1. Introduction

Civilian aircraft might experience noise and vibrations perceptible to the cockpit and cabin crew during flights, such as fluid-induced vibrations of the front landing gear hatch [

1,

2,

3] or the failure of air pressure seals [

4,

5]. These vibrations not only affect the overall comfort of the flight but also create psychological pressure on both the pilot and passengers. In severe cases, they can pose safety risks such as structural fatigue damage, seal failure, and even casualties [

6,

7,

8]. When such vibrations occur under fluid-induced conditions, it is crucial for the ground crew to identify and rectify the source of the fault promptly. This is necessary to ensure flight safety, enhance aircraft comfort, and alleviate any psychological concerns for the pilot.

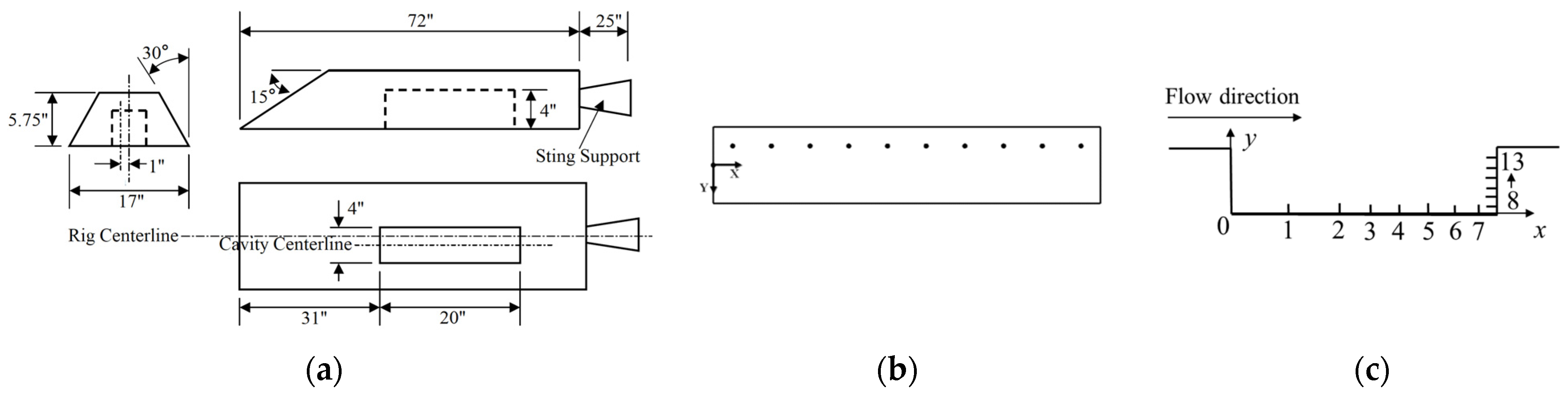

One key factor contributing to fluid-induced vibrations is the improper closing of the front landing gear hatch during retraction, which sometimes happens accidentally. The resulting fluctuating loads are unexpected and different from the commonly experienced unsteady aerodynamic loads such as those caused by a gust, rudder control, etc. The unwanted hatch opening leads to airflow flowing in and out through the gap between the hatch and the landing gear compartment, as well as between the hatches. These disturbances interact with various components within the main landing gear compartment, including the landing gear itself and the tires, resulting in complex flow patterns. Therefore, a detailed model of the front landing gear compartment, including the cavity, hatch, landing gear, and other relevant components, is needed to accurately study the load characteristics and mechanisms. The following sections will provide an overview of the research on the cavity, cavity + hatch, cavity + landing gear, and other related aspects.

Many research studies have been conducted on cavity noise, and over the past decades, numerous review papers have summarized and evaluated the progress in this field. For instance, S.J. Lawson [

9] et al. reviewed the numerical simulation methods for cavity flow under high-speed incoming flow conditions, highlighting the promising application prospects of DES (Detached Eddy Simulation) and LES (Large Eddy Simulation) methods in the aerospace domain. This review provided valuable insights into the computational aeroacoustics problem raised by Christopher K.W. Tam [

10]. Furthermore, the influence of key parameters such as shape and structural vibration on cavity-induced noise in compressible flow was elucidated, and the research status and limitations of cavity noise control technology were summarized. The review papers also addressed the challenges and future trends in dealing with cavity-induced noise. Mojtaba Sadeghian et al. [

11], for instance, reviewed the feasibility of aircraft noise reduction technology in the industrial sector and discussed the subsequent trends and challenges in this area. Given the extensive coverage and comprehensive analysis provided by these review papers, this article refrains from duplicating the research progress concerning cavities.

Regarding the landing gear compartment (cavity) + hatch model, Xu Jinjin et al. [

12] utilized the finite element method to analyze the impact of the airtightness of the landing gear hatch structure on the transmission stiffness. They provided a formula to determine the axial preload of the tie rod that satisfies the required airtightness. Zhang Haitao et al. [

13] conducted load measurements on a landing gear hatch of a specific aircraft type and developed a strain-based method to measure the hatch load under flight conditions. This served as a basis for subsequent hatch response analysis and design optimization of the landing gear hatch and its retractable mechanism. Tao Liuyuan et al. [

14] employed the finite element method to analyze the causes of cracks in the landing gear cabin’s skin. They identified that the static load resulting from aircraft maneuvering overload, along with the dynamic load generated by vibration, particularly in the triangle area of the landing gear cabin, was the main factor contributing to crack formation. Mou Yongfei et al. [

4] simulated two models of the high-fidelity nose landing gear of a civilian aircraft, one with hatches and one without hatches. They investigated the flow field and far-field radiation noise characteristics, comparing and analyzing the interference-blocking effect of the nose landing gear hatch on the flow field and the noise of the landing gear. They also examined the influence of the hatch on far-field radiation noise. Their findings highlighted that the flow field in the nose gear cabin + landing gear structure differed from that of a pure cavity flow field, with stronger pressure waves. The landing gear hatch exhibited a noise-shielding effect on the side, and the area between the hatches experienced sound wave interference. Hu Chenying et al. [

15] utilized an acoustic–solid coupling analysis method to study the vibration–acoustic radiation characteristics of a typical hatch structure. They emphasized that resonance noise is significantly amplified when the vibration modal frequency of the hatch structure coincides with the acoustic modal frequency of the cabin. They proposed the addition of a constrained damping layer to the hatch as a means of noise reduction. Li Xiaodong et al. [

16] conducted numerical simulations to study the influence of a moving hatch on the unsteady flow field of the buried bomb bay (cavity) and the noise characteristics in the cabin. They found that the noise distribution of the moving buried bomb bay hatch was similar to that of a clean cavity, but the second-order Rossiter modal noise value was higher than that of a clean cavity. Liu Yu et al. [

17] analyzed the aerodynamic noise characteristics of the cavity with and without the hatch using numerical simulation methods. They observed that adding the hatch significantly increased the SPL (sound pressure level) inside the cavity, particularly for the second-order dominant mode, which increased by up to 15 dB. S. Redonnet [

18] reviewed the work conducted by ONERA over the past decade, focusing on their use of the hybrid method to calculate overall noise. They also introduced several reliable aeroacoustics calculation techniques developed by ONERA during that period. Garret C. Y. Lam et al. [

19] studied the aerodynamic noise characteristics of the NACA0018 airfoil with a cavity using numerical simulations. They noted that opening the cavity in the airfoil resulted in a change in the lift-to-drag ratio from 0 to 5.3 at a 0° angle of attack, reducing the aerodynamic noise by 1.2 to 2.6 decibels.

For the landing gear compartment (cavity) + landing gear model, Li Yongbin et al. [

20] conducted a study using numerical simulation methods to optimize and topologically optimize the main landing gear compartment structure. Their objective was to distribute materials effectively and reduce the structural weight. Guo [

21] proposed a semi-empirical method to predict landing gear noise based on Fink’s work. This method enables the separate prediction of low-frequency, intermediate-frequency, and high-frequency noise. It is utilized by the Aircraft Noise Prediction Project (ANOPP) for landing gear noise prediction. Yi Jiang et al. [

22] presented a comprehensive prediction method for landing gear noise in traditional passenger aircraft, incorporating the radiated noise from various components, including the landing gear compartment. They validated their method using Airbus A320, Boeing 737, and 777 aircraft models and achieved good agreement with the test results. Philippe R. Spalart et al. [

23] calculated the aerodynamic noise of the landing gear compartment + landing gear model using the DES + FW-H (Detached Eddy Simulation with Ffowcs Williams and Hawkings) method. They emphasized the effectiveness of the DES and FW-H methods in predicting the surface noise variations and noted that the noise should be proportional to the seventh to eighth power of the incoming flow. Gareth J. Bennett et al. [

24] investigated the aerodynamic noise of a full-scale nose/nose gear compartment/landing gear model through wind tunnel tests. They identified multiple peak frequencies within the 400 Hz range and highlighted the proportional relationship between the noise and the seventh power of the incoming flow velocity. Hu Ning et al. [

25] utilized the numerical simulation method DDES (Delayed Detached Eddy Simulation) to examine the influence of wind tunnel blockage on the measurement of landing gear aerodynamic noise. They concluded that the aerodynamic noise characteristics of the model were closely related to the average flow characteristics under different degrees of blockage. Tulio R. Ricciardi et al. [

26] employed the DES method to simulate the noise of the LAGOON landing gear. They successfully reproduced the noise generation process and utilized the POD (Proper Orthogonal Decomposition) method to identify the causes of peak noise.

The research mentioned above provides valuable technical references for the study of vibration load characteristics induced by fluid during hatch retraction, and it establishes a foundation for mechanistic research. The complex geometric shape of landing gear and its interaction with aerodynamics present challenges for theoretical and experimental studies on landing gear noise. Furthermore, fluid-induced vibrations resulting from hatch retraction involve complex interactions between the forward landing gear compartment, hatch, and landing gear, leading to intricate flow behaviors. Therefore, further research is needed to understand the characteristics and mechanisms of vibration excitation. Previous research has mainly focused on noise and vibration analysis of partial models; our model includes all components of the forward landing gear compartment, resulting in more complex flow characteristics and flow interactions between components. The NLAS method used in this paper demonstrates significantly higher computational efficiency when compared to URANS and DES + FW-H simulation methods. Through numerical simulation of the unsteady flow field after hatch retraction, we analyze pressure–time history data extracted from each component, study load characteristics, and discuss potential load mechanisms.

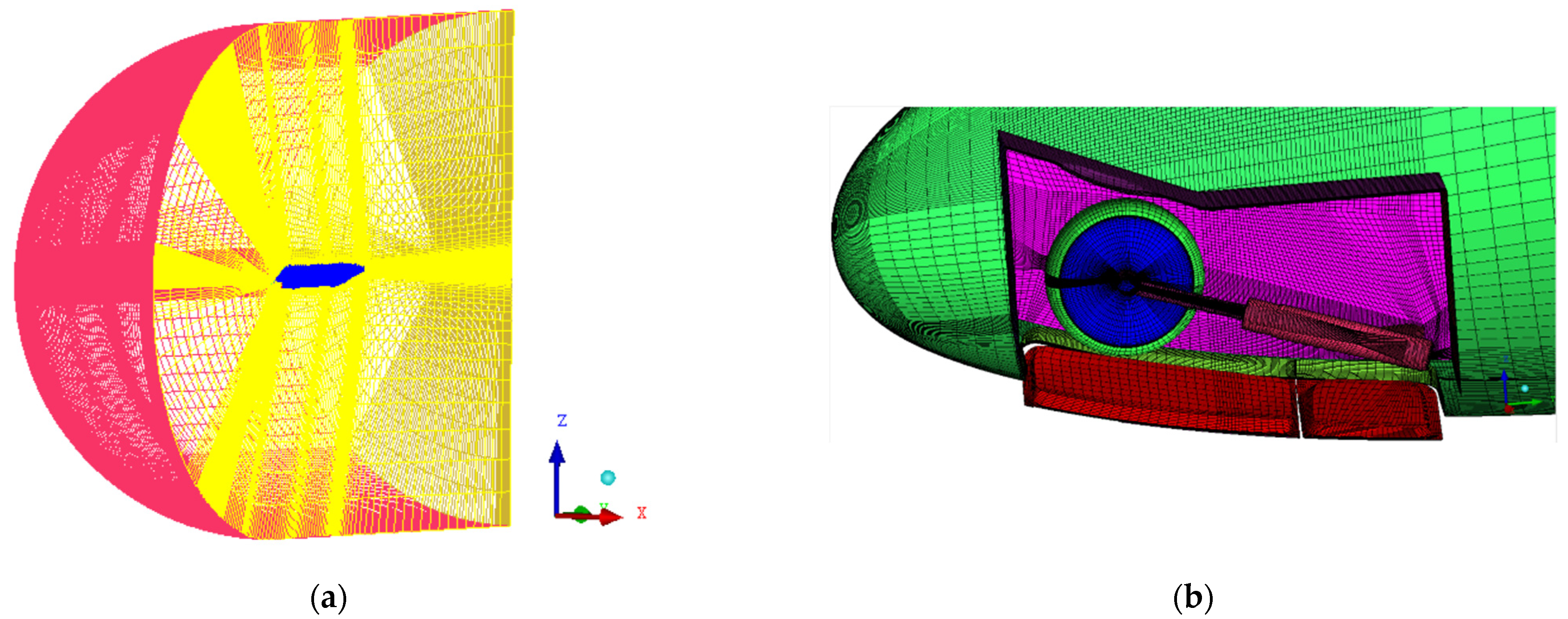

3. Results and Discussion

Since fluid-induced vibration occurs during the aircraft’s cruising state, it is important to focus on the front landing gear compartments as the source of the fluid-induced vibration load. As the front landing gear compartments are located upstream of the wing, it is necessary to optimize the computational efficiency by reducing the computational workload. This can be achieved by excluding components such as the wing, vertical tail, horizontal tail, and engine nacelle from the calculation domain. Thus, only the fuselage is retained, as well as the landing gear compartments. Then, multiple structured grids are generated, as depicted in

Figure 4.

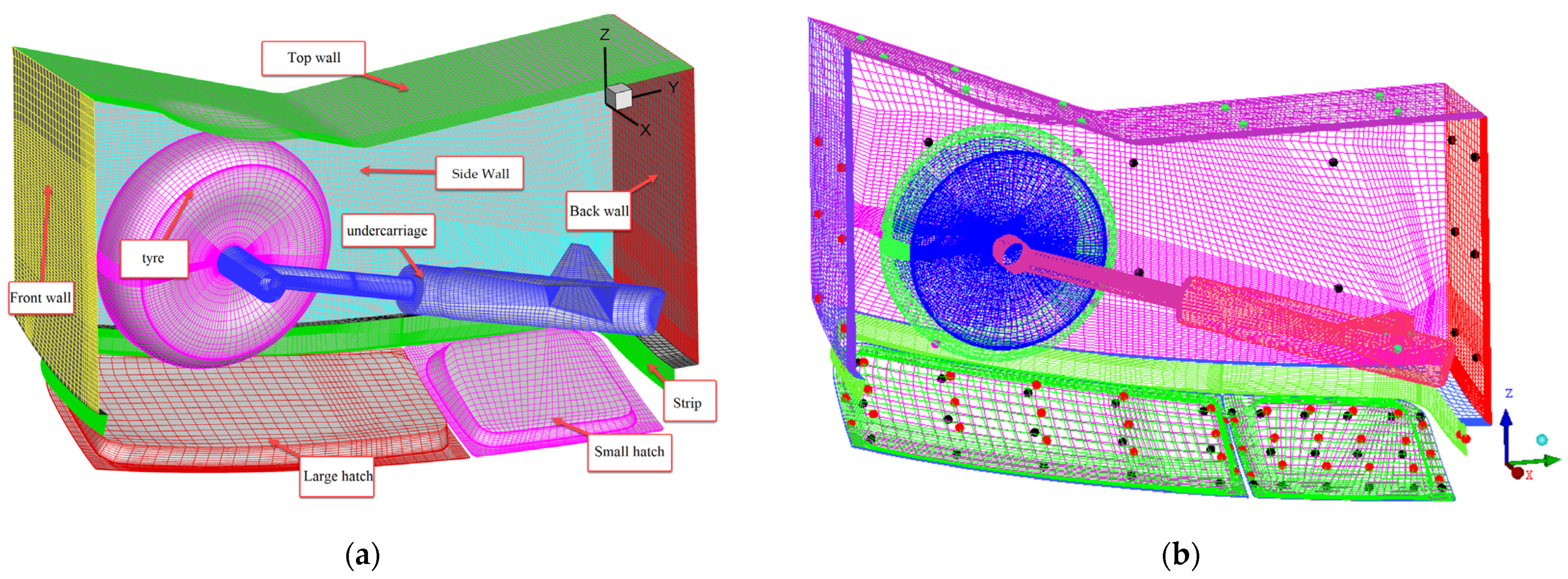

For various components (as shown in

Figure 5a), specific monitoring points were established (

Figure 5b). Due to the extensive number of monitoring points and space limitations, this paper focuses on presenting the number of monitoring points on the inner and outer walls of the large and small hatches, as depicted in

Figure 6.

To address the issue of unsteady aerodynamic loads causing vibration, the hatch gap is characterized by the hatch opening angle, and its impact on the load is investigated. Specifically, the hatch opening angles considered in this study are 0°, 5°, 10°, 15°, and 20°. The load time history data for each monitoring point is computed by solving the NLAS equation.

In the structural response analysis, the RMS of the fluid-induced vibration load “Prms” is used to characterize the statistical average behavior of the fluctuating load. The Prms values of the monitoring points on the right hatch are calculated under different opening angle conditions. From

Figure 7, it is seen that, as the hatch opening angle increases from 0° to 15°, the RMS of cumulative pressure loads on both the small and large hatches under different opening angles continuously increases. However, as the hatch opening angle increases from 15° to 20°, the RMS of cumulative pressure loads decreases. Hence, the peak value of the fluctuating load occurs at a hatch opening angle of 15°, whereas excessively small or large opening angles do not result in significant fluid-induced vibration loads.

The Prms of fluid loads is influenced and determined by variation of aerodynamic geometry. As shown in

Figure 5 and

Figure 6, a sharp variation of hatch thickness can be seen at their ends in both the body axis direction and spanwise direction of both hatches, respectively. Also, the gaps between these hatches, and the gaps between hatches and strip, can be respectively discerned. To examine the variation of RMS of pressure loads with the hatch opening angle, these monitoring points in

Figure 6 are categorized into three groups for both the inner and outer wall (namely, the “Streamwise_inner wall_*”, and “Streamwise_outer wall_*”, where “*” can be 1, 2, 3.) in a streamwise direction, respectively. In the names of the six figures from

Figure 8a–f, the number “1” indicates that these points are close to the symmetry plane of the airplane, while the number “3” means that these points are near to the sidewall of the landing gear compartment. The monitoring points in each categorized group are presented in

Table 4.

In

Figure 8, the horizontal axis denoted by “Y(m)” is the coordinate in the airplane body axis. For these two hatches, the y coordinate ranges from 0.953 m to 2.698 m. The large hatch ends at y = 2.094 m; the small hatch begins at y = 2.112 m. In the body axis direction, the distance from the minimum large hatch coordinate to the strip, and from the maximum small hatch coordinate to the strip, are 0.0198 m and 0.0193 m, respectively.

The Prms result plotted in

Figure 7 gives the RMS of cumulative pressure loads. To examine the detailed RMS distribution of pressure loads in streamwise direction, the pressure load RMS of six groups of monitoring points are shown in

Figure 8a to

Figure 8f, respectively. For the inner wall, as shown in

Figure 8a–c, with the thickness increase at the leading edge of the large hatch (at about y = 1.05 m), the Prms increases obviously; then, the Prms values decrease for each group at each hatch opening angle. In the geometrically central zone of the inner wall of the small hatch, the decrease in Prms values for each group at different hatch opening angles can be discerned.

Besides similar trends for these three group points, differences can also be found. At the streamwise location near the trailing edge of the large hatch, the differences are as follows: The Prms variations shown a sharp increase–decrease variation for the monitoring points near the symmetry plane, as shown in

Figure 8a. This is due to the gap attributed to the hatch opening, where the flow in the gap influences the flow behavior obviously. In

Figure 8b, the Prms variation is relatively small, and this is due to the fact that this group of monitoring points reside nearly on the geometrical center line in a spanwise direction of the small hatch; thus, the influence of gap flow around the symmetry plane and cavity sidewall is relatively small. In

Figure 8c, as the hatch opening angle increases, the gap between the hatch and strip decreases; thus, the Prms value shows decreased variation. Then, with the sharp increase of thickness at the leading edge of the small hatch, the Prms value increases.

At the streamwise location near the trailing edge of the small hatch, the differences are as below: In

Figure 8a, Prms decreases at the trailing edge. And with the increase in hatch opening angle, the Prms decreases more sharply. This is due to the fact that the air flows out of the cavity at this location; thus, the flow becomes less unsteady, inducing weaker pressure loads. The same reason is applicable to the Prms decrease with the increase of the hatch opening angle in

Figure 8b. In

Figure 8b, when the hatch opening angle is small (0°, 5°), the Prms variation is small, for little flow separation occurs on the inner wall of the small hatch. In

Figure 8c, the Prms increases with the increase of the hatch opening angle in the angle range [0°, 15°], and this is due to the strength increase of vortices in the separation zone. When the hatch opening angle increases to 20°, the strength of vortices decreases, resulting in a decrease in Prms.

For the outer wall, as shown in

Figure 8d–f, the Prms increases obviously at the leading edge of the large hatch (in the y range [0.95 m, 1.30 m]); then, the Prms values decrease for each group at each hatch opening angle. Then, at the streamwise zone between the trailing edge of the large hatch and the leading edge of the small hatch, the Prms exhibit increase–decrease variation. In the geometrically central zone of the outer wall of the small hatch, the decrease in Prms values for each group at different hatch opening angles can be seen. The differences between these three group of RMS results occur at the trailing edge of the small hatch, as depicted below: for the monitoring points near the symmetry plane (

Figure 8d), the Prms decreases for a hatch opening angle [0°, 15°], while it increases at the hatch opening angle 20°. This increase is due to much more air outflow from the landing gear cavity, causing severe flow separation at this outer wall zone. As monitoring points move to the centerline of the small hatch outer wall in a spanwise direction (

Figure 8e), the air outflow from the landing gear cavity causes evident flow separation in the hatch opening angle range [10°, 20°], thus resulting in a sharp increase in Prms. For the monitoring points near the sidewall of the landing gear cavity, evident flow separation occurs at a hatch opening angle range [0°, 20°]; thus, the Prms increases for all angles.

In these six figures, an increase in the RMS of cumulative pressure loads can be observed with a hatch opening angle from 0° to 15°. As the hatch opening angle increases from 15° to 20°, the RMS of cumulative pressure loads from the inner wall does not vary obviously, while the RMS of cumulative pressure loads from the outer wall evidently decreases, explaining the variation in Prms in

Figure 7 within the hatch opening angle range [15°, 20°].

From

Figure 8a–c, it can be seen that the Prms of the “Streamwise_Inner_Wall_1” curve exhibit locally the largest values at the inner wall leading edge of the large hatch; hence, monitoring points 4 and 7 (as shown in

Figure 6) are selected to examine the amplitude–frequency distribution characteristics of fluid-induced vibration loads using PSD (power spectral density). Meanwhile, for the Prms results of monitoring points on the small hatch surface (from

Figure 8a,d), the No. 22 and 55 points are locally the largest ones compared to other point results; hence, they are selected to depict the amplitude–frequency distribution characteristics of fluid-induced vibration loads at the leading edge of the small hatch.

Figure 9a plots the No. 4 and No. 7 PSD results, and

Figure 9b plots the No. 22 and No. 55 PSD results. For convenience of comparison, the PSD range of these two figures is set the same.

From

Figure 9a, it can be seen that the PSD results exhibit broadband characteristics, whose energy is primarily concentrated below 150 Hz. In the frequency range [0 Hz, 75 Hz], the pulsating energy of the No. 4 point is larger than that of No. 7 point. This is due to the fact that sharp aerodynamic geometry variation can cause accelerated flow with separation, inducing pulsating loads with large amplitude. At the No. 7 location, the inner wall surface of the large hatch is smooth; thus, separated flow generates relatively smaller-amplitude pulsating loads. From

Figure 9b, it is observed that the fluid-induced vibration loads of the No. 55 point distribute a large amount of energy at about 75 Hz, which is the largest value in all these four monitoring point PSD results. This is caused by the flow separation at the outer surface leading edge of the small hatch, which is depicted by streamlines in the following discussion. The PSD results of fluid-induced vibration loads of the No. 22 point show relatively evenly distributed energy in the frequency range [0 Hz, 300 Hz]. This is caused by the complex flow interference between different parts as discussed below.

To examine the reason for the variation in RMS of cumulative pressure loads with hatch opening angles, the iso-surfaces of Q = 100,000 based on Q-criterion [

40] are extracted and rendered by vorticity magnitude. To have a clear examination, only the right parts of the iso-surfaces inside the cavity are plotted, as shown in

Figure 10. In

Figure 10a, it is seen that flow separation is relatively small from the inner surface of both large and small hatches. Small vortices are generated from both the symmetry gap and the gap between the hatches and strip. With the increase in the hatch opening angle, flow separations from the inner wall obviously become more intensive, e.g., at a hatch opening angle 5° (

Figure 10b), flow separation can be seen at the leading edge of the large hatch and small hatch, and the trailing edge of the small hatch, respectively. The separated flow attaches to the surface of the landing gear tire. Meanwhile, the vortices generated from both the symmetry gap and the gap between the hatches and strip also become stronger. In

Figure 10c, the separation zones enlarge themselves with the increase in the hatch opening angle, and the attached zone on the surface of the landing gear tire also becomes larger. The intensity of vortices from the symmetry gap and the gap between the hatches and strip continuously increases. In

Figure 10d, the intensity of separation and vortices reaches their maxima, resulting in the peak value of RMS of cumulative pressure loads. Then, as the hatch opening angle increases to 20° (

Figure 10e), the size of the vortices from the symmetry gap and the gap between the hatches and strip decreases, indicating a descent in intensity, which induces a drop in RMS of cumulative pressure loads.

To further analyze the origin of the fluctuating loads, both spatial streamlines in the landing gear compartment and streamlines on different cross-sections are presented, as shown in

Figure 11,

Figure 12 and

Figure 13, respectively. In these figures, the legend “P” is the static pressure in “Pa”, “V” is the velocity component along the

y axis in “m/s”, and “W” denotes the velocity component along the

z axis in “m/s”.

Figure 11 shows the spatial streamlines in the landing gear compartment to give a global perspective of the flow characteristics. In

Figure 11a, air flows into the landing gear compartment from the gap between the strip and the leading edge of the large hatch. The inflow air travels downstream near the inner wall of both the large and small hatches, then flows out from the gaps, which are the gaps between the small hatches and strips, the gap between small hatches, etc., respectively. The downstream-flowing air shears the air in the landing gear compartment, forming the principal vortex in the landing gear compartment. The principal vortex reaches the landing gear tires. In

Figure 11b, the downstream-flowing air travels out from the landing gear compartment at a location just upstream of the trailing edge of the large hatch, from the gaps between the large hatches, and the gaps between the large hatch and the sidewall. In

Figure 11c, the spanwise flow is depicted at the gap between the large hatch and the small hatch on the right side. In the zone upstream of the sharp increase in hatch thickness in the small hatch, the air flows toward the sidewall when the height is below the thickness; while, when the height exceeds the inner wall of the small hatch, the air flows to the symmetrical plane. In

Figure 11d, spatial streamlines at the gap between the large hatch and the small hatch on the left side are plotted, and similar flow characteristics can be found compared to that of

Figure 11c at the gap between the large and small hatches. The streamlines differ from those in

Figure 11c due to the sidewall being half empty and the air being able to flow into the cavity on the left of the sidewall with a very low-velocity magnitude compared to the downstream flow in

Figure 11b. The spatial streamlines in these four figures exhibit complex flow interference between different parts, as depicted by circulating flow, spanwise flow, etc.

Figure 12 illustrates the streamlines on different X cross-sections to examine the details of the flow characteristics.

Figure 12a shows the streamlines on the symmetrical plane at X = 0.00 m. The downward-flowing air is seen to shear the air in the compartment and flows out of it from gaps. The shear effect establishes the principal vortex in the compartment, and flow with characteristics comparable to the cavity is formed. Due to the presence of tires, as shown in

Figure 12b, a vortex is formed above the undercarriage. In

Figure 12b, the hatches are cut, and the airflow accelerates into the compartment at the gap between the strip and the leading edge of the large hatch. Air also flows into the compartment from the gap between the large and small hatches. The incoming air then flows out of the compartment from the gap between the strip and the trailing edge of the small hatch. These two hatches act similarly to flat plates arranged in a line. The tire acts similarly to a small length-to-diameter ratio circular cylinder. The vortex near the tire becomes larger. The flow characteristics of the streamlines in

Figure 12c are similar to that in

Figure 12b, with the vortex continuously expanding. In

Figure 12d, the vortex forms flow characteristics similar to that of a clean cavity. Meanwhile, the air flows into and out of the compartment.

Figure 13 shows the streamlines at different Y cross-sections in the landing gear compartment. In

Figure 13a, the flow enters the compartment at the mid-span of the large hatch, while going out of it spanwise from the gaps between the sidewall and the large hatch and the gap between large hatches. In

Figure 13b, it is found that the air leaves the compartment. The circular cylinder baffles the airflow, and asymmetrical flow is formed at this cross-section because air flows into the compartment from the portside cavity. The vortex beneath the circular cylinder is the wake vortex behind the tire. In

Figure 13c, the sidewall on the portside is present, and flow asymmetry becomes weaker. At the leading edge of the small hatches, air flows to the sidew all near the inner wall. The limit streamlines occur nearby the thick inner wall. By referring to the special streamlines in

Figure 11, it can be determined that the air above the limit streamlines goes to the compartment’s back wall, similar to that of clean cavity flow. In

Figure 13d, the flow streamlines are nearly symmetrical due to the wall confinement of the sidewall on the portside. The flow goes out of the compartment from all gaps. Meanwhile, the air flows upward, forming the cavity flow in the compartment.