Abstract

The utilization of plant biostimulants has gained importance as a strategy by which to improve plant productivity and soil health. Two independent trials were conducted across two seasons (2021 and 2023) to evaluate the effects of foliar or soil applications of various commercial organo-mineral fertilizers (Futuroot®, Radicon® Amifort®) with biostimulant action that is exerted on yield and fruit characteristics of processing tomato crops (cv Taylor F1) that have been exposed to mineral macronutrients. These treatments were administered three times during the season: at the transplanting, pre-flowering and berry development stages. In the first trial, conducted in two fields characterized respectively by low and high fertility, foliar applications of Radicon®, which is based on humic acid and amino acids, increased the leaf greenness index SPAD compared with the control. Furthermore, the leaf green colour intensity (SPAD index), measured during the reproductive phases of the tomato exhibited a positive correlation (R2 = 0.726) with the marketable yield obtained. This increase in marketable yield was significant in the biostimulant treatment compared with the control in both soils, especially in the soil characterized by lower fertility (16.1%), when compared with the more fertile soil (6.8%). In the second trial, conducted in the low-fertility field mentioned above, soil applications of all biostimulants (Futuroot®, Radicon® and the combinations [Radicon® + Amifort-Plus®]) significantly increased the marketable yield by 27.8%, 13.5% and 27.7%, respectively, compared with the control. The most significant beneficial effects of both Futuroot® and [Radicon® + Amifort®] could be attributed to the combination of humic acids and auxins, cytokinins or microelements (Zn, Mn, MgO) present in the formulation of these products. Furthermore, the increase in marketable yield obtained when Radicon® was applied to leaves was higher (16.1%) than that observed with soil application (13.5%). In both trials, no relevant effects of biostimulant products were observed on most of the physicochemical characteristics of tomato fruits. In conclusion, the biostimulants based on humic acid and amino acids combined with chemical fertilizers tested in the present study and applied by fertigation were more effective in improving tomato yield, and therefore they can be recommended for efficient agricultural production.

1. Introduction

Tomato (Lycopersicon esculentum Mill.) is the vegetable crop with the highest demand and greatest economic value worldwide. Therefore, it is one of the most cultivated horticultural crops globally [1]. In 2022, the annual world tomato yield reached 186.821 million metric tonnes over a cultivated area of 4,917,735 hectares [2]. In the province of Foggia, the cultivation of processing tomatoes holds the Italian record, covering an area of over 15,000 hectares and boasting a production of approximately 1.425 million tons. This represents 89% and 25% of Apulian and national production, respectively [3].

The current method of fertilizing tomato in mineral intensive forms of agriculture primarily relies on the application of chemical fertilizers, rather than organic. As a result, most soils are deficient in organic matter [4]. Therefore, the integration of inorganic chemical fertilizers with sources of organic fertilization, such as organo-mineral fertilizers with biostimulant action, becomes crucial. These agricultural biostimulants (Abs) are commercial products based on a wide range of compounds, including humic and fulvic acids, hydrolysed protein and nitrogen-containing compounds, seaweeds and plant extracts, chitosan and other biopolymers, and beneficial microorganisms [5,6]. Biostimulants are becoming increasingly significant in agriculture, being considered environmentally sustainable and economically favourable solutions to the optimization of crop productivity. In recent time they have become an increasingly popular tool as a source of plant nutrition, either as an alternative to synthetic fertilizers or in conjunction with them. Their effects are still largely unknown today, but they typically have a positive effect on plants [7,8,9]. Their action on plants is exerted through several mechanisms, including hormone-like activity production, enhancement of photosynthesis, and the promotion of plant–soil microorganism activity [10,11]. Furthermore, given the value consumers place on hedonic measures of fruits and vegetables, there is interest in strategies that farmers can use to improve these quality measures of their tomato fruits [12]. Particularly, amino acid and humic acid compounds, derived from the decomposition of plant and animal substances, play a significant role in optimizing the physical and biological properties of agricultural soils, managing nutrient availability and improving the growth and metabolism of some plants [13,14]. The current use of these substances, initially applied exclusively to the soil, now includes foliar application [15,16,17], with the aim of stimulating natural processes that enhance nutrient absorption and utilization efficiency [18]. Their action on soil nutrient availability and uptake has been attributed to several mechanisms affecting soil processes and plant physiology [15,19,20,21]. Furthermore, their effectiveness is highly influenced by soil fertility conditions and is pronounced under conditions of poor fertility and low organic matter content [5]. Numerous studies conducted on tomato crops in a controlled environment or pods [22,23,24,25,26,27,28,29,30,31,32] have reported positive influenced on yield and on morphological and physiological parameters. However, reports on the potential of biostimulants in the field are less explored. This is mainly due to the variety of underlying factors in crop fields, including weather variability, climate fluctuations, soil type, and field management [14]. Furthermore, the application of biostimulants has recently been extensively studied on tomato crops under abiotic stress conditions (temperature, drought, salinity, nutrition) to enhances growth, improve yield and quality, and minimize the negative effects of stress [23,33,34,35,36,37,38]. Several studies have also been conducted under mineral nutritional conditions [17,39,40], but comparative research on fields of different levels of fertility is lacking.

The aim of this research was to evaluate the potential use of different organo-mineral fertilizers, mainly based on humic acids and amino acids, applied via foliar or soil fertigation, on the yield and characteristics of the fruit of processing tomatoes grown in two soils with different fertility levels, under a standard level of synthetic fertilizer.

2. Materials and Methods

The research was structured as shown in Table 1.

Table 1.

Articulation of the research.

2.1. Site Description and Experimental Setup

Two open-field separate trials were conducted in Foggia province (Apulia region, southern Italy) to assess the efficacy of various organo-mineral fertilizers with biostimulant properties on processing tomato crops (cv Taylor F1). This cultivar, provided by Nunhems Italia–BASF Electrical Seeds and belonging to the pear-shaped fruit type, is commonly grown in the agricultural areas in which the experiments took place. Prior to transplanting, a biodegradable black mulching film (15 µm thick MaterBi®, Novamont, Novara, Italy) was manually placed on each row.

The first trial (named “Trial A”) was conducted in 2021, in two separate farms: Croella (41°26′53.1″ N; 15°35′31.1″ E; 41 m a.s.l) (Field 1) and Palumbo (41°24′11.6″ N; 15°40′47.3″ E; 41 m a.s.l) (Field 2), approximately 3 km apart.

The second trial (named “Trial B”) was carried out in 2023, in the same Croella farm (Field 1).

The soils in these farms are clayey vertisol of alluvial origin (1.20 m depth) (Typic Chromoxerert, fine, thermic, according to the Soil Taxonomy–USDA–NRCS [41]). Table 2 presents the main physico-chemical characteristics of surface soil, indicating differences between the two farms. The average percentage of sand was higher in Field 1 (36.8%) than in field 2 (18.9%), while clay and silt were higher in field 2 (45.1 and 36.0%, respectively) than in Field 1 (30.5 and 32.7%, respectively). Therefore, the textural class of the first soil was clay–loam, while the second soil was clay. Furthermore, although overall the chemical fertility of both soils is classified as well endowed, Field 1 had a slightly lower nutritional content (organic matter = 1.4%, N = 1.5‰, P2O5 = 56 mg kg−1, K2O = 1390 mg kg−1) and higher Ca (3128 mg kg−1) compared with field 2 (organic matter = 1.7%, N = 2.1‰, P2O5 = 75 mg kg−1, K2O = 1640 mg kg−1, Ca = 3008 mg kg−1).

Table 2.

Main physico-chemical characteristics of the soils at the two experimental fields.

In “Trial A”, tomato seedlings were transplanted on 20 April and harvested on 30 August in both fields. Radicon® [42], a commercial organo-mineral fertilizer, was applied in each field by foliar spraying. This product is a non-microbial biostimulant that can be included in the class of humic and amino acid substances. The treatments were applied three times during the growing season (at transplantation, pre-flowering and enlargement of berry fruit development), compared with a control (no biostimulants added). The plants were sprayed until runoff, in conditions of low evapotranspiration demand (relative humidity: >70%; air temperature: <25 °C; wind speed: <8 km/h), typical of the early morning and late evening hours. This timing was chosen as the water in the solution in which the biostimulant is dissolved tends to evaporate slowly, thereby increasing the absorption of bioactive substances.

In “Trial B” tomato seedlings were transplanted at a later period than 2021 (on 20 May 2023) due to a prolonged period of rain that occurred in April and early May of this year (see Section 2.2), while the harvest took place on 12 September. Three commercial organo-mineral fertilizers were applied by fertigation as follows: Futuroot® [Nutribiotech Srl] [43]; Radicon® (Fertek) [42]; combinations of [Radicon® + Amifort-Plus®] (Fertek). Similar to “Trial A”, these treatments were carried out in three waterings during the tomato crop cycle (at transplant, in pre-flowering and berry development), compared with the untreated control (Table 3).

Table 3.

Formulations and doses of foliar e/o fertigation application of agricultural biostimulant products used in the experiments.

In both trials, tomato seedlings (with 4–5 leaves and 100–150 mm height) were manually transplanted in the field in mulched paired rows (40 cm apart) spaced 180 cm apart, with the plants at a distance of 30 cm from each other along each single row, reaching a density of 3.7 plants m−2. Drip irrigation was used with lines between each pair of plant rows under the black plastic mulch. The crop was fully irrigated, meeting 100% of the crop evapotranspiration (ETC) calculated daily using the Doorembos and Pruitt equation [44]: ETc = EV × Kc(EV), where ETc is the maximum daily crop evapotranspiration (mm), EV is the class A pan evaporation (mm), and Kc(EV) is the crop coefficient referred to the class A evaporation pan, and the values of which depend on the growth stage of the plant (the values vary between 0.35 and 1.06). The Kc(EV) values used in this study were 0.35 for the transplanting–rooting phase, 0.6 for the vegetative growth phase, 0.95 for the flowering phase, 1.07 for the fruit set, and 0.7 for the final phase [45]. Each irrigation was applied so as to maintain an interval of 3–4 days and was stopped 10 days before harvest. Applied irrigation volumes were measured using a water meter. Chemical fertilizers were used to meet the nutritional demands of crops based on the Apulia Region Fertilization Guide [46]. The nutrient needs were calculated: for pre-transplant fertilization, 35 kg ha−1 N and 70 kg ha−1 P2O5 were applied, while, during the tomato crop cycles, 75 kg ha−1 N and 100 kg ha−1 P2O5 were added by fertigation. Weed and pest control, and other agricultural managements employed were those commonly adopted by local farmers (weed control is carried out mechanically).

The experimental design in both “Trials” was a randomized block with three replications, and each treatment was compared in plots of 20 m2.

2.2. The Climate

The research site had a typical semi-arid area with a Mediterranean climate characterized as an accentuated thermo-Mediterranean climate [47], and further by the strong speed wind. The temperatures in this region can range from below 0 °C in winter to exceeding 40 °C in summer. The precipitation is unevenly distributed throughout the year, with the majority concentrated in the winter months, resulting in a long-term annual average of 559 mm [48]. Daily climate parameters, including maximum and minimum temperatures, wind speed and total precipitation, during the two growing seasons, were recorded from the weather station closest to the experimental area, provided by Syngenta [49], while evaporation from the class A pan evaporimeter (EV) was measured at the Croella farm. Table 4 outlines the climate conditions for the 2021 and 2023 seasons. The weather conditions between the two seasons were quite different. In fact, although the maximum and minimum temperatures for both seasons were similar (average of 29.9 °C and 14.3, respectively, in 2021, and 29.4 °C and 15.3, respectively, in 2023), in particular the month of July 2023, which saw an average maximum temperature that was much warmer (37.9 °C) compared with 2021 (35.4 °C). The average daily wind speed varied between 3.3 and 4.3 m s−1. Furthermore, in 2023, prolonged rainfall was recorded in the months of April and early May (66.2 and 73.6 mm, respectively) which, as previously mentioned, delayed the transplanting of tomato seedlings (Table 4).

Table 4.

Average monthly maximum and minimum temperatures (Tmax, Tmin), wind speed (Ws), total precipitation (P), total evaporation from the class A pan evaporimeter (EV) and average crop coefficient referring to the class A pan evaporation (Kc(EV)) for the 2021 and 2023 seasons.

2.3. Leaf Green Color Intensity (SPAD)

In “Trial A”, the leaf green colour intensity (SPAD) was measured during the reproductive phase of the tomato on three days: 1, 8 and 28 June 2021 (a respective 42, 49 and 69 days after transplanting (DAT) in Field 1, and 28, 35, and 55 DAT in Field 2). The SPAD, an indirect measurement index of chlorophyll, was taken from the youngest fully expanded leaves, using a SPAD-502 portable chlorophyll meter (Konica-Minolta corporation, Ltd., Osaka, Japan). Ten leaves per plot were randomly measured to obtain an average of 20 readings (10 on each side of the leaf) per plot.

2.4. Harvesting, Fruit Collection, Yield and Fruit Qualitative Analysis

At tomato harvest, on a 6 m2 sampling area, the following yield components were evaluated: marketable yield (t ha−1), unmarketable yield (t ha−1) (green fruits and rotten fruits) and green plant biomass (t ha−1). On a sample of 10 marketable fruits from each plot, the following quality parameters were measured: mean fresh weight (Wm; g), fruit length (L; mm), fruit width (W; mm), dry-matter content (DM; % fruit fresh matter); soluble solids content (SSC; °Brix), pH, titratable acidity (TA; g citric acid per 100 mL−1 fresh juice) [50] and a*/b* ratio (CI) [51].

The colour parameters were measured using a spectrophotometer (CM-700d; Minolta Camera Co., Ltd., Osaka, Japan) as the CIELAB coordinates (i.e., L*, a*, b*) on four randomly selected areas of the fruit surface. Only the a*/b* ratio has been reported, which represents an index that describes the colour differences of tomato fruit [52,53]. The total phenol content was determined according to the method of Singleton and Rossi [54] and expressed as mg gallic acid equivalents (mg GAE/g dw). Lycopene content was analysed by HPLC on a reversed-phase C30 column and binary gradient made of a methanol/water solution and dichloromethane [55] and expressed as mg/100 g fw.

2.5. Statistical Analysis

The measured data from SPAD and from each of the continuum variables relating to the qualitative/quantitative traits of the tomato fruit were processed using analysis of variance (ANOVA) performed with JMP® software version 8 (SAS Institute Inc., Cary, NC, USA). Average values were compared using Tukey’s test with a degree of confidence of 95% (p < 0.05). Standard deviations (SD) were calculated using Excel software from the Office 2007® suite (Microsoft Corporation, Redmond, WA, USA). Percentage values were transformed to arcsine before conducting the analysis of variance.

3. Results

3.1. Trial A: Fields 1 and 2

3.1.1. SPAD Index, Yield and Fruit Quality

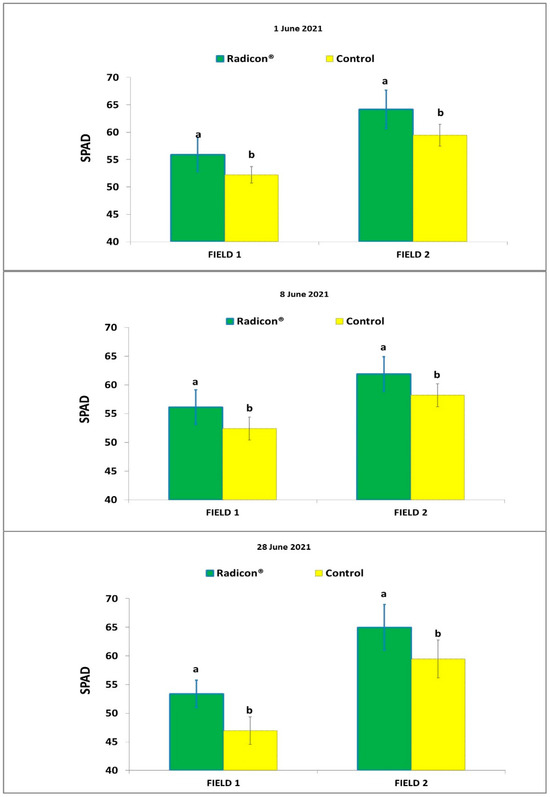

SPAD readings over three days during the tomato crop cycle (Figure 1) were significantly higher for plants supplied with Radicon® (average 55.3 in Field 1 and 63.8 in Field 2) than those of the control (average 49.8 in Field 1, and 58.0 in Field 2).

Figure 1.

Average SPAD values ± std. dev. detected on 1, 8 and 28 June 2021, on tomato plants treated with biostimulant and the untreated control grown in Fields 1 and 2. Different letters indicate significant differences at p < 0.05, according to Tukey’s test.

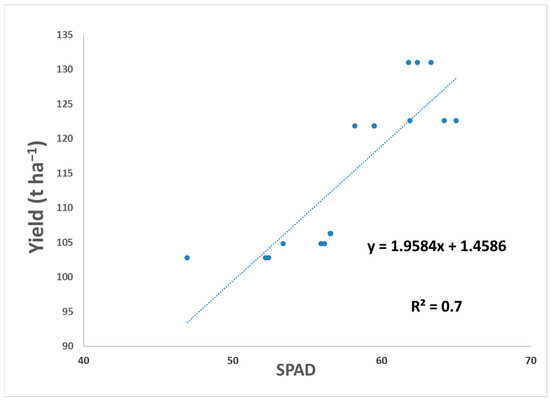

Furthermore, as seen in Figure 2, a linear relationship was found between the SPAD index and marketable yield (R = 0.726), where the increase in yield was directly related to the increase in SPAD values.

Figure 2.

Linear SPAD index—marketable yield ratio obtained for biostimulant-treated and untreated control tomato crops grown in both Fields 1 and 2.

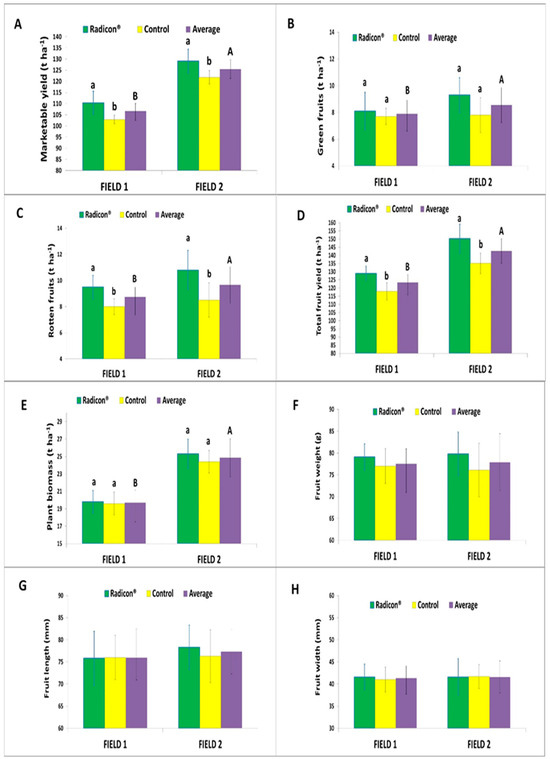

The impact of the biostimulant Radicon® on the quantitative and qualitative components of the tomato crops’ yield is shown in Figure 3. In both Fields 1 and 2, significantly higher marketable yields were observed with the biostimulant treatment (averaging 119.4 and 129.1 t ha−1, respectively) compared with the controls (averaging 102.8 and 120.8 t ha−1, respectively). Thus, foliar application of Radicon® increased marketable yield by 16.1% in Field 1 and 6.8% in Field 2 compared with controls. However, the marketable yield, on average, was greater in the fertile Field 2 (125.0 t ha−1) than in Field 1 (111.1 t ha−1).

Figure 3.

Effect of biostimulant treatment and control on (A) marketable yield, (B) green fruits, (C) rotten fruits, (D) total yield, (E) plant biomass, (F) fruit weight, (G) fruit length, and (H) fruit width. Average values ± std. dev. of biostimulant treatment and control in each field and the relative average of two fields are shown (different lowercase letters per field and different capital letters between fields each indicate significant differences at p < 0.05). Graph without letters means there were no significant differences between mean.

For both green and rotten fruits, no significant differences were found between the treatment and control in both Fields 1 and 2. However, the average values were significantly higher in Field 2 (8.7 and 10.1 t ha−1, respectively) compared with Field 1 (7.9 and 9.1 t ha−1 respectively.)

Similar differences were observed for the total fruit yield, with significantly higher yields in both Fields 1 and 2 with Radicon® treatment (on average 137.0 and 149.2 t ha−1, respectively) than the control (averaging 119.2 and 138.1 t ha−1, respectively).

No significant differences were found in plant biomass between the biostimulant treatment and control in both Fields 1 and 2 (on average 22.2 t ha−1), but higher mean values were observed in Field 2 (averaging 24.8 t ha−1) compared with Field 1 (averaging 19.7 t ha−1).

Regarding the weight, length and width of fruits, statistical differences were noted neither between the biostimulant treatment and control, nor between fields (on averaging 77.7 g, 76.6 mm, 41.4 mm, respectively). Notably, fruit weight in both fields was slightly higher in the treated crop (on averaging 79.4 g) compared with the control (averaging 76.5 g) (Figure 3).

3.1.2. Physico-Chemical Parameters of the Fruit

Table 5 shows the mean values for the qualitative physico-chemical characteristics of the processing tomato fruit concerning the Radicon® treatment and the control at the two separate fields.

Table 5.

Average values for the fruit chemical–physical parameters of the tomato crops treated with biostimulant by foliar application and the control at Fields 1 and 2 (“Trial A”, 2021 season).

The fruit parameters—SSC, TA, pH, DM, total phenols, lycopene and colour index (CI)—showed no statistically significant differences between either of the two biostimulant treatments and control nor between fields. The mean values varied between 4.1 and 4.4 °Brix for SSC, 0.39 and 0.41 g citric acid 100 mL−1 juice for TA, 4.21 and 4.34 for pH, 5.5 and 6.1% for DM, 2.21 and 2.30 mg GAE/g dw for total phenols, 0.80 and 0.91 mg/g fw for lycopene, and 0.95 and 1.18 for the colour index (a*/b* ratio).

However, it should be noted that the values for DM and lycopene tended to be higher with Radicon® treatment (averaging 6.0% and 0.90 mg/g fw) compared with control (averaging 5.5% and 0.83 mg/g fw).

3.2. Trial B (2023 Season)

3.2.1. Yield and Fruit Quality

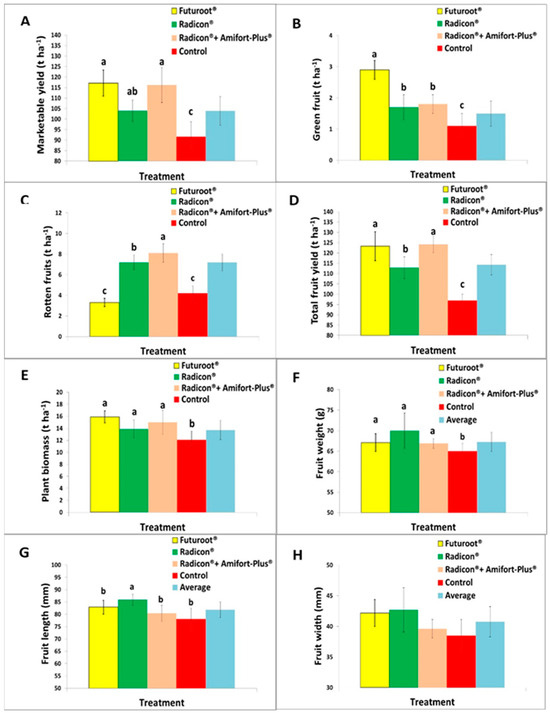

Figure 4 illustrates the impact of biostimulant treatments with Futuroot®, Radicon® and the combination of [Radicon® + Amifort®] on quantitative and qualitative components of yield. The average marketable yield showed significantly higher values for both Futuroot® (117.1 t ha−1) and [Radicon® + Amifort®] (116.2 t ha−1) compared with Radicon® (104.0 t ha−1), which, in turn, was significantly higher than the control (96, 9 t ha−1). Thus, soil application of Futuroot®, [Radicon® + Amifort®], and Radicon® increased the average marketable yield by 27.8%, 27.7% and 13.5%, respectively, over the controls.

Figure 4.

Effect of biostimulant treatments and control on (A) marketable yield, (B) green fruits, (C) rotten fruits, (D) total yield, (E) plant biomass, (F) fruit weight, (G) fruit length, and (H) fruit width. Average values ± std. dev. of biostimulant treatments and control are shown (different lowercase letters indicate significant differences at p < 0.05). Graph without letters means there were no significant differences between mean.

Green fruits at harvest were significantly higher in the Futuroot® (2.9 t ha−1) compared with both Radicon® (1.7 t ha−1) and [Radicon® + Amifort®] (1.8 t ha−1) treatments, which, in turn, were significantly higher than the control (on average 1.1 t ha−1). Furthermore, rotten fruits were significantly higher in the [Radicon® + Amifort®] (8.1 t ha−1) than Radicon® (7.2 t ha−1), which, in turn, were significantly higher than both Futuroot® (3.8 t ha−1) and the control (4.2 t ha−1). Similar to the marketable yield, the total fruit yields obtained in both Futuroot® (123.3 t ha−1) and [Radicon® + Amifort®] (128.1 t ha−1) were significantly higher than Radicon® (112.9 t ha−1), which, in the shift, was significantly higher than the control (112.6 t ha−1). Furthermore, plant biomass was also significantly higher in the [Radicon® + Amifort®] (15.9 t ha−1), Radicon® (13.9 t ha−1), and Futuroot® (t 15.0 t ha−1) treatments than the control (12.1 t ha−1).

Regarding the average weight of the fruits, although no difference was noted between the treatments (on average 68.1 g), they were significantly higher than the control (65.0 g).

Finally, concerning the length and width of the fruits, slightly higher values were detected for the biostimulant treatments (averaging 83.1 and 41.4 mm, respectively) compared with the control (averaging 78.1 and 38.5 mm, respectively) (Figure 4).

As regards the plant biomass, all biostimulant treatments provided values significantly higher (on average 15.0 t ha−1) than the control (13.7 t ha−1).

3.2.2. Physico-Chemical Parameters of the Fruit

None of the fruit physico-chemical parameters—SSC, TA, pH, DM, total phenols, lycopene and colour index (CI)—showed statistically significant differences between biostimulant treatments and control. The mean values varied between 4.90 and 5.17 °Brix for SSC, 0.30 and 0.31 g citric acid 100 mL−1 juice for TA, 4.66 and 4.74 for pH, 5.63 and 6.36% for DM, 2.30 and 2.41 mg GAE/g dw for total phenols, 0.80 and 0.91 mg/g fw for lycopene, and 1.03 and 1.17, for the colour index (a*/b*ratio) (Table 6).

Table 6.

Average values for the fruit physico-chemical parameters of the tomato crop treated with biostimulants applied by fertigation and the control (Trial B, 2023 season).

4. Discussion

To increase agriculture production, the application of chemical fertilisers is indispensable. However, intensive cultivation and monoculture have contributed to the widespread use of chemical fertilizers, leading to a decline in organic soil fertility [56]. This negative effect can be reduced by adopting new agricultural technological practices, including the application of soil biostimulants that improve soil organic matter and nutrient content [57].

The present study, consisting of two independent trials conducted in two different years (2021 and 2023), reports the results of three foliar or soil applications of different organo-mineral fertilizers with biostimulant action, given during the crop cycle, on the yield and quality of processing tomato (cv Taylor F1).

In Trial A (2021 season), the foliar application of Radicon®, containing humic and fulvic acids, was investigated on tomatoes grown in two soils with different physical-chemical fertility (Field 1: less fertile; Field 2: fertile).

The results show that the plants sprayed with Radicon® significantly increased the relative chlorophyll content, as measured by SPAD testing, in tomato leaves during plant development, compared with an untreated control. This result was similar to those obtained in a previous study on tomato in which a biostimulant composed of algae, fish and humus extracts [15] or two Chlorophyta microalgae [58] were used, but was different from another study [59] in which no effect was noted using two formulations obtained from A. nodosum. The SPAD assessment serves as a reliable indicator of photosynthetic activity, leaf nitrogen status and leaf chlorophyll content [60,61]; therefore, higher SPAD values reflect better plant health [62]. A linear positive relationship was found between the SPAD index and marketable yield (R = 0.726). This result is in line with that obtained by Nemeskéri et al., 2019 [63]. In this regard, our SPAD values are higher in plants grown in the field characterized by better fertility.

Plants treated with Radicon significantly increased tomato productivity in both soil conditions. These results are consistent with those recorded in previous studies [37,64,65] in which biostimulants based on humic acids were used on plants. Furthermore, the statistical analysis of the results reveal that, although the marketable yield, as a field average, was greater in the fertile soil (125.0 t ha−1) than in the less fertile one (111.1 t ha−1), significant increases were greater in less fertile soil (16.1%) than in fertile ones (6.8%). These results are in agreement with those recorded in previous studies [17,65,66]. In general, the yield increases obtained with the Radicon can be explained by the heavier fruit (79.4 g), although with values slightly higher than the control (76.5 g).

No relevant effects of Radicon® treatment on some quality attributes of tomato fruits (SSC, TA, pH, total phenols and CI) were observed. These results are in agreement with those found in previous research [64], but are in disagreement with others [32,67] in which the same parameters were improved by biostimulants.

As for DM and lycopene content, the average values tended to be higher in the biostimulant treatment (average 6.0% and 0.90 mg/g fw) compared with control (average 5.5% and 0.83 mg/g dw). In this regard it is known that high values of these parameters are also desirable characteristics for the canned tomato industry as it improves the quality of the processed product [32,53,68,69]. It is clear that the foliar application of Radicon® in tomato crop may be a practical option for achieving higher marketable yields and some quality attributes of tomato fruits, increasing the market value of the crop.

In Trial B (2023 season), the soil application of Futuroot®, Radicon®, and the combination of [Radicon® + Amifort-Plus®] in the same less fertile soil as that used in the first trial, significantly increased the marketable yield by 27.8%, 13.5% and 27.7%, respectively, compared with the control. Similar increases were obtained in total fruit yield by 27.2%, 16.5% and 28.1%, respectively, compared with the control. In general, these yield increases obtained in crops treated with biostimulants can be explained by the heavier fruits (on average 68.1 g) and/or the higher plant biomass (on average 15.0 t ha−1) compared with the control (on average, 65.0 g and (13.7 t ha−1, respectively).

Our yield increases are consistent with those recorded in previous studies [34,38,70] in which humic or protein hydrolysate-based biostimulant were added to the soil.

The best beneficial effect ascribed in the case of Futuroot® could be due not only to the humic acids but also to the auxins, cytokinins and microelements (Zn and Mn) present in it, and in the case of [Radicon® + Amifort Plus®] to the combined distribution of the humic acids present in Radicon® and the magnesium and n-chelated microelements (MgO) present in Amifort Plus®, which improved plant productivity. These results are in agreement with those found in previous research [71,72] where the application of Zn and chelated trace elements (MgO) significantly increased fruit yield in tomato. Furthermore, in the crop treated with Futuroot® the greatest weight of green fruits was recorded at harvest, indicating that not all the fruits of the last bunches were yet ripe on the plants slightly late in the ripening phase.

Finally, in this trial the physico-chemical parameters of the fruit (SSC, TA, pH, DM, total phenols, lycopene and CI) were statistically different neither among the biostimulant treatments nor between these and the control. In this regard, it is highlighted that the effects of different biostimulants on tomato quality obtained in the literature are very different from each other. These differences could be due to several factors, among which are the biostimulant composition [35] and the technique of their application (when and how to apply) [73,74], the tomato genotype used [17,70] and the climatic conditions, such as temperature [75].

From the comparison between the results obtained in Trials 1 and 2, it is highlighted that, in general, the final yield of the tomato, although at different levels, showed an increase with all of the biostimulant formulations used, when applied three times during the crop cycle both to the leaves and in the soil, when compared with the untreated control. Furthermore, it should be noted that, when Radicon® was applied alone in both experiments on the same Field 1, increases in marketable yield compared with the control were slightly higher with foliar application (16.1%) than with the soil application (13.5%). However, the soil application of Futuroot® or [Radicon® + Amifort-Plus®], containing not only biostimulant compounds but also microelements (Z, Mg, Mn), provided the best tomato yield.

Regarding the qualitative aspects, the following can be stated. Our data of DM (varied between 5.5% and 6.4%) SSS (varied between, and 4.3 °Brix and 5.2 °Brix) are in agreement with [76], which reports values ranging from 4 to 7% and from 3.3 °Brix to 5.5 °Brix, respectively, in a wide field experiment carried out in the Mediterranean basin aiming to compare the quality characteristics of 33 tomato genotypes. The average TA data varied between 0.39 and 0.45%, which is very close to the average acidity of processing tomatoes, which is generally around 0.35 [77]. The pH range values (4.21–4.74) were within the typical range of tomato fruits [78] and showed their slightly acidic nature.

The CI, which is commonly used as a quality redness index (brightness of red colour) of tomatoes was found in the range from 0.95 to 1.18, in agreement with the range from 0.95 to 1.21 observed by [79] on tomato fruits at the red stage of maturity.

Finally, as reported by Riga et al. [80], tomato quality is more dependent on temperature than on photosynthetically active radiation.

5. Conclusions

It should be considered that, unless part of the research concerns the comparison between the treatment with Radicon® conducted in the same field, it is not possible to draw unifying conclusions between the two trials conducted in different sites. However, for each of them the results provided very interesting indications. In general, biostimulant treatments through application of the Radicon® product by foliar or by fertigation increased the yield when compared with the untreated control, while slight effects were found on some qualitative attributes of tomato fruits. Furthermore, through the foliar application of the Radicon® product, the best production results were obtained in low fertility soil conditions and there was a significant increase in the total chlorophyll pigment content compared with the control. The soil application of Futuroot® or the combination [Radicon® + Amifort-Plus®) products containing not only biostimulant compounds but also auxins, cytokinins and microelements (Z, Mg, Mn), also increased yield compared with the untreated control, while slight effects were found on some qualitative attributes of tomato fruits. Furthermore, when also considering the higher production costs, Futuroot® or the combination of [Radicon® + Amifort-Plus®] applied to soil by fertigation are considered particularly optimal for regular use in conventional agricultural practices of processing tomato crop. Ultimately, the findings of this study, in terms of yield mentioned above, can be helpful to assist growers in the practice of fertilizing tomato crop and ensuring product quality for industrialists.

Author Contributions

Conceptualization, G.D. and L.F.; methodology, G.D. and L.F.; software, G.D., A.T. and L.F.; validation, G.D., A.T. and L.F.; formal analysis G.D., A.T. and L.F.; investigation, G.D. and L.F.; data curation, G.D. and L.F.; writing—original draft preparation, G.D., A.T. and L.F.; writing—review and editing, G.D. and L.F.; visualization, G.D. and L.F.; supervision, G.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Leogrande, R.; Lopedota, O.; Vitti, C.; Ventrella, D.; Montemurro, F. Saline water and municipal solid waste compost application on tomato crop: Effects on plant and soil. J. Plant Nutr. Soil. SC 2016, 39, 491–501. [Google Scholar] [CrossRef]

- FAOSTATS. 2022. Available online: https://www.fao.org/faostat/en/#search/almond (accessed on 23 March 2024).

- ISTAT. Electronic Information System on Agriculture and Livestock; Italian National Statistical Institute (ISTAT): Rome, Italy, 2023; Available online: http://agri.istat.it/ (accessed on 20 December 2023).

- Tarantino, E.; Frabboni, L.; Giuliani, M.M.; Gatta, G.; Disciglio, G.; Libutti, A.; Basso, G.; de Simone, G. Lotta alla Desertificazione; Prgetto: PLI Sez. 2.2–1.3 fase. G.A.L. “Piana del Tavoliere”; G.A.L. Cerignola: Cerignola, Italy, 2008; p. 81. ISBN 978-88-7427-015-6. [Google Scholar]

- du Jardin, P. Plant biostimulants: Definition, concept, main categories and regulation. Sci. Hortic. 2015, 196, 3–14. [Google Scholar] [CrossRef]

- Franzoni, G.; Cocetta, G.; Prinsi, B.; Ferrante, A.; Espen, L. Biostimulants on crops: Their impact under abiotic stress conditions. Horticulturae 2022, 8, 189. [Google Scholar] [CrossRef]

- Rouphael, Y.; Colla, G. Biostimulants in agriculture. Front. Plant Sci. 2020, 11, 40. [Google Scholar] [CrossRef]

- Weisser, M.; Mattner, S.W.; Southam-Rogers, L.; Hepworth, G.; Arioli, T. Effect of a Fortified Biostimulant Extract on Tomato Plant Productivity, Physiology, and Growing Media Properties. Plants 2024, 13, 4. [Google Scholar] [CrossRef] [PubMed]

- Toscano, S.; Romano, D.; Massa, D.; Bulgari, R.; Franzoni, G.; Ferrante, A. Biostimulant applications in low input horticultural cultivation systems. Italus Hortus 2018, 25, 27–36. [Google Scholar] [CrossRef]

- Hellequin, E.; Monard, C.; Chorin, M.; Daburon, V.; Klarzynski, O.; Binet, F. Responses of active soil microorganisms facing to a soil biostimulant input compared to plant legacy effects. Sci. Rep. 2020, 10, 13727. [Google Scholar] [CrossRef] [PubMed]

- Della Lucia, M.C.; Bertoldo, G.; Broccanello, C.; Maretto, L.; Ravi, S.; Marinello, F.; Sartori, L.; Marsilio, G.; Baglieri, A.; Romano, A.; et al. Novel effects of leonardite-based applications on sugar beet. Front. Plant Sci. 2021, 12, 646025. [Google Scholar] [CrossRef] [PubMed]

- Distefano, M.; Mauro, R.P.; Page, D.; Giuffrida, F.; Bertin, N.; Leonardi, C. Aroma volatiles in tomato fruits: The role of genetic, preharvest and postharvest factors. Agronomy 2022, 12, 376. [Google Scholar] [CrossRef]

- Delgado, A.; Madrid, A.; Kassem, S.; Andreu, L.; del Campillo, M.C. Phosphorusfertilizer recovery from calcareous soils amended with humic and fulvic acids. Plant Soil 2002, 245, 277–286. [Google Scholar] [CrossRef]

- Jindo, K.; Lopes Olivares, F.; da Paixão Malcher, D.J.; Sánchez-Monedero, M.-A.; Kempenaar, C.; Canellas, L.P. From Lab to field: Role of humic substances under open-Field and greenhouse conditions as biostimulant and biocontrol agent. Front. Plant Sci. 2020, 11, 426. [Google Scholar] [CrossRef] [PubMed]

- Halpern, M.; Bar-Tal, A.; Ofek, M.; Minz, D.; Muller, T.; Yermiyahu, U. The use of biostimulants for enhancing nutrient uptake. Adv. Agron. 2015, 130, 141–174. [Google Scholar] [CrossRef]

- Weber, J.; Chen, Y.; Jamroz, E.; and Miano, T. Preface: Humic substances in the environment. J. Soils Sediments 2018, 18, 2665–2667. [Google Scholar] [CrossRef]

- Klokić, I.; Koleška, I.; Hasanagić, D.; Murtić, S.; Bosančić, B.; Todorović, V. Biostimulants’ influence on tomato fruit characteristics at conventional and low-input NPK regime. Acta Agric. Scand. Sect. B Soil Plant Sci. 2020, 70, 233–240. [Google Scholar] [CrossRef]

- European Biostimulants Industry Council (EBIC). What Are Biostimulants? 2012. Available online: https://biostimulants.eu (accessed on 10 January 2024).

- Rouphael, Y.; Colla, G. Synergistic biostimulatory action: Designing the next generation of plant biostimulants for sustainable agriculture. Front. Plant Sci. 2018, 9, 1655. [Google Scholar] [CrossRef] [PubMed]

- Nardi, S.; Ertani, A.; Francioso, O. Soil–root cross-talking: The role of humic substances. J. Plant Nutr. Soil Sci. 2017, 180, 5–13. [Google Scholar] [CrossRef]

- Gerke, G. Review Article: The effect of humic substances on phosphate and iron acquisition by higher plants: Qualitative and quantitative aspects. J. Plant Nutr. Soil Sci. 2021, 184, 329–338. [Google Scholar] [CrossRef]

- Colla, G.; Cardarelli, M.; Bonini, P.; Rouphael, Y. Foliar applications of protein hydrolysate, plant and seaweed extracts increase yield but differentially modulate fruit quality of greenhouse tomato. HortScience 2017, 52, 1214–1220. [Google Scholar] [CrossRef]

- Gedeon, S.; Ioannou, A.; Balestrini, R.; Fotopoulos, V.; Antoniou, C. Application of biostimulants in tomato plants (Solanum lycopersicum) to enhance plant growth and salt stress tolerance. Plants 2022, 11, 3082. [Google Scholar] [CrossRef]

- Hamedani, S.R.; Rouphael, Y.; Colla, G.; Colantoni, A.; Cardarelli, M. Biostimulants as a tool for improving environmental sustainability of greenhouse vegetable crops. Sustainability 2020, 12, 5101. [Google Scholar] [CrossRef]

- Hernández-Herrera, R.M.; Santacruz-Ruvalcaba, F.; Ruiz-López, M.A.; Norrie, J.; Hernández-Carmona, G. Effect of liquid seaweed extracts on growth of tomato seedlings (Solanum lycopersicum L.). J. Appl. Phycol. 2014, 26, 619–628. [Google Scholar] [CrossRef]

- Sudiro, C.; Guglielmi, F.; Hochart, M.; Senizza, B.; Zhang, L.; Lucini, L.; Altissimo, A. A Phenomics and Metabolomics Investigation on the Modulation of Drought Stress by a Biostimulant Plant Extract in Tomato (Solanum lycopersicum L.). Agronomy 2022, 12, 764. [Google Scholar] [CrossRef]

- Niu, C.; Wang, G.; Sui, J.; Liu, G.; Ma, F.; Bao, Z. Scientia Horticulturae Biostimulants alleviate temperature stress in tomato seedlings. Sci. Hortic. 2022, 293, 110712. [Google Scholar] [CrossRef]

- Paul, K.; Sorrentino, M.; Lucini, L.; Rouphael, Y.; Cardarelli, M.; Bonini, P.; Miras Moreno, M.B.; Reynaud, H.; Canaguier, R.; Trtílek, M.; et al. Combined phenotypic and metabolomic approach for elucidating the biostimulant action of a plant-Derived protein hydrolysate on tomato grown under limited water availability. Front. Plant Sci. 2019, 10, 493. [Google Scholar] [CrossRef] [PubMed]

- Lucini, L.; Rouphael, Y.; Cardarelli, M.; Bonini, P.; Baffi, C.; Colla, G. A vegetal biopolymer-based biostimulant promoted root growth in melon while triggering brassinosteroids and stress-related compounds. Front. Plant Sci. 2018, 9, 472. [Google Scholar] [CrossRef] [PubMed]

- Abdelkader, M.M.; Gaplaev, M.S.; Terekbaev, A.A.; Puchkov, M.Y. The influence of biostimulants on tomato plants cultivated under hydroponic systems. J. Hortic. Res. 2021, 29, 107–116. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, H.; Wu, G.; Chen, X.; Gruda, N.; Li, X.; Dong, J.; Duan, Z. Dose dependent application of straw-derived fulvic acid on yield and quality of tomato plants grown in a greenhouse. Front. Plant Sci. 2021, 12, 736613. [Google Scholar] [CrossRef]

- Tallarita, A.V.; Vecchietti, L.; Golubkina, N.A.; Sekara, A.; Cozzolino, E.; Mirabella, M.; Cuciniello, A.; Maiello, R.; Cenvinzo, V.; Lombardi, P.; et al. Effects of plant biostimulation time span and soil electrical conductivity on greenhouse tomato ‘Miniplum’ yield and quality in diverse crop seasons. Plants 2023, 12, 1423. [Google Scholar] [CrossRef] [PubMed]

- Caradonia, F.; Ronga, D.; Flore, A.; Barbieri, R.; Moulin, Z.L.; Terzi, V.; Francia, E. Biostimulants and cherry rootstock increased tomato fruit yield and quality in sustainable farming systems. Ital. J. Agron. 2020, 15, 121–131. [Google Scholar] [CrossRef]

- Abdellatif, I.A.M.; Abdel-Ati, Y.Y.; Abdel-Mageed, Y.T.; Hassan, M.A.M. Effect of humic acid on growth and productivity of tomato plants under heat stress. J. Hortic. Res. 2017, 25, 59–66. [Google Scholar] [CrossRef]

- Liava, V.; Chaski, C.; Añibarro-Ortega, M.; Pereira, A.; Pinela, J.; Barros Spyridon, L.; Petropoulos, A. The effect of biostimulants on fruit quality of processing tomato grown under deficit irrigation. Horticulturae 2023, 9, 1184. [Google Scholar] [CrossRef]

- Bulgari, R.; Franzoni, G.; Ferrante, A. Biostimulants application in horticultural crops under abiotic stress conditions. Agronomy 2019, 9, 306. [Google Scholar] [CrossRef]

- Mona, H.; McKenna, A.M.; Fontain, R.; Lamar, R.T. Bioactivity of humic acids extracted from shale ore: Molecular characterization and structure-activity relationship with tomato plant yield under nutritional stress. Front. Plant Sci. 2021, 12, 660224. [Google Scholar] [CrossRef] [PubMed]

- Francesca, S.; Cirillo, V.; Raimondi, G.; Maggio, A.; Barone, A.; Rigano, M.M. Novel protein hydrolysate-based biostimulant improves tomato performances under dought stress. Plants 2021, 10, 783. [Google Scholar] [CrossRef] [PubMed]

- Disciglio, G.; Frabboni, L.; Tarantino, A.; Tarantino, E. Applying natural fertilizers to herbaceous crops. J. Life Sci. 2014, 8, 504–510. [Google Scholar]

- Disciglio, G.; Carlucci, A.; Tarantino, A.; Giuliani, M.M.; Gagliardi, A.; Frabboni, L.; Libutti, A.; Raimondi, M.L.; Lops, F.; Gatta, G. Effect of olive-mill wastewater application, organo-mineral fertilization, and transplanting date on the control of Phelipanche ramosa in open-field processing tomato crops. Agronomy 2018, 8, 92. [Google Scholar] [CrossRef]

- Soil Survey Staff, USDA. Soil Survey Staff, USDA. Soil Taxonomy: A Basic System of Soil Classification for Making and Interpreting Soil Surveys. In Agriculture Handbook, 2nd ed.; USDA: Washington, DC, USA, 1999; No. 436. Available online: https://www.nrcs.usda.gov/sites/default/files/2022-06/Soil%20Taxonomy.pdf (accessed on 20 December 2023).

- Fertek. Available online: https://www.fertek.it (accessed on 20 December 2023).

- Nutribiotech.Srl. Available online: https://www.nutribiotech.it (accessed on 20 December 2023).

- Doorembos, J.; Pruitt, W.O. Crop Water Requuirements; Paper No. 24; FAO Irrigation and Drainage: Rome, Italy, 1977; p. 144. [Google Scholar]

- Tarantino, E.; Caliandro, A. Water requirements and crop coefficients of different crops in Italy as related to the climatic characteristics and the growth stage. In Proceeding of International Conference on Crop Water Requirements, Paris, France, 11–14 September 1984. [Google Scholar]

- Disciplinare di Produzione Integrata Pomodoro da Industria. Regione Puglia. Boll. Uff. Della Reg. Puglia 2023, 19, 383.

- UNESCO/FAO. Bioclimatic Map of the Mediterranean Zone; Explanatory Notes, Arid Zone Research; UNESCO/FAO: Rome, Italy, 1963; Volume 2217, p. 26. [Google Scholar]

- Ventrella, D.; Charfeddine, M.; Moriondo, M.; Rinaldi, M.; Bindi, M. Agronomic adaptation strategies under climate change for winter durum wheat and tomato in southern Italy: Irrigation and nitrogen fertilization. Reg. Environ. Chang. 2012, 12, 407–412. [Google Scholar] [CrossRef]

- Syngenta. Center for Experimentation and Valorization of Mediterranean Crops—Foggia. Available online: https://www.syngenta.it/agrometeo (accessed on 20 December 2023).

- AOAC. Official Method of Analysis (No 934, 06); Association of Official Analytical Chemists (AOAC): Washington, DC, USA, 1990. [Google Scholar]

- Jimenez-Cuesta, M.; Cuquerella, J.; Martinez–Javaga, J.M. Determination of color index for citrus fruits degreening. Proc. Int. Soc. Citric. 1981, 2, 750–753. [Google Scholar]

- Francis, F.J.; Clydesdale, F.M. Food Colorimetry: Theory and Applications; AVI Publ. Co.: Westport, CT, USA, 1975; p. 477. [Google Scholar]

- Favati, F.; Lovelli, S.; Galgano, F.; Miccolis, V.; Di Tommaso, T.; Candido, V. Processing tomato quality as affected by irrigation scheduling. Sci. Hortic. 2009, 122, 562–571. [Google Scholar] [CrossRef]

- Singleton, V.; Rossi, J. Colorimetry of Total Phenolic Compounds with Phosphomolybdic-Phosphotungstic Acid Reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar] [CrossRef]

- De Sio, F.; Servillo, L.; Loiudice, R.; Castaldo, D. A Chromatographic procedure for the determination of carotenoids and chlorophylls in vegetable products. Acta Aliment. 2001, 30, 395–405. [Google Scholar] [CrossRef]

- Bisht, N.; Chauhan, N.P. Excessive and disproportionate use of chemicals cause soil contamination and nutritional stress. In Soil Contamination; InTech Open: London, UK, 2020. [Google Scholar] [CrossRef]

- Turan, M.E.; Kinci, M.; Argin, S.; Brinza, M.; Yildirim, E. Drought stress amelioration in tomato (Solanum lycopersicum L.) seedlings by biostimulant as regenerative agent. Front. Plant Sci. 2023, 14, 1211210. [Google Scholar] [CrossRef]

- Gitau, M.M.; Farkas, A.; Ördög, V.; Gergely Maróti, G. Evaluation of the biostimulant effects of two Chlorophyta microalgae on tomato (Solanum lycopersicum). J. Clean. Prod. 2022, 364, 132689. [Google Scholar] [CrossRef]

- Carmody, N.; Goñi, O.; Łangowski, Ł.; Connel, S.O. Ascophyllum nodosum extract biostimulant processing and its impact on enhancing heat stress tolerance during tomato fruit set. Front. Plant Sci. 2020, 11, 807. [Google Scholar] [CrossRef] [PubMed]

- Sim, C.C.; Rahman, Z.A.; Tan, M.S.; Goh, K. Rapid determination of leaf chlorophyll concentration, photosynthetic activity and NK concentration of elaies guineensis via correlated SPAD-502 Chlorophyll Index. Asian J. Agric. Res. 2015, 9, 132–138. [Google Scholar] [CrossRef]

- Jiang, C.; Johkan, M.; Hohjo, M.; Tsukagoshi, S.; Maruo, T.A. Correlation analysis on chlorophyll content and SPAD value in tomato leaves. Hortic. Res. 2017, 71, 37–42. [Google Scholar] [CrossRef]

- Singha, S.; Townsend, E. Relationship between chromaticity values and chlorophyll concentration in apple, grape, and peach leaves. Hortic. Sci. 1989, 24, 1034. [Google Scholar] [CrossRef]

- Nemeskéri, E.; Neményi, A.; Bőcs, A.; Pék, Z.; Helyes, L. Physiological factors and their relationship with the productivity of processing Tomato under different water supplies. Water 2019, 11, 586. [Google Scholar] [CrossRef]

- Yildirim, E. Foliar and soil fertilization of humic acid affect productivity and quality of tomato. Acta Agric. Scand. Sect. B Soil. Plant Sci. 2007, 57, 182–186. [Google Scholar] [CrossRef]

- Turan, M.; Yildirim, E.; Ekinci, M.; Argin, S. Effect of biostimulants on yield and quality of cherry tomatoes grown in fertile and stressed soils. Hortic. Sci. 2021, 56, 414–423. [Google Scholar] [CrossRef]

- Zuzunaga-Rosas, J.; Silva-Valdiviezo, D.; Calone, R.; Luput, I.; Ibáñez-Asensio, S.; Boscaiu, M.; Moreno-Ramón, H.; Vicente, O. Biochemical responses to salt stress and biostimulant action in tomato plants grown in two different soil types. Horticulturae 2023, 9, 1209. [Google Scholar] [CrossRef]

- Cozzolino, E.; Di Mola, I.; Ottaiano, L.; El-Nakhel, C.; Rouphael, Y.; Mori, M. Foliar application of plant-based biostimulants improve yield and upgrade qualitative characteristics of processing tomato. Ital. J. Agron. 2021, 16, 1825. [Google Scholar] [CrossRef]

- De Pascale, S.; Maggio, A.; Fogliano, V.; Ambrosino, P. Irrigation with saline water improves carotenoids content and antioxidant activity of tomato. J. Hortic. Sci. Biotechnol. 2001, 76, 447–453. [Google Scholar] [CrossRef]

- Shi, J.; Le Maguer, M. Lycopene in tomatoes: Chemical and physical properties affected by food process. Crit. Rev. Biotechnol. 2000, 20, 293–334. [Google Scholar] [CrossRef]

- Francesca, S.; Arena, C.; Hay Mele, B.; Schettini, C.; Ambrosino, P.; Barone, A.; Rigano, M.M. The use of a plant-based biostimulant improves plant performances and fruit quality in tomato plants grown at elevated temperatures. Agronomy 2020, 10, 363. [Google Scholar] [CrossRef]

- Gurmani, A.R.; Din, J.U.; Khan, S.U.; Andaleep, R.; Waseem, K.; Khan, A. Soil Application of zinc improves growth and yield of tomato. Int. J. Agric. Biol. 2012, 14, 91–96. Available online: http://www.fspublishers.org (accessed on 28 December 2023).

- Ahmed, R.; Uddin, K.; Quddus, A.; Samad, M.Y.A.; Haque, A.N.A. Impact of foliar application of zinc and zinc oxide nanoparticles on growth, yield, nutrient uptake and quality of tomaato. Horticulturae 2023, 9, 162. [Google Scholar] [CrossRef]

- Andreotti, C.; Rouphael, Y.; Colla, G.; Basile, B. Rate and timing of application of biostimulant substances to enhance fruit tree tolerance toward environmental stresses and fruit quality. Agronomy 2022, 12, 603. [Google Scholar] [CrossRef]

- Russo, M.; Di Sanzo, R.; Marra, F.; Carabetta, S.; Maffia, A.; Mallamaci, C.; Muscolo, A. Waste-derived fertilizer acts as biostimulant, boosting tomato quality and aroma. Agronomy 2023, 13, 2854. [Google Scholar] [CrossRef]

- Agbodjato, N.A.; Assogba, S.A.; Babalola, O.O.; Koda, A.D.; Aguégué, R.M.; Sina, H.; Dagbénonbakin, G.D.; Adjanohoun, A.; Baba-Moussa, L. Formulation of biostimulants based on arbuscular mycorrhizal fungi for maize growth and yield. Front. Agron. 2022, 4, 894489. [Google Scholar] [CrossRef]

- Turhan, A.; Seniz, V. Estimation of certain chemical constituents of fruits of selected under abiotic stress conditions. Agronomy 2019, 9, 306. [Google Scholar]

- Garcia, E.; Barret, D.M. Evaluation of processing tomato from two consecutive growing seasons: Quality attributes, peelability and yield. J. Food Process. Preserv. 2006, 30, 20–36. [Google Scholar] [CrossRef]

- Hong, J.H.; Mills, D.J.; Coffman, C.B.; Anderson, J.D.; Camp, M.J.; Gross, K.C. Tomato cultivation systems affect subsequent quality of fresh-cut fruit slices. J. Am. Soc. Hortic. Sci. 2000, 125, 729–735. [Google Scholar] [CrossRef]

- Batu, A. Determination of acceptable firmness and colour values of tomatoes. J. Food Eng. 2004, 61, 471–475. [Google Scholar] [CrossRef]

- Riga, P.; Anza, M.; Garbisu, C. Tomato quality is more dependent on temperature than on photosynthetically active radiation. J. Sci. Food Agric. 2008, 88, 158–166. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).