1. Introduction

Aerospike nozzles represent a class of advanced nozzle concepts, offering a promising alternative to the conventional bell nozzles utilised in almost all launcher systems. They are well-known for their height-adaptive capabilities and additional performance potential compared to their bell nozzle counterparts [

1,

2,

3,

4,

5]. The potential for replacing the F-1 engine in the Saturn V rocket (J-2T-250K) with an aerospike engine was discussed. Subsequently, this concept was considered for implementation as main engines for the Space Shuttle and for its successor, the Venture Star (XRS-2200) [

6].

Despite the fact that aerospike engines were not deployed by any launch service provider yet, they have retained their appeal as a research topic in both academia and in the space industry. For instance, the students of the California Launch Vehicle Education Initiative (CALVEIN) [

7] demonstrated the first successful flight of a bi-liquid-propelled aerospike rocket engine. On the other hand, the Dryden Aerospike Rocket Tests [

8] yielded flight data for three solid-propelled high-power rockets utilising a conventional bell nozzle and two aerospike nozzles. However, the performance data for the aerospike engines did not demonstrate the anticipated performance benefits. Compared to the conventional nozzle counterpart, the aerospikes had lower combustion chamber pressure, correspondingly resulting in lower thrust. It was postulated that a larger throat area of the aerospike nozzles than the conventional ones might have been responsible for the discrepancy. In 2021, Pangea Aerospace [

9] achieved stable combustion for a longer time in an annular aerospike engine operating on the propellants methane and liquid oxygen. This boosted the confidence in the possibility to deploy aerospike engines for practical application. In order to further enhance the application perspective, it is necessary to implement a method of thrust vector control (TVC). A literature review of Bach et al. [

10] indicated secondary injection thrust vector control (SITVC) as a favourable solution for steering rockets and spacecrafts with aerospike nozzles, particularly for single-chambered engines. The utilisation of SITVC ceases the need for heavy gimballing and differential throttling.

To the best of our knowledge, aerospike engines with SITVC have been the subject of experimental research and development in the past by two main actors: Rocketdyne in the 1960s (as reported by Silver) and Eilers et al. in the 2010s (at Utah State University). Silver [

11] reported 33 hot-fire tests, where the effects of thrust-vectoring in an annular aerospike nozzle for a variety of secondary injection positions and secondary mass flows were studied. He concluded that, for optimal performance of SITVC, a downstream injection position and higher mass flow rates were beneficial. On the other hand, in the MUPHyN project, Eilers et al. [

12,

13] conducted cold-flow experiments with three different secondary injection positions, where they evaluated the performance of side-force generation in terms of the side-specific impulse. Here too, they confirmed the performance advantage for a downstream injection position. Furthermore, the results demonstrated that, for equivalent mass flow ratios, a smaller orifice diameter for the injection was beneficial. Moreover, experimental evidence presented that the interaction of the main flow with the injection flow generated additional side-force components when compared to the secondary injection flow alone. This generation of additional side force was recently confirmed during the cold-gas experiments conducted at TUD, where the secondary injections were maintained at sonic speed for a geometric variety of injection orifices [

14]. Additionally for linear nozzles, the optimal injection angle was observed to be slightly inclined towards the main flow. For both linear and annular nozzles, the optimal injection position was identified further downstream. However, no experimental data on the pressure distribution of linear or annular nozzles involving SITVC could be found.

The flow field and pressure distribution on linear aerospike nozzles with SITVC is considered analogous to the widely investigated canonical flow of a sonic jet in supersonic cross-flow over a flat plate. In this context, Spaid and Zukowski [

15] conducted experimental analysis of the pressure field on the flat plate, where a high-pressure zone upstream and a low-pressure zone downstream of the injection were observed. They attributed these phenomena to the interaction of the jet and the cross-flow, where the two pressure zones exert a side force on the plate, together with the momentum flux of the jet, for which they derived an analytical formulation [

16]. In contrast, as the cross-flow over an aerospike nozzle is accelerated rather than constant, the pressure distribution and corresponding side-force generation may behave differently.

In recent years, numerical simulations have been conducted by Propst et al. [

17] and Ferlauto et al. [

18] for linear aerospike nozzles with SITVC. Both analyses confirmed the comparable flow structure with the sonic jet in cross-flow situations, characterised by the high-pressure zone upstream and the low-pressure zone downstream of the injection. A preliminary verification of the simulations was conducted through shallow water experiments, which demonstrated the existence of the high-pressure zone in a qualitative manner [

19,

20]. However, an adequate quantitative measurement of the flow field could not be derived.

In order to address the paucity of experimental data, in summer 2019, a test campaign utilising two-dimensional, linear aerospike nozzles with SITVC was conducted in collaboration with the Flows Group of the Space Propulsion Institute in Lampoldshausen (German Aerospace Center, DLR). The experiments yielded comprehensive insights into the flow phenomena and pressure distribution on the nozzle and base surface. To the best of our knowledge, the data obtained represent the first experimental pressure data related to such flow conditions. In particular, the high-pressure region upstream and the low-pressure region downstream of the injection location could be experimentally verified.

Section 2 (Materials and Methods) provides a general overview of the experimental setup and specimen utilised in the presented investigation. It also presents the adaptability of the test specimen to test different truncation lengths and secondary injection (SI) positions. The surface and base pressure measurements are presented in

Section 3 for all plugs in the two main flow conditions (under-expanded and over-expanded) with active SI. This is followed by a discussion and assessment of the results in

Section 4.

2. Materials and Methods

The experimental setup was designed and realised for implementation at the DLR’s cold-gas test bench P6.2. In the following subsections, a general description of the test bench is provided, followed by a detailed explanation of the test specimen design. This section is concluded with the realisation of the test specimen. The presented description is an updated and shortened version of the preceding publication [

21], which focused on the pre-test campaign held in December 2018. Further details are documented in [

22].

2.1. Cold-Gas Test Bench P6.2

The cold-flow test facility P6.2 was implemented at the Space Propulsion Institute at Lampoldshausen in late 1998. The test facility provides up to three gaseous nitrogen (GN2) feeding lines, which can be pressure controlled separately. For the presented experiment, two out of three feed lines were used; one for the primary flow of the aerospike nozzle, expanding into ambient, and the other for secondary injection.

The fluidic interface for the test specimen was a rectangular flange of a Börger-contraction [

23,

24], with a flow cross-section of

. Upstream, a diffuser and a flow straightener provided a homogeneous, rotation-free flow. In this location, the total pressure of the main flow

was measured. The second feeding line for the secondary injection flow was realised with a corrugated metal hose having an inner diameter of

, which was connected via a straight stainless steel tube with an inner diameter of

. Two variations of a mounted test specimen with the feed lines are depicted in

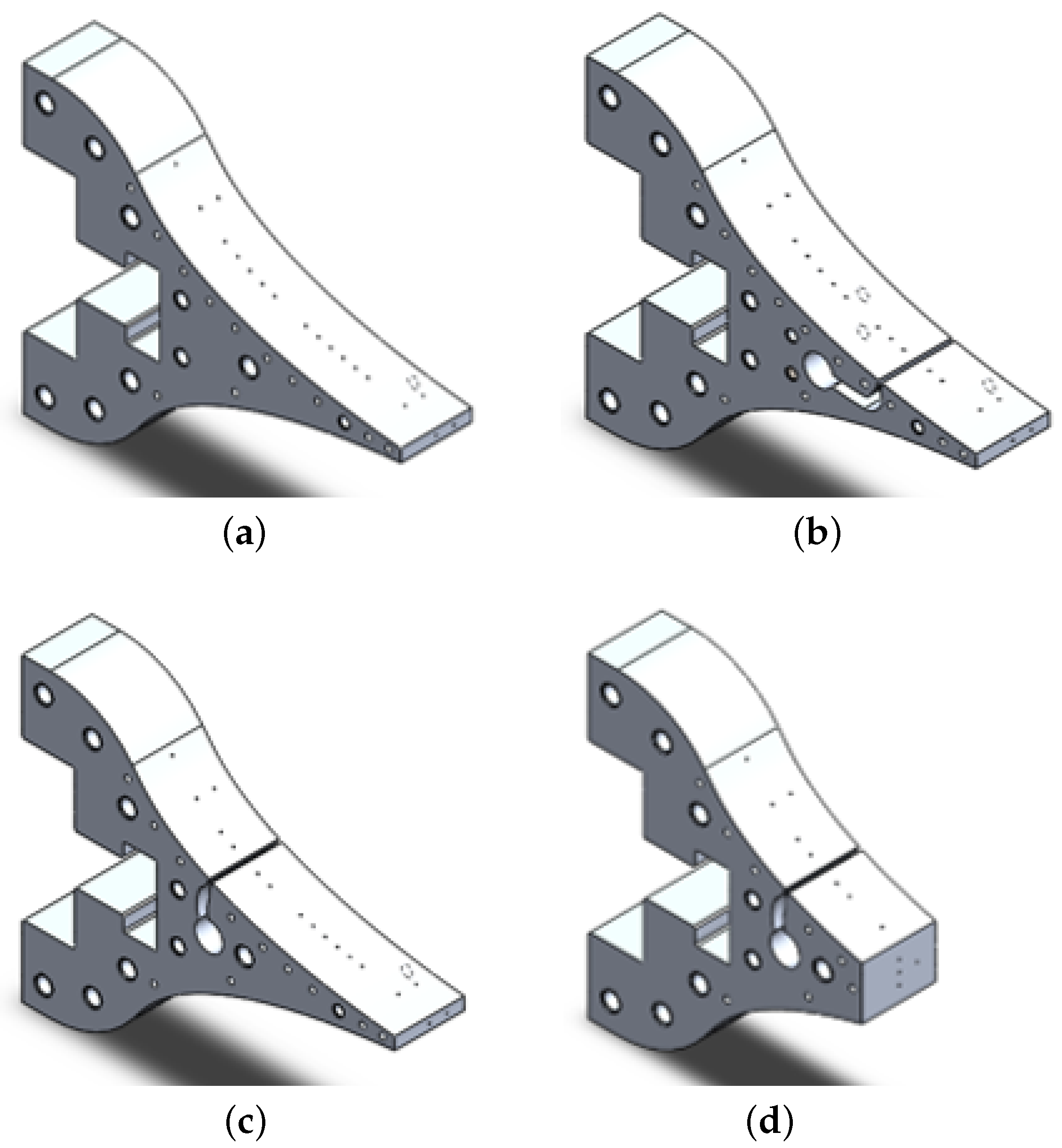

Figure 1.

The measurement interface was defined for the integration of the pressure sensors. Kulite® pressure transducers (Kulite, Leonia, NJ, USA) with pressure ranges of 0–0.1 … and a calibrated full-scale accuracy of were used. The sensors were directly connected to the test specimen via Teflon tubes.

In addition to the measurement of surface pressure, the visualisation of flow was a key aspect of this campaign. Two distinct flow-visualisation systems were employed for this purpose. The first one was a Z-Schlieren setup, which captured the flow in a perpendicular orientation to the two-dimensional nozzle plane, while the second system, a Background-Oriented Schlieren (BOS) system, captured the flow in a lateral orientation from within the aforementioned plane (see

Figure 1). Both systems were capable of visualising changes in brightness caused by the deflection of light resulting from changes in the density gradient and, consequently, the refractive index of the flow. Consequently, they are well-suited to the detection of shocks and other flow phenomena that are to be expected in a supersonic flow.

2.2. Test Specimen Design

The test specimen and, in particular, the supersonic part of the nozzle were designed to fit the test-bench capabilities. These capabilities were limited to a maximum mass flow rate of

and a maximum total pressure of

[

25,

26,

27]. The maximum throat area was calculated to be

using

and the gas properties for GN2 at room temperature.

An adaptation of the FORTRAN program of C. C. Lee [

28] was used to obtain the normalised contour for linear aerospike nozzles based on the Prandtl–Meyer expansion. In order to derive a specific contour, further input parameters, such as the gas properties and the design pressure ratio, were required. The latter is defined as

, the ratio of the total chamber pressure

to the nozzle exit pressure

. In this particular configuration, the nozzle expands to ambient pressure

. Accordingly,

is set equal to

. Consequently,

is constrained to ≈60, taking

into account. In order to test all flow states from over-expanded

and adapted

to under-expanded

, a slightly lower design pressure ratio of

was chosen. Here, the nozzle pressure ratio was used in the following formulation:

. Hence, an under-expanded flow

is characterised through a nozzle exit pressure higher than the ambient pressure

. Consequently, an over-expanded flow would exit the nozzle fully expanded at a pressure below the ambient pressure

if no pressure adaptation of the flow occurred. At last, a combination of nozzle width

and nozzle radius

(technically, the nozzle height in the case of the linear nozzle) was selected in order to achieve the desired throat area [

21].

Table 1 provides a summary of the final input parameters for nozzle sizing and key results.

Figure 2 presents the final nozzle contour with the two chosen truncations of

and

, and the two secondary injection sites at

and

with respect to the full nozzle length. The truncations were selected to represent a relatively large and correspondingly small nozzle, both of which can be manufactured and provide sufficient accessibility for pressure measurement holes. On the other hand, the two injection locations were selected to achieve a downstream injection corresponding to the respective nozzle truncations. The nozzles were designed to accommodate one or two pressure measurement locations downstream of the injection. The injection port itself was a straight slit across the entire width of the nozzle with a thickness of

. In conjunction with an upstream converging inlet, a perpendicular injection to the local main flow direction was ensured.

2.3. Realisation of the Test Specimen

Figure 3 illustrates the four types of plugs (supersonic part of the nozzle) used for the experiment. Each of the plugs differs from its numerical predecessor in a single geometric parameter. Plug 1 serves as the reference plug, exhibiting the longest truncation without secondary injection. Plug 2 shares the same length but with corresponding downstream secondary injection site. The plug analogous to the truncation length of plug 2 with an upstream injection site is labelled plug 3. Finally, plug 4 shares the injection site with plug 3, but has the shortest truncation length. Each injection site is fed symmetrically by the second gas supply line through a steel tube with an inner diameter of

.

The plugs were manufactured with a number of pressure measurement holes, which were all aligned the plug’s median line. On the side of the plug with the secondary injection, the measurement positions were spaced with an axial distance of ≈7 mm with a doubled density near the injection sites (named suffix A). The locations of the secondary injection sites coincide with pressure measurement positions 04 and 07A.

In order to ensure comparable pressure measurements among all plugs, two measurement positions were duplicated on the opposite wall of the injection side, indicated as u. Three additional measurement positions were added at a distance of to one side wall, indicated as w. These were used to evaluate whether the wall shear layer development due to the acrylic side plates affects the pressure measurements along the median line.

At the base, each plug was equipped with two measurement positions, one in the centre and the other near the wall. The larger base of plug 4 allowed two additional pressure measurement positions along the median line with a lateral displacement. This allowed us to analyse whether the secondary injection had an influence on the symmetry of the pressure distribution at the nozzle base. All pressure measurement locations and the measurement ranges of the connected pressure sensors are summarised in

Appendix A Table A1.

The test specimen was designed and manufactured as a screwed assembly. It consisted of the subsonic flow chamber, four different plugs and two acrylic side plates. The latter were used to ensure a two-dimensional flow by separating the nozzle from any lateral ambient influence. The assembled specimen is shown in

Figure 4. Furthermore, in the case of plugs 2–4 with active secondary injection, the acrylic plates separated the two asymmetric nozzle flows from each other and prevented backflow around the plug due to the differential pressure.

The subsonic flow chamber serves as the mechanical interface between the specimen and the test bench. Furthermore, it realises the gas flow distribution by adapting the flow cross-section to a rectangle of , which aligns with the nozzle width . Further downstream, the flow is then separated by two symmetric channels, which continuously decrease in cross-sectional area towards the nozzle throat.

3. Results

Following the description of the test setup in the last section, the measurement results are presented here. First of all, an overview of the test sequence used for the different plugs is given. The surface pressure measurements are then analysed for the different plugs and flow states, including their dependence on secondary injection pressure. Finally, the base pressure measurements are presented and analysed with respect to their dependency on the secondary injection.

3.1. Test Sequence

For a measurement run, the maximum feeding pressures of both the primary and injection flows were set to the maximum desired value (

and

, if not otherwise specified), while the control valves were used to achieve the specified pressure levels.

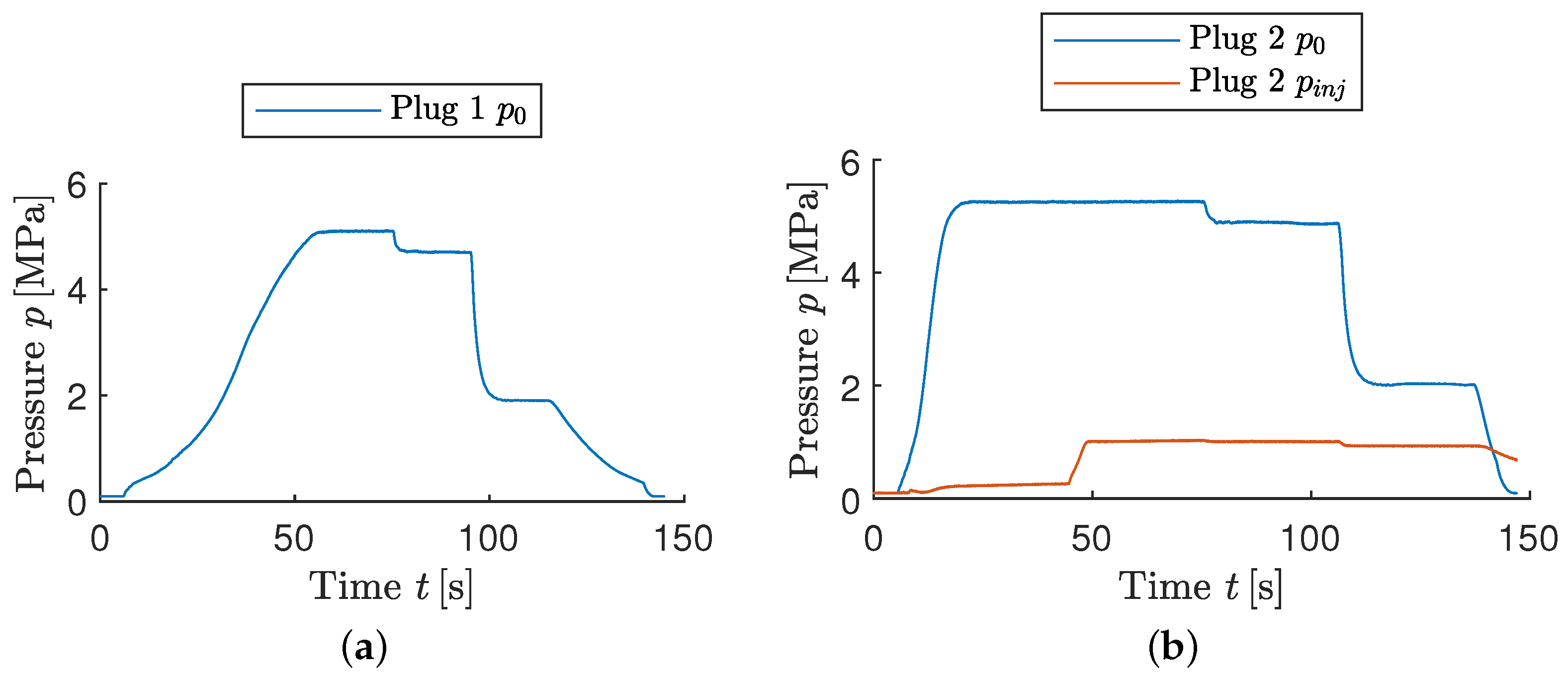

Figure 5 shows the applied test sequences for reference nozzle plug 1 and plugs 2–4 with active injection.

Both test sequences had a similar main flow total pressure profile, which began with a ramp-up transition to the highest level. After reaching the first plateau, two further steady flow conditions followed at lower pressure levels. Each of the plateaus lasted . The main flow valve was then closed and the test was completed.

In the case of active secondary injection, the first main flow plateau consists of two phases of

each. The first had no active injection, but the second did. Then,

after the start of the test, the injection flow control valve was fully opened and remained unchanged during the test, as did the pressure regulators.

Figure 5 shows two sensor patterns that were not directly intuitive. First, during the test time between 5 and

, the pressure reading for

increased. This could be due to the filling of the cavity between the control valve and the injection site. The injection site, therefore, acted as a pressure measurement port with a large time constant. The second pattern was observed at about

, where

decreased significantly as

dropped. Here, both pressures seemed to be coupled, a topic that is discussed in detail in

Section 4.2.

3.2. Plug Surface Pressure

With the test sequences defined, the measurement results are presented, starting with the plug surface pressure. The pressure measurements are shown as averaged values of the stead-state phases for the main and secondary injection flows at different flow conditions.

3.2.1. Reference Nozzle—Plug 1

The pressure distribution of the reference plug 1 is shown in

Figure 6 for different main flow conditions. For the under-expanded flow conditions of

and

, the normalised pressure ratio

decreased continuously in an almost identical and ideal isentropic manner. This behaviour was due to the fact that, above the design pressure ratio (

), the pressure adaptation of the nozzle flow was only realised beyond the nozzle surface and, therefore, did not affect the normalised pressure distribution on the plug surface. A deviation from this behaviour was seen at the most downstream measurement positions for the over-expanded flow condition of

. Here, the normalised pressure ratio increased downstream from the nozzle position

. This was due to the recompression that occurs downstream of the last expansion wave originating from the outer nozzle lip, which expanded the flow to

. As the nozzle contour was designed for further expansion, the flow had turned further and created compression waves [

3,

4]. The compression waves then propagated to the outer shear layer, from which a second expansion fan started. The last expansion wave and the first compression line can be seen in the corresponding Schlieren images in

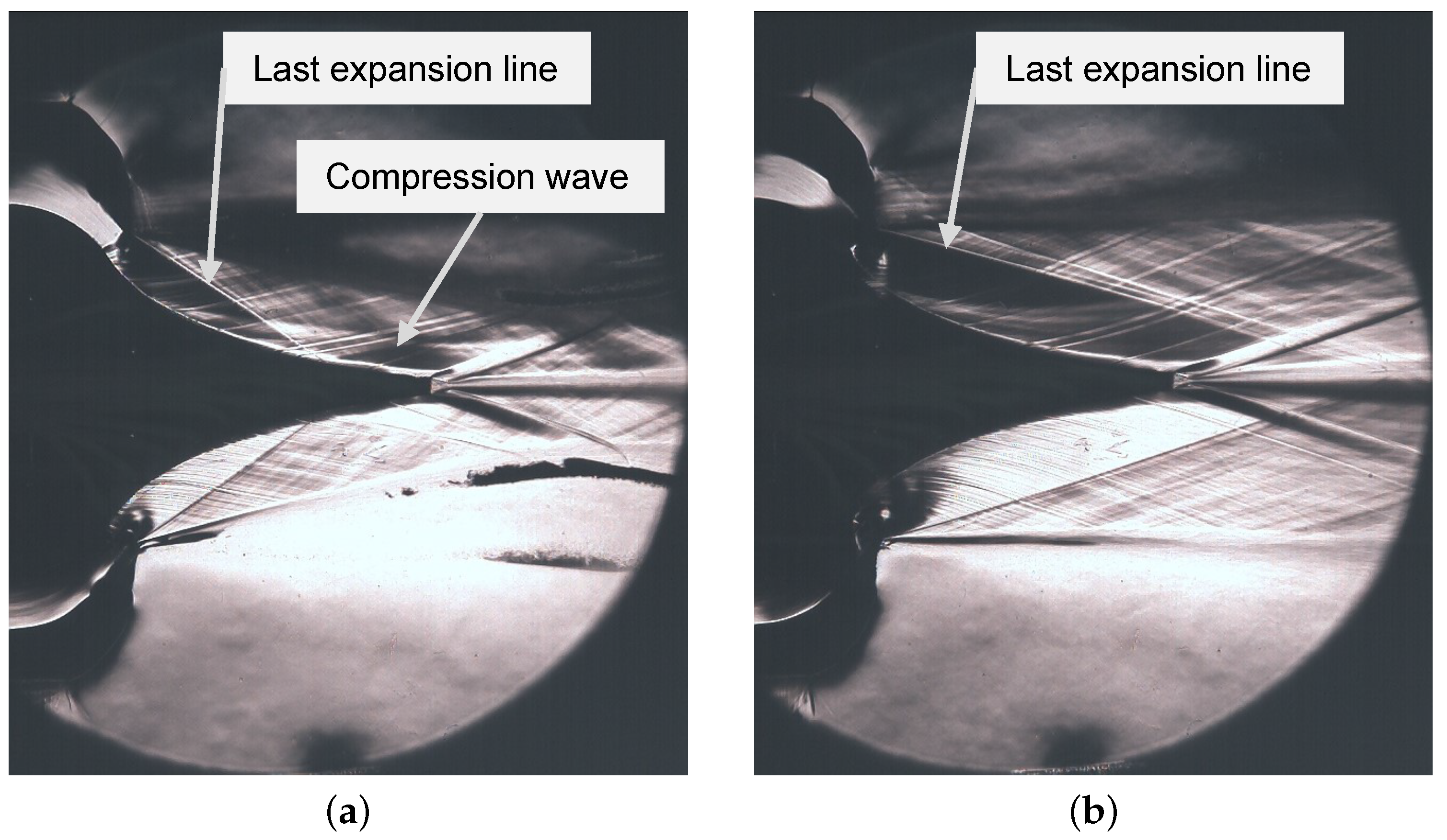

Figure 7.

3.2.2. Nozzles with Secondary Injection—Plugs 2–4

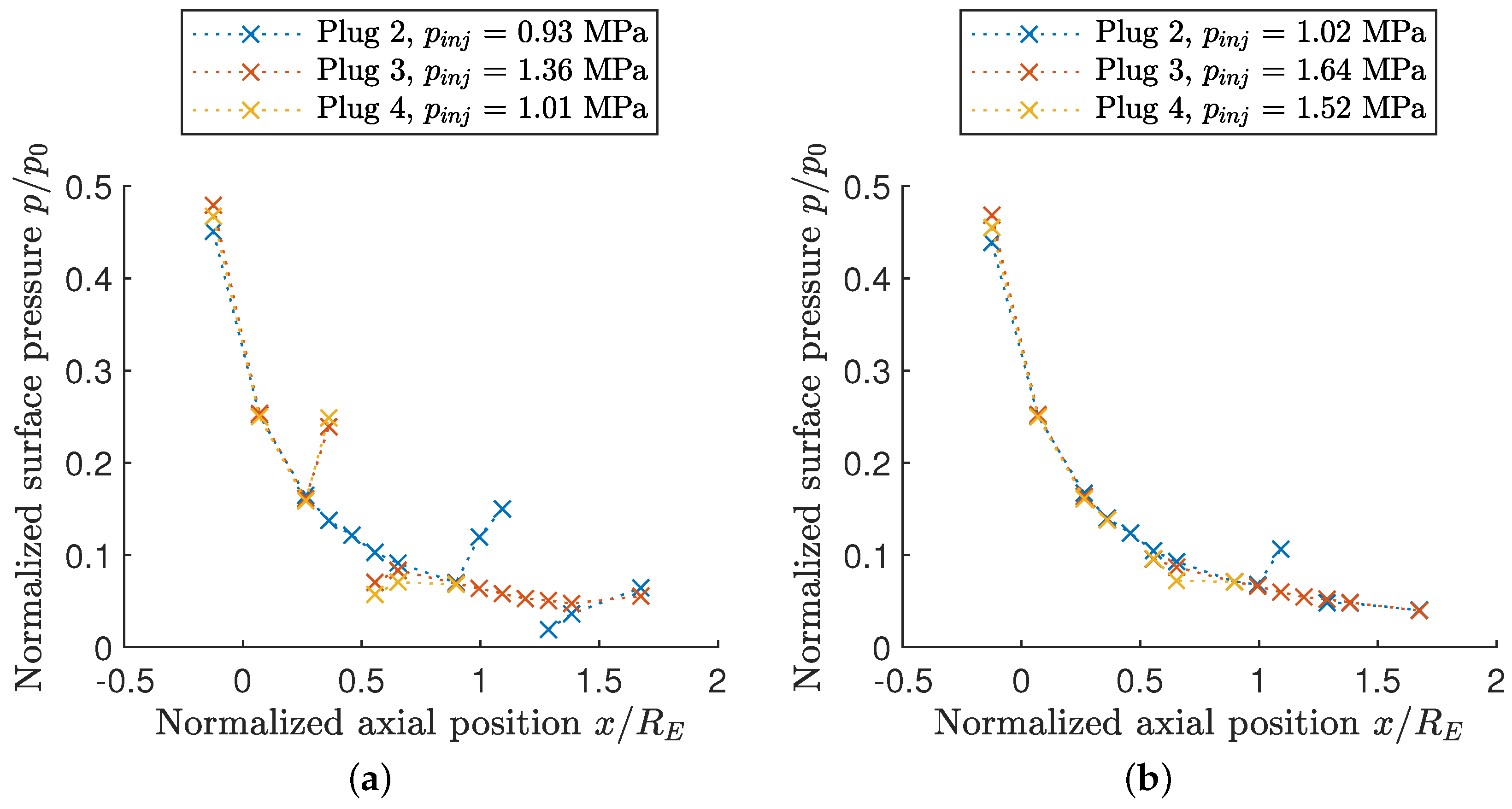

The surface pressure analysis with active SITVC is described for two flow conditions. The measurements of

and

were used here, as the second under-expanded flow condition

was very similar to the latter.

Figure 8a shows the measured pressure ratios for plugs 2 to 4. In the case of the over-expanded flow condition (

), there was a distinct pressure increase upstream from the respective injection position for each plug. This narrow high-pressure region was found to be very similar for the identical injection positions of plugs 3 and 4. For plug 2 with the downstream injection position, the pressure rise was more extended with a gentler gradient. Downstream from the injection, a pressure drop was measured for all three plugs, where it was the highest directly at the injection site and then leveled off further downstream. For plug 3 in particular, this zone of reduced pressure appeared to be regionally confined. This confinement cannot be clearly stated for plug 4, as it was truncated at the axial position

, which coincided with the approximate end of the low-pressure region. In general, this region of reduced pressure was very similar for plugs 3 and 4, whereas a different behaviour was observed for the injection downstream from plug 2. Here, a reduced pressure increase for plug 3 was observed with respect to plug 2, indicating an interaction of the compression waves with the injection flows, depending on their respective positions.

For the under-expanded flow condition of

, the measured influence of the secondary injection on the primary flow pressure distribution was significantly less pronounced, as shown in

Figure 8b. A high-pressure region in front of the upstream injection (plugs 3 and 4) could not be measured with the test specimens under these conditions. Only the downstream injection at plug 2 showed such a high-pressure region. On the other hand, the low-pressure regions downstream from the injection are clearly visible for the upstream injections (

), while, for the downstream injection at

, there is no significant pressure drop.

Finally, it should be noted that the measured static injection pressure

diverged significantly for both flow conditions (

/

)—see the legend for

Figure 8. This occurred despite the fact that the pressure regulator setting and the control valve opening were not changed during the test of each plug, indicating a back-coupling of the main flow static pressure into the injection flow. This back-coupling suggested that, at least for some flow conditions, the injection flow was subsonic.

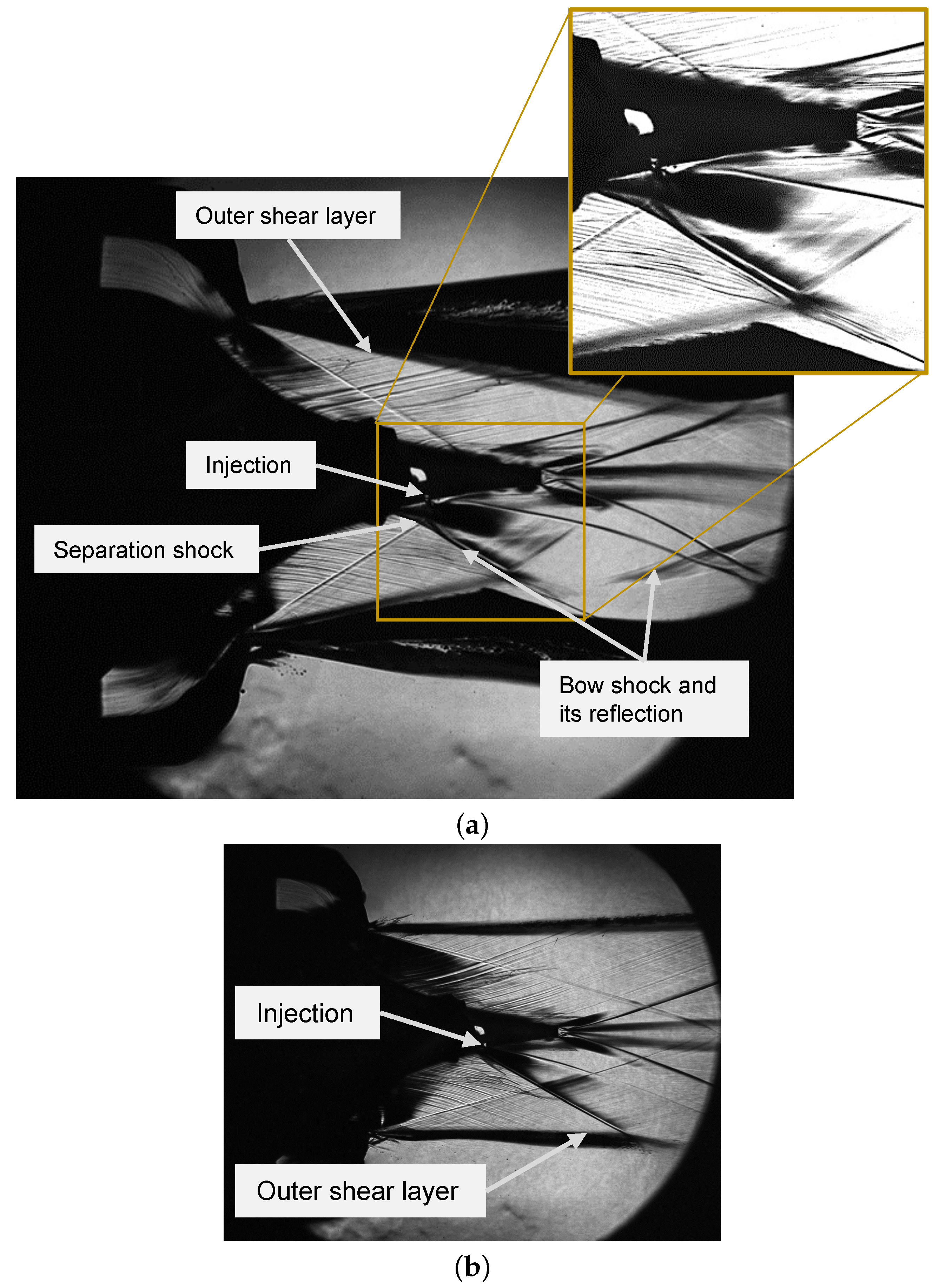

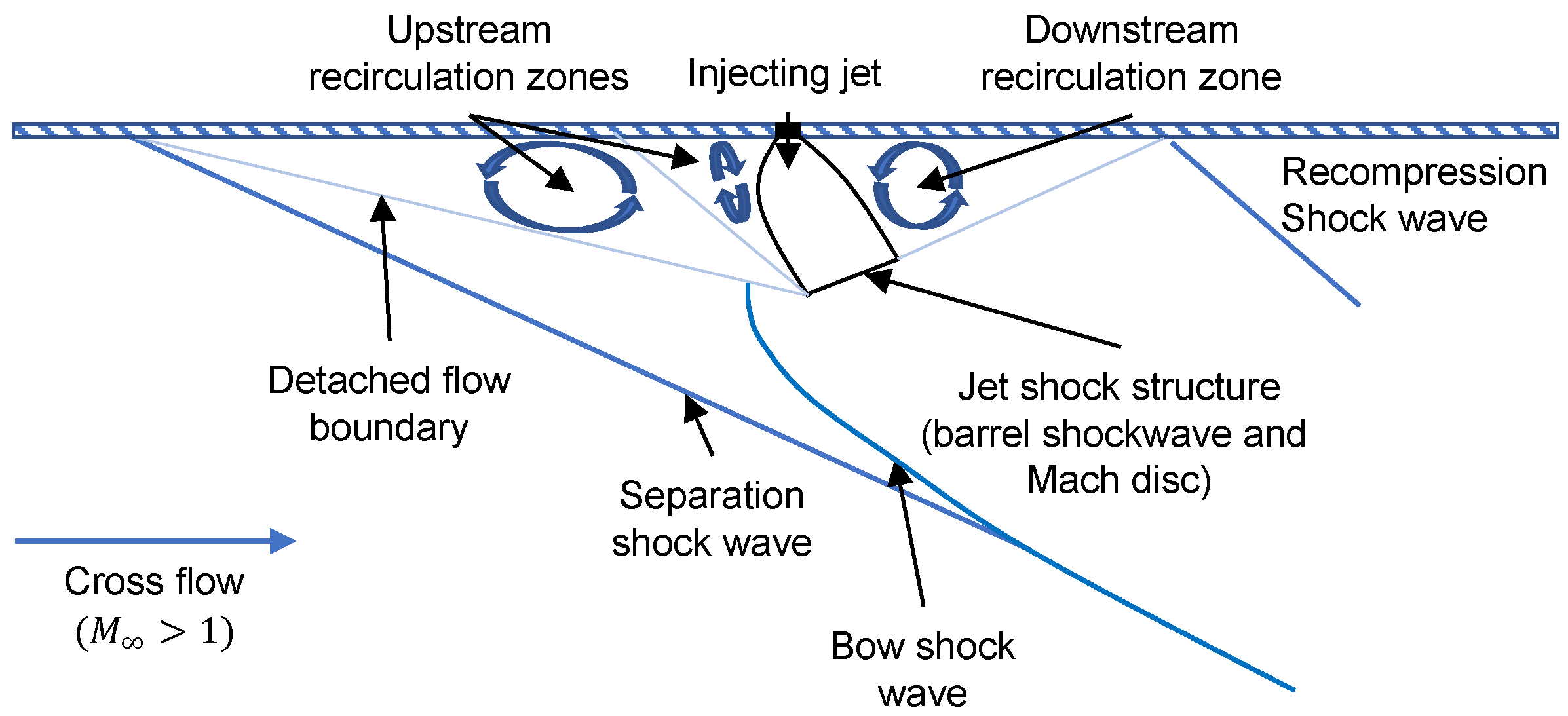

For visualisation purposes, the corresponding Schlieren images obtained during the experiments are shown in

Figure 9 for plug 2 and the flow conditions discussed in

Figure 8. The relevant flow characteristics of an aerospike nozzle flow caused by secondary injection are highlighted using a scheme for a sonic jet in cross-flow (see

Figure 10; according to Gruber et al. [

29] and Yan et al. [

30]) and a Schlieren image of plug 2 at

(see

Figure 9a). The additional complex shock system induced in the aerospike nozzle flow was caused by the injection flow acting as an obstacle to the main flow. As a result, the supersonic main flow was deflected by an oblique shock, the separation shock, upstream from the injection position. A pair of counter-rotating recirculation zones was formed between the detached flow and the nozzle wall, creating the high-pressure zone. The separation shock joined the bow shock downstream, which originated near the injection location. The bow shock extended to the outer shear layer, buckling it, and was reflected back towards the nozzle axis. Downstream from the injection site, the flow reattached to the wall and confined the low-pressure zone formed by a third recirculation zone. In the case of the over-expanded flow in

Figure 9a, a dedicated recompression shock wave due to SI could not be clearly distinguished from the compression wave originating from the reflected last expansion wave. In

Figure 9b, such a dedicated recompression shock wave can be identified, which is missing on the opposite side of the nozzle flow.

Figure 9b shows the corresponding Schlieren image for plug 2 in the under-expanded flow condition. Comparing the two images, it can be seen that the formation of the flow phenomena was much more pronounced for the over-expanded main flow: the injection zone between the bow and the reattachment shock was much more bulbous and the buckling of the shear layer was more pronounced. This was due to a higher mass flow ratio of the injection flow with respect to the main flow. Furthermore, it can be observed that the central flow, downstream from the plug, was significantly asymmetric and had bent downwards, indicating a significant deflection of the thrust vector. Conversely, in the case of the under-expanded flow, the effect of the SI on the overall flow was less effective. To complete the set of Schlieren images,

Figure A1 in

Appendix A shows the flow states of

and

for plugs 3 and 4, respectively.

3.2.3. Influence of Injection Pressure on Plugs 2–4

This section presents the investigation of the influence of secondary injection pressure on the surface pressure distribution on the nozzle. This analysis has been carried out for plugs 2–4 at three different injection regulator settings between and . All data presented here are for the over-expanded flow condition of each plug at . The pressure distribution for each plug and the corresponding measured injection line pressures are shown in the following graphs.

First,

Figure 11 shows the normalised surface pressure obtained for plug 2 at

= 0.61–0.93

. These data show that the high-pressure region upstream and the low-pressure region downstream from the injection location were spread at least over the two adjacent measurement points. Therefore, their length was determined to be at least

. The upstream high-pressure region was shorter than

because position 06 was not affected by the injection. At the downstream injection, the length could not be determined precisely, as the last measurement position 10 depicted small deviations. This indicated either a very small influence of the injection or small variations in the total pressure

of the main flow. For the latter, this means that a variation in the contact position of the last expansion wave and the corresponding pressure increase downstream was imminent due to the compression waves. Furthermore, as

increased, the pressure profile changed from concave to linear to convex, indicating an increasing length of the high-pressure region. For example, for

, the pressure signal at position 06A (

) seems to be almost unaffected by the injection, suggesting that the origin of the separation shock was very close to this position. Finally, it can be seen from these measurements that, as

increases, the deviation of the pressure in the highand low-pressure regions caused by the injection also increases accordingly.

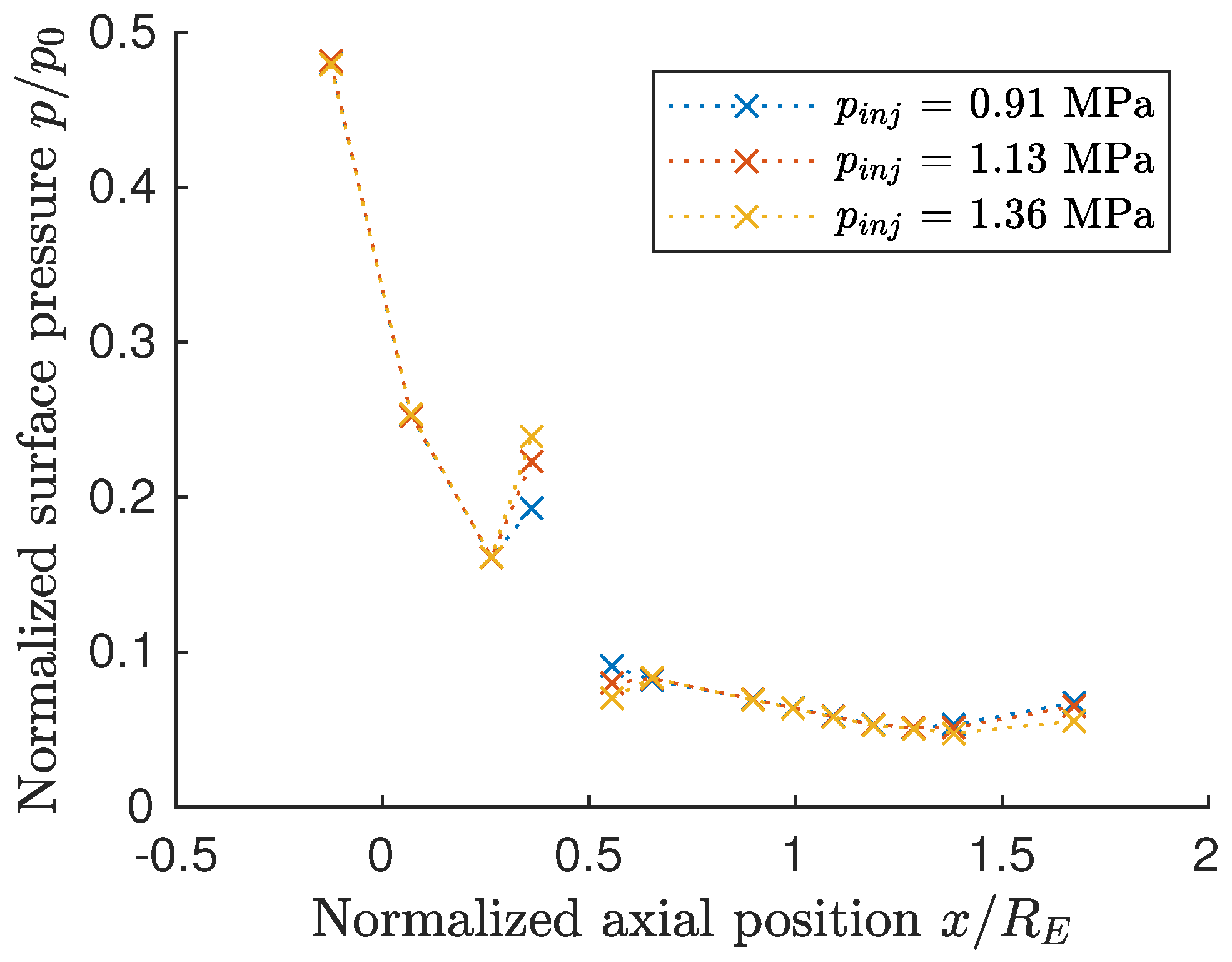

Figure 12 shows the measurements obtained for plug 3 at injection pressures

= 0.91–1.36

. Firstly, it can be seen that the high-pressure region upstream from the injection is smaller than on plug 2 when compared to the distribution shown in

Figure 11. The length can, therefore, be determined to be between

and

, as only one measurement position was affected. The length of the downstream low-pressure region is also limited, for which the data also show almost negligible deviations in the second following position 05 (

). Further downstream, there were no deviations in the pressure signal, except at the very last position. This variation corresponds again to the slight deviations in the contact point between the nozzle surface and the last expansion wave. The high- and low-pressure regions differ significantly in their respective magnitudes. While the pressure increase upstream from the injection was clearly visible, the pressure decrease in the low-pressure region was almost negligible.

The final analysis with respect to injection pressure is shown in

Figure 13 for plug 4 and

= 0.68–1.01

. The general pressure signal was comparable to that of plug 3 up to the nozzle truncation. The length of the upstream high-pressure region could be estimated to be between

and

, as only one pressure measurement location was effected. The downstream low-pressure region, however, extended beyond position 05

, but not to position 06.

To conclude this analysis, it can be stated that the high- and low-pressure regions were directly influenced by the injection pressure. The size of these regions increased with increasing pressure, but depended even more on the injection location and, therefore, on the static pressure of the main flow. It has also been shown experimentally that higher injection pressure led to a higher pressure increase upstream and lower pressure decrease downstream from the injection location. However, in order to quantify the surface pressure distribution in more detail, a higher measurement density would be required for this test setup.

3.3. Base Pressure Measurements

The base pressure measurements are the second set of results presented here. These values are not averaged but evaluated over time during the transition between pressure levels. This allows the correlation between base pressure and nozzle pressure ratio to be analysed as a function of truncation and secondary injection.

3.3.1. Base Pressure without Secondary Injection

In the first transient phase of each test sequence, the base pressure ratio

with secondary injection inactive was evaluated with respect to the

. This correlation of

and

is shown in

Figure 14 for all plugs and measurement positions over the entire captured

range.

It can be seen that the two truncation variants ( for plugs 1–3; for plug 4) show similar but different behaviour. Up to , the base pressure ratio for all plugs decreased continuously and more steeply than the ambient pressure, followed by a series of sharp oscillations up to . Furthermore, the -behaviour started to differ depending on the truncation. The base pressure ratio for plugs 1–3 (longer plugs) continued to decrease to a local minimum, followed by a local maximum near , where the base pressure locally exceeded the ambient pressure. At higher s, the base pressure ratio fell back below the ambient pressure and decreased monotonically up to , where it became constant at . This means that the base pressure depended solely on the total main flow pressure and was independent of the ambient pressure . This behaviour is widely known in the literature as ‘wake closure’. In the observed closed-wake state of plugs 1–3, the base pressure remained below the ambient pressure. Therefore, a higher would be required to achieve a net thrust gain for the base area.

For the shorter plug 4, the local maximum of the base pressure ratio occurred at , which was also above the ambient pressure ratio . The maximum was followed by a monotonous decrease, until became constant with for . At above , the base pressure exceeded the ambient pressure and, thus, caused a net thrust gain for the base area.

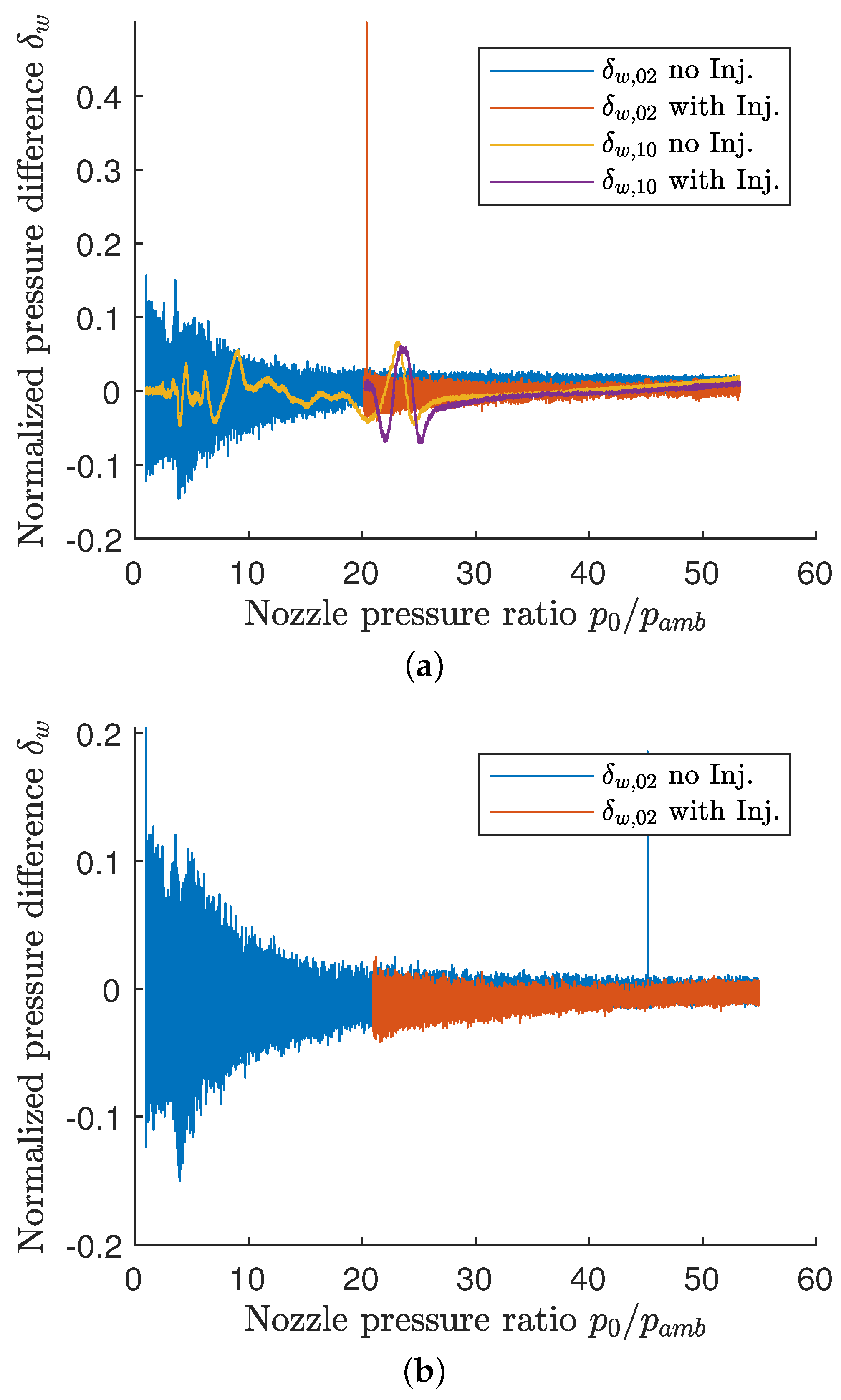

3.3.2. Impact of Secondary Injection on the Base Pressure

Two transients during the main flow pressure reduction (from

to

) were used to evaluate the influence of the secondary injection flow on the base pressure.

Figure 15 shows the base pressure ratios for the central measurements with and without injection flow for plugs 2–4. For the longer plugs 2 and 3, a minimal increase in base pressure from

without secondary injection to

with SI was observed. For higher

above 40, this pressure increase due to SI seemed to disappear for the more upstream injection for plug 3. However, the effects near the wake transition were different. For plug 2, the

measurement in the injection case closely followed the non-injection case with a small offset.

As for plug 3, the base pressure with active injection behaved differently. On the one hand, the wake-closing transition was slightly shifted to a lower from ≈32 to ≈28. On the other hand, for below the transition phase, the base pressure was slightly below the non-injection case, except for a narrow range of intersection around .

For the shorter plug 4, there was no change in base pressure due to secondary injection observed. remained identical to the closed-wake condition for the non-injection case. However, the wake-closing transition was significantly shifted to a lower from ≈24 to ≈21 for the injection case.

In order to rule out any hysteresis effects on the wake-closing behaviour, the base pressure measurements for plug 1 (without secondary injection) are shown in

Figure 16 for the same main flow transitions as the above studied plugs 2–4. It can be observed that the base pressure measurements behaved in the same way for the ramp-down of the

and for the transition phase of the ramp-up. Hence, there was no significant hysteresis effect of the base pressure behaviour with respect to the gradient and direction of the

progression. Consequently, the observed change in

for the wake-closing transition was most likely due to the secondary injection.

At this point, it can be summarised for the injection position that, for the case of upstream injection (plugs 3 and 4), active secondary injection shifts the wake-closing transition to a lower . On the other hand, for the case of downstream injection (plug 2), the secondary injection seemed to have no effect on the transition. With respect to truncation, the base pressure level showed a slight increase for the less-truncated plugs (plugs 2 and 3). However, in the case of higher truncation (plug 4), it appeared to remain unaffected by the injection flow. Consequently, the secondary injection creates opposing effects on the thrust component generated by the pressure acting on the base surface. In those cases where the base pressure is increased, the base thrust is increased. Conversely, if the wake-closing transition is shifted to lower s, the base thrust is decreased through the influence of secondary injection.

3.3.3. Flow Symmetry Analysis of Plug 4

Finally, a possible flow asymmetry due to axis-asymmetric secondary injection was investigated for plug 4.

Figure 17 shows the pressure ratio for the three centreline measurements for the inactive and active injection cases. Once again, the secondary injection appeared to have no significant effect on the overall pressure level at the base in closed-wake mode. However, SI shifted the wake-closing transition to a smaller

—from ≈24 to ≈21. Furthermore, active injection did not cause a significant difference between the pressure measurement closer to the injection side

and the opposite side

.

Table 2 shows the base pressure measurements for each position averaged in the closed-wake condition of

. These figures show that the overall pressure increase due to SI was greater than any asymmetry in the base pressure measurements. Therefore, only a small wake asymmetry could be observed with this setup and flow condition. The only significant deviation in the measurements can be observed up to

, where the axial measurement

was significantly lower than the non-axial ones (

and

). This could be attributed to the different distances between the measuring positions from the truncation edge, along with the corresponding suction effect of the detaching primary flow.

4. Discussion

The results presented are briefly discussed and analysed in the following section. First, the influence of the acrylic side plates on the pressure measurements obtained is examined. Subsequently, a follow-up test campaign in our own laboratory is briefly described and evaluated to further analyse the reason for the variations in injection pressure and to verify the assumption of a potential subsonic injection flow.

4.1. Analysis of the Impact of the Side Plates on the Two-Dimensional Flow

An analysis to evaluate the quality of the measurements was carried out with respect to the pressure deviations in the lateral direction of the nozzle surface. For this purpose, the data obtained at the measurement positions close to the wall (index

w) are compared with those of the centre line using the following normalised pressure difference:

with positions # = [02;10]. The results of this assessment are shown in

Figure 18 for plugs 2 and 4 over the full

range during

ramp-up without secondary injection and during ramp-down with SI active.

Figure 18a shows

for measurement positions 02 and 10. It can be seen that the data differed significantly depending on the position.

appears to be a constant line with an average of +0.6% over the full

span for inactive SI, while no significant deviation could be observed for the case with active SI. However, the noise on the signal is clearly noticeable, especially at low

s. This high noise ratio is due to the high measuring range of 700 and 3500 kPa for the sensors at position 02, whereas the measuring range of the sensors at position 10 was only 100 kPa. At higher

s, the noise became less pronounced due to a better signal-to-noise ratio. However,

shows a significantly less noisy signal over the

range with average values of +0.6% for inactive SI and +0.1% for active SI. Furthermore, the downstream measurement

depicts a different behaviour. While the noise is much lower, the locally averaged value over

was not constant. On the contrary, in the range of

3–26, there are significant deviations from a near-zero average, especially in the range of

20–26, where the last expansion wave interacts with the end of the plug surface (see

Section 3.2.1)—these deviations reach values up to

. The wavy nature of

indicates that the interaction of the last expansion wave with the plug surface occurs at different

s. This implies that the contact line between the last expansion wave and the surface might exhibit slight curvature, indicating a deviation from the ideal two-dimensional flow.

For comparison,

Figure 18b shows these data for plug 4 at measurement position 02. It can be seen that

behaves almost identically to plug 2, except for minor artefacts. The averaged values of

are −0.6% with inactive injection and −0.8% with active injection.

Based on the evaluation of the pressure differences for the two positions on the spike surface, it can be concluded that, for the more upstream pressure measurement position 02, two-dimensional flow can be guaranteed for all s in the investigated range. For the downstream location 10, this is true when the last expansion wave has passed this location for s above 30. Hence, it appears that the shear layer created by the side plates had a significant influence on the shape of the expansion system in the lateral nozzle direction. Furthermore, this analysis shows a small effect of the secondary injection on the normalised pressure difference. For the upstream position 02 and both plugs, this difference seems to be slightly reduced. On the other hand, for the downstream position 10, the SI seems to increase the amplitude and slightly decrease the mean value of the wave within the range of 20–26. Though the effects are limited, an influence of the side plates on the measured pressure values cannot be completely excluded.

4.2. Injection Velocity

As mentioned in

Section 3.1,

changed simultaneously with the total main flow pressure

during the test run, despite the fact that the pressure setting in the regulator and the control valve setting were unchanged. Therefore, a coupling of

and

was assumed, which would imply that the injection was at least partially subsonic rather than sonic over the entire cross-section of the injection port.

In order to verify this assumption, this test campaign was repeated in the vacuum wind tunnel test bench [

14,

31] at TUD using sub-scale nozzle models. These nozzles were scaled down by a factor of 5 in the throat area and by a factor of 10 in pressure to match the capabilities of the test bench. With this setup, a series of measurements were made for the two primary flow states: over-expanded (

) and under-expanded (

). The injection pressure

was varied over a wide range to capture the pressure ratios

experienced in the original campaign (and beyond). Based on these measurements, the mass flow ratio

is derived from the injection mass flow with active

and inactive

primary flow at specific injection pressures

. The reason for this

investigation is that, without a primary flow, the secondary injection (SI) flow is always sonic due to an injection to ambient pressure ratio of

. Therefore, when

, the injection mass flow depends not only on

but also on the injection exit conditions implied by the primary flow, resulting in a subsonic flow.

The obtained

–pressure ratio correlations are shown in

Figure 19 for the different nozzle and primary flow conditions. In addition, the

–pressure ratio correlations for the flow conditions investigated in

Section 3 are marked. In general, it can be seen from this figure that there are three distinct areas in the plots. At very low

, the

increases linearly with the pressure ratio. Above a certain pressure ratio, which correlates with the injection position (plug 2:

, plugs 3 and 4:

), the

becomes unity. There is a curved transition zone between these two linear correlations.

It is clear from

Figure 19 that, in the under-expanded primary flow condition at

, the

remained below 1 for all three plugs and the injection was subsonic. The situation is different for the under-expanded primary flow condition at

: for plug 2 with downstream injection,

is high enough to ensure sonic injection. The pressure ratio for plug 3 is very close to the critical value required for sonic injection and appears to be just above this threshold. However, the injection flow of plug 4 is below the threshold and in the transitional range close to full sonic injection.

It can, therefore, be concluded that sub- or transsonic injection has been achieved in most of the experiments conducted. Sonic injection was only achieved in a few experimental phases, particularly in the over-expanded primary flow state. It is, therefore, critical to achieve a pressure ratio above the threshold to ensure sonic injection. In the presented test campaign, it is assumed that the relatively small diameter of the metal hose in the injection line caused a high pressure loss, which prevented the required pressure ratio for sonic injection from being achieved across all experimental phases.

However, these results are not only relevant in terms of knowledge gain and CFD validation per se, but are also essential for engineering such SITVC systems for thrust-vectoring aerospike nozzles. The engineer can either ensure sonic injection by maintaining a ratio above the threshold or can adapt the controller for the more complex interactions with the main flow when subsonic injection conditions occur. The latter is particularly applicable when the SITVC is not simply switched on and off, like in a fast-opening and -closing solenoid valve, but rather with a continuously adjustable flow control valve.