3D Printed End of Arm Tooling (EOAT) for Robotic Automation

Abstract

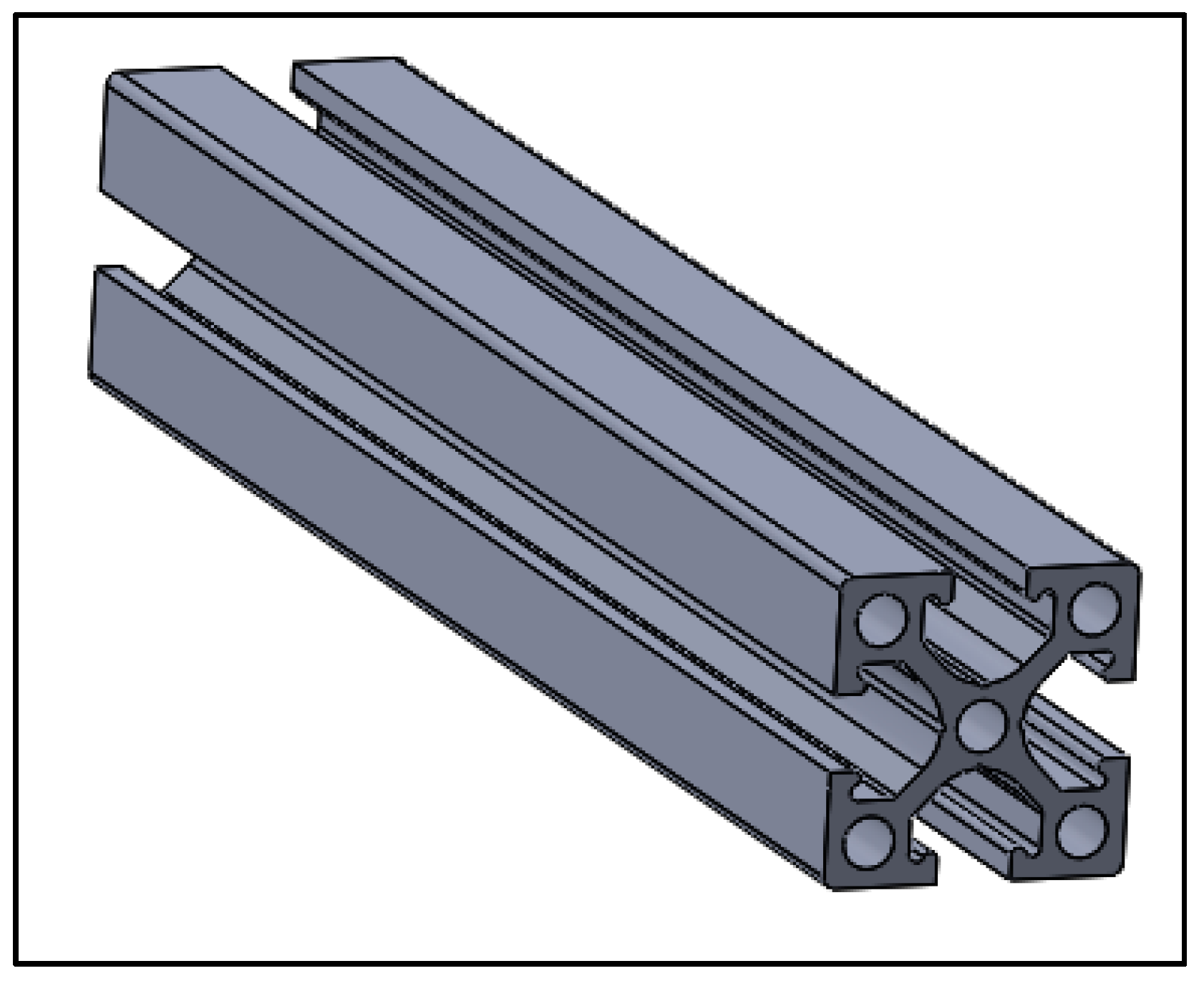

1. Introduction

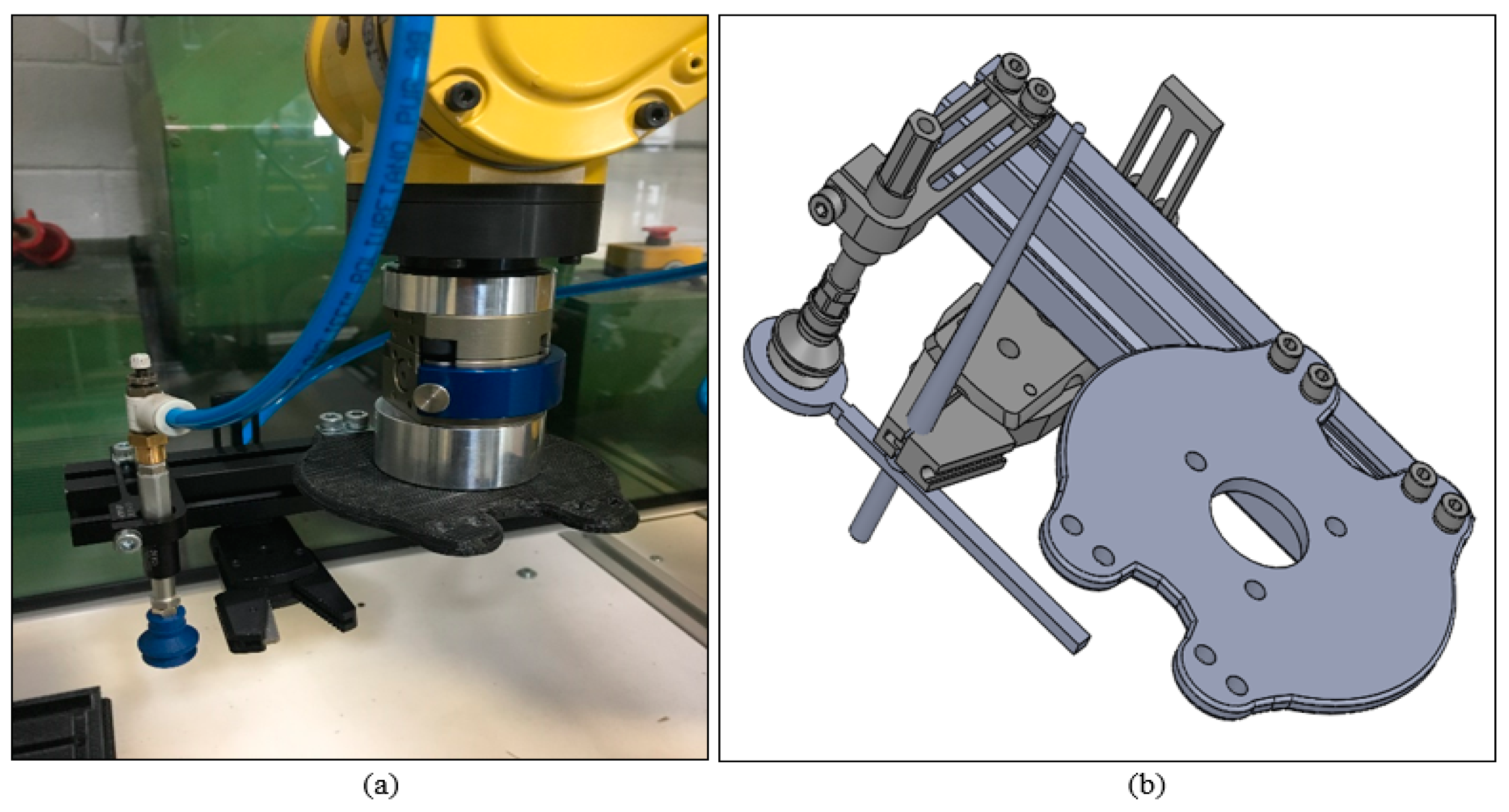

2. Materials and Methods

2.1. Acrylonitrile Butadiene Styrene (ABS)

2.2. Nylon

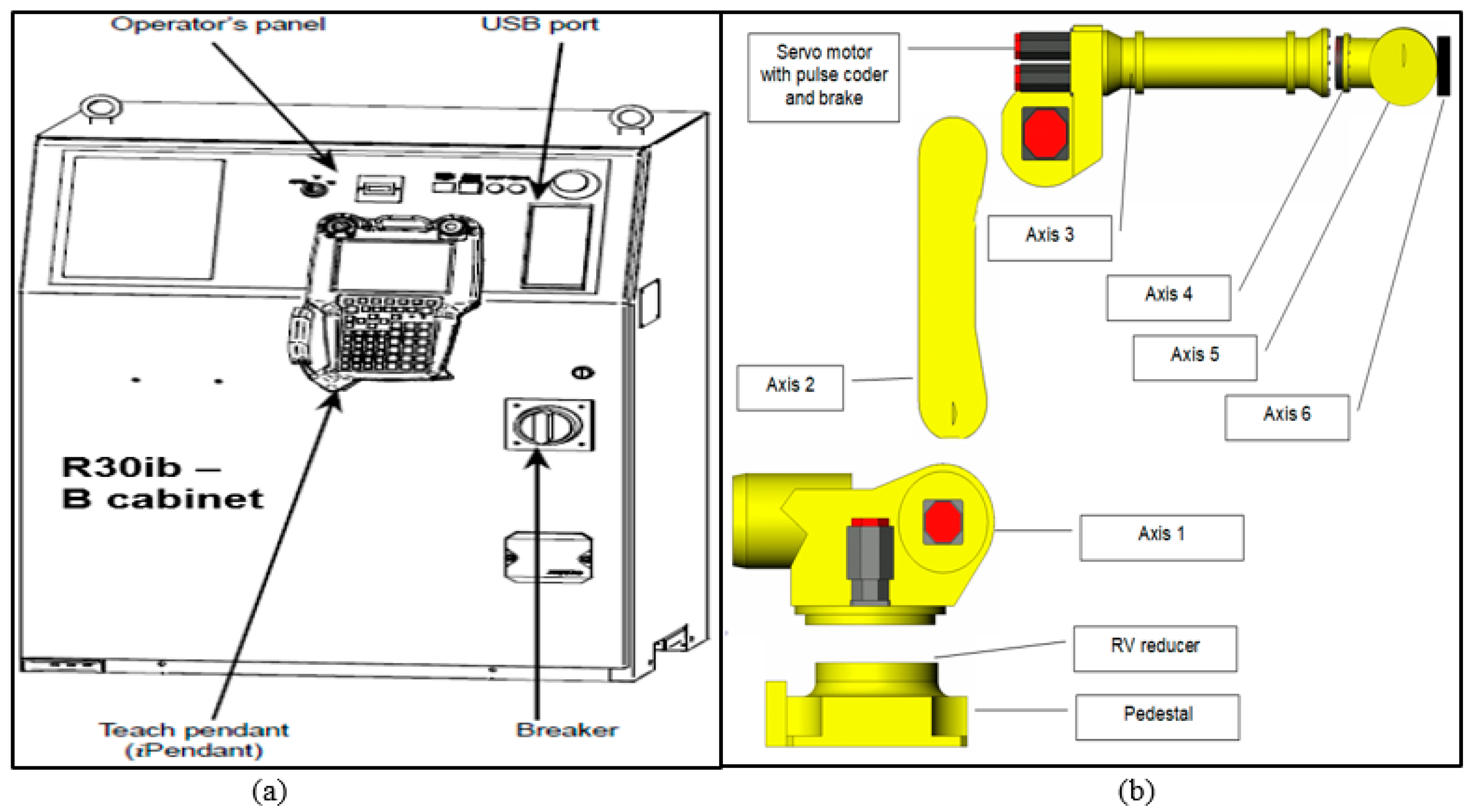

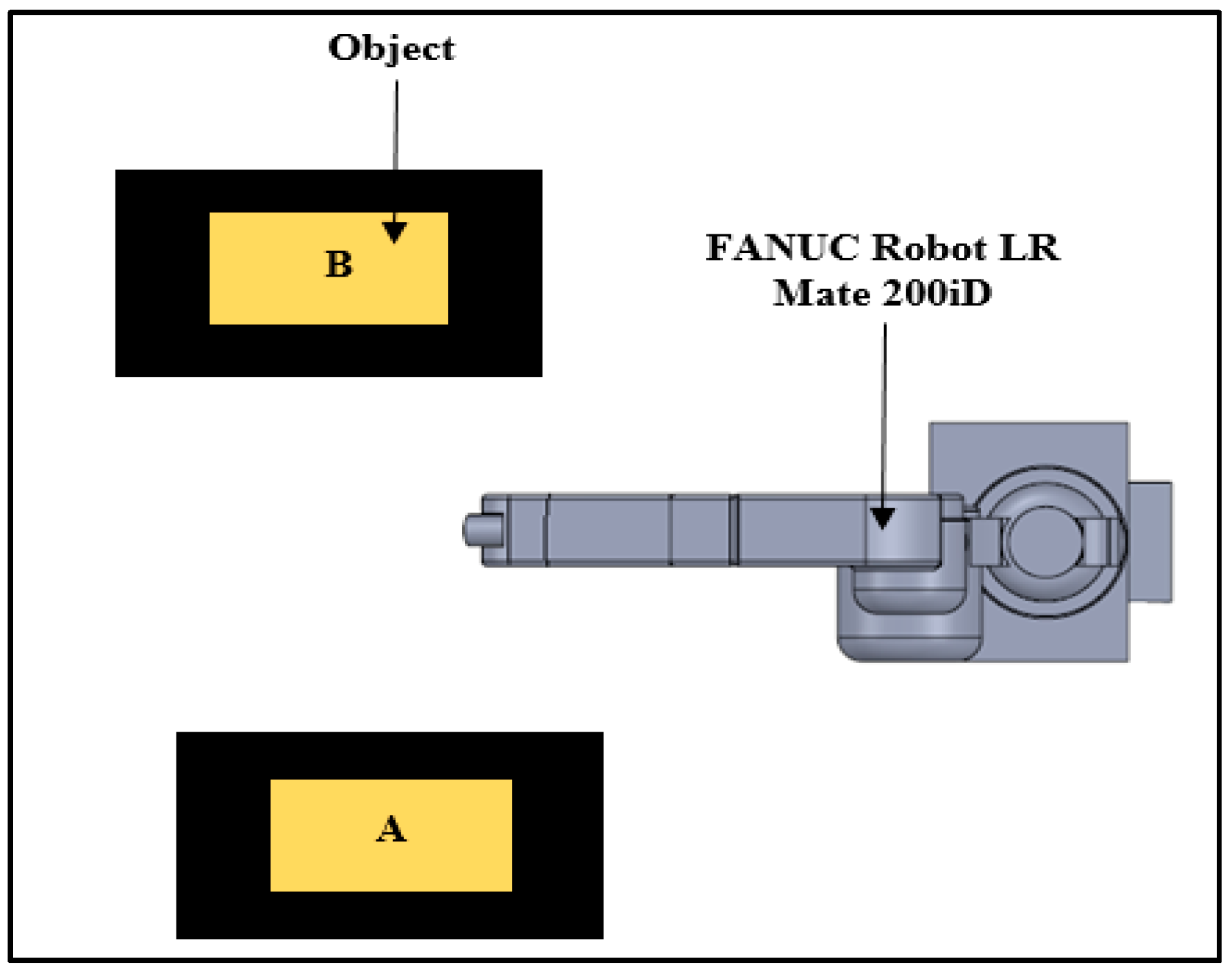

2.3. FANUC Robot LR Mate 200iD

- P = Power (W)

- I = Current (A)

- V = Voltage (V)

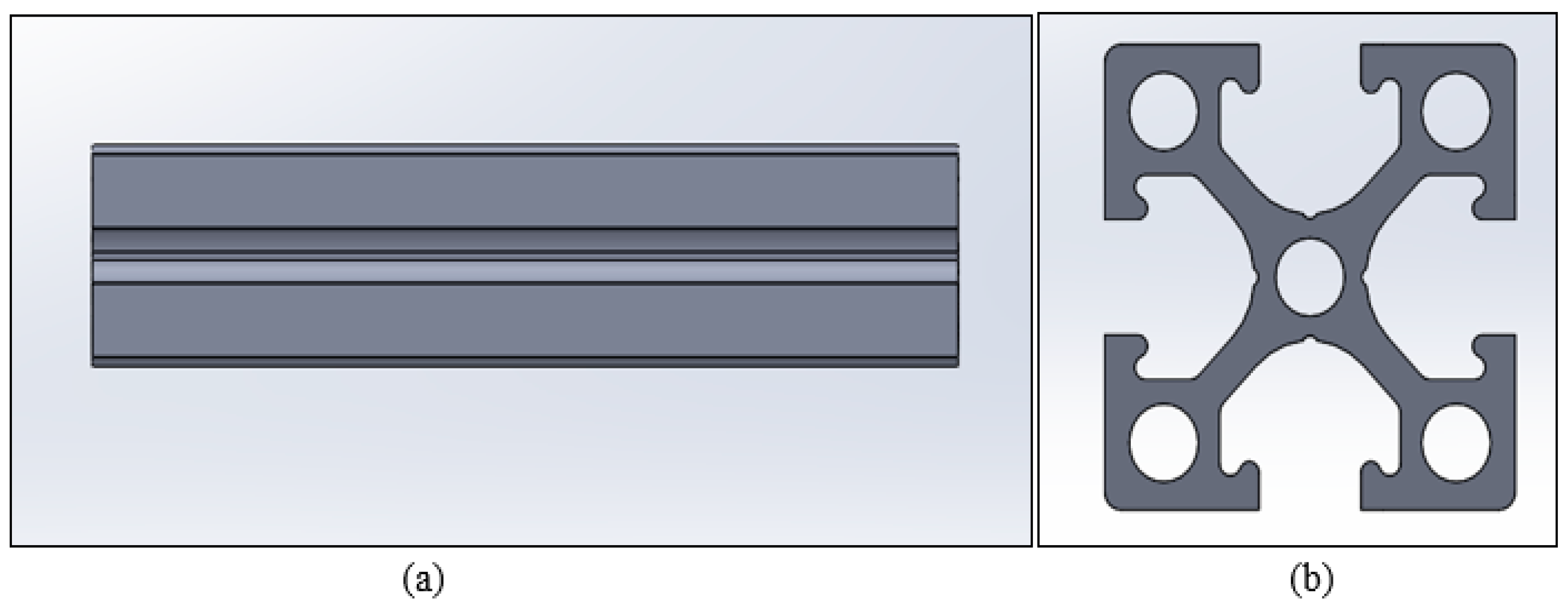

2.4. 3D Printer

2.5. Density Test

2.6. Three-Point Flexural Test

- σf = Stress in outer fibers at midpoint, (MPa)

- εf = Strain in the outer surface, (mm/mm)

- Ef = flexural Modulus of elasticity, (MPA)

- F = load at a given point on the load deflection curve, (N)

- L = Support span, (mm)

- b = Width of test beam, (mm)

- d = Depth or thickness of tested beam, (mm)

- m = The gradient of the initial straight-line portion of the load deflection curve, (N/mm)

- y = deflection at load point (mm)

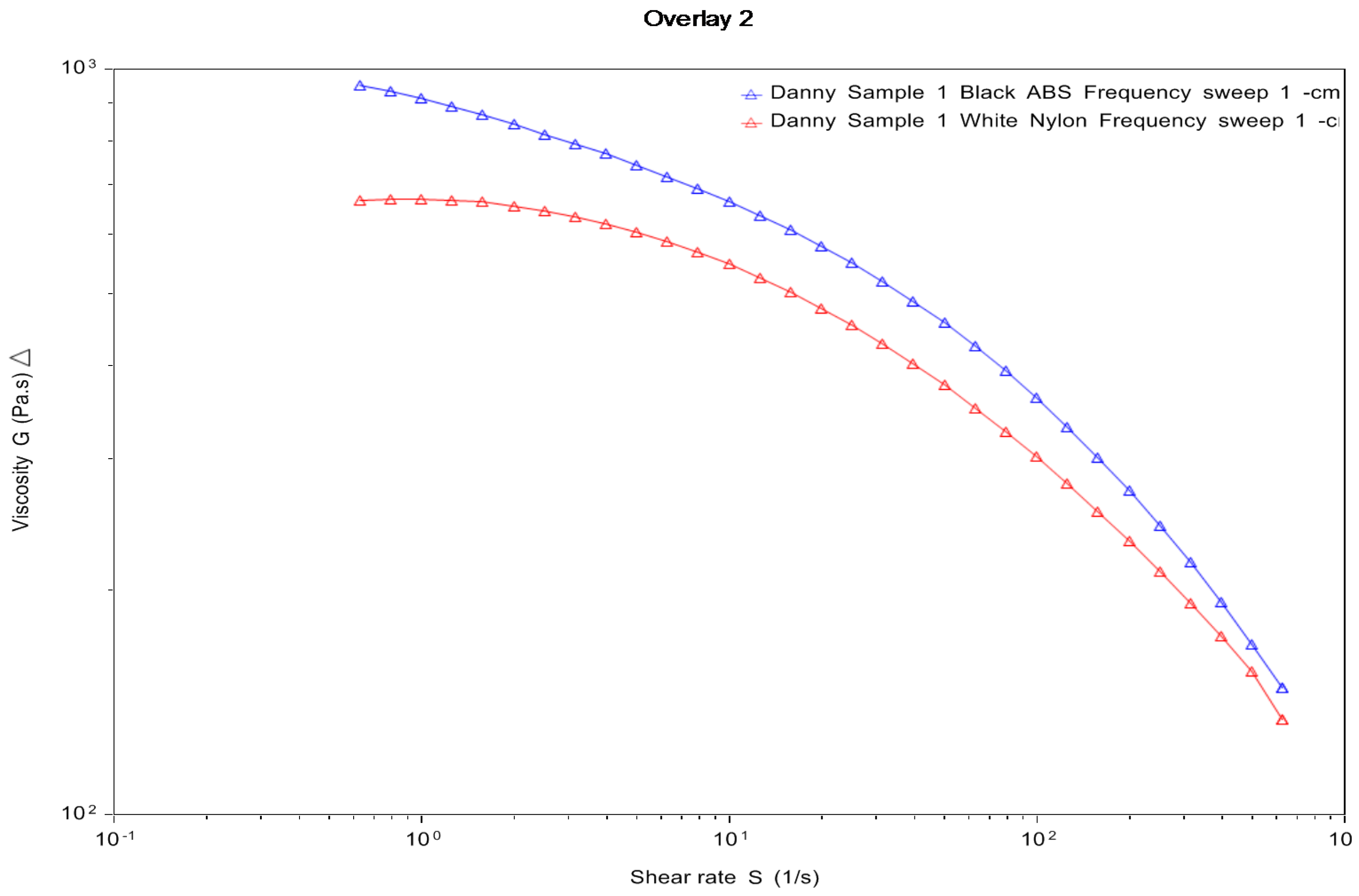

2.7. Rheology

3. Results & Discussion

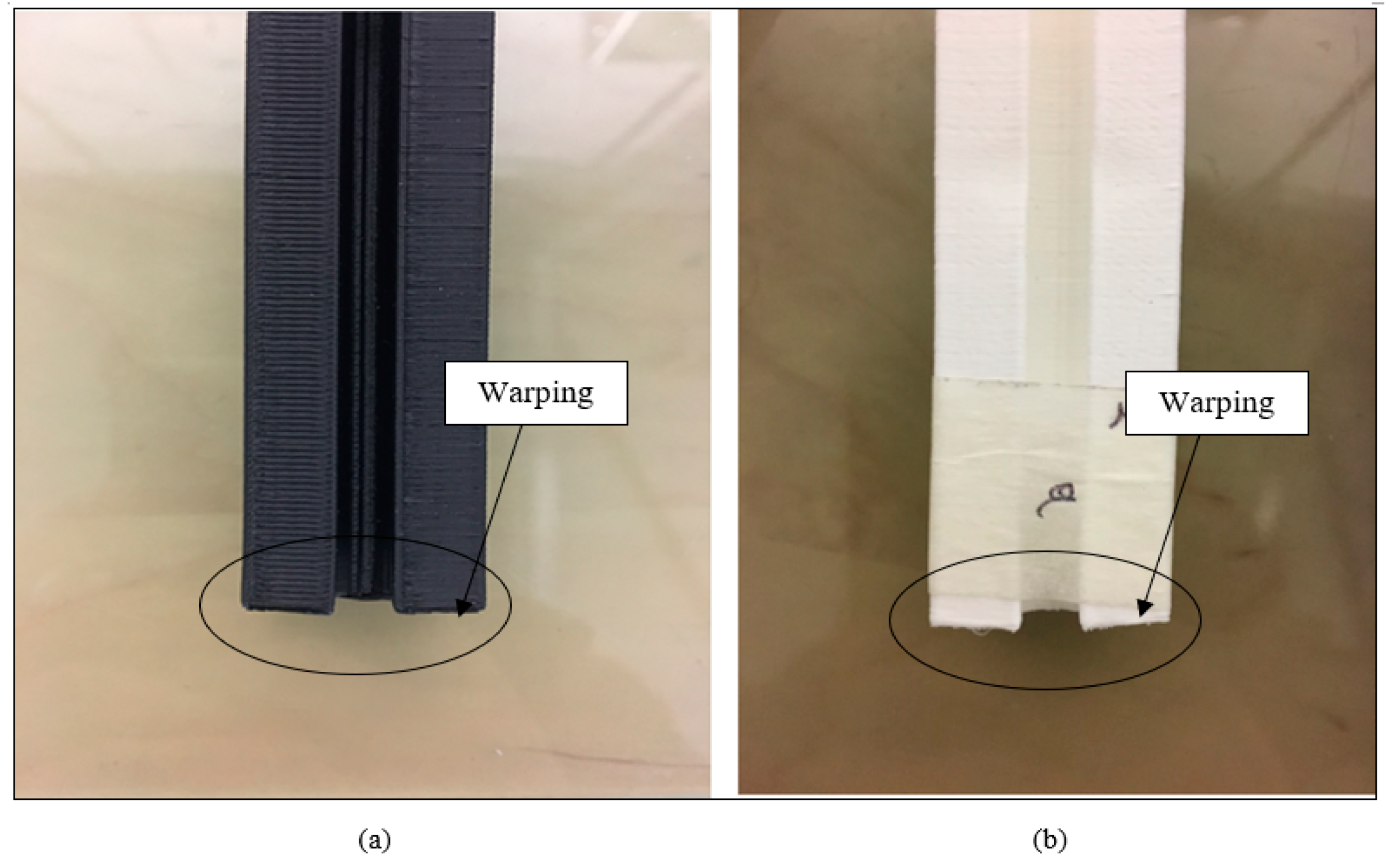

3.1. 3D Printer

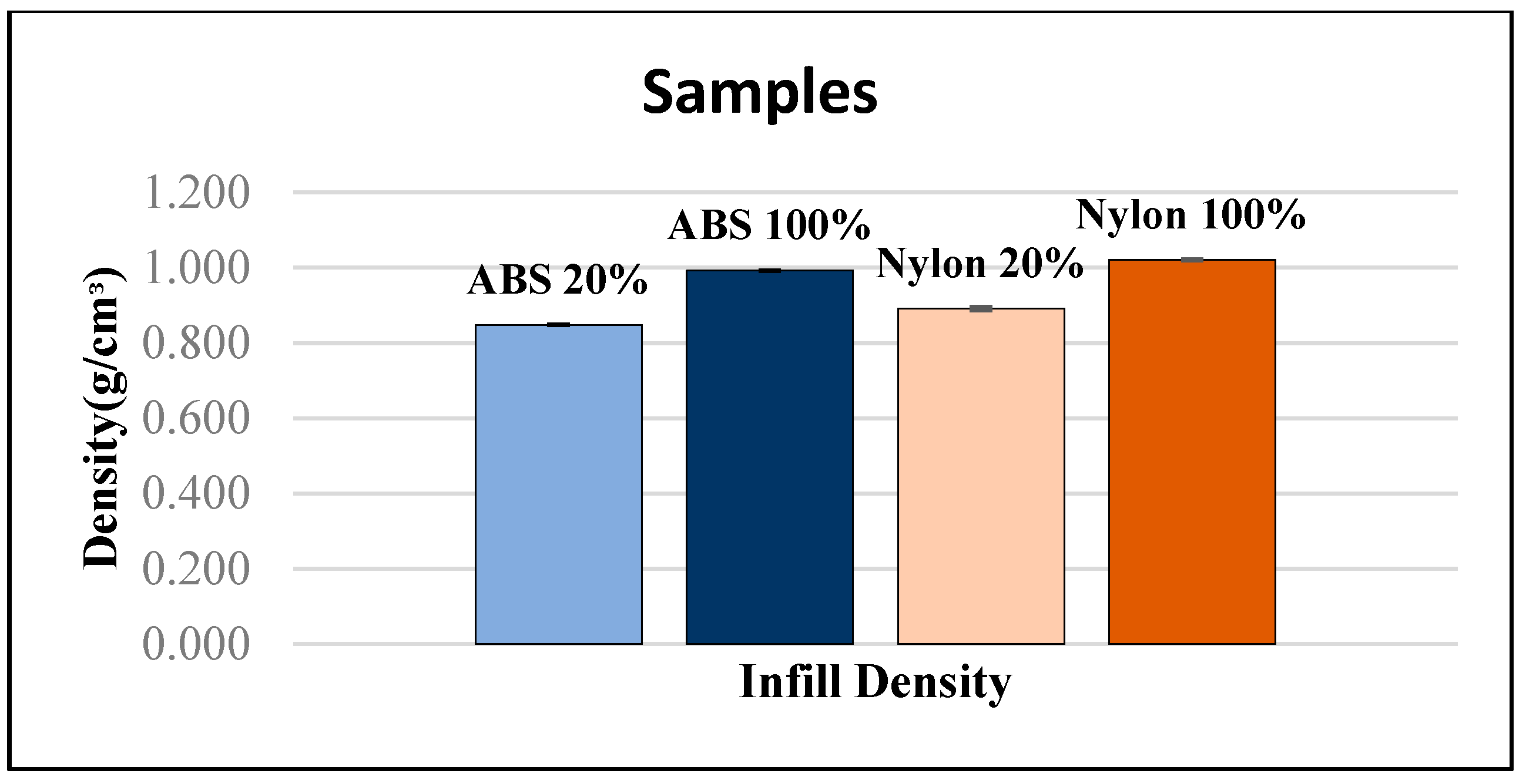

3.2. Density Test

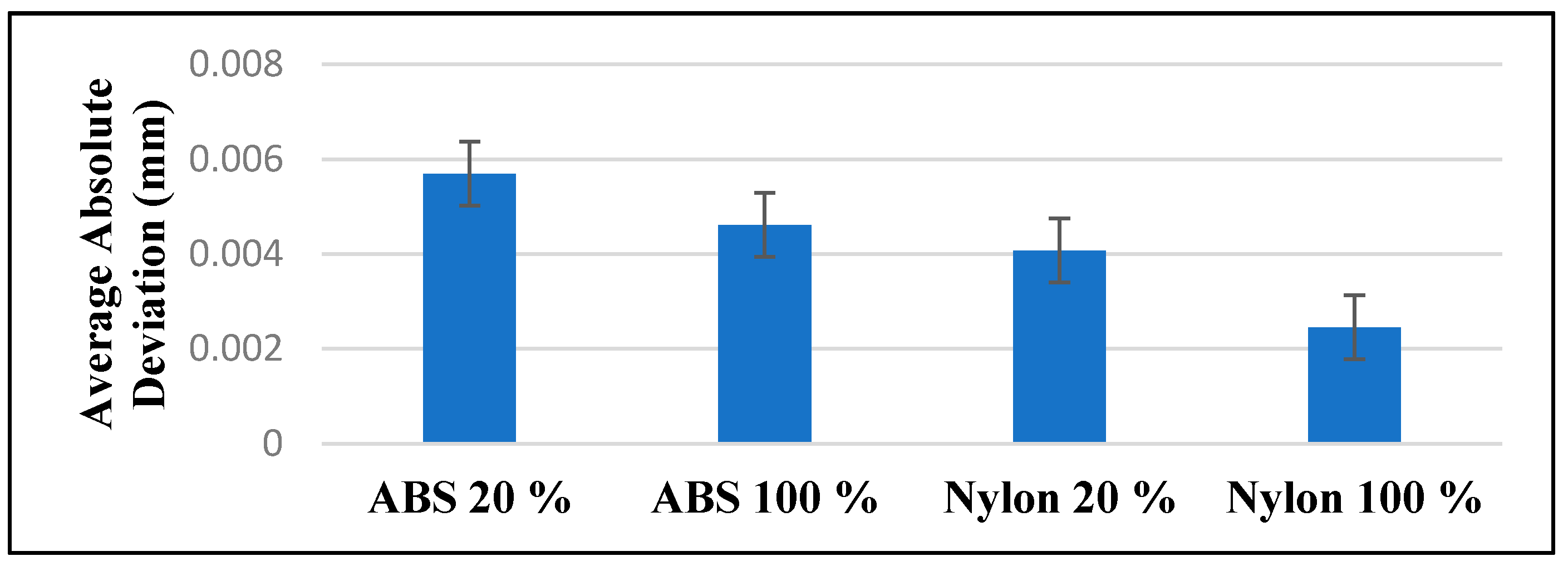

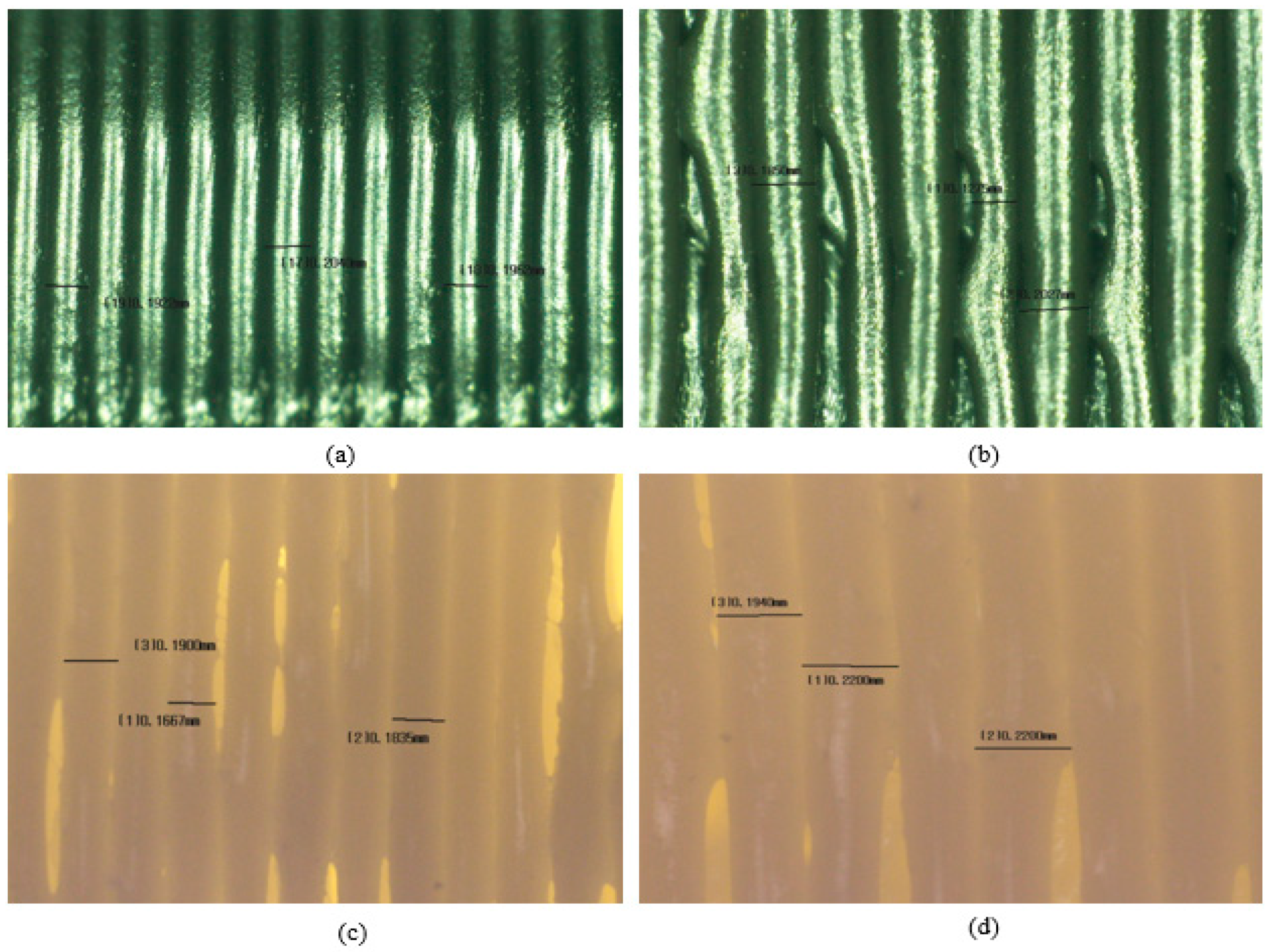

3.3. Digital Microscopy

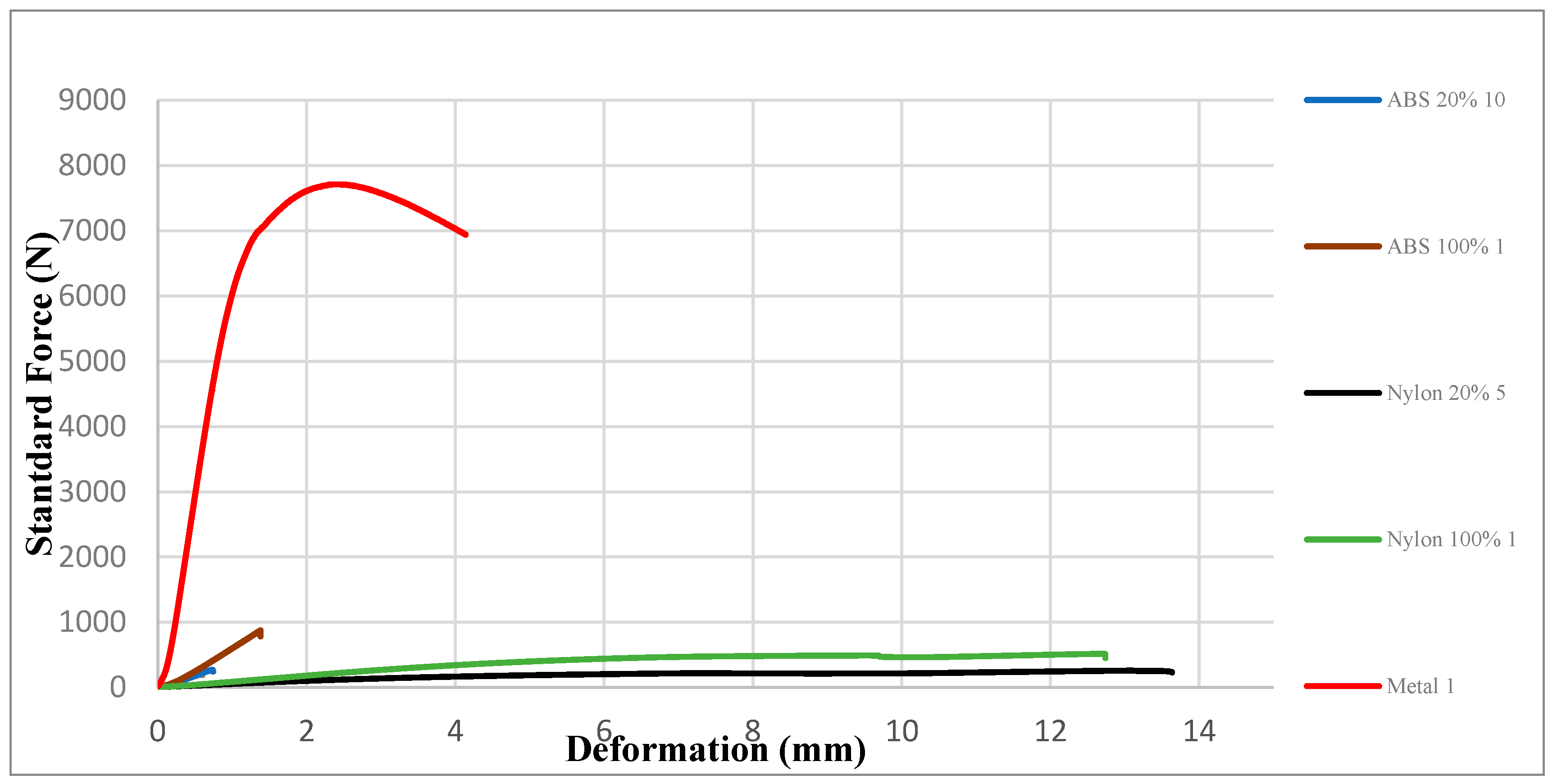

3.4. Three-Point Flexural Test

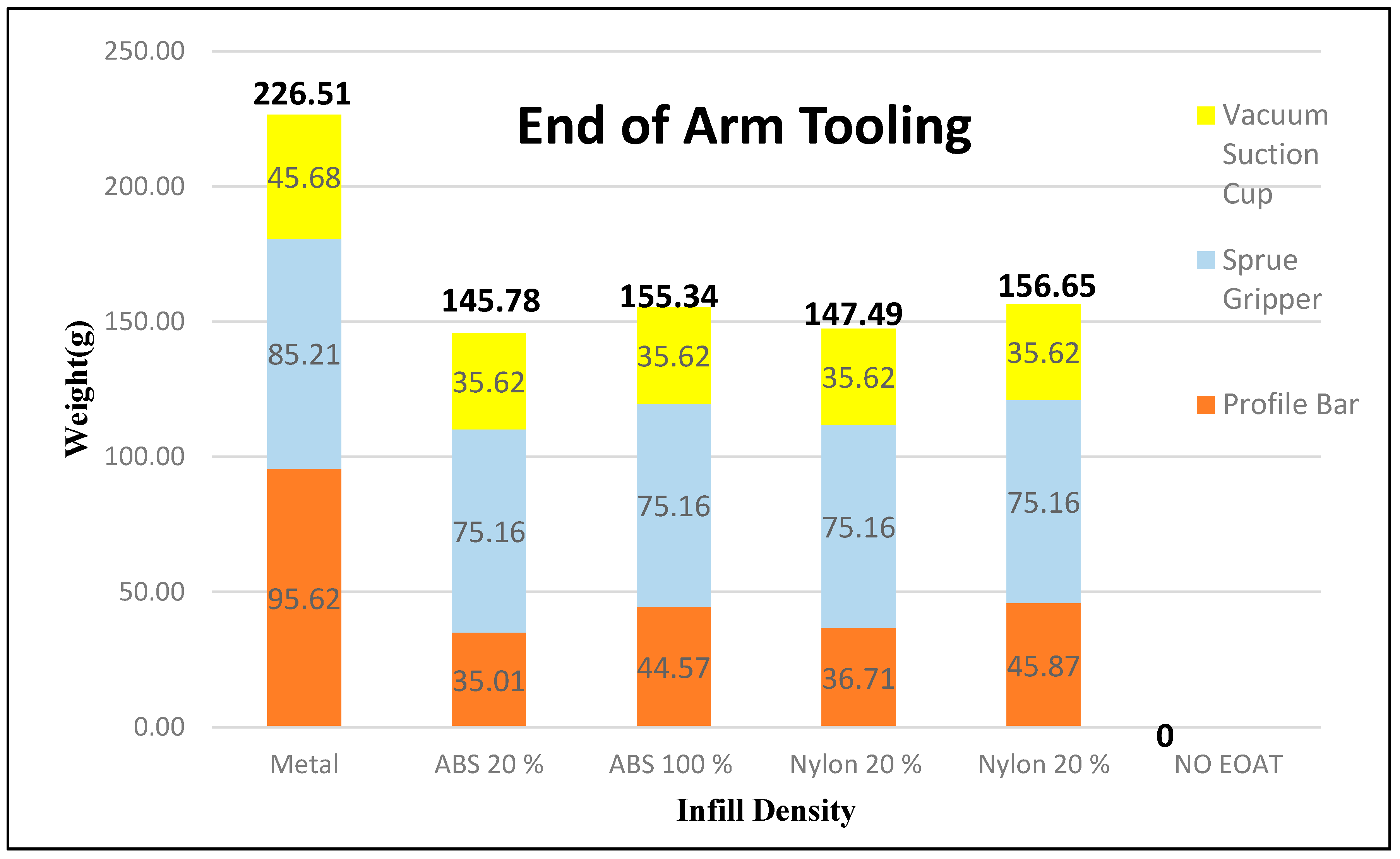

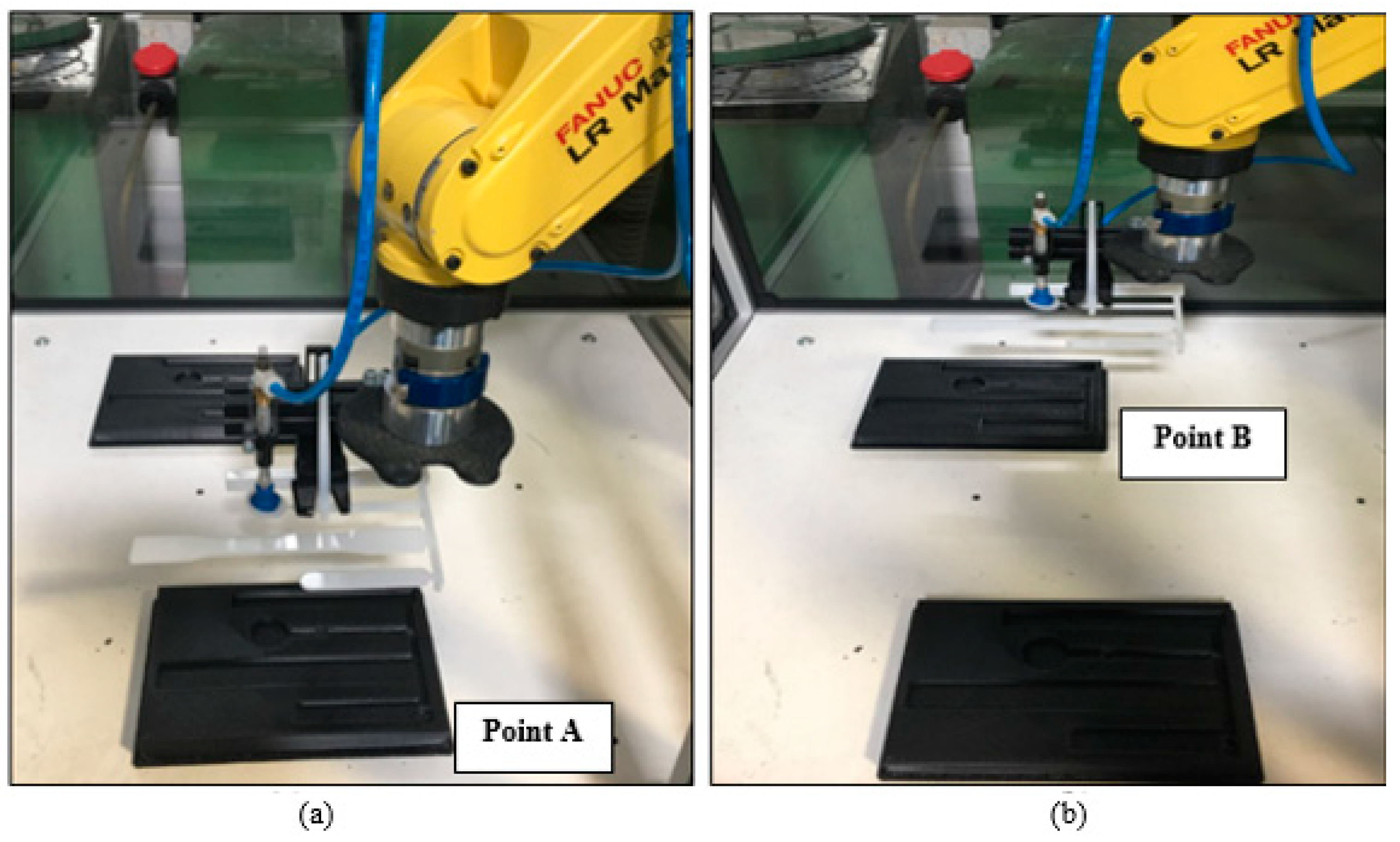

3.5. FANUC Robot LR Mate 200iD

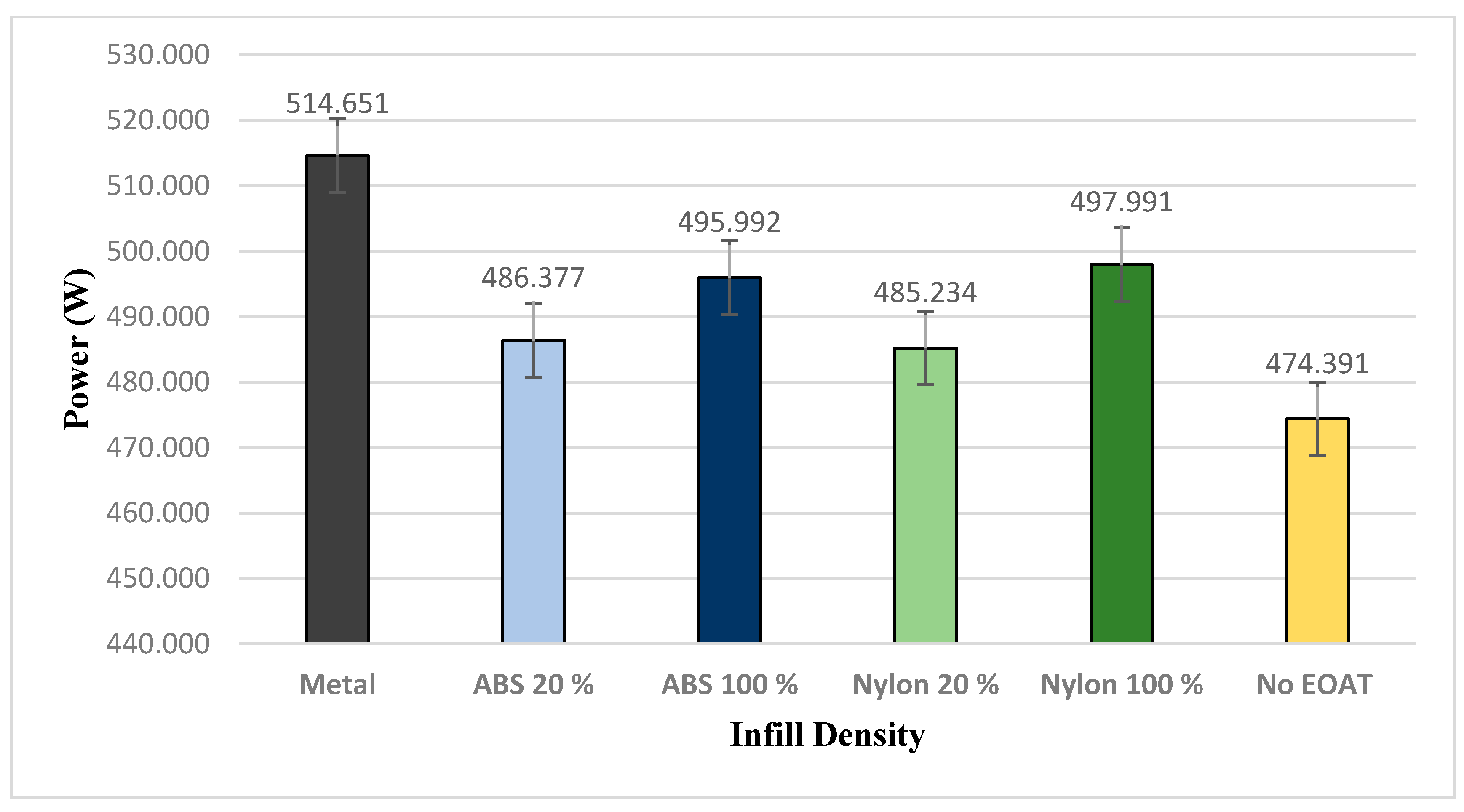

Peak Power Measurement

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Elfasakhany, A.; Yanez, E.; Baylon, K.; Salgado, R. Design and Development of a Competitive Low-Cost Robot Arm with Four Degrees of Freedom. Mod. Mech. Eng. 2011, 1, 47–55. [Google Scholar] [CrossRef]

- Palmerini, E.; Bertolini, A.; Battaglia, F.; Koops, B.J.; Carnevale, A.; Salvini, P. RoboLaw: Towards a European framework for robotics regulation. Robot. Auton. Syst. 2016, 86, 78–85. [Google Scholar] [CrossRef]

- National Bureau of Standards; NBS/RIA Robotics Research Workshop: Washington, DC, USA, 1981.

- Al-faiz, M.Z.; Shanta, A.F. Kinect-Based Humanoid Robotic Manipulator for Human Upper Limbs Movements Tracking. Intell. Control Autom. 2015, 6, 29–37. [Google Scholar] [CrossRef]

- Zhang, Y.; Chou, K. A parametric study of part distortions in fused deposition modelling using three-dimensional finite element analysis. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2008, 222, 959–968. [Google Scholar] [CrossRef]

- Love, L.J.; Kunc, V.; Rios, O.; Duty, C.E.; Elliott, A.M.; Post, B.K.; Smith, R.J.; Blue, C.A. The importance of carbon fiber to polymer additive manufacturing. J. Mater. Res. 2014, 29, 1893–1898. [Google Scholar] [CrossRef]

- Casavola, C.; Cazzato, A.; Moramarco, V.; Pappalettera, G. Residual stress measurement in Fused Deposition Modelling parts. Polym. Test. 2017, 58, 249–255. [Google Scholar] [CrossRef]

- Jiang, C.; Zhao, G.-F. A Preliminary Study of 3D Printing on Rock Mechanics. Rock Mech. Rock Eng. 2014, 48, 1041–1050. [Google Scholar] [CrossRef]

- Aburaia, M.; Stuja, E.M.K. New concept for design and control of 4 axis robot usin. The additive manufacturing technology. Energy Procedia 2015, 100, 1364–1369. [Google Scholar] [CrossRef]

- Boboulos, M.A. CAD-CAM & Rapid Prototyping Application Evaluation; Bookboon: London, UK, 2010. [Google Scholar]

- Glodde, A.; Afrough, M. Energy efficiency evaluation of an underactuated robot in comparison to traditional robot kinematics. Procedia CIRP 2014, 23, 127–130. [Google Scholar] [CrossRef]

- Petrick, I.J.; Simpson, T.W. 3D Printing Disrupts Manufacturing: How Economies of One Create New Rules of Competition. Res. Manag. 2013, 56, 12–16. [Google Scholar] [CrossRef]

- FANUC Training Academy. Available online: https//www.fanuc.eu/fi/en/lifetime-management/academy (accessed on 20 June 2018).

- Baich, L.; Manogharan, G.; Marie, H. Study of infill print design on production cost-time of 3D printed ABS parts. Int. J. Rapid Manuf. 2015, 5, 308. [Google Scholar] [CrossRef]

- Wang, T.M.; Xi, J.T.; Jin, Y. A model research for prototype warp deformation in the FDM process. Int. J. Adv. Manuf. Technol. 2007, 33, 1087–1096. [Google Scholar] [CrossRef]

- Alsoufi, M.S.; Elsayed, A.E. Warping deformation of desktop 3D printed parts manufactured by open source fused deposition modeling (FDM) system. Int. J. Mech. Mechatron. Eng. 2017, 17, 7–16. [Google Scholar]

- Christiyan, K.G.J.; Chandrasekhar, U.; Venkateswarlu, K. A study on the influence of process parameters on the Mechanical Properties of 3D printed ABS composite. IOP Conf. Ser. Mater. Sci. Eng. 2016, 114, 012109. [Google Scholar] [CrossRef]

- Salih, S.E.; Hamood, A.F.; Alsalam, A.H.A. Comparison of the characteristics of LDPE: PP and HDPE: PP polymer blends. Mod. Appl. Sci. 2013, 7, 33–42. [Google Scholar] [CrossRef]

- Ahn, S.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef]

- Ramanath, H.S.; Chua, C.K.; Leong, K.F.; Shah, K.D. Melt flow behaviour of poly-ε-caprolactone in fused deposition modeling. J. Mater. Sci. Mater. Med. 2008, 19, 2541–2550. [Google Scholar] [CrossRef] [PubMed]

- Walia, P.S.; Lawton, J.W.; Shogren, R.L.; Felker, F.C. Effect of moisture level on the morphology and melt flow behavior of thermoplastic starch/poly (hydroxy ester ether) blends. Polymer 2000, 41, 8083–8093. [Google Scholar] [CrossRef]

- Sanatgar, R.H.; Campagne, C.; Nierstrasz, V. Investigation of the adhesion properties of direct 3D printing of polymers and nanocomposites on textiles: Effect of FDM printing process parameters. Appl. Surf. Sci. 2017, 403, 551–563. [Google Scholar] [CrossRef]

- Turner, B.N.; Strong, R.; Gold, S.A. A review of melt extrusion additive manufacturing processes: I. Process design and modeling. Rapid Prototyp. J. 2014, 20, 192–204. [Google Scholar] [CrossRef]

- Alic, A.; Zitko, R. Physics of 3D Printing; Seminar Ib: Ljubljana, Slovenia, 2017. [Google Scholar]

- Halidi, S.N.A.M.; Abdullah, J. Moisture effects on the ABS used for Fused Deposition Modeling rapid prototyping machine. In Proceedings of the 2012 IEEE Symposium on Humanities, Science and Engineering Research, Kuala Lumpur, Malaysia, 24–27 June 2012; pp. 839–843. [Google Scholar]

- Vigliotti, A.; Pasini, D. Stiffness and strength of tridimensional periodic lattices. Comput. Meth. Appl. Mech. Eng. 2012, 229–232, 27–43. [Google Scholar] [CrossRef]

- Song, J.; Helmig, C.; Schulz, A. Bending Test of Contact Materials. In Proceedings of the 52nd IEEE Holm Conference on Electrical Contacts, Montreal, QC, Canada, 25–27 September 2006; pp. 207–210. [Google Scholar]

- Belter, J.T.; Dollar, A.M. Strengthening of 3D printed fused deposition manufactured parts using the fill compositing technique. PLoS ONE 2015, 10, 1–19. [Google Scholar] [CrossRef] [PubMed]

- Soares, F.A.; Nachtigall, S.M.B. Effect of chemical and physical foaming additives on the properties of PP/wood flour composites. Polym. Test. 2013, 32, 640–646. [Google Scholar] [CrossRef]

- Peirson, B. Comparison of Specific Properties of Engineering Materials. In EGR 250—Materials Science and Engineering; Laboratory Module, School of Engineering, Grand Valley State University: Allendale, MI, USA, 28 June 2005. [Google Scholar]

- Helms, H.; Lambrecht, U.L. The potential contribution of light-weighting to reduce transport energy consumption. Int. J. Life Cycle Assess 2007, 12, 58–64. [Google Scholar]

- Wyatt, H.; Wu, A.; Thomas, R.; Yang, Y. Life Cycle Analysis of Double-Arm Type Robotic Tools for LCD Panel Handling. Machines 2017, 5, 8. [Google Scholar] [CrossRef]

| Material | Density (g/cm3) | Flexural Strength, Yield (MPa) | Specific Strength (kN·m/kg) |

|---|---|---|---|

| Metal (Al) | 2.70 | 67.021 | 24.823 |

| ABS 20% | 0.848 | 3.041 | 3.586 |

| ABS 100% | 0.992 | 7.237 | 7.295 |

| Nylon 20% | 0.892 | 2.162 | 2.424 |

| Nylon 100% | 1.036 | 4.479 | 4.323 |

| Material | Weight (g) | Power (W) | Power to Weight Ratio (W/Kg) |

|---|---|---|---|

| Metal (Al) | 226.51 | 514.641 | 2272 |

| ABS 20% | 145.78 | 486.377 | 3336 |

| ABS 100% | 155.34 | 495.992 | 3192 |

| Nylon 20% | 147.49 | 485.234 | 3289 |

| Nylon 100% | 156.65 | 497.991 | 3179 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ong U Jing, D.; Devine, D.M.; Lyons, J. 3D Printed End of Arm Tooling (EOAT) for Robotic Automation. Robotics 2018, 7, 49. https://doi.org/10.3390/robotics7030049

Ong U Jing D, Devine DM, Lyons J. 3D Printed End of Arm Tooling (EOAT) for Robotic Automation. Robotics. 2018; 7(3):49. https://doi.org/10.3390/robotics7030049

Chicago/Turabian StyleOng U Jing, Daniel, Declan M. Devine, and John Lyons. 2018. "3D Printed End of Arm Tooling (EOAT) for Robotic Automation" Robotics 7, no. 3: 49. https://doi.org/10.3390/robotics7030049

APA StyleOng U Jing, D., Devine, D. M., & Lyons, J. (2018). 3D Printed End of Arm Tooling (EOAT) for Robotic Automation. Robotics, 7(3), 49. https://doi.org/10.3390/robotics7030049