1. Introduction

Every component of a business can be seen as a challenging process that can be controlled with the aid of specialized tools [

1]. Business process management (BPM) is a concept that was developed as a result of approaches, strategies, and tools that make it possible to design, implement, manage, and analyze business processes [

2]. This approach sees business as a set of operational processes and provides a number of advantages. The BPM has benefits in terms of cost, flexibility, time savings, quality, and operational sustainability [

3,

4]. Corporate management is incredibly challenging today, nevertheless, due to market instability and current globalization processes [

5]. Even while there are many cutting-edge management strategies available, their implementation still requires a deep understanding of internal workings, which cannot be executed without human assistance [

6,

7]. The use of diverse procedures and automated technology does not offer any assurance either [

8]. Business owners consequently usually develop or find a better management method [

9,

10]. Procedure, staff, and technology are the three components that make up every business implementation [

11]. Fortunately, the BPM strategy successfully combines each of these components [

12]. The process design must support the company’s strategy and be focused on attaining its objectives [

13]. The individuals in this chain are responsible for putting the specified processes into practice [

14]. While acting as a change agent, technology is merely a tool to support operations [

15]. Business processes cannot remain constant since industrial expansion has affected every facet of modern life. To reduce costs and human error, a number of processes have been automated [

16]. There is potential for BPM automation through the use of robotic process automation (RPA) [

17]. Both concepts should ideally be included as parts of a comprehensive business process automation strategy. The basis for automated business processes is BPM, which needs to be researched [

18]. RPA can incorporate BPM practices with other platforms’ and systems’ technological infrastructures [

19].

RPA makes automation possible by mimicking human-created tasks via the graphical user interface (GUI) while keeping track of the user’s actions [

20]. The RPA is different from its prior technical adjustments in that there is no need to fundamentally alter the current internal system or process [

21,

22,

23]. Manufacturing automation in Industry 4.0 is shifting toward mass production and mass customization via human–robot collaboration. The diverse human–robot collaboration methodologies and their suitability for diverse manufacturing methods are discussed [

24]. The benefits of cutting expenses in corporate processes have been demonstrated in a number of studies [

25]. To reduce corporate expenditures and procedures, however, appropriate RPA approaches are needed [

26]. This indicates that several requirements should be met by the actions in business processes. Jobs requiring low-skilled labor, frequent execution, and execution failure brought on by human error, for instance, are typical [

27]. As a result, the RPA can be used to implement various business standards [

28,

29]. The RPA organizes workflow optimization, which boosts the systems’ flexibility, scalability, and adaptability [

30], despite the fact that poor managerial communication and overblown optimism have been connected to the deployment of RPA [

31].

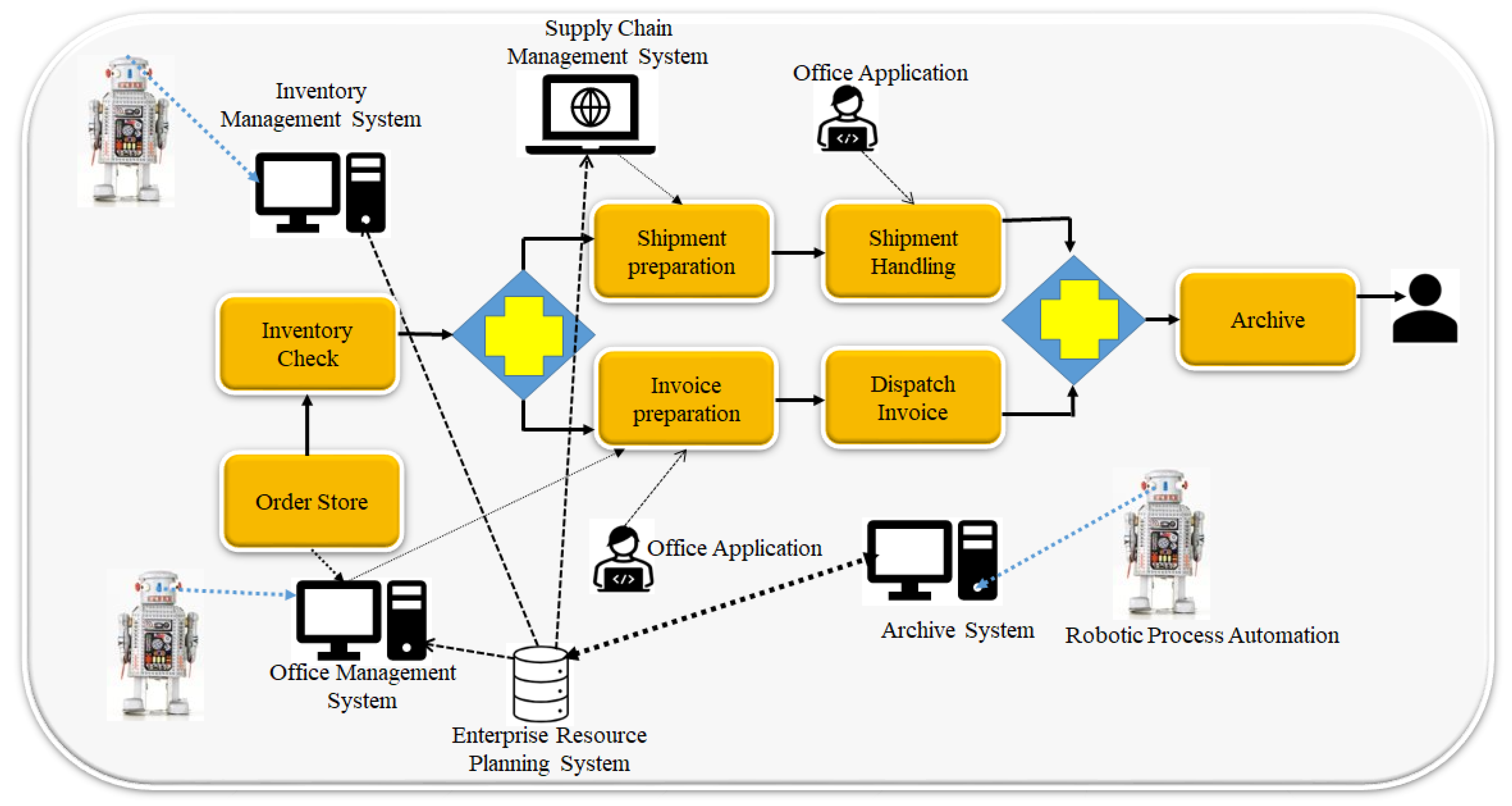

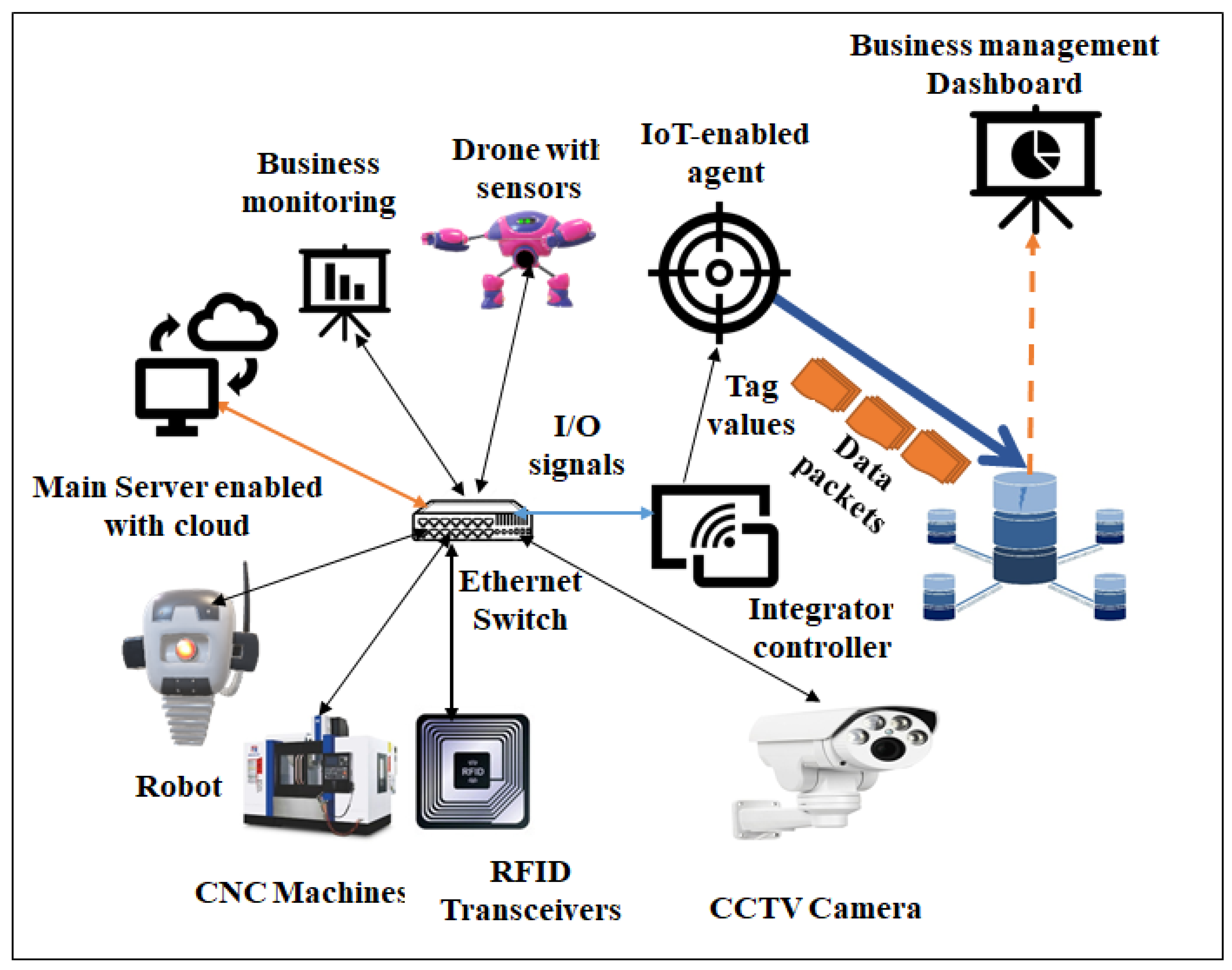

The cutting-edge solution RPABPM, which combines RPA and BPM features to generate speedier, more efficient, and cost-effective business management processes by reducing power consumption, is suggested to address current challenges in business process management and robot automation. In this article, the BPM strategy is discussed along with how it effectively incorporates RPA and other automation technologies. The deployment of a complicated logistic system is approached in a more logical and efficient way when BPM and RPA technologies are combined. The suggested approach offers the idea of deploying robots to run and manage the company. It is among the commonly challenging issues that are researched. The proposed method is one of the few that not only concentrates on integrating the business automation process through the use of robots, but also tries to reduce business management costs through faster activities and more efficient processes that may support many businesses in the future. The simple business-enabled RAP is shown in

Figure 1. The main contributions of this article are summarized as follows:

- ▪

Five stages make up the RPABPM integration: design, modelling, execution, monitoring, and optimization. These processes offer a quicker and more effective robotic automation procedure for power preservation to carry out various activities.

- ▪

Problem formulation demonstrates how the combination of RPA and BPM lowers management-related costs and expedites processes.

- ▪

An integration solution for RPA with BPM is presented from the standpoint of software architecture and technology. For effective business management, the prototype software solution is reviewed and deployed.

- ▪

Three empirical investigations are conducted to assess the practicability and precision of the proposed RPABPM technique. The initial study’s primary goal is to establish the feasibility and precision of the approach used to evaluate the acceptance, possibility, significance, and integration of RPA with BPM. The second study seeks to validate the method’s high-quality features. The final study looks at how well the technique is at assessing and identifying BPMs that are best suited for RPA.

The remainder of the paper is organized as follows:

Section 2 discusses the related work that provides the most significant insights into the recent contributions. The problem formulation for efficient integration and cost reduction is provided in

Section 3. The proposed integration of BPM with RPA is described in

Section 4. The results of the tests are shown in

Section 5. The advantages and disadvantages of the proposed work are discussed in

Section 6. The entire article is finally concluded in

Section 7.

2. Related Work

This section describes the insights into existing approaches. Therefore, an integrative method is applied to synthesize existing business process management that focuses on automation processes by utilizing AI, RFID, and IoT-based management systems. Relevance, credibility, theoretical framework, methodological relevance, literature review quality, clarity, and accessibility are all factors to consider while selecting related literature. Sgarbossa et al. [

32] show how the logistic system is a common and difficult management and control challenge. The warehouse’s reasoning is adequately described, which helps to understand why it utilizes less time, energy, and money than is necessary. Furthermore, the importance of modern technologies such as radio-frequency identification (RFID), the Internet of Things (IoT), and artificial intelligence (AI) is explored. However, no implementation of these new technologies is available. Al-Talib et al. [

33] proposed smart warehouse management systems (ISWMS) based on IoT. The technique helps to improve the systems’ real-time responsiveness, efficiency, and visibility as well as to stop inventory shortages and counterfeiting. The proposed system can only be used for process monitoring, though. The application of AI for the warehouse control and management system (AIWCMS) was suggested by Uni et al. [

34]. The AI-based programme supports order selecting, initial product allocation, a stock-to-choosing zone transfer method, stock management, transport, and tracking activities for the best management. The suggested application, however, only offers managerial help for digitization; no physical support is offered. Tan et al. [

35] give the most recent research that is currently accessible as well as any new trends related to the usage of RFID-IoT in supply chain management (SCM). A thorough, in-depth analysis of the most recent research is advised in order to raise productivity, lower costs, and improve management system effectiveness. This work also examines the current problems with the adoption of RFID-IoT in the supply chain in the papers under consideration. The conceptual framework model was created using the following four significant SCM viewpoints: product creation, shipping and distribution, inventory, and retail store. Yan and Jie [

36] used an RFID tagging system (RFIDTS) that improved administration while saving time and money on storage costs. This approach also eliminated mistakes brought on by human administration and control. The suggested strategy illustrates how modern approaches deal with the common problems that affect any logistic system.

König et al.’s [

37] example of integrating RPA into BPM shows how to connect their technology and combine their standardized processes. The technique enables RPA to utilize the knowledge and insights provided by BPM. The basic implementation of RPA processes in BPM systems can be made possible by the integration solution that is offered. A simple structural bridge prototype has been used to investigate the hypothetical idea of seamlessly integrating RPA operations into a BPMS while keeping the BPM abstraction. The RPA-driven BPM lifecycle draws attention to RPA approaches that are integrated within the broader BPM discipline and benefits from synergies produced from BPM tools and methodology. This method is constrained to case studies, though.

Before introducing any of these efficient modern tools into logistic operations, a fundamental automation paradigm must be chosen. With the proper knowledge and representation of the numerous roles and processes of each system, as recommended by Kir and Erdogan [

38], modelling business processes can be performed efficiently. There are several great options for that, and each one can be customized to focus on a certain facet of process modelling, such as flexibility, scope, usability, and understandability. These elements can be described based on an accurate description of what might be anticipated from business process management.

All of the present techniques either provide an abstract idea of connecting robot automation processes with business process management systems or focus on the conceptual application of IoT-based technology. To address the limitations of existing techniques, RPA and BPM are merged and built as prototypes. Furthermore, the five stages (design, modelling, execution, monitoring, and optimization) are combined in the integration for an efficient optimization process and energy efficiency.

The qualities and restrictions of the current approaches are listed in

Table 1.

3. Problem Formulation for Efficient Integration

This section describes the mathematical model that is used to build robot that monitors the clothing transportation process to automate the business operations . The robot can help in loading and reloading the bags of clothes from out of the building and into the trucks. The mathematical modeling is based on a list of the following assumptions:

Assumption 1. It is assumed that the robot must monitor in all directions (360 degrees) to perform the automation process.

Assumption 2. It is assumed that all of the processes in the clothing industry are at a maturity level that is supported by compatible technology.

Assumption 3. When calculating the number of carts in use, it is required to define the cart unload and reload times even though it is assumed that every cart is completely loaded before delivery. Based on personal conversations with the employees and anecdotal information, the unloading and reloading times are set at 7 min each.

Assumption 4. The efficiency of the system for transportation is also determined by the elevator, which is another crucial mobility barrier in the clothing supply chain system; its speed is fixed at 1 m/s. It is also further assumed that the movement reality of the lifts’ acceleration and deceleration are adjusted to 0.8 m/s and 2 m/s, respectively.

Assumption 5. It is assumed that each elevator can only transfer one clothes bag at a time. When a vehicle comes to an elevator choice node in each building, IoT is used to check the accessibility of both elevators in that tower. If both elevators are accessible, we anticipate that one will be less used on that particular day. Alternatively, an accessible elevator will become available.

Assumption 6. It should be assumed that the robot’s batteries will remain fully charged throughout the automation process, negating the need to interrupt it by charging the batteries.

The functions of the robot are to monitor and carry the bags of clothing to the vehicles outside of the building to perform the business automation process as follows:

where

denotes the number of robots and activities;

shows the location of the robot; and

denotes the operating process of the robot.

where

denotes the detection intensity of the robot.

Equation (2) indicates that both the intensity and the maximum number of robots should be significantly higher. This is significant in the case of robots because values can only be recognized more precisely when they are much closer in distance. With an increase in distance, the monitored readings attenuate and diverge from their initial values. Such problems can be avoided by using a bidirectional robot with a high detecting intensity. Even if the distance is higher at that point, two-directional tuples in that direction are taken into account.

where

indicates the values for two tuples that are located at the measurement angle,

indicates the distance between robot and objects, and

describes the associated attenuation.

The complete territory where all objects and people work cannot be simultaneously covered by the offered method for identifying organized enterprises. Thus, it is necessary to separate all potential exposure pathways by setting the coordinates at the beginning location, which is thought of as one end and denotes where a certain person has begun handling the objects. The exposure route’s opposite end is then placed on the exact opposite side. Therefore, in the robotic field denoted by a high-dimensional probability,

may be utilized to define the “bi-directional robot”

where

denotes the initial position of business object from the robot,

determines the separation of all corresponding pathways,

indicates total number of business objects for monitoring, and

determines a random distance between the object and the robot.

The relationship between a robot and a business can be represented as high-dimensional probability denoting a non-linear process that can only be resolved by segmenting all relevant paths into a number of sub-interval points.

where

denotes the sub-interval points in the pathways.

The corresponding sub-interval points should be minimized for the optimum data aggregation method, according to a non-differentiable equation. The robotic system needs to use this strategy in order to keep track of business activities, and it works perfectly when the distribution and destination of two directions are appropriately established. If a certain business activity is moved to the robot’s opposite side, a minimal level of familiarity is attained. Robots are connected to one another to track the business automation process at these two node sites. The weight of the robot must also be considered. The weight of robots

in a permanent expanse can be computed using the following equation:

Therefore, .

Different weights of the robots can constantly be established in the RPABPM approach that has been presented, since each robot can perform various business functions. As a result, several robot weights are introduced. Sending and receiving data to the appropriate robots should also be used to set separate robot-monitoring times for the data gathering procedure. This variable time for the robots for monitoring different activities may be calculated as follows:

The RPABPM approach that has been provided constantly establishes different weights for the robots because each robot executes a variety of business operations. Several robot weights are consequently introduced. Separate robot-monitoring times for the data collection process should also be defined using the sending and receiving of data to the relevant robots. The robots’ variable time

for keeping an eye on various activities can be calculated as follows:

where

denotes the total number of the robots,

denotes the data transmission rate of the robots for carrying out the business activities, and

is the buffering time of storing data.

To study how robots operate, it is also necessary to establish the cost of each robot. This is important since each robot has a specific weight and must carry out a range of tasks to efficiently monitor business operations and a significant amount of data. As a result, the following formula may be used to estimate the cost of installing robots

to monitor business operations:

where

represents the decision-making process.

The desired outcome

of the proposed RPABPM approach may be expressed mathematically as follows by integrating Equations (1)–(8):

The proposed RPABPM is projected to reduce costs and sub-interval locations while recommending an increase in robot detection intensity. It also implies that robots should maximize detection intensity while minimizing expense and sub-interval locations.

4. Proposed Integration of Business Process Management with Robotic Process Automatic

The RPABPM encourages organizations to view themselves as a collection of highly integrated processes. The RPABPM comprises of architecture and stages for integration of BPM and ARP.

- ▪

RPABPM architecture;

- ▪

RPABPM integration methodology;

- ▪

Intelligence and Autonomy of the Industrial Robots for RPABPM.

4.1. RPABPM Architectural Design

In this section, we present an architecture for merging RPA and BPM systems. This architecture aims to create an optimal operating environment for RPA systems, to offer a technological foundation for RPA-to-BPM connectivity, and to make it easier to integrate RPA activities inside an organizational structure. Calling an RPA from a BPM is already technically possible. These solutions reveal the specifics of the link between the two platforms. Despite its widespread application in business process improvement, business process management (BPM) combines corporate objectives with consumer expectations through effective management of end-to-end processes. BPM is broken into three stages, as shown in Algorithm 1. The technical level, which permits automated operations and gives the two levels that follow the requisite information technology (IT), is the first level. The process level, which offers real-time monitoring at the level of an input receiving input, is the second level. A behavioral analysis, which is at the third level, offers the strategic process as a result of the key performance indicators (KPIs).

| Algorithm 1: End-to-end process for effective management using BPM. |

- 1.

Initialization: { Technical level; : Process level; Behavioral level; : Automated operation; : Real-time monitoring, environment for behavioral analysis; : Task; : Total tasks; : completion process; : User} - 2.

Input: {,,} - 3.

Output: {, T} - 4.

Set - 5.

Initiate RPA - 6.

Activate BPM - 7.

For - 8.

Compute - 9.

If then - 10.

Compute - 11.

If then - 12.

Process // Behavioral level of user - 13.

Return - 14.

End if - 15.

End if - 16.

End for

|

An effective approach to end-to-end management is shown in Algorithm 1. Step 1 sets the variables that Algorithm 1 will use. The input and output procedures are shown in steps 2–3. The delivery of tasks to the model is demonstrated in Step 4, after which tasks will be assigned. In steps 5–8, the robotic process automation is shown and the business process management model is activated, and tasks are sent to the technical level of BPM, where they are automatically processed. In the event that an automated operation procedure is finished, the tasks are finished at the process level and real-time monitoring is started, as explained in steps 9–11. The behavioral level procedure is started and activities are processed for behavioral analysis environment as shown in step 12. At step 13, the task is finished.

The primary purpose of establishing a software “robot” for a corporation is to determine which workflows should be automated. It indicates that the process must be repeatable and determinable by the application of human rules, since it may not affect a company’s entire IT solution. For example, if the workflow needs to be adjusted or a new one is to be built, it is simple to turn off the “robot” and adjust the automatic processes. As a result, production costs are reduced and operational performance is improved. Both approaches are frequently used in digital transformation programs and are geared for automation because neither can totally replace the other. BPM provides a more comprehensive solution by allowing integration with other external technologies. RPA, on the other hand, works well when automating repetitive operations. In a larger sense, BPM is the ongoing endeavor of documenting, understanding, assessing, and improving the processes that steer a company’s everyday operations. BPM abstractions should incorporate implementation details to reduce the amount of development work required each time a corporation wants to automate an RPA operation. This section’s goal is to offer an architecture that allows for the methodical integration of RPA and BPM systems. The integrated architecture outlines a solution for connecting the BPM and RPA domains.

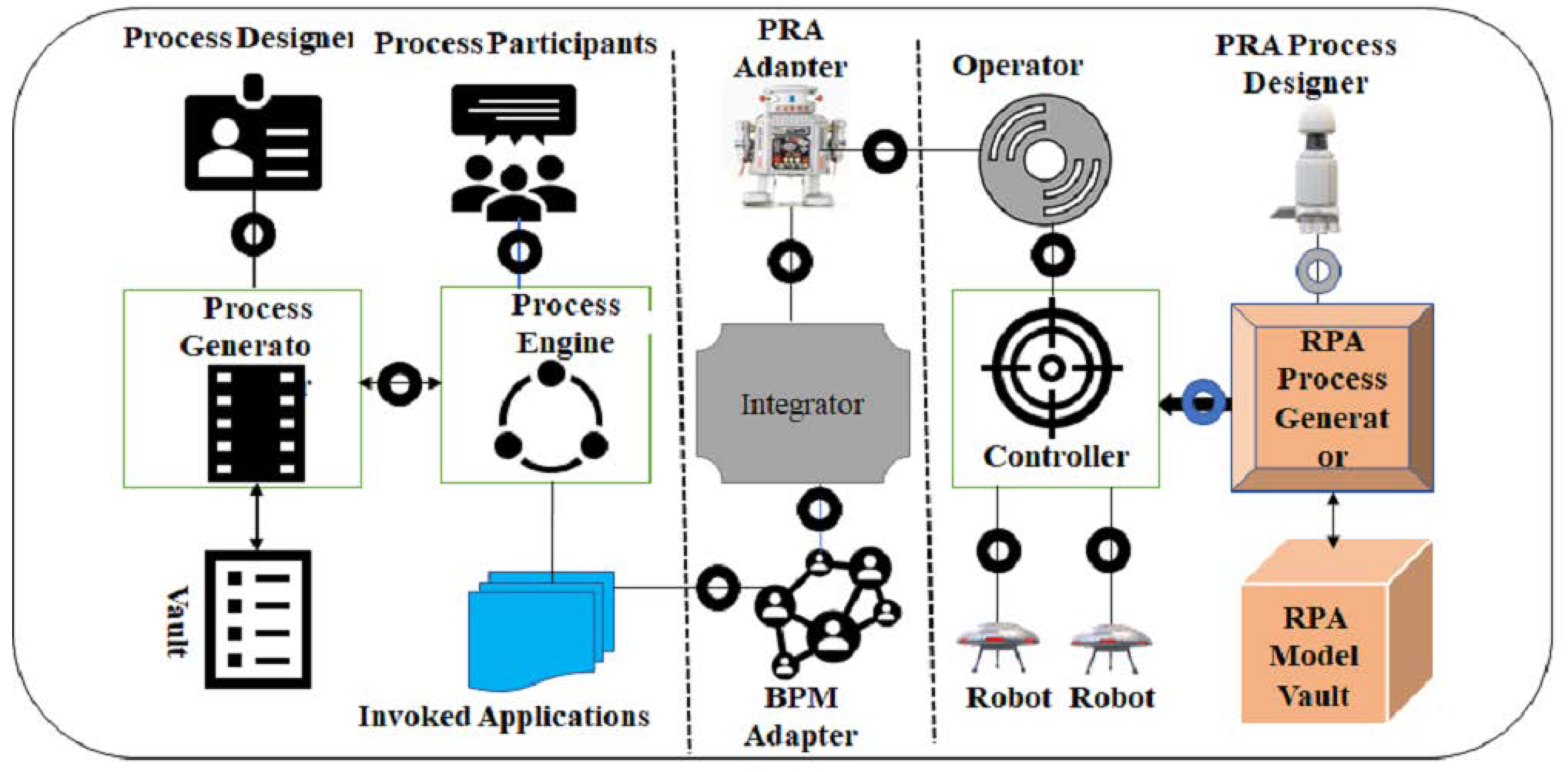

The system enables the creation and execution of a robotically automated task within the context of a larger business process without the need for human intervention. Configured process models should only offer the process specification, not the actual implementation. As a result, process designers only need to identify the inputs and outputs of an activity and do not need to worry about technological details. The system architecture is based on the following principles, assuming that both the RPA and BPM systems are already configured and capable of functioning independently: it is non-invasive because the functionality of neither of the independent systems is hindered. Furthermore, the design is not reliant on a single BPM or RPA vendor. The usage of robots in conjunction with BPM can increase the performance of the business process represented in

Figure 2.

Lemma 1. The integration of robots into business automation reduces the cycle time of events for achieving results.

Proof: It is possible to analyze both robot and business-level performance simultaneously by merging discrete and continuous models within the integrated business. Integration results in a change in state and dynamic activity. It is necessary to convert the signal from being event-based to being time-based and to provide input parameters before starting the continuous dynamic simulation. The dynamic robot inputs for industrial equipment are defined by the sequence of operations or programs that must be executed in each state. A robot initiates the event

in the discrete model that activates both transitions from

to

and dynamic model instigation (set ϑ = 0) concurrently. At the stochastic period Š, the robot event monitoring system (REMS) sends back transition to state

while the procedure continues until deterministic time

. Let us assume that integration of robot with business automation is a single input event

which results in continuous and discrete outputs. The discrete output of the robot is a vector ὕ representing the event’s cycle time. The time-series vectors of the robot denoted by the matrices Ű and

are the continuous outputs that provide achievable outcomes. Thus, the event’s cycle time is given by:

where

is the number of input events,

y is the constant input vector for business automation, and

x is the constant state variable vector for the robot. □

In order to lighten an organization’s workload, the integration implementation process should just require one setup and customization phase. Each system is in charge of what it was designed to do when it comes to the RPA and BPM’s respective areas of interest. The level of abstraction of the automated operations is not constrained by the system architecture. Instead, the enterprise chooses the level of business process extensibility at which to deploy the RPA process. However, we assume that the BPM manages the top process level. The actual design solution is depicted in

Figure 3. This integration solution adds another component between the RPA and BPM systems by connecting to the BPM as an external application that may be assigned to handle a job’s processing. However, it makes use of the RPA’s application programming interface (API) as an interface to play the part of an RPA operator.

The integrated system has separate adapters for the RPA and BPM systems and a core system in the center. In accordance with the reasoning, we chose the following design options: in order to guarantee the logic of vendor independence, the integration is composed of two replaceable adapters and a core system with features that can be used for any vendor pairs. By utilizing the BPM’s already-existing interfaces, notably the activity execution delegates the RPA, the systems are not altered. Consequently, they are not subject to any limitations as a result of the integration.

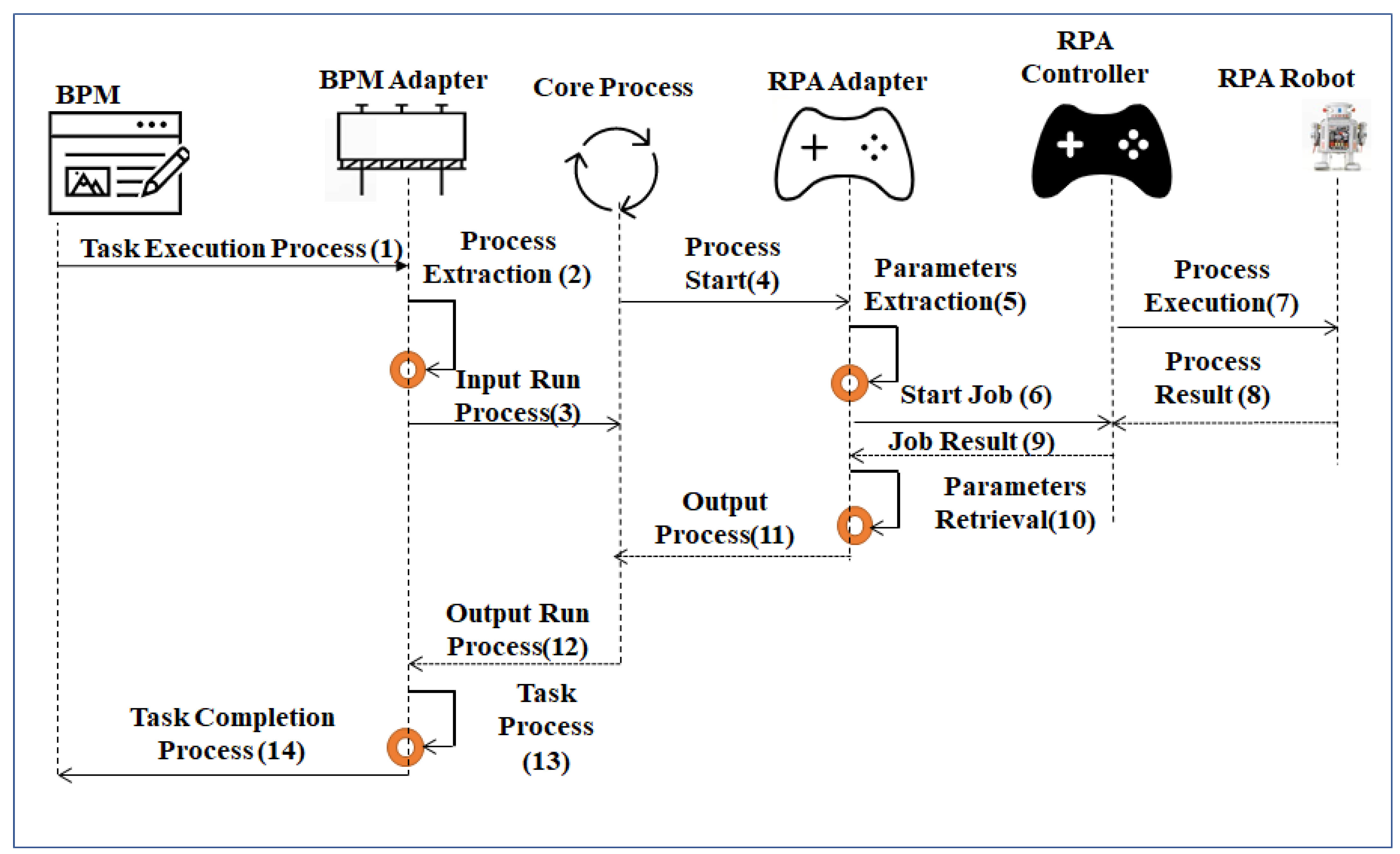

The core system, which has separate adapters for the RPA and BPM systems, is located in the center of the integrated system shown in

Figure 4. In accordance with the reasoning, we chose the following design options: a core system with characteristics that can be used for all vendor pairs and two replaceable adapters make up the integration, which is designed to guarantee the logic of vendor independence. By utilizing the already-existing interfaces of the RPA’s operator API and the BPM’s activity execution delegates, respectively, the systems are not affected. As a result, the integration does not place any limitations on them. A unique adaptor for BPMs is given the task of carrying out an action instance of the sort specified by the BPM. This adaptor converts the BPM process’s information and activity inputs to a typical RPA process input format. The primary system, which also manages the RPA process, distributes these data to an adapter created specifically for RPA. The phases of this governing include starting the RPA process, waiting for it to be finished, and obtaining the result. The RPA adaptor, which also interacts with the robot controller via the controller API and converts the RPAS-specific process outcomes into a standard RPA process result format, implements this regulating interface.

The findings are initially received by the core, which then sends them to the BPM adaptor. The BPM adaptor then updates the variables in the BPM process and concludes the activity.

Definition 1. Its discrete-state representation and business process management are both examined. Robotic process automation obtains information about an input event that may help it perform more quickly. The state-space variables and results are investigated using a deterministic model. Business operations can be analyzed as a system made up of inputs, outputs, and state variables. The differential equation presented can be used to illustrate the automation of a robot which is given as follows:where is the vector of continuous state variables, denotes the continuous input vector, and is the continuous time. 4.2. RPABPM Integration Methodology

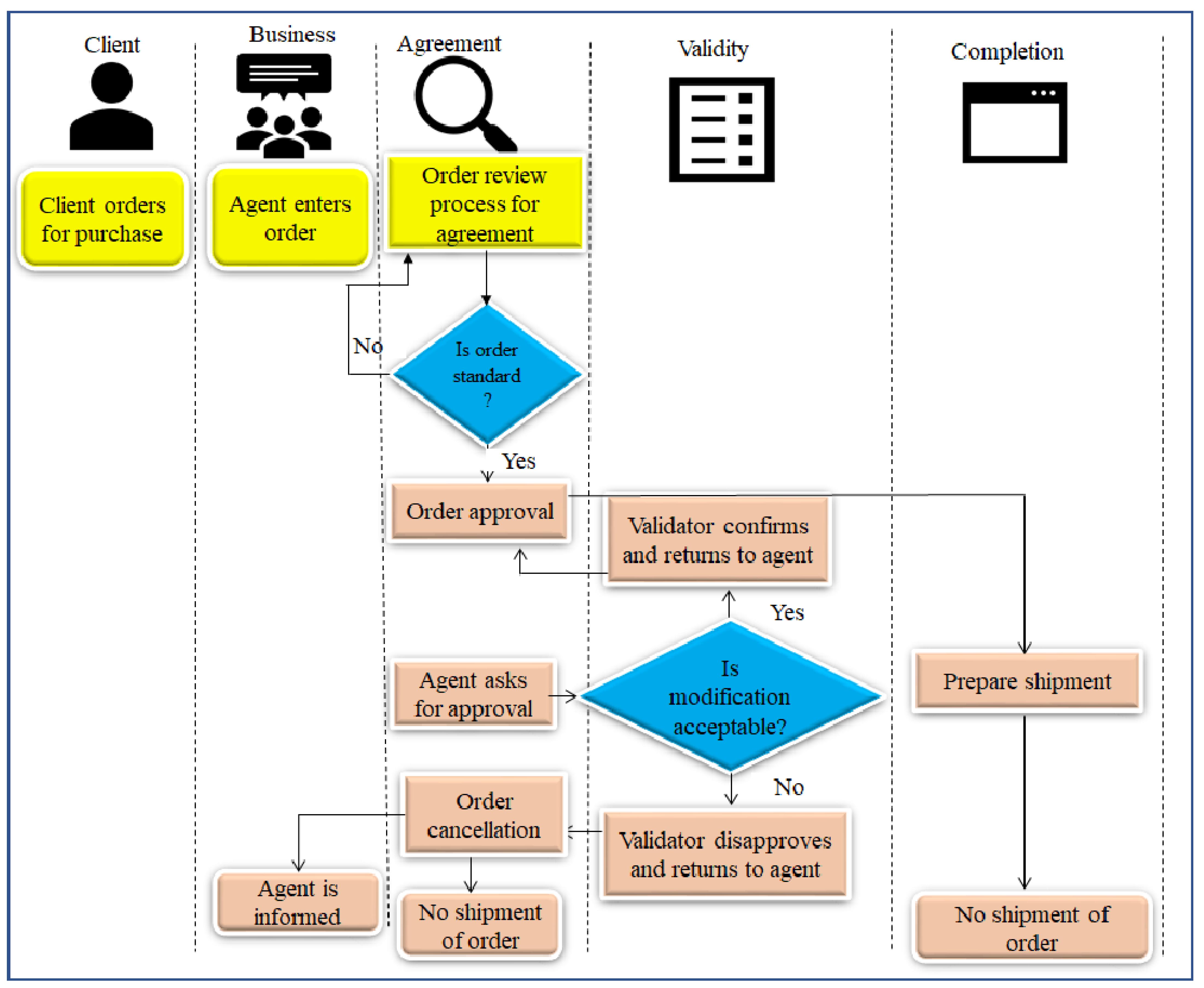

A research gap on how to integrate RPA process configuration and execution into the BPM methodology is filled by merging RPA methodologies with the BPM lifecycle. The advantages of this combination are then addressed. The resulting method provides a clear framework for fusing RPA and BPM. It makes it possible to use current BPM techniques to design, configure, implement, and evaluate RPA procedures. We approach the development of our technique by modifying the present BPM methodology to realize RPA. The resulting RPA realization techniques are then included back into the BPM strategy. Since RPA can only automate operations with a low level of abstraction, it is thought of as being an extension of a parent business process. As a result, they could be handled in that way, and if the underlying BPM framework carried out operations on activities, they would also be carried out on the RPA processes. In this strategy, techniques for RPA processes have the same access to data and resources as strategies for external processes. The five steps of the BPM lifecycle, which are modified to create the RPA-aware lifecycle, are shown in

Figure 5.

- ▪

Design;

- ▪

Modeling;

- ▪

Execution;

- ▪

Monitoring;

- ▪

Optimization.

Based on each business case, each stage enables the creation of a list of requirements and expectations.

Figure 4 shows how BPM gives management of the company the opportunity to analyze every area of business handling. Robotic assistance is also provided for organizational management, monitoring, execution, and design phases.

4.2.1. Design

In order to achieve a company’s goals, new processes must be implemented from scratch. It helps teams develop scalable, easily replicable, effective, and well-defined processes and workflows. New businesses engage in business process design at the design phase when they start considering how they will produce and distribute their products and services. Businesses create business processes as they implement completely new procedures or reorganize existing ones. Organizations can do this covertly or in a more formal, organized way. An action plan and a goal of visualization are just two instances of implicit methods used in business process design. The product design, business design, execution design, and enterprise design are the four categories that make up the RPABPM design. Using the y-axis and horizontal projection, the robot’s design can be created as follows:

Equation (12) is obtained by vertically projecting the robot

along z-axis,

where

denotes the mass of the robot and g is the acceleration of gravity for the robot.

In Equation (13), is the distance from the production area to the elevator, is the distance between the elevator to the vehicle, and is the robot’s tilting angle.

Equation (14) represents the non-slipping condition

.

where

denotes the friction coefficient that is obtained by employing the coulomb friction law.

The non-slipping condition can be rewritten by combining Equations (12) and (14).

Furthermore,

can be obtained by combining Equations (11) and (13).

By combining Equations (15) and (16), the design of the robot can be constructed for the business automation

.

where

is the distance of the robot from the tasks.

4.2.2. Modeling

Modeling describes the plan the company has for making money. It includes a list of any anticipated costs as well as the products or services the business plans to offer, together with its chosen target market. Strong business models are necessary for both new and seasoned businesses. Two cutting-edge modelling kinds (process modelling and data modelling) are used in the RPABPM modelling. Business processes are graphically represented through process modelling. For a thorough understanding of the tasks involved in the process as they relate to the business environment, each stage of the process is broken down into its component pieces, much like a flow chart. It also provides an analytical representation, or to put it another way, an illustration, of how a company’s operating processes work. An essential component of effective business process management is process modelling. Modeling gives a detailed analysis of organizational “as-is” processes and contrasts them with “to-be” procedures to increase their effectiveness. Additionally, it can help in locating connected processes and inferring expected behavior from them. Tools for business process modelling evaluate current practices and simulate ideal ones to produce better results. Data modelling, on the other hand, evaluates and characterizes every sort of data the firm generates and collects, as well as the relationships between those data pieces. A strong data model is the foundation for efficient operational systems, business intelligence (BI), and analytics solutions that provide value to the firm by transforming corporate data into a useful information asset. In

Figure 6, the ideal business modelling is displayed.

The modelling stage is the most important since it dictates how all the business components should be broken down and graphically represented in the last three levels. Although the exact structure of the process is not obvious, the model is currently thought to be structured, meaning that only an outside observer can detect irrelevant input components. This indicates that each activity in the external world has a list of “inputs” and “outputs” available. The terms “inputs” and “outputs” relate to resources and constraints, respectively, and the results of actions. The modelling approach makes use of both functional and process modelling. Through the use of functional modelling, the company is viewed as a process, having entry and exit points.

It is advantageous to see the business plan from the standpoint of performance since it demonstrates the inputs made and the results attained. Process modelling defines the process as a sequence of actions having origins and ends. Let modelling be the integration’s strongest element. Thus, the business robot can be modelled using a two-dimensional kinematic model

.

where

are the cartesian coordinates of the robot,

is the sway velocities, which can be illustrated in the robot’s body-fixed frame, and

is the robot’s heading angle. It should be noted that the determinant of

should always be 1 whatever the value of

. So, it is proved that the inverse should exist. Thus, the inverse matrix for the dimensional kinematic model can analytically be written as:

Hence, Equation (19) should be transformed into an integrator model by illustrating a new controller input metric

, which can be satisfied as:

where

denotes the integrator model that contains the robot’s entire dynamical system.

As a result, the inverse matrix of the dimensional kinematic model can be satisfied by the integrator model, which contains the whole dynamical system of the robot and is given by:

The approach relies on a set of actions carried out within predetermined boundaries, whereas functional modeling considers the business model in terms of the resources at hand and the desired results.

Regardless of the modelling strategy employed, they provide the customer with thorough data for subsequent implementation. Numerous tactics and methods are explained and looked at in the next section. The business process modelling approaches can model all or some of the components, depending on the technique’s focus. The approach’s initial paradigm of development and the domain for which it was designed (e.g., systems engineering, software development, etc.) are two examples of the factors that may affect the focus. While some systems might not provide an explicit description of any of the aforementioned components, they do provide structures that could be used to implicitly represent them.

4.2.3. Execution

The management process is started at the execution step, and any modifications are monitored at the monitoring stage. The developed model can be optimised following the initial findings and then reintroduced into operation. The three parts that make up the system execution procedures are task management, workflow management, and execution control. There are normally two important flows in the process. One is control flow. It covers the management strategies, operational rules, and control criteria used in the task management phase, workflow phase, and auction execution phase. The input data flow is the other flow. As it moves from the lower phase to the upper phase, it incorporates the sensory data that were obtained in real-time by the on-site execution robots. In order to enable the dynamic and reliable control of the numerous participating robots, a closed loop may be made in this way. An organisation selects the robot deployment plan and the RPA system it will use. The robots can be run on physical or virtual machines. An executable RPA process model is then created from the semi-formal process description. The model will then be sent to the microcontroller, the controller will be configured, and the robots will be installed.

Therefore, it is feasible to employ the infrastructure that currently supports the BPM deployment. The installed RPA system needs to be tested before it is released to the public. The execution results in the implementation of robot process models and the readiness of the RPAS infrastructure.

The majority of experts emphasise how important job execution is when choosing an RPA procedure. Economy of scale is made possible by regularly completed jobs, allowing firms to save a lot of money and benefit from automation. Equation (22) operationalizes the execution characteristic as a measure of a process’s automatability. The number of activities is counted

that are a part of the same process

while calculating efficiency

.

where

is a finite set of processes,

is the stream of different activities,

is another component of the processes,

is an activity type, and

are processes, cases, and tasks, respectively.

4.2.4. Monitoring

One of the biggest challenges in company monitoring is sifting through the massive amount of information that robots produce on a daily basis. It is crucial that the precise data can be located and made available when required. Depending on who is seeing the robot, the sort of business information required could also be altered. A mechatronics engineer could be curious to learn why a robot occasionally stumbles, shuts down unexpectedly, or is unable to grasp certain objects. Therefore, it is critical to extract data that give them the ability to pinpoint possible improvement areas inside a more comprehensive business automation process. The robot can also give monitoring adjustments to help with this problem. The specific data can be recovered from the way they are shown via monitoring by adding or removing widgets that represent the underlying telemetry streams. The visualisation can be created using HTML, JavaScript, and CSS. This suggests that all pertinent information may be seen and comprehended by looking and that only the information that is required can be brought to the surface. Given a sequence of input events , we track residuals of both continuous and discrete variables for each robot job performed for the BPM.

The timeseries of the input tasks (

and outputs

produced by robots for BMP are monitored. Hence, executing effective monitoring processes

results in energy savings for the robot, which may be quantified by:

where

denotes the total tasks performed by the robot during each event,

denotes correct input events, and

is the number of wrong input events.

4.2.5. Optimization

The main priorities of the business when thinking about investing in IT solutions are a better customer experience and increased efficiency. It is vital to employ intelligent automation to redesign their current process because this technology may be able to eliminate the following bottlenecks in their business operations.

- ▪

Businesses may reduce costs by giving employees menial and unneeded tasks.

- ▪

By automating workplace procedures like paper filing, doing boring work can be avoided. Saving time and money allows the organization to focus on more important projects.

- ▪

Reducing human error is something that more than half of the companies agree the BPA does.

- ▪

Enhance customer satisfaction by processing service information more rapidly and provide prompt service to customers.

Consider a company issue where the provision of optimization calls for the use of robots. It can therefore be said to be:

where

,

and

are the decision variables specified by the robots for optimization,

denotes high-level user input, and

is the robot’s tilting angle distance.

The robot requires proper contact forces and position

, which can be obtained as:

Equation (24) illustrates the beginning state and finishing state of the robot, as well as the overall time of the trajectory , which serve as high-level user input .

4.3. Intelligence and Autonomy of the Industrial Robots for PRABPM

The levels of autonomy are used to express how self-reliant a robot is when carrying out a task. The difference between the autonomy and intelligence of the industrial robot is that the robot provides task completion when autonomous while intelligence provides problem-solving.

4.3.1. Intelligence of Industrial Robots for RPABPM

A machine that is intelligent and has the capacity to act and decide is referred to as an intelligent robot. Robots lack the same level of intelligence that people do. Even the developers of the technology admit this. These robots are fairly competent in some conversations, but they are less able than most people to react to the unexpected. Technology in industrial robotics is mostly developing toward intelligence. Industrial robots are becoming more and more in-demand due to ongoing technological advancements and the growth of the manufacturing sector. Industrial robot technology is primarily developing in the following directions to achieve human–machine coordination: (i) intelligent algorithm optimization and mathematical modeling are no longer sufficient. The intelligent development of industrial robots can be facilitated by the equally fascinating field of artificial intelligence. (ii) Increase capacity for flexible work. For some of the lower-level jobs, industrial robots have been able to replace workers; yet, robots are still unable to finish some difficult and specialized work. This issue can be improved by using bulk materials, improving the load/weight ratio, etc. (iii) At the moment, touchpads, remote controllers, and similar devices are mostly used to interface with industrial robots. Through interactive techniques like gestures and voices, we can investigate the interactive issues of low tolerance and low intellect. Intelligent industrial robots that interact with people are able to understand not only what they should be doing but also what other people are doing. Additionally, it is also feasible to anticipate human behavior and thought processes. Multiple robots will be able to communicate with one another and total awareness will be improved. There are four levels of study being performed on intelligent robots in the industry. The intelligence of the industrial robots for RPABPM consists of the following levels:

Level-I: Basic frontier technology: the key issues include the development of novel robot mechanisms for the industry, the theory and practice of intelligent development, and the examination of future-generation robot verification platforms such as reciprocal collaboration and human behavior enhancement.

Level-II: Common technology: this consists mostly of fundamental components, robot software, robot-specific sensors, safety/test/reliability, and other critical common technologies.

Level-III: Key technology and equipment: these mostly consist of industrial robots, service-oriented robots used in specialized environments, and robots used in medicine and rehabilitation.

Level-IV: Demonstration application: the focus of demonstration applications is on industrial robots and other industries.

4.3.2. Autonomy of Industrial Robots for RPABPM

The autonomy of the industrial robots for RPABPM consists of the following levels:

Level-I Autonomy: A human must constantly be in the robot’s line of sight. For instance, a human should accompany an industrial robot for RPABPM as it moves throughout the industry. In this situation, the human must handle unforeseeable circumstances.

Level-II Autonomy: The human operators become supervisors rather than following the robots; even if the robots are out of their line of sight, the human operators must continue to work in the same area and keep an eye on them in case they need assistance for completing RPABPM. This capacity serves as an enabler for high-value applications across numerous industries. For instance, at Level 2, an industrial robot would be able to follow a set path using waypoints while avoiding the majority of obstacles and only sometimes getting lost. The goal is to wait an hour or so between interventions. The human may be able to perform other jobs in the sector at this level of autonomy, but they are probably capable of supervising one or two robots that are operating autonomously.

Level-III Autonomy: This level marks a turning point where large-scale implementations start to gain appeal. One person can oversee many robots or a robotic team’s ability to handle edge cases for several days. The majority of industrial systems with many robots start to scale up at this point, although occasionally a human may still be needed in the field to change batteries, make repairs, or rescuing a stranded robot for RPABPM.

Level-IV Autonomy: At this level, labor costs are not a barrier to the deployment of autonomous robots on a broad scale. The autonomous robots are capable of handling numerous edge cases on their own, becoming sufficiently autonomous that humans no longer feel the need to work in the industry for RPABPM. Additionally, they offer a strong on-site automated assistance infrastructure. The robots have the ability to locate their base stations, obtain fresh batteries, carry out quick fixes, and escape sticky situations. In addition to established on-robot software, this level of autonomy also requires automated on-industry infrastructure and, typically, a solid relationship with remote users for finalizing efficient RPABPM.

Level-V Autonomy: The robots start to use the lessons they have learned from their interactions with humans to perform tasks better than the human designers had intended for RPABPM. They gain knowledge from local robot teams as well as from other places’ robot teams. They develop the ability to foresee how events will affect their capacities and to plan ahead. Consider the interaction with the multi-robot industrial autonomy example to illustrate how human engagement with the system changes as autonomy levels rise.

5. Experimental Setup and Performance Evaluation Result

This section provides an experimental setup process and performance evaluation.

5.1. Experimental Setup

Robots are used to build a hybrid model in real-time that combines discrete and continuous information to evaluate production system productivity and machine operations. Deterministic systems with continuous dynamics are used to model robots [

39]. The system-level behavior can be explored by expanding the deterministic model to include the interactions of various components such as processors and buffers. Real-time hybrid testing necessitates a distinct method of tracking and analyzing manufacturing performance. We validated our results on the industrial robot manufactured by ABB with a six-axis IRB140 and supported with Windows CE-based Flex Pendant (teach pendant). The IRC5 controller is used to run RobotWare 5.13.10371. It can carry a payload of up to 6 kg. The IRB140 is cage-required with default parameters and common safety precautions. The industrial robot cost is USD 123,500 which involves cabling, controller, cage, compressed air pipes, installation fees, and experimental setup, excluding the vendor’s service and maintenance cost. A .NET Compact Framework 3.5 is installed. It is made to execute unique programs created with the help of a vendor-provided .NET-based SDK. The Flex Pendant has safety features that are Ethernet-linked to the main computer (MC) and electrically attached to the panel board. The VxWorks 5.5.1 RTOS is used by the MC, which is based on the Intel x86 architecture. It regulates the completion of tasks and coordinates the controller’s components while being in charge of action, task, and primitive level control: it handles task execution, selects the optimum control strategy, applies forward and reverse kinematics, and executes the path planning strategy. Task programme code written in ABB’s RAPID language is translated by it. The servo level is implemented by the Axis Computer (AXC) that is the PowerPC-based board that supports the VxWorks 5.4.2 RTOS. Through the drive and contactor units, the computer operates the servo motors that move the joints. The contactor unit is an electronic switch that regulates the motors’ status (on/off). Additionally, the AXC relays any information required for planning to the MC. Finally, it obtains the position and state of each servo motor via sensors to calculate the error and finish the control loop that generates the signals. When safety-critical conditions arise, the panel board, or safety board, which is mostly composed of discrete integrated circuits and relays, disables the robot. It puts into practice the safety requirements. A heartbeat packet detailing the robot’s current status, including whether the motors are on or off and whether an emergency stop is in effect, as well as its operating mode, reduced the manual speed and increased the automatic process that is sent from the PB to the MC via a 5 MHz RS485 single duplex link. Each time there is a shift in the operational state, the MC will interrupt itself and send a keepalive command to the PB. This is carried out effectively using an FPGA connected to the PCI board of the MC. The MC is the most significant part of the robot since it communicates with the teach pendant and all other external devices via Ethernet connections. Internally, a typical Ethernet connection is used by the MC and AXC to interact. Through the LAN Ethernet port, the controller and ultimately the MC can be connected to a local network, while a second Ethernet port allows for direct communication with a client host for service and programming. The MC connects the service port to the Flex Pendant’s Ethernet connection, despite the fact that any host connected to the service port by default receives an IP address on a different subnet.

The implementation platform is shown in

Figure 7.

Table 2 shows the summarized parameters for conducting the experiment.

5.2. Empirical Study

We present findings from three empirical investigations that were performed to assess the practicality and precision of the proposed approach. The first objective of the initial study is to confirm the practicality and precision of the methods employed to evaluate the acceptance, possibility, significance, and integration of RPA with BPM. The second study attempts to verify the method’s high-quality characteristics. A crucial component of the overall approach is to assert that the technology is based on the following grounds:

- (a)

Generic (applied to many business areas);

- (b)

Efficient;

- (c)

Usable by non-RPA professionals such as business analysts;

- (d)

Energy-efficient.

The third study attempts to assess the method’s effectiveness in analyzing and identifying BPMs that are best suited for RPA. These aspects can only be validated by experts who have the appropriate expertise that enables them to walk through the proposed method.

These features can only be confirmed by specialists who have the necessary competence to navigate through the suggested technique. We chose four business processes from the insurance and banking areas to conduct the four empirical studies.

Table 3 depicts three BMPs.

We sought three RPA professionals from the finance and insurance sectors who volunteered to take part in this study in order to perform the three empirical experiments. All professionals have extensive knowledge of business analysis, BPM, and automation in addition to their experience with RPA. The profiles of the respondents are summarized in

Table 4. We gathered all RPA experts in one place and performed the three empirical studies. A number of documents have been created to serve as resources for the experiments. The materials included (a) instructional slides outlining the goal of the study’s task, (b) a description of the RPABPM outlining all processes, and (c) a questionnaire for data collection for each experimental study. This questionnaire was designed to allow experts to respond to binary questions (Yes/No). An additional field in the questionnaire enabled experts to provide comments as needed. We set aside 90 min without a time constraint to perform the experimental tasks, and no interaction amongst experts was permitted.

The eight properties (degree of standardization, efficient automation, manual interaction with a software application, degree of maturity, transaction volume, use of business rules, power reduction, and degree of complexity) are used in the proposed method to analyze and categorize business processes for the RPA approach. This initial study’s goal is to assess the applicability and accuracy of methods used to assess each property when determining if a process is appropriate for RPA. More specifically, this study intends to confirm the applicability and accuracy of the methods employed to evaluate following:

- ▪

RPABPM development and standardization;

- ▪

RPABPM Suitability processes to be automated;

- ▪

RPABPM significance of methods;

- ▪

RPABPM classification of methods.

5.2.1. RPABPM Development and Standardization

The proposed RPABPM method examines the amount of development and standardization of a process to validate its suitability for RPA. The experts evaluate the stability and predictability of the business process development level. As a result, we ask the business analyst to respond to the questions in

Table 5. To assess the amount of process standardization, we question business experts to confirm that the organization is using a standard procedure to achieve the business goal.

5.2.2. RPABPM Suitability of Processes to Be Automated

This step evaluates a business process’s suitability for automation using the RPABPM methodology. We define a suitability process of the RPABPM as its ability to set up software robots to carry out tasks that were previously performed by human actors. There are two tasks in this step. The first task is to determine the suitable weight for each process action to be automated using RPABPM. In order to determine the RPABPM suitability weight of the entire business process, the second task combines the results of the first task.

5.2.3. RPABPM Significance of Methods

This step evaluates the applicability of using RPABPM to automate a business process. Reference [

40] asserts that the RPABPM approach works effectively for processes with a lot of transactions but not much complexity. The average daily transaction rate is used to define the volume of transactions. The average amount of time is used, which takes everything to finish the process to gauge process complexity. There are two tasks in this step. The first task determines the significant weight for each process action to be automated using RPABPM. In order to determine the RPABPM prospective weight of the entire business process, the second task compiles the findings of the first task. A basic process takes a human only a few minutes to complete, whereas a complex process could take hours or days. The proposed method assesses a business process’s complexity level and transaction volume in order to determine whether it is relevant for RPABPM. Two complementing tasks make up this analysis. The first task weighs the importance of RPABPM for automating each process activity using the RPA approach. The results from the first assignment are used in the second task to determine how relevant it is to use RPA to automate the entire business process.

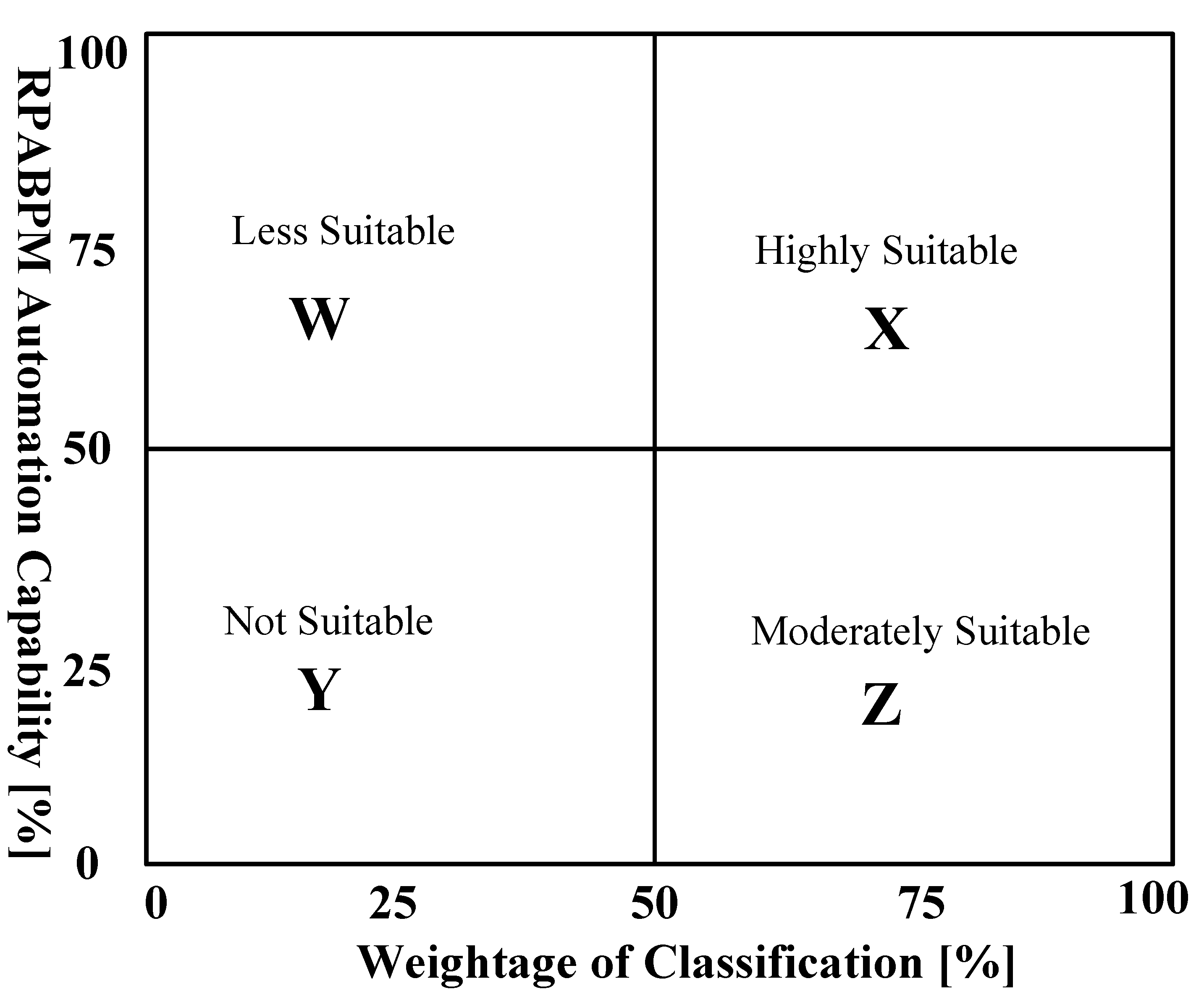

5.2.4. RPABPM Classification of Methods

The RPABPM has been classified into four categories. If the probability

of the effectiveness of the proposed RPABPM is

it is considered highly suitable for the RPABPM approach. Its category is in

. A business process that is somewhat suitable for the RPABPM technique has both a high RPABPA promise and low RPABPM relevance. It is assigned the category Z. A business process that has both high RPABPM relevance and low RPABPM potential is less suited to the RPA strategy. It falls under the categorization of W. Finally, when a business process’s RPA possibility and applicability are limited, it is not appropriate to automate it using the RPA approach. Let us assume that the

is the automation capability of the RPABPM and

is the weightage of the classification for RPABPM, if both

and

have a robotic process automation capability and a weightage classification of 75%, which shows that 75% of the processes can be handled automatically, which falls in the category of the X that is highly suitable for BPM. If the

and

have a robotic process automation capability of 50% and weightage is 50%, which falls in the category of Z, that is moderately suitable. If the

75% and

, which fall in category W, that is considered less suitable. Finally, if the

50% and

which fall in the category of Y, that is not suitable for BPM.

Figure 8 shows the suitability of the PRABPM.

5.3. Experimental Design

The purpose of the experiment, according to the purpose Question Metric model [

41], is to evaluate the applicability and validity of the method’s procedures. This study’s research question is formulated as follows:

Research question-1: Are the methodologies utilized by the method to examine RPABPM properties appropriate and correct?

We incorporate four questions to ensure that the approaches used to examine RPABPM qualities in the overall setting of the process of experimentation are suitable and correct when designing this empirical investigation. Each of these four approaches is represented by a single question. The question has been codified, as shown in

Table 6. The four questions and four arbitrarily chosen business processes are listed in

Table 3 and were presented to the experts. After that, we questioned each question’s instantiation within a specific business process, and they were able to respond. The approaches’ applicability to processes from many domains can be determined empirically in this way, allowing us to improve our understanding of the procedures. As a result, we have four factors that are tagged from Q1 to Q4 to assess the suitability and accuracy of the methods for all of the four processes that were chosen in

Table 3. Both 0 and 1 are viable values for these variables. The number 0 indicates that the expert concluded that the technique was either inappropriate or inaccurate for assessing the RPA qualities in the larger setting of the chosen business process. Value 1 indicates that the procedure is appropriate and correct according to the experts.

We contend that a technique for RPABPM analysis and recommendation of business processes must possess certain qualities that make it practical and suitable for businesses. Our claim that our approach is practical, widely accepted, generic, and usable by users like business analysts without them needing to be RPABPM experts is one of its primary selling points. This study’s research question is given as follows:

Research question-2: Is the method general, efficient, simple to use by non-technical users like business analysts, and widely accepted?

We created a question for every single criterion in

Table 6 from Q5 through Q8 that helps in designing the experiment. Then, we gave the formulated questions to the experts and asked them to respond to each one in the setting of the trial business processes. The values 0 and 1 were set for the variables. The approach does not satisfy the quality attribute, as shown by the value 0, according to the experts. Value 1 indicates that the approach satisfies the quality attribute according to the expert.

5.4. Datasets and Process

We have provided datasets at

https://github.com/drfarhad17/RPABPM: accessed on 1 August 2023 for the robot to analyze the performance of automaticity. The programmable logic controller (PLC) is used to collect data via an IoT adaptor. An IoT adaptor is used to gather data from the financial sectors. Variables for performance monitoring are momentarily recorded on tags within PLC. Data are gathered in discrete time based on the PLC scan rates that determined the key step. Rockwell Automation’s IoT adaptor is used to retrieve discrete and continuous signals from the PLC. In order to control transitions in the computerized numerical control (CNC), additional PLC logic has been implemented to monitor NCC’s activities. The PLC’s turn-over device and machining task were both initiated by a binary signal. Once the machining operation is complete, the CNC sent a binary signal back to the PLC, causing the TOD to stop. Multiple performance factors are subjected to univariate and multivariate analysis, which serve as the cornerstone of the RPABPM strategy. The cycle times, or the length of time the CNC machine spends processing a part when it is in the “Busy” state, were monitored. The robot is seen keeping track of time as they do pick-and-place jobs. The trajectory requirements for a certain task are also carefully scrutinized. An automated manufacturing process is managed using a PLC function for control, which coordinates operations based on input/output signals. Data from sensors and devices can be temporarily stored in a memory area known as “tags.” Additionally, tags can be used to store the binary or numerical values required for performance analysis. The programme is scanned by the user to make it machine readable. The form data are then automatically extracted by the robot using text recognition and written to a CSV file. If the robot is unable to parse the text, the user must manually create it. A validation service has now validated the CSV file. If the data are correct, a robot automatically inserts it into the online interface. A service is then utilized to prepare a request for a valid application, which is subsequently submitted to the applicant. Aside from the business process model, the corporation provides textual documentation as a semi-formal representation of the robotically automated processes.

5.5. Performance Evaluation and Results

The following cutting-edge parameters have been evaluated based on the experimental results.

- ▪

Efficient automation process.

- ▪

Power Consumption.

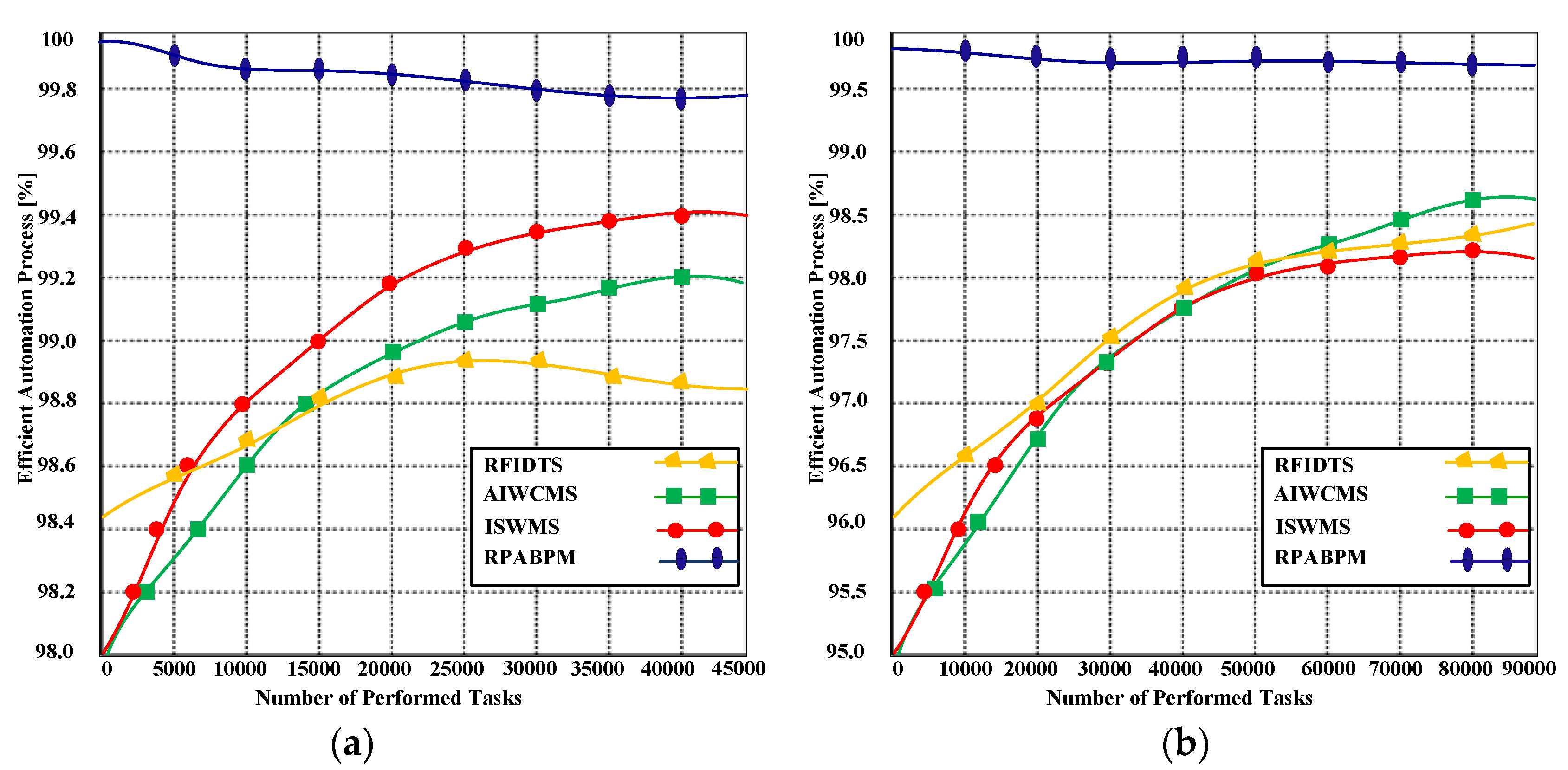

5.5.1. Efficient Automate Process

Automated techniques can do jobs faster and more efficiently than manual ones. Automation will increase productivity levels. In addition to automating operations, process automation integrates information and reduces the requirement for human involvement during work completion. The efficient automation process

can be calculated as follows:

where

represents value-added time, which has a direct influence on the result of a process, such as creating a sales contract or establishing quote estimates, and

is the cycle time.

Figure 9 illustrates the productive automation procedure. To assess the effectiveness of automation, there were two trials run. As seen in

Figure 9a, a maximum of 45,000 tasks are finished during the first trial. The results show that the suggested approach, RPABPM, produces a nearly consistent efficiency of 99.77%. Contrarily, the competing strategies improve by 98.77–99.4%. RFIDTS is less effective. When there are 90,000 tasks, the proposed approach obtains 99.75% as depicted in

Figure 9b, which illustrates how well the suggested technique works. As a result, it is shown that increasing the number of tasks has no impact on productivity. Contrarily, the competing methods employ 98.12–98.62% with a maximum of 90,000 completed tasks.

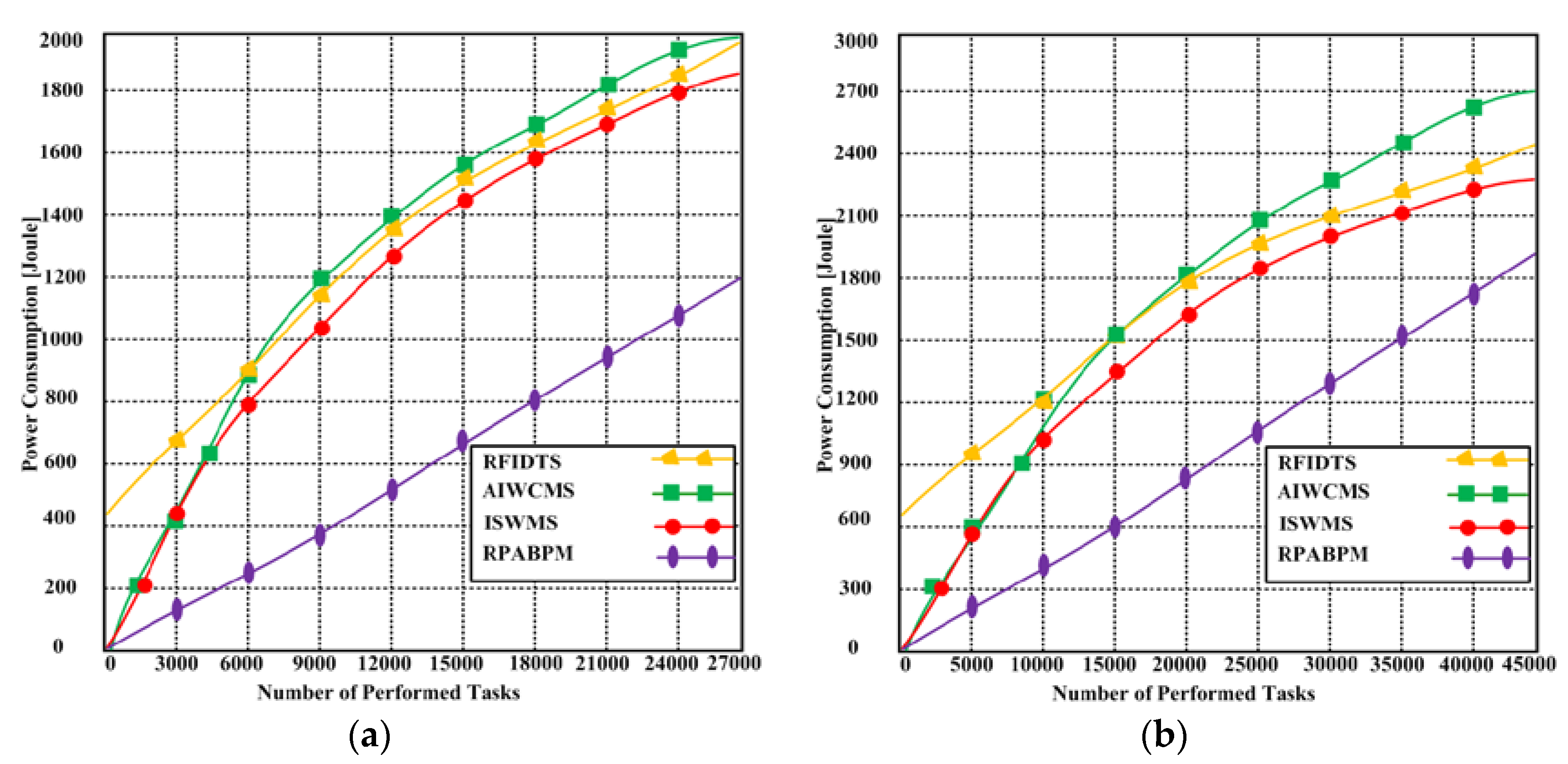

5.5.2. Power Consumption

Utilizing automated industrial robot systems can reduce the amount of energy used. These investigations (AIWCMS, ISWMS, and RFIDTS) examine and contrast the proposed technique RPABPM with cutting-edge methods. The relationship between power utilization and the number of finished jobs is shown in

Figure 10. In

Figure 10a, a maximum of 27,000 activities are carried out, and the suggested strategy consumes 1199 joules of energy. On the other side, the competing solutions use more power than the suggestion. The competing strategies use between 1845 and 1998 joules of electricity. The proposed strategy continues to use the least amount of electricity (1886 joules) when the number of jobs is increased to 45,000, as shown in

Figure 10b, whereas the competing alternatives use more power, ranging from 2265 to 2698 joules. The reason for the proposed approach’s low power consumption is the adoption of the five-step integration methodology, which has five phases.

6. Discussion of Results

The main benefit of the suggested RPABPM is that it closes the research gap by laying out a workable strategy for adopting RPA in a BPM environment. Because of this, RPA adoption and implementation within businesses are made easier, especially when BPM infrastructure and skills are already there. Contrary to ad hoc usage, not every company needs to develop their own approach. Instead, they may extend the RPA-aware BPM lifecycle. Along with additional research, organizational experience may help in improving the method. Using tried-and-true methods reduces the possibility that initiatives will fail for the businesses. The fact that BPM techniques and technology have undergone extensive testing, and are therefore reliable, reduces these risks even further.

Table 7 provides comparative analysis of the proposed RPABPM based on the experimental results.

BPM also scales well, enabling the management of numerous processes. The RPA-aware BPM lifecycle also provides the tools to manage multiple RPA operations because of its complete integration. Because RPA scales with BPM, it becomes scalable. The RPA-aware lifecycle addresses the negative aspects of RPA: the knowledge created during the BPM lifecycle is crucial for RPA, or at the very least useful. The overhead created by running two systems simultaneously is reduced since process information must be acquired in both scenarios. BPM provides information on the traits, inputs, and outputs of the process as well as information about how it was carried out during the analysis and implementation phases.

As demonstrated by the example, this information may be used to discover and create new RPA processes as well as to improve existing ones. In addition to process optimization, the BPM provides documentation and standards for all operations not under the RPA’s control.

Overcoming RPA flaws is made easier by the RPA-aware lifecycle. BPM exception handling, which provides a standardized and tried way for handling business exceptions, lessens employee stress. Errors in the RPA processes are discovered more rapidly when the BPM is monitored. Technical inspection tools provided by the BPM can identify execution flaws and provide basic management. RPA processes may be improved in the following rounds by using data from the implementation phase, making the processes more accurate and dependable.

By integrating an RPA with a BPM, the functionalities that an RPA lacks are supplemented. The BPM and its associated tools are in charge of high-level process orchestration, non-RPA operation execution, process monitoring, resource management, process mining, and other features. Despite the benefits, not every aspect of the RPA-to-BPM connection has been handled. Although this approach provides methods for integrating software on a methodological and architectural level, it does not account for organizational change management, such as employee training. The imaginary firm must persuade the workers to relocate and find them new jobs. The proposed RPABPM strategy also falls short of developing a solution tailored specifically to RPA’s requirements. As a result, some RPA-specific issues may not be addressed or resolved.

Take the issue of RPA process testing as an example, which demands the development of special settings. Additionally, the lifecycle does not include any brand-new capabilities for error and exception management that are designed expressly for RPA. This method is also fairly sparse in the amount of information it provides for each phase. There is not a formal pre-implementation process available. Furthermore, the merits of the proposed RPABPM are assessed and compared with other existing models in

Table 8.