1. Introduction

Accurate reliability estimation for critical components of a mechanical system is crucially important in the aviation industry [

1,

2]. Reliability information can be obtained from various sources, including degradation data and failure lifetime data [

3]. Failure lifetime data represent the reliability information for mechanical component on the time scale. However, sufficient lifetime data are very difficult to obtain only by life testing or even accelerated life testing for those mechanical components with the characteristics of long life and small sample [

4]. Degradation data describe the entire degradation process from start to failure [

5]. Degradation data can be monitored and collected by sensors. Making full use of available reliability information of mechanical components, including degradation data and failure lifetime data, can improve the accuracy of the reliability estimation and guide optimal maintenance [

6].

According to Zhang et al. [

7], three main types of reliability estimation models have been developed in recent years, namely knowledge-based, physical-based and data-driven models. A data-driven model is much more flexible to implement and perform the reliability estimation of mechanical components [

8]. Regarding degradation data-based models, a stochastic process degradation model is commonly used to build the degradation model of mechanical components, such as the Wiener process, inverse Gaussian (IG) process and Gamma process [

9,

10,

11]. However, uncertainties and discreteness cannot be ignored when using the degradation data to model the degradation process [

12,

13]. Regarding lifetime data-based models, various statistical distribution [

14,

15,

16] can be used to describe the failure lifetime distribution. However, only enough failure lifetime data can ensure the required prediction accuracy [

17], and it is quite hard to obtain sufficient lifetime data for certain high reliability mechanical components even by accelerated life testing. Given that neither of these two types of reliability data can provide a large enough sample to assess reliability, it is reasonable and meaningful to incorporate degradation data and failure lifetime data to support and improve reliability estimation.

Multiple performance indicators can reflect the degradation of mechanical components. Additionally, these performance indicators might be dependent on each other due to the same failure mode or the same working operations. Considering that dependent performance indicators can improve the accuracy of reliability estimation [

18,

19], the copula function, which is a flexible method to describe the dependent structure, has been widely used in the reliability field [

20,

21,

22]. The copula function can not only be used to establish the joint distribution of multiple variables, but also describe the dependence among the multiple margins. The input marginal distribution for copula function can be degradation data or failure lifetime data. Sun et al. [

20] built a multivariate-dependent accelerated degradation model using the nonlinear Wiener process and D-vine copula considering multiple sources of uncertainties. Fang et al. [

21] used stochastic processes to describe the degradation process of two performance indicators, using different copula functions to establish the dependent relationship between two indicators, and the Bayesian information criterion (BIC) to choose the best degradation model. Saberzadeh et al. [

23] used stochastic models and copula function to build a system reliability model. Andersen et al. [

24] presented replacement optimization framework in multi-component systems. The degradation models for components are described by a multivariate gamma process model and the dependent structure is described by Lévy copula. Zhang et al. [

25] analyzed two dependent failure modes of solid lubricated bearings and built an accelerated life testing model based on the Weibull distribution and time-varying Frank copula. The deviance information criterion (DIC) is used to determine the best lifetime model.

In order to make full use of multiple sources of reliability information, it is natural to employ a Bayesian method with available data. From a system reliability perspective, Li et al. [

26] proposed a Bayesian multi-level information aggregation method to model the system level reliability. Jackson et al. [

27] developed a model for the reliability estimation of a multi-state on-demand system with overlapping failure lifetime data. Regarding the reliability model for mechanical components, Wang et al. [

28] integrated the field data and accelerated degradation data from the laboratory using calibration factors to predict the reliability of components under the actual field conditions. Pan [

29] also used the calibration factor method to construct the link between accelerated life testing data and field failure data. Wang et al. [

30] developed a comprehensive model using Bernoulli data, lifetime data and degradation data to improve the accuracy of reliability estimation. Ma et al. [

31] used the IG process, taking measurement errors into account, to describe the degradation process, and integrated accelerated lifetime tests (ALT) and accelerated degradation test (ADT) to build a reliability estimation model. Guo et al. [

32] integrated both failure lifetime data and degradation data to obtain accurate reliability analysis under Bayesian framework. Guo et al. [

33] also built a degradation model based on the Gamma process taking individual heterogeneity into account. Original information about the equipment manufacturers is used as prior information for the degradation analysis of information from the monitoring of the conditions. Wang et al. [

34] used accelerated degradation data as prior information. The prior distribution types of random parameters are determined by Anderson–Darling statistic. The reliability model is constructed based on the Wiener process with random effects. Tang et al. [

35] proposed a two-step RUL prediction method based on the Wiener process fusing failure lifetime data and field degradation data. These studies aimed to solve the problem of evaluating the reliability of system components or systems. However, most of them only consider degradation or failure time data or consider only one performance indicator or two independent performance indicators. Few of them contribute to the model considering both dependent performance indicators and combining different types of data source.

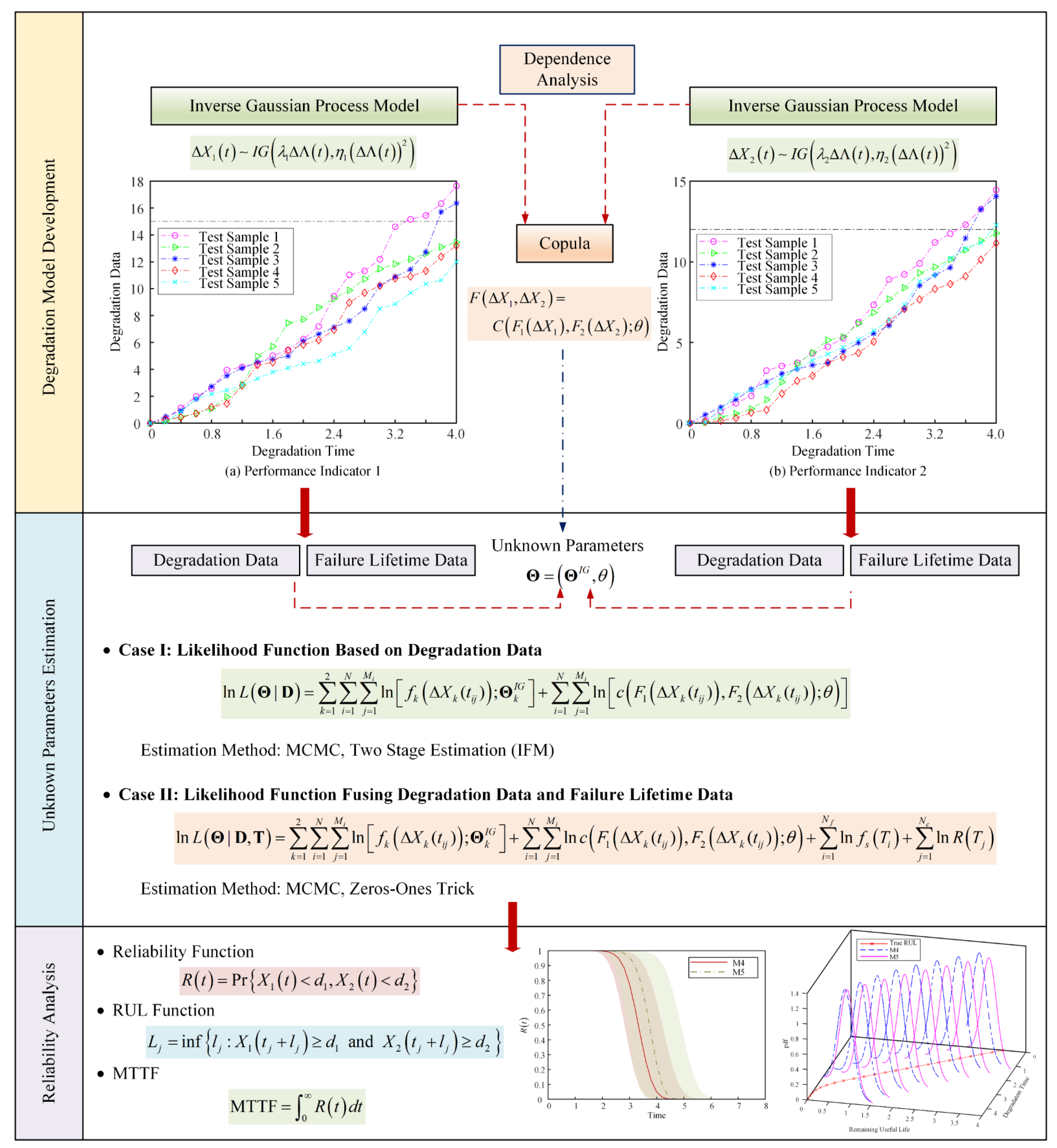

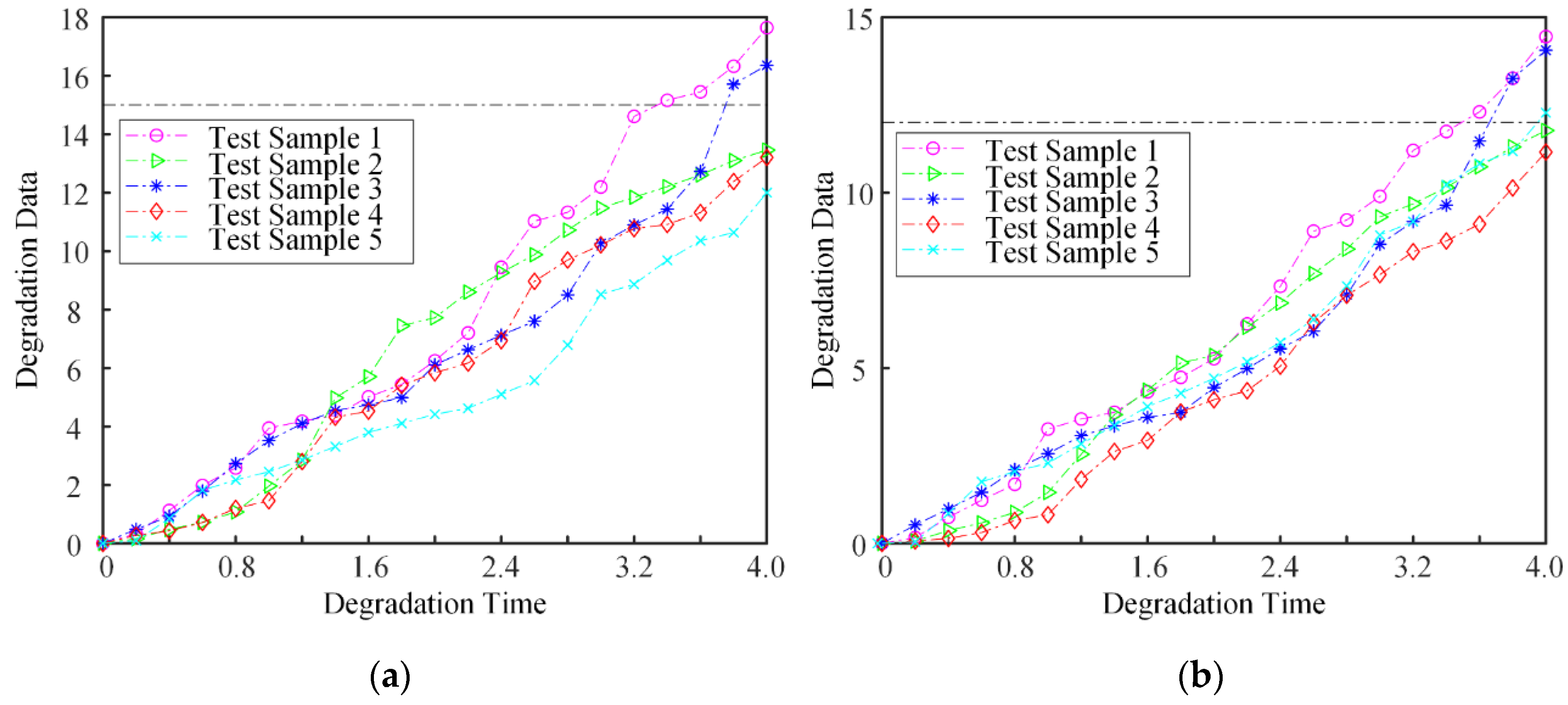

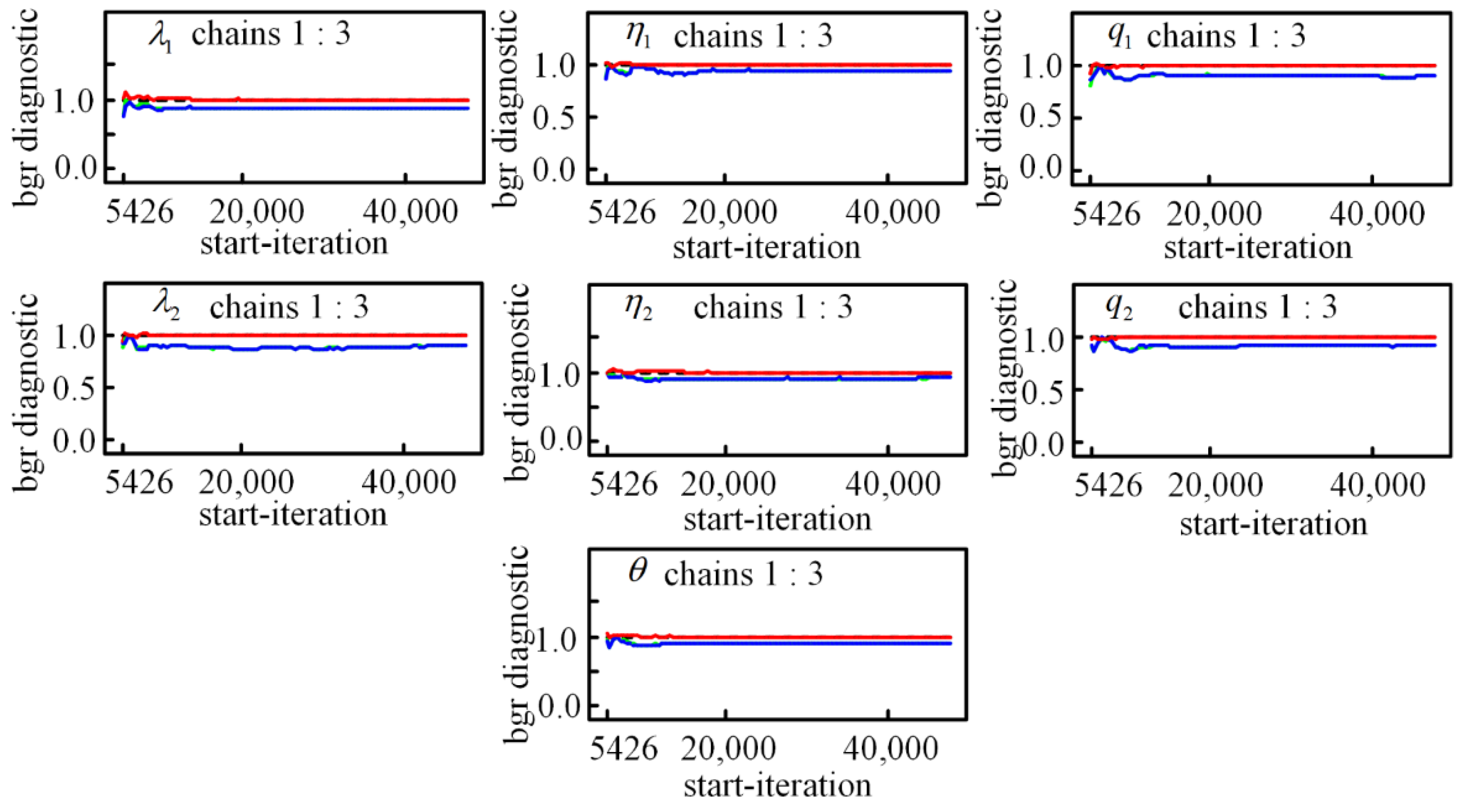

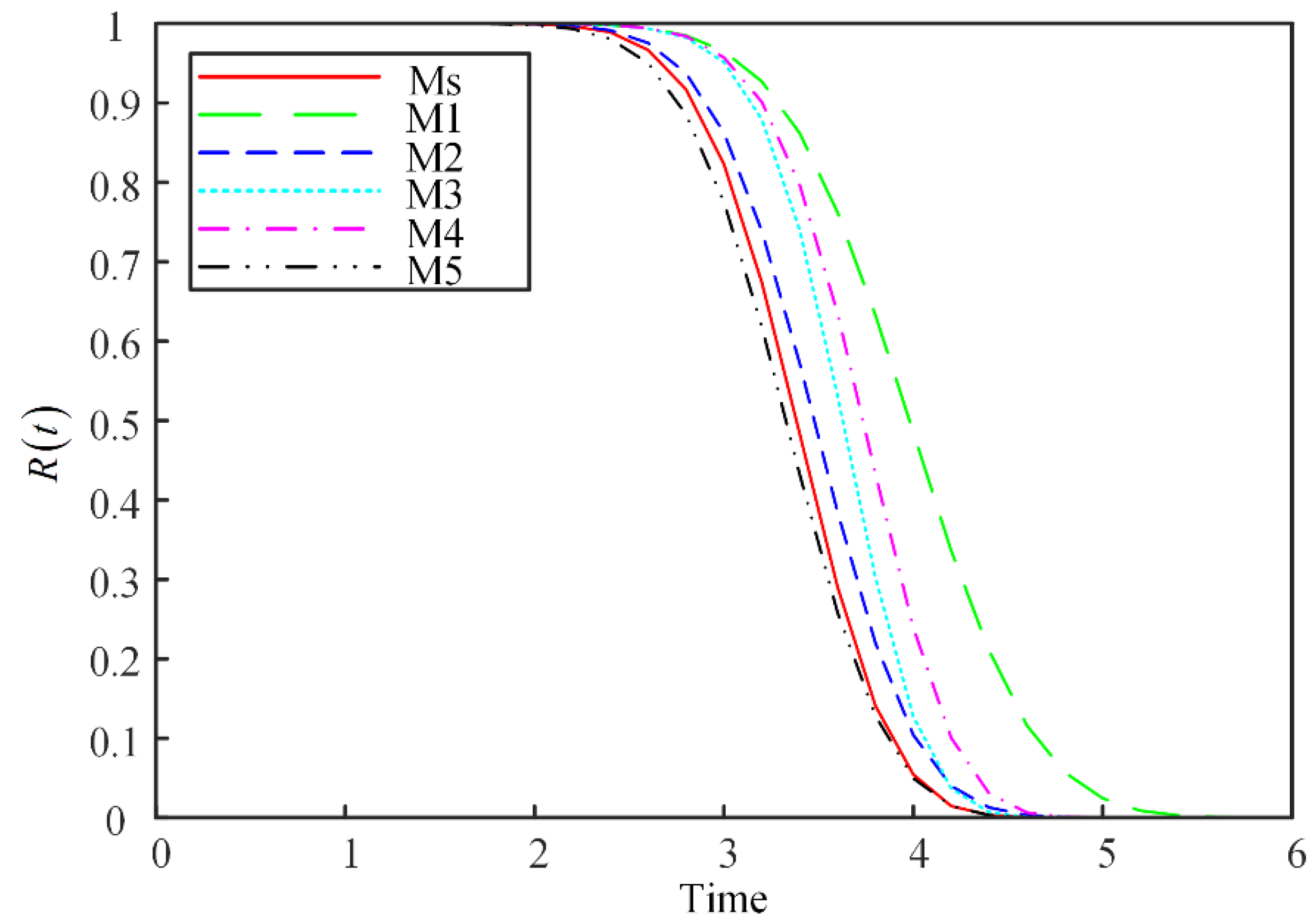

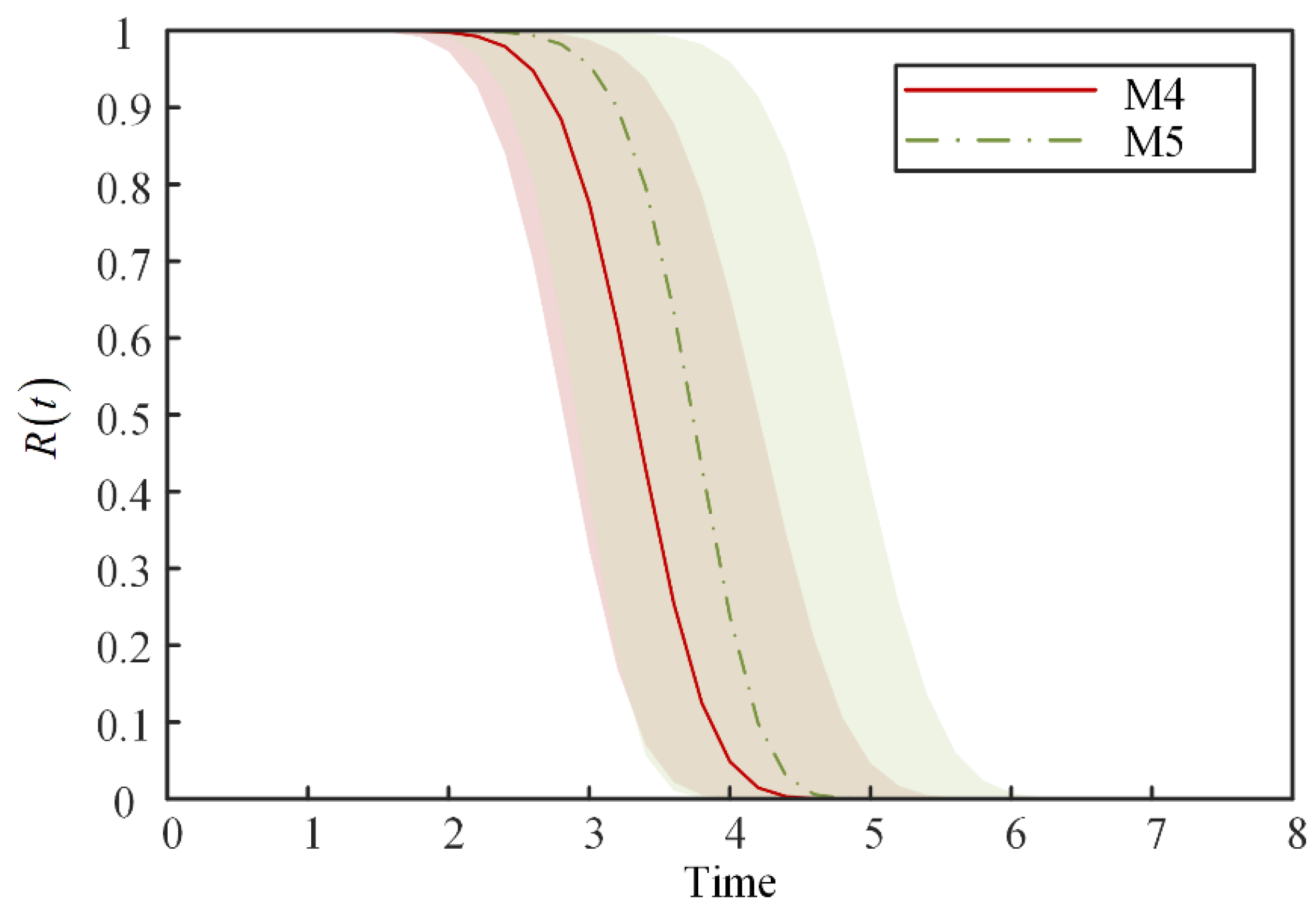

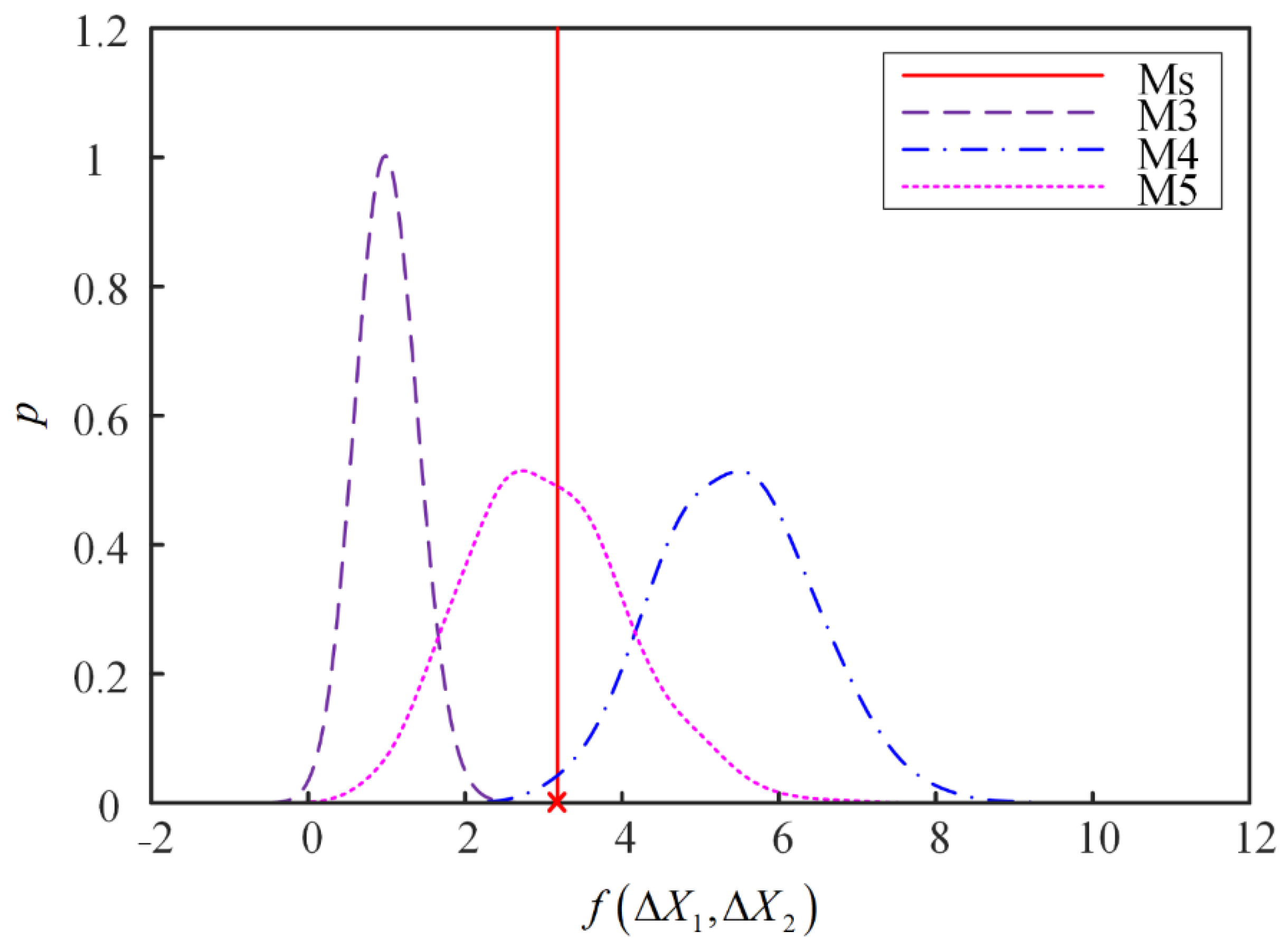

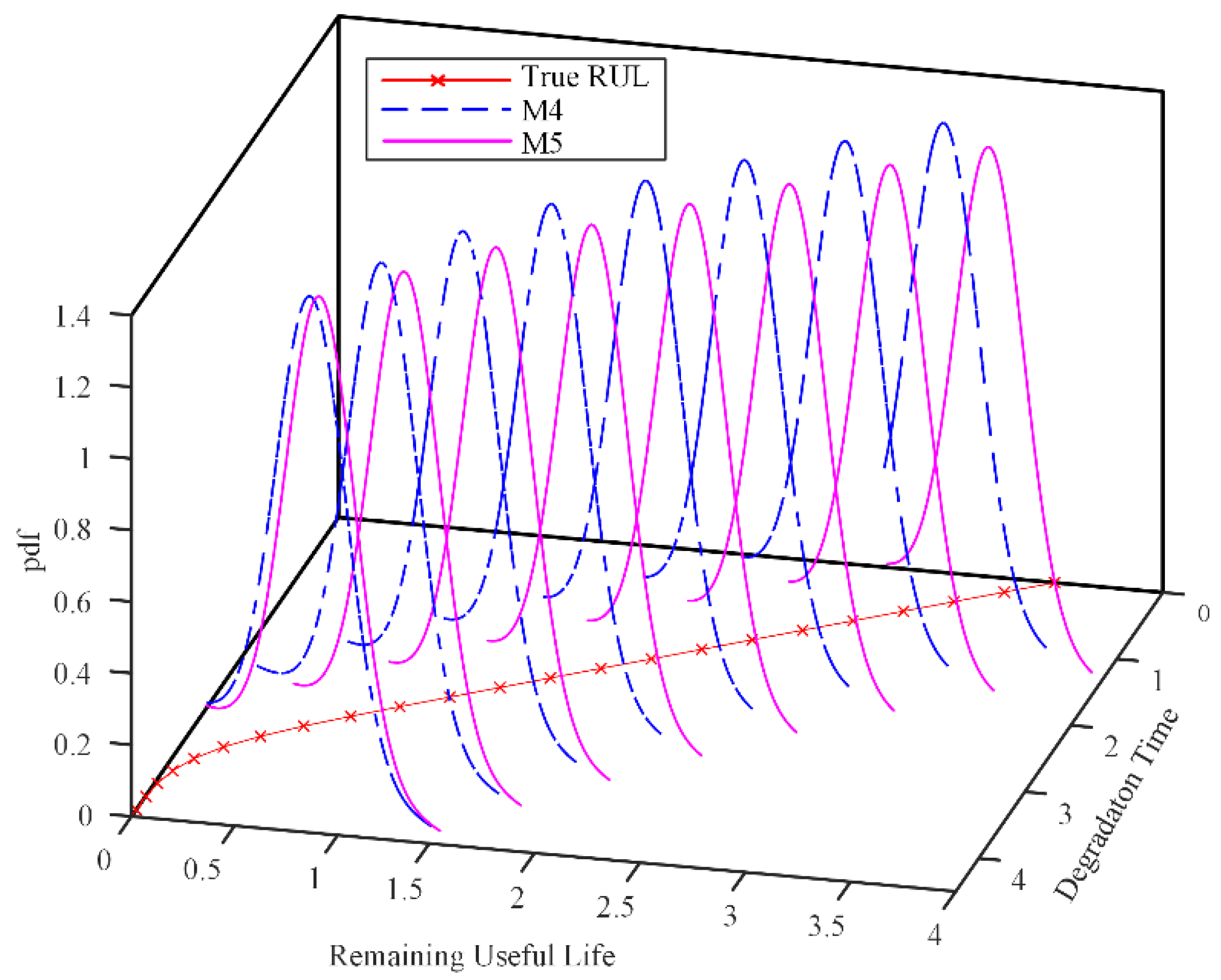

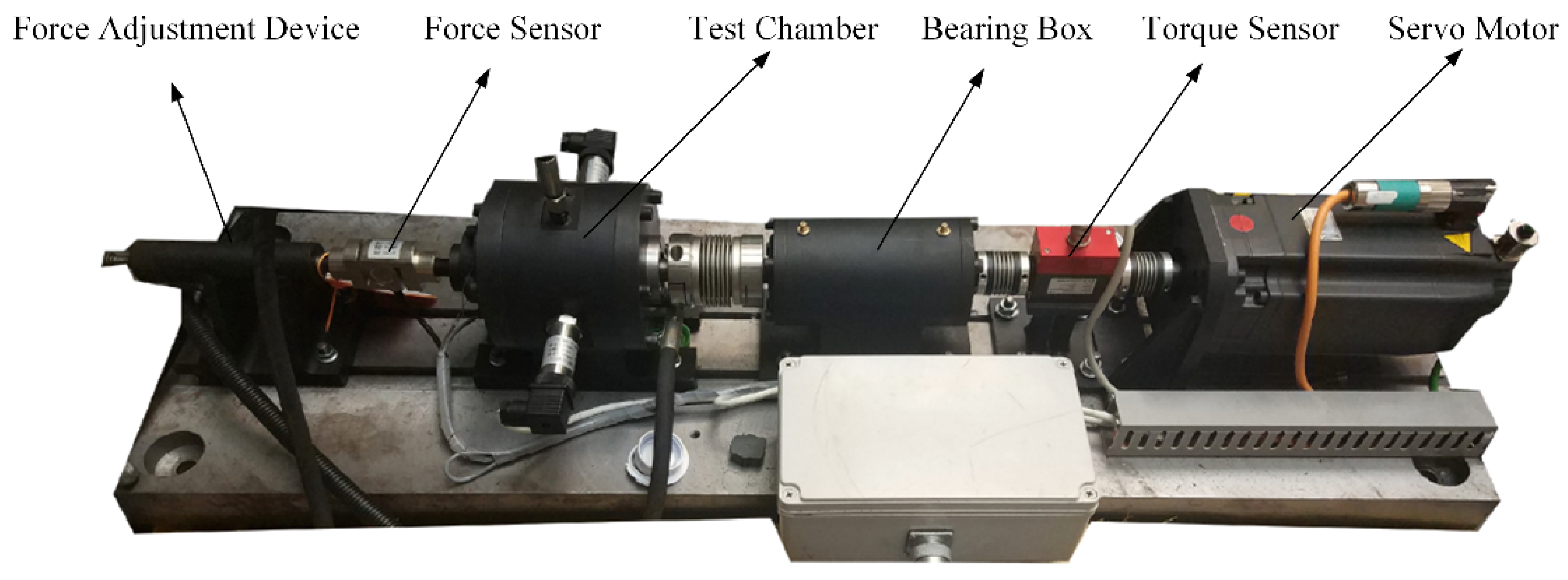

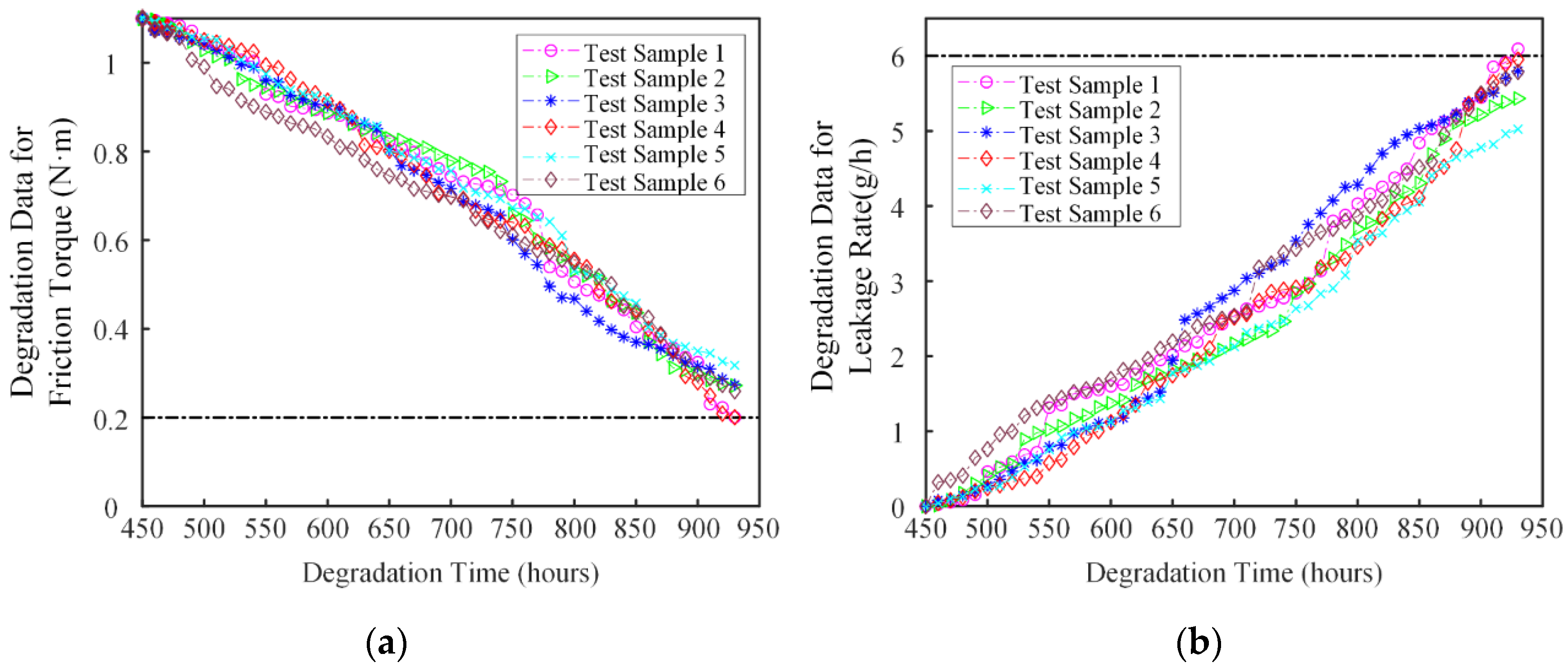

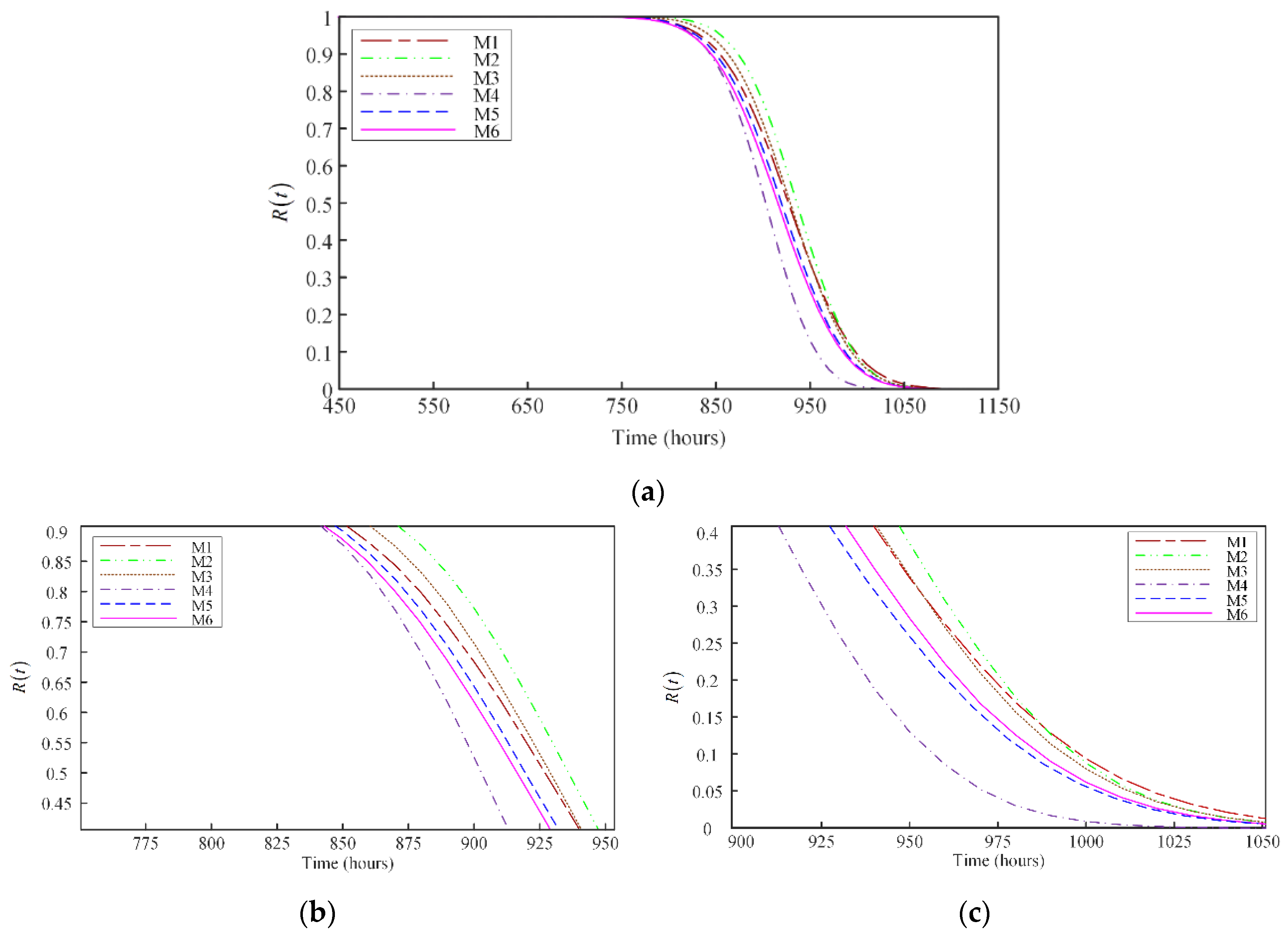

To solve this problem and improve the accuracy of the reliability evaluation and life prediction for lifecycle management, this study develops a reliability evaluation method by integrating likelihood functions with both degradation data and failure lifetime data considering two dependent performance indicators. First, the degradation trajectories of the two performance indicators of the components are both described by the IG process, and copula functions are used to describe the dependency relationship between the two performance indicators. Different from the existing bivariate copula reliability models, both the degradation data and failure lifetime data are integrated in order to improve the accuracy of the reliability estimation and remaining useful life (RUL) prediction. The zeros-ones trick and Bayesian Markov chain Monte Carlo (MCMC) method are used to estimate the unknown parameters. The Akaike information criterion (AIC) and BIC are used to select the best copula function linking two marginal distributions of the two performance indicators. Finally, the reliability estimation and RUL prediction are performed based on the proposed model and it is validated by the simulation study and mechanical seal degradation experiments.

The rest of this paper is organized as follows. In

Section 2, the reliability estimation model based on the IG process and copula function is presented.

Section 3 shows the likelihood functions built for two cases, where the first one only considers degradation data and the second one considers both degradation data and failure lifetime data. Parameter estimation procedures are performed based on different likelihood functions. In

Section 4, a simulation study is described to illustrate the accuracy of the proposed model. In

Section 5, the degradation data and failure lifetime data from mechanical seal are used to validate the proposed model. In

Section 6, the overall conclusions of this study are summarized.

6. Conclusions and Future Work

This study evaluated the reliability estimation model based on the IG process model and bivariate dependence analysis by copula functions, fusing two sources of reliability information, namely the degradation data and failure lifetime data. First, the IG process model for each performance indicator was established to describe the degradation process. The bivariate-dependent model was developed using copula functions to describe the dependent structures between two performance indicators. Then, the likelihood functions were constructed considering different types of reliability information, including only degradation data, only failure lifetime data and both degradation data and failure lifetime data. The MLE and Bayesian MCMC methods were used to estimate the unknown parameters in the degradation model considering the various types of likelihood functions. Ultimately, the reliability and RUL values for the mechanical components were obtained from the unknown parameter estimation results and Monte Carlo method. Comparative analysis of the simulation study and real case study showed the effectiveness of the proposed model.

The main contributions provided by this study are as follows:

- (1)

The development of a reliability estimation model considering dependent degradation performance indicators using the IG process model and copula functions.

- (2)

To fully use the reliability information obtained, the likelihood functions are constructed using the degradation data and failure lifetime data based on the developed reliability model. Since the likelihood function contains information from different sources, unknown parameters in the model are estimated by transforming the likelihood function using the zeros-ones trick.

Future research will be focused on the improvement of parameters for real-time updating based on the offline reliability information and online new reliability information. Combining the physical of failure model and data-driven model in dependent analysis with multiple performance indicators will also be considered in future studies.