2.1. BSG Samples Proximate Composition

Proximate composition of the raw materials is displayed in

Table 1. Protein content of the wheat flour (WF) was the lowest (10.03%), while BSG samples’ protein content ranged between 24.00 to 25.80%. According to a large body of literature, BSG protein content could vary between 24.0 to 15.2%, [

17] while Shih et al. [

18] mentioned a protein value content ranging from 14.2 to 31 g/100 g. Moisture parameter did not differ significantly between BSG samples (7.21% to 7.52%), while WF value (14.5%) was significantly different (

p < 0.05).

Regarding the BSG total lipids content (

Table 1), a significant difference (

p < 0.05) was highlighted between BSG samples, with the smallest amount being exhibited by BSG3 (5.96%), while BSG2 recorded a value of 7.05% total lipids. The results are in line with those mentioned in the literature, with Fărcaș et al. [

7] reporting a BSG lipid value ranging between 5.40 to 11%. Triacylglycerols, free fatty acids, diacylglycerols, monoacylglycerols, phospholipids and steroid compounds were reported by Fărcaș et al. [

7] as being predominant BSG lipid classes.

The total ash content in the present study ranged between 2.85 and 3.46%. This result aligned with previous studies, where ash was reported in a range of 2.4–4.6% by Mussatto et al., [

17] between 2.68–4.10 g/100 g by Shih et al. [

18], and in a total amount between 2.2–7.9%, as mentioned by Aliyu et al. [

19].

With respect to crude fiber content (

Table 1), the differences between BGS samples were not significantly different (

p < 0.05), while WF registered the smallest fiber amount. The main BSG fibers are cellulose, hemicellulose and lignin, and registered values between 60–70 g/100 g d.w., as emphasized by Shih et al. [

18]. Amoriello et al. [

6] reported arabinoxylans and beta-glucan as the main representative of soluble and insoluble fibers involved in the prevention of different gastro-intestinal disorders, the regulation of serum cholesterol and in the treatment of ulcerative colitis. Furthermore, beta-glucan was reported as a potential prebiotic with a positive influence on gastrointestinal tract, while arabinoxylans could contribute to glucose reduction [

9]. Moreover, there is a daily recommendation of 25 g of dietary fiber, as emphasized by Ajanaku et al. [

16]. The variations in BSG samples chemical composition could be related to several factors, such as barley variety, type of used malt, harvesting conditions, the brewing process and the time when BSG is taken out from the brewing process [

20].

Regarding the raw materials total phenols content (

Table 1), the highest values were reached by BSG3, followed by BSG4 and BSG1, with values of 258.12 mg GAE/100 g f.w, 242.56 mg GAE/100 g f.w. and 236.31 mg GAE/100 g fw, respectively. The high amounts of polyphenols could be justified by the fact that the majority of the polyphenolic content are identified in the husk barley grain, which represent the main component of BSG [

17]. In the same vein, Socaci et al. [

21] underlined that BSG could be considered as a rich source in phenolic compounds, being mainly composed of coat-pericarp-husk layers barley grain. Moreover, using scanning electron microscopy, Ktenioudaki et al. [

22] emphasized once again that BSG structure is formed mainly of barley husks and fiber filaments, and the idea was straightened by Fărcaș et al. [

23], who defined BSG as being mainly composed of barley grain husk, with only minor fractions of pericarp and barley endosperm.

A higher total phenols BSG content was reported also by Moreira et al. [

11], who emphasized that BSG obtained from a malt kilning temperature of 160 °C contained a higher amount of total phenols, compared with BSG obtained from a malt kilning temperature higher than 200 °C. Contrarily, the high kilning temperature could be able to break up the acetal, ether and esters bonds that entrap phenolics, improving the bioactive compound amount [

18]. Another important parameter that could influence the extraction of phenols from BSG is the extraction technique used, considering that BSG could be characterized as a lignocellulosic material that might entrap the phenolic acid in the cell-wall [

21].

The difference between BSG total phenols samples could be explained by the type of malt used in the brewing process but also by melanoidins, which are compounds formed during the kilning malt process through Maillard reaction [

13]. Melanoidins are defined as brown hydrophilic polymers which are formed in the last stage of Maillard reaction, due to the interaction between proteins and carbohydrates (polyphenols being sometimes also involved) [

24,

25]. Melanoidins are reported as having antioxidant and antimicrobial properties, prebiotic activity and antihypertensive implications, which are mainly found in dark beer, malt, cocoa, coffee and toast [

24]. Furthermore, melanoidins from coffee were claimed to have a positive role in colon cancer pathogenesis [

24].

With respect to radical scavenging activity, BSG3 reached the highest extended value (26.77%), followed by BSG4 (24.59%) and BSG1 (24.31%), respectively. BSG extracts from Pilsen and black malt were reported by Moreira et al. [

13] as having a strong in vivo antioxidant activity, being able to protect the cells yeast of

Saccharomyces cerevisiae against oxidative DNA damage.

2.2. BSG (Brewer Spent Grains) and WF (Wheat Flour) Color Characteristics

BSG color parameters such as lightness (

L* value), redness (

a* value) and yellowness (

b* value) are displayed in

Table 2. CIE color values are calculated using a mathematical model based on a white light source, object and human observer that represent all colors in terms of

L* lightness,

a* redness-greenness and

b* blueness-yellowness [

26].

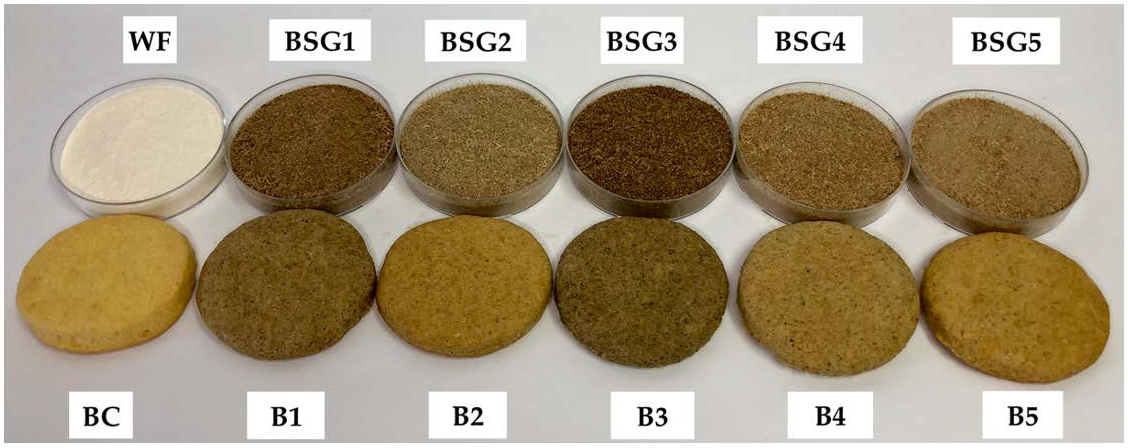

With respect to lightness, significant differences (

p < 0.05) were identified between WF and BSG samples (

Table 2). The lowest value of

L* was registered by BSG3 samples, being the most brown sample of all the selected BSGs (

Figure 1).

The darker color of BSG3 samples could be explained by the type of malt used and by kilning temperature. At higher temperature reactions such as Maillard, caramelization and pigment degradation could take place and changed the BSG color, reducing its brightness [

8]. In the last stage of Maillard reaction, during malt kilning, a brown high molecular compound could be formed, such as melanoidins, which was mainly identified in dark BSG [

11,

27].

Regarding

a* and

b* values, the lowest values were recorded by WF, while BSG1 registered the highest

a* value and BSG5 the highest

b* value (

Table 2). Changing in color parameters by addition of BSG have also been reported by a large body of literature [

8,

15,

28,

29].

2.3. Mineral Determination

Mineral content of the raw materials is presented in

Table 3. BSG is a rich source of macrominerals and microminerals, from which calcium (Ca), sodium (Na), magnesium (Mg), phosphorus (P) and zinc (Zn) reached higher values in all BSG samples. This is in line with Waters et al. [

30], who showed that BSG is a rich source in minerals such as Ca and Mg, being able to ensure the human daily recommended requirements for Mg (255 mg/day).

With respect to BSG minerals content, Bonifácio-Lopes et al., (Bonifácio-Lopes, Teixeira and Pintado 2020) mentioned that BSG minerals content could vary, as follows: P (1400–600 mg/kg), Ca (2200–3515 mg/kg), Mg (1900–2400 mg/kg), Na (258.1–700 mg/kg). Furthermore, Naibaho et al. [

8] justified the difference in BSG mineral content through the type of processing beer, handling and the drying method of the spent grain used, corelated with the treatment during storage. Likewise, a study of BSG from Brazil, Portugal and Ireland emphasized that minerals content could vary, and this is attributed to several factors such as barley type, harvest time, cultivation conditions and type of adjuncts used during wort elaboration [

31].

2.4. Volatile Aroma Compounds

A total number of 26 aroma volatile BSG compounds were separated, identified and displayed in

Table 4 and illustrated in

Figure 2. For a matter of facilitation, the volatile compounds were divided in alcohols, aldehydes, ketones, terpenes and terpenoids and others. From the alcohols group, the smallest amount was identified in BSG1 (1-pentanol: 2.72%), while BSG5 registered a 1-pentanol amount of 5.36%.

The aldehydes group was mainly represented by 2 methylpropanal, 3-methylbutanal, 2-methylbutanal and hexanal (

Table 4), which registered values of 29.8% (BSG 2 sample), 29.05% (in BSG 3), 24.19% in BSG3 and 19.81% (in BSG2 sample), respectively. These results aligned with Ktenioudaki et al. [

32], who also identified the aforementioned aldehydes compounds in BSG flour, and explained their provenience through fermentation process and the Maillard reaction. Moreover, the content of aldehydes is a consequence of kilning and roasting malt processes, as a result of lipid enzymolysis and volatilization. The suitable manipulation of the malting process could influence the total amount of aldehydes, as mentioned by Dong et al. [

33].

Ketones were characterized by 2-heptanone (1.09% for BSG2 sample), ethanone, 1-[4-(1-methylethyl) phenyl]- mostly identified in BSG1 sample and 3-Octen-2-one (0.52% in BSG3 sample), which are responsible for odor perception such as fruity, fungal, buttery, warm spicy, woody, herbaceous and earthy, spicy, herbal, sweet, nutty and fermented, respectively (

Table 4). Odor perception such as citrus, fresh, sweet and fresh citrus, terpenic, woody and spicy were mainly exhibited by D-limonene and

p-cymene, who registered significant amounts in BSG2 and BSG1 samples, respectively.

With respect to WF, a total number of only five aroma volatile compounds were identified, the main representative being 2-methyl-propanal (52.1%), hexanal (37.05%), acetophenone (8.12%) and D-limonene (0.63%); 2-methyl-propanal is responsible for odor perception such as wine, solvent, malty, fruity, hexanal for odors such as intense green, aldehydic, fruity, oily, meantime acetophenone gave odor perception of floral, must, spicy, almond, nutty and D-limonene exhibited odor perception such as citrus, fresh and sweet (

Table 4). This result is in line with Fărcaș and al. [

34], who showed that WF is a poor source in aroma volatile compounds, based mainly on aldehydes (91.99%) and ketones (8.02%).

2.5. Proximate Composition of the Final Baked Goods

Proximate composition of the samples is illustrated in

Table 5. BSG addition increased the protein, ash and crude fiber cookies content, being statistically different (

p < 0.05) from the control sample (

Table 5). The cookies moisture content is significantly higher compared to the BC sample, mainly because of fiber BSG composition, which leads to better water absorption [

34]. On the other hand, the physical fat entrapment during mixing, thanks to the newly formed network and the strong interaction between fat and BSG protein content, could lead to better fat absorption [

35], and therefore to a higher moisture sample content. Moreover, BSG fiber plays an important role in water absorption, due to the greater number of hydroxyl groups, which allows more water interaction through hydrogen bonding [

36].

The increased moisture of final products samples with increased BSG addition was also recently emphasized by Odeseye et al. [

35], who showed that a moisture content smaller than 12% is able to inhibit enzymatic and microbial activities, improving the stability and shelf life of the biscuits.

The highest content of protein was identified in B5 sample (8.89%), while the BC sample registered a value of 6.65%. This result could be attributed to BSG higher protein content compared to the WF. Similar patterns of biscuits and cookies protein enrichment through the utilization of BSG were reported by Guo et al., Odeseye et al. and Öztürk et al. [

28,

35,

37]. With respect to crude fiber content, addition of BSG increased the total crude fiber amount compared to that of BC samples, mainly due to BSG high content in crude fiber (ranging between 14.28% to 15.02%,

Table 1). These results aligned with previous studies, which reported a linear increasement of cookies dietary fiber and baked snacks total fiber content, with increasing BSG levels [

28,

32]. In this light, Odeseye et al. [

35] showed that the BSG biscuits fiber increment was attributed mainly to cellulose, lignin and hemicellulose BSG content, but also to the transition of insoluble fiber to soluble dietary fiber, owing to their alteration and formation of resistant starch.

The addition of BSG decreased total carbohydrate samples content (

Table 5) compared to the BC sample. A possible explanation of decreasing carbohydrate BSG samples amount is mainly because of BSG’s low starch content (42.32%), considering that during the mashing process, the majority of starches were solubilized and digested [

35]. Furthermore, the cookies energy (kcal/1005) decreased through BSG addition, mainly because of its lower carbohydrate content (42.12–43.77%,

Table 1) compared to WF (74.78%,

Table 1).

The total phenols higher values of baked samples compared to the BC sample could be explained by BSG’s higher total phenols content (211–258 mg GAE/100 g f.w.,

Table 1) compared to those of WF (31.14 mg GAE/100 g f.w.

Table 1). This increment could be justified by BSG content in hydroxycinnamic acids such as p-coumaric, ferulic, sinapic and caffeic acids [

38], as well as through its content in p-hydroxybenzoic, protocatechuic and chlorogenic acids, together with ferulic, p-coumaric and sinapic acids [

21]. Ferulic and p-coumaric acids are identified in bigger amounts in BSG (35–490 mg/100 g d.w and 6.7–180 mg/100 g d.w., respectively), with ferulic acid being considered as the BSG target product [

39]. Moreover, ferulic acid has similar effect to vitamin C, being used in prevention of food oxidation [

39]. With respect to samples with different types of BSG addition, the highest total phenols amount was reached by the B4 sample, followed by B3 and B1 sample, respectively (

Table 5). A strong Pearson relationship (r

2 = 0.9965) was identified between BSG raw material and their corresponding final baked goods.

The phenolic molecules have been claimed by literature as having high antioxidant activity, exhibiting a potential protective role against chronic diseases such as diabetes, cancer and cardiovascular diseases [

6,

7]. Furthermore, hydroxycinnamic acids revealed anti-inflammatory, anti-platelet aggregation and antibacterial effects [

40], and ferulic acid was claimed to have a positive influence on the gastrointestinal tract, being able to mediate a prebiotic modulation in gut microbiota [

29].

In the present study, the BSG cookies antioxidant activity (

Table 5) is bigger than the BC sample (

Table 5), mainly due to higher BSG radical scavenging activity (22.56–25.41%,

Table 2), compared to those of WF (7.98%,

Table 1). A strong Pearson correlation (r

2 = 0.9717) between BSG and final baked goods antioxidant activity emphasized the influence exhibited by the different types of BSG. The increased level of total phenols by the addition of BSG was emphasized also by Shih et al. [

18] who showed that muffins with 20% BSG exhibited higher values of total phenols and antioxidant activity compared to the control sample. BSG total phenols could act as antioxidants in food manufacturing and processing, enhancing the antioxidant activity of the final baked products [

18].

2.6. Mineral Samples Content

The cookies’ mineral content is displayed in

Table 6. The addition of different BSG types influence in a positive way the macro and mineral content of the baked goods, excepting Na content, which was bigger in the BC sample. This could be justified by the higher amount of Na in WF (1284.05 mg/kg,

Table 2) compared to BSG samples (486.14–514.37 mg/kg). Generally, BC sample is poorer in minerals (

Table 6) compared to BSG samples, mainly due to less wheat flour minerals content (

Table 3). In view of this, it is important to mention that, as reported by Gómez et al. [

41], refined wheat flour, mainly used for bakery and pastry products, is a poor source in minerals, as follows: Ca (150 mg/kg), Mg (220 mg/kg), P (1080 mg/kg), Fe (11.70 mg/kg).

From the macro-minerals group, the richest sample in Ca and Mg was B3, registering values of 320 mg/kg and 159.49 mg/kg, respectively (

Table 6). Microminerals such as Fe registered a higher value in B3 sample, while P was significantly higher in B5 sample (952.25 mg/kg). Pearson correlations of r

2 = 0.998 and r

2 = 0.997 showed a strong relationship between the total amount of BSG macro and micro-minerals compared with the final baked products.

Minerals such as Ca and Mg are reported by the literature as being involved in human metabolism by having a positive influence on bone structure, water and salt balance, while Zn deficiency could lead to dry skin, brittle nails and respiratory tract infections [

42]. Furthermore, in the USA, the fortification of cereals goods in Ca is considered a positive factor in reducing the apparition of cancer colon and osteoporosis. A diet supplemented in Mg is highly recommended, since this could offer protection against obesity and diabetes mellitus type 2 [

30].

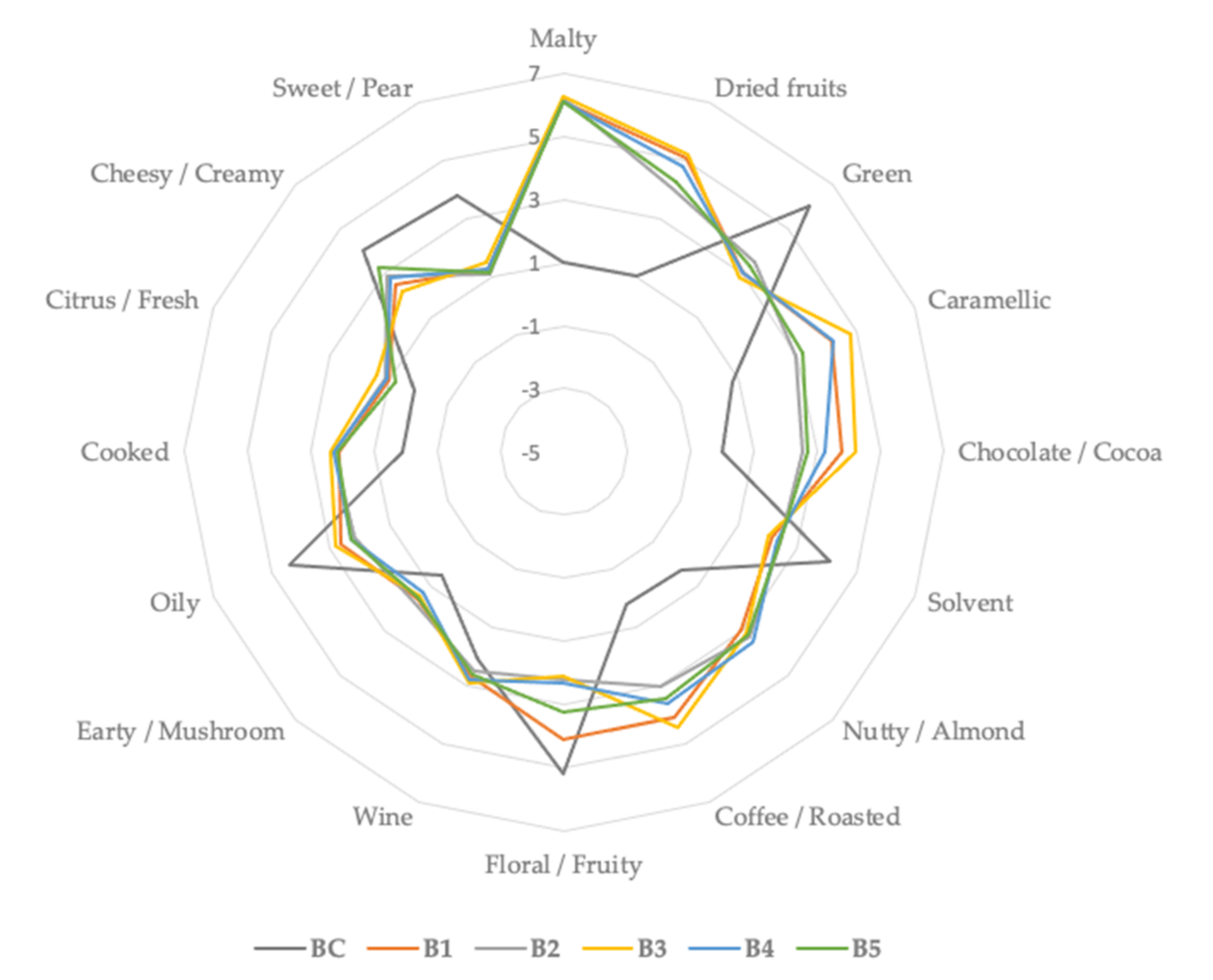

2.7. Volatile Aroma Compounds Analysis

The aroma volatile profile of the final baked products and their odor perception are displayed in

Table 7, and divided into six groups as follows: alcohols, aldehydes, ketones, esters, terpene and terpenoids and other compound classes. Positive Pearson correlations were identified between alcohols, aldehydes and ketones groups (r

2 = 0.801, 0.798, 0.732) from BSG samples and final baked goods. The predominant volatile aroma compounds are aldehydes, with a total amount of 64.39% for the control sample and 68.31% to 75.37% for the BSG final baked samples. From the aldehydes group, the main compounds from BC sample were hexanal (32.03%), followed by 2-methyl-propanal (22.14%), while acetic acid, hexyl ester (10.81%) and 2-heptanone (8.6%) were the main representants of the esters and ketones group.

With respect to cookies samples with different BSG type addition, from the aldehydes, group 2-methyl-propanal reached the highest content in the B1 sample (25.03%), followed by hexanal, which was identified in a total amount of 20.29% in the B2 sample, by 3-methyl-butanal, mainly identified in the B3 sample and 2-methyl-butanal, mainly identified in the B1 sample (15.8%). The aforementioned compounds from the aldehydes group are responsible for odor perception such as malty, fruity, dry fruits, nutty, chocolate, cocoa, fatty and caramelly, leading to a pleasant consumer odor perception, and have been also identified in bigger amount in BSG samples (

Table 4 and

Figure 3). This finding suggests that the different BSG types exhibited a positive influence of the final baked aroma volatile compounds samples. For a better comprehension of the cookie’s aroma profile, samples were grouped considering their odor perception and illustrated in

Figure 3.

The results are in line with those obtained by Fărcaș et al. [

34], who mentioned almost the same aldehydes compounds in final baked goods such as bread, by replacing wheat flour with a different BSG addition. In snacks manufacturing, Ktenioudaki et al. [

32] identified as main BSG aldehydes compounds 3-methyl-butanal, 2-methyl-butanal, pentanal and butanal, showing that the source of 2-methyl-butanal and 3-methyl-butanal might be through fermentation and the Maillard reaction, while 2-methyl-propanal could be exhibited through fermentation and dough processing.

The Maillard reaction is defined as a non-enzymatic process based on the reaction of amino-acids and sugars, which leads to the formation of melanoidins (brown pigments) and various volatile compounds such as aldehydes, amino-ketones, pyrazines, pyrroles, oxazole’s and thiophenes [

43]. There are two main stages during the Maillard reaction: Strecker degradation and Ehrlich pathway. It seems that during Strecker degradation, thanks to the reaction between amino-acids and dehydroreductones, aldehydes are formed. For instance, 3-methyl-butanal was corelated to leucine amino-acids, 2-methyl-butanal to isoleucine and 2-methyl-propanal with valine amino-acid [

43]. The formation of aldehydes, thanks to Strecker degradation, is sustainable considering that BSG is a rich source in amino-acids such as leucine (6.12% total protein), isoleucine (4.64% total protein) and valine (4.61% total protein), according to [

9].

Hexanal (from the aldehydes group) is a result of lipid oxidation process, and is was reported by Bernal et al. as an off-flavor compound [

44]. Hexanal was identified in a larger amount in control cookies samples (32.03%), while in BSG cookies the amount ranged between 16.18% to 20.29%. The higher hexanal amount in the BCM sample could be explained by the fact that WF is abundant in hexanal (37.05%,

Table 3), while BSG hexanal content was identified in a range of 12.06% to 19.01%.

From the alcohols group, two compounds were identified (1-Pentanol, 1-Octen-3-ol), which according to Fărcaș et al. [

23], are considered as lipid oxidation products with a bready, balsamic, green and earthy odor. 2-Heptanone and acetophenone were the identified compounds from ketones group, responsible for odor perception such as sweet fruity, fresh ripe and slightly green.

2.8. Color Parameters and Physical Characteristics of Cookies

The color of the cookies changed in a significant way by BSG addition (

Figure 1), with

L*,

a* and

b* values being significantly different (

p < 0.05) from the control sample, as displayed in

Table 8. The control sample had the highest values for

L* and

b*, while

a* value was the lowest one. In the same vein, Heredia-Sandoval et al. [

29] highlighted that

L* and

a* values were negatively influenced by the increased BSG levels, while

b* value recorded a positive trend.

Likewise, Amoriello et al. [

6] stated that BSG addition changed in a significant way the color intensity of the final baked products such as pizza, breadsticks and bread by decreasing lightness and yellowness (

b*) parameters, while redness (

a*) parameter registered increased levels. This could be mainly justified by BSG’s high amino-acid content, which favored the Maillard reaction and influenced the lightness and redness parameters [

6]. In this vein, BSG is a rich in histidine (26.27% total protein), glutamic acid (16.59% total protein), aspartic acid (4.81% total protein), valine (4.62% total protein), arginine (4.51% total protein) but also in essential amino-acids such as lysine (14.31% total protein), leucine (6.12% total protein) and phenylalanine (4.64% total protein) [

45], being able to facilitate Maillard reaction.

The main physical evaluation of cookies is considered as width (diameter) and thickness [

29]. Moreover, Man et al. [

46] mentioned spread ratio and weight as other physical characteristics that should be analyzed, together with color [

29]. The physical cookies characteristics are displayed in

Table 7. Regarding weight, there was a significant difference between control samples and BSG cookie (

p < 0.05) mainly due to BSG higher content of protein and fibre, which better retained water during thermal treatment. Diameter did not differ in a significant way, while spread ratio encountered significant differences (

p < 0.05) between the control sample and BSG samples (

Table 7). Our results are in line with those reported by Guo et al. [

40], who mentioned no significant differences on biscuits diameter, while thickness value registered only slightly variation with increasing BSG levels. With respect to spread ratio, significant differences were recorded between control samples and BSG cookies, and could be explained by the higher protein content of BSG compared to WF, which during the mixing and baking process is able to form a protein network able to enhance spread ratio values [

8]. Moreover, Naibaho et al. [

8] mentioned that higher BSG addition could be involved in reducing diameter values, and therefore influence the spread ratio value in a positive way.

2.9. Sensory Analysis

Combest et al. [

47] highlighted that BSG addition could influence the sensorial features of the final baked goods such as odor, color, texture and flavor, and therefore the consumers’ sensory analysis regarding the acceptance of the new developed products is highly required. The use of BSG in food manufacturing was associated with a positive effect in increasing food’s appeal, consumers placing sensory properties after health issues [

8,

48].

In the present study, for the appearance attribute significant differences were encountered between control sample and B3 sample (

p < 0.05). This could indicate that panelists were able to visually discriminate the sample based on their color and final surface cookies degree imperfections. The highest appearance score was registered by the B3 sample, followed by B4 and B1 (

Table 9). It was stated that BSG used in food manufacturing is expected to increase food appeals, based on consumers’ awareness to place health food benefits as a main criterion in food selection. Most of the published researchers suggested that an addition of BSG as a substitution ingredient between 20–25% is considered to be effective from the nutritional point of view [

8]. For instance, the phrase “high in fiber” is associated by consumers with outcomes such as “better digestion”, “satiety”, “natural and pure” and “weight control” [

48]. Moreover, Naibaho et al. [

8] stated that the addition of BSB had changed the color of the final baked goods into a unique dark color, which is assumed to be healthier. The color changes could be also a result of pigment degradation, caramelization, Maillard reaction and hydrolysis.

Texture was analyzed from attributes such as hardness, chewiness and crispiness (

Table 9). Crispiness was defined as the force and noise produced, while the sample breaks during the chewing sample on the molar teeth [

49]. With respect to hardness and chewiness, addition of BSG increased the samples’ score, but to levels which were appreciated by consumers (

Table 8). The increased hardness values in BSG cookies compared to BC could be explained by pentopans, a fiber BSG component that might cause hardening through gluten protein cross linking [

36]. In the same vein, Petrovic et al. [

15] showed a linear positive hardness and chewiness increasement on cookies, as the BSG level increased due to its high content in proteins and fiber.

With respect to taste and aroma attribute, the B3 sample registered the highest hedonic score (8.75), followed by B4 and B5 samples, respectively (

Table 9). The aroma of the final baked products could be influenced by the volatile compounds identified previously (

Table 7), such as aldehydes group from which 2-methyl-butanal, 2-methyl-propanal, 3-methyl-butanal and hexanal reached higher values and odor perception, such as fruity, chocolate, coffee, malty, nutty and rummy, characterized the aforementioned aroma volatile compounds; this could also explain the consumers’ preferences towards the B3 sample. In the same idea, a study realized by Combest et al. [

47] with 37 college students as panelists emphasized that BSG presented as a raw material in mason jars was characterized as having odor perceptions such as “sweet”, “warm”, “earthy” and “nutty”. Moreover, BSG aroma snacks was related to the fresh aroma of homemade bread, characterized as smelling “like home”.

The overall appreciation attribute encountered that the B3 sample was highly appreciated by consumers with a hedonic score of 8.97, followed by the B4 and B1 samples (

Table 8).