Date Palm Extract (Phoenix dactylifera) PEGylated Nanoemulsion: Development, Optimization and Cytotoxicity Evaluation

Abstract

1. Introduction

2. Results and Discussion

2.1. Estimation of Total Phenolic Content and Flavonoid Content

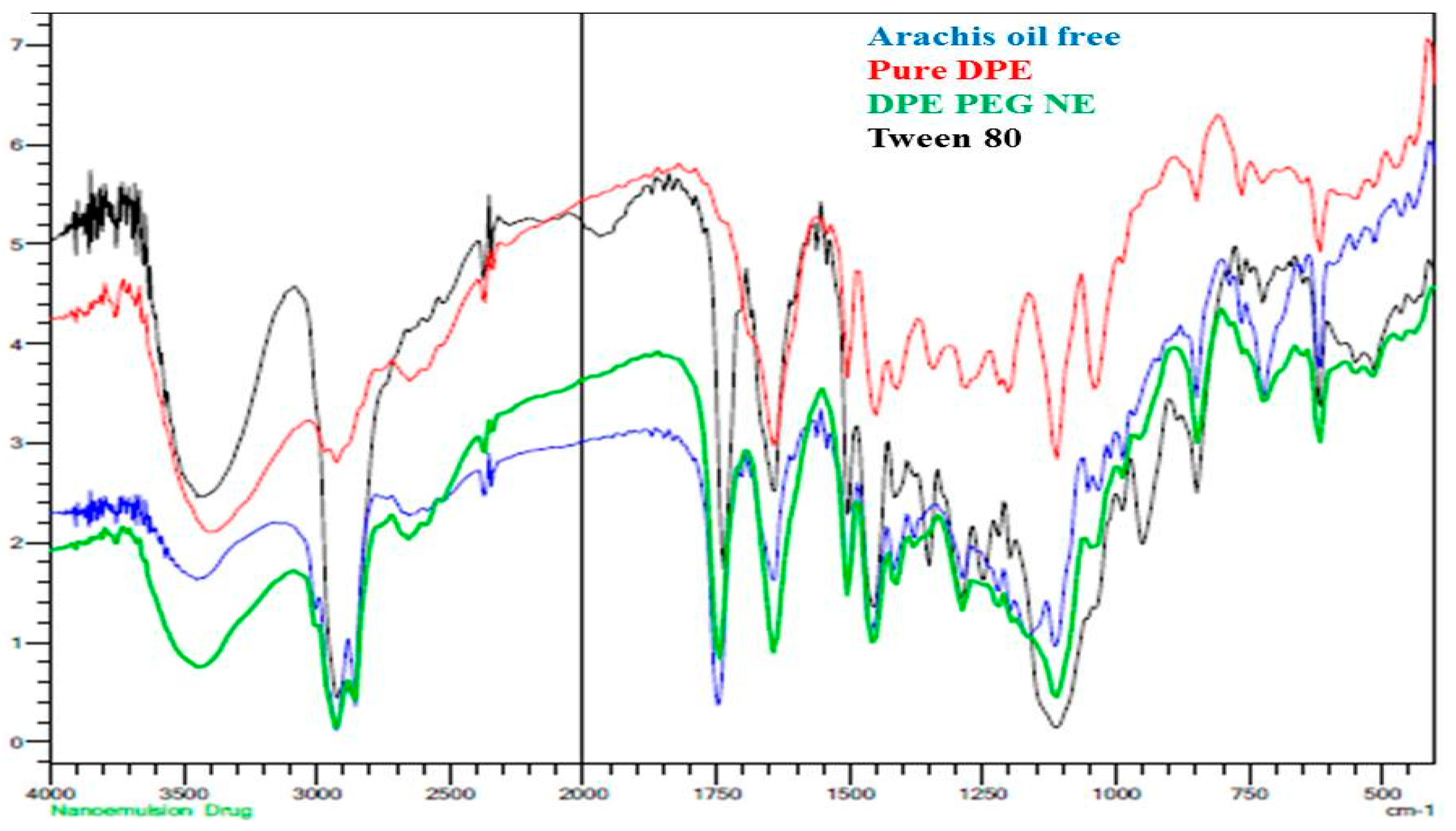

2.2. Determination of Drug-Excipient Compatibility Study (FTIR Characterization)

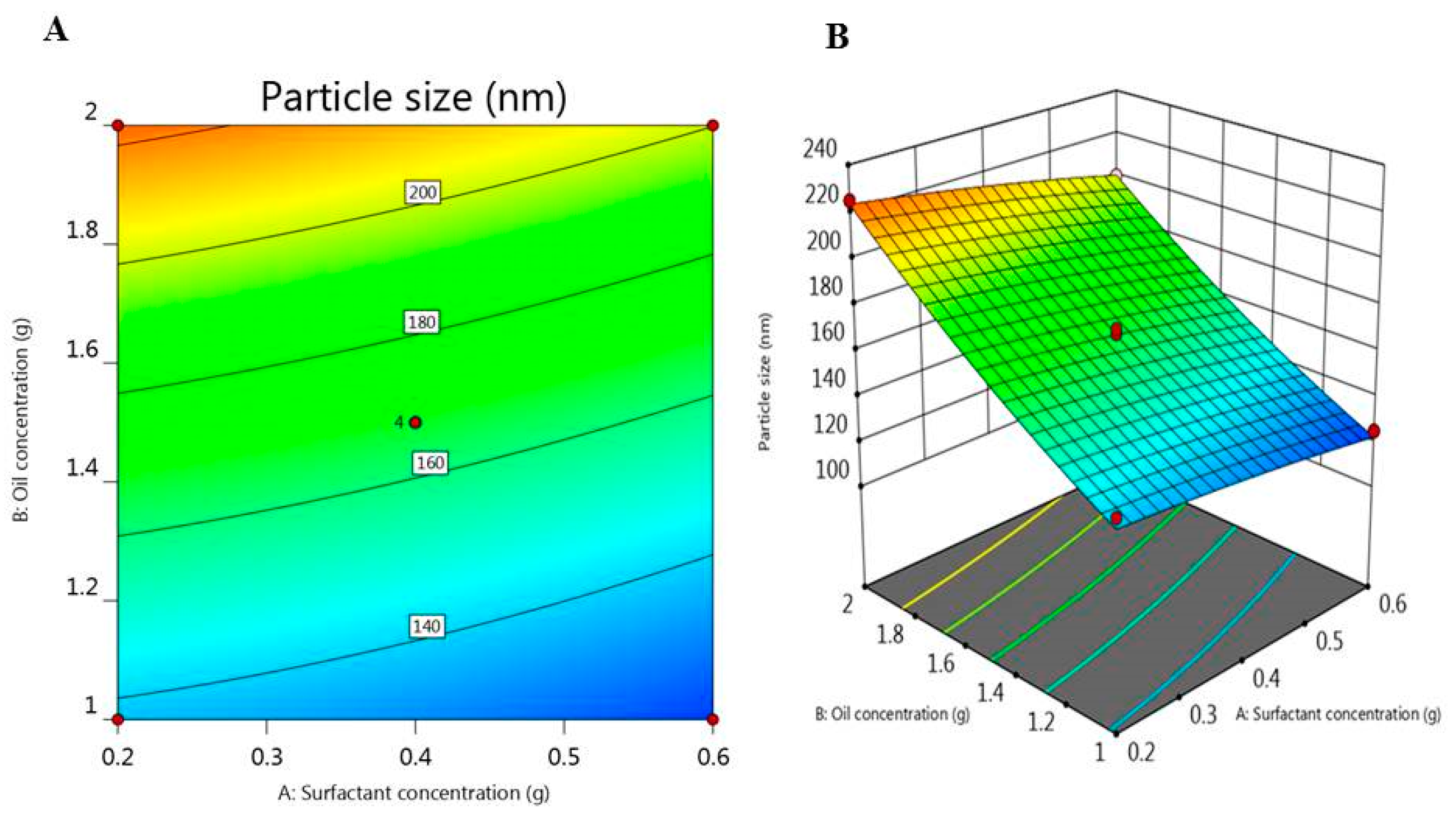

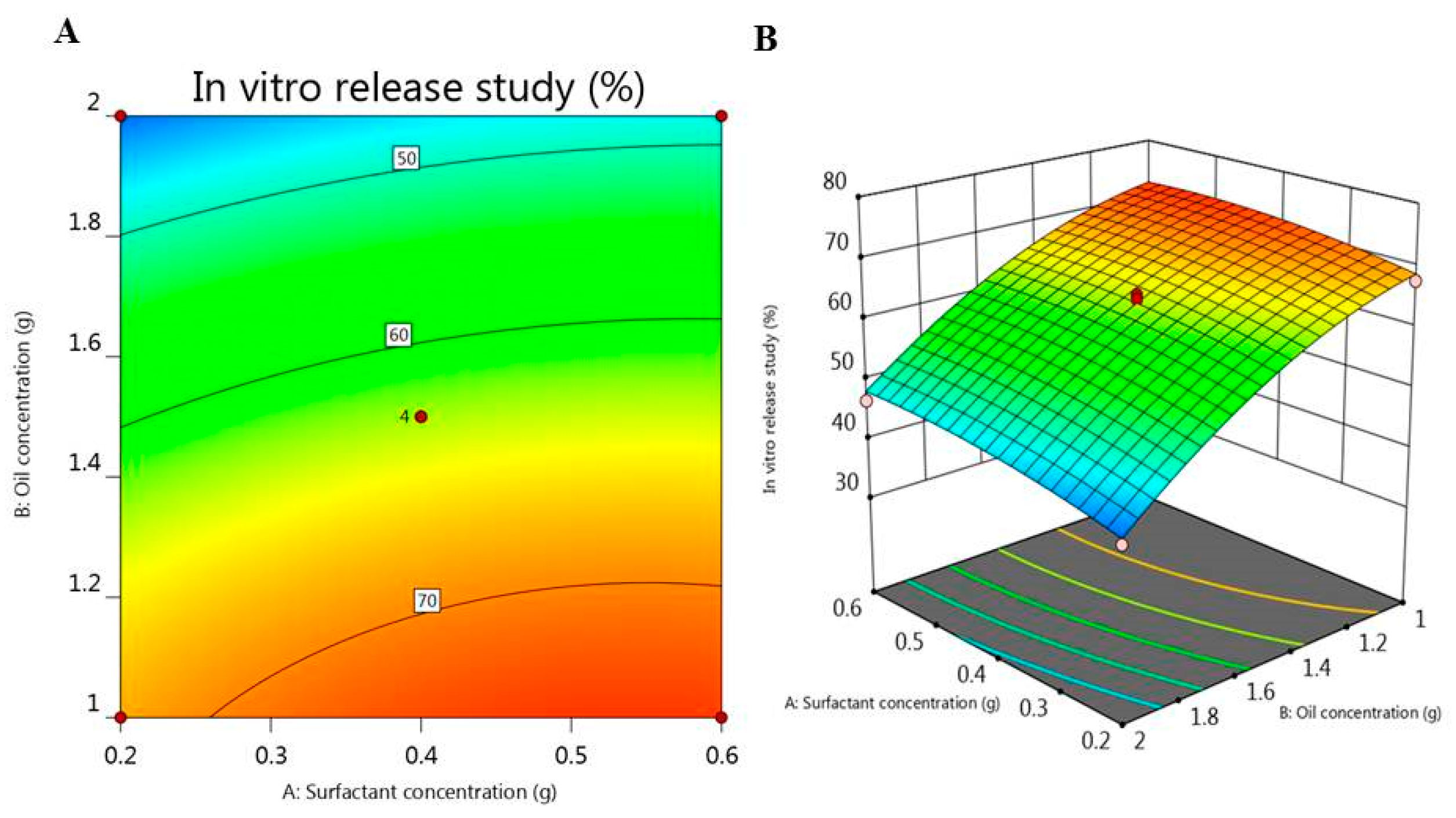

2.3. Full Factorial Experimental Design

2.3.1. Fitting the Model

2.3.2. Statistical Analysis of the Data

2.4. Viscosity Measurement

2.5. Size and Size Distribution (PDI) Determination

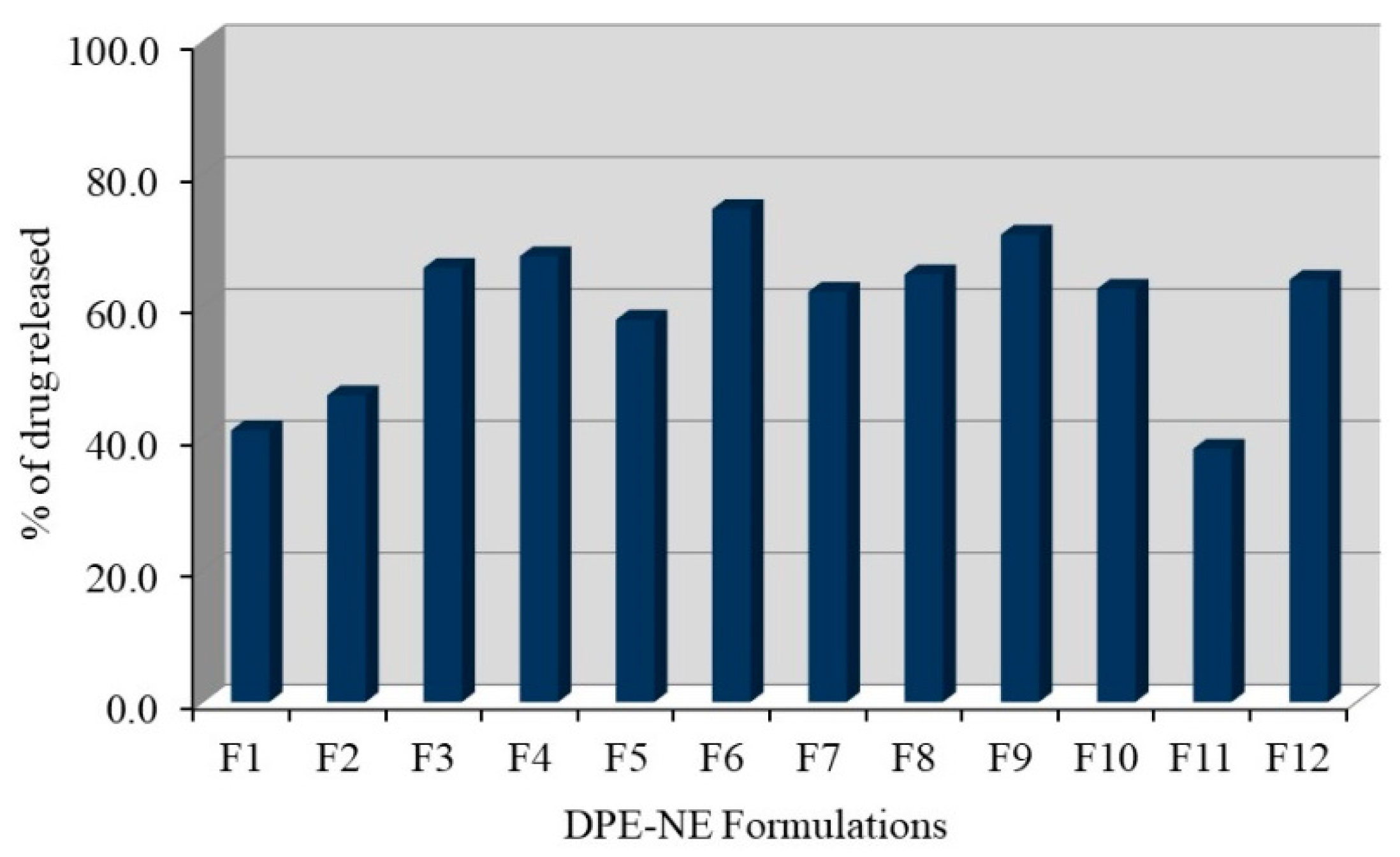

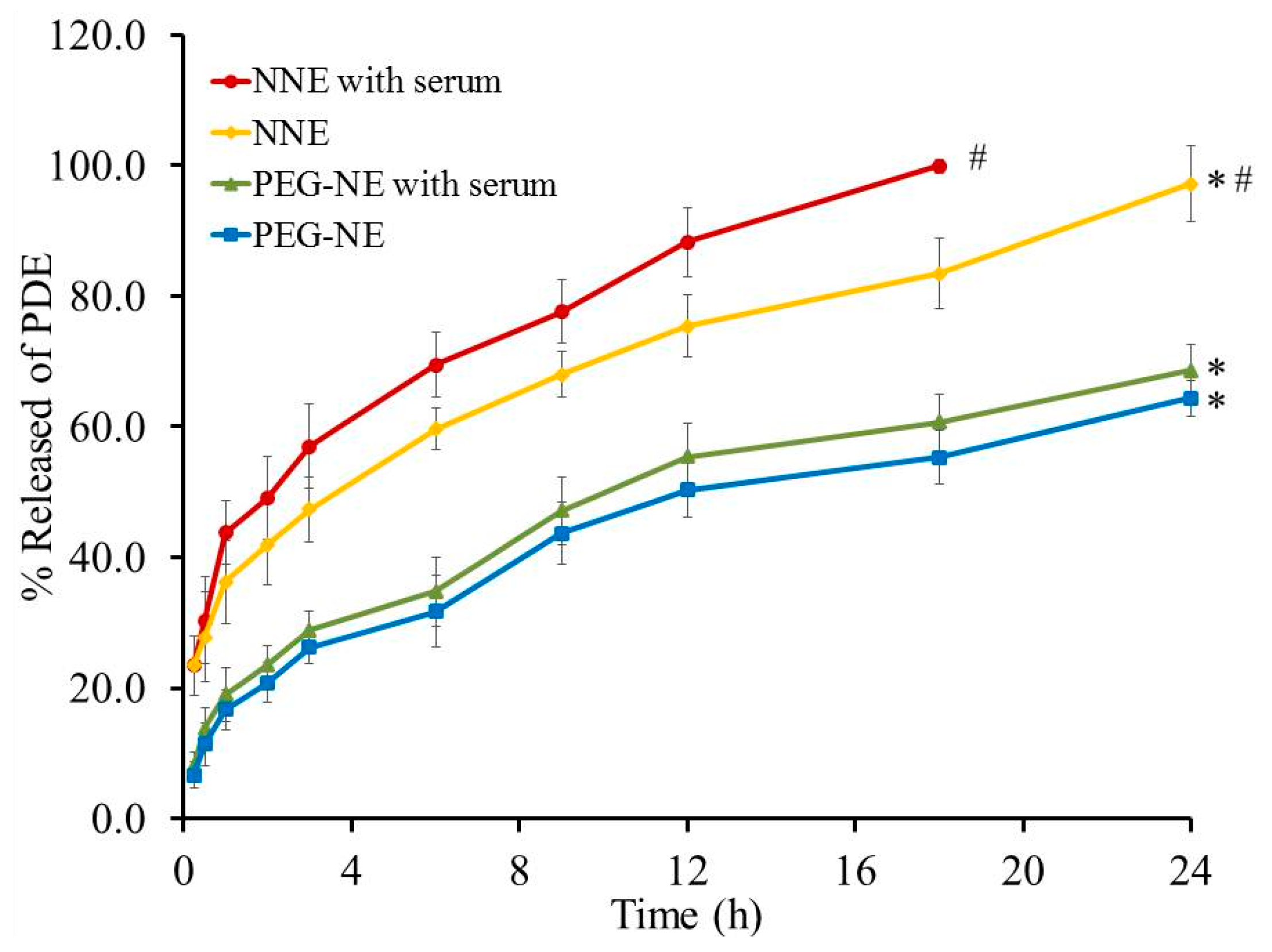

2.6. Studies of DPE In Vitro Release from NE Formulations

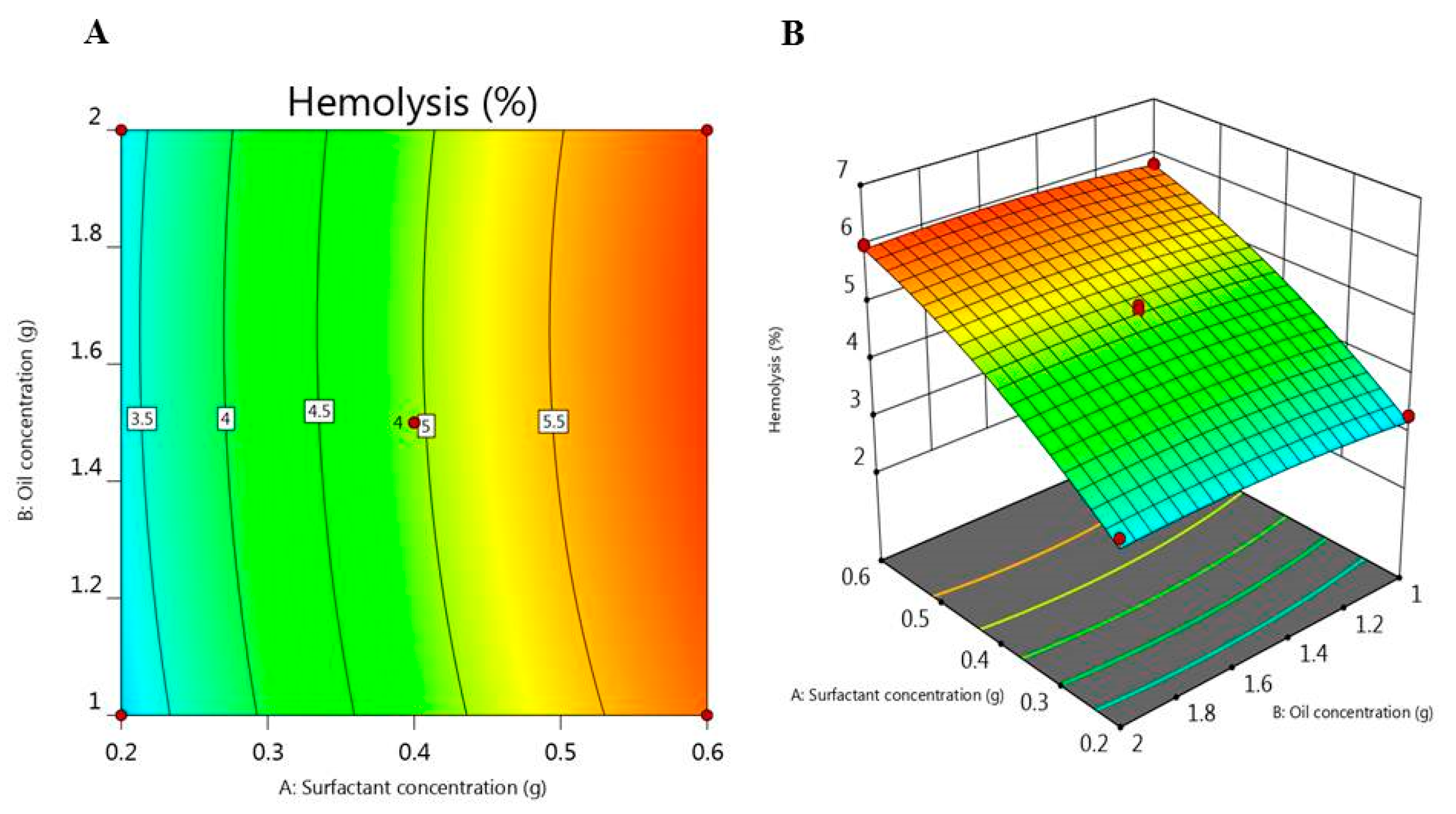

2.7. Hemolytic Activity

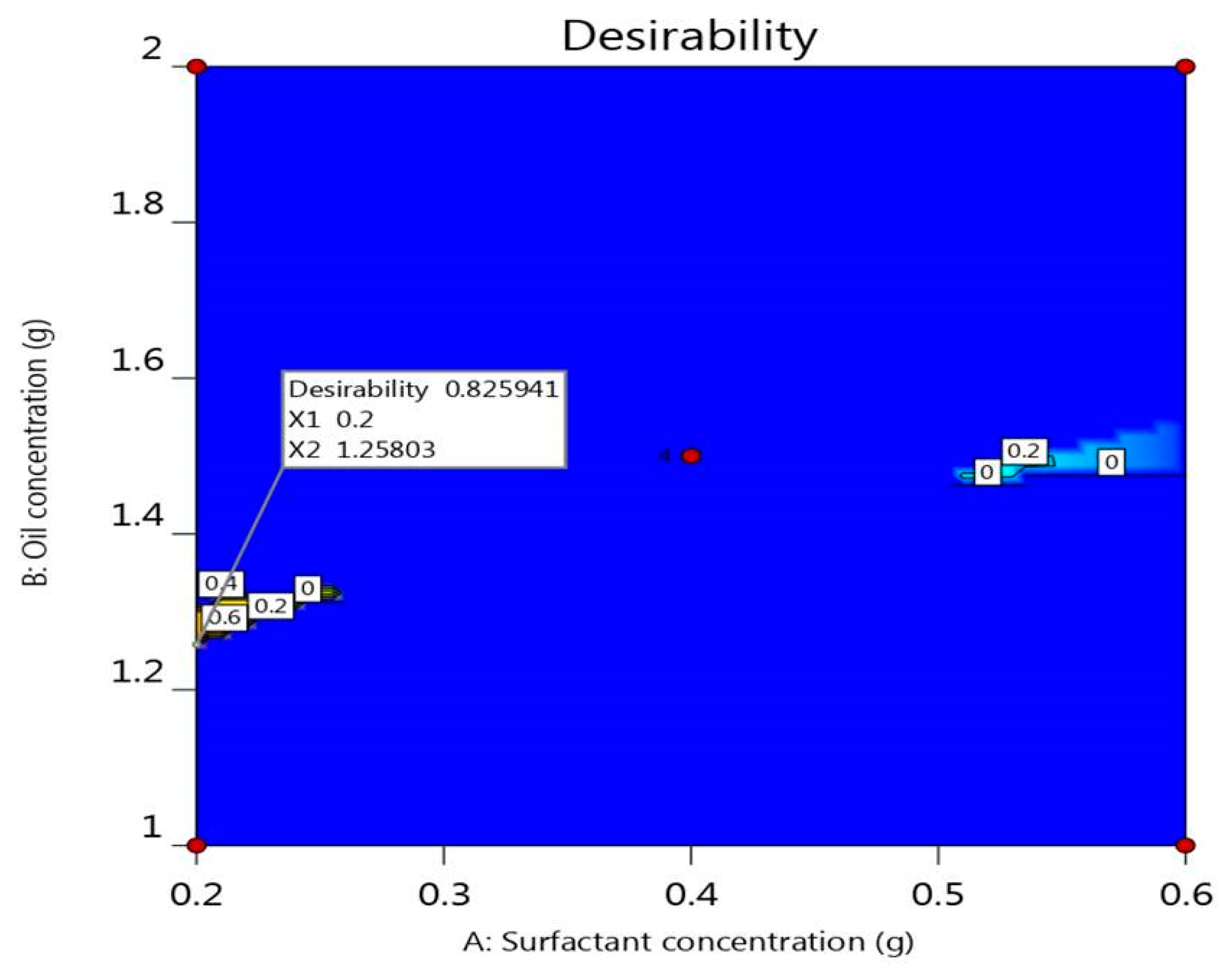

2.8. Optimization of Independent Variables

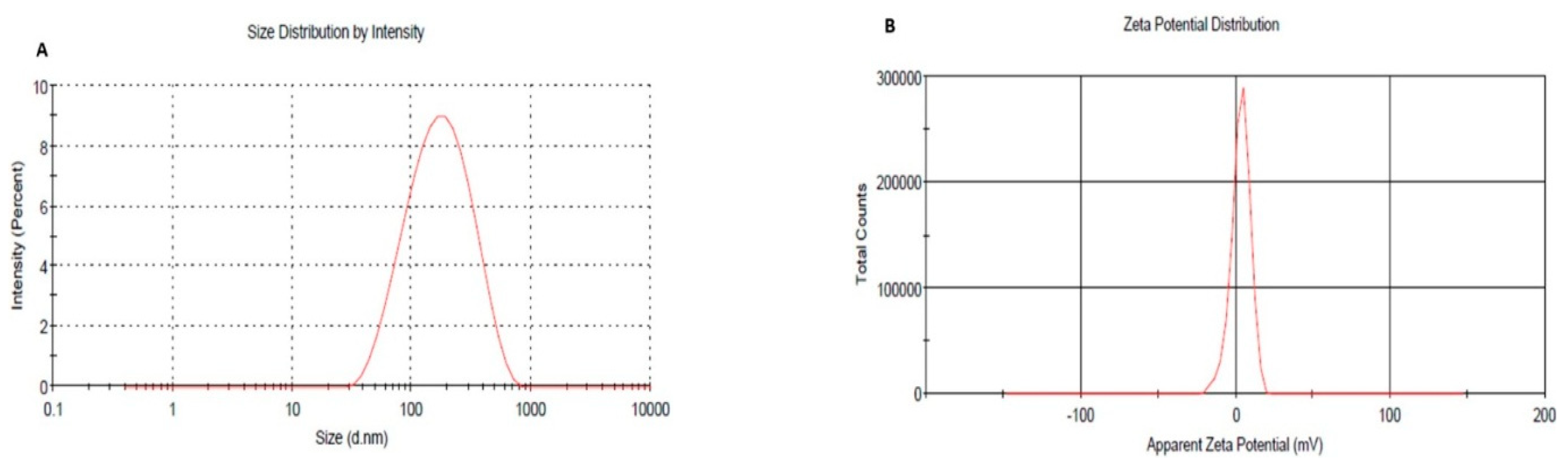

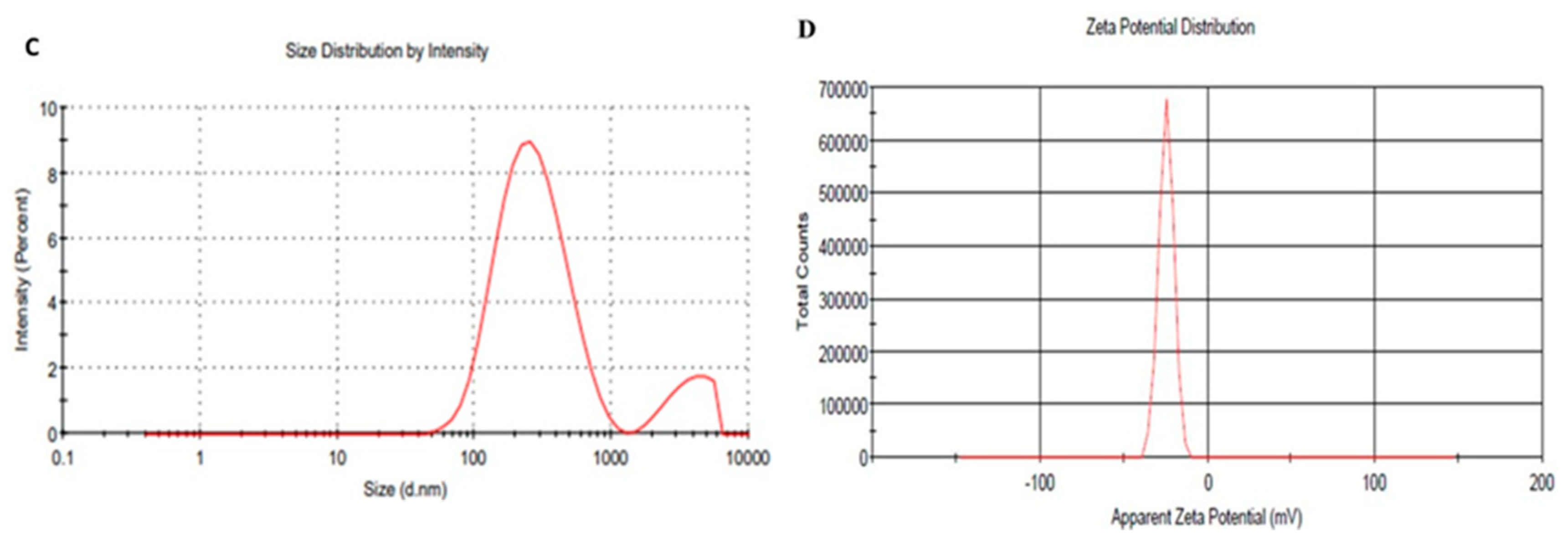

2.9. Particle Size and Zeta Potential Assessment

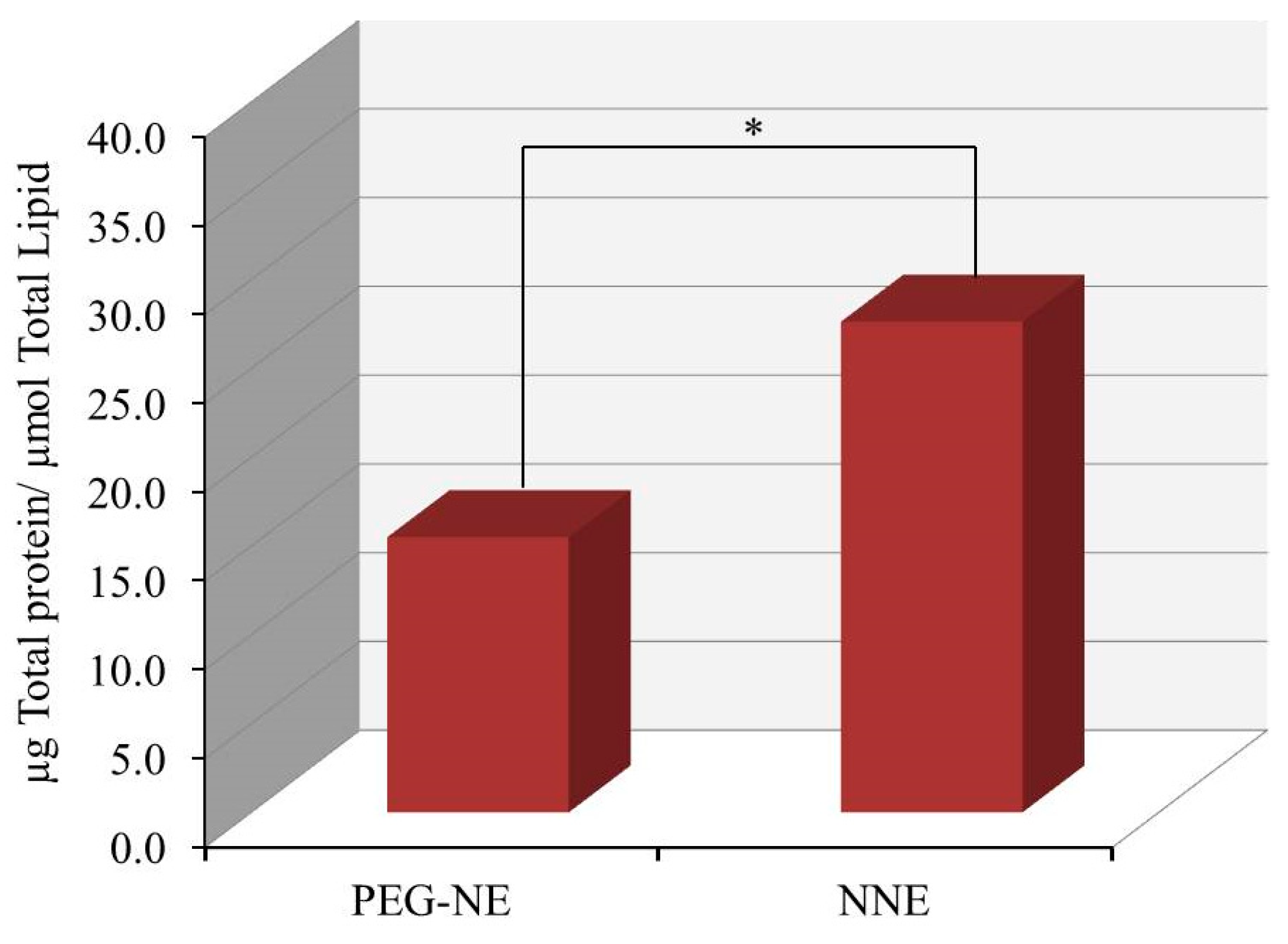

2.10. Determination of Serum Protein Associated on the Surface of NE Quantitatively

2.11. Studies of DPE In Vitro Release from Optimized NE (before and after Serum Incubation)

2.12. In Vitro Cytotoxicity

3. Material and Methods

3.1. Material

3.2. Attainment of Date Palm Extract (DPE)

3.2.1. Dates Identification and Collection

3.2.2. Crude Extract Preparation

3.2.3. Estimation of Total Phenolic Content

3.2.4. Estimation of Total Flavonoid Content

3.3. Drug-Excipient Compatibility Study (FTIR Characterization)

3.4. Experimental Design Study

3.5. Development of PEGylated DPE-NEs

3.6. Characterization of DPE-NE Formulations

3.6.1. Viscosity

3.6.2. Size and Size Distribution (PDI) Determination

3.7. Study of DPE In Vitro Release from NE Formulations

3.8. Hemolytic Activity

3.9. Development of Naked DPE-NE

3.10. Zeta Potential Measurement

3.11. Determination of Serum Protein Associated on the Surface of NE Quantitatively

3.12. Studies of DPE In Vitro Release from Optimized NE (before and after Serum Incubation)

3.13. In Vitro Cytotoxicity

3.14. Statistics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Saafi, E.B.; El Arem, A.; Issaoui, M.; Hammami, M.; Achour, L. Phenolic content and antioxidant activity of four date palm (Phoenix dactylifera L.) fruit varieties grown in Tunisia. Int. J. Food Sci. Technol. 2009, 44, 2314–2319. [Google Scholar] [CrossRef]

- Boeing, H.; Bechthold, A.; Bub, A.; Ellinger, S.; Haller, D.; Kroke, A.; Leschik-Bonnet, E.; Müller, M.J.; Oberritter, H.; Schulze, M. Critical review: Vegetables and fruit in the prevention of chronic diseases. Eur. J. Nutr. 2012, 51, 637–663. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, S.A.; Awad, M.A.; El-Dengawy, E.-R.F.; Abdel-Mageed, H.M.; El-Badry, M.O.; Salah, H.A.; Abdel-Aty, A.M.; Fahmy, A.S. Total phenolic and flavonoid contents and antioxidant activities of sixteen commercial date cultivars grown in Saudi Arabia. RSC Adv. 2016, 6, 44814–44819. [Google Scholar] [CrossRef]

- Hussain, M.I.; Semreen, M.H.; Shanableh, A.; Khattak, M.N.K.; Saadoun, I.; Ahmady, I.M.; Mousa, M.; Darwish, N.; Radeef, W.; Soliman, S.S. Phenolic composition and antimicrobial activity of different Emirati date (Phoenix dactylifera L.) pits: A comparative study. Plants 2019, 8, 497. [Google Scholar] [CrossRef] [PubMed]

- Brima, E.I. Evaluation of Selected Essential Elements in Khalas Dates from Date Palm Determined by Inductively Coupled Plasma-Mass Spectrometry. Int. J. Anal. Chem. 2019, 2019. [Google Scholar] [CrossRef] [PubMed]

- Alahyane, A.; Harrak, H.; Ayour, J.; Elateri, I.; Ait-Oubahou, A.; Benichou, M. Bioactive compounds and antioxidant activity of seventeen Moroccan date varieties and clones (Phoenix dactylifera L.). South Afr. J. Bot. 2019, 121, 402–409. [Google Scholar] [CrossRef]

- Manickavasagan, A.; Essa, M.M.; Sukumar, E. Dates: Production, Processing, Food, and Medicinal Values; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Al-Mssallem, I.S.; Hu, S.; Zhang, X.; Lin, Q.; Liu, W.; Tan, J.; Yu, X.; Liu, J.; Pan, L.; Zhang, T. Genome sequence of the date palm Phoenix dactylifera L. Nat. Commun. 2013, 4, 1–9. [Google Scholar] [CrossRef]

- Vayalil, P.K. Antioxidant and antimutagenic properties of aqueous extract of date fruit (Phoenix dactylifera L. Arecaceae). J. Agric. Food Chem. 2002, 50, 610–617. [Google Scholar] [CrossRef]

- Dayang, J.; Reuben, C.; Raji, F. Nutritional, socioeconomic and health benefits of dates. Int. J. Food Nutr. Sci. 2014, 3, 63. [Google Scholar]

- Baliga, M.S.; Baliga, B.R.V.; Kandathil, S.M.; Bhat, H.P.; Vayalil, P.K. A review of the chemistry and pharmacology of the date fruits (Phoenix dactylifera L.). Food Res. Int. 2011, 44, 1812–1822. [Google Scholar] [CrossRef]

- Rivas, M.; Barbieri, R.L.; Maia, L.C.d. Plant breeding and in situ utilization of palm trees. Ciência Rural 2012, 42, 261–269. [Google Scholar] [CrossRef][Green Version]

- Alhaider, I.A.; Mohamed, M.E.; Ahmed, K.; Kumar, A.H. Date palm (Phoenix dactylifera) fruits as a potential cardioprotective agent: The role of circulating progenitor cells. Front. Pharmacol. 2017, 8, 592. [Google Scholar] [CrossRef]

- Bawazir, A.; Saddiq, A. Antimicrobial activity of date palm (Phoenix dactylifera) pits extracts and its role in reducing the side effect of methyl prednisolone on some neurotransmitter content in the brain, hormone testosterone in adulthood. In Proceedings of the IV International Date Palm Conference 882, Abu Dhabi, United Arab Emirates, 15–17 March 2010; pp. 665–690. [Google Scholar]

- Sahyon, H.A.; Al-Harbi, S.A. Antimicrobial, anticancer and antioxidant activities of nano-heart of Phoenix dactylifera tree extract loaded chitosan nanoparticles: In vitro and in vivo study. Int. J. Biol. Macromol. 2020, 160, 1230–1241. [Google Scholar] [CrossRef] [PubMed]

- El Abed, H.; Chakroun, M.; Abdelkafi-Koubaa, Z.; Drira, N.; Marrakchi, N.; Mejdoub, H.; Khemakhem, B. Antioxidant, Anti-Inflammatory, and Antitumoral Effects of Aqueous Ethanolic Extract from (Phoenix dactylifera) L. Parthenocarpic Dates. Biomed Res. Int. 2018, 2018, 1542602. [Google Scholar] [CrossRef] [PubMed]

- Rahmani, A.H.; Aly, S.M.; Ali, H.; Babiker, A.Y.; Srikar, S. Therapeutic effects of date fruits (Phoenix dactylifera) in the prevention of diseases via modulation of anti-inflammatory, anti-oxidant and anti-tumour activity. Int. J. Clin. Exp. Med. 2014, 7, 483. [Google Scholar]

- Al Juhaimi, F.; Özcan, M.M.; Adiamo, O.Q.; Alsawmahi, O.N.; Ghafoor, K.; Babiker, E.E. Effect of date varieties on physico-chemical properties, fatty acid composition, tocopherol contents, and phenolic compounds of some date seed and oils. J. Food Process. Preserv. 2018, 42, e13584. [Google Scholar] [CrossRef]

- Idowu, A.T.; Igiehon, O.O.; Adekoya, A.E.; Idowu, S. Dates palm fruits: A review of their nutritional components, bioactivities and functional food applications. Aims Agric. Food 2020, 5, 734. [Google Scholar] [CrossRef]

- Djojosubroto, M.W.; Choi, Y.S.; Lee, H.W.; Rudolph, K.L. Telomeres and telomerase in aging, regeneration and cancer. Mol. Cells 2003, 15, 164–175. [Google Scholar]

- Elsewedy, H.S.; Al Dhubiab, B.E.; Mahdy, M.A.; Elnahas, H.M. A Review Article on the Basic Concepts of Drug Delivery Systems as Targeting Agents. Int. J. Pharma Med. Biol. Sci. 2021, 10, 23–29. [Google Scholar]

- Thiruvengadam, M.; Rajakumar, G.; Chung, I.-M. Nanotechnology: Current uses and future applications in the food industry. 3 Biotech 2018, 8, 74. [Google Scholar] [CrossRef]

- Din, F.U.; Aman, W.; Ullah, I.; Qureshi, O.S.; Mustapha, O.; Shafique, S.; Zeb, A. Effective use of nanocarriers as drug delivery systems for the treatment of selected tumors. Int. J. Nanomed. 2017, 12, 7291–7309. [Google Scholar] [CrossRef] [PubMed]

- Soliman, W.E.; Shehata, T.M.; Mohamed, M.E.; Younis, N.S.; Elsewedy, H.S. Enhancement of Curcumin Anti-Inflammatory Effect via Formulation into Myrrh Oil-Based Nanoemulgel. Polymers 2021, 13, 577. [Google Scholar] [CrossRef] [PubMed]

- Wahgiman, N.A.; Salim, N.; Rahman, M.B.A.; Ashari, S.E. Optimization of nanoemulsion containing gemcitabine and evaluation of its cytotoxicity towards human fetal lung fibroblast (MRC5) and human lung carcinoma (A549) cells. Int. J. Nanomed. 2019, 14, 7323. [Google Scholar] [CrossRef] [PubMed]

- Nayak, A.K.; Ahmed, S.A.; Beg, S.; Tabish, M.; Hasnain, M.S. Chapter 18—Application of Quality by Design for the Development of Biopharmaceuticals. In Pharmaceutical Quality by Design; Beg, S., Hasnain, M.S., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 399–411. [Google Scholar] [CrossRef]

- Rahman, Z.; Zidan, A.S.; Habib, M.J.; Khan, M.A. Understanding the quality of protein loaded PLGA nanoparticles variability by Plackett–Burman design. Int. J. Pharm. 2010, 389, 186–194. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Wang, L.; Wang, B. Optimization of encapsulation efficiency and average particle size of Hohenbuehelia serotina polysaccharides nanoemulsions using response surface methodology. Food Chem. 2017, 229, 479–486. [Google Scholar] [CrossRef] [PubMed]

- Tang, S.Y.; Manickam, S.; Wei, T.K.; Nashiru, B. Formulation development and optimization of a novel Cremophore EL-based nanoemulsion using ultrasound cavitation. Ultrason. Sonochemistry 2012, 19, 330–345. [Google Scholar] [CrossRef] [PubMed]

- Benmeddour, Z.; Mehinagic, E.; Le Meurlay, D.; Louaileche, H. Phenolic composition and antioxidant capacities of ten Algerian date (Phoenix dactylifera L.) cultivars: A comparative study. J. Funct. Foods 2013, 5, 346–354. [Google Scholar] [CrossRef]

- Oliveira, R.N.; Mancini, M.C.; Oliveira, F.C.S.d.; Passos, T.M.; Quilty, B.; Thiré, R.M.d.S.M.; McGuinness, G.B. FTIR analysis and quantification of phenols and flavonoids of five commercially available plants extracts used in wound healing. Matéria (Rio de Janeiro) 2016, 21, 767–779. [Google Scholar] [CrossRef]

- Choudhury, S.R.; Mandal, A.; Chakravorty, D.; Gopal, M.; Goswami, A. Evaluation of physicochemical properties, and antimicrobial efficacy of monoclinic sulfur-nanocolloid. J. Nanoparticle Res. 2013, 15, 1–11. [Google Scholar] [CrossRef]

- Thamaraiselvi, J.; Kalpanadevi, S. Determination of some properties of reused cooking ground nut oil using FTIR spectroscopy. Orient. J. Chem. 2012, 28, 1777. [Google Scholar] [CrossRef]

- Ibrahim, H.M.; Ahmed, T.A.; Hussain, M.D.; Rahman, Z.; Samy, A.M.; Kaseem, A.A.; Nutan, M.T. Development of meloxicam in situ implant formulation by quality by design principle. Drug Dev. Ind. Pharm. 2014, 40, 66–73. [Google Scholar] [CrossRef]

- Sathyamoorthy, N.; Magharla, D.; Chintamaneni, P.; Vankayalu, S. Optimization of paclitaxel loaded poly (ε-caprolactone) nanoparticles using Box Behnken design. Beni Suef Univ. J. Basic Appl. Sci. 2017, 6, 362–373. [Google Scholar] [CrossRef]

- Araújo, F.; Kelmann, R.; Araújo, B.; Finatto, R.; Teixeira, H.; Koester, L. Development and characterization of parenteral nanoemulsions containing thalidomide. Eur. J. Pharm. Sci. 2011, 42, 238–245. [Google Scholar] [CrossRef]

- Elsewedy, H.S.; Aldhubiab, B.E.; Mahdy, M.A.; Elnahas, H.M. Brucine PEGylated nanoemulsion: In vitro and in vivo evaluation. Colloids Surf. A Physicochem. Eng. Asp. 2021, 608, 125618. [Google Scholar] [CrossRef]

- Harun, S.N.; Nordin, S.A.; Abd Gani, S.S.; Shamsuddin, A.F.; Basri, M.; Basri, H.B. Development of nanoemulsion for efficient brain parenteral delivery of cefuroxime: Designs, characterizations, and pharmacokinetics. Int. J. Nanomed. 2018, 13, 2571. [Google Scholar] [CrossRef]

- Danaei, M.; Dehghankhold, M.; Ataei, S.; Hasanzadeh Davarani, F.; Javanmard, R.; Dokhani, A.; Khorasani, S.; Mozafari, M.R. Impact of Particle Size and Polydispersity Index on the Clinical Applications of Lipidic Nanocarrier Systems. Pharmaceutics 2018, 10, 57. [Google Scholar] [CrossRef]

- Sarheed, O.; Dibi, M.; Ramesh, K.V. Studies on the Effect of Oil and Surfactant on the Formation of Alginate-Based O/W Lidocaine Nanocarriers Using Nanoemulsion Template. Pharmaceutics 2020, 12, 1223. [Google Scholar] [CrossRef]

- Laxmi, M.; Bhardwaj, A.; Mehta, S.; Mehta, A. Development and characterization of nanoemulsion as carrier for the enhancement of bioavailability of artemether. Artif. Cells Nanomed. Biotechnol. 2015, 43, 334–344. [Google Scholar] [CrossRef]

- Efentakis, M.; Al-Hmoud, H.; Buckton, G.; Rajan, Z. The influence of surfactants on drug release from a hydrophobic matrix. Int. J. Pharm. 1991, 70, 153–158. [Google Scholar] [CrossRef]

- Cabello-Alvarado, C.; Andrade-Guel, M.; Pérez-Alvarez, M.; Cadenas-Pliego, G.; Cortés-Hernández, D.A.; Bartolo-Pérez, P.; Ávila-Orta, C.; Cruz-Delgado, V.; Zepeda-Pedreguera, A. Graphene nanoplatelets modified with amino-groups by ultrasonic radiation of variable frequency for potential adsorption of uremic toxins. Nanomaterials 2019, 9, 1261. [Google Scholar] [CrossRef]

- Mehmood, T.; Ahmed, A.; Ahmad, A.; Ahmad, M.S.; Sandhu, M.A. Optimization of mixed surfactants-based β-carotene nanoemulsions using response surface methodology: An ultrasonic homogenization approach. Food Chem. 2018, 253, 179–184. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.; Liu, M.; Hu, H.; Liu, D.; Zhou, S. Development, Optimization, and Characterization of PEGylated Nanoemulsion of Prostaglandin E1 for Long Circulation. Aaps Pharmscitech 2016, 17, 409–417. [Google Scholar] [CrossRef] [PubMed]

- Suk, J.S.; Xu, Q.; Kim, N.; Hanes, J.; Ensign, L.M. PEGylation as a strategy for improving nanoparticle-based drug and gene delivery. Adv. Drug Del. Rev. 2016, 99, 28–51. [Google Scholar] [CrossRef] [PubMed]

- Shehata, T.; Ogawara, K.-i.; Higaki, K.; Kimura, T. Prolongation of residence time of liposome by surface-modification with mixture of hydrophilic polymers. Int. J. Pharm. 2008, 359, 272–279. [Google Scholar] [CrossRef]

- Shen, L.; Guo, A.; Zhu, X. Tween surfactants: Adsorption, self-organization, and protein resistance. Surf. Sci. 2011, 605, 494–499. [Google Scholar] [CrossRef]

- Buszello, K.; Harnisch, S.; Müller, R.H.; Müller, B.W. The influence of alkali fatty acids on the properties and the stability of parenteral O/W emulsions modified with solutol HS 15. Eur. J. Pharm. Biopharm. 2000, 49, 143–149. [Google Scholar] [CrossRef]

- Fredslund, F.; Laursen, N.S.; Roversi, P.; Jenner, L.; Oliveira, C.L.; Pedersen, J.S.; Nunn, M.A.; Lea, S.M.; Discipio, R.; Sottrup-Jensen, L.; et al. Structure of and influence of a tick complement inhibitor on human complement component 5. Nat. Immunol. 2008, 9, 753–760. [Google Scholar] [CrossRef]

- Shehata, T.; Kimura, T.; Higaki, K.; Ogawara, K.I. In-vivo disposition characteristics of PEG niosome and its interaction with serum proteins. Int. J. Pharm. 2016, 512, 322–328. [Google Scholar] [CrossRef]

- Tyner, K.M.; Zou, P.; Yang, X.; Zhang, H.; Cruz, C.N.; Lee, S.L. Product quality for nanomaterials: Current US experience and perspective. Wiley Interdiscip. Rev. Nanomed. Nanobiotechnol. 2015, 7, 640–654. [Google Scholar] [CrossRef] [PubMed]

- Germain, M.; Caputo, F.; Metcalfe, S.; Tosi, G.; Spring, K.; Åslund, A.K.; Pottier, A.; Schiffelers, R.; Ceccaldi, A.; Schmid, R. Delivering the power of nanomedicine to patients today. J. Control. Release 2020, 326, 164–171. [Google Scholar] [CrossRef] [PubMed]

- Murugan, C.; Rayappan, K.; Thangam, R.; Bhanumathi, R.; Shanthi, K.; Vivek, R.; Thirumurugan, R.; Bhattacharyya, A.; Sivasubramanian, S.; Gunasekaran, P.; et al. Combinatorial nanocarrier based drug delivery approach for amalgamation of anti-tumor agents in breast cancer cells: An improved nanomedicine strategy. Sci. Rep. 2016, 6, 34053. [Google Scholar] [CrossRef]

- Ma, Y.; Li, Z.; Wang, Y.; Feng, J. Brucine induces the apoptosis of U266 multiple myeloma cells by phosphorylation of c-Jun. Mol. Med. Rep. 2013, 7, 481–484. [Google Scholar] [CrossRef] [PubMed]

- Abdel-Wahab, N.M.; Hamed, A.N.; Khalil, H.E.; Samy, M.N.; Wanas, A.S.; Fouad, M.A.; Kamel, M.S. Phenolic acid glycosides from Parmentiera cereifera Seem. (Candle tree). Phytochem. Lett. 2014, 9, 74–77. [Google Scholar] [CrossRef]

- El-Halawany, A.M.; Abdallah, H.M.; Hamed, A.R.; Khalil, H.E.; Almohammadi, A.M. Phenolics from Barleria cristata var. Alba as carcinogenesis blockers against menadione cytotoxicity through induction and protection of quinone reductase. BMC Complement. Altern. Med. 2018, 18, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Khalil, H.E.; Al Ahmed, A. Phytochemical Analysis and Free Radical Scavenging Activity of Carthamus oxyacantha growing in Saudi Arabia: A Comparative Study. Int. J. Pharm. Sci. Rev. Res. 2017, 45, 51–55. [Google Scholar]

- Khalil, H.E.; Aljeshi, Y.M.; Saleh, F.A.; Mohamed, T.S. Assessment of chemical composition and the antimicrobial and antioxidant activities of Bassia eriophora growing in Eastern province of Saudi Arabia. JOCPR 2017, 9, 210–215. [Google Scholar]

- Soliman, W.E.; Khan, S.; Rizvi, S.M.D.; Moin, A.; Elsewedy, H.S.; Abulila, A.S.; Shehata, T.M. Therapeutic Applications of Biostable Silver Nanoparticles Synthesized Using Peel Extract of Benincasa hispida: Antibacterial and Anticancer Activities. Nanomaterials 2020, 10, 1954. [Google Scholar] [CrossRef]

- Shehata, T.M.; Nair, A.B.; Al-Dhubiab, B.E.; Shah, J.; Jacob, S.; Alhaider, I.A.; Attimarad, M.; Elsewedy, H.S.; Ibrahim, M.M. Vesicular Emulgel Based System for Transdermal Delivery of Insulin: Factorial Design and in Vivo Evaluation. Appl. Sci. 2020, 10, 5341. [Google Scholar] [CrossRef]

- Shah, J.; Nair, A.B.; Shah, H.; Jacob, S.; Shehata, T.M.; Morsy, M.A. Enhancement in antinociceptive and anti-inflammatory effects of tramadol by transdermal proniosome gel. Asian J. Pharm. Sci. 2020, 15, 786–796. [Google Scholar] [CrossRef]

- Uchegbu, I.F.; Duncan, R. Niosomes containing N-(2-hydroxypropyl) methacrylamide copolymer-doxorubicin (PK1): Effect of method of preparation and choice of surfactant on niosome characteristics and a preliminary study of body distribution. Int. J. Pharm. 1997, 155, 7–17. [Google Scholar] [CrossRef]

- Xu, M.-R.; Wei, P.-F.; Suo, M.-Z.; Hu, Y.; Ding, W.; Su, L.; Zhu, Y.-D.; Song, W.-J.; Tang, G.-H.; Zhang, M.; et al. Brucine Suppresses Vasculogenic Mimicry in Human Triple-Negative Breast Cancer Cell Line MDA-MB-231. Biomed. Res. Int. 2019, 2019, 6543230. [Google Scholar] [CrossRef] [PubMed]

- Khalil, H.E.; Mohamed, M.E.; Morsy, M.A.; Kandeel, M. Flavonoid and phenolic compounds from Carissa macrocarpa: Molecular docking and cytotoxicity studies. Pharmacogn. Mag. 2018, 14, 304. [Google Scholar] [CrossRef]

- Deng, X.; Yin, F.; Lu, X.; Cai, B.; Yin, W. The Apoptotic Effect of Brucine from the Seed of Strychnos nux-vomica on Human Hepatoma Cells is Mediated via Bcl-2 and Ca2+ Involved Mitochondrial Pathway. Toxicol. Sci. 2006, 91, 59–69. [Google Scholar] [CrossRef] [PubMed]

| Formula | Independent Variables | Response Values | |||

|---|---|---|---|---|---|

| A (g) | B (g) | Y1 (nm) | Y2 (%) | Y3 (%) | |

| F1 | 0.2 | 2 | 225 | 45.4 | 3.5 |

| F2 | 0.6 | 2 | 200 | 46.5 | 6 |

| F3 | 0.68 | 1.5 | 150 | 62.8 | 6.2 |

| F4 | 0.2 | 1 | 142 | 67.6 | 3.3 |

| F5 | 0.11 | 1.5 | 175 | 61.9 | 2.4 |

| F6 | 0.4 | 0.79 | 125 | 74.7 | 4.6 |

| F7 | 0.4 | 1.5 | 170 | 58.2 | 4.8 |

| F8 | 0.4 | 1.5 | 166 | 60.8 | 5 |

| F9 | 0.6 | 1 | 130 | 70.8 | 5.8 |

| F10 | 0.4 | 1.5 | 168 | 58.6 | 5.1 |

| F11 | 0.4 | 2.2 | 235 | 40.4 | 4.7 |

| F12 | 0.4 | 1.5 | 166 | 60 | 4.9 |

| Source | Y1 | Y2 | Y3 | |||

|---|---|---|---|---|---|---|

| F-Value | p-Value | F-Value | p-Value | F-Value | p-Value | |

| Model | 247.23 | <0.0001 | 88.36 | <0.0001 | 122.65 | <0.0001 |

| A | 64.32 | 0.0002 * | 14.43 | 0.0090 * | 588.76 | <0.0001 * |

| B | 1154.38 | <0.0001 * | 393.75 | <0.0001 * | 1.60 | 0.2523 |

| AB | 1.38 | 0.2853 | 0.3336 | 0.5846 | 0.0000 | 1.0000 |

| A² | 1.14 | 0.3272 | 3.93 | 0.0946 * | 22.16 | 0.0033 * |

| B² | 12.75 | 0.0118 * | 32.55 | 0.0013 * | 3.16 | 0.1257 |

| Lack of Fit | 5.34 | 0.1011 | 3.51 | 0.1651 | 1.74 | 0.3299 |

| R2 analysis | ||||||

| R² | 0.9952 | 0.9866 | 0.9903 | |||

| Adjusted R² | 0.9911 | 0.9754 | 0.9822 | |||

| Predicted R² | 0.9697 | 0.9206 | 0.9499 | |||

| Adequate Precision | 48.0496 | 28.0624 | 34.3150 | |||

| Formulation | Viscosity (cp) | Formulation | Viscosity (cp) |

|---|---|---|---|

| F1 | 3.42 ± 0.23 | F7 | 2.65 ± 0.14 |

| F2 | 2.83 ± 0.25 | F8 | 2.67 ± 0.32 |

| F3 | 2.70 ± 0.28 | F9 | 2.98 ± 0.25 |

| F4 | 3.14 ± 0.15 | F10 | 2.85 ± 0.28 |

| F5 | 2.97 ± 0.25 | F11 | 2.38 ± 0.27 |

| F6 | 2.49 ± 0.15 | F12 | 2.92 ± 0.23 |

| Independent Variable | Symbol | Level of Variation | ||

|---|---|---|---|---|

| −1 | 0 | +1 | ||

| Surfactant concentration (g) | A | 0.2 | 0.4 | 0.6 |

| Oil concentration (g) | B | 1.5 | 2 | 2.5 |

| Dependent variables | Symbol | Constraints | ||

| Particle size (nm) | Y1 | In range (140–160 nm) | ||

| In vitro drug release (%) | Y2 | In range (55–65%) | ||

| Hemolysis (%) | Y3 | Minimize | ||

| Response | Predicted Values | Experimental Values |

|---|---|---|

| Y1 (nm) | 156.067 | 159.33 ± 3.4 |

| Y2 (%) | 65 | 64.3 ± 1.82 |

| Y3 (%) | 3.314 | 3.2 ± 0.15 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khalil, H.E.; Alqahtani, N.K.; Darrag, H.M.; Ibrahim, H.-I.M.; Emeka, P.M.; Badger-Emeka, L.I.; Matsunami, K.; Shehata, T.M.; Elsewedy, H.S. Date Palm Extract (Phoenix dactylifera) PEGylated Nanoemulsion: Development, Optimization and Cytotoxicity Evaluation. Plants 2021, 10, 735. https://doi.org/10.3390/plants10040735

Khalil HE, Alqahtani NK, Darrag HM, Ibrahim H-IM, Emeka PM, Badger-Emeka LI, Matsunami K, Shehata TM, Elsewedy HS. Date Palm Extract (Phoenix dactylifera) PEGylated Nanoemulsion: Development, Optimization and Cytotoxicity Evaluation. Plants. 2021; 10(4):735. https://doi.org/10.3390/plants10040735

Chicago/Turabian StyleKhalil, Hany Ezzat, Nashi K. Alqahtani, Hossam M. Darrag, Hairul-Islam Mohamed Ibrahim, Promise M. Emeka, Lorina I. Badger-Emeka, Katsuyoshi Matsunami, Tamer M. Shehata, and Heba S. Elsewedy. 2021. "Date Palm Extract (Phoenix dactylifera) PEGylated Nanoemulsion: Development, Optimization and Cytotoxicity Evaluation" Plants 10, no. 4: 735. https://doi.org/10.3390/plants10040735

APA StyleKhalil, H. E., Alqahtani, N. K., Darrag, H. M., Ibrahim, H.-I. M., Emeka, P. M., Badger-Emeka, L. I., Matsunami, K., Shehata, T. M., & Elsewedy, H. S. (2021). Date Palm Extract (Phoenix dactylifera) PEGylated Nanoemulsion: Development, Optimization and Cytotoxicity Evaluation. Plants, 10(4), 735. https://doi.org/10.3390/plants10040735