The Impact of In-Flight Acceleration Environments on the Performance of a Phase-Change Heat Exchanger Unit with Layered Porous Media

Abstract

1. Introduction

2. Theoretical Models and Numerical Solution Methods

2.1. Heat Transfer Process

2.2. Microscopic Scale Heat and Mass Transfer Model

2.2.1. Governing Equations for Metal Porous Medium

- (1)

- The skeletal material is copper with a thermal conductivity of 385 W/m·K.

- (2)

- The porous medium is isotropic in all directions.

- (3)

- The pore density is uniform, and the porosity remains constant.

2.2.2. Governing Equations for PCM

- (1)

- The phase-change material is paraffin, a pure substance, with a thermal conductivity of 0.558 W/m·K and a latent heat of 230 kJ/kg.

- (2)

- The internal structure of the phase-change material is isotropic.

- (3)

- After melting, the phase-change material exhibits laminar flow, is incompressible, and features a mushy zone during the phase-change process.

- (4)

- The material properties of paraffin remain constant in the solid and liquid phases, independent of temperature, while exhibiting linear variations in the mushy zone.

- (5)

- Post-melting, paraffin adheres to the Boussinesq assumption, wherein density changes affect only the volume force term in the momentum equation.

- (6)

- The influence of surface tension is neglected.

2.3. Macroscopic-Scale Heat and Mass Transfer Model

- (1)

- The material properties of the metal framework and phase-change material are isotropic.

- (2)

- The pore density is uniform, and the porosity remains constant.

- (3)

- The phase-change material, post-melting, exhibits laminar flow, is incompressible, and complies with Darcy’s law.

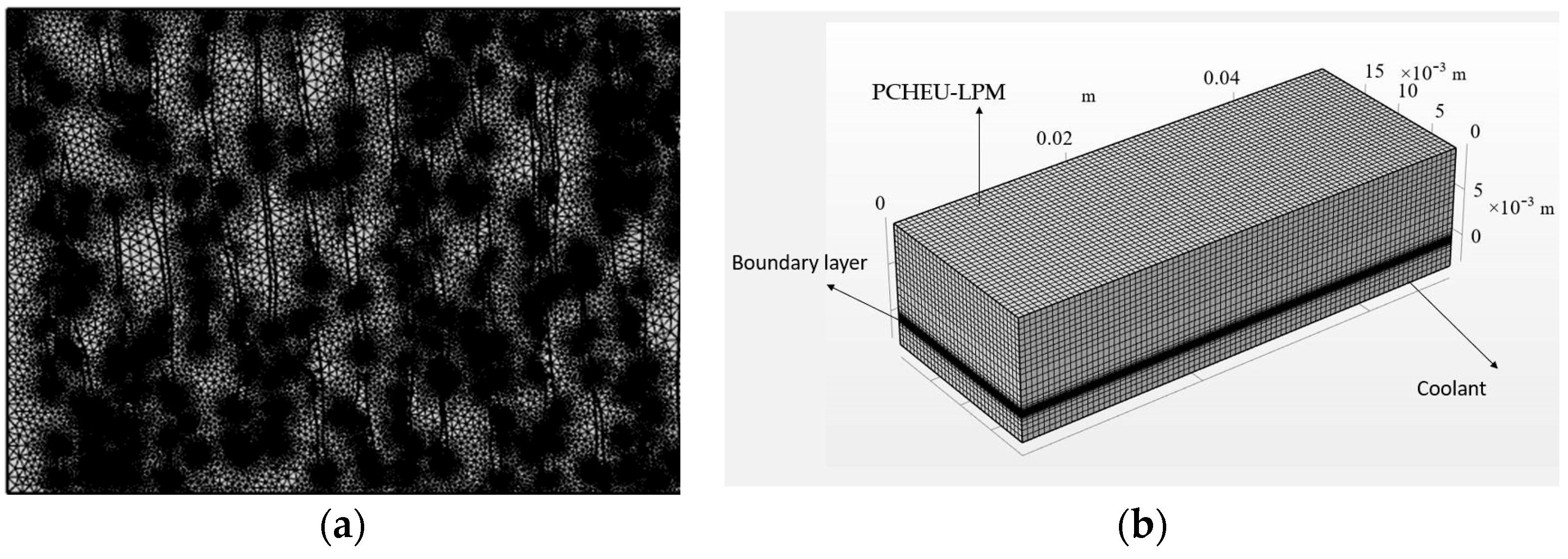

2.4. Meshing Method

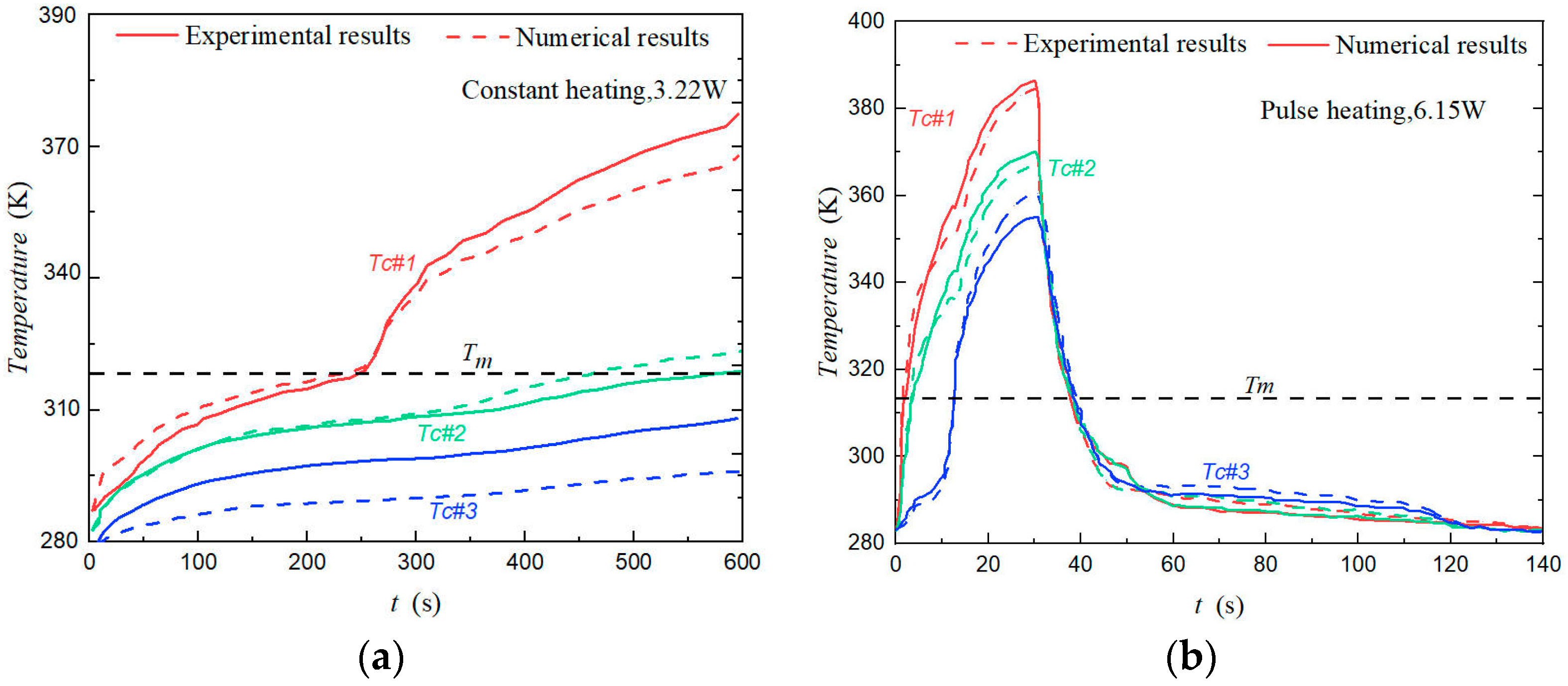

2.5. Model Verification

3. Simulation Results and Discussion

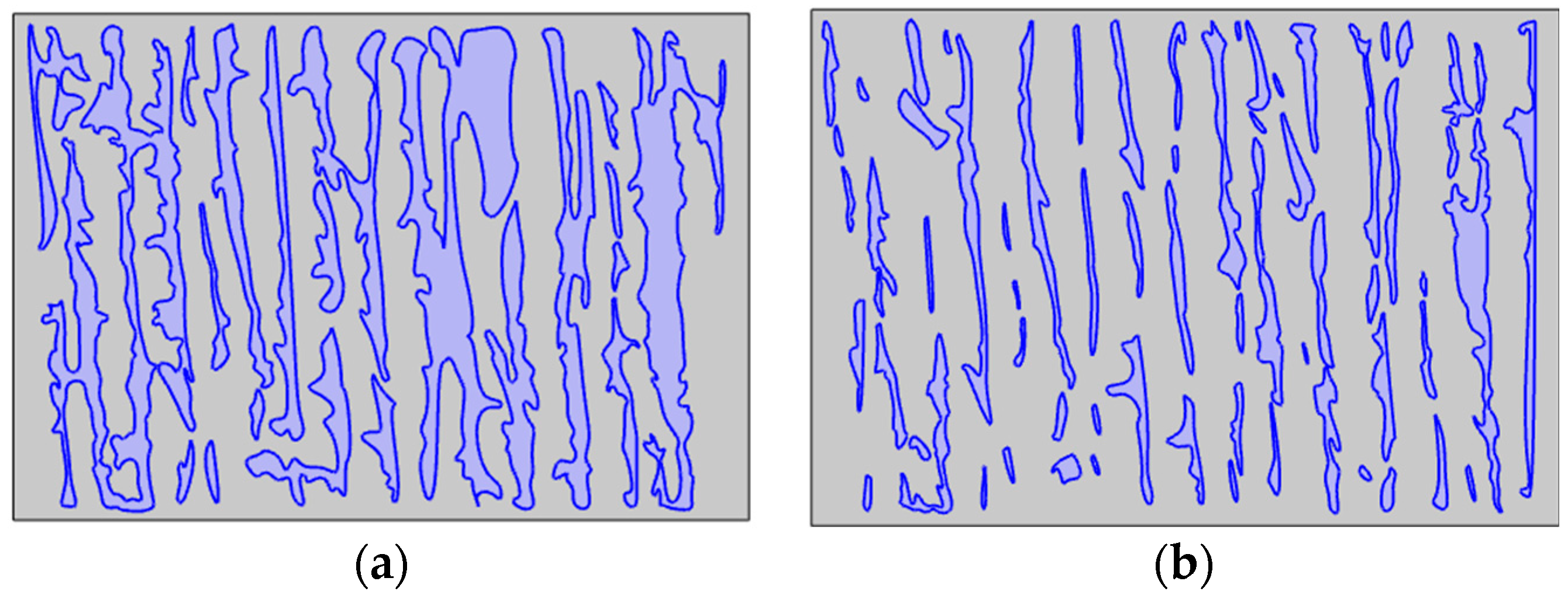

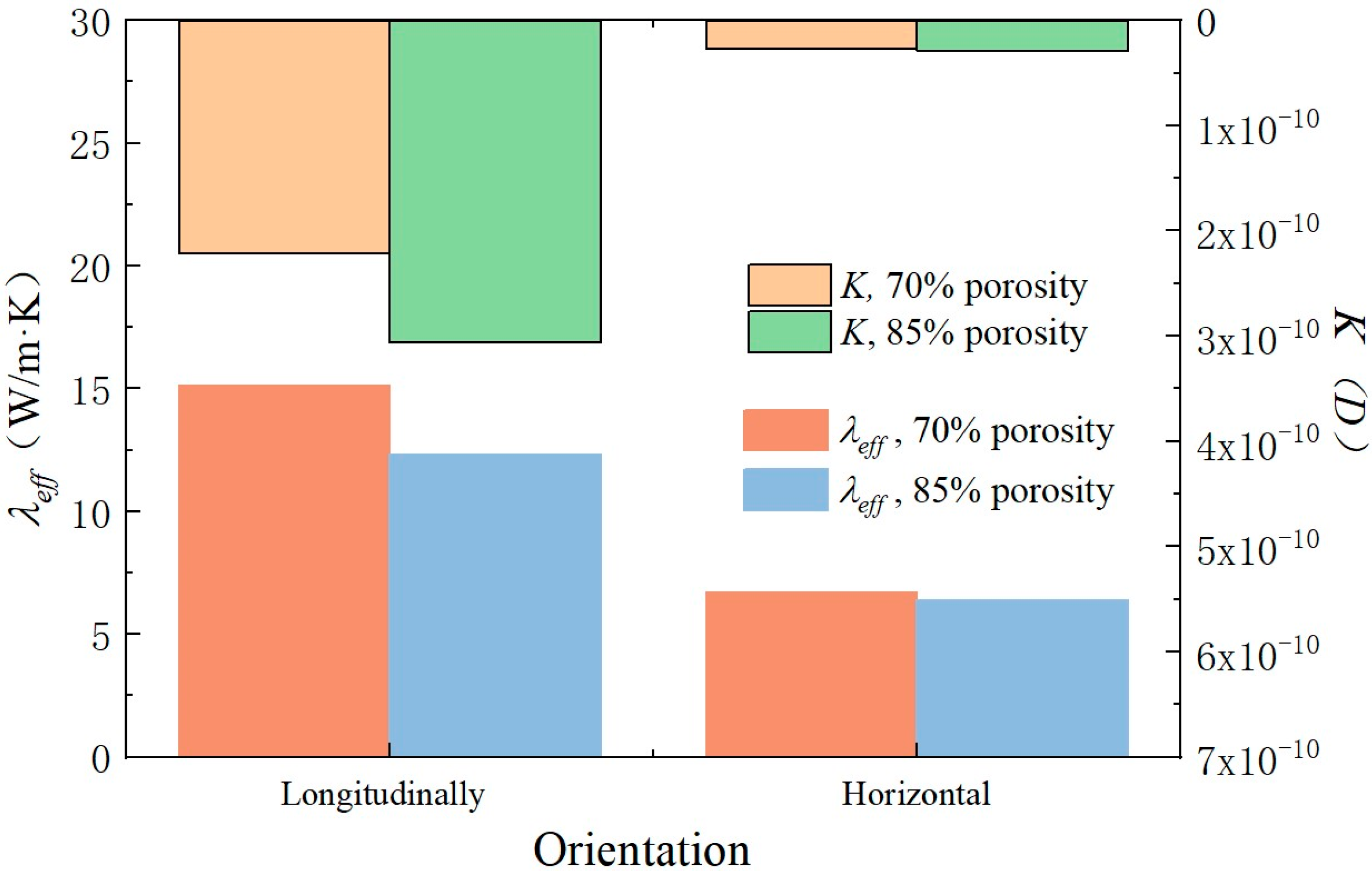

3.1. Determination of Equivalent Thermal Conductivity and Permeability

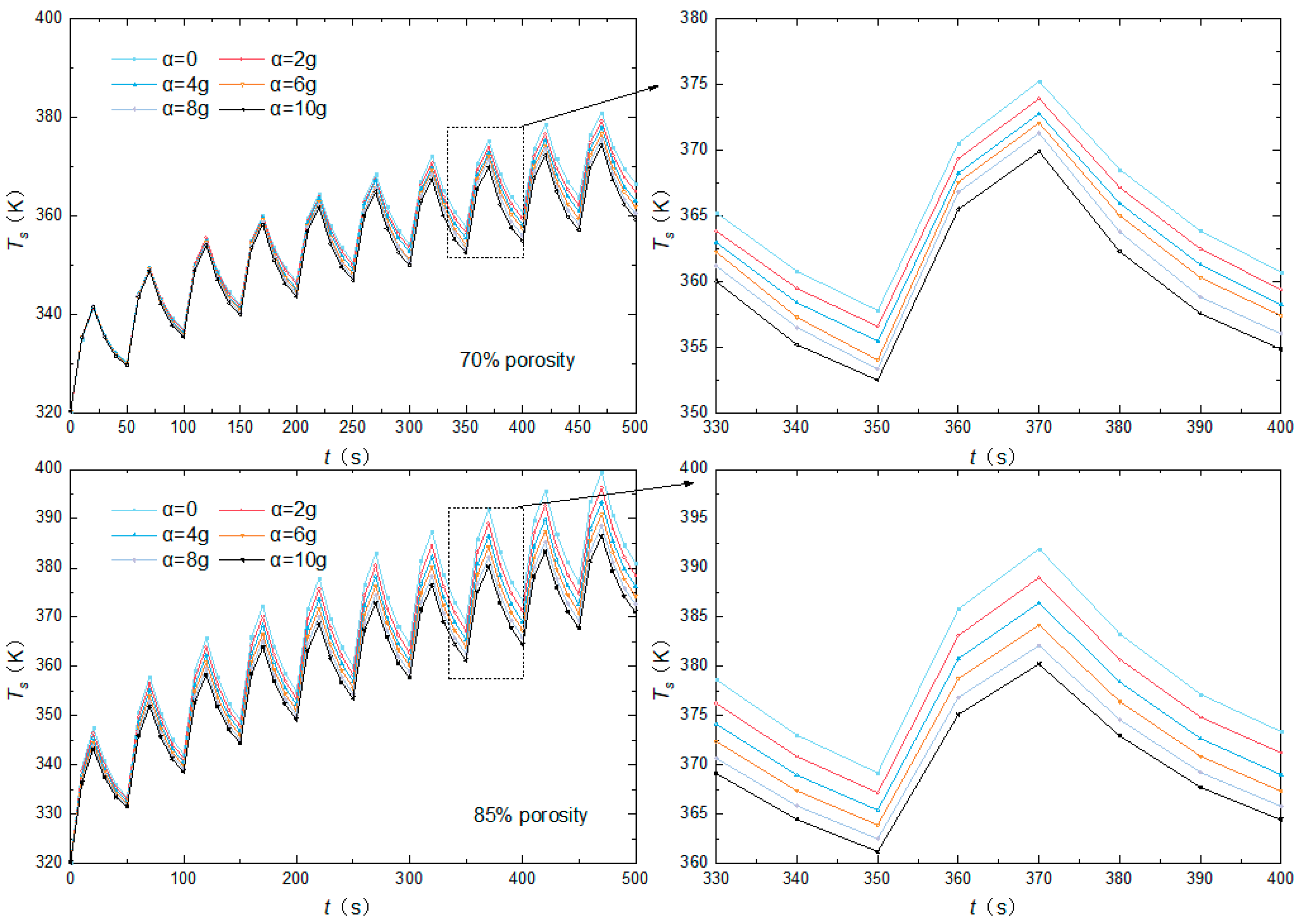

3.2. Influence of Acceleration Magnitude on Thermal Performance

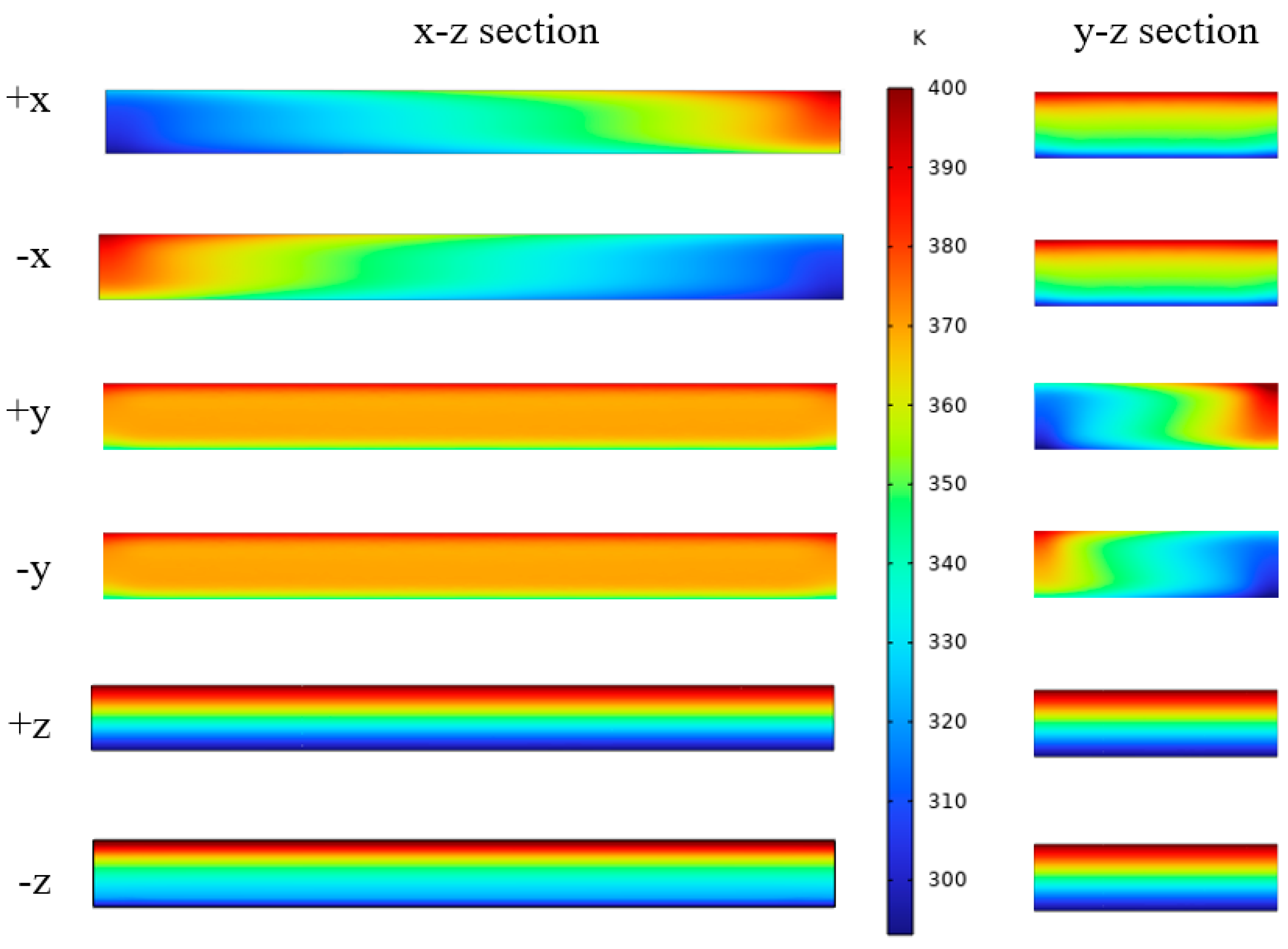

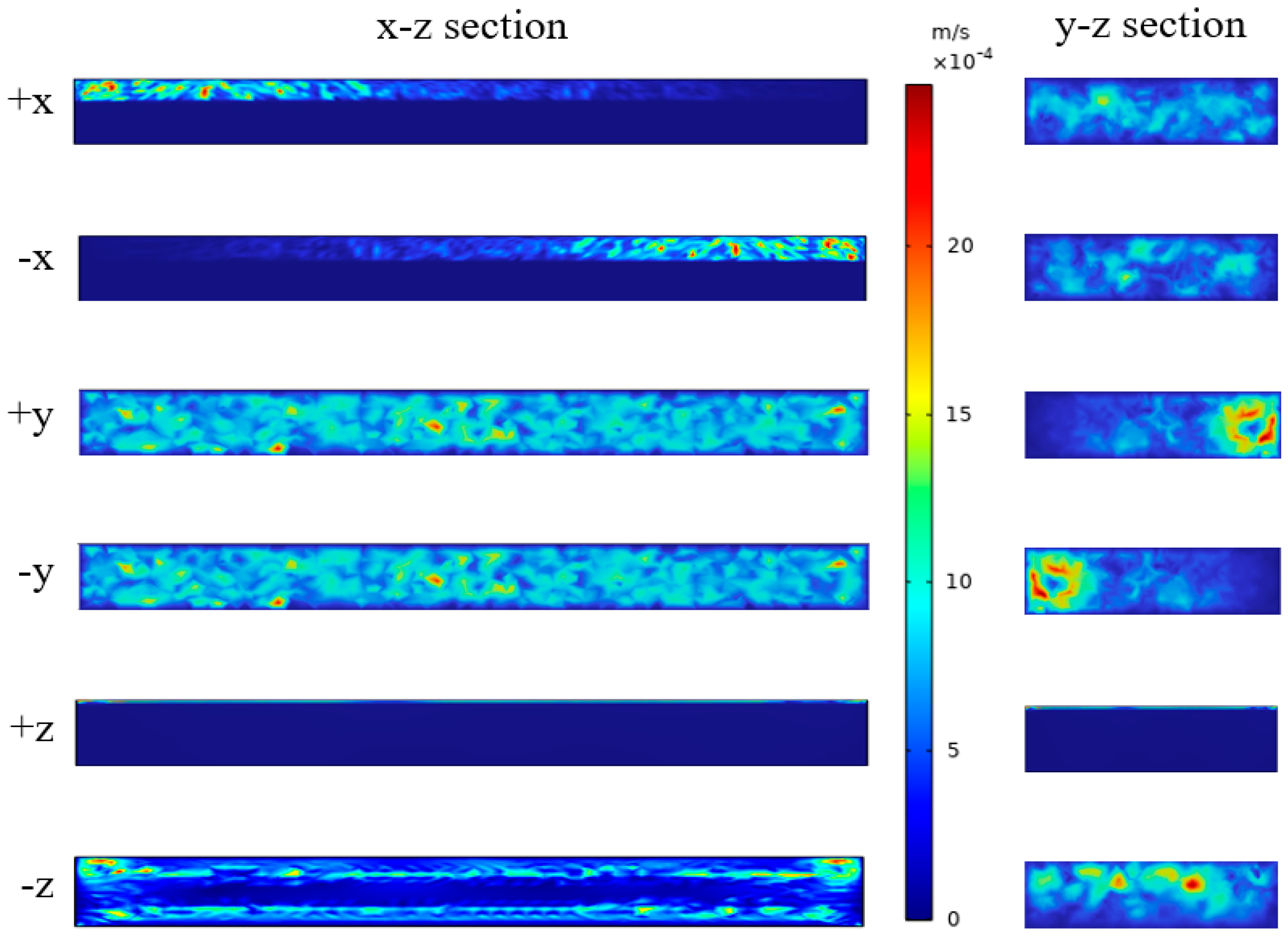

3.3. Influence of Acceleration Direction on Thermal Performance

4. Conclusions

- (1)

- For porous medium morphological structures, layered structures exhibit smaller tortuosity and higher thermal conductivity.

- (2)

- Changes in porosity lead to variations in the equivalent thermal conductivity representing heat exchange capacity and permeability characterizing flow capacity. For layered porous media, porosity primarily alters the longitudinal equivalent thermal conductivity and permeability.

- (3)

- Increasing acceleration magnifies the volume force term in the momentum equation, intensifying the natural convection of the phase-change material.

- (4)

- Higher porosity results in more significant changes in the temperature and phase fields with varying acceleration.

- (5)

- The porous medium structure, impeding natural convection through the framework, breaks down vortices induced by natural convection into smaller vortices, effectively suppressing temperature non-uniformity. This suppression effect improves with increasing gravity.

- (6)

- Heat dissipation is most effective when the acceleration direction aligns with the heat flow direction, is least effective when they oppose each other, and falls between the two in perpendicular alignment.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Parameter name | ||

| Specific heat capacity | J/kg·K | |

| F | Coefficient of inertia resistance | |

| Convective heat transfer coefficient | W/m2·K | |

| Thermal conductivity | W/m·K | |

| K | Permeability | md |

| L | Latent heat of phase change | KJ/kg |

| P | Pressure | Pa |

| Heat flow | W/m2 | |

| Q | Permeation flow rate per unit time | m3/s |

| s | Phase interface location | m |

| Body-force | N/m3 | |

| Temperature | K | |

| X-direction speed | m/s | |

| v | Velocity | m/s |

| Y-direction speed | m/s | |

| Z-direction speed | m/s | |

| ds | Interface distance | mm |

| Greek alphabet | ||

| Acceleration | m/s2 | |

| γ | Linear expansion coefficient | |

| δ | Thickness | m |

| Porosity or liquid phase ratio | ||

| Proportion | ||

| Thermal conductivity | W/m·K | |

| Sport viscosity | Pa-s | |

| Density | Kg/m3 | |

| Time | s | |

| ψ | heat quantity | W |

| Subscript | ||

| 0 | Initial state | |

| c | Cold fluids | |

| eff | equivalent | |

| g | Metal porous medium | |

| l | Liquid phase | |

| m | Phase-change state | |

| Directional vector at the phase interface | ||

| p | PCM | |

| Solid phase | ||

| w | External thermal excitation | |

| Abbreviations | ||

| PCEU-LPM | Phase-Change Heat Exchanger Unit in Layered Porous Media | |

| SEM | Scanning Electron Micrograph | |

| PCM | Phase-change materials |

References

- Butt, N.J.; Wolff, M.; Roberts, R.A.; Thomas, S. A Cryogenic Palletized High Energy Pulse System. In Proceedings of the 2018 International Energy Conversion Engineering Conference, Cincinnati, OH, USA, 9 July 2018; American Institute of Aeronautics and Astronautics: Cincinnati, Ohio, 2018. [Google Scholar]

- Yang, X.; Lu, Z.; Bai, Q.; Zhang, Q.; Jin, L.; Yan, J. Thermal Performance of a Shell-and-Tube Latent Heat Thermal Energy Storage Unit: Role of Annular Fins. Appl. Energy 2017, 202, 558–570. [Google Scholar] [CrossRef]

- Lachheb, M.; Adili, A.; Albouchi, F.; Mzali, F.; Ben Nasrallah, S. Carbon Fiber. Appl. Therm. Eng. 2016, 102, 922–931. [Google Scholar] [CrossRef]

- Alimohammadi, M.; Aghli, Y.; Alavi, E.S.; Sardarabadi, M.; Passandideh-Fard, M. Experimental Investigation of the Effects of Using Nano/Phase Change Materials (NPCM) as Coolant of Electronic Chipsets, under Free and Forced Convection. Appl. Therm. Eng. 2017, 111, 271–279. [Google Scholar] [CrossRef]

- Poplaski, L.M.; Benn, S.P.; Faghri, A. Thermal Performance of Heat Pipes Using Nanofluids. Int. J. Heat Mass Transf. 2017, 107, 358–371. [Google Scholar] [CrossRef]

- Pizzolato, A.; Sharma, A.; Maute, K.; Sciacovelli, A.; Verda, V. Topology Optimization for Heat Transfer Enhancement in Latent Heat Thermal Energy Storage. Int. J. Heat Mass Transf. 2017, 113, 875–888. [Google Scholar] [CrossRef]

- Chen, J.; Yang, D.; Jiang, J.; Ma, A.; Song, D. Research Progress of Phase Change Materials (PCMs) Embedded with Metal Foam (a Review). Procedia Mater. Sci. 2014, 4, 389–394. [Google Scholar] [CrossRef]

- Beckermann, C.; Viskanta, R. Natural Convection Solid/Liquid Phase Change in Porous Media. Int. J. Heat Mass Transf. 1988, 31, 35–46. [Google Scholar] [CrossRef]

- Yun, H.; Fangfang, M.A.; Guo, X.; Chen, B. Mesoscopic Pore-Scale Simulations of Natural Convection of Porous Media in Closed Square Cavity by Using LBM. Procedia Eng. 2017, 205, 4009–4016. [Google Scholar] [CrossRef]

- Mesalhy, O.; Lafdi, K.; Elgafy, A.; Bowman, K. Numerical Study for Enhancing the Thermal Conductivity of Phase Change Material (PCM) Storage Using High Thermal Conductivity Porous Matrix. Energy Convers. Manag. 2005, 46, 847–867. [Google Scholar] [CrossRef]

- Li, W.Q.; Qu, Z.G.; He, Y.L.; Tao, W.Q. Experimental and Numerical Studies on Melting Phase Change Heat Transfer in Open-Cell Metallic Foams Filled with Paraffin. Appl. Therm. Eng. 2012, 37, 1–9. [Google Scholar] [CrossRef]

- Xu, H.; Wang, Y.; Han, X. Analytical Considerations of Thermal Storage and Interface Evolution of a PCM with/without Porous Media. HFF 2019, 30, 373–400. [Google Scholar] [CrossRef]

- Yao, Y.; Wu, H. Numerical Simulation of Melting in Metal Foam/Paraffin Composite Phase Change Material Using a Physically More Reasonable Macroscale Model. In Proceedings of the ASME 2019 Heat Transfer Summer Conference, American Society of Mechanical Engineers, Bellevue, WA, USA, 14 July 2019; p. V001T02A007. [Google Scholar]

- Gómez-Martín, A.; Orihuela, M.P.; Becerra, J.A.; Martínez-Fernández, J.; Ramírez-Rico, J. Permeability and Mechanical Integrity of Porous Biomorphic SiC Ceramics for Application as Hot-Gas Filters. Mater. Des. 2016, 107, 450–460. [Google Scholar] [CrossRef]

- Scotti, K.L.; Dunand, D.C. Freeze Casting—A Review of Processing, Microstructure and Properties via the Open Data Repository, FreezeCasting.Net. Prog. Mater. Sci. 2018, 94, 243–305. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, R.; Zhang, J.; Zhang, J. The Impact of In-Flight Acceleration Environments on the Performance of a Phase-Change Heat Exchanger Unit with Layered Porous Media. Aerospace 2024, 11, 335. https://doi.org/10.3390/aerospace11050335

Zhang R, Zhang J, Zhang J. The Impact of In-Flight Acceleration Environments on the Performance of a Phase-Change Heat Exchanger Unit with Layered Porous Media. Aerospace. 2024; 11(5):335. https://doi.org/10.3390/aerospace11050335

Chicago/Turabian StyleZhang, Ruoji, Jingyang Zhang, and Jingzhou Zhang. 2024. "The Impact of In-Flight Acceleration Environments on the Performance of a Phase-Change Heat Exchanger Unit with Layered Porous Media" Aerospace 11, no. 5: 335. https://doi.org/10.3390/aerospace11050335

APA StyleZhang, R., Zhang, J., & Zhang, J. (2024). The Impact of In-Flight Acceleration Environments on the Performance of a Phase-Change Heat Exchanger Unit with Layered Porous Media. Aerospace, 11(5), 335. https://doi.org/10.3390/aerospace11050335