1. Introduction

Electric traction units for locomotives are prevalent in today’s rail traffic because they can provide more power to the wheels. In [

1], the authors extensively discussed the challenges related to the initial movement of electric vehicles.

A comparative analysis of the interaction conditions of locomotive wheels with rails under electric and diesel traction for open-pit railway transport [

2] is provided. Conditions that promote the formation of welding bridges (setting) between microbridges of the contacting surfaces are described. Conclusions are drawn on the influence of the interaction modes of locomotive wheels with the rails on their traction ability.

The work [

3] presents and discusses the effect of different tangential contact models on the vehicle’s dynamic response.

The paper [

4] investigates the effect of slip rate on the traction coefficient of the wheel/rail interface using a twin-disc machine under replicated tribological and locomotive operating conditions. The traction coefficient decreases with increasing slip rate.

The study [

5] investigated wheel–rail contact, particularly the multifaceted aspects of wear phenomena in railway engineering, focusing on their significant implications for environmental costs and operational efficiency. Experimental trials were conducted using a high-performance bi-disc apparatus, evaluating various materials, contact pressures, and lubrication conditions.

The paper [

6] presents the electric traction system of the main line of two-unit freight diesel locomotives. Modernising a combined diesel engine startup system and a power supply for consumers of an onboard network using a synchronous machine in starter/generator mode increases the efficiency of locomotive electrical equipment usage. There are ways to improve regular axle control to increase diesel locomotive traction and power characteristics. Suggested solutions enhance the traction and anti-slip locomotive characteristics by modernising the traction transmission system and electrical equipment microprocessor control algorithms. According to the tests and operations carried out, axle control allows individual control of the tangential tractive effort of each axis of the locomotive. The benefits of such methods are as follows: limiting the speed of excessive sliding of the wheelset (no more than 1–3 m/s) with loss of adhesion, reducing the wheelset wear by 16%, minimising sand consumption by 20%, and minimising the loss of tangential power during wheel slippage. Thus, electronic control of the axle during traction aims to increase the tangential tractive effort and, accordingly, the traction coefficient of the locomotive by 12–15%, resulting in a 15% increase in the tonnage rating of the transported goods.

Controlling traction is improved using dedicated methods, such as direct torque control applied for dual-star induction motors, to reduce harmonic currents, torque ripples, and steady-state torque error [

7].

The stick–slip phenomenon, which commonly affects the starting of freight locomotives, is presented in [

8] as an example of stick–slip and stick–slip-separation waves.

The study [

9] discusses the implications of obstacle curvature, material orthotropy, and friction to the flutter and divergence instabilities of elastic media.

The presented work is focused on researching the dynamical effects of a rail vehicle while running on a railway track created in a commercial multibody model [

10].

The paper [

11] analyses the results of acceleration signal measurements obtained from the Rail Vehicle and Rail Track Monitoring System prototype. This prototype measures acceleration signals on designated elements of the electric multiple unit (EMU), which comprise components such as bogie frames, wheels, and bodies of railway vehicles.

The study [

12] states that structural dynamics are essential for understanding and assessing any engineering product performance, and knowledge of dynamic structural response is fundamental to ensuring a sustainable and safe product’s functioning. By using piezo sensors and FEM analysis, the authors aim to validate the dynamic finite elements model realised to certify the crashworthiness of locomotive design and to evaluate the body interaction with bogie and track to avoid locomotive structural resonance phenomena.

Bogie-hunting instability is one of the common faults in railway vehicles. It not only affects ride comfort but also threatens operational safety. Due to the lower operating speed of metro vehicles, their bogie-hunting stability is often overlooked. Acceleration and displacement sensors are installed on metro vehicles to collect data, which are processed in real-time in 2 s intervals [

13].

Several works deal with the measured dynamical response of a vehicle (vertical acceleration of rails and noise emission of a car), which is analysed in the time and frequency domain [

14,

15].

Previous work [

16] focused on compensating for the elimination of load transfer effects by using an algorithm to redistribute the traction effort between the tractive axles equipped with electric traction motors.

Conventional vibration monitoring systems relying on wired sensors present several limitations for continuous monitoring projects on many structures. In the work [

17], an intelligent wireless monitoring system is developed for bridge modal identification to provide an alternative tool to wired sensors in this field. The main peculiarities of the designed wireless accelerometers are the low cost, the ease of installation on the structure, and the long-term autonomy granted by using energy harvesting techniques.

In the paper [

18], several acceleration sensors for online measurement were installed on the lateral sides of the wheel axle of a test bogie. The accelerometers used are wireless three-axis sensors with a capacity of 60 g, and data were acquired at 6000 Hz.

The research presented in [

19] examined how vibration signals could be used for real-time train and track control. Experiments are essential to validate these methods when studying vibration in transportation because it is essential to consider various nonlinear dynamic forces that can occur during travel.

The reviews [

20] and [

21] provide more information about the vibration sensors used in railway equipment.

Faced with these challenges, the authors propose a method to evaluate the stick–slip phenomenon using electronic acceleration sensors placed on the wheel. They also propose a new method for mitigating the effects of the stick–slip phenomenon during the locomotive’s start by using a dampener on the wheelset. Simulations are used to prove that the dampener solution can improve the locomotive’s behaviour.

2. Materials and Methods

2.1. Selecting the Acceleration Sensors (Material, Range)

To validate the mathematical model used in the simulations of the stick–slip phenomenon, we measured and recorded the phenomenon produced at the axles of the 5100 kW electric locomotive.

For the measurement, we used an accelerometer mounted on one of the axle wheels where the stick–slip movement was generated. The accelerometer was positioned to measure the wheel’s tangential acceleration during stick–slip movement.

The data measured by this accelerometer were recorded on an SD card and subsequently transferred to a laptop for processing and analysis. It was impossible to connect directly to the computer and record the data in real time because the measurement and recording system rotated with the wheel on which it was mounted.

2.1.1. The Accelerometer

Selecting the acceleration sensor, we aim to use a low-weight device with low consumption and high accuracy.

Measuring range regarding acceleration is ±10 to ±20 g.

The accelerometer used to perform the measurements of stick–slip movement must meet the following conditions:

- -

smaller mass and dimensions;

- -

low power consumption to be able to power it from a small battery;

- -

measurement accuracy (not more than 0.5% measurement errors);

- -

immunity to electromagnetic disturbances;

- -

immunity to strong magnetic fields;

- -

be simple to connect with the recording installation.

The selected device was the MPU-6050 [

22] accelerometer produced by InvenSense Inc. This device is a three-axis accelerometer combined with a three-axis gyroscope integrated into a single 4 × 4 × 0.9 mm chip in MEMS technology.

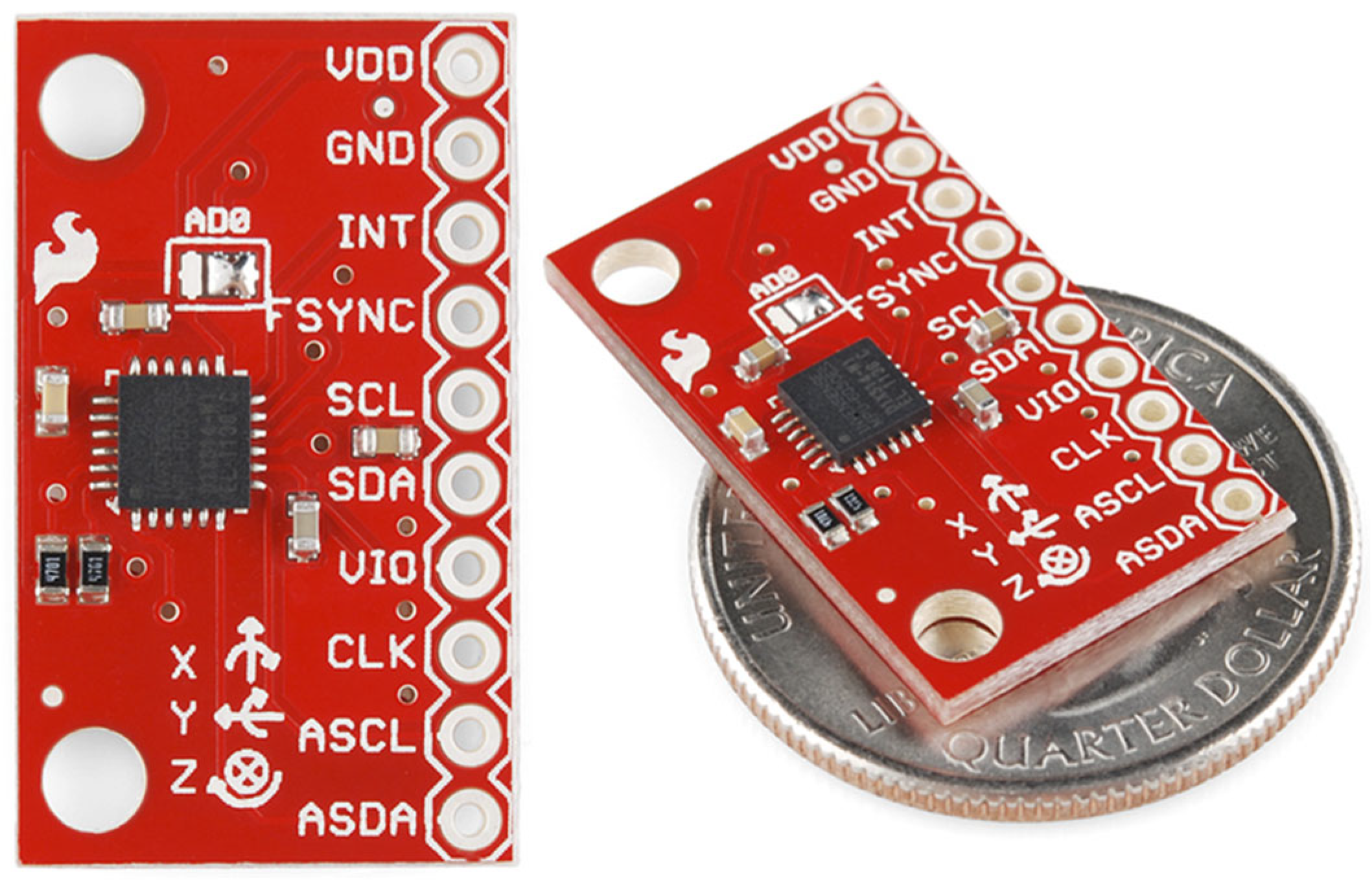

The integrated MPU-6050 accelerometer can be purchased as a SparkFun development board [

23]. The sensor is mounted on a printed circuit board with all the necessary peripheral components, as presented in

Figure 1. It is easy to use by simply connecting to a microcontroller.

Characteristics of the integrated MPU-6050 accelerometer that are relevant for this application are as follows:

Wiring plate dimensions: 27 × 15 × 4 mm;

Supply voltage: 2.3–3.4 Vdc;

Three–axes accelerometer measurement available scales: ±2 g, ±4 g, ±8 g or ±16 g;

Built-in temperature sensor;

Serial output data are transmitted using I2C protocol;

Integrated 16-bit analog-to-digital converter;

Current consumption: 500 μA;

Shock resistance: 10,000 g;

Operating temperature: −40 °C ÷ 85 °C;

Temperature sensitivity variation: ±0.02 %/°C;

Maximum sampling frequency: 1 kHz;

Mass: 1.5 g.

2.1.2. The Microcontroller

The microcontroller uses a serial communication channel with the accelerometer and must receive the transmitted data, format them, and save them to the microSD card as text files.

In addition to managing the received data, the microcontroller uses a start–stop button that commands the start and stop of the recording, as well as two LEDs that provide the status signal of the microcontroller.

The visual information displayed on those two LEDs are:

- -

blinking red: state of sleep (waiting);

- -

blinking green: data recording;

- -

red flash blinking intermittently: write error on micro SD card (missing card, full card, or defective card);

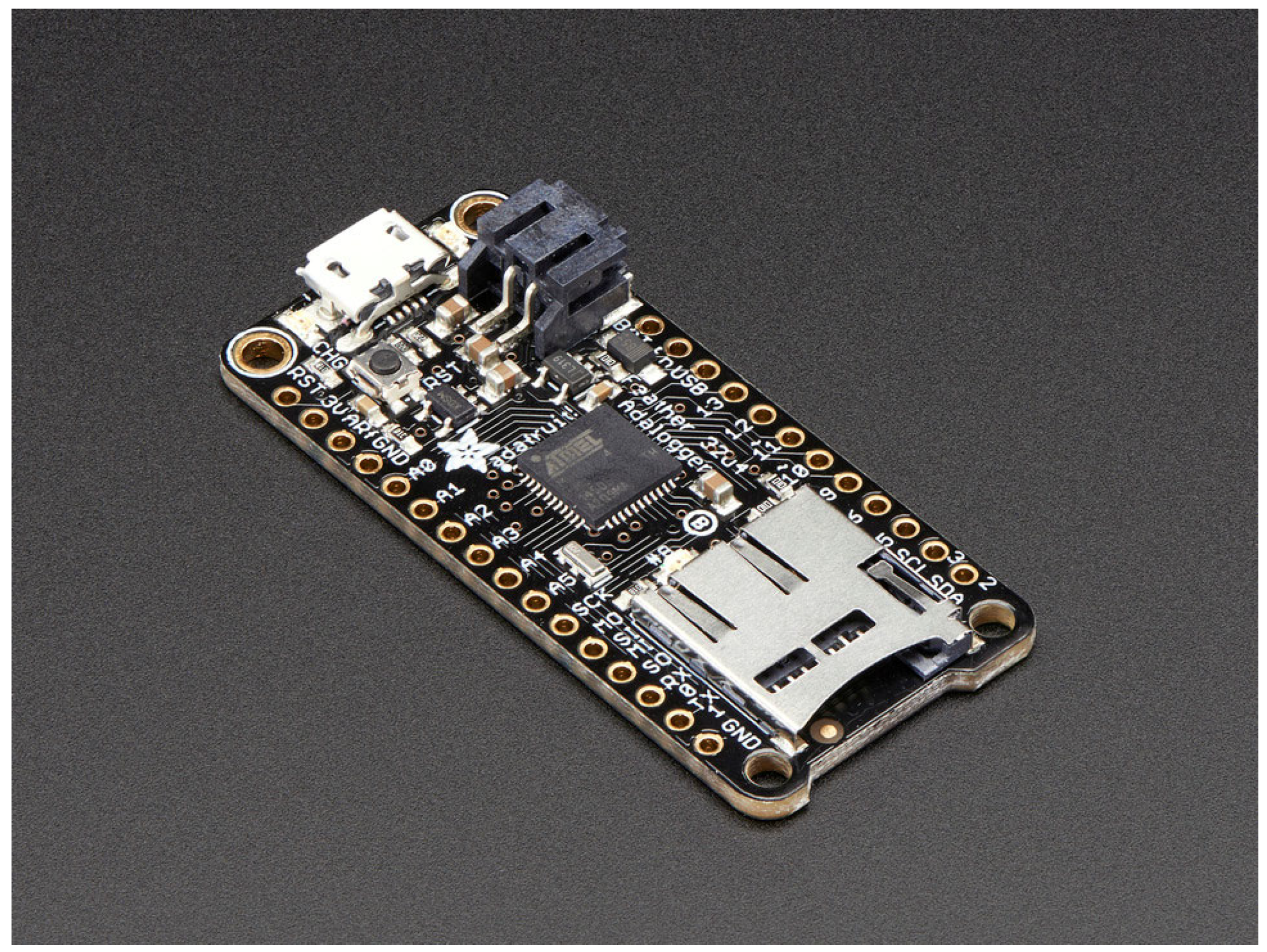

We chose an Atmega32u4 microcontroller card equipped with a micro SD card slot for storing data. Adafruit built the card’s commercial version, known as Adafruit Feather 32u4 Adalogger [

24], as presented in

Figure 2.

This microcontroller board has the following characteristics:

Dimensions: 51 mm × 23 mm × 8 mm;

Mass: 5.1 g;

ATmega32u4 microcontroller @ 8 MHz with 3.3 V logic;

Voltage regulator of 3.3 V and 500 mA;

Micro USB connector for programming, troubleshooting, and communications;

Hardware for serial communications, I2C, and SPI;

Seven pins with PWM capabilities;

Ten pins of analogue inputs and outputs.

This microcontroller board was mounted on a printed wiring circuit board and placed alongside the other components (connectors, start–stop button, battery switch, etc.) in an aluminium box for mechanical protection and protection against electromagnetic interference.

2.2. The Hardware of the Experimental Model Is Based on an Acceleration Sensor

Although theoretically, the acceleration sensor could have been placed in the same case as the microcontroller, we opted to separate them to protect the sensor from the resonance frequencies and harmonics coming from the vibrations of the rest of the components.

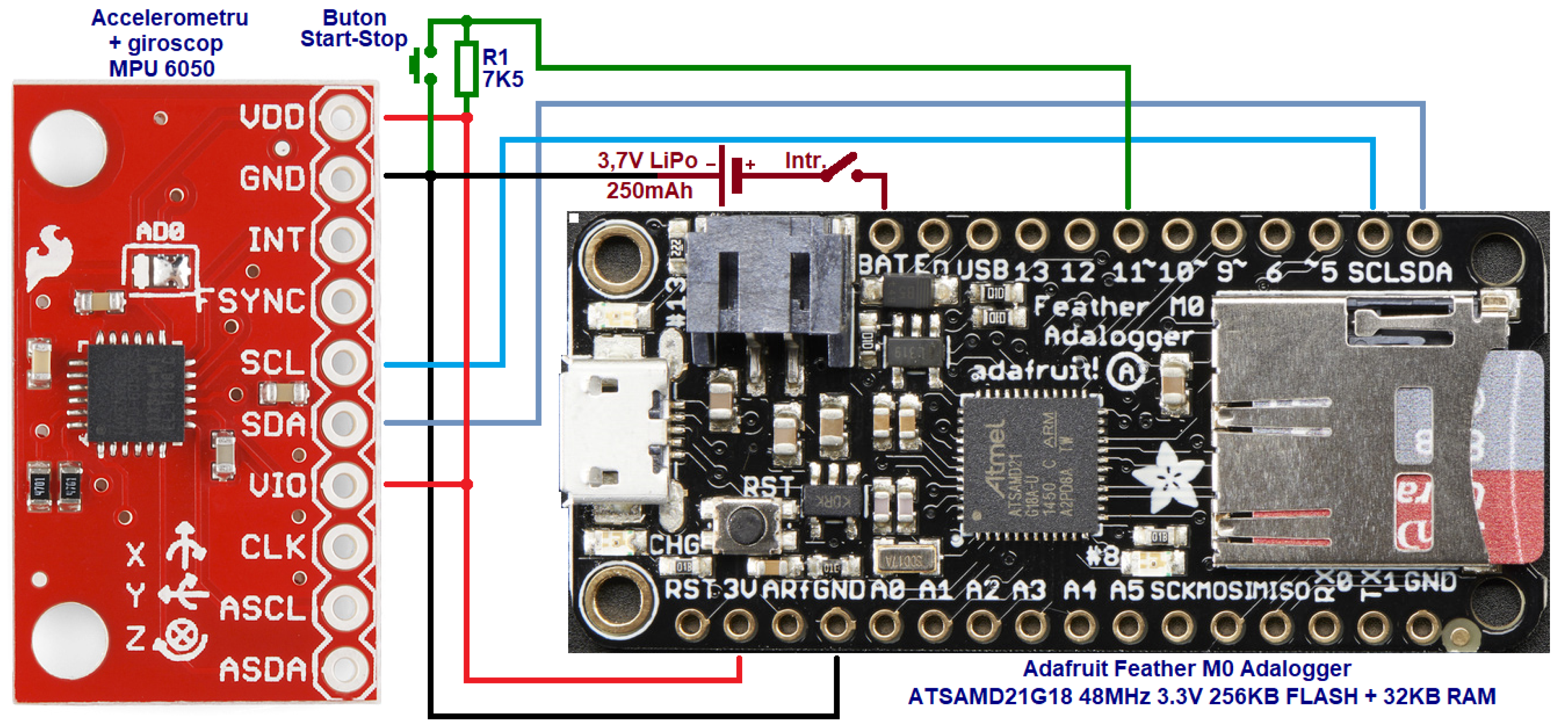

The electrical diagram of the measuring system is provided in

Figure 3.

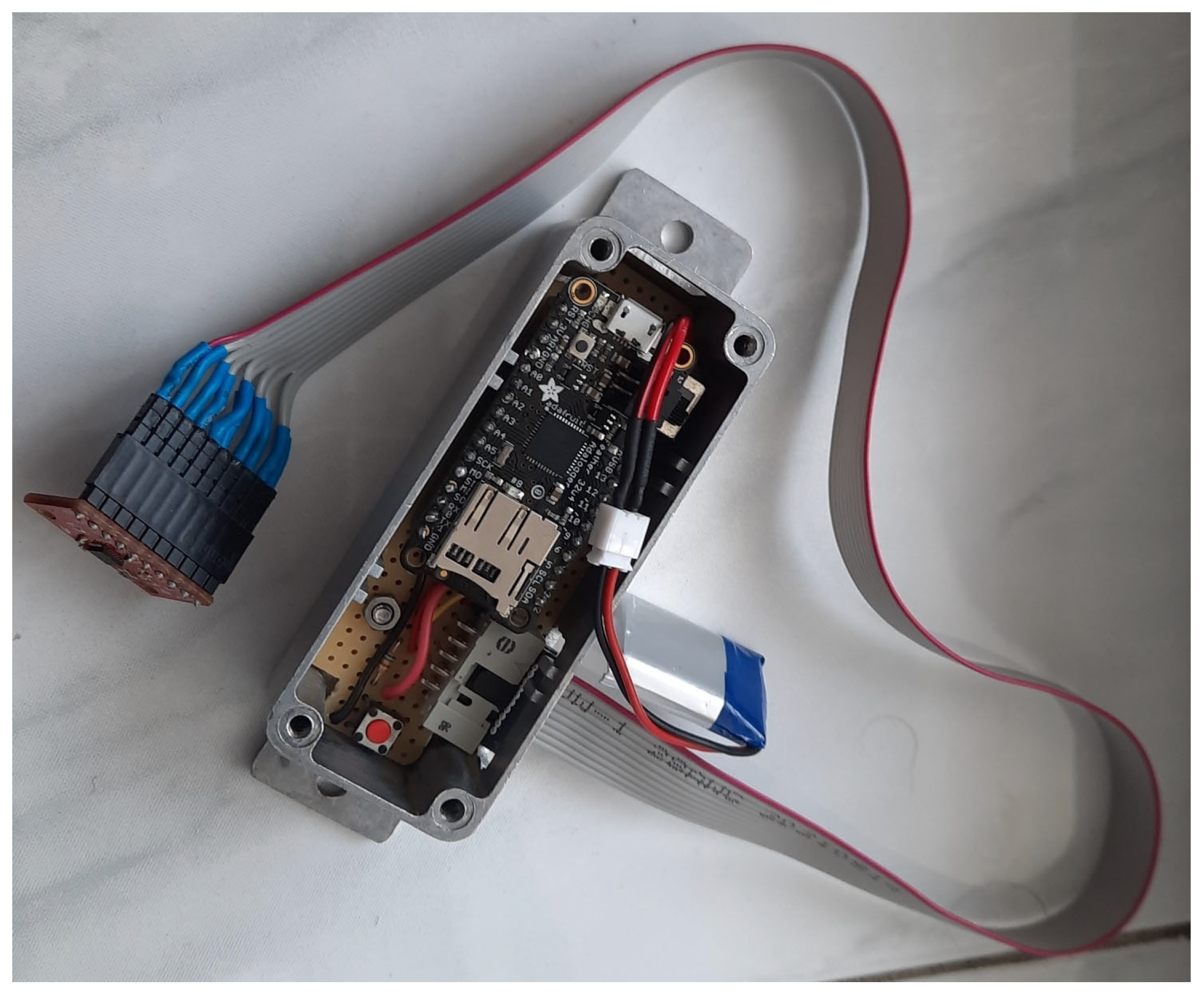

Figure 4 shows the fully assembled measuring system, and

Figure 5 shows the system attached to the wheel.

2.3. Mounting the Acceleration Sensors on the Wheel

The aluminium box, including the microcontroller, was also fixed to the wheel with solid magnets (made of Neodym).

A 10-wire ribbon cable with connectors at both ends connected the accelerometer and the microcontroller.

The experimental setup was mounted on the wheel’s interior without any mechanical drills on the metal part of the wheel. Magnets were used to properly attach the components of the experimental model to the wheel, making them easy to disassemble at the end of the tests. The tests were performed on the powerful locomotive available [

25] when trying to push another blocked locomotive, thus generating the stick–slip located at the tractive wheels.

2.4. Software Developed for the Experimental Model

The microcontroller’s main task was to read the data transmitted serially by the acceleration sensor and write them to the microSD card.

Also, the microcontroller was required to display the status using two LEDs and to periodically read the status of the start–stop button.

Even though the acceleration sensor performed acceleration measurements at 1000 samples per second, the system’s speed was much lower. The limiting factor was the low write speed on the micro SD card.

For this reason, the microcontroller’s program had to be optimised to achieve an acceptable sampling speed. Mitigating the number of accesses to the micro SD card was necessary. Ultimately, we obtained a measured sampling speed of 304,135 Hz, which is enough for the intended purpose. This sampling speed allows for the recording of a spectrum of frequencies up to 152 Hz.

The microcontroller program was written in C++, compiled, and loaded into the microcontroller’s memory with the Arduino development environment.

2.5. Hydraulic Shock Absorbers for the Experimental Model

Due to the adverse effects manifested during the stick–slip movements of the driving axles, including the accentuated wear of the wheels on the treads and oscillatory tensions in the mounted axle, we searched for a method that would eliminate this phenomenon. We proposed a system of damping stick–slip movement at the driving axles.

2.5.1. Solution for Reducing the Stick–Slip Phenomenon

The proposed technical solution uses a set of shock absorbers on the wheel discs and axle drive gear.

A shock absorber is a flywheel encapsulated in a metal housing filled with a viscous liquid (mineral oil). The flywheel can rotate freely from the housing. The play between the flywheel and the housing is small enough, and the relative movement of the flywheel to the housing produces significant viscous friction, which achieves energy dissipation and damping of oscillations.

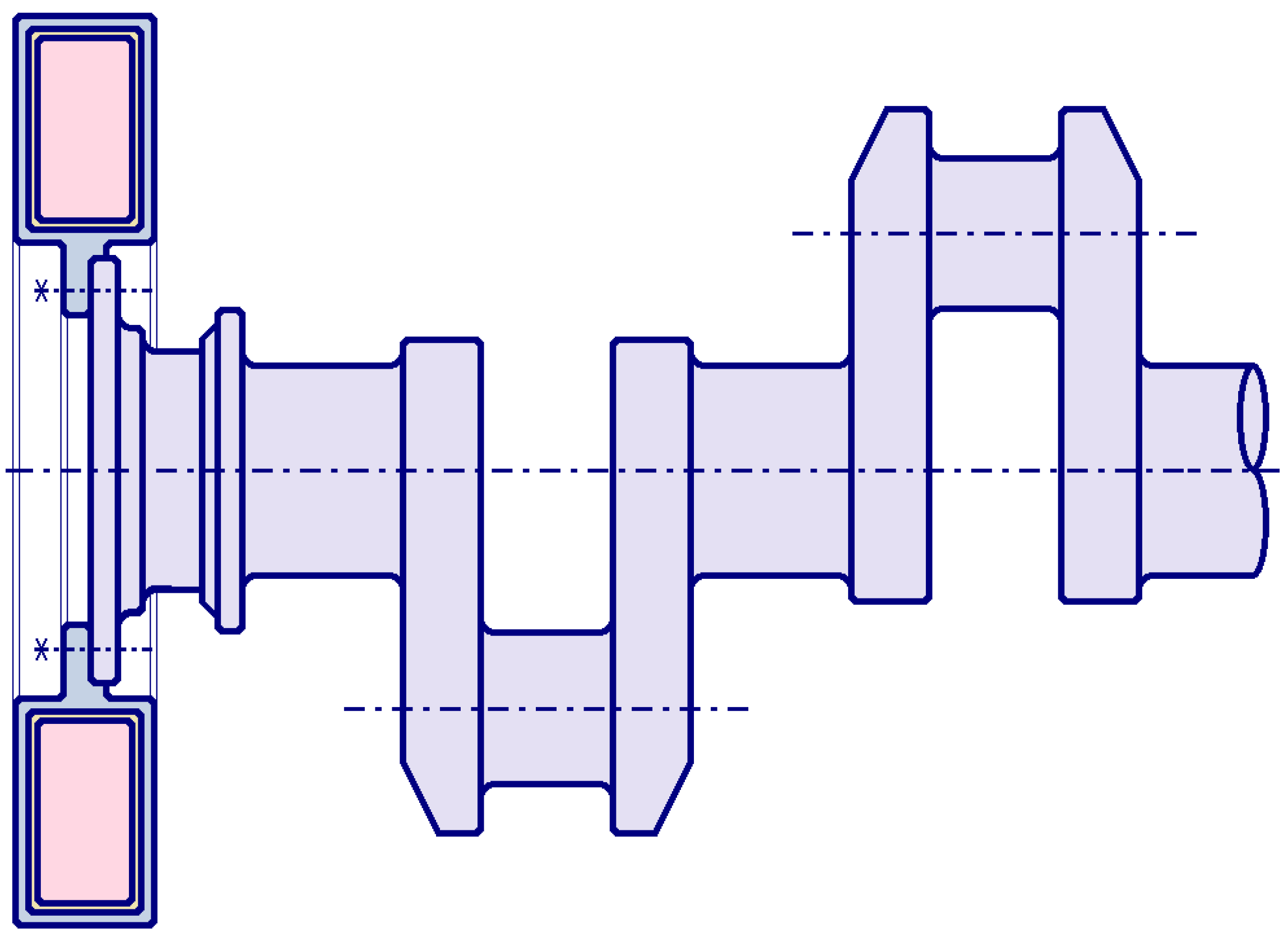

This technical solution was identified in the flywheel used in the 12LDA28 diesel engine [

26] with which 060DA electric diesel locomotives [

27] are equipped, as presented in

Figure 6. The two crankshafts at the free end are provided with viscous dumpers [

28] used as shock absorbers to reduce the torsion vibrations to which these shafts are subjected during the motor’s operation.

The operation of such an oscillation damper is as follows: the damper housing tracks the movement of the shaft, which consists of a constant-speed component superimposed on an oscillating component. Due to the relatively high inertia, the flywheel tends toward uniform movement. The difference in gears between the flywheel and its housing generates viscous friction forces between the housing and the flywheel, and the torque of these forces dampens the shaft’s oscillations.

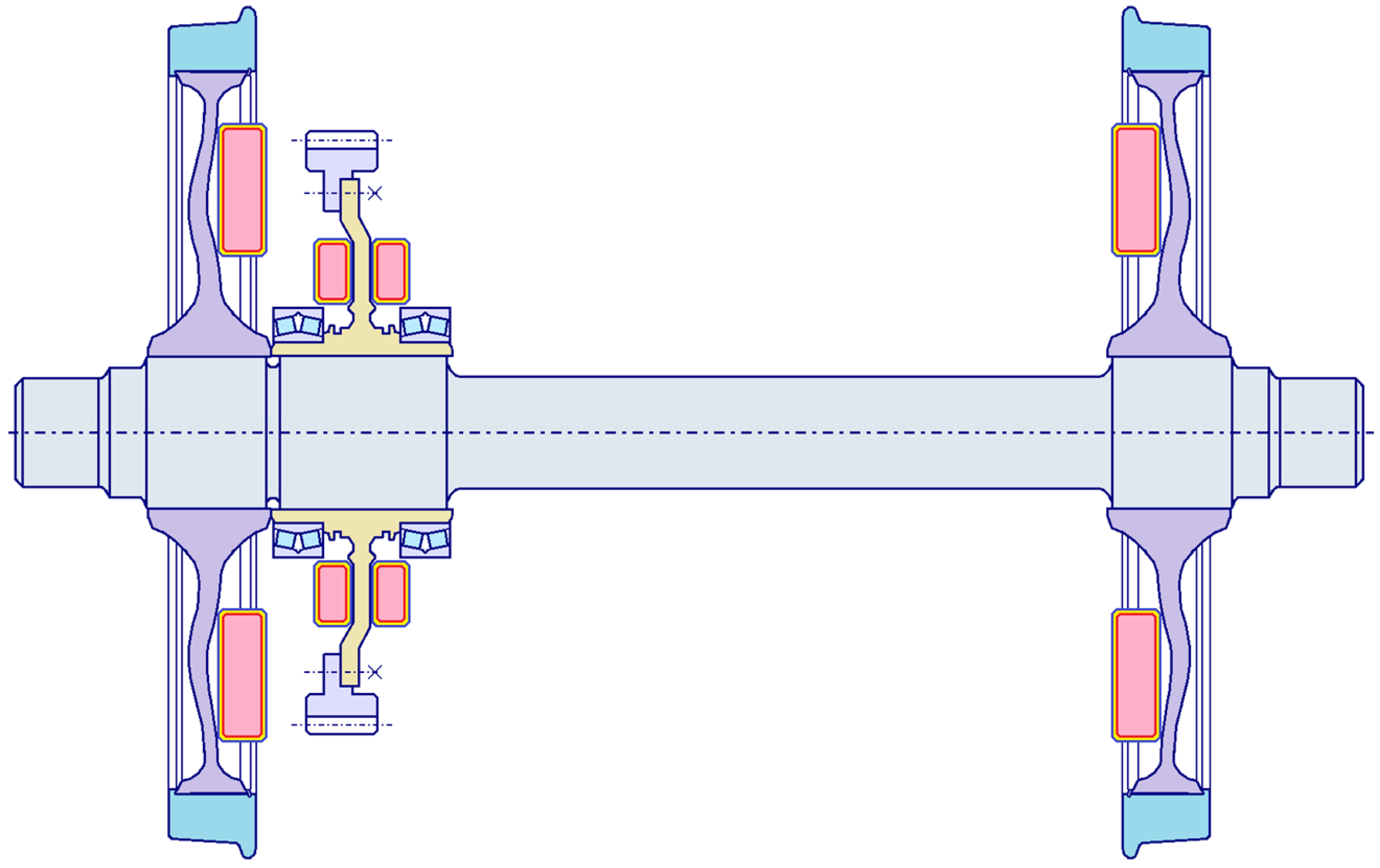

To reduce the oscillations of the driving axle’s stick–slips, we propose using vibration dampers, like the ones shown in

Figure 7, on the locomotive axle.

We identified two solutions for placing the dampers on the wheelset: one on the wheel’s interior and the other inside the drive gear, as presented in

Figure 8.

The presence of wheel-mounted brake discs limits the installation of shock absorbers on the axle wheels. The space available in the gear housing also affects the possibility of mounting the dampers on the axle drive gear.

2.5.2. The Mathematical Model Used for the Simulation

We studied the efficiency of such a damping system through simulations of the stick–slip behaviour of a driving axle fitted with two shock absorbers mounted on the discs of the two wheels, as presented in [

29]. We have rewritten the system of differential equations used in previous simulations to model the stick–slip behaviour of such an axle provided with a damping system. To carry this out, we have completed the differential equations corresponding to the movement of the two wheels with terms expressing the resistance torque applied to the wheels by the two shock absorbers.

3. Results

3.1. The Presentation of the Rough Data Saved during the Tests

The microcontroller’s data were saved in text format to be quickly examined immediately after the measurements were finished.

The data in text format were converted to Excel format for quick visualisation as charts. In this format, it was also possible to remove the data that were not of interest (areas before the start of the measurements and regions after the end of the measurements).

Writing software that graphically represents the acquired data was necessary to visualise them. The first recording was made with the immobilised wheel to record the noise of the acceleration signal. While recording, we checked the noise level of the recorded signal and the presence of the sound signal of some components resulting from electromagnetic disturbances in the railway environment (50 Hz components and their harmonics coming from electric traction installations or 75 Hz components from the signalling installations). The values are steady, and a −1.85 m/s2 offset was recorded; this background noise affects the measurement values by only 0.0457%. Also, checking the noise spectrum recorded using a scope, no dominant components with 50 Hz, 75 Hz, or multiples of these frequencies were found.

Tests were carried out with the active locomotive providing the tractive force, having the accelerometer mounted on the front wheel, and trying to move a blocked locomotive. This simulates the most significant effort during a train’s launch: the initial movement when the brakes are closed and must be opened with the movement.

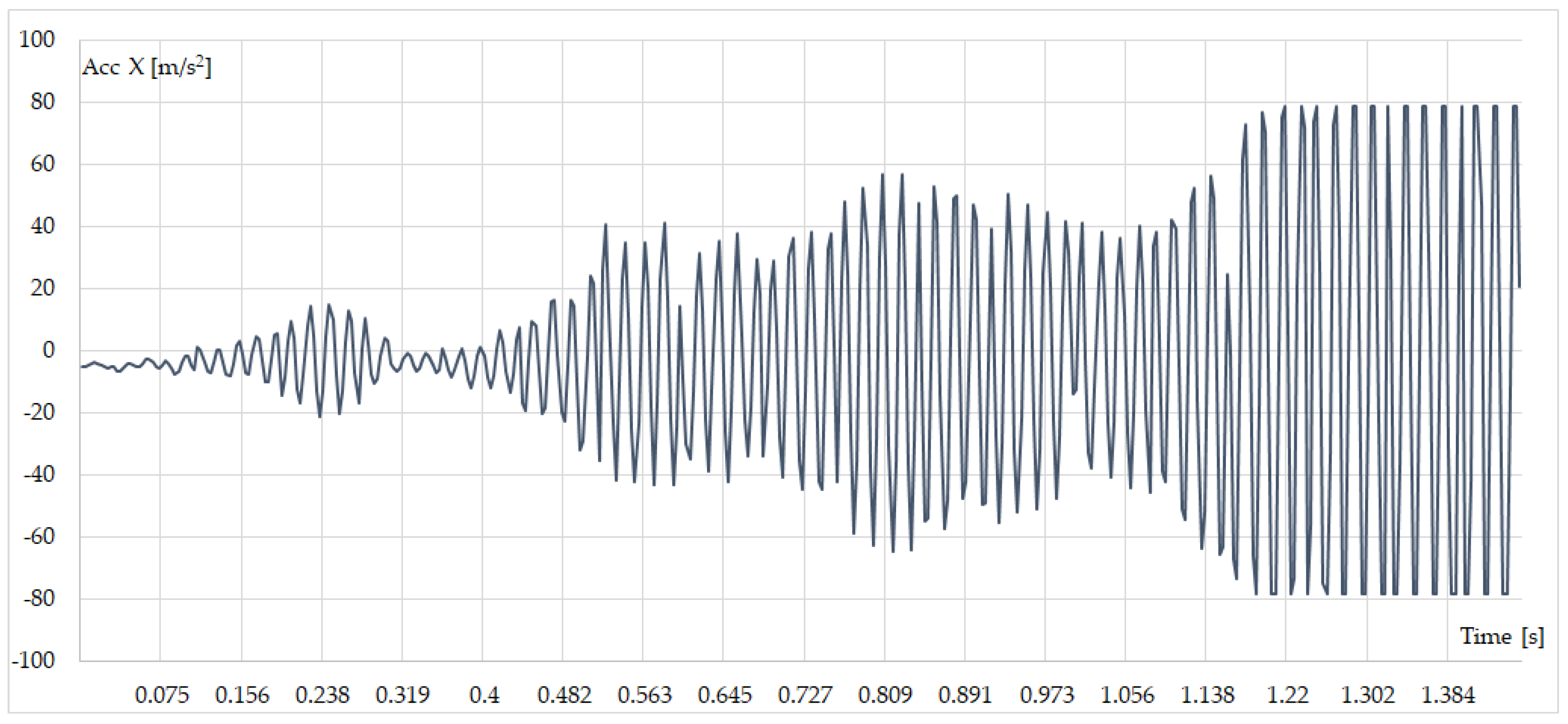

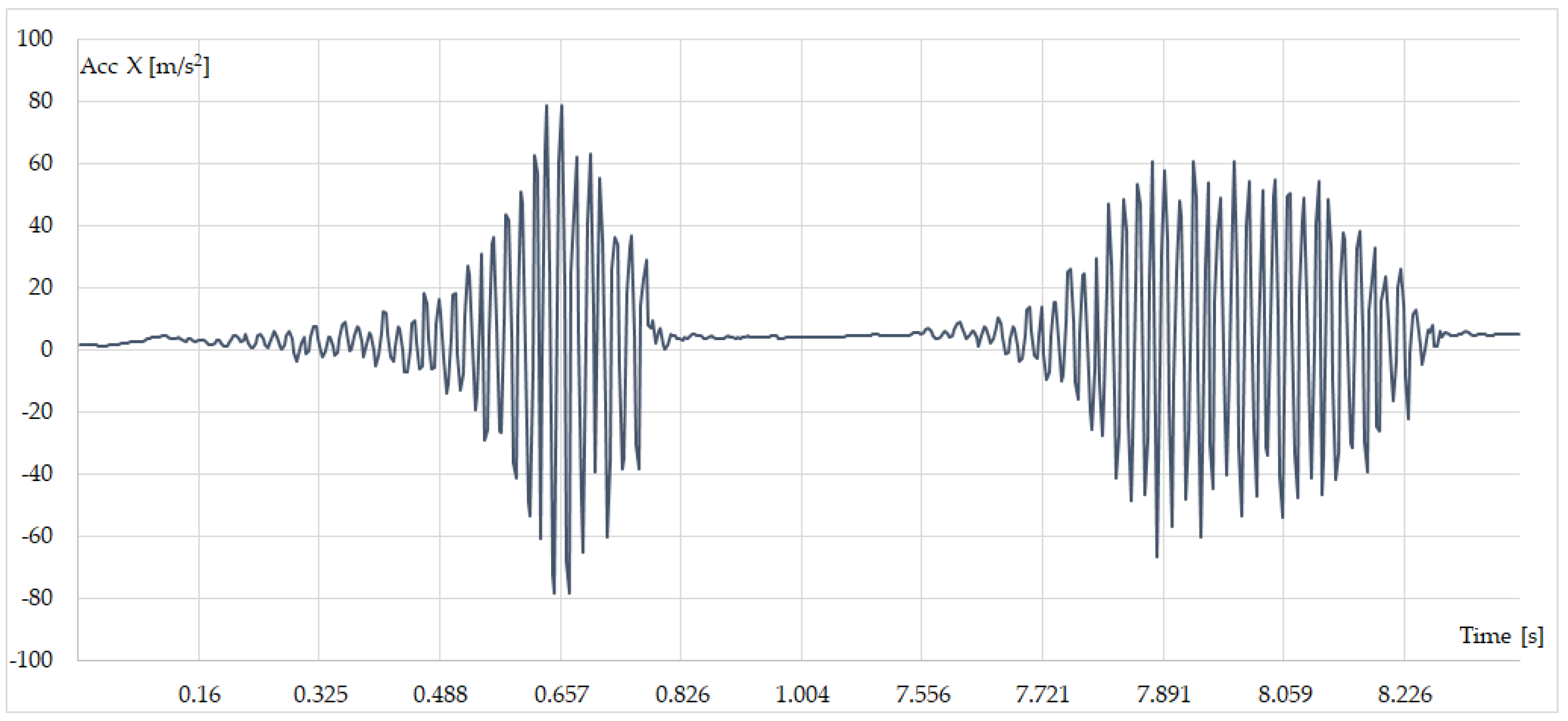

Figure 9 shows one of the recordings made when the wheel starts the stick–slip phenomenon. The amplitude of the acceleration rises to 78 m/s

2. The frequency can be measured on the graphic, with two successive peak values of 0.018 s, corresponding to a 55 Hz oscillation.

In

Figure 9,

Figure 10,

Figure 11 and

Figure 12, the vibrations were so strong that, in some portions, they exceeded the sensor’s maximum measuring range (8∙g). The analysis of these datasets was carried out only on the portion where the level of the measured accelerations was within the transducer’s measuring range.

Figure 9,

Figure 10 and

Figure 11 show that after exceeding the adhesion limit, the amplitude of the oscillations increases then decreases a little, a situation that differs from the graphs resulting from the simulations. This decrease in amplitude is caused by a slight increase in the coefficient of friction between the wheel and the rail because, due to friction, the impurities existing on the surface of the wheel and rail are partially removed.

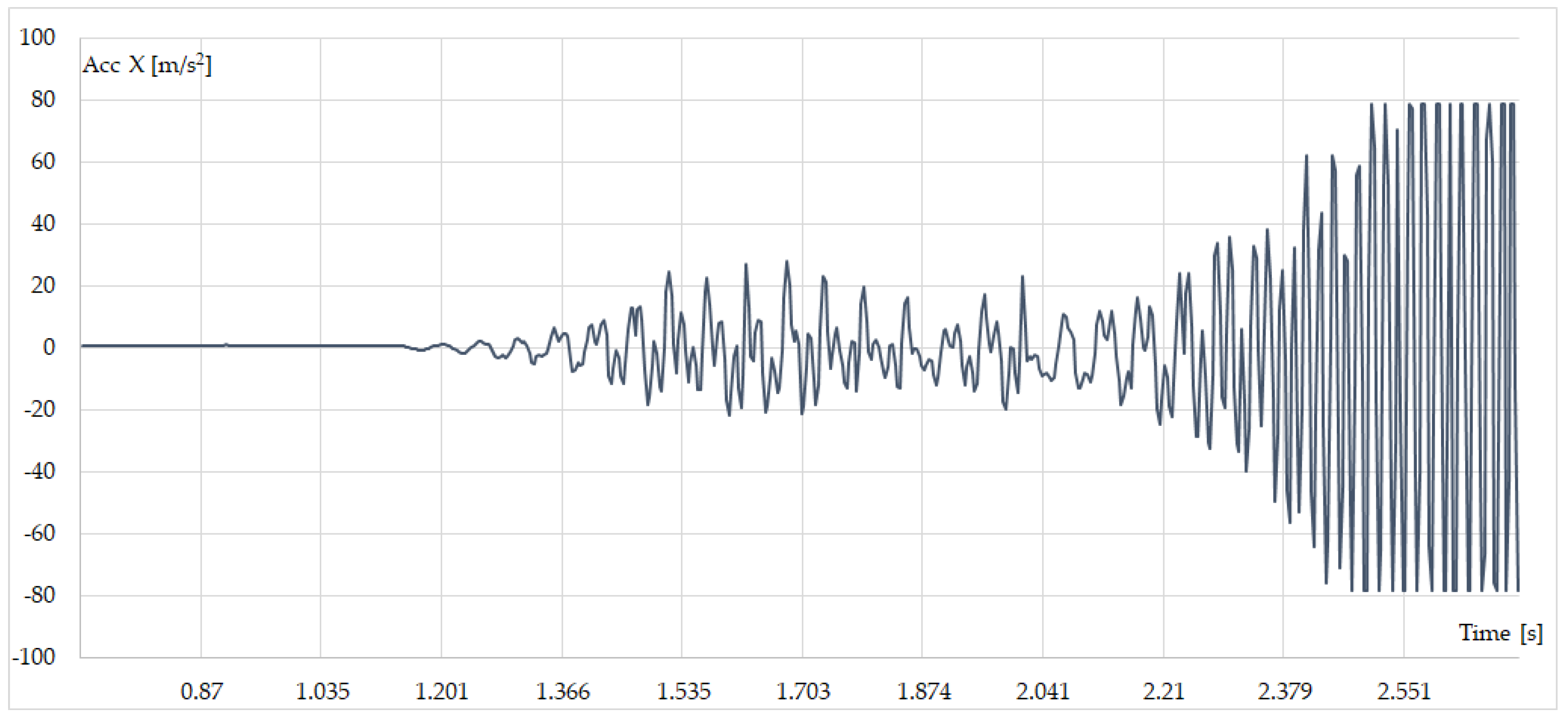

In

Figure 10, the measuring system records some wheels sliding in the time intervals of 1.2–2.21 s until correct sanding of the rail-wheel surface increases the adherence, and the amplitude of the vibrations rises to central values after the 2.4 s point.

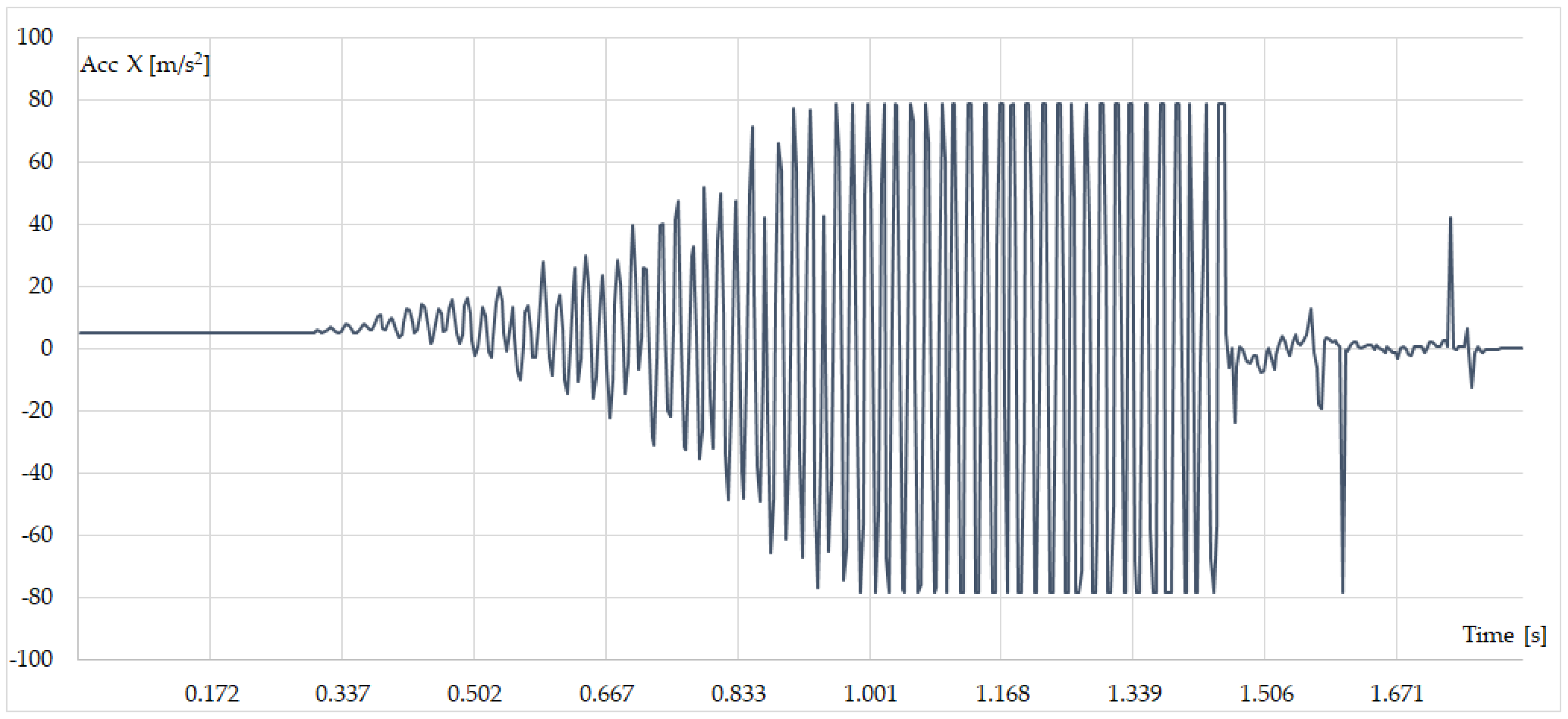

In

Figure 11, it can be seen that the measuring system recorded the start of the tandem locomotives, with the initial stick–slip at low amplitude and duration (maximum 75 m/s

2 for 0.3 s), when the first locomotive has the pneumatical brake released, the bumpers compressed, and a new brake release with stick–slip with a maximum acceleration of 60 m/s

2 (for 0.5 s).

In

Figure 12, it can be seen that the measuring system detached from the wheel surface at some point, causing the amplitude of the vibrations to drop sharply to zero.

The frequency spectra obtained from simulations and measurements are similar except for the noise in the spectrum of the measurement data. This noise is attributed to the sensors’ offset and the irregularities on the wheel and rail surfaces.

The acceleration frequency is 55 Hz, which each measurement can detect. This value is essential for finding the proper shock absorbers.

3.2. Presentations of the Effects of Hydraulic Shock Absorbers

To highlight the two-wheeled shock absorbers’ effect, we integrated the differential Equations (23)–(28) systems from [

29], first without shock absorbers and then with shock absorbers. The two integrations were carried out strictly with the same parameters and starting from the same initial conditions, the difference being only the presence or absence of shock absorbers. The results of the two integrations (graphs of the angular speeds of the two wheels) were then compared.

The simulation was made with a program obtained by adapting the program used in stick–slip simulations, which achieves the parallel integration of the two systems of differential equations.

The two-wheeled shock absorbers were supposedly identical with the following parameters:

Several simulations were carried out for different drive torques at the wheel cover, starting from the torque corresponding to the adhesion limit.

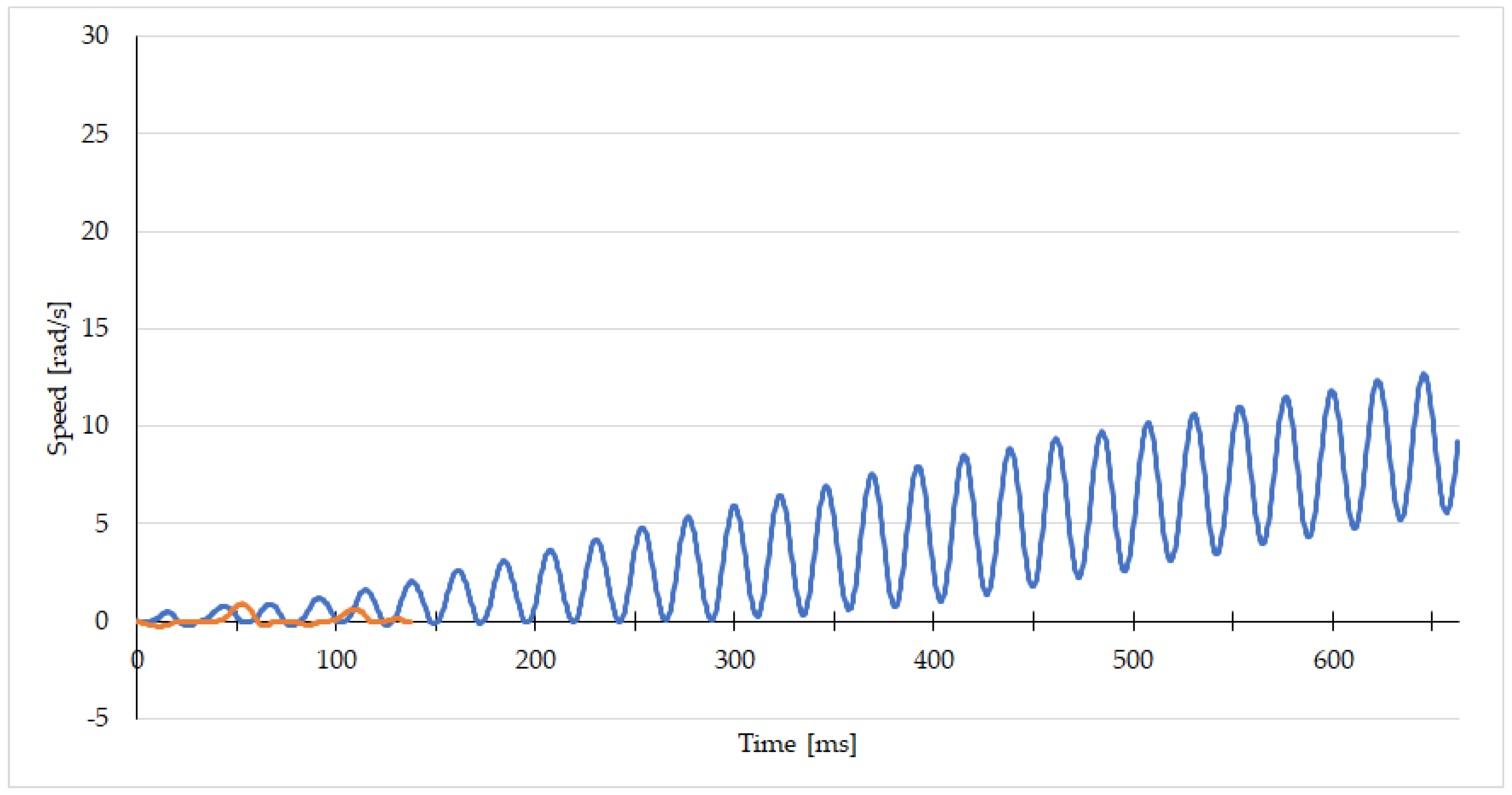

The first simulation was carried out at a wheel cover torque of 8720 N∙m. At this torque value, the adhesion limit is slightly exceeded.

At these conditions, the skating of the axle begins, accompanied by a stick–slip (the blue line from

Figure 13). In the absence of the damping system, the oscillation amplitude increases to infinity. In the presence of the damping system, the stick–slip phenomenon is triggered. Still, after a few oscillations, it pays off, restoring adhesion (the orange line from

Figure 13). This behaviour is explained by the fact that at values close to the adhesion limit, the energy input in the oscillating system of the driving axle is small enough to be picked up and dissipated immediately by the damping system.

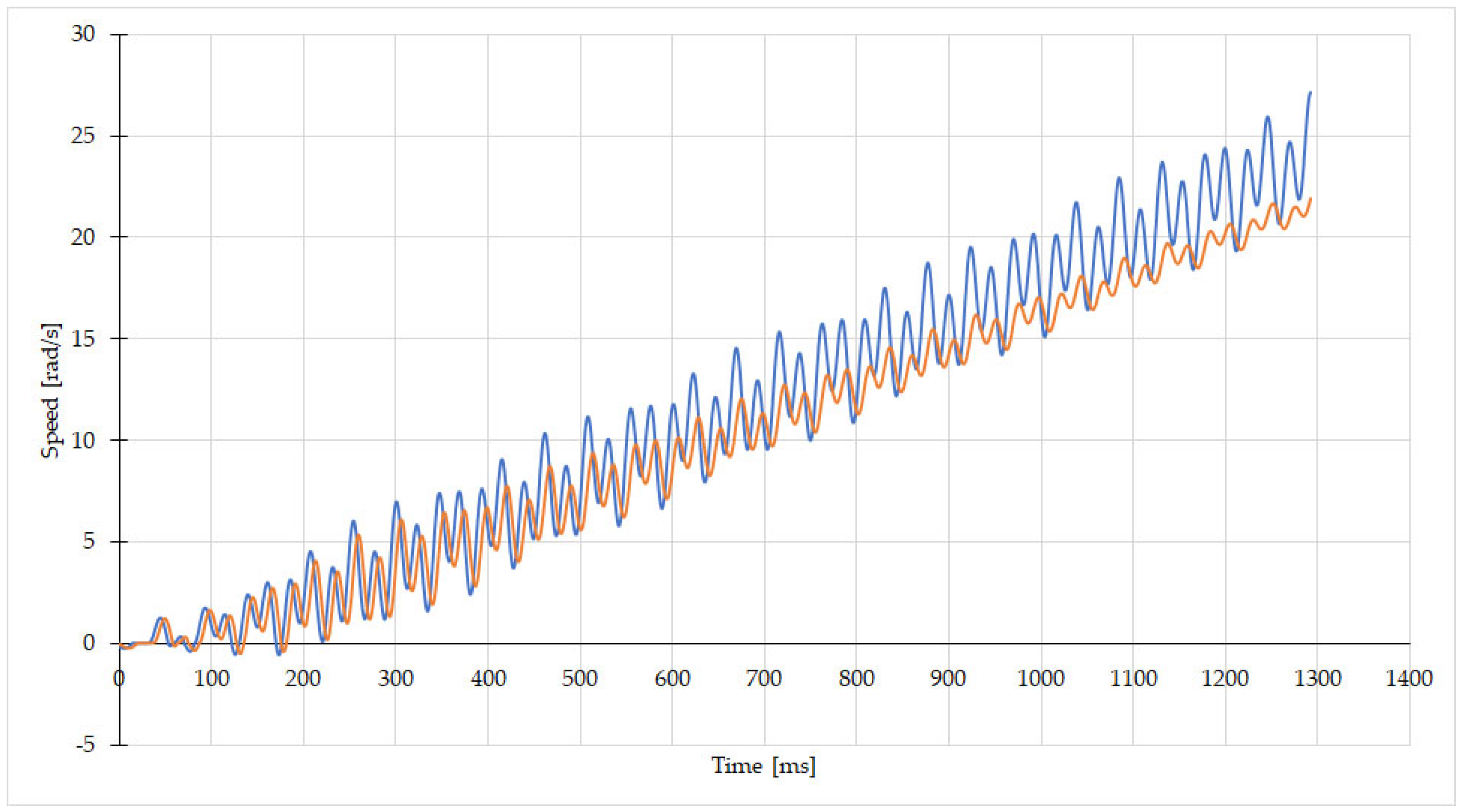

At higher torque (9040 Nm), the axle begins skating, and shock absorbers cannot avoid the wheel movement but affect the oscillation amplitude, as seen in

Figure 14.

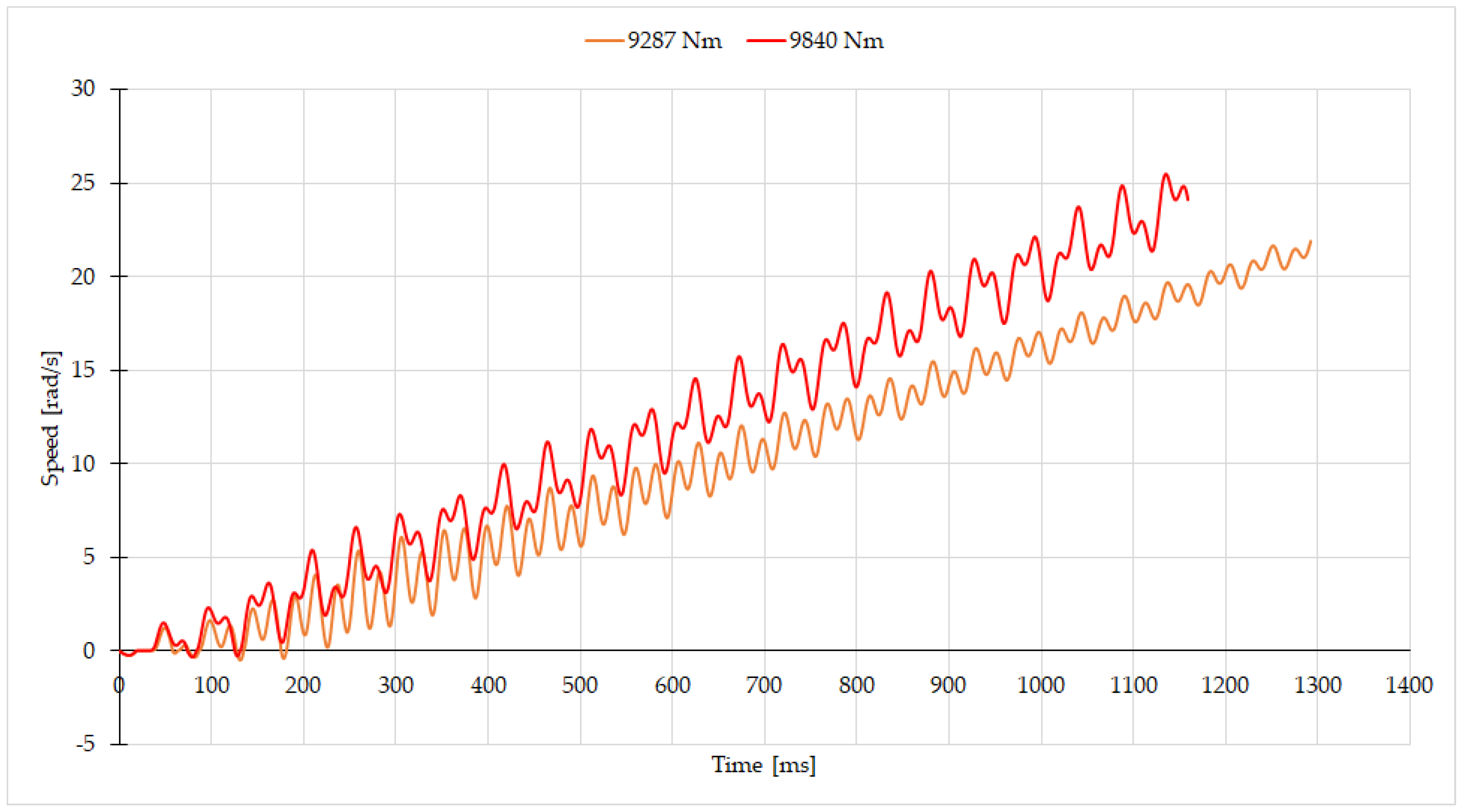

Simulations performed with higher torque show that the axle will begin skating and that the acceleration is proportional to the applied torque. Even in the presence of the shock absorbers, the wheels skate but do so with reduced oscillations. In

Figure 15, we present the skating of the wheel, while using shock absorbers, at major torque of 9840 Nm and 9287 Nm. The simulations with increasing motor torque values were carried out to evaluate the conformity of the simulation, as the higher the torque applied, the higher the acceleration is.

4. Discussion

The results are adjusted for a locomotive equipped with DC traction motors, which are known to have significant problems during startup. However, the solution can also be applied to locomotives powered by AC. Minimising the amplitude of the stick–slip phenomenon can enhance the available traction force and reduce wheel wear. It has been observed that the simulation data obtained using the proposed mathematical model sufficiently approximates the data obtained from measurements.

Variations in the coefficient of friction can cause differences in friction between the wheel and rail. These variations are caused by substances contaminating the surfaces of the wheel or rail, such as water, oil, dust, and metal powders, as well as the roughness and wear condition of the wheel surface and rail.

Based on the simulations, the damping system does not eliminate the stick–slip phenomenon. However, it does reduce the amplitude of the phenomenon and, to a lesser extent, the frequency of the oscillations produced, which is beneficial during operation. Additionally, the damping system improves the behaviour of the axle when the wheels lock during braking.

The simulations show that at higher torque values, the shock absorbers can no longer fully take over the energy introduced into the elastic system by wheel skating. This results in skating accompanied by stick–slips, and the amplitude of the oscillations increases towards infinity. However, the amplitude of stick–slip oscillations is reduced in the presence of shock absorbers, and the frequency of oscillations is significantly lower. This benefits the operation of the tread wear and the axle’s fatigue stress.

The disadvantages of using the damping system include increasing the unsprung mass of the axle, which has adverse effects, especially at high speeds. Additionally, the limited space available in the area of the driving axles makes it challenging to mount shock absorbers, especially when the brake discs are mounted on wheels.

One can consider implementing systems for the elastic retention of the wheel or axle dampers to reduce unsprung mass. If brake discs are present, these shock absorbers can be situated between them and the wheels.

Freight trains running on steep inclines may experience a phenomenon called stick–slip over a prolonged period. This can cause the shock absorbers to generate significant heat, so cooling fins may be necessary to dissipate heat effectively.

Developments in the field of stick–slip detection are related to increasing the freight transportation payload and can include the use of electronic sensors powered by batteries, in a similar constriction as the pressure sensors used by cars, to help the automatic launch procedure performed by the traction control unit of the locomotive. Also, for old-fashioned locomotives using DC traction motors, the use of such shock absorbers as presented can reduce the effect of the stick–slip phenomena.

5. Conclusions

The developed measurement system for the wheel’s centripetal acceleration can detect the critical accelerations involved during stick–slip phenomena at acceleration rates up to 200 m/s2. As described in the article, the system was used to record data for estimating the amplitude and frequency of the stick–slip movement of the tractive wheels for a DC traction locomotive. The experimental setup can detect stick–slip phenomena, and can signalise to the driver when stick–slip phenomena is detected, for acceleration values starting with 1 g.

The system can be enhanced to provide signals to the control system and the driver. Based on the alarms generated during the detected stick–slip, the tractive force can be automatically or manually reduced. After extensive testing, the information obtained during slipping can be used to improve the train’s starting.

The proposed method of reducing the amplitude of the stick–slip phenomenon using special hydraulic dampers and viscous dampers mounted on the locomotive’s tractive axles prevents slipping during acceleration, as demonstrated using numerical simulation with two vibrations dampeners consisting of the flywheels used in the 12LDA28 diesel engine [

26], with which the 060DA electric diesel locomotive is equipped, mounted on the wheels of a DC traction locomotive.

Installing shock absorbers to reduce the oscillation amplitude caused by stick–slip could be particularly effective in locomotives designed for pulling freight trains. Due to the significant forces, the stick–slip phenomenon occurs at high frequencies and lower traffic speeds, and the extra unsprung mass of the driving axle has no adverse effects.

Author Contributions

Conceptualization, G.P. and M.A.; methodology, G.P. and M.A.; software, M.A.; validation, G.P., E.T. and G.I.; formal analysis, E.T. and I.V.; investigation, M.A. and G.I.; resources, M.A.; data curation, E.T.; writing—original draft preparation, M.A.; writing—review and editing, E.T. and I.V.; visualisation, I.V.; supervision, G.I.; project administration, G.P.; funding acquisition, G.P. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by National University of Science and Technology POLITEHNICA Bucharest through Project PubArt, and partially by the Ministry of Research, Innovation, and Digitalization, through Nucleus Program 42N/2023, project number PN23140102.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All the data substantiating the conclusion of this study are included. Other primary datasets are available, upon reasonable request, from the author.

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the study’s design, data collection, analysis, interpretation, or manuscript writing or in the decision to publish the results.

References

- Popa, G.; Tudor, E. Vehicule Feroviare de Tracțiune cu Motoare Asincrone (Traction Rail Vehicles with Asynchronous Motors), 3rd ed.; Editura MatrixRom: Bucharest, Romania, 2024; pp. 46–67. [Google Scholar]

- Keropyan, A.M. Features of interaction of traction wheels of an electric locomotive and a diesel locomotive with rails in the conditions of open mountain works. J. Frict. Wear 2016, 37, 78–82. [Google Scholar] [CrossRef]

- Millan, P.; Pagaimo, J.; Magalhães, H.; Ambrósio, J. Clearance joints and friction models for the modelling of friction damped railway freight vehicles. Multibody Syst. Dyn. 2022, 58, 21–45. [Google Scholar] [CrossRef]

- Rahaman, M.L.; Bernal, E.; Spiryagin, M.; Bosomworth, C.; Sneath, B.; Wu, Q.; Cole, C.; McSweeney, T. An investigation into the effect of slip rate on the traction coefficient behaviour with a laboratory replication of a locomotive wheel rolling/sliding along a railway track. Tribol. Int. 2023, 187, 108773. [Google Scholar] [CrossRef]

- Zani, N.; Mazzù, A.; Solazzi, L.; Petrogalli, C. Examining Wear Mechanisms in Railway Wheel Steels: Experimental Insights and Predictive Mapping. Lubricants 2024, 12, 93. [Google Scholar] [CrossRef]

- Shamardina, V.N.; Anishchenko, M.V.; Lemeshko, S.M.; Kanunnikov, R.V. Functional efficiency enhancement of diesel-electric locomotive traction system. In Proceedings of the International Conference on Modern Electrical and Energy Systems (MEES), Kremenchuk, Ukraine, 15–17 November 2017; pp. 20–23. [Google Scholar] [CrossRef]

- Guedida, S.; Tabbache, B.; Nounou, K.; Benbouzid, M. Direct torque control scheme for less harmonic currents and torque ripples for dual star induction motor. Rev. Roum. Des Sci. Tech. Sér. Électrotech. Énergétique 2023, 68, 331–338. [Google Scholar] [CrossRef]

- Moirot, F.; Nguyen, Q.-S.; Oueslati, A. An example of stick–slip and stick–slip–separation waves. Eur. J. Mech. A/Solids 2003, 22, 107–118. [Google Scholar] [CrossRef]

- Pinto da Costa, A.; Agwa, M.A. Frictional instabilities in orthotropic hollow cylinders. Comput. Struct. 2009, 87, 1275–1286. [Google Scholar] [CrossRef]

- Dižo, J.; Blatnický, M.; Harušinec, J.; Suchánek, A. Assessment of Dynamics of a Rail Vehicle in Terms of Running Properties While Moving on a Real Track Model. Symmetry 2022, 14, 536. [Google Scholar] [CrossRef]

- Kostrzewski, M. Analysis of selected acceleration signals measurements obtained during supervised service conditions—A study of hitherto approach. J. Vibroengineering 2018, 20, 1850–1866. [Google Scholar] [CrossRef]

- Manea, I.; Sebesan, I.; Ghita, G.; Matache, M.-G.; Arsene, S. Experimental modal analysis of an electric locomotive body. MATEC Web Conf. 2017, 112, 07008. [Google Scholar] [CrossRef]

- Zheng, B.; Wei, L.; Zeng, J.; Zhang, D. Experimental and Numerical Investigation of Bogie Hunting Instability for Railway Vehicles Based on Multiple Sensors. Sensors 2024, 24, 4027. [Google Scholar] [CrossRef] [PubMed]

- Hába, A.; Zelenka, J.; Musil, M.; Vágner, J.; Kohout, M.; Havlíček, P. Diagnostics of railway vehicle based on dynamical response measurement. Vibroeng. Procedia 2014, 3, 272–277. [Google Scholar]

- Zanelli, F.; Debattisti, N.; Mauri, M.; Argentino, A.; Belloli, M. Development and Field Validation of Wireless Sensors for Railway Bridge Modal Identification. Appl. Sci. 2023, 13, 3620. [Google Scholar] [CrossRef]

- Andrei, M.; Popa, G.; Tudor, E.; Anghelița, P.; Matache, M.-G. The Electric Traction Motors Balancing for Load Transfer Effects Compensation. INMATEH-Agric. Eng. 2023, 71, 290–300. [Google Scholar] [CrossRef]

- Gonzalo, A.-P.; Entezami, M.; Weston, P.; Roberts, C.; Garcia Marquez, F.-P. Railway Track and Vehicle Onboard Monitoring: A Review. E3S Web Conf. 2023, 409, 02014. [Google Scholar] [CrossRef]

- Cho, H.; Park, J.; Park, K. Analysis of Axial Acceleration for the Detection of Rail Squats in High-Speed Railways. CivilEng 2023, 4, 1143–1156. [Google Scholar] [CrossRef]

- Celiński, I.; Burdzik, R.; Młyńczak, J.; Kłaczyński, M. Research on the Applicability of Vibration Signals for Real-Time Train and Track Condition Monitoring. Sensors 2022, 22, 2368. [Google Scholar] [CrossRef] [PubMed]

- Kostrzewski, M.; Melnik, R. Condition Monitoring of Rail Transport Systems: A Bibliometric Performance Analysis and Systematic Literature Review. Sensors 2021, 21, 4710. [Google Scholar] [CrossRef] [PubMed]

- Bernal, E.; Spiryagin, M.; Cole, C. Onboard Condition Monitoring Sensors, Systems and Techniques for Freight Railway Vehicles: A Review. IEEE Sens. J. 2019, 19, 4–24. [Google Scholar] [CrossRef]

- MPU-6050. Available online: https://invensense.tdk.com/products/motion-tracking/6-axis/mpu-6050/ (accessed on 11 July 2024).

- MPU-6000A. Available online: https://cdn.sparkfun.com/datasheets/Components/General%20IC/PS-MPU-6000A.pdf (accessed on 11 July 2024).

- Adalogger. Available online: https://www.adafruit.com/product/2795 (accessed on 11 July 2024).

- 060-EA Locomotives. Available online: https://ro.dbcargo.com/rail-ro-en/db-cargo-romania-fleet/locomotives/5-100-kW-060-EA-type-locomotives (accessed on 11 July 2024).

- 060-DA Locomotives. Available online: https://ro.dbcargo.com/rail-ro-en/db-cargo-romania-fleet/locomotives/060-DA-Diesel-locomotives (accessed on 11 July 2024).

- Sulzer 12LDA28C Engine. Available online: https://www.derbysulzers.com/12LDA28C.html (accessed on 11 July 2024).

- Viscous Damper. Available online: https://www.vibratechtvd.com/torsional-dampers#crankshaft (accessed on 11 July 2024).

- Andrei, M.; Popa, G.; Ilie, G.; Tudor, E. Stick-Slip Movement in Driving Axles of Railway Vehicles equipped with Damping Devices. Electroteh. Electron. Autom. 2023, 71, 32–39. [Google Scholar] [CrossRef]

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).