Bamboo for the Future: From Traditional Use to Industry 5.0 Applications

Abstract

1. Introduction

2. Bamboo as a Cash Crop

2.1. Bamboo as a Sustainable Energy and Environmental Solution

2.2. Carbon Sequestration and Climate Change Mitigation

3. Nourishing and Healing: Bamboo’s Dual Role in Food and Pharmaceuticals

3.1. Edible Forms of Bamboo

3.2. Nutritional Status of Bamboo

3.3. Bamboo in Pharmaceuticals

4. Bamboo as a Source of Cosmetics

Bamboo in Fabrics and Bio-Composites

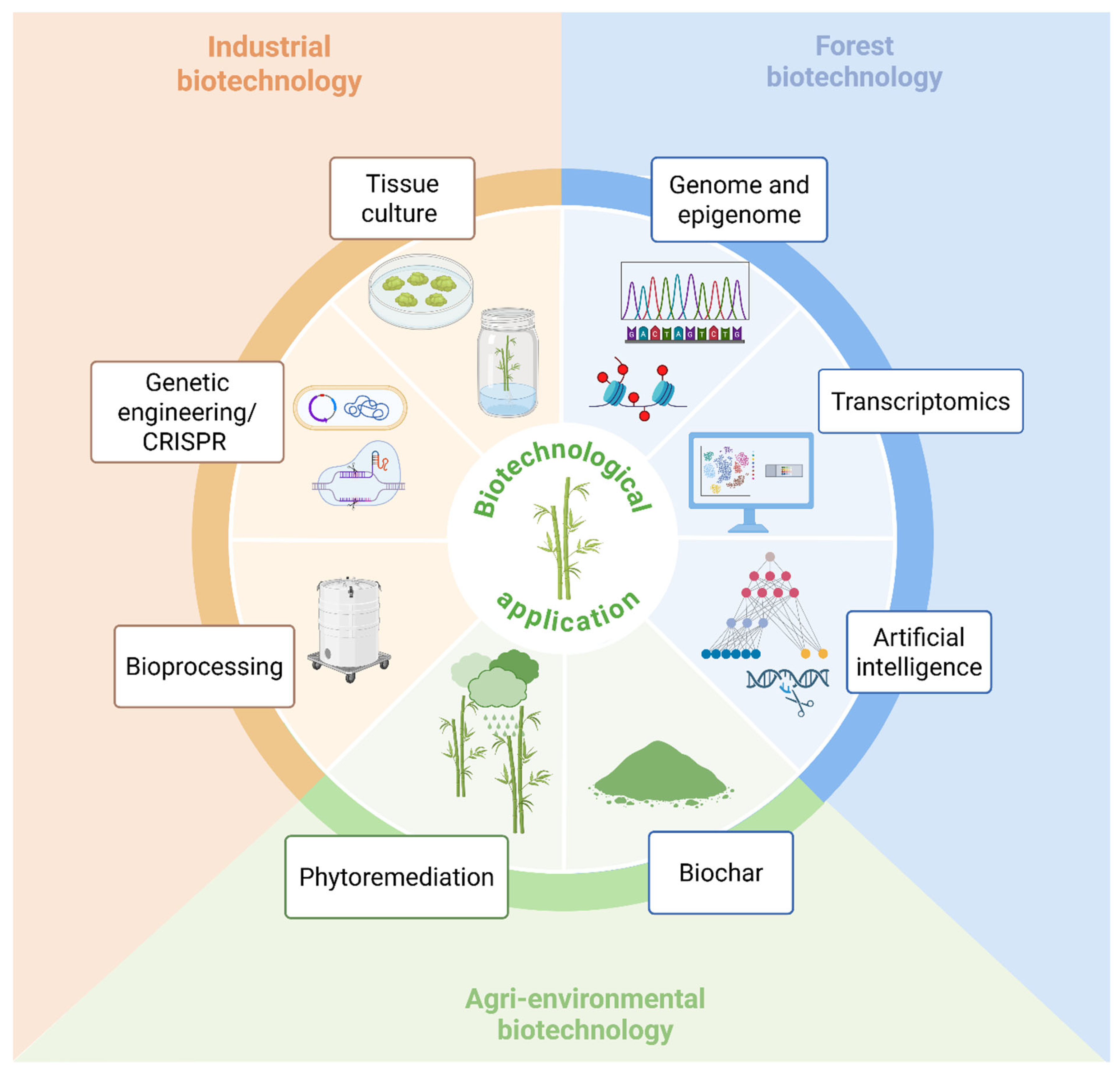

5. Application of Bamboo in Biotechnology

6. Bamboo as a Structural Material

6.1. Use of Full/Half Culm Bamboo in Construction

6.2. Use of Engineered Bamboo in Construction

7. Use of Bamboo in the Manufacturing Industry

8. Use of Bamboo in Sustainable Agriculture and Agroforestry

9. Biological, Agronomic, and Genetic Advances in Bamboo: Challenges, Stress Responses, and Prospects for Improvement

9.1. Physiological and Agronomic Characteristics of Bamboo Cultivation

9.2. Biotic Constraints: Pest and Diseases in Bamboo

9.3. Bamboo Genetics: Resistance Genes and Targets for Crop Improvement

9.4. Progress in Sustainable Cultivation, Conservation and Utilization

Technological, Logistical, and Economic Limitations

10. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, M.; Guo, L.; Ramakrishnan, M.; Fei, Z.; Vinod, K.K.; Ding, Y.; Jiao, C.; Gao, Z.; Zha, R.; Wang, C.; et al. Rapid growth of Moso bamboo (Phyllostachys edulis): Cellular roadmaps, transcriptome dynamics, and environmental factors. Plant Cell 2022, 34, 3577–3610. [Google Scholar] [CrossRef] [PubMed]

- Binfield, L.; Nasir, V.; Dai, C. Bamboo industrialization in the era of Industry 5.0: An exploration of key concepts, synergies and gaps. Environ. Dev. Sustain. 2024, 1–32. [Google Scholar] [CrossRef]

- Ramakrishnan, M.; Yrjälä, K.; Vinod, K.K.; Sharma, A.; Cho, J.; Satheesh, V.; Zhou, M. Genetics and genomics of moso bamboo (Phyllostachys edulis): Current status, future challenges, and biotechnological opportunities toward a sustainable bamboo industry. Food Energy Secur. 2020, 9, e229. [Google Scholar] [CrossRef]

- Emamverdian, A.; Ding, Y.; Ranaei, F.; Ahmad, Z. Application of bamboo plants in nine aspects. Sci. World J. 2020, 2020, 7284203. [Google Scholar] [CrossRef]

- Ahmad, Z.; Upadhyay, A.; Ding, Y.; Emamverdian, A.; Shahzad, A. Bamboo: Origin, habitat, distributions and global prospective. In Biotechnological Advances in Bamboo: The “Green Gold” on the Earth; Ahmad, Z., Ding, Y., Shahzad, A., Eds.; Springer: Singapore, 2021; pp. 1–31. [Google Scholar]

- Zhang, Y.; Wu, L.; Li, Y.; Yang, J.; Yang, H.; Zhao, Y.; Chen, G. Bamboo shoot and its food applications in last decade: An undervalued edible resource from forest to feed future people. Trends Food Sci. Technol. 2024, 146, 104399. [Google Scholar] [CrossRef]

- Banerjee, S.; Basak, M.; Dutta, S.; Chanda, C.; Dey, A.; Das, M. Ethnobamboology: Traditional Uses of Bamboos and Opportunities to Exploit Genomic Resources for Better Exploitation. In Biotechnological Advances in Bamboo: The “Green Gold” on the Earth; Ahmad, Z., Ding, Y., Shahzad, A., Eds.; Springer: Singapore, 2021; pp. 313–352. [Google Scholar]

- Chaudhary, U.; Malik, S.; Rana, V.; Joshi, G. Bamboo in the pulp, paper and allied industries. Adv. Bamboo Sci. 2024, 7, 100069. [Google Scholar] [CrossRef]

- Adier, M.F.V.; Sevilla, M.E.P.; Valerio, D.N.R.; Ongpeng, J.M.C. Bamboo as sustainable building materials: A systematic review of properties, treatment methods, and standards. Buildings 2023, 13, 2449. [Google Scholar] [CrossRef]

- Ly, P.; Pillot, D.; Lamballe, P.; de Neergaard, A. Evaluation of bamboo as an alternative cropping strategy in the northern central upland of Vietnam: Above-ground carbon fixing capacity, accumulation of soil organic carbon, and socio-economic aspects. Agric. Ecosyst. Environ. 2012, 149, 80–90. [Google Scholar] [CrossRef]

- Das, A.; Sarma, A.K. (Eds.) Unlocking the potential applications of bamboo, as an energy resource and bamboo-based activated carbon: A Comprehensive Review. BioEnergy Res. 2025, 18, 77. [Google Scholar] [CrossRef]

- Ahmad, Z.; Ding, Y.; Shahzad, A. (Eds.) Biotechnological Advances in Bamboo: The “Green Gold” on the Earth; Springer: Singapore, 2021. [Google Scholar]

- Vivas, K.A.; Vera, R.E.; Phillips, R.B.; Forfora, N.; Azuaje, I.; Zering, K.; Chang, H.M.; Delborne, J.; Saloni, D.; Dasmohapatra, S. An economic analysis of bamboo plantations and feedstock delivered cost in the Southern US for the manufacturing of fiber-based bioproducts. Biofuels Bioprod. Biorefining 2024, 18, 1455–1474. [Google Scholar] [CrossRef]

- Zhang, Y.-X.; Guo, C.; Li, D.-Z. A new subtribal classification of Arundinarieae (Poaceae, Bambusoideae) with the description of a new genus. Plant Divers. 2020, 42, 127–134. [Google Scholar] [CrossRef]

- Kelchner, S.A.; Group, B.P. Bamboo Phylogeny Group. Higher level phylogenetic relationships within the bamboos (Poaceae: Bambusoideae) based on five plastid markers. Mol. Phylogenet. Evol. 2013, 67, 404–413. [Google Scholar] [CrossRef]

- Sun, H.; Di, X.; Gao, Z. Leveraging artificial intelligence for bamboo breeding in the context of “bamboo as a substitute for plastic” initiative. Ind. Crops Prod. 2025, 228, 120896. [Google Scholar] [CrossRef]

- Li, Y.; Wang, N.; Latiff, A.R.A. Development of the bamboo forest economy: Reviewing China’s ‘bamboo as a substitute for plastic initiative’ and its development. Adv. Bamboo Sci. 2025, 11, 100130. [Google Scholar] [CrossRef]

- Zhan, W.; Xie, Y.; Xie, X.; Chen, Z.; Deng, C.; Huang, H. Multidimensional Environmental Drivers of Bamboo Species Richness on Subtropical Islands. Diversity 2025, 17, 46. [Google Scholar] [CrossRef]

- Irawan, B.; Ihsan, M.; Permana, M.D.; Noviyanti, A.R. A review of bamboo: Characteristics, components, and its applications. J. Nat. Fibers 2025, 22, 2522928. [Google Scholar] [CrossRef]

- Rathour, R.; Hemant, K.; Komal, P.; Prathmesh, A.; Manish, K.; Atya, K.; Ashok, P.; Mukesh, K.A.; Singh, L. Multifunctional applications of bamboo crop beyond environmental management: An Indian prospective. Bioengineered 2022, 13, 8893–8914. [Google Scholar] [CrossRef]

- Zhaohua, Z.; Wei, J. Sustainable Bamboo Development; CABI: Oxfordshire, UK, 2018; pp. 1–315. [Google Scholar]

- Patel, H.R.; Mathakia, R.; Mangroliya, U.C.; Mandaliya, V.B. Sustainable bamboo: Technological innovations and patent insights for a greener future. Adv. Bamboo Sci. 2025, 10, 100127. [Google Scholar] [CrossRef]

- Qin, S.; Yu, C.; Jin, Y.; Zhang, G.; Xu, W.; Wang, A.; Fan, M.; Sun, K.; Wang, S. Assessing the techno-economic feasibility of bamboo residue-derived hard carbon. Appl. Sci. 2025, 15, 7113. [Google Scholar] [CrossRef]

- Janssen, J.J.A. Designing and Building with Bamboo; International Network for Bamboo and Rattan: Beijing, China, 2000. [Google Scholar]

- Dixon, P.G.; Gibson, L.J. The structure and mechanics of Moso bamboo material. J. R. Soc. Interface. 2014, 11, 20140321. [Google Scholar] [CrossRef]

- Aydin, S.; Yardimci, M.Y.; Ramyar, K. Mechanical properties of four timber species commonly used in Turkey. Turk. J. Eng. Environ. Sci. 2007, 31, 19–27. [Google Scholar]

- Drury, B.; Padfield, C.; Russo, M.; Swygart, L.; Spalton, O.; Froggatt, S.; Mofidi, A. Assessment of the compression properties of different giant bamboo species for sustainable construction. Sustainability 2023, 15, 6472. [Google Scholar] [CrossRef]

- Ogunbiyi, M.A.; Olawale, S.O.; Tudjegbe, O.E.; Akinola, S.R. Comparative analysis of the tensile strength of bamboo and reinforcement steel bars as structural member in building construction. Int. J. Sci. Technol. Res 2015, 4, 551–553. [Google Scholar]

- Rusch, F.; Wastowski, A.D.; De Lira, T.S.; Moreira, K.C.C.S.R.; De Moraes Lúcio, D. Description of the component properties of species of bamboo: A review. Biomass Convers. Biorefinery 2023, 13, 2487–2495. [Google Scholar] [CrossRef]

- Dutta, S.; Gorain, S.; Roy, J.; Das, R.; Banerjee, S.; Gorai, S.K.; Roy Choudhury, M.; Das, S. Bamboo for global sustainability: A systematic review of its environmental and ecological implications, climate action, and biodiversity contributions. Environ. Rev. 2025, 33, 1–26. [Google Scholar] [CrossRef]

- FAO. Global Forest Resources Assessment 2020—Key Findings; FAO: Rome, Italy, 2020. [Google Scholar]

- Chiti, T.; Blasi, E.; Chiriacò, M.V. Carbon sequestration in a bamboo plantation: A case study in a Mediterranean area. J. For. Res. 2024, 35, 51. [Google Scholar] [CrossRef]

- Goh, Y.; Yap, S.P.; Tong, T.Y. Bamboo: The emerging renewable material for sustainable construction. Encycl. Renew. Sustain. Mater. 2020, 2, 365–376. [Google Scholar]

- Son, T. Sustainability Investing in Bamboo Industry. Bachelor’s Thesis, Haaga-Helia University of Applied Sciences, Helsinki, Finland, 2025. [Google Scholar]

- Hsu, W.-T.; Domenech, T.; McDowall, W. Closing the loop on plastics in Europe: The role of data, information and knowledge. Sustain. Prod. Consum. 2022, 33, 942–951. [Google Scholar] [CrossRef]

- Kubíková, L.U.; Rud, S. The current global situation of plastics and forecast of plastic waste. In Proceedings of the EDAMBA 2023: 26th International Scientific Conference for Doctoral Students and Post-Doctoral Scholars, Bratislava, Slovakia, 13–14 September 2023. [Google Scholar]

- Chaturvedi, K.; Singhwane, A.; Dhangar, M.; Mili, M.; Gorhae, N.; Naik, A.; Prashant, N.; Srivastava, A.K.; Verma, S. Bamboo for producing charcoal and biochar for versatile applications. Biomass Convers. Biorefinery 2024, 14, 15159–15185. [Google Scholar] [CrossRef]

- Solarte, A.; Hidalgo, J.P.; Torero, J.L. Flammability studies for the design of fire-safe bamboo structures. In Proceedings of the 2018 World Conference on Timber Engineering, Seoul, Republic of Korea, 20–23 August 2018. [Google Scholar]

- Samsudin, M.S.; Ali, N.I.M.; Mohamad, N.S.; Kasavan, S.; Azid, A. The market value of bamboo fibre and its future perspective. In Bamboo-Based Polymer Composites; Woodhead Publishing: Cambridge, UK, 2025; pp. 397–421. [Google Scholar]

- Aarthi, P.; Maheswari, M.; Sugumaran, M.; Maragatham, N. Assessment of biomass carbon storage potential and oxygen release of Beema bamboo (Bambusa balcooa) plantations. Pharm. Innov. 2021, 10, 2098–2102. [Google Scholar]

- Chambers, E.; Hassall, M.; Johnson, D.; Mcgoran, C.; Williams, O.; Blair, A.; Catlow, F.; Saha, B. From bamboo to biochar: A critical review of bamboo pyrolysis conditions and products with a focus on relevance to the developing world. RSC Sustain. 2025, 3, 2712–2732. [Google Scholar] [CrossRef]

- Sharma, R.; Wahono, J.; Baral, H. Bamboo as an alternative bioenergy crop and powerful ally for land restoration in Indonesia. Sustainability 2018, 10, 4367. [Google Scholar] [CrossRef]

- Tsegaye, M.; Chandravanshi, B.; Feleke, S.; Redi-Abshiro, M. Enhanced cellulose efficiency of pressurized hot water pretreated highland ethiopian bamboo (Yushania alpina): A potential feedstock for ethanol production. Chem. Int. 2021, 7, 53–61. [Google Scholar] [CrossRef]

- Ekawati, D.; Karlinasari, L.; Soekmadi, R.; Machfud. A model of integrated community-based bamboo management for the bamboo industry in Ngada Regency, East Nusa Tenggara, Indonesia. Sustainability 2023, 15, 977. [Google Scholar] [CrossRef]

- Pan, C.; Zhou, G.; Shrestha, A.K.; Chen, J.; Kozak, R.; Li, N.; Li, J.; He, Y.; Sheng, C.; Wang, G. Bamboo as a nature-based solution (NBS) for climate change mitigation: Biomass, products, and carbon credits. Climate 2023, 11, 175. [Google Scholar] [CrossRef]

- Sharma, A.K.; Dutt, D.; Upadhyaya, J.S.; Roy, T.K. Anatomical, morphological, and chemical characterization of Bambusa tulda, Dendrocalamus hamiltonii, Bambusa balcooa, Malocana baccifera, Bambusa arundinacea, and Eucalyptus tereticornis. BioResources 2011, 64, 5062–5073. [Google Scholar] [CrossRef]

- Liang, Z.; Neményi, A.; Kovács, G.P.; Gyuricza, C. Potential use of bamboo resources in energy value-added conversion technology and energy systems. GCB Bioenergy 2023, 15, 936–953. [Google Scholar] [CrossRef]

- Chantarat, P.; Poolsiri, R.; Wannalangka, I.; Kaitpraneet, S.; Puangchit, L.; Jenke, M. Aboveground biomass productivity and nutrient use dynamics of clumping tropical bamboos in Northern Thailand. Forests 2023, 14, 1450. [Google Scholar] [CrossRef]

- Song, Y.; Lee, Y.G.; Lee, D.-S.; Nguyen, D.-T.; Bae, H.-J. Utilization of bamboo biomass as a biofuels feedstocks: Process optimization with yeast immobilization and the sequential fermentation of glucose and xylose. Fuel 2022, 307, 121892. [Google Scholar] [CrossRef]

- Zhan, Y.; Cheng, J.; Liu, X.; Huang, C.; Wang, J.; Han, S.; Fang, G.; Meng, X.; Ragauskas, A.J. Assessing the availability of two bamboo species for fermentable sugars by alkaline hydrogen peroxide pretreatment. Bioresour. Technol. 2022, 349, 126854. [Google Scholar] [CrossRef]

- Dai, N.H.; Vo, T.T.; Le, L.P.M.; Van Tran, M.; Nguyen, T.A.D. Hydrogen production from acidic, alkaline, and steam-exploded Bambusa stenostachya hydrolysates in dark fermentation process. Biomass Conv. Bioref. 2022, 12, 3435–3446. [Google Scholar] [CrossRef]

- Li, N.; Meng, F.; Yang, H.; Shi, Z.; Zhao, P.; Yang, J. Enhancing enzymatic digestibility of bamboo residues using a three-constituent deep eutectic solvent pretreatment. Bioresour. Technol. 2022, 346, 126639. [Google Scholar] [CrossRef] [PubMed]

- Zhuang, X.; Gan, Z.; Chen, D.; Cen, K.; Ba, Y.; Jia, D. A new insight into high quality syngas production from co-pyrolysis of light bio-oil leached bamboo and heavy bio-oil using response surface methodology. Fuel 2022, 324, 124721. [Google Scholar] [CrossRef]

- Zhuang, X.; Gan, Z.; Chen, D.; Cen, K.; Ba, Y.; Jia, D. An approach for upgrading bio-oil by using heavy bio-oil co-pyrolyzed with bamboo leached with light bio-oil. Fuel 2023, 331, 125931. [Google Scholar] [CrossRef]

- Yuan, Z.; Wen, Y.; Kapu, N.S.; Beatson, R.; Mark Martinez, D. A biorefinery scheme to fractionate bamboo into high-grade dissolving pulp and ethanol. Biotechnol. Biofuels 2017, 10, 38. [Google Scholar] [CrossRef]

- Awogbemi, O.; Desai, D.A. Harnessing the potentials of bamboo as a sustainable feedstock for bioenergy production. Adv. Bamboo Sci. 2025, 12, 100173. [Google Scholar] [CrossRef]

- Hao, H.; Tam, L.-h.; Lu, Y.; Lau, D. An atomistic study on the mechanical behavior of bamboo cell wall constituents. Compos. Part B Eng. 2018, 151, 222–231. [Google Scholar] [CrossRef]

- Tan, M.; Jiang, X.; Ke, H.; Wu, W.; Xia, R. Experimental investigations on the mechanical properties of bamboo fiber and fibril. Fibers Polym. 2020, 21, 1382–1386. [Google Scholar] [CrossRef]

- Youssefian, S.; Rahbar, N. Molecular origin of strength and stiffness in bamboo fibrils. Sci. Rep. 2015, 5, 11116. [Google Scholar] [CrossRef]

- Fuke, P.; T, M.M.; Kumar, M.; Sawarkar, A.D.; Pandey, A.; Singh, L. Role of microbial diversity to influence the growth and environmental remediation capacity of bamboo: A review. Ind. Crops Prod. 2021, 167, 113567. [Google Scholar] [CrossRef]

- Chen, D.; Zhuang, X.; Gan, Z.; Cen, K.; Ba, Y.; Jia, D. Co-pyrolysis of light bio-oil leached bamboo and heavy bio-oil: Effects of mass ratio, pyrolysis temperature, and residence time on the biochar. Chem. Eng. J. 2022, 437, 135253. [Google Scholar] [CrossRef]

- Saha, N.; Fillerup, E.; Thomas, B.; Pilgrim, C.; Causer, T.; Herren, D.; Klinger, J. Improving bamboo’s fuel and storage properties with a net energy export through torrefaction paired with catalytic oxidation. Chem. Eng. J. 2022, 440, 135750. [Google Scholar] [CrossRef]

- Xu, M.; Ji, H.; Zhuang, S. Carbon stock of Moso bamboo (Phyllostachys pubescens) forests along a latitude gradient in the subtropical region of China. PLoS ONE 2018, 13, e0193024. [Google Scholar] [CrossRef] [PubMed]

- Isagi, Y. Carbon stock and cycling in a bamboo Phyllostachys bambusoides stand. Ecol. Res. 1994, 9, 47–55. [Google Scholar] [CrossRef]

- Jember, A.A.; Taye, M.A.; Gebeyehu, G.; Mulu, G.; Long, T.T.; Jayaraman, D.; Abebe, S. Carbon stock potential of highland bamboo plantations in northwestern Ethiopia. Carbon Balance Manag. 2023, 18, 3. [Google Scholar] [CrossRef]

- Song, X.; Zhou, G.; Jiang, H.; Yu, S.; Fu, J.; Li, W.; Wang, W.; Ma, Z.; Peng, C. Carbon sequestration by Chinese bamboo forests and their ecological benefits: Assessment of potential, problems, and future challenges. Environ. Rev. 2011, 19, 418–428. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, X.; Zhang, Y.; Booth, T.; He, X. Changes of carbon stocks in bamboo stands in China during 100 years. For. Ecol. Manag. 2009, 258, 1489–1496. [Google Scholar] [CrossRef]

- Lou, Y.P.; Henley, G. Biodiversity in Bamboo Forests: A Policy Perspective for Long Term Sustainability; Working Paper 59; International Network for Bamboo and Rattan (INBAR): Beijing, China, 2010; pp. 1–17. [Google Scholar]

- Choudhury, D.; Sahu, J.K.; Sharma, G.D. Value addition to bamboo shoots: A review. J. Food Sci. Technol. 2012, 49, 407–414. [Google Scholar] [CrossRef]

- Tahir, P.M.; Lee, S.H.; Al-Edrus, S.O.; Uyup, M.K.A. Multifaceted Bamboo; Springer: Berlin/Heidelberg, Germany, 2023. [Google Scholar]

- Zhou, G.; Meng, C.; Jiang, P.; Xu, Q. Review of carbon fixation in bamboo forests in China. Bot. Rev. 2011, 77, 262–270. [Google Scholar] [CrossRef]

- Yuen, J.Q.; Fung, T.; Ziegler, A.D. Carbon stocks in bamboo ecosystems worldwide: Estimates and uncertainties. For. Ecol. Manag. 2017, 393, 113–138. [Google Scholar] [CrossRef]

- Sarangle, S.; Rajasekaran, A.; Benbi, D.K.; Chauhan, S. Biomass and carbon stock, carbon sequestration potential under selected land use systems in Punjab. Forest Res. Eng. Int. J. 2018, 9, 75–80. [Google Scholar] [CrossRef]

- Ji, H.; Ni, W.; Shao, J.F. Comparison and assessment of nutritional composition in shoots of six bamboo species in Southeast China. Adv. Bamboo Sci. 2024, 7, 100087. [Google Scholar] [CrossRef]

- Li, M.; Yao, Y.; Dong, Y.; Huang, H.; Ou, X.; Ayala, J.; Yan, H.; Wang, H.; Lv, R.; Song, C. Comparative study of nutrient composition in 31 species of staple food bamboos consumed by giant panda in China. J. Food Qual. 2025, 2025, 6648176. [Google Scholar] [CrossRef]

- Awol, A. Nutrient, mineral and bioactive constituent evaluation of bamboo shoots grown in Masha area, South-West of Ethiopia. Am. Sci. Res. J. Eng. Technol. Sci. (ASRJETS) 2015, 7, 15–25. [Google Scholar]

- Narendra Prasad, S.; Hegde, M.S.; Gadgil, M.; Hegde, K.M. An experiment in eco-development in Uttara Kannada District of Karnataka. South Asian Anthropol. 1985, 6, 73–83. [Google Scholar]

- Collins, R.J.; Keilar, S.M. The Australian Bamboo Shoot Industry: A supply Chain Approach; Rural Industries Research and Development Corporation: Kinston, Australia, 2005; pp. 1–89. [Google Scholar]

- Chongtham, N.; Bisht, M.S.; Haorongbam, S. Nutritional properties of bamboo shoots: Potential and prospects for utilization as a health food. Compr. Rev. Food Sci. Food Saf. 2011, 10, 153–168. [Google Scholar] [CrossRef]

- Nongdam, P.; Tikendra, L. The nutritional facts of bamboo shoots and their usage as important traditional foods of Northeast India. Int. Sch. Res. Not. 2014, 2014, 679073. [Google Scholar] [CrossRef]

- Chongtham, N.; Bisht, M. Bamboo Shoot: Superfood for Nutrition, Health and Medicine, 1st ed.; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Giri, S.S.; Janmejay, L.S. Effect of bamboo shoot fermentation and aging on nutritional and sensory qualities of Soibum. J. Food Sci. Technol.-Mysore 2000, 37, 423–426. [Google Scholar]

- Singhal, P.; Satya, S.; Naik, S. Fermented bamboo shoots: A complete nutritional, anti-nutritional and antioxidant profile of the sustainable and functional food to food security. Food Chem. Mol. Sci. 2021, 3, 100041. [Google Scholar] [CrossRef]

- Nirmala, C.; David, E.; Sharma, M.L. Changes in nutrient components during ageing of emerging juvenile bamboo shoots. Int. J. Food Sci. Nutr. 2007, 58, 612–618. [Google Scholar] [CrossRef]

- Madamba, P.S. Physical changes in bamboo (Bambusa phyllostachys) shoot during hot air drying: Shrinkage, density, and porosity. Dry. Technol. 2003, 21, 555–568. [Google Scholar] [CrossRef]

- Cheng, H.P. Vacuum cooling combined with hydrocooling and vacuum drying on bamboo shoots. Appl. Therm. Eng. 2006, 26, 2168–2175. [Google Scholar] [CrossRef]

- Ma, T.; Mo, W.; Lv, B.; Wang, W.; He, H.; Jian, C.; Liu, X.; Li, S.; Guo, Y. A review of the nutritional composition, storage challenges, processing technology and widespread use of bamboo shoots. Foods 2024, 13, 3539. [Google Scholar] [CrossRef]

- Yu, L.; Pei, J.; Zhao, Y.; Wang, S. Physiological changes of bamboo (Fargesia yunnanensis) shoots during storage and the related cold storage mechanisms. Front. Plant Sci. 2021, 12, 731977. [Google Scholar] [CrossRef] [PubMed]

- Kleinhenz, V.; Gosbee, M.; Elsmore, S.; Lyall, T.; Blackburn, K.; Harrower, K.; Midmore, D. Storage methods for extending shelf life of fresh, edible bamboo shoots [Bambusa oldhamii (Munro)]. Postharvest Biol. Technol. 2000, 19, 253–264. [Google Scholar] [CrossRef]

- Wu, P.-R.; Hwang, S.-G.; Chen, C.-L.; Lin, H.-L. Effects of storage duration and temperature on browning and quality of postharvest bamboo shoots. Horticulturae 2024, 10, 616. [Google Scholar] [CrossRef]

- Zhou, J.; Lv, P.; He, B.; Wu, J.; Wang, G.; Ma, H.; Wang, Y.; Chen, G. Optimisation of the ethanol fermentation process using hydrothermal pretreatment of cellulose waste—Effect of fermentation pattern and strain. Molecules 2024, 29, 5266. [Google Scholar] [CrossRef]

- Li, W.; He, S. Research on the utilization and development of bamboo resources through problem analysis and assessment. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019. [Google Scholar]

- Ekawati, D.; Karlinasari, L.; Soekmadi, R. Drivers, barriers, and strategies in the community-based supply of bamboo for industrial-scale bamboo utilization in Ngada regency, east Nusa Tenggara, Indonesia. Sustainability 2022, 14, 5970. [Google Scholar] [CrossRef]

- Okokpujie, I.; Akinlabi, E.; Fayomi, O. Assessing the policy issues relating to the use of bamboo in the construction industry in Nigeria. Heliyon 2020, 6, e04042. [Google Scholar] [CrossRef]

- Ferreira, V.L.P.; Yotsuyanagi, K.; Carvalho, C.R.L. Elimination of cyanogenic compounds from bamboo shoots Dendrocalamus giganteus Munro. Trop. Sci. 1995, 35, 342–346. [Google Scholar]

- Kumbhare, V.; Bhargava, A. Effect of processing on nutritional value of central Indian bamboo shoots. Part I. J. Food Sci. Technol.-Mysore 2007, 44, 29–31. [Google Scholar]

- Santosh, O.; Bajwa, H.K.; Bisht, M.S.; Chongtham, N. Application of bamboo in the food and pharmaceutical industry. In Biotechnological Advances in Bamboo: The “Green Gold” on the Earth; Ahmad, Z., Ding, Y., Shahzad, A., Eds.; Springer: Singapore, 2021; pp. 401–429. [Google Scholar]

- Park, E.-J.; Jhon, D.-Y. The antioxidant, angiotensin converting enzyme inhibition activity, and phenolic compounds of bamboo shoot extracts. LWT-Food Sci. Technol. 2010, 43, 655–659. [Google Scholar] [CrossRef]

- Verma, S.; Mili, M.; Hada, V.; Kalita, P.; Hashmi, S.A.R.; Rathore, S.K.S.; Srivastava, A.K. Bamboo leaves: Sustainable feedstock in pharmaceuticals, food, and agricultural sector. Environ. Technol. Rev. 2022, 11, 266–281. [Google Scholar] [CrossRef]

- Nirmala, C.; Bisht, M.S.; Bajwa, H.K.; Santosh, O. Bamboo: A rich source of natural antioxidants and its applications in the food and pharmaceutical industry. Trends Food Sci. Technol. 2018, 77, 91–99. [Google Scholar] [CrossRef]

- Wu, H.; Wang, Y.; Zhang, B.; Li, Y.L.; Ren, Z.X.; Huang, J.J.; Zhang, Z.Q.; Lin, Z.J.; Zhang, X.M. Smilax glabra Roxb.: A review of its traditional usages, phytochemical constituents, pharmacological properties, and clinical applications. Drug Des. Devel. Ther. 2022, 16, 3621–3643. [Google Scholar] [CrossRef] [PubMed]

- Jin, Y.-C.; Yuan, K.; Zhang, J. Chemical composition, and antioxidant and antimicrobial activities of essential oil of Phyllostachys heterocycla cv. Pubescens varieties from China. Molecules 2011, 16, 4318–4327. [Google Scholar]

- Wedler, J.; Daubitz, T.; Schlotterbeck, G.; Butterweck, V. In vitro anti-inflammatory and wound-healing potential of a Phyllostachys edulis leaf extract—Identification of isoorientin as an active compound. Planta Med. 2014, 80, 1678–1684. [Google Scholar] [CrossRef]

- Zhao, R.; Shang, T.; Yuan, B.; Zhu, X.; Zhang, X.; Yang, X. Osteoporotic bone recovery by a bamboo-structured bioceramic with controlled release of hydroxyapatite nanoparticles. Bioact. Mater. 2022, 17, 379–393. [Google Scholar] [CrossRef]

- Yansen, I.A.; Budhy, T.I.; Adam, D.; Fahria, F. Potential of bamboo shoots against breast cancer: A review. Malays. J. Med. Health Sci. 2023, 19, 144–148. [Google Scholar]

- Ton, T.N.T.S.; Samonte, S.L.; Berry, M.J.; Panee, J. Abstract B155: Effects of bamboo extract on breast cancer. Mol. Cancer Ther. 2009, 8 (Suppl. 12), B155. [Google Scholar] [CrossRef]

- Heuer, M.; Zhang, Y.; Roberts, W.; Huang, L. Bamboo Extracts, Compositions and Uses Thereof. U.S. Patent 20150201661A1, 23 July 2015. [Google Scholar]

- Gautam, N.; Rajesh, Y.; Kale, N.; Jagtap, M.; Chaudhari, H.; Pansare, S. Silica extraction from bamboo leaves using alkaline extraction method. Mater. Today Proc. 2024, 111, 155–160. [Google Scholar] [CrossRef]

- Hoyweghen, L.V.; Beer, T.D.; Deforce, D.; Heyerick, A. Phenolic compounds and anti-oxidant capacity of twelve morphologically heterogeneous bamboo species. Phytochem. Anal. 2012, 23, 433–443. [Google Scholar] [CrossRef]

- Kozukue, E.; Kozukue, N.; Kurosaki, T. Organic acid, sugar and amino acid composition of bamboo shoots. J. Food Sci. 1983, 48, 935–938. [Google Scholar] [CrossRef]

- Adesina, B.T.; Okon, E.M.; Falana, B.M.; Oyawoye, E.O.; Adesina, O.A.; Inape, S.E.; Akinwole, A.O.; Adeosun, F.I.; Ajibade, A.O. Amino acid composition of bamboo materials (Bambusa vulgaris) as potential organic fish feed supplements. Pak. J. Nutr. 2020, 19, 191–196. [Google Scholar] [CrossRef][Green Version]

- Zhu, H.; Zhang, S.; Zheng, H.; Wang, G. Enhanced triglyceride adsorption by steam-activated bamboo charcoal based on molecular dynamics investigations. Sci. Rep. 2024, 14, 6237. [Google Scholar] [CrossRef] [PubMed]

- Son, S.-h.; Choi, E.; Lee, S.-H. The effect of bamboo therapy perception on the job satisfaction for skin beauty workers. J. Korean Soc. Cosmetol. 2021, 27, 790–799. [Google Scholar] [CrossRef]

- Indira, A.; Joshi, B.; Kalyan, N.; Chongtham, N. Bamboos as a Rich Source of Antioxidants. In Exploring Medicinal Bamboos; CRC Press: Boca Raton, FL, USA, 2025; pp. 72–82. [Google Scholar]

- Lee, H.-J.; Chae, S.-L.; Kim, S.-H. The effect of bamboo (Phyllostachys nigra var. henenis strapf) leaf extract on epidermal melanocytes in ultraviolet B-irradiated mice. J. Radiat. Prot. Res. 2007, 32, 59–64. [Google Scholar]

- Ji, X.; Tan, Z.; Yang, H.; Shi, Z.; Yang, J.; Alhadhrami, A.; Zhang, J.; Mersal, G.A.M.; El-Bahy, Z.M.; Guo, Z.; et al. Sustainable bamboo charcoal based nanocomposite catalysts for rapid adsorption and photo-Fenton degradation of toxic dyes. Sustain. Mater. Technol. 2024, 41, e01080. [Google Scholar] [CrossRef]

- Yang, H.; Shi, Z.; Xu, G.; Qin, Y.; Deng, J.; Yang, J. Bioethanol production from bamboo with alkali-catalyzed liquid hot water pretreatment. Bioresour. Technol. 2019, 274, 261–266. [Google Scholar] [CrossRef]

- Nurul Fazita, M.R.; Jayaraman, K.; Bhattacharyya, D.; Mohamad Haafiz, M.K.; Saurabh, C.K.; Hussin, M.H.; Abdul Khalil, H.P.S. Green composites made of bamboo fabric and poly (lactic) acid for packaging applications—A review. Materials 2016, 9, 435. [Google Scholar] [CrossRef]

- Alvarez, J.; Ławińska, K.; Falkiewicz-Dulík, M. Quality assessment of viscose bamboo fabrics intended for use inside children’s and special footwear. Fibres Text. East. Eur. 2020, 28, 82–88. [Google Scholar]

- Samanta, K.K.; Basak, S.; Chattopadhyay, S.K. Potential of ligno-cellulosic and protein fibres in sustainable fashion. In Environmental Footprints and Eco-Design of Products and Processes Sustainable Fibres for Fashion Industry; Muthu, S.S., Gardetti, M., Eds.; Springer: Singapore, 2016; pp. 61–109. [Google Scholar]

- Nayak, R.; Jajpura, L.; Khandual, A. 1—Traditional Fibres for Fashion and Textiles: Associated Problems and Future Sustainable Fibres. In Sustainable Fibres for Fashion and Textile Manufacturing; Nayak, R., Ed.; Woodhead Publishing: Cambridge, UK, 2023; pp. 3–25. [Google Scholar]

- Kabir, M.M. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- Al-Oqla, F.M.; Sapuan, S.M. Natural fiber reinforced polymer composites in industrial applications: Feasibility of date palm fibers for sustainable automotive industry. J. Clean. Prod. 2014, 66, 347–354. [Google Scholar] [CrossRef]

- Ramesh, M.; Deepa, C.; Ravanan, A. Bamboo Fiber Reinforced Concrete Composites. In Bamboo Fiber Composites: Processing, Properties and Applications; Jawaid, M., Rangappa, S.M., Siengchin, S., Eds.; Springer: Singapore, 2021; pp. 127–145. [Google Scholar]

- Amin, K.F.; Asrafuzzaman Sharif, A.; Hoque, M.E. Bamboo/Bamboo Fiber Reinforced Concrete Composites and Their Applications in Modern Infrastructure. In Bamboo Fiber Composites: Processing, Properties and Applications; Jawaid, M., Rangappa, S.M., Siengchin, S., Eds.; Springer: Singapore, 2021; pp. 271–297. [Google Scholar]

- Gan, J.; Chen, M.; Semple, K.; Liu, X.; Dai, C.; Tu, Q. Life cycle assessment of bamboo products: Review and harmonization. Sci. Total Environ. 2022, 849, 157937. [Google Scholar] [CrossRef]

- Young, L.; Kaminski, S.; Kovacs, M.; Zea Escamilla, E. A Comparative Life Cycle Assessment (LCA) of a Composite Bamboo Shear Wall System Developed for El Salvador. Sustainability 2024, 16, 7602. [Google Scholar] [CrossRef]

- Thomas, R.; Jebin, N.; Saha, R.; Sarma, D.K. Antioxidant and antimicrobial effects of kordoi (Averrhoa carambola) fruit juice and bamboo (Bambusa polymorpha) shoot extract in pork nuggets. Food Chem. 2016, 190, 41–49. [Google Scholar] [CrossRef] [PubMed]

- Antonio Bizzo, W.; Lenço, P.C.; Carvalho, D.J.; Veiga, J.P.S. The generation of residual biomass during the production of bio-ethanol from sugarcane, its characterization and its use in energy production. Renew. Sustain. Energy Rev. 2014, 29, 589–603. [Google Scholar] [CrossRef]

- Sorn, V.; Chang, K.-L.; Phitsuwan, P.; Ratanakhanokchai, K.; Dong, C.-D. Effect of microwave-assisted ionic liquid/acidic ionic liquid pretreatment on the morphology, structure, and enhanced delignification of rice straw. Bioresour. Technol. 2019, 293, 121929. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Ullah, F.; Zhou, D.-X.; Yi, M.; Zhao, Y. Mechanisms of ROS regulation of plant development and stress responses. Front. Plant Sci. 2019, 10, 800. [Google Scholar] [CrossRef]

- Han, S.; An, X.; He, X.; Ren, X.; Sichone, J.; Wu, X.; Zhang, Y.; Wang, H.; Sun, F. Temporal Dynamics of Fungal Communities in Alkali-Treated Round Bamboo Deterioration under Natural Weathering. Microorganisms 2024, 12, 858. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, Y.; Yu, S. Co-production of functional xylooligosaccharides and fermentable sugars from corncob with effective acetic acid prehydrolysis. Bioresour. Technol. 2017, 234, 343–349. [Google Scholar] [CrossRef]

- He, M.-X.; Wang, J.-L.; Qin, H.; Shui, Z.-X.; Zhu, Q.-l.; Wu, B.; Tan, F.-R.; Pan, K.; Hu, Q.-C.; Dai, L.-C.; et al. Bamboo: A new source of carbohydrate for biorefinery. Carbohydr. Polym. 2014, 111, 645–654. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Fei, B.; Jiang, Z. Effect of steam explosion pretreatment on bamboo for enzymatic hydrolysis and ethanol fermentation. BioResources 2015, 10, 1037–1047. [Google Scholar] [CrossRef]

- Yang, J.; Xu, H.; Jiang, J.; Zhang, N.; Xie, J.; Zhao, J.; Wei, M. Enhanced enzymatic hydrolysis and structure properties of bamboo by moderate two-step pretreatment. Appl. Biochem. Biotechnol. 2021, 193, 1011–1022. [Google Scholar] [CrossRef] [PubMed]

- Singh, R.D.; Banerjee, J.; Arora, A. Prebiotic potential of oligosaccharides: A focus on xylan derived oligosaccharides. Bioact. Carbohydr. Diet. Fibre. 2015, 5, 19–30. [Google Scholar] [CrossRef]

- Manandhar, R.; Jin-Hee, K.; Kim, J.-T. Environmental, social and economic sustainability of bamboo and bamboo-based construction materials in buildings. J. Asian Archit. Build. Eng. 2019, 18, 49–59. [Google Scholar] [CrossRef]

- Nurdiah, E.A. The potential of bamboo as building material in organic shaped buildings. Procedia Soc. Behav. Sci. 2016, 216, 30–38. [Google Scholar] [CrossRef]

- Chen, H.; Cheng, H.; Wang, G.; Yu, Z.; Shi, S.Q. Tensile properties of bamboo in different sizes. J. Wood Sci. 2015, 61, 552–561. [Google Scholar] [CrossRef]

- Pradhan, N.P.N.; Paraskeva, T.S.; Dimitrakopoulos, E.G. Quasi-static reversed cyclic testing of multi-culm bamboo members with steel connectors. J. Build. Eng. 2020, 27, 100983. [Google Scholar] [CrossRef]

- Liliefna, L.D.; Nugroho, N.; Karlinasari, L.; Sadiyo, S. Development of low-tech laminated bamboo esterilla sheet made of thin-wall bamboo culm. Constr. Build. Mater. 2020, 242, 118181. [Google Scholar] [CrossRef]

- Liu, X.; Smith, G.D.; Jiang, Z.; Bock, M.C.D.; Boeck, F.; Frith, O.; Gatóo, A.; Liu, K.; Mulligan, H.; Semple, K.E.; et al. Nomenclature for engineered bamboo. BioResources 2016, 11, 1141–1161. [Google Scholar] [CrossRef]

- Tang, G.; Yin, L.; Li, Z.; Li, Y.; You, L. Structural behaviors of bolted connections using laminated bamboo and steel plates. Structures 2019, 20, 324–339. [Google Scholar] [CrossRef]

- Kumar, A.; Vlach, T.; Laiblova, L.; Hrouda, M.; Kasal, B.; Tywoniak, J.; Hajek, P. Engineered bamboo scrimber: Influence of density on the mechanical and water absorption properties. Constr. Build. Mater. 2016, 127, 815–827. [Google Scholar] [CrossRef]

- Sharma, B.; van der Vegte, A. 21—Engineered Bamboo for Structural Applications. In Nonconventional and Vernacular Construction Materials, 2nd ed.; Harries, K.A., Sharma, B., Eds.; Woodhead Publishing: Cambridge, UK, 2020; pp. 597–623. [Google Scholar]

- Bansal, A.K.; Zoolagud, S. Bamboo composites: Material of the future. J. Bamboo Ratt. 2002, 1, 119–130. [Google Scholar] [CrossRef]

- Liu, D.; Song, J.; Anderson, D.P.; Chang, P.R.; Hua, Y. Bamboo fiber and its reinforced composites: Structure and properties. Cellulose 2012, 19, 1449–1480. [Google Scholar] [CrossRef]

- Boukehili, H.; Nguyen-Tri, P. Helium gas barrier and water absorption behavior of bamboo fiber reinforced recycled polypropylene. J. Reinf. Plast. Comp. 2012, 31, 1638–1651. [Google Scholar] [CrossRef]

- Waite, M. Sustainable textiles: The role of bamboo and a comparison of bamboo textile properties. J. Text. Appar. Technol. Manag. 2009, 6, 1–21. [Google Scholar]

- Suhaily, S.S.; Jawaid, M.; Abdul Khalil, H.P.S.; Mohamed, A.R.; Ibrahim, F. A review of oil palm biocomposites for furniture design and applications: Potential and challenges. BioResources 2012, 7, 4400–4423. [Google Scholar] [CrossRef]

- Lin, H.C.; Murase, Y.; Shiah, T.-C.; Hwang, G.S.; Chen, P.K.; Wu, W.L. Application of Moso bamboo vinegar with different collection temperature to evaluate fungi resistance of Moso bamboo materials. J. Fac. Agric. Kyushu Univ. 2008, 53, 107–113. [Google Scholar] [CrossRef]

- Phimmachanh, S.; Ying, Z.; Beckline, M. Bamboo resources utilization: A potential source of income to support rural livelihoods. Appl. Ecol. Environ. Sci 2015, 3, 176–183. [Google Scholar]

- Borowski, P.F. Bamboo as an innovative material for many branches of world industry. Ann. WULS For. Wood Technol. 2019, 107, 13–18. [Google Scholar] [CrossRef]

- Marsh, J.; Smith, N. New bamboo industries and pro-poor impact: Learning from China. Enterp. Dev. Microfinance. 2007, 18, 216–240. [Google Scholar] [CrossRef]

- Felisberto, M.H.F.; Beraldo, A.L.; Clerici, M.T.P.S. Young bamboo culm flour of Dendrocalamus asper: Technological properties for food applications. LWT-Food Sci. Technol. 2017, 76, 230–235. [Google Scholar] [CrossRef]

- Bal, L.M.; Singhal, P.; Satya, S.; Naik, S.N.; Kar, A. Bamboo shoot preservation for enhancing its business potential and local economy: A review. Crit. Rev. Food Sci. Nutr. 2012, 52, 804–814. [Google Scholar] [CrossRef] [PubMed]

- Desh, R. Experiences in waste land development: A case study. In Renewable Energy and Environment. Proceedings of the International Solar Energy Conservation, Udaipur, India, 1-3 December 1989; Mathur, A.N., Rathore, N.S., Eds.; Himanshu Publications: Udaipur, India, 1990; pp. 139–143. [Google Scholar]

- Arunachalam, A.; Arunachalam, K. Evaluation of bamboos in eco-restoration of ‘jhum’ fallows in Arunachal Pradesh: Ground vegetation, soil and microbial biomass. For. Ecol. Manag. 2002, 159, 231–239. [Google Scholar] [CrossRef]

- Venkatesh, M.; Bhatt, B.; Kumar, K.; Majumdar, B.; Singh, K. Soil properties influenced by some important edible bamboo species in the North Eastern Himalayan region, India. J. Bamboo Ratt. 2005, 4, 221–230. [Google Scholar] [CrossRef]

- Van der Lugt, P. Design Interventions for Stimulating Bamboo Commercialization—Dutch Design Meets Bamboo as a Replicable Model; Delft University of Technology: Delft, The Netherlands, 2008; p. 421. [Google Scholar]

- Tu, Z.; Lihua, C.; Xinxiao, Y.; Zheng, Y. Rhizosphere soil enzymatic and microbial activities in bamboo forests in southeastern China. Soil Sci. Plant Nutr. 2014, 60, 134–144. [Google Scholar] [CrossRef]

- Zhang, C.; Xie, G.; Fan, S.; Zhen, L. Variation in vegetation structure and soil properties, and the relation between understory plants and environmental variables under different Phyllostachys pubescens forests in southeastern China. Environ. Manag. 2010, 45, 779–792. [Google Scholar] [CrossRef]

- Nath, A.; Das, A. Carbon pool and sequestration potential of village bamboos in the agroforestry system of Northeast India. Trop. Ecol. 2012, 53, 287–293. [Google Scholar]

- Gray, C.L.; Simmons, B.I.; Fayle, T.M.; Mann, D.J.; Slade, E.M. Are riparian forest reserves sources of invertebrate biodiversity spillover and associated ecosystem functions in oil palm landscapes? Biol. Conserv. 2016, 194, 176–183. [Google Scholar] [CrossRef]

- Hiwale, S. Sustainable Horticulture in Semiarid Dry Lands; Springer: New Delhi, India, 2015. [Google Scholar]

- Partey, S.T.; Sarfo, D.A.; Frith, O.; Kwaku, M.; Thevathasan, N.V. Potentials of bamboo-based agroforestry for sustainable development in Sub-Saharan Africa: A review. Agric. Res. 2017, 6, 22–32. [Google Scholar] [CrossRef]

- Peixoto, M.M.; Sage, T.L.; Busch, F.A.; Pacheco, H.D.N.; Moraes, M.G.; Portes, T.A.; Almeida, R.A.; Graciano-Ribeiro, D.; Sage, R.F. Elevated efficiency of C3 photosynthesis in bamboo grasses: A possible consequence of enhanced refixation of photorespired CO2. GCB Bioenergy 2021, 13, 941–954. [Google Scholar] [CrossRef]

- Huang, W.; Ding, Y.; Wang, S.; Song, C.; Wang, F. Growth and development responses of the rhizome-root system in Pleioblastus pygmaeus to light intensity. Plants 2022, 11, 2204. [Google Scholar] [CrossRef] [PubMed]

- Ghode, N. Manual on Bamboo Cultivation: Bamboo Cultivation in Chhattisgarh, India: A Sustainable and Economically Viable Solution; Shashwat Publication: Chhattisgarh, India, 2023. [Google Scholar]

- Zhang, M.; Chen, S.; Jiang, H.; Lin, Y.; Zhang, J.; Song, X.; Zhou, G. Water-use characteristics and physiological response of Moso bamboo to flash droughts. Int. J. Environ. Res. Public Health 2019, 16, 2174. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Ma, Y.; Qiu, H.; Zhou, L.; He, K.; Ye, Y. Wake up: The regulation of dormancy release and bud break in perennial plants. Front. Plant Sci. 2025, 16, 1553953. [Google Scholar] [CrossRef]

- Kotangale, P.; Agashe, A.; Sawarkar, R.; Dewangan, C.; Tijare, G.; Singh, L. Unlocking the hidden power of bamboo rhizomes: A comprehensive review of their role in nutrient storage, water retention, and plant growth. Adv. Bamboo Sci. 2025, 10, 100122. [Google Scholar] [CrossRef]

- Canavan, S.; Richardson, D.; Visser, V.; Le Roux, J.; Vorontsova, M.; Wilson, J. The global distribution of bamboos: Assessing correlates of introduction and invasion. AoB Plants 2017, 9, plw078. [Google Scholar] [CrossRef]

- Jiao, Y.; Hu, Q.; Zhu, Y.; Zhu, L.; Ma, T.; Zeng, H.; Zang, Q.; Li, X.; Lin, X. Comparative transcriptomic analysis of the flower induction and development of the Lei bamboo (Phyllostachys violascens). BMC Bioinform. 2019, 20, 687. [Google Scholar] [CrossRef]

- Kobayashi, K.; Nishiyama, N.; Kashiwagi, H.; Shibata, S. Mass-flowering of cultivated Moso bamboo, Phyllostachys edulis (Poaceae) after more than a half-century of vegetative growth. J. Jpn. Bot. 2022, 97, 145–155. [Google Scholar]

- Zheng, X.; Lin, S.; Fu, H.; Wan, Y.; Ding, Y. The bamboo flowering cycle sheds light on flowering diversity. Front. Plant Sci. 2020, 11, 381. [Google Scholar] [CrossRef]

- Hou, D.; Li, L.; Ma, T.; Pei, J.; Zhao, Z.; Lu, M.; Wu, A.; Lin, X. The SOC1-like gene BoMADS50 is associated with the flowering of Bambusa oldhamii. Hortic. Res. 2021, 8, 133. [Google Scholar] [CrossRef]

- Ye, S.; Wei, X.; Chen, J.; Luo, S.; Jiang, T.; Yang, J.; Zheng, R.; Chen, S. Research on Key Genes for Flowering of Bambusaoldhamii Under Introduced Cultivation Conditions. Genes 2025, 16, 811. [Google Scholar] [CrossRef]

- Wang, W.; Cao, H.; Wang, J.; Zhang, H. Recent advances in functional assays of WRKY transcription factors in plant immunity against pathogens. Front. Plant Sci. 2025, 15, 1517595. [Google Scholar] [CrossRef]

- Sun, H.; Wang, J.; Li, H.; Li, T.; Gao, Z. Advancements and challenges in bamboo breeding for sustainable development. Tree Physiol. 2023, 43, 1705–1717. [Google Scholar] [CrossRef] [PubMed]

- Lombardo, E. An overview of bamboo cultivation in Southern Italy. Adv. Bamboo Sci. 2022, 1, 100002. [Google Scholar] [CrossRef]

- Isukuru, E.J.; Ogunkeyede, A.O.; Adebayo, A.A.; Uruejoma, M.F. Potentials of bamboo and its ecological benefits in Nigeria. Adv. Bamboo Sci. 2023, 4, 100032. [Google Scholar] [CrossRef]

- Dey, S.; Biswas, S.; Kundu, A.; Pal, A.; Das, M. Current understanding on major bamboo diseases, pathogenicity, and resistance genes. In Genetics, Genomics and Breeding of Bamboos; CRC Press: Boca Raton, FL, USA, 2023; pp. 256–278. [Google Scholar]

- Raza, S.T.; Khan, A.H.; Hameed, A.; Muhammad, N.; Grewal, A.G.; Malik, M.T.; Imran, M.; Mustafa, G.; Iqbal, A. A review on white mango scale biology, ecology, distribution and management. Agriculture 2023, 13, 1770. [Google Scholar] [CrossRef]

- Roychoudhury, N.; Mishra, R.K. Bamboo leaf roller, Crypsiptya coclesalis and its management-An update. Pestology 2022, 46, 33–38. [Google Scholar]

- Sadiku, N.A.; Bada, O.S.; Oluyege, A.O.; Ajayi, B. Natural resistance of Bambusa vulgaris to termite and powder-post beetle attack. J. Trop. For. Sci. 2021, 33, 398–405. [Google Scholar] [CrossRef]

- Kainthola, C.; Harsh, N.S.K.; Ginwal, H.S.; Tripathi, A.; Saha, R.; Pandey, A. New report of Fusarium flocciferum causing rot of emerging culm in Dendrocalamus strictus. Indian For. 2021, 147, 1220–1225. [Google Scholar] [CrossRef]

- Li, L.; Wang, Y.; Yu, C.; Li, S.; Lin, T.; Han, S.; Zhu, T.; Li, S. Seasonal changes in the abundance Fusarium proliferatium, microbial endophytes and nutrient levels in the roots of hybrid bamboo Bambusa pervariabilis × Dendrocalamopsis grandis. Front. Plant Sci. 2023, 14, 1185449. [Google Scholar] [CrossRef] [PubMed]

- Mohapatra, A. Incidence of Major Insect Pests in Important Bamboo Species and Management of Ghoon Borers. Master’s Thesis, Department of Natural Resource Management, OUAT, Bhubaneswar, India, 2022. [Google Scholar]

- Takudzwa, N.; Varaidzo, G.O.; Tatenda, R.J.; Edmore, G.; William, M.; Elizabeth, N. Efficacy of Trichoderma harzianum as a biological control agent against Fusarium oxysporum in tomatoes (Solanum esculentum L.). Food Agri Econ. Rev. (FAER) 2022, 2, 7–11. [Google Scholar] [CrossRef]

- Hikal, W.M.; Baeshen, R.S.; Said-Al Ahl, H.A.H. Botanical insecticide as simple extractives for pest control. Cogent Biol. 2017, 3, 1404274. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhao, M.; Qin, H.; Li, S.; Yang, X. Genome-wide analysis of NBS-LRR genes revealed contribution of disease resistance from Saccharum spontaneum to modern sugarcane cultivar. Front. Plant Sci. 2023, 14, 1091567. [Google Scholar] [CrossRef]

- Zheng, C.; Yang, Q.; Wang, X.; Chen, Y.; He, R.; Li, X.; Pan, H.; Zhuo, R.; Qu, T.; Qiu, W. Transcription Factors Involved in Plant Stress and Growth and Development: NAC. Agronomy 2025, 15, 949. [Google Scholar] [CrossRef]

- Peng, Z.; Lu, Y.; Li, L.; Zhao, Q.; Feng, Q.I.; Gao, Z.; Lu, H.; Hu, T.; Yao, N.; Liu, K. The draft genome of the fast-growing non-timber forest species Moso bamboo (Phyllostachys heterocycla). Nat. Genet. 2013, 45, 456–461. [Google Scholar] [CrossRef]

- Liu, J.; Cheng, Y.; Ruan, M.; Ye, Q.; Wang, R.; Yao, Z.; Zhou, G.; Liu, C.; Wan, H. Phylogenetic, Structural, and Evolutionary Insights into Pepper NBS-LRR Resistance Genes. Int. J. Mol. Sci. 2025, 26, 1828. [Google Scholar] [CrossRef]

- Wang, G. Two Roads to Lignin: Uncovering the Role of C4H in Rice Lignification; Oxford University Press: New York, NY, USA, 2025. [Google Scholar]

- Dutta, S.; Biswas, P.; Chakraborty, S.; Mitra, D.; Pal, A.; Das, M. Identification, characterization and gene expression analyses of important flowering genes related to photoperiodic pathway in bamboo. BMC Genom. 2018, 19, 190. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, J.; Meng, Y.; Li, Z.; Fei, B.; Das, M.; Jiang, Z. Bamboo and rattan: Nature-based solutions for sustainable development. Innovation 2022, 3, 100337. [Google Scholar] [CrossRef]

- Sherpa, T.; Kumari, K.; Jha, D.K.; Tripathy, M.K.; Dey, N. CRISPR/Cas Based Genome Editing and Its Possible Implication in Bamboo Research. In Genetics, Genomics and Breeding of Bamboos; CRC Press: Boca Raton, FL, USA, 2023; pp. 338–353. [Google Scholar]

- Ahmad, Z.; Teixeira da Silva, J.A.; Shahzad, A.; Lin, S.; Ding, Y.; Ramakrishnan, M. Biotechnological interventions in bamboo plants. Plant Cell Tissue Organ Cult. (PCTOC) 2023, 153, 459–487. [Google Scholar] [CrossRef]

- FAO. Agricultural Production Statistics 2000–2020; FAO: Rome, Italy, 2022; ISSN 2709-0078. [Google Scholar]

- Zhao, H.; Zhao, S.; Fei, B.; Liu, H.; Yang, H.; Dai, H.; Wang, D.; Jin, W.; Tang, F.; et al.; International Network for Bamboo and Rattan Announcing the Genome Atlas of Bamboo and Rattan (GABR) project: Promoting research in evolution and in economically and ecologically beneficial plants. GigaScience 2017, 6, gix046. [Google Scholar] [CrossRef]

- Aizuddin, K.; Lai, K.-S.; Baharum, N.A.; Yong, W.T.L.; Hoon, L.N.; Hamid, M.Z.A.; Cheng, W.H.; Abdullah, J.O. Bamboo for biomass energy production. Bioresources 2023, 18, 2386–2407. [Google Scholar] [CrossRef]

- Germain, N.M.; Khumalo, S.M.; Pearl, M.T.; Sphesihle, M.; Tshibangu, M.M.; Kapuku, B.J. Valorization of Lignocellulosic Biomass to Biofuel: A Systematic Review. ChemEngineering 2025, 9, 58. [Google Scholar] [CrossRef]

- Chilton, K.; Kadivar, M.; Hinkle, H. From Problems to Possibilities: Overcoming Commercialization Challenges to Scale Timber Bamboo in Buildings. Sustainability 2025, 17, 1575. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, H.; Lu, Y.-Y.; Ren, Z.-Q.; Gao, N.; Wang, J.-J.; Huang, B.-C.; Jin, R.-C. In-situ synthesis of lanthanum-coated sludge biochar for advanced phosphorus adsorption. J. Environ. Manag. 2025, 373, 123607. [Google Scholar] [CrossRef]

| Property | Bamboo | Timber (Hardwood) | Steel | Plastic | References |

|---|---|---|---|---|---|

| Density (kg/m3) | 600–800 | 500–900 | ~7850 | 900–970 | [12,24] |

| Tensile strength (MPa) | 140–370 (age & species dependent) | 40–100 | 400–550 (mild steel) | 20–40 | [24,25] |

| Compressive Strength (MPa) | 40–80 | 30–70 | 250–500 | 5–20 | [26,27,28] |

| Elastic Modulus (GPa) | 10–30 | 8–14 | ~200 | 0.8–1.5 | [25,29] |

| Carbon Sequestration (t C/ha) | Up to 259 | 50–150 | None | None | [30,31,32] |

| Renewability | Fast (3–5 years) | Slow (10–30 years) | Non-renewable | Non-renewable | [33,34] |

| Biodegradability | Biodegradable (untreated) | Biodegradable | Non-biodegradable | Non-biodegradable | [35,36] |

| Recyclability | Emerging (e.g., biochar, composites) | Limited | High | Limited | [35,37] |

| Flammability | High (untreated) | Moderate (moisture-dependent) | Non-flammable | Highly flammable | [36,38] |

| Cost (USD/ton) | 80–120 (species/region dependent) | 150–250 | 500–1000 | 1000–1500 | [39] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, Z.; Kumari, R.; Mir, B.; Saeed, T.; Firdaus, F.; Vijayakanth, V.; Keerthana, K.; Ramakrishnan, M.; Wei, Q. Bamboo for the Future: From Traditional Use to Industry 5.0 Applications. Plants 2025, 14, 3019. https://doi.org/10.3390/plants14193019

Ahmad Z, Kumari R, Mir B, Saeed T, Firdaus F, Vijayakanth V, Keerthana K, Ramakrishnan M, Wei Q. Bamboo for the Future: From Traditional Use to Industry 5.0 Applications. Plants. 2025; 14(19):3019. https://doi.org/10.3390/plants14193019

Chicago/Turabian StyleAhmad, Zishan, Ritu Kumari, Bilal Mir, Taiba Saeed, Fatima Firdaus, Venkatesan Vijayakanth, Krishnamurthi Keerthana, Muthusamy Ramakrishnan, and Qiang Wei. 2025. "Bamboo for the Future: From Traditional Use to Industry 5.0 Applications" Plants 14, no. 19: 3019. https://doi.org/10.3390/plants14193019

APA StyleAhmad, Z., Kumari, R., Mir, B., Saeed, T., Firdaus, F., Vijayakanth, V., Keerthana, K., Ramakrishnan, M., & Wei, Q. (2025). Bamboo for the Future: From Traditional Use to Industry 5.0 Applications. Plants, 14(19), 3019. https://doi.org/10.3390/plants14193019