A Computational Framework for Enhancing Industrial Operations and Electric Network Management: A Case Study

Abstract

1. Introduction

2. Objectives

- Identification and Reorganization of Electrical Switchboards: This entails a comprehensive audit and restructuring of electrical switchboards across various departments within the organizational framework. The project aims to minimize energy wastage and enhance overall system performance by streamlining and optimizing the placement of these switchboards.

- Designing Electrical Systems Layout: The project will delve into the intricate task of designing the layout of electrical systems within the industrial facility. Emphasis will be placed on optimizing the positioning of frames and electrical facilities to ensure seamless integration and efficient operation.

- Certification of Energy Needs: A critical aspect of the project involves certifying the energy requirements of different equipment and determining their associated usage fees. This comprehensive assessment will provide valuable insights into energy consumption patterns and aid in devising cost-effective energy management strategies.

- Development of Energy Analysis Tool: Central to the project’s objectives is the creation of a sophisticated energy analysis tool. This tool will leverage advanced computational algorithms to identify critical energy capacities and pinpoint potential areas for expansion. The tool will enable proactive decision-making and facilitate continuous improvement initiatives by providing real-time insights into energy usage patterns.

3. Development Method and Management Tool

- Identification and reorganization of all the electrical switchboards in the industrial facility by developing electrical schematics.

- Electrical switchboard site survey and tagging, jointly with the facilities management team, regarding their location and peer-to-peer linkages within the factory, as exemplified in Figure 2.

- Electrical switchboard energy supply analysis for factory installation.

- Energy needs checking of all the connected equipment, from production line machines to deriving switchboards and electric breakers, and their variation according to the usage rate.

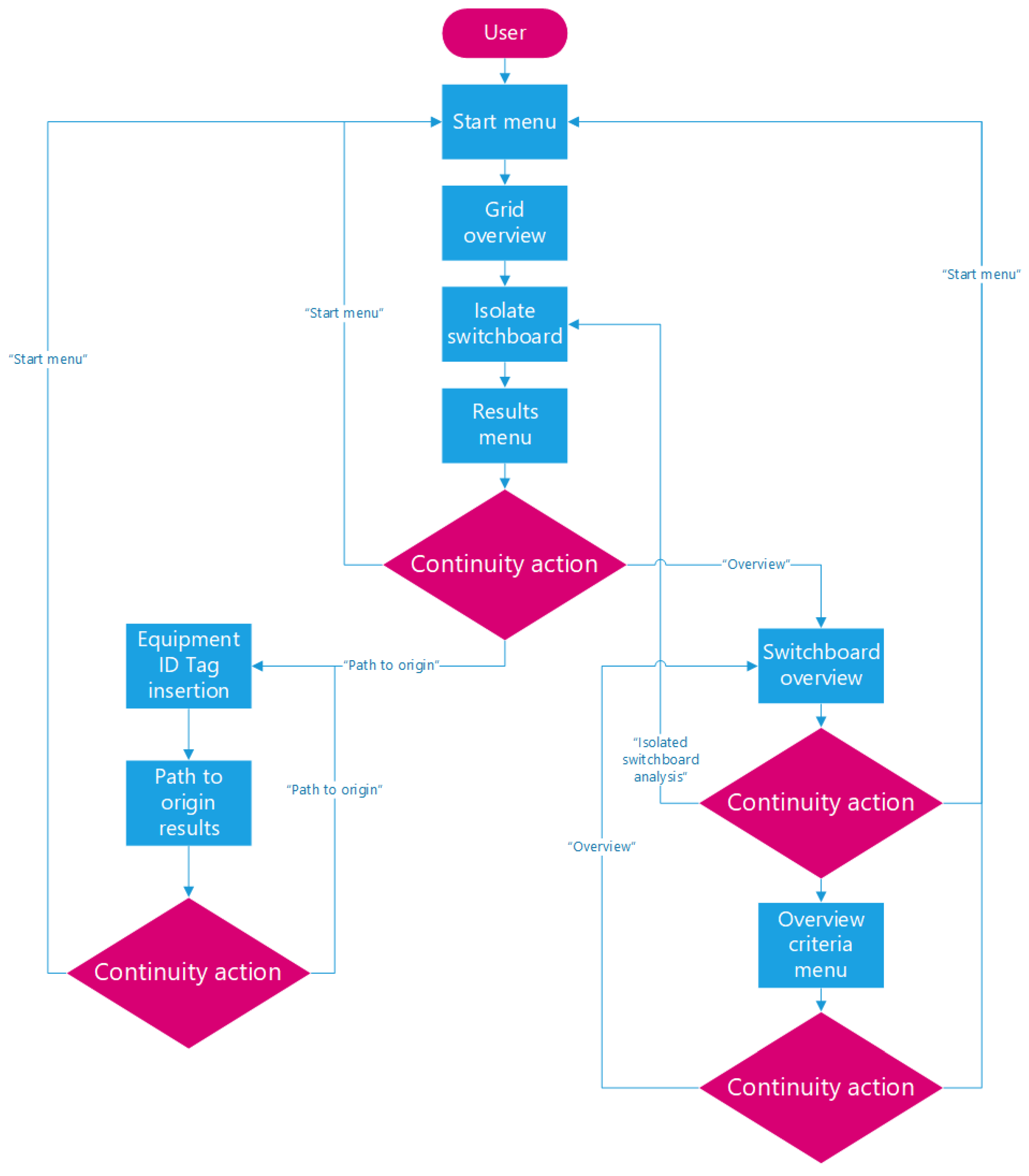

- Development of a computational analysis tool in Visual Basic (VBA) language, using Microsoft® Visual Studio™, which will provide users with an understanding of the factory energy load at each point so that critical points and possible zones of expansion are quickly identified.

- Compile and validate the obtained improvements, comparing the newer management solution with the previous tagging model.

3.1. Equipment Insertion

- Machine: The user assigns a piece of equipment that purely consumes electrical energy and, therefore, occupies an available space allocation, increasing the flow of electric current consumed in the frame supplier. This selection strictly applies to groups of one, two and three pieces of equipment.

- Switchboard: This insertion option allows accommodation of possible expansions of the electrical network through the allocation of supplier equipment of energy in the energy network.

- Electric breaker: The user can expand the network by adding dependent energy supply equipment and updating existing equipment. This type of individual expansion can have various fundamentals, such as adapting the electrical panel to allocate specific equipment or decreasing space criticality within the supplier equipment.

3.1.1. Machine Insertion

- The electric circuit breaker must be inserted within the chosen APU zone and must not have any equipment previously attached.

- The equipment electric phases (single or three-phased) shall comply with the electric breaker.

- The connection breaker used to add the equipment to the switchboard must be an end connection breaker, i.e., none of the other circuit breakers present in the program’s database can have its nomenclature as precedent identification.

- The circuit breaker must still have an equal or higher admissible electric current than the machine’s electrical consumption.

3.1.2. Switchboard Insertion

3.1.3. Electric Circuit Breaker Insertion

3.2. Equipment Removal

- By tag.

- By location.

3.3. Grid Overview

3.3.1. Grid Database, Pending Tags and Facility Plan

3.3.2. Locate Equipment

3.3.3. Isolate Switchboard

3.3.4. Grid General Overview

- Occupied electric breakers (OEBs), number of electric circuit breakers inside a switchboard with coupled equipment.

- Available electric breakers (AEBs), number of circuit breakers inside a switchboard.

- %Space, allowing the user to perceive and anticipate the possible space criticalities of switchboards. The ratio between the number of breakers with attached equipment and the total number of breakers in the switchboard establishes the variable given by Equation (1):

- Space representation, one of the three most graphical variables, represents the percentage of space occupation. Each column represented in red equals 10% of the occupied space with attached equipment, while those represented in green correspond to that available for equipment allocation.

- Occupied electric current (OEC) is the electric current consumed, defined as the sum of currents emitted by the switchboard to feed the equipment with energy needs, coupled through connections downstream of the energy flow.

- The AEC is the switchboard electric current available to supply possible incoming equipment.

- The ECL% represents the percentage of OEC effectively used by equipment coupled over the total electric current (TEC). It is a relation described in Equations (2) and (3). The parameter ECL% provides perception and identification of the criticality points in the facility’s energy-supplying equipment. It allows an analysis concerning the compromise between installing newer equipment and the risk of the analyzed switchboard’s rupture and, consequently, determines which points are most suitable for network expansion.

- Electric current representation, likewise, space representation, has the function of representing the ECL%. Each column represented in red equals 10% of the electric current consumed by the equipment attached to the switchboard.

- The percentage of global criticality (%Global) appears as a combination of the %Space and ECL% in a single analysis factor criticality of the power supply equipment.

- The global representation has the function of graphically representing the percentage of global criticality through columns of green or red color.

- Space evaluation (SE) concerns the numerical evaluation of the percentage of the %Space, as addressed in Table 1. With a straightforward color system interpretation, equipment that does not meet the %Space criteria is filled in red. The equipment that respects the %Space but must be kept under observation is painted in yellow, and those that are entirely under control will be in green,

- Electric current evaluation (ECE) refers to the numerical evaluation of the percentage of total available current in use, as addressed in Table 1. The algorithm is analogous to the one used with the SE.

- Global evaluation (GE) is the arithmetic sum of the SE and ECE numeric values, as described in Equation (4). The combination is performed by the sum of the two numerical evaluations on a single property, following criteria established by the user in the Criteria Overview Menu, which are all numerical values attributed to the free space and ECL(%), as described in Table 1. The color scheme is the same for the SE and ECE cases.

4. Results

5. Discussion

6. Conclusions

- Effective integration of open-source algorithms into the electrical management system.

- Enhanced administration methods and tools for integrating new equipment without interrupting production lines.

- Open-source code availability allows for swift extrapolation and application across small and medium-sized organizations requiring high-flexibility layouts.

- The program’s transformative potential significantly adds value to the company, becoming a crucial industrial asset.

- Efficient transformation of vast quantities of dispersed information into accessible, filtered options.

- Improved electrical grid management.

- Recognition of the lack of electrical management in almost 90% of Portuguese small and medium enterprises.

- A comprehensive system for managing electrical flows, enhancing organizational flexibility and competitiveness.

- Applicability of the tool’s principles to solve similar problems in other industries, with adaptations to specific cases.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Majumdar, S. Chapter 17—Cloud-Based Smart-Facilities Management. In Internet of Things; Buyya, R., Vahid Dastjerdi, A., Eds.; Morgan Kaufmann: Burlington, MA, USA, 2016; pp. 319–339. [Google Scholar]

- Awang, M.; Mohammed, A.H.; Rahman, M.S.A.; Abdullah, S.; Mod, M.Z.C.; Sani, S.I.A.; Hamadan, N. Facility Management Competencies in Technical Institutions. Procedia Soc. Behav. Sci. 2012, 65, 755–760. [Google Scholar] [CrossRef]

- Leygonie, R.; Motamedi, A.; Iordanova, I. Development of quality improvement procedures and tools for facility management BIM. Dev. Built Environ. 2022, 11, 100075. [Google Scholar] [CrossRef]

- Kang, C.-N.; Kung, L.-C.; Chiang, P.-H.; Yu, J.-Y. A service facility location problem considering customer preference and facility capacity. Comput. Ind. Eng. 2023, 177, 109070. [Google Scholar] [CrossRef]

- ISO 41001:2018(E); Facility Management—Management Systems—Requirements with Guidance for Use. International Organization for Standardization: Geneva, Switzerland, 2018; p. 56.

- Burova, A.; Mäkelä, J.; Heinonen, H.; Palma, P.B.; Hakulinen, J.; Opas, V.; Siltanen, S.; Raisamo, R.; Turunen, M. Asynchronous industrial collaboration: How virtual reality and virtual tools aid the process of maintenance method development and documentation creation. Comput. Ind. 2022, 140, 103663. [Google Scholar] [CrossRef]

- Zhao, Y.; Taib, N. Cloud-based Building Information Modelling (Cloud-BIM): Systematic literature review and Bibliometric-qualitative Analysis. Autom. Constr. 2022, 142, 104468. [Google Scholar] [CrossRef]

- Gao, X.; Pishdad-Bozorgi, P. BIM-enabled facilities operation and maintenance: A review. Adv. Eng. Inform. 2019, 39, 227–247. [Google Scholar] [CrossRef]

- Di Biccari, C.; Calcerano, F.; D’Uffizi, F.; Esposito, A.; Campari, M.; Gigliarelli, E. Building information modeling and building performance simulation interoperability: State-of-the-art and trends in current literature. Adv. Eng. Inform. 2022, 54, 101753. [Google Scholar] [CrossRef]

- Xu, W.; Wu, R.; Wang, L.; Zhao, X.; Li, X. Solving a multi-objective distributed scheduling problem for building material equipment group enterprises by measuring quality indicator with a product gene evaluation approach. Comput. Ind. Eng. 2022, 168, 108142. [Google Scholar] [CrossRef]

- Yilmaz, G.; Akcamete, A.; Demirors, O. BIM-CAREM: Assessing the BIM capabilities of design, construction and facilities management processes in the construction industry. Comput. Ind. 2023, 147, 103861. [Google Scholar] [CrossRef]

- Deng, M.; Tan, Y.; Singh, J.; Joneja, A.; Cheng, J.C.P. A BIM-based framework for automated generation of fabrication drawings for façade panels. Comput. Ind. 2021, 126, 103395. [Google Scholar] [CrossRef]

- Wang, W.; Guo, H.; Li, X.; Tang, S.; Li, Y.; Xie, L.; Lv, Z. BIM Information Integration Based VR Modeling in Digital Twins in Industry 5.0. J. Ind. Inf. Integr. 2022, 28, 100351. [Google Scholar] [CrossRef]

- Pan, Y.; Stark, R. An interpretable machine learning approach for engineering change management decision support in automotive industry. Comput. Ind. 2022, 138, 103633. [Google Scholar] [CrossRef]

- Djordjevic, I.; Petrovic, D.; Stojic, G. A fuzzy linear programming model for aggregated production planning (APP) in the automotive industry. Comput. Ind. 2019, 110, 48–63. [Google Scholar] [CrossRef]

- Andres, B.; Poler, R.; Sanchis, R. A data model for collaborative manufacturing environments. Comput. Ind. 2021, 126, 103398. [Google Scholar] [CrossRef]

- Iaksch, J.S.; Borsato, M. Method for digital evaluation of existing production systems adequacy to changes in product engineering in the context of the automotive industry. Adv. Eng. Inform. 2019, 42, 100942. [Google Scholar] [CrossRef]

- Einabadi, B.; Mahmoodjanloo, M.; Baboli, A.; Rother, E. Dynamic predictive and preventive maintenance planning with failure risk and opportunistic grouping considerations: A case study in the automotive industry. J. Manuf. Syst. 2023, 69, 292–310. [Google Scholar] [CrossRef]

- Dias, P.; Silva, F.J.G.; Campilho, R.D.S.G.; Ferreira, L.P.; Santos, T. Analysis and Improvement of an Assembly Line in the Automotive Industry. Procedia Manuf. 2019, 38, 1444–1452. [Google Scholar] [CrossRef]

- Moreira, B.M.D.N.; Gouveia, R.M.; Silva, F.J.G.; Campilho, R.D.S.G. A Novel Concept of Production and Assembly Processes Integration. Procedia Manuf. 2017, 11, 1385–1395. [Google Scholar] [CrossRef]

- Hribernik, K.; Cabri, G.; Mandreoli, F.; Mentzas, G. Autonomous, context-aware, adaptive Digital Twins—State of the art and roadmap. Comput. Ind. 2021, 133, 103508. [Google Scholar] [CrossRef]

- Arnarson, H.; Yu, H.; Olavsbråten, M.M.; Bremdal, B.A.; Solvang, B. Towards smart layout design for a reconfigurable manufacturing system. J. Manuf. Syst. 2023, 68, 354–367. [Google Scholar] [CrossRef]

- Habibi, S. Chapter 2—The disciplines of architectural design and construction technology. In Building Automation and Digital Technologies, Habibi, S., Ed.; Woodhead Publishing: Cambridge, UK, 2022; pp. 39–88. [Google Scholar]

- Khorasany, M.; Najafi-Ghalelou, A.; Razzaghi, R.; Mohammadi-Ivatloo, B. Transactive energy framework for optimal energy management of multi-carrier energy hubs under local electrical, thermal, and cooling market constraints. Int. J. Electr. Power Energy Syst. 2021, 129, 106803. [Google Scholar] [CrossRef]

- Elavarasan, R.M.; Mudgal, V.; Selvamanohar, L.; Wang, K.; Huang, G.; Shafiullah, G.M.; Markides, C.N.; Reddy, K.S.; Nadarajah, M. Pathways toward high-efficiency solar photovoltaic thermal management for electrical, thermal and combined generation applications: A critical review. Energy Convers. Manag. 2022, 255, 115278. [Google Scholar] [CrossRef]

- Habibi, S. Chapter 4—The role of environmental studies in driving automation and digital transformation. In Building Automation and Digital Technologies, Habibi, S., Ed.; Woodhead Publishing: Cambridge, UK, 2022; pp. 121–160. [Google Scholar]

- Gubbi, J.; Buyya, R.; Marusic, S.; Palaniswami, M. Internet of Things (IoT): A vision, architectural elements, and future directions. Future Gener. Comput. Syst. 2013, 29, 1645–1660. [Google Scholar] [CrossRef]

- Pokojski, J.; Oleksiński, K.; Pruszyński, J. knowledge based processes in the context of conceptual design. J. Ind. Inf. Integr. 2019, 15, 219–238. [Google Scholar] [CrossRef]

- Morariu, C.; Morariu, O.; Răileanu, S.; Borangiu, T. Machine learning for predictive scheduling and resource allocation in large scale manufacturing systems. Comput. Ind. 2020, 120, 103244. [Google Scholar] [CrossRef]

- Do, N. Application of OLAP to a PDM database for interactive performance evaluation of in-progress product development. Comput. Ind. 2014, 65, 636–645. [Google Scholar] [CrossRef]

- Trappey, A.J.C.; Hsiao, D.W. Applying collaborative design and modularized assembly for automotive ODM supply chain integration. Comput. Ind. 2008, 59, 277–287. [Google Scholar] [CrossRef]

| Free Space | Free Space Evaluation | ECL (%) | ECL (%) Evaluation | Global Evaluation | Criterion | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| ≤ | 1 | 1 | > | 85 | ≤ | 100 | 1 | Critical | ≤ | 3 |

| = | 2 | 2 | > | 75 | ≥ | 85 | 2 | Reasonable | = | 4 |

| ≥ | 3 | 3 | ≥ | 0 | < | 75 | 3 | Good | ≥ | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pedroso, A.F.V.; Silva, F.J.G.; Campilho, R.D.S.G.; Sales-Contini, R.C.M.; Pinto, A.G.; Moreira, R.R. A Computational Framework for Enhancing Industrial Operations and Electric Network Management: A Case Study. Technologies 2024, 12, 91. https://doi.org/10.3390/technologies12060091

Pedroso AFV, Silva FJG, Campilho RDSG, Sales-Contini RCM, Pinto AG, Moreira RR. A Computational Framework for Enhancing Industrial Operations and Electric Network Management: A Case Study. Technologies. 2024; 12(6):91. https://doi.org/10.3390/technologies12060091

Chicago/Turabian StylePedroso, André F. V., Francisco J. G. Silva, Raul D. S. G. Campilho, Rita C. M. Sales-Contini, Arnaldo G. Pinto, and Renato R. Moreira. 2024. "A Computational Framework for Enhancing Industrial Operations and Electric Network Management: A Case Study" Technologies 12, no. 6: 91. https://doi.org/10.3390/technologies12060091

APA StylePedroso, A. F. V., Silva, F. J. G., Campilho, R. D. S. G., Sales-Contini, R. C. M., Pinto, A. G., & Moreira, R. R. (2024). A Computational Framework for Enhancing Industrial Operations and Electric Network Management: A Case Study. Technologies, 12(6), 91. https://doi.org/10.3390/technologies12060091