1. Introduction

During the last few years, the constant evolution of the construction industry and the increasing attention to sustainability has led the building industry sector to study new construction materials, which would respect not only the performance in terms of structural and durability requirements but also the minimum environmental criteria established by the different countries and their regulations. For this reason, the use of industrial waste in the production of construction materials, such as concrete, has been characterized by an outstanding development. Concrete is the most widely used building material, although its production process is one of the most energy-consuming, causing high CO2 emissions in the atmosphere. For this reason, the study of waste materials for use in concrete mix design is ongoing, in order to reduce the exploitation of raw materials and the impact on the atmosphere.

Several researchers have investigated the possibility of using industrial waste in concrete mix design, evaluating the advantages and disadvantages in terms of both mechanical properties and sustainability, the latter especially in terms of CO

2 reduction [

1,

2,

3,

4,

5,

6,

7]. One of the most important industrial wastes used in concrete mix design is fly ash [

8,

9]. Nuaklong et al. [

10] investigated the strength and post-fire performance of fiber-reinforced alkali-activated fly ash concrete containing granite industry waste. Ho and Huynh [

11] analyzed the mechanical properties and the durability of high-strength concrete (HSC) containing fly ash sourced in Vietnam. Magalhães et al. [

12] evaluated the influence of Brazilian fly ash on the concrete compressive strength and modulus of elasticity.

Another industrial waste used in concrete mix design is silica fume, used both as cement replacement and as an additive [

13,

14,

15]. Vijayan et al. [

16] presented a detailed review of the application of silica fume in concrete mix design, highlighting the advantages of its use in several application fields. In Tak et al. [

17], the effects of using silica fume as partial replacement of cement in concrete are investigated, determining that the ideal percentage of silica fume for concrete is approximately 11%. Chishi and Gautam [

18] studied the possibility of using silica fume in green cement concrete production, focusing the attention on the sustainability aspect.

In the last years, the use of metakaolin as partial replacement of cement in concrete mix design has undergone an important development as shown by the recent literature [

19,

20,

21]. Kumar et al. [

22] analyzed the effects of metakaolin on the mechanical properties and durability of mortar and concrete, showing that metakaolin is a highly reactive pozzolanic material that reacts with calcium hydroxide and produces additional cementitious compounds enhancing the compression strength. Asghari et al. [

23] studied the influence of metakaolin on the mechanical properties of self-consolidating concrete, highlighting that metakaolin could be a valuable partial substitute of cement in concrete mix design. In Sankar and Ramadoss [

24], the influence of metakaolin on the concrete compressive strength at 28 days is evaluated using statistical techniques such as linear regression, multi-logistic regression, nonlinear regression and response surface methodology.

Fly ash, silica fume and metakaolin are the industrial wastes usually considered in the literature as substitutes for cement in mix designs of structural concrete, and they also find wide application in practice, being admitted by several national and international regulations. Two other possible waste materials to consider are perlite and rhyolite, which however, have been less studied so far compared with the above-mentioned industrial wastes.

Perlite is a natural, amorphous siliceous volcanic rock widely accessible in the world, extensively used in expanded form as aggregate material in concrete or mortar since the 20th century because of its light weight, thermal insulation skill and fire resistance [

25,

26,

27,

28]. More recently, some authors have investigated the pozzolanic effect of perlite powder added to concrete and evaluated the pros and cons of its use [

29,

30]. Stratoura et al. [

31] examined the effect of perlite on concrete durability, demonstrating that the mix design provides adequate strength and durability for structural applications. Ramezanianpour et al. [

32] investigated the effect of calcined perlite powder, used as a partial replacement of ordinary Portland cement, on the compressive strength and concrete resistance to chloride ions. El Mir and Nehme [

33] investigated the use of waste perlite powder, provided by production of the expanded perlite process, at a high content as filler material in self-compacting concrete. Bakhshi et al. [

34] analyzed the potential optimization of lightweight-reinforced concrete containing expanded perlite under impact loading. Stefanidou et al. [

35] investigated the use of waste perlite products in lime-based mortars and grouts.

Rhyolite is an extrusive igneous rock with a very high silica content. Its use as a concrete component is not as common as perlite. Elsheikh et al. [

36] tested the feasibility of using coarse aggregate composed of andesite and rhyolite to produce a green high-strength self-compacting concrete. Karahüseyin and Erdoğdu [

37] performed an experimental study where mortar mixtures were produced by substituting cement with rhyolite and metakaolin at different ratios by weight of cement in view of preventing delayed ettringite formation in the long term. Abdelfattah et al. [

38] investigated the applicability of perlite and rhyolite tuff as additives materials in lightweight aggregates (LWAs) production, explaining how the high amorphous content can improve the bloating properties of expandable clays and the properties of the LWAs produced. In Baki et al. [

39], the pozzolanic activities of ground trachyte and rhyolite in mortars were investigated comparatively by several methods, concluding that the ground trachyte may be utilized as a pozzolanas in the cement industry, while the ground rhyolite does not meet some limits prescribed by the related standard.

It is important to highlight that perlite and rhyolite are not generally used in the structural concrete mix design as partial replacement of cement because they do not have the same physical-mechanical characteristics as other industrial waste materials such as metakaolin, fly ash and silica fume, already widely studied and adopted by the product standards.

Furthermore, as reported in [

40], the use of rhyolite with reactive silica in the concrete mix design may cause an alkali-silica reaction. For this reason, in some cases, calcium nitrate is added [

41].

The results achieved up to now demonstrate that the use of perlite secondary products and rhyolite in building materials such as mortar and concrete is feasible. However, the possibility of their use as a partial replacement of cement in structural concrete mix design still remain an open issue. Despite the growing interest in using perlite and rhyolite in concrete, there is a limited amount of research specifically addressing their effectiveness as partial cement replacements in structural concrete, particularly with respect to their impact on both mechanical and environmental performance. This study aims to fill this gap by providing a detailed evaluation of their properties in concrete mix design.

In this frame, this paper presents the results of an extensive campaign of laboratory tests aimed at evaluating the influence of the use of perlite and rhyolite as partial replacement of cement in structural concrete mix design. Effects on the compressive strength and modulus of elasticity are discussed and compared with the results obtained using (i) fly ash, (ii) metakaolin and (iii) silica fume as other cement replacement materials [

42,

43,

44]. The results are also compared with a reference mix (M0) of standard C25/30 concrete. In particular, two different cement substitution percentages, 15% and 30%, are considered when evaluating the compressive strength after 7 and 28 days, and two different particle sizes, 20 μm and 63 μm, are considered when using perlite. Moreover, two non-destructive tests, ultrasonic testing [

45,

46] and the rebound hammer test [

47], have been carried out on the specimens to evaluate whether possible inner or superficial properties could affect the mechanical and physical properties of the concrete. The results show that the compressive strength, and to a lesser extent the modulus of elasticity, are influenced by the type of industrial waste used, by the percentage of substitution and by the degree of micronization. In particular, while the mix designs with perlite, especially in low percentages of substitution, allow us to achieve physical-mechanical performances comparable with those of the other mixes analyzed and adequate for structural concrete, the mix designs containing rhyolite offer low performances, making the use of rhyolite as a substitute for cement still questionable. In addition, an analysis of the equivalent CO

2 produced by the mix designs considered was carried out, highlighting that the use of industrial waste generally leads to a reduction, often significant, of harmful emissions, and that perlite offers a good compromise between mechanical performance and reduction of the impact on the atmosphere.

After this brief introduction,

Section 2 presents the experimental program, followed by the results in

Section 3. The analysis and discussion are covered in

Section 4, with the environmental impact evaluation in

Section 5. Finally, some conclusive remarks are drawn in

Section 6.

The main goal of this research work is to evaluate the possible use of perlite secondary products and rhyolite in the mix designs of structural concrete as partial replacement of cement to improve the sustainability level of the construction.

4. Discussion

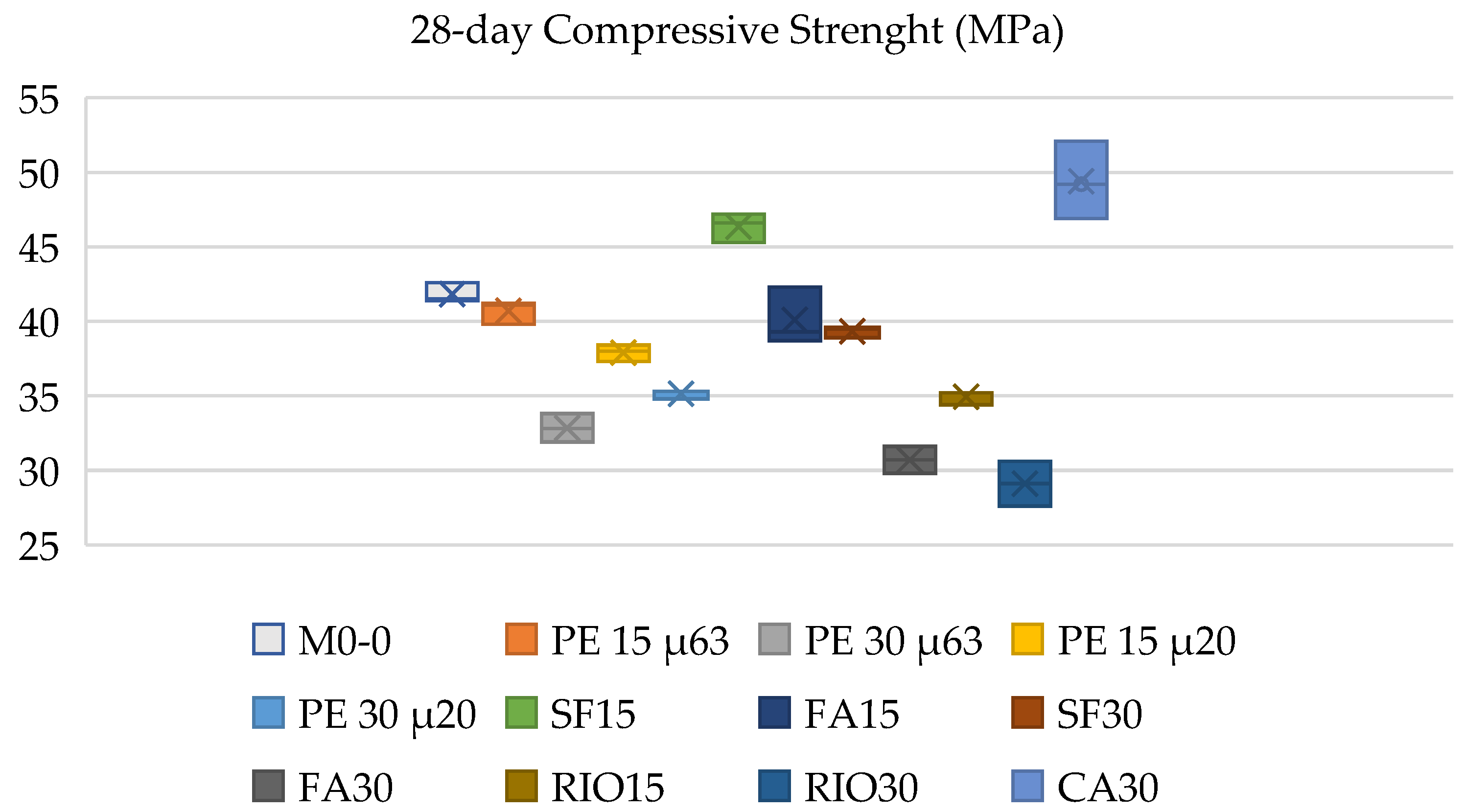

A synthesis of the results presented in the previous section is shown in

Figure 10,

Figure 11,

Figure 12 and

Figure 13, where the average value is denoted by a cross while the standard deviation is reported as a bar for each mix and for each property. It is possible to highlight the following aspects.

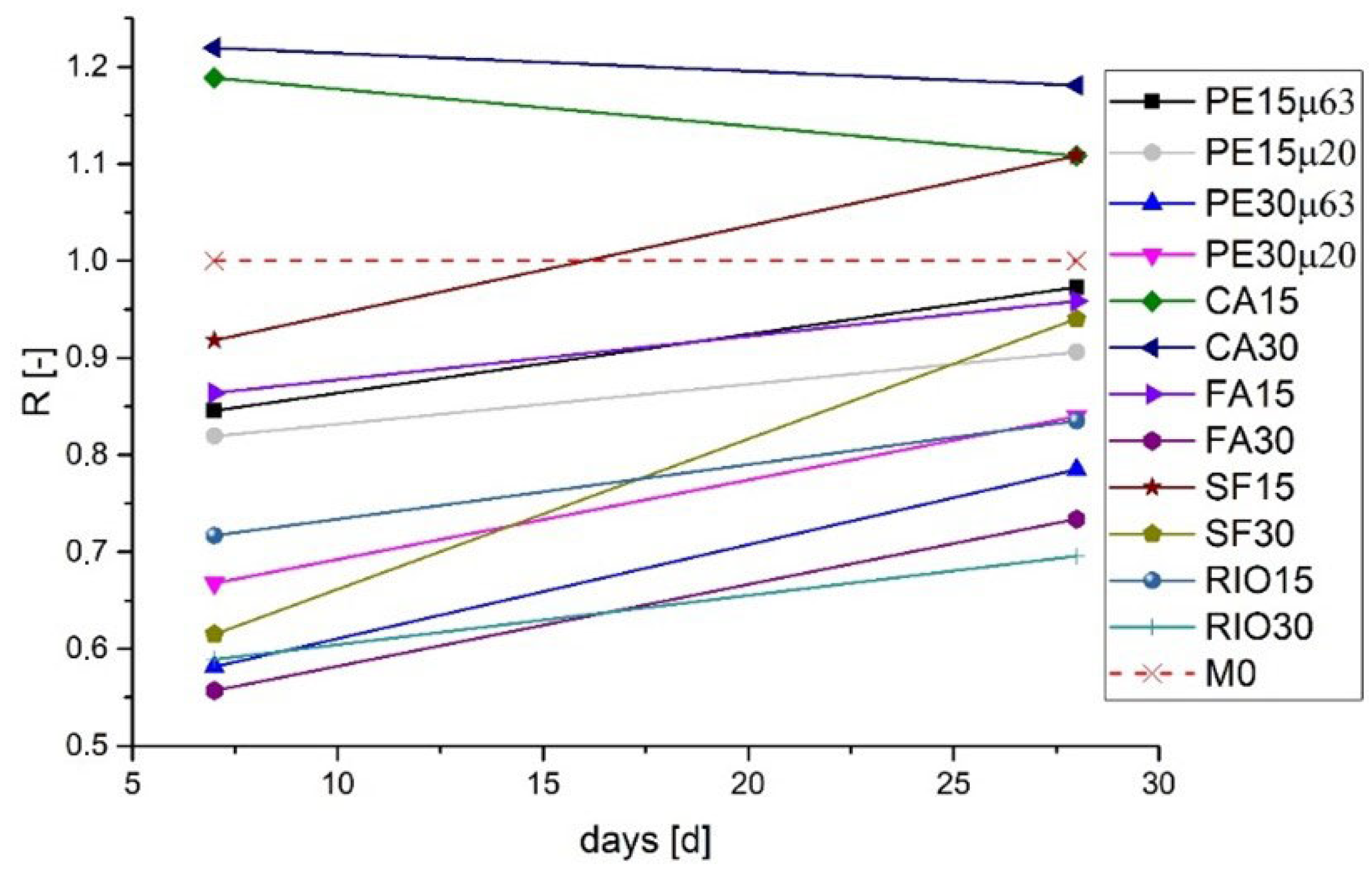

Regarding the compressive strength, see

Figure 10; when the percentage of cement replacement using industrial waste materials increases, a decrease in concrete compressive strength occurs for all mix designs, except for the mixes CA15, CA30 and SF15. Focusing on PE, the mix designs PE15μ63, PE15μ20, PE30μ63 and PE30μ20 are characterized by a compressive strength lower than that obtained for the reference mix M0 both at 7 and 28 days. The loss of mean strength at 28 days is limited for mixes with a lower replacement percentage (PE15μ63, PE15μ20), for which it does not exceed 10%, while it becomes significant for mixes with a 30% replacement (PE30μ63, PE30μ20), for which it goes beyond 20%. Overall, the behavior of PE15 mixes is intermediate between that of mixes with CA and SF, which offer high strength, even higher than M0, and that of mixes with FA. However, in all cases, the mean strength of PE mixes remains above 30 MPa, an acceptable value for use in structural concrete. Focusing on RIO, the RIO15 and RIO30 mixes show the lowest strength at 28 days compared with all the other mix designs. The loss of mean strength compared with M0 is over 16% for the RIO15 mix and over 30% for the RIO30 mix, whose final mean strength does not reach 30 MPa, making its use in structural concrete questionable.

Regarding the dynamic modulus of elasticity, see

Figure 11; due to the rather limited variability of the values, it is not possible to identify with certainty an increase or decrease trend either with the percentage of cement replacement variation nor with respect to reference mix design M0. However, it is interesting to note that, using the empirical relationship (3) proposed by the British testing standard BS8110 Part 2 [

49] for the evaluation of the static modulus of elasticity E

t at 28 days as a function of E

dyn, the mean E

t of the mixes M0, PE15μ63, PE15μ20, PE30μ63, PE30μ20, RIO15 and RIO30 takes the values 29 GPa, 31 GPa, 31 GPa, 31 GPa, 31 GPa, 27 GPa and 26 GPa, respectively, highlighting the similarity between M0 and PE and the worse performance of the RIO mix designs, which once again makes their use in structural concrete questionable.

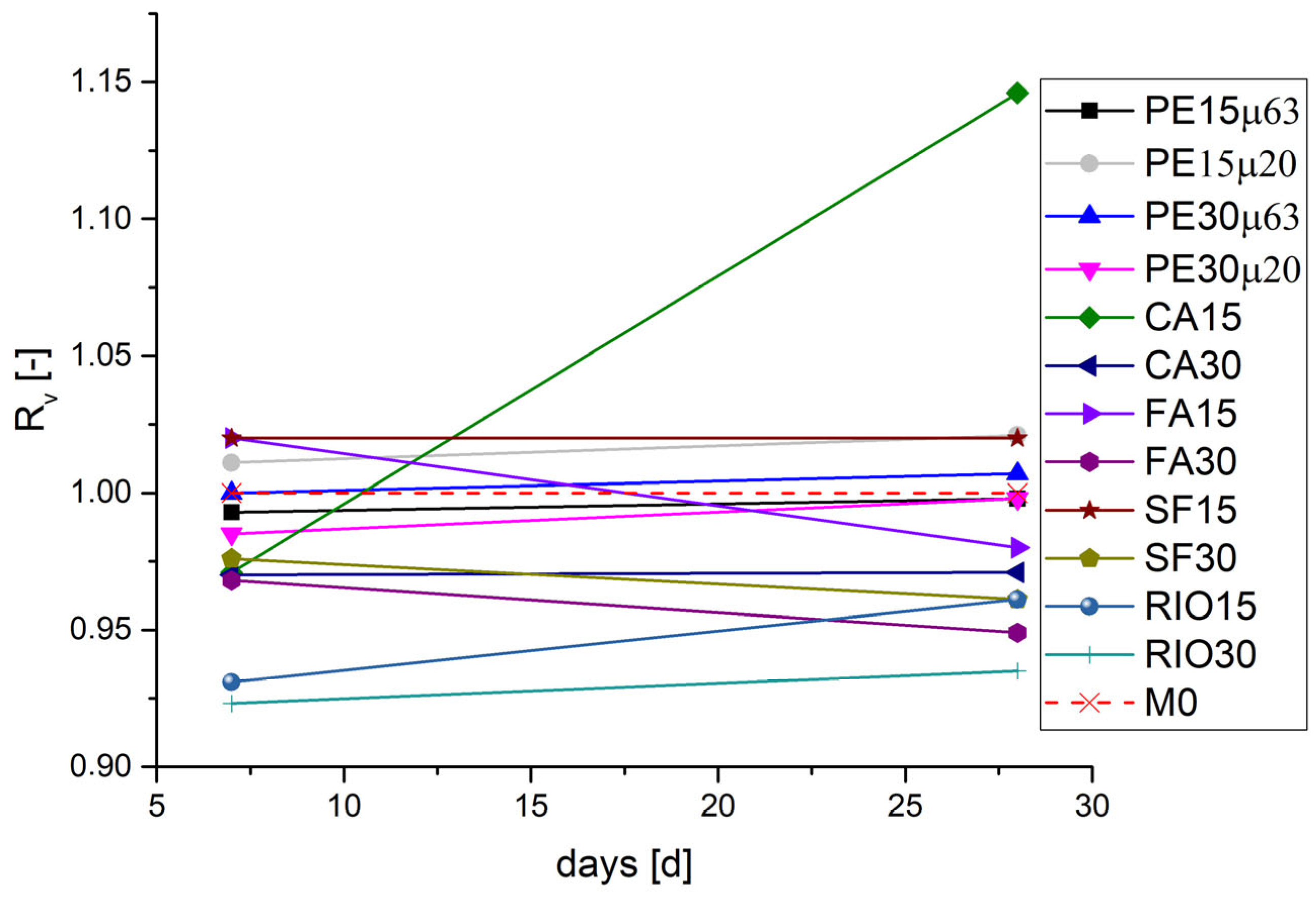

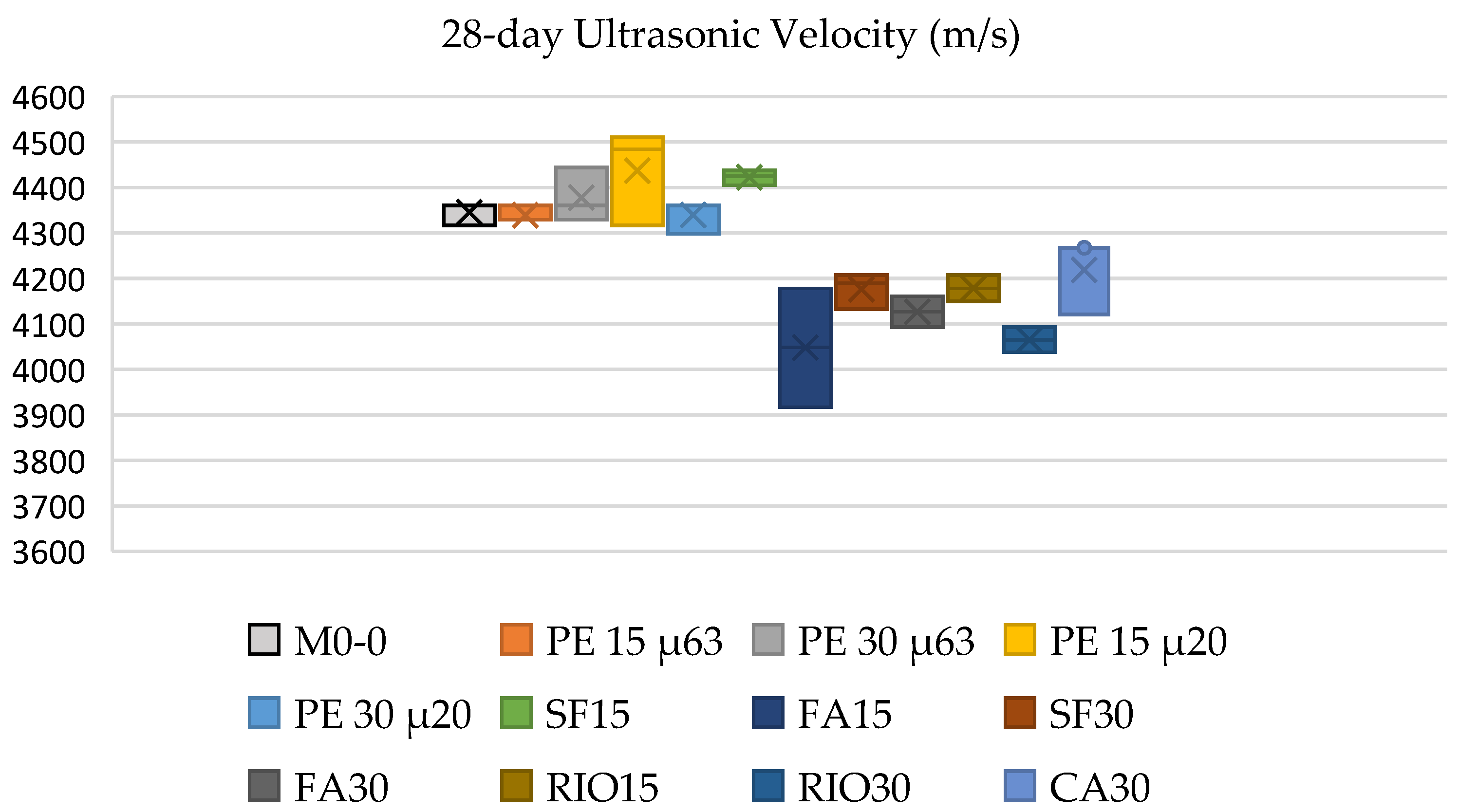

Regarding the ultrasonic velocity, see

Figure 12; the values determined for the various mixes are quite similar to each other and to the reference mix and show minimal variability also in relation to the percentage of cement replacement. This may indicate that the specimens in general have a similar degree of volumetric homogeneity, not influenced by the presence of waste materials in the mix design. This consideration is supported by the poor dispersion of the density values of the tested specimens. The high degree of correlation between velocity and dynamic modulus of elasticity makes the qualitative estimation of the stiffness through non-invasive measurement of velocity acceptable from an engineering perspective.

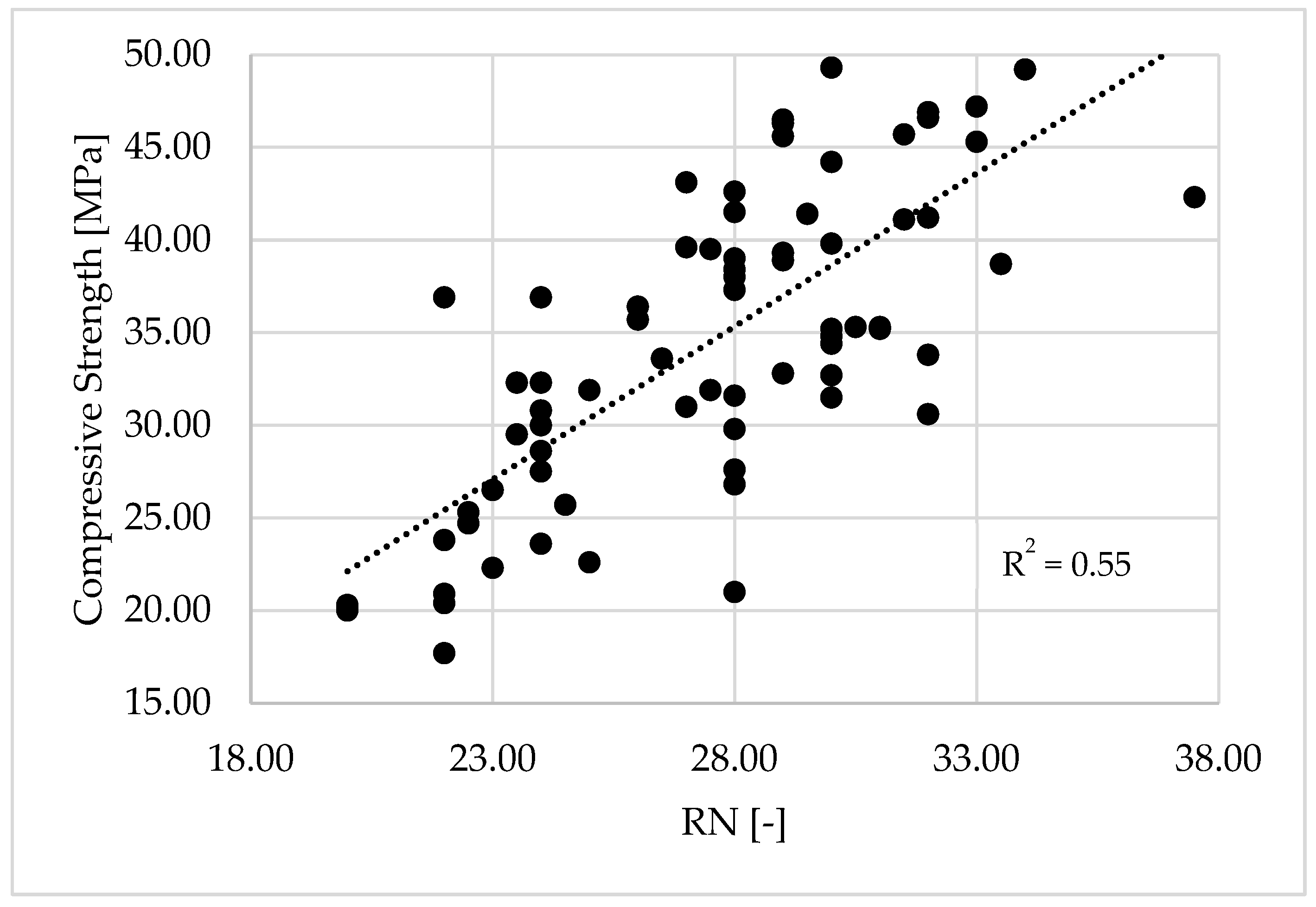

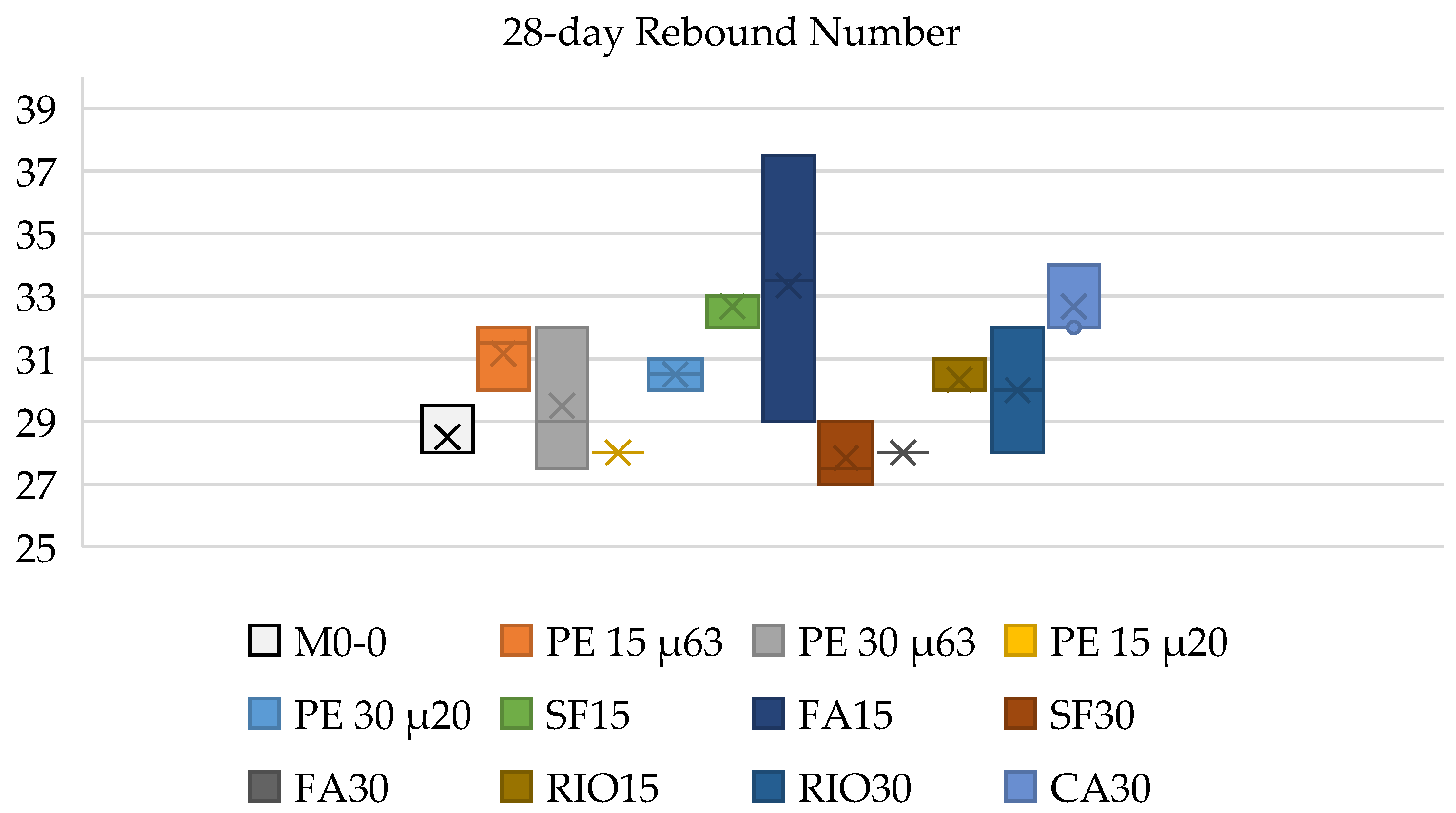

Regarding the rebound number see

Figure 13; in general, the values at 28 days are included in the range of 27–33 and therefore present a fairly limited variability. It is possible to highlight that the observed variability can be attributed to the variation of surface conditions of the specimens in terms of roughness and hardness.

5. Considerations About CO2 Production

Together with studies of mechanical properties of concrete created using industrial waste, another important aspect that led to the ever-increasing use of industrial waste materials in concrete production is represented by the reduction in the quantities of carbon dioxide released into the atmosphere, according to the values of equivalent CO

2 production reported in the main international database [

50,

51,

52].

Table 10 reports the equivalent CO

2 produced unit value (kg/ton) that characterizes the materials considered, and

Table 11 summarizes the equivalent CO

2 produced considering the mix designs reported in

Table 1. Δ indicates the reduction of equivalent CO

2 produced to realize the considered mix design with respect to M0.

It could be observed that the use of industrial waste materials as a partial replacement of cement in concrete mix design leads to a significant reduction in equivalent CO

2 production with respect to the reference mix design, representing an important aspect from the sustainability point of view. The maximum reduction of equivalent CO

2 produced was obtained for the SF30 mix design, which showed a compressive strength decrease at 28 days of about 6% (

Table 6). The minimum abatement of equivalent CO

2 produced was obtained for the CA15 mix design, which instead increased the compressive strength at 28 days by about 10% (

Table 6). The FA mixes offered a good balance both in terms of compressive strength (with an increase of about 4% and 26,6% for FA15 and FA30, respectively) and in terms of equivalent CO2 production reduction (10.9% and 21.8%). Focusing on PE15 mixes, it can be noted that they showed a reduction in equivalent CO

2 produced of 11.8%, limiting at the same time the compressive strength reduction to less than 10% after 28 days (

Table 6). PE30 mix designs showed a higher reduction of equivalent CO

2 produced, which reached 23.4%, and a 28-day compressive strength reduction, which went beyond 20% (

Table 6). Regarding RIO mixes, they entailed a great equivalent CO

2 produced reduction at 12% for RIO15 and 24% for RIO30, respectively, but showed the highest compressive strength reduction at 28 days, which went beyond 16% and 30%, respectively, as discussed in

Section 4. For these reasons, the feasibility of using rhyolite as a partial substitution of cement in concrete mix design is currently questionable and needs further research.

6. Conclusions

This paper illustrated an experimental campaign aimed at analyzing the physical-mechanical performances of structural concrete specimens that incorporate various waste materials as partial replacements for cement. This study also evaluated the environmental impact in terms of equivalent CO2 produced. The focus was on the effect of perlite and rhyolite, two waste materials still little studied for this specific use, on the mix design of structural concrete. The performances of the specimens containing perlite and rhyolite were compared with those of specimens produced with a standard C25/30 reference (M0) concrete, as well as the performances of specimens containing other commonly used industrial wastes, such as fly ash, silica fume and metakaolin. The waste materials were introduced in the mix design in two percentages of replacement for cement, 15% and 30%; moreover, perlite was introduced in two different particle sizes, 20 μm and 63 μm. The impact of these materials on both the internal and surface conditions of the specimens was analyzed by using ultrasonic and rebound hammer tests.

From the obtained results, the following main observations can be drawn.

The 28-day compressive strength of specimens with waste materials is generally lower than that of reference specimens, except for those containing CA and SF15. Specimens with PE achieve an average strength well above 30 MPa, an acceptable value for use in structural concrete, as do specimens with RIO15. Specimens with RIO30 instead offer an average strength significantly lower than 30 MPa, making its use in structural concrete questionable. In general, it is observed that the use of PE and RIO in cement replacement percentages higher than 15% is not convenient from the point of view of compressive strength. The use of RIO mixes also determines lower performances in terms of modulus of elasticity.

The rebound hammer test generally produces results weakly correlated to the compressive strength and largely influenced, as expected, by the conditions of hardness and surface roughness of the specimens. The ultrasonic test provides globally poorly dispersed velocity values, indicating the low influence of the mix design on the internal characteristics of the specimens and highly correlated with the modulus of elasticity; this makes the qualitative estimation of the stiffness through non-invasive measurement of velocity acceptable from an engineering perspective.

The use of industrial waste generally leads to a reduction, with respect to the reference mix design, of the equivalent CO2 produced; the greatest reduction is guaranteed by SF30, RIO30 and PE30 mixes, while the least reduction is guaranteed by CA15. In terms of physical-mechanical performance, the best balance between mechanical performance and reduction of the polluting impact is offered by the SF30 mix design, which marks a final mean compressive strength of about 39 MPa and a reduction in the equivalent CO2 produced of about 24%; moreover, if a compressive strength of around 33–35 MPa is acceptable, an excellent compromise is achieved by the PE15 mix design, which marks a reduction in the equivalent CO2 produced of around 23%.

In summary, the use of perlite as a partial substitute for cement in structural concrete offers a good compromise between maintaining mechanical properties and reducing the equivalent CO2 compared with the reference mix design, in line with other waste materials already used for the same purpose. Rhyolite, on the other hand, despite an appreciable reduction in equivalent CO2, causes an excessive drop in mechanical properties compared with the reference mix; therefore, its use as a partial substitute for cement in structural concrete appears, at the moment, questionable.

Therefore, further research is essential to expand the sample size and gain deeper insights into the long-term performance and suitability of both perlite and rhyolite in concrete applications, particularly with respect to their mechanical behavior and environmental impact.

An important further development of the research work is the evaluation of the durability of structural concrete created using perlite and rhyolite within the mix design to consider their possible use in the realization of structural elements exposed to aggressive environmental conditions.