 2012, 47, 221–234. [Google Scholar] [CrossRef]

- Tyagi, A.; Pandey, S.M.; Walia, R.S.; Murtaza, Q. Characterization and parametric optimization of tribological properties of Mo blend composite coating. Mater. Res. Express 2019, 6, 086428. [Google Scholar] [CrossRef]

- Picas, J.A.; Forn, A.; Matthäus, G. HVOF coatings as an alternative to hard chrome for pistons and valves. Wear 2006, 261, 477–484. [Google Scholar] [CrossRef]

- Chakradhar, R.P.S.; Prasad, G.; Venkateswarlu, K.; Rameshbabu, N. An Investigation on the Wear and Corrosion Behavior of HVOF-Sprayed WC-12Co-Al2O3 Cermet Coating. J. Mater. Eng. Perform. 2018, 27, 1241–1248. [Google Scholar] [CrossRef]

- Sundararajan, G.; Joshi, S.V.; Rama Krishna, L. Engineered Surfaces for Automotive Engine and Power Train Components. Curr. Opin. Chem. Eng. 2016, 11, 1–6. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, Y.; Liao, B. A Review on Preparation Process and Tribological Performance of Coatings for Internal Combustion Engine Piston Ring. Adv. Mech. Eng. 2023, 15. [Google Scholar] [CrossRef]

- Zheng, Y. Plating Hard Chrome Plating Alternative Technologies—HVOF Tungsten Carbide Coating. Adv. Mater. Res. 2013, 712–715, 395–398. [Google Scholar] [CrossRef]

- Hazra, S.; Sabiruddin, K.; Bandyopadhyay, P.P. Plasma and HVOF Sprayed WC–Co Coatings as Hard Chrome Replacement Solution. Surf. Eng. 2012, 28, 37–43. [Google Scholar] [CrossRef]

- Picas, J.A.; Punset, M.; Baile, M.T.; Martín, E.; Forn, A. Tribological Evaluation of HVOF Thermal-Spray Coatings as a Hard Chrome Replacement. Surf. Interface Anal. 2011, 43, 1346–1353. [Google Scholar] [CrossRef]

- Bolelli, G.; Lusvarghi, L.; Barletta, M. HVOF-Sprayed WC–CoCr Coatings on Al Alloy: Effect of the Coating Thickness on the Tribological Properties. Wear 2009, 267, 944–953. [Google Scholar] [CrossRef]

- Mueller, C.J.; Cannella, W.J.; Bays, J.T.; Bruno, T.J.; DeFabio, K.; Dettman, H.D.; Gieleciak, R.M.; Huber, M.L.; Kweon, C.; McConnell, S.S.; et al. Diesel Surrogate Fuels for Engine Testing and Chemical-Kinetic Modeling: Compositions and Properties. Energy Fuels 2016, 30, 1445–1461. [Google Scholar] [CrossRef] [PubMed]

- Hazar, H.; Gul, H. New Modeling and Experimental Study Regarding Tungsten-Carbide-Coated Parts of the Combustion Chamber of a Compression-Ignition Engine. Energy Fuels 2016, 30, 5148–5157. [Google Scholar] [CrossRef]

- Öz, A.; Gürbüz, H.; Yakut, A.K.; Kıvak, T.; Ayyıldız, M. Braking Performance and Noise in Excessively Worn Brake Discs Coated with HVOF Thermal Spray Process. J. Mech. Sci. Technol. 2017, 31, 535–543. [Google Scholar] [CrossRef]

- Federici, M.; Menapace, C.; Moscatelli, A.; Gialanella, S.; Straffelini, G. Pin-on-Disc Study of a Friction Material Dry Sliding Against HVOF Coated Discs at Room Temperature and 300 °C. Tribol. Int. 2017, 115, 89–99. [Google Scholar] [CrossRef]

- Straffelini, G.; Federici, M. HVOF Cermet Coatings to Improve Sliding Wear Resistance in Engineering Systems. Coatings 2020, 10, 886. [Google Scholar] [CrossRef]

- Kılıç, H.; Mısırlı, C. Investigation of Tribological Behavior of 20NiCrBSi-WC12Co Coated Brake Disc by HVOF Method. Mater. Res. Express 2020, 7, 016560. [Google Scholar] [CrossRef]

- Hinrichs, R.; Soares, M.R.F.; Lamb, R.G.; Vasconcellos, M.A.Z. Phase Characterization of Debris Generated in Brake Pad Coefficient of Friction Tests. Wear 2011, 270, 515–519. [Google Scholar] [CrossRef]

- Gultekin, D.; Uysal, M.; Aslan, S.; Alaf, M.; Guler, M.O.; Akbulut, H. The Effects of Applied Load on the Coefficient of Friction in Cu-MMC Brake Pad/Al-SiCp MMC Brake Disc System. Wear 2010, 270, 73–82. [Google Scholar] [CrossRef]

- Kılıç, H.; Misirli, C.; Mutlu, İ. Investigating the Braking and Tribological Features of Granite Powder Additive Brake Linings. J. Balk. Tribol. Assoc. 2018, 28, 52–63. [Google Scholar]

- Timur, M.; Kılıç, H. Marble Waste Using Produced of Automotive Brake Pad of Friction Coefficient Different Pad Brake Pads with Comparison. Pamukkale Univ. J. Eng. Sci. 2013, 19, 10–14. [Google Scholar] [CrossRef]

- Österle, W.; Urban, I. Third Body Formation on Brake Pads and Rotors. Tribol. Int. 2006, 39, 401–408. [Google Scholar] [CrossRef]

- Federici, M.; Menapace, C.; Moscatelli, A.; Gialanella, S.; Straffelini, G. Effect of Roughness on the Wear Behavior of HVOF Coatings Dry Sliding Against a Friction Material. Wear 2016, 368–369, 326–334. [Google Scholar] [CrossRef]

- Wank, A.; Schmengler, C.; Krause, A.; Müller-Roden, K.; Wessler, T. Environmentally Friendly Protective Coatings for Brake Disks. J. Therm. Spray Technol. 2023, 32, 443–455. [Google Scholar] [CrossRef]

- Vostřák, M.; Brodský, J.; Houdková, Š.; Šulcová, P. Possibilities of Using Thermally Sprayed Coatings for Surface Treatment of Rail Vehicles Components. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1178, 012065. [Google Scholar] [CrossRef]

- Vostřák, M.; Šulcová, P.; Naďová, J. Corrosion Resistance of Selected Rail Vehicles Components Treated by Thermal Spraying. Metal 2021, 30, 852–857. [Google Scholar] [CrossRef]

- Khuengpukheiw, R.; Wisitsoraat, A.; Saikaew, C. Wear Behaviors of HVOF-Sprayed NiSiCrFeB, WC-Co/NiSiCrFeB and WC-Co Coatings Evaluated Using a Pin-on-Disc Tester with C45 Steel Pins. Wear 2021, 484–485, 203699. [Google Scholar] [CrossRef]

- Wesmann, J.A.R.; Espallargas, N. Effect of Atmosphere, Temperature and Carbide Size on the Sliding Friction of Self-Mated HVOF WC–CoCr Contacts. Tribol. Int. 2016, 101, 301–313. [Google Scholar] [CrossRef]

- Prasad, C.D.; Soni, P.K.; Nagaraja, K.C.; Eswaran, A.; Kumar, R.S.; Deshmukh, K.; Shrivastava, R.; Tiwari, A. Studies on Wear and Microstructure Assessment of WC-Co Reinforced Iron-Based HVOF Coating. Results Surf. Interfaces 2024, 15, 100237. [Google Scholar] [CrossRef]

- Bolelli, G.; Berger, L.-M.; Bonetti, M.; Lusvarghi, L. Comparative Study of the Dry Sliding Wear Behaviour of HVOF-Sprayed WC–(W,Cr)2C–Ni and WC–CoCr Hard Metal Coatings. Wear 2014, 309, 96–111. [Google Scholar] [CrossRef]

- Aristizabal, M.; Ardila, L.C.; Veiga, F.; Arizmendi, M.; Fernandez, J.; Sánchez, J.M. Comparison of the Friction and Wear Behaviour of WC–Ni–Co–Cr and WC–Co Hard Metals in Contact with Steel at High Temperatures. Wear 2012, 280–281, 15–21. [Google Scholar] [CrossRef]

- Ulmanu, V.; Bădicioiu, M.; Călțaru, M.; Zecheru, G.; Drăghici, G.; Minescu, M.; Preda, C. Research Regarding the Hardfacing of Petroleum Gate Valves by Using High Velocity Oxygen Fuel Technology. J. Balk. Tribol. Assoc. 2010, 16, 551–557. [Google Scholar]

- Călțaru, M.; Bădicioiu, M.; Rîpeanu, R.G. Establishing the Tribological Behaviour of HVOF Hardfacing Applied at Petroleum Gate Valves. J. Balk. Tribol. Assoc. 2013, 19, 448–460. [Google Scholar]

- Ozkavak, H.V.; Sahin, S.; Sarac, M.F.; Alkan, Z. Wear Properties of WC–Co and WC–CoCr Coatings Applied by HVOF Technique on Different Steel Substrates. Mater. Test. 2020, 62, 1235–1242. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Muktanova, N.; Kakimzhanov, D.; Satbayeva, Z.; Kassenova, L.; Magazov, N. Investigation of the Influence of Powder Fraction on Tribological and Corrosion Characteristics of 86WC-10Co-4Cr Coating Obtained by HVOF Method. Coatings 2024, 14, 651. [Google Scholar] [CrossRef]

- Bouaricha, S.; Marple, B.R. Phase Structure–Mechanical Property Relationships in HVOF-Sprayed WC-12Co Coatings. In Proceedings of the International Thermal Spray Conference (ITSC 2004), Osaka, Japan, 10–12 May 2004; pp. 516–524. [Google Scholar] [CrossRef]

- de Villiers Lovelock, H.L. Powder/Processing/Structure Relationships in WC-Co Thermal Spray Coatings: A Review of the Published Literature. J. Therm. Spray Technol. 1998, 7, 357–373. [Google Scholar] [CrossRef]

- Jonda, E.; Łatka, L.; Lont, A.; Gołombek, K.; Szala, M. The Effect of HVOF Spray Distance on Solid Particle Erosion Resistance of WC-Based Cermets Bonded by Co, Co-Cr and Ni Deposited on Mg-Alloy Substrate. Adv. Sci. Technol. Res. J. 2024, 18, 115–128. [Google Scholar] [CrossRef]

- Wank, B.; Wielage, H.; Pokhmurska, E.; Friesen, G.; Reisel, G. Comparison of Hard Metal and Hard Chromium Coatings Under Different Tribological Conditions. Surf. Coat. Technol. 2006, 201, 1975–1980. [Google Scholar] [CrossRef]

- Houdková, Š.; Zahálka, F.; Kašparová, M.; Berger, L.-M. Comparative Study of Thermally Sprayed Coatings Under Different Types of Wear Conditions for Hard Chromium Replacement. Tribol. Lett. 2011, 43, 139–154. [Google Scholar] [CrossRef]

- Matikainen, V.; Bolelli, G.; Koivuluoto, H.; Sassatelli, P.; Lusvarghi, L.; Vuoristo, P. Sliding Wear Behaviour of HVOF and HVAF Sprayed Cr3C2-Based Coatings. Wear 2017, 388–389, 57–71. [Google Scholar] [CrossRef]

- European Parliament and Council. Regulation (EC) No 1907/2006 of 18 December 2006 Concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH), Establishing a European Chemicals Agency. Off. J. Eur. Union 2006, L396, 1–849. [Google Scholar]

- Viegas, V. Self-Classification of Cobalt Compounds for Reproductive Toxicity under UN GHS; Cobalt Institute: London, UK, 2019; Available online: https://coilink.org/20.500.12592/jx9z7d (accessed on 8 February 2025).

- Tercero Espinoza, L.A.; Hummen, T.; Brunot, A.; Peña Garay, I.; Velte, D.; Smuk, L.; Todorovic, J.; van der Eijk, C.; Joce, C. CRM InnoNet Substitution of Critical Raw Materials: Critical Raw Materials Substitution Profiles, September 2013; Revised May 2015; European Commission: Brussels, Belgium, 2015. [CrossRef]

- International Nickel Study Group. The World Nickel Factbook 2021; INSG: Lisbon, Portugal, 2021; Available online: https://insg.org/wp-content/uploads/2022/02/publist_The-World-Nickel-Factbook-2021.pdf (accessed on 15 February 2025).

- Chandramouli, T.V.; Joladarashi, S.; Ramesh, M.R.; Rahman, M.R. Microstructure, Mechanical Properties, and Tribological Properties of Fe-Based Composite Coatings Reinforced with WC-Co and Cr3C2. J. Mater. Eng. Perform. 2024, 34, 10323–10338. [Google Scholar] [CrossRef]

- Terajima, T.; Takeuchi, F.; Nakata, K.; Adachi, S.; Nakashima, K.; Igarashi, T. Composite Coating Containing WC/12Co Cermet and Fe-Based Metallic Glass Deposited by High-Velocity Oxygen Fuel Spraying. J. Alloys Compd. 2010, 504 (Suppl. 1), S288–S291. [Google Scholar] [CrossRef]

- Ma, X.; Ruggerio, P. A Comparative Investigation of Feedstock Materials on Multiple Properties of HVOF-Formed Cr3C2-NiCr Coatings: Size Effects of Powders and Carbides on Sliding Abrasive Wear Behavior. In Proceedings of the International Thermal Spray Conference (ITSC 2024), Singapore, 29 April–1 May 2024; pp. 558–569. [Google Scholar] [CrossRef]

- Matthäus, G.; Bobzin, K.; Lugscheider, E.; Zwick, J. Coating Properties of HVOF Sprayed Carbide-Based Ultrafine Powders. In Proceedings of the International Thermal Spray Conference (ITSC 2006), Seattle, WA, USA, 15–17 May 2006; pp. 673–678. [Google Scholar] [CrossRef]

- Valarezo, A.; Bolelli, G.; Choi, W.B.; Sampath, S.; Cannillo, V.; Lusvarghi, L.; Rosa, R. Damage Tolerant Functionally Graded WC–Co/Stainless Steel HVOF Coatings. Surf. Coat. Technol. 2010, 205, 2197–2205. [Google Scholar] [CrossRef]

- Matějíček, J.; Kavka, T.; Mušálek, R.; Ctibor, P.; Medřický, J.; Vilémová, M.; Nevrlá, B.; Degot, S.; Denoirjean, A. Tungsten steel Composites and FGMs Prepared by Argon-Shrouded Plasma Spraying. Surf. Coat. Technol. 2021, 406, 126746. [Google Scholar] [CrossRef]

- Bolelli, G.; Cannillo, V.; Lusvarghi, L.; Rosa, R.; Valarezo, A.; Choi, W.B.; Dey, R.; Weyant, C.; Sampath, S. Functionally Graded WC–Co/NiAl HVOF Coatings for Damage Tolerance, Wear and Corrosion Protection. Surf. Coat. Technol. 2012, 206, 2585–2601. [Google Scholar] [CrossRef]

- Ranjan, P.; Kumar, R.; Walia, R.S.; Yadav, V.K. Experimental and Computational Investigation of FGM Coated Cylinder Liners Prepared Using HVOF Technique. Phys. Scr. 2024, 99, 085045. [Google Scholar] [CrossRef]

- Zhang, S.J.; Zhu, X.P.; Yuan, J.R.; Lei, M.K. Impact Resistance of Thick WC-Ni-Coated Steel Components by Thermal Spray. J. Therm. Spray Technol. 2023, 32, 1796–1810. [Google Scholar] [CrossRef]

- Jonda, E.; Łatka, L.; Godzierz, M.; Olszowska, K. Microstructure, Residual Stress and Mechanical Properties of Double Carbides Cermet Coatings Manufactured on AZ31 Substrate by High Velocity Oxy-Fuel Spraying. Arch. Civ. Mech. Eng. 2024, 24, 61. [Google Scholar] [CrossRef]

- Ibarra, J.J.; González, M.A.; Rodríguez, E.; Vásquez, G.I.; Medina, A.; Bernal Ponce, J.L.; Aguilar, C.; Velez, E.E. Enhanced Fracture Toughness of WC-CoCr Thermally Sprayed Coatings by the Addition of NiCrFeSiBC and Mo and Its Influence on Sliding Wear Behavior. Coatings 2024, 14, 1207. [Google Scholar] [CrossRef]

- Bobzin, K.; Wietheger, W.; Burbaum, E.; Johann, L.M.; Rempe, L.J.; Matikainen, V.; Kanerva, U.; Karhu, M.; Lagerbom, J.; Kaunisto, K.; et al. Investigation of Novel Nano-Carbide WC/CoCr Coatings Applied by HVAF. J. Therm. Spray Technol. 2023, 32, 1772–1779. [Google Scholar] [CrossRef]

- Venturi, F.; Rincón Romero, A.; Hussain, T. SiC/YAG Composite Coatings by a Novel Liquid Fuelled High Velocity Oxy-Fuel Suspension Thermal Spray. Surf. Coat. Technol. 2023, 471, 129865. [Google Scholar] [CrossRef]

- Taghian, M.; Heydarian, M.; Torkian, S.; Dabir, M.P.; Bahrami, A.; Mousavi Anijdan, S.H.; Park, N. High-Velocity Oxy-Fuel (HVOF) Spray Coating of Inconel, Colmonoy, and Aluminum on AISI 316L Stainless Steel: A Comparative Investigation of the Microstructure and Corrosion Resistance of Coatings. Coatings 2023, 13, 204. [Google Scholar] [CrossRef]

- Shu, W.; Deng, X.; Guo, W.; Shi, W.; Li, S.; Zhang, B.; Cui, Q. Microstructure and Wear Resistance of HVOF Sprayed WC-10Co-4Cr Coating on Ti-6Al-4V. Heat Treat. Surf. Eng. 2022, 4, 70–75. [Google Scholar] [CrossRef]

- Guo, L.; Lu, L.; Wang, G.; Zhang, F.; Luo, B.; Huang, H.; Lin, J.; Yang, J. Design, Preparation and Diffusion Research of the W Coating Used in W-Based Cermet for Nuclear Thermal Propulsion. Int. J. Refract. Met. Hard Mater. 2024, 122, 106716. [Google Scholar] [CrossRef]

- Nemanič, V.; Zajec, B.; Dellasega, D.; Passoni, M. Hydrogen Permeation through Disordered Nanostructured Tungsten Films. J. Nucl. Mater. 2012, 429, 92–98. [Google Scholar] [CrossRef]

- Gordillo, N.; Gómez de Castro, C.; Tejado, E.; Pastor, J.Y.; Balabanian, G.; Panizo-Laiz, M.; Gonzalez-Arrabal, R.; Perlado, J.M.; del Rio, J. On the Thermal Stability of the Nanostructured Tungsten Coatings. Surf. Coat. Technol. 2017, 325, 588–593. [Google Scholar] [CrossRef]

- Singh, S.; Osi, A.; Joshi, V.V.; Wade, S.; Berndt, C.C.; Schläfer, T.; Howse, H.; Ang, A.S.M. Development of Fine WC-NiCr Powder Coatings by Optimising HVOF Spray Parameters. Int. J. Refract. Met. Hard Mater. 2024, 121, 106667. [Google Scholar] [CrossRef]

- Murugan, K.; Ragupathy, A.; Balasubramanian, V.; Sridhar, K. Optimizing HVOF Spray Process Parameters to Attain Minimum Porosity and Maximum Hardness in WC–10Co–4Cr Coatings. Surf. Coat. Technol. 2014, 247, 90–102. [Google Scholar] [CrossRef]

- Baumann, I.; Hagen, L.; Tillmann, W.; Hollingsworth, P.; Stangier, D.; Schmidtmann, G.; Tolan, M.; Paulus, M.; Sternemann, C. Process Characteristics, Particle Behavior and Coating Properties during HVOF Spraying of Conventional, Fine and Nanostructured WC-12Co Powders. Surf. Coat. Technol. 2021, 405, 126716. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, B.; Jia, C.; Gao, F.; Yu, Y.; Chu, K.; Zhang, M.; Zhao, X. Influence of Carbide Grain Size and Crystal Characteristics on the Microstructure and Mechanical Properties of HVOF-Sprayed WC-CoCr Coatings. Int. J. Refract. Met. Hard Mater. 2017, 69, 138–152. [Google Scholar] [CrossRef]

- Lekatou, A.; Sioulas, D.; Karantzalis, A.E.; Grimanelis, D. A Comparative Study on the Microstructure and Surface Property Evaluation of Coatings Produced from Nanostructured and Conventional WC–Co Powders HVOF-Sprayed on Al7075. Surf. Coat. Technol. 2015, 276, 539–556. [Google Scholar] [CrossRef]

- Ali, O.; Ahmed, R.; Alawadhi, H.; Shameer, M.; Faisal, N.H.; Al-Anazi, N.M.; Goosen, M.F.A. Comparison of Wear Performance of Thermal Sprayed Cermet (WC-Co) Coatings from Suspension and Feedstock Powders. In Proceedings of the International Thermal Spray Conference (ITSC 2017), Yokohama, Japan, 16–19 October 2017; pp. 681–686. [Google Scholar] [CrossRef]

- Mittal, G.; Paul, S. Suspension and Solution Precursor Plasma and HVOF Spray: A Review. J. Therm. Spray Technol. 2022, 31, 1443–1475. [Google Scholar] [CrossRef]

- Zhou, W.; Zhou, K.; Li, Y.; Deng, C.; Zeng, K. High Temperature Wear Performance of HVOF-Sprayed Cr3C2-WC-NiCoCrMo and Cr3C2-NiCr Hardmetal Coatings. Appl. Surf. Sci. 2017, 416, 33–45. [Google Scholar] [CrossRef]

- Vishnoi, M.; Murtaza, Q.; Kumar, P. Effect of Rare Earth Elements on Coatings Developed by Thermal Spraying Processes (TSP)—A Brief Review. Mater. Today Proc. 2020, 44, 4053–4058. [Google Scholar] [CrossRef]

- Zhao, G.M.; Wang, K.L. Effect of La2O3 on Corrosion Resistance of Laser Clad Ferrite-Based Alloy Coatings. Corros. Sci. 2006, 48, 273–284. [Google Scholar] [CrossRef]

- Zhang, B.; Shi, W.; Lin, Y.; Jiang, L.; Wang, L.; He, K. Effect of CeO2 Content on Microstructure and Wear Resistance of Laser-Cladded Ni-Based Composite Coating. Lubricants 2024, 12, 227. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, Z.; Liang, B.; La, P. Effects of CeO2 on Friction and Wear Characteristics of Fe–Ni–Cr Alloy Coatings. Tribol. Int. 2006, 39, 971–978. [Google Scholar] [CrossRef]

- Xie, G.; Zhang, B.; Liu, H.; Xin, D.; Cai, Y.; Mu, W. Simultaneous Enhancement of Hardness and Toughness of Nano-CeO2 Modified Multi-Scale WC-10Co-4Cr Coating via HVOF. Mater. Lett. 2025, 390, 138418. [Google Scholar] [CrossRef]

- Singh, H.; Chatha, S.S.; Sidhu, B.S. High Temperature Corrosion Performance of HVOF and D-Gun Formulated Cr3C2-NiCr and Rare Earth Element Doped Cr3C2-NiCr Coating on TP347H Austenite Steel. J. Fail. Anal. Prev. 2024, 24, 1419–1441. [Google Scholar] [CrossRef]

- Singh, V.; Kaur, S.; Vishnoi, M.; Bansal, A. Slurry Erosion Resistance Through HP-HVOF-Sprayed WC–10Co–4Cr Coatings with Rare Earth Elements and Response Surface Methodology Analysis. Arab. J. Sci. Eng. 2025, 50, 1–15. [Google Scholar] [CrossRef]

- Du, J.; Li, F.; Li, Y.; Lu, H.; Qi, X.; Yang, B.; Li, C.; Yu, P.; Wang, J.; Gao, L. The influence of nano-CeO2 on tribological properties and microstructure evolution of Cr3C2-NiCrCoMo composite coatings at high temperature. Surf. Coat. Technol. 2021, 428, 127913. [Google Scholar] [CrossRef]

- Yin, B.; Zhang, L.; Wang, Y.; Li, J.; Liu, X. Microstructures and Properties of Plasma Sprayed FeAl/CeO2/ZrO2 Nano-Composite Coating. Appl. Surf. Sci. 2010, 256, 3597–3603. [Google Scholar] [CrossRef]

- Vishnoi, M.; Murtaza, Q.; Kumar, P. Mechanical and Surface Characterization of Er2O3/La2O3/CeO2 Doped Carbide Coating Developed Using High Velocity Oxy Fuel (HVOF). Phys. Scr. 2023, 98, 115618. [Google Scholar] [CrossRef]

- Mi, P.; Zhao, H.; Wang, T.; Ye, F. Sliding Wear Behavior of HVOF Sprayed WC-(Nano-WC-Co) Coating at Elevated Temperatures. Mater. Chem. Phys. 2018, 206, 1–6. [Google Scholar] [CrossRef]

- Mi, P.; Wang, T.; Ye, F. Influences of the Compositions and Mechanical Properties of HVOF Sprayed Bimodal WC-Co Coating on Its High Temperature Wear Performance. Int. J. Refract. Met. Hard Mater. 2017, 69, 158–163. [Google Scholar] [CrossRef]

- Purushotham, N.; Parthasarathi, N.L.; Babu, P.S.; Sivakumar, G.; Rajasekaran, B. Effect of Thermal Expansion on the High Temperature Wear Resistance of Ni-20%Cr Detonation Spray Coating on IN718 Substrate. Surf. Coat. Technol. 2023, 462, 129490. [Google Scholar] [CrossRef]

- Niranatlumpong, P.; Koiprasert, H. The Effect of Mo Content in Plasma-Sprayed Mo-NiCrBSi Coating on the Tribological Behavior. Surf. Coat. Technol. 2010, 205, 483–489. [Google Scholar] [CrossRef]

- Dilawary, S.A.A.; Motallebzadeh, A.; Afzal, M.; Atar, E.; Cimenoglu, H. Laser Surface Melting of 10 wt% Mo Alloyed Hardfacing Stellite 12 Plasma Transferred Arc Deposits: Structural Evolution and High Temperature Wear Performance. Opt. Laser Technol. 2018, 101, 404–412. [Google Scholar] [CrossRef]

- Alam, M.S.; Das, A.K. Advancement in Cermet-Based Coating on Steel Substrate: A Review. Mater. Today Proc. 2022, 56, 805–810. [Google Scholar] [CrossRef]

- Behera, N.; Sarmah, P.; Chandramouli, T.V.; Ramesh, M.R. Effect of Molybdenum on High-Temperature Tribological Performance in HVOF Sprayed WC-Based Coatings on Superni-76. Tribol. Mater. Surf. Interfaces 2025, 19, 97–110. [Google Scholar] [CrossRef]

- Behera, N.; Ramesh, M.R.; Rahman, M.R. Elevated Temperature Wear and Friction Performance of WC-CoCr/Mo and WC-Co/NiCr/Mo Coated Ti-6Al-4V Alloy. Mater. Charact. 2024, 215, 114207. [Google Scholar] [CrossRef]

- Al-Mutairi, S.; Hashmi, M.S.J.; Yilbas, B.S.; Stokes, J. Microstructural Characterization of HVOF/Plasma Thermal Spray of Micro/Nano WC–12%Co Powders. Surf. Coat. Technol. 2015, 264, 175–186. [Google Scholar] [CrossRef]

- Fauchais, P.; Montavon, G.; Bertrand, G. From Powders to Thermally Sprayed Coatings. J. Therm. Spray Technol. 2010, 19, 56–80. [Google Scholar] [CrossRef]

- Wang, H.; Qiu, Q.; Gee, M.; Hou, C.; Liu, X.; Song, X. Wear Resistance Enhancement of HVOF-Sprayed WC-Co Coating by Complete Densification of Starting Powder. Mater. Des. 2020, 191, 108586. [Google Scholar] [CrossRef]

- Derelizade, K.; Venturi, F.; Wellman, R.G.; Kholobysov, A.; Hussain, T. Wear Performance of Graphene Nano Platelets Incorporated WC-Co Coatings Deposited by Hybrid High Velocity Oxy Fuel Thermal Spray. Wear 2021, 482–483, 203974. [Google Scholar] [CrossRef]

- Jordan, E.H.; Jiang, C.; Gell, M. The Solution Precursor Plasma Spray (SPPS) Process: A Review with Energy Considerations. J. Therm. Spray Technol. 2015, 24, 1153–1165. [Google Scholar] [CrossRef]

- Kiilakoski, J.; Puranen, J.; Heinonen, E.; Koivuluoto, H.; Vuoristo, P. Characterization of Powder-Precursor HVOF-Sprayed Al2O3-YSZ/ZrO2 Coatings. J. Therm. Spray Technol. 2019, 28, 98–107. [Google Scholar] [CrossRef]

- Chadha, S.; Jefferson-Loveday, R.; Venturi, F.; Hussain, T. A Computational and Experimental Investigation into Radial Injection for Suspension High Velocity Oxy-Fuel (SHVOF) Thermal Spray. J. Therm. Spray Technol. 2019, 28, 1198–1210. [Google Scholar] [CrossRef]

- Ding, X.; Cheng, X.; Yu, X.; Li, C.; Yuan, C.; Ding, Z. Structure and Cavitation Erosion Behavior of HVOF Sprayed Multi-Dimensional WC–10Co4Cr Coating. Trans. Nonferrous Met. Soc. China 2018, 28, 487–494. [Google Scholar] [CrossRef]

- Du, P.C.; Zhu, X.P.; Meng, Y.; Feng, H.; Wang, Q.F.; Lei, M.K. Water-Lubricated Tribological Behavior of WC-Ni Coatings Deposited by Off-Angle HVOF Spraying. Surf. Coat. Technol. 2017, 309, 663–670. [Google Scholar] [CrossRef]

- Singh, N.K.; Vinay, G.; Singh, H.; Bandyopadhyay, P.P. Effect of Laser Remelting on the Microstructural and Mechanical Properties of High-Velocity Oxy-Fuel (HVOF)-Sprayed WC-NiCr Coating. J. Therm. Spray Technol. 2024, 33, 1484–1495. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, H.; Xu, B. Optimized Microstructure and Properties of Cr3C2-NiCr Cermet Coating by HVOF/Laser Hybrid Processing. J. Therm. Spray Technol. 2019, 28, 1072–1080. [Google Scholar] [CrossRef]

- Olakanmi, E.O. Optimization of the Quality Characteristics of Laser-Assisted Cold-Sprayed (LACS) Aluminum Coatings with Taguchi Design of Experiments (DOE). Mater. Manuf. Process. 2015, 31, 1490–1499. [Google Scholar] [CrossRef]

- Wang, S.; Yan, F.; Chen, A. Tribological Effects of Laser Surface Texturing and Residual Stress. Ind. Lubr. Tribol. 2018, 70, 126–132. [Google Scholar] [CrossRef]

- Vishnoi, M.; Singh, V.; Bansal, A.; Murtaza, Q.; Kumar, P. Effect of Laser Ablation over Cavitation, Slurry Erosion, and Surface Properties of 86WC-10Co-4Cr Based Ceramic Coating Developed Using HP-HVOLF. Surf. Coat. Technol. 2024, 492, 129148. [Google Scholar] [CrossRef]

- Jatavallabhula, J.K.; Shabana, S.; Pappula, B. Development and Evaluation of Machine Learning Based Predictive Models for Tribological Properties of Blended Coatings at Elevated Temperature. J. Bio-Tribo-Corros. 2025, 11, 25. [Google Scholar] [CrossRef]

- Gerner, D.; Azarmi, F.; McDonnell, M.; Okeke, U. Application of Machine Learning for Optimization of HVOF Process Parameters. J. Therm. Spray Technol. 2024, 33, 504–514. [Google Scholar] [CrossRef]

- Singh, J.; Singh, S.; Vasudev, H.; Katiyar, J.K. Artificial Neural Network Model for Wear Characteristic Analysis of WC-10Co4Cr and Stellite 6 Thermal Spray Coatings. Tribol. Int. 2024, 199, 109924. [Google Scholar] [CrossRef]

- Becker, A.; Fals, H.D.C.; Roca, A.S.; Siqueira, I.B.A.F.; Caliari, F.R.; da Cruz, J.R.; Vaz, R.F.; de Sousa, M.J.; Pukasiewicz, A.G.M. Artificial Neural Networks Applied to the Analysis of Performance and Wear Resistance of Binary Coatings Cr3C2-37WC-18M and WC-20Cr3C2-7Ni. Wear 2021, 477, 203797. [Google Scholar] [CrossRef]

- Singh, J.; Singh, S. Neural Network-Supported Study on Erosive Wear Performance Analysis of Y2O3/WC-10Co4Cr HVOF Coating. J. King Saud Univ. Eng. Sci. 2024, 36, 662–676. [Google Scholar] [CrossRef]

- Singh, J.; Kumar, S.; Kumar, R. Support Vector Machine Based Prediction of Wear in Ni-20Cr3C2 Thermal Spray Coating under Bottom Ash Slurry Conditions. J. Tribol. 2023, 39, 84–105. [Google Scholar]

- Gui, L.; Wang, B.; Cai, R.; Yu, Z.; Liu, M.; Zhu, Q.; Xie, Y.; Liu, S.; Killinger, A. Prediction of In-Flight Particle Properties and Mechanical Performances of HVOF-Sprayed NiCr–Cr3C2Coatings Based on a Hierarchical Neural Network. Materials 2023, 16, 6279. [Google Scholar] [CrossRef]

- Singh, J. Tribo-Performance Analysis of HVOF Sprayed 86WC-10Co4Cr & Ni-Cr3C2 on AISI 316L Steel Using DOE-ANN Methodology. Ind. Lubr. Tribol. 2021, 73, 727–735. [Google Scholar] [CrossRef]

- Liu, M. Research and Implementation of Artificial Neural Networks Models for High Velocity Oxygen Fuel Thermal Spraying. Ph.D. Thesis, Université Bourgogne Franche-Comté, Dijon, France, 2020. [Google Scholar]

- Liu, M.; Yu, Z.; Zhang, Y.; Wu, H.; Liao, H.; Deng, S. Prediction and Analysis of High Velocity Oxy Fuel (HVOF) Sprayed Coating Using Artificial Neural Network. Surf. Coat. Technol. 2019, 378, 124988. [Google Scholar] [CrossRef]

- Matos, S.; Viardot, E.; Sovacool, B.K.; Geels, F.W.; Xiong, Y. Innovation and Climate Change: A Review and Introduction to the Special Issue. Technovation 2022, 117, 102612. [Google Scholar] [CrossRef]

- International Finance Corporation (IFC). Environmental, Health and Safety Guidelines for Thermal Power Plants; World Bank Group: Washington, DC, USA, 2008. [Google Scholar]

- Viswanathan, V.; Katiyar, N.K.; Goel, G.; Matthews, A.; Goel, S. Role of Thermal Spray in Combating Climate Change. Emerg. Mater. 2021, 4, 1515–1529. [Google Scholar] [CrossRef]

- Kaddoura, M.; Majeau-Bettez, G.; Amor, B.; Poirier, D.; Margni, M. Estimating and Reducing Dissipative Losses in Thermal Spray: A Parametrized Material Flow Analysis Approach. J. Clean. Prod. 2024, 450, 141978. [Google Scholar] [CrossRef]

- Morgan, T. White Paper: Reducing Thermal Spray Hazards with Proper Dust Collection; The Fabricator: Elgin, IL, USA, 2017. [Google Scholar]

- Lashmi, P.G.; Ananthapadmanabhan, P.V.; Unnikrishnan, G.; Aruna, S.T. Present Status and Prospects of Plasma Sprayed Multilayered Thermal Barrier Coating Systems. J. Eur. Ceram. Soc. 2020, 40, 2731–2745. [Google Scholar] [CrossRef]

- Vardavoulias, M.; Tsetsekou, A.; Papoulias, E.; Papapanos, G. Recycling of Waste Material of a Thermal Spray Shop. In Proceedings of the 20th International Conference on Surface Modification Technologies (SMT20), Vienna, Austria, 25–29 September 2006. [Google Scholar]

- Antonini, J.M.; McKinney, W.G.; Lee, E.G.; Afshari, A.A. Review of the Physicochemical Properties and Associated Health Effects of Aerosols Generated during Thermal Spray Coating Processes. Toxicol. Ind. Health 2021, 37, 47–58. [Google Scholar] [CrossRef]

- Serres, N.; Hlawka, F.; Costil, S.; Langlade, C.; Machi, F. Microstructures and Environmental Assessment of Metallic NiCrBSi Coatings Manufactured via Hybrid Plasma Spray Process. Surf. Coat. Technol. 2010, 205, 1039–1046. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles andFramework. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- Korobov, Y.; Shalimov, M. Energy efficiency by thermal spraying. WIT Trans. Ecol. Environ. 2014, 190, 455–466. [Google Scholar] [CrossRef]

- Igartua, A.; Mendoza, G.; Fernandez, X.; Zabala, B.; Alberdi, A.; Bayon, R.; Aranzabe, A. Surface Treatments Solutions to Green Tribology. Coatings 2020, 10, 634. [Google Scholar] [CrossRef]

- Montavon, G.; Vardelle, A.; Krishnan, N.; Ulloa, P.; Costil, S.; Liao, H. Life Cycle Assessment (LCA) of Thermal-Sprayed and Chromium Electroplated Coatings. In Proceedings of the International Thermal Spray Conference, Washington, DC, USA, 15–18 May 2006; pp. 1399–1406. [Google Scholar] [CrossRef]

- Krishnan, N.; Vardelle, A.; Legoux, J. A Life Cycle Comparison of Hard Chrome and Thermal Sprayed Coatings: A Case Example of Aircraft Landing Gears. In Proceedings of the International Thermal Spray Conference (ITSC 2008), Maastricht, The Netherlands, 2–4 June 2008. [Google Scholar]

- Merlo, A.; Duminica, F.; Daniel, A.; Léonard, G. Techno-Economic Analysis and Life Cycle Assessment of High-Velocity Oxy-Fuel Technology Compared to Chromium Electrodeposition. Materials 2023, 16, 3678. [Google Scholar] [CrossRef]

- Rúa Ramirez, E.; Silvello, A.; Torres Diaz, E.; Tornese, F.; Gnoni, M.G.; Garcia Cano, I. A Comparison of Cold Spray, Atmospheric Plasma Spray and High Velocity Oxy Fuel Processes for WC-Co Coatings Deposition through LCA and LCCA. Heliyon 2024, 10, e38961. [Google Scholar] [CrossRef]

- Rua Ramirez, E.; Silvello, A.; Diaz, E.; Vaz, R.; Cano, I.G. A Comparative Study of the Life Cycle Inventory of Thermally Sprayed WC-12Co Coatings. Metals 2024, 14, 431. [Google Scholar] [CrossRef]

- Tegelkamp, L.; Grimm, M.; Conze, S.; Berger, L.-M.; Lindner, T.; Lampke, T. Microstructure and Wear Resistance of Environmentally Friendly NbC-FeCr Coatings: An Evaluation of HVOF Process Parameters. Surf. Coat. Technol. 2025, 509, 132208. [Google Scholar] [CrossRef]

- Bolelli, G.; Colella, A.; Forlin, E.; Gehlen, L.R.; Lusvarghi, L.; Miconi, L.; Pintaude, G.; Puddu, P. Tribological Performance of NbC-Based Hardmetal HVOF Coatings with Fe-Cr-Mo Matrix. Wear 2025, 564–565, 205680. [Google Scholar] [CrossRef]

- Panchal, H.; Amin, S. A Review on Thermal Spray Coating Processes. Int. J. Curr. Trends Eng. Res. 2016, 2, 556–563. [Google Scholar]

- Rannetbauer, W.; Hambrock, C.; Hubmer, S.; Ramlau, R. Virtual Sensors and Thermal Modelling for Quality Control in Industrial Thermal Spraying. Procedia Comput. Sci. 2025, 253, 2049–2062. [Google Scholar] [CrossRef]

- Rannetbauer, W.; Hubmer, S.; Hambrock, C.; Ramlau, R. A Practical Guide to Optimizing Industrial Thermal Spraying through Comparative Multi-Objective Optimization. arXiv 2025, arXiv:2504.18357. [Google Scholar]

| Process | Type of Feedstock | Heating Source | Temperature (°C) of the Gun | Particle Velocity (m/s) | Coating Materials | Porosity (vol.%) | Hardness Rc | Bond Strength |

|---|---|---|---|---|---|---|---|---|

| HVOF | Powder | Oxypropylene/Hydrogen/Propane/LPG | 3100 | 1350 | Metallic and ceramic | 0.1–2 | 50 | Excellent |

| Plasma spraying (APS) | Powder | Plasma arc | 16,000 | 120–600 | Metallic/Ceramic/com-pound/plastic | 1–7 | 50 | Very good to excellent |

| Detonation gun | Powder | Gas detonation Oxygen/Acetylene/Nitrogen | 4500 | 800 | Metallic/Ceramic/com-pound/plastic | 0.1–1 | ** | Excellent |

| Electric arc | Wire | Arc between electrodes | 6000 | 240 | Ductile Materials | 10–20 | 35 | Good |

| Flame spraying | Powder Wire | Oxyhydrogen/Oxyacethylene | 2800 | 180 | Metallic and ceramic | 10–20 | 20 | Fair |

| Cold spray | Powder | Compressed gas/Helium/Nitrogen/Air | 500–600 | 500–1200 | Metallic and ceramic | <2 | ** | Fair |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ben Difallah, B.; Mebdoua, Y.; Serdani, C.; Kharrat, M.; Dammak, M. Advanced HVOF-Sprayed Carbide Cermet Coatings as Environmentally Friendly Solutions for Tribological Applications: Research Progress and Current Limitations. Technologies 2025, 13, 281. https://doi.org/10.3390/technologies13070281

Ben Difallah B, Mebdoua Y, Serdani C, Kharrat M, Dammak M. Advanced HVOF-Sprayed Carbide Cermet Coatings as Environmentally Friendly Solutions for Tribological Applications: Research Progress and Current Limitations. Technologies. 2025; 13(7):281. https://doi.org/10.3390/technologies13070281

Chicago/Turabian StyleBen Difallah, Basma, Yamina Mebdoua, Chaker Serdani, Mohamed Kharrat, and Maher Dammak. 2025. "Advanced HVOF-Sprayed Carbide Cermet Coatings as Environmentally Friendly Solutions for Tribological Applications: Research Progress and Current Limitations" Technologies 13, no. 7: 281. https://doi.org/10.3390/technologies13070281

APA StyleBen Difallah, B., Mebdoua, Y., Serdani, C., Kharrat, M., & Dammak, M. (2025). Advanced HVOF-Sprayed Carbide Cermet Coatings as Environmentally Friendly Solutions for Tribological Applications: Research Progress and Current Limitations. Technologies, 13(7), 281. https://doi.org/10.3390/technologies13070281