Omnidirectional Nonprehensile Manipulation Using Only One Actuator

Abstract

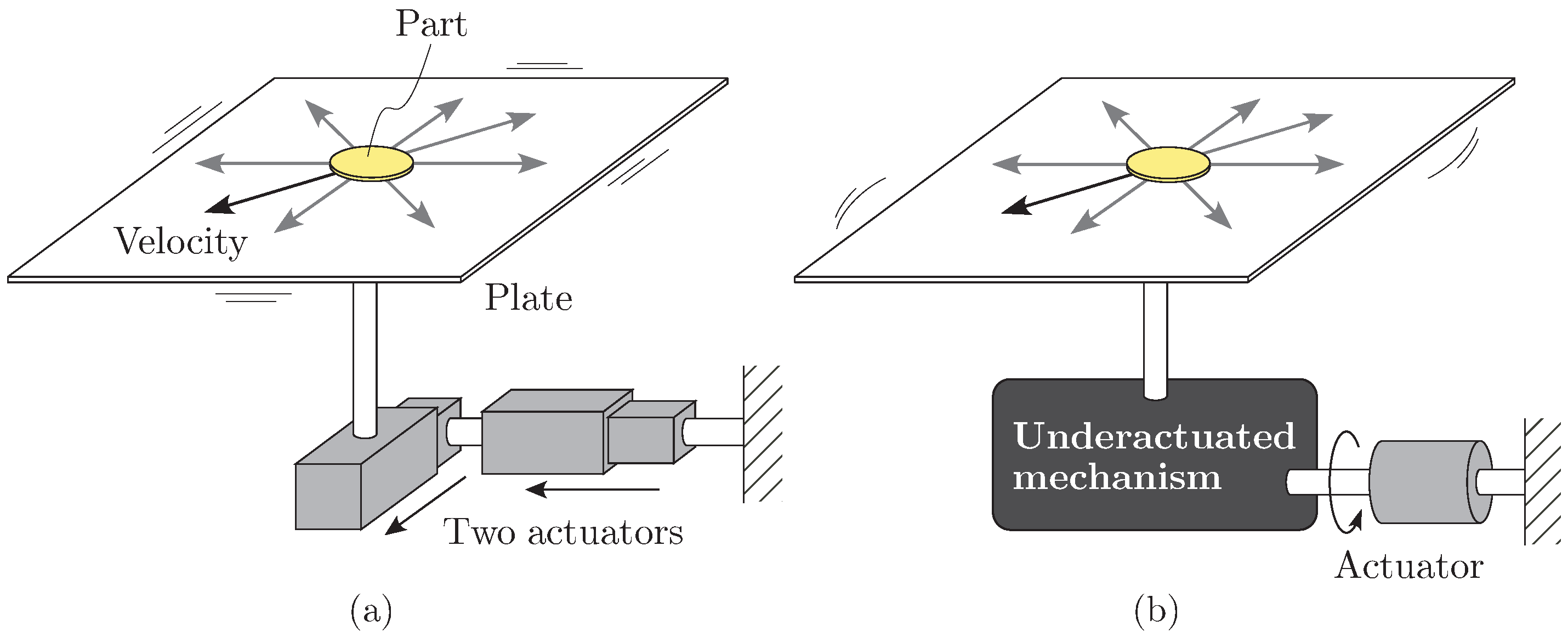

1. Introduction

2. Related Works

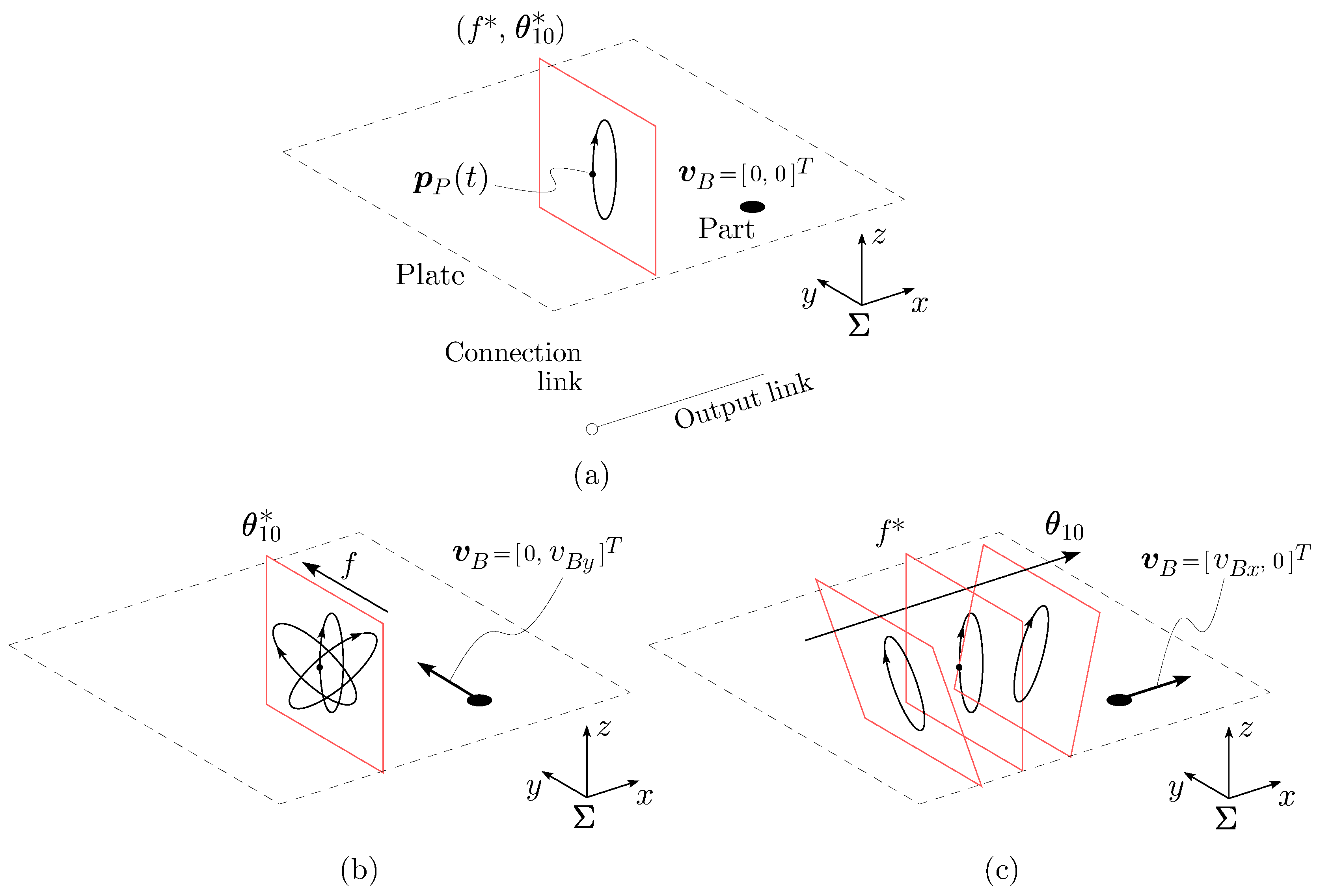

3. Model of Manipulator

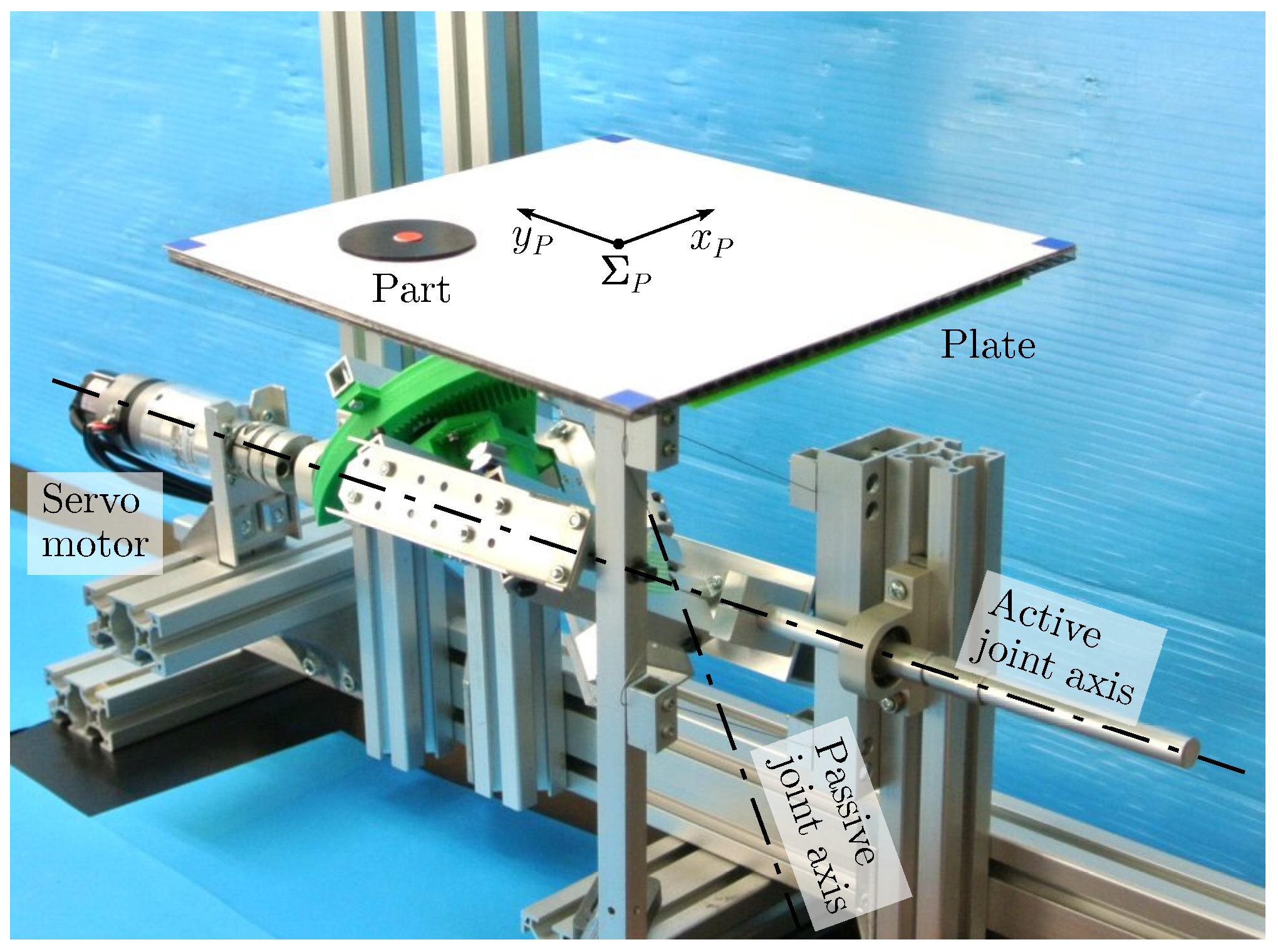

3.1. Underactuated Joint Mechanism

3.2. Vibrational Orbit of Plate and Manipulated Part

- The actuator has sufficiently high power to guarantee that the active joint traces the required arbitrary trajectory.

- The gravitational torque acting on the passive joint is negligible compared to the restoring and resistance torques of the viscoelastic element.

- The mass of the part manipulated on the plate is small, and thus, it does not influence the orbit of the plate.

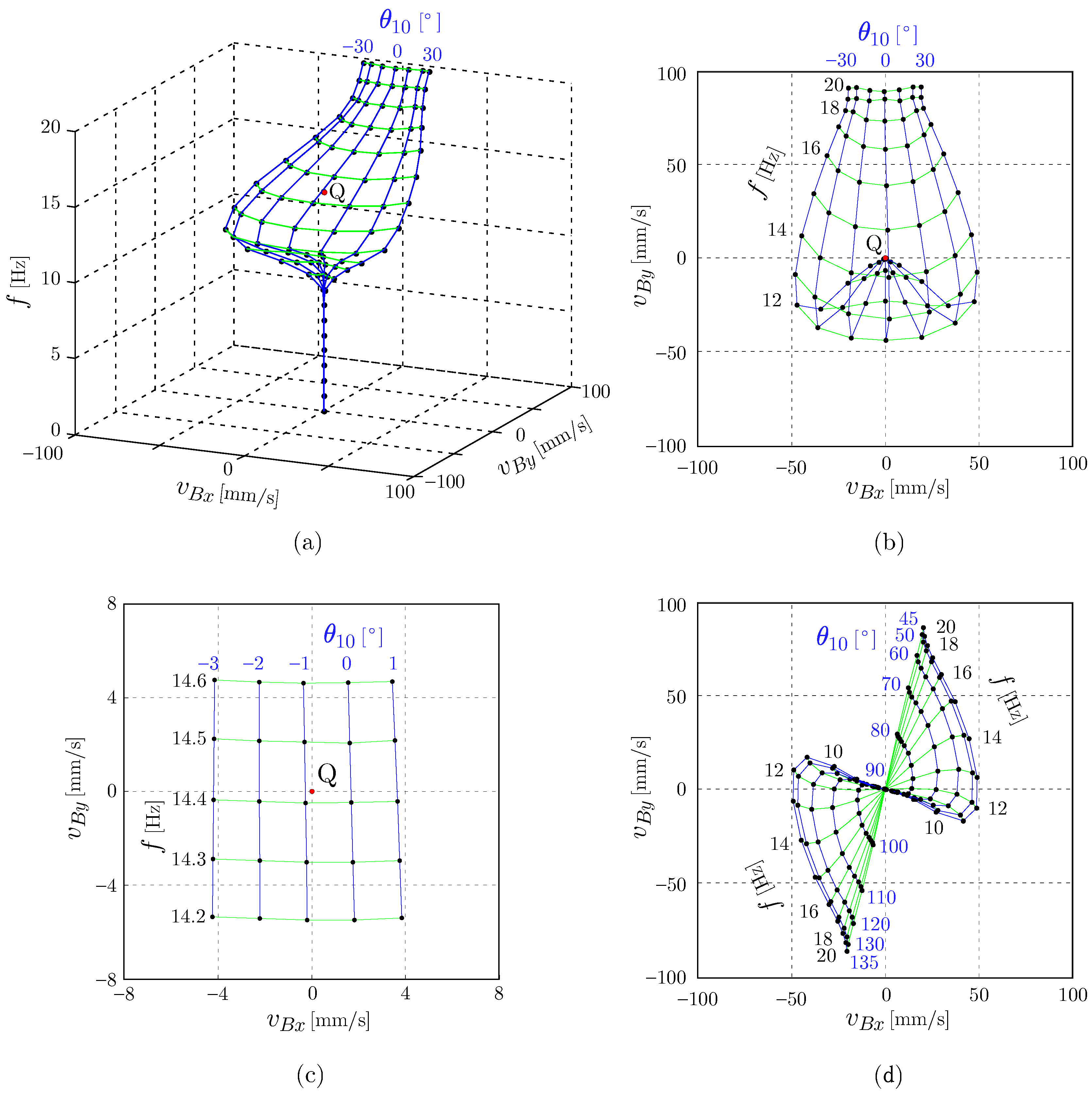

4. Omnidirectionally Induced Velocity of A Part

4.1. Simulation Setting

4.2. Velocity Map

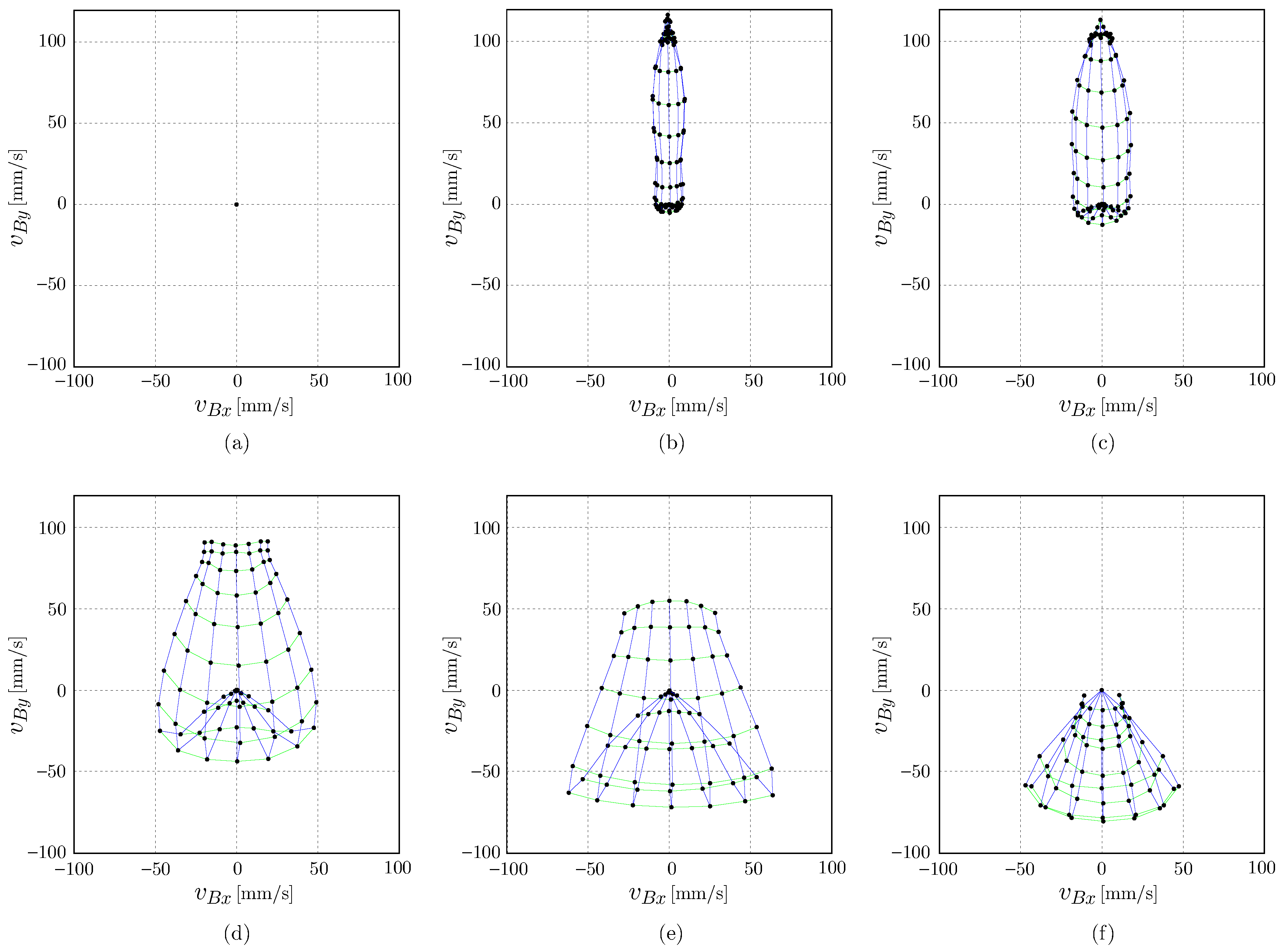

4.3. Influence of Friction Property

5. Visual Feedback Control

6. Experiments

6.1. Experimental Setup

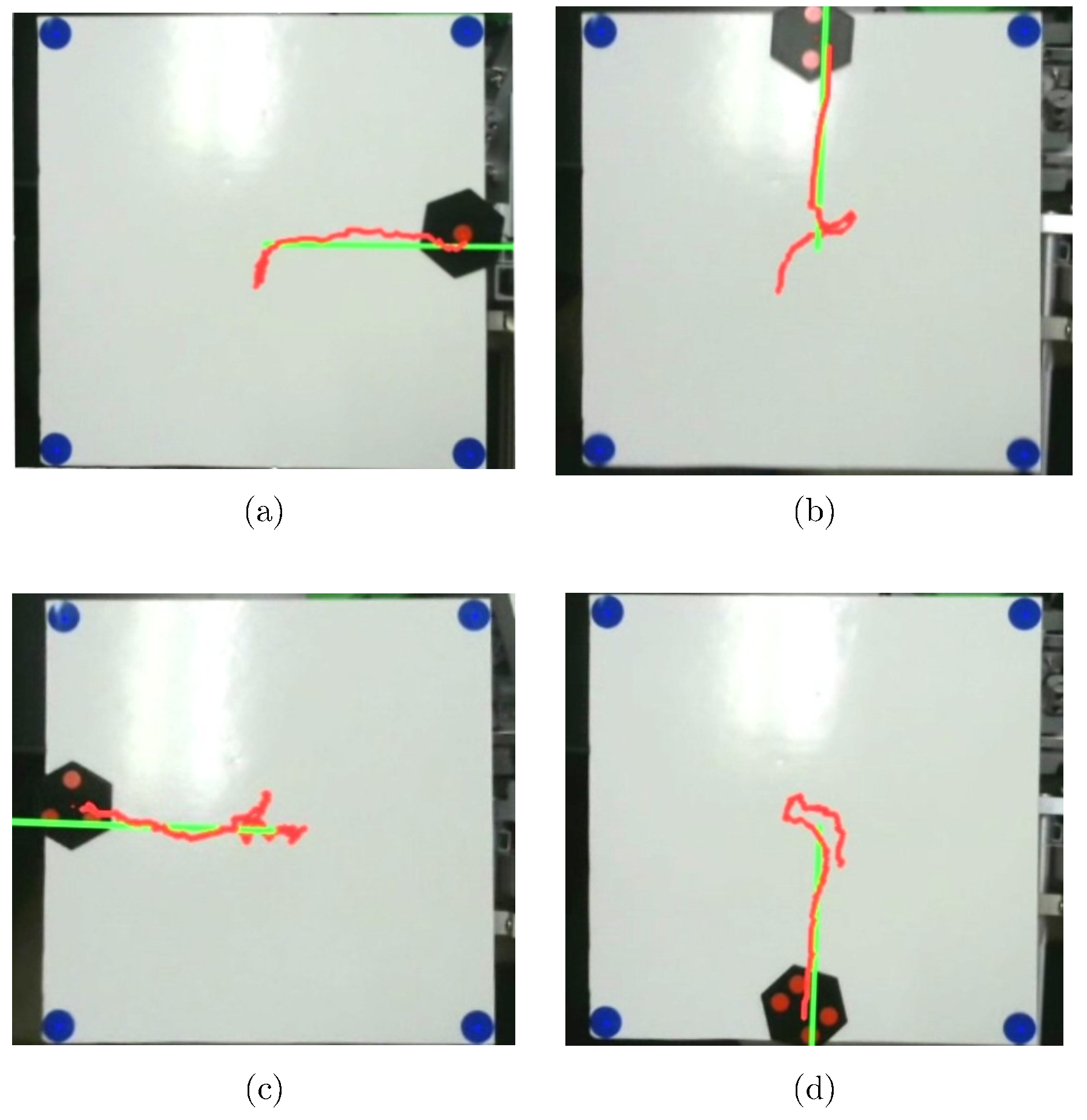

6.2. Experimental Results

7. Conclusions

- A manipulator with an underactuated mechanism with a viscoelastic element and a nonparallel axis layout was introduced. The vibrational orbit of a plate end effector varies based on the sinusoidal displacement input to an actuator.

- Via simulation analyses, the velocity map of a part was explored. It was revealed that the manipulator can produce an arbitrary velocity of the part omnidirectionally.

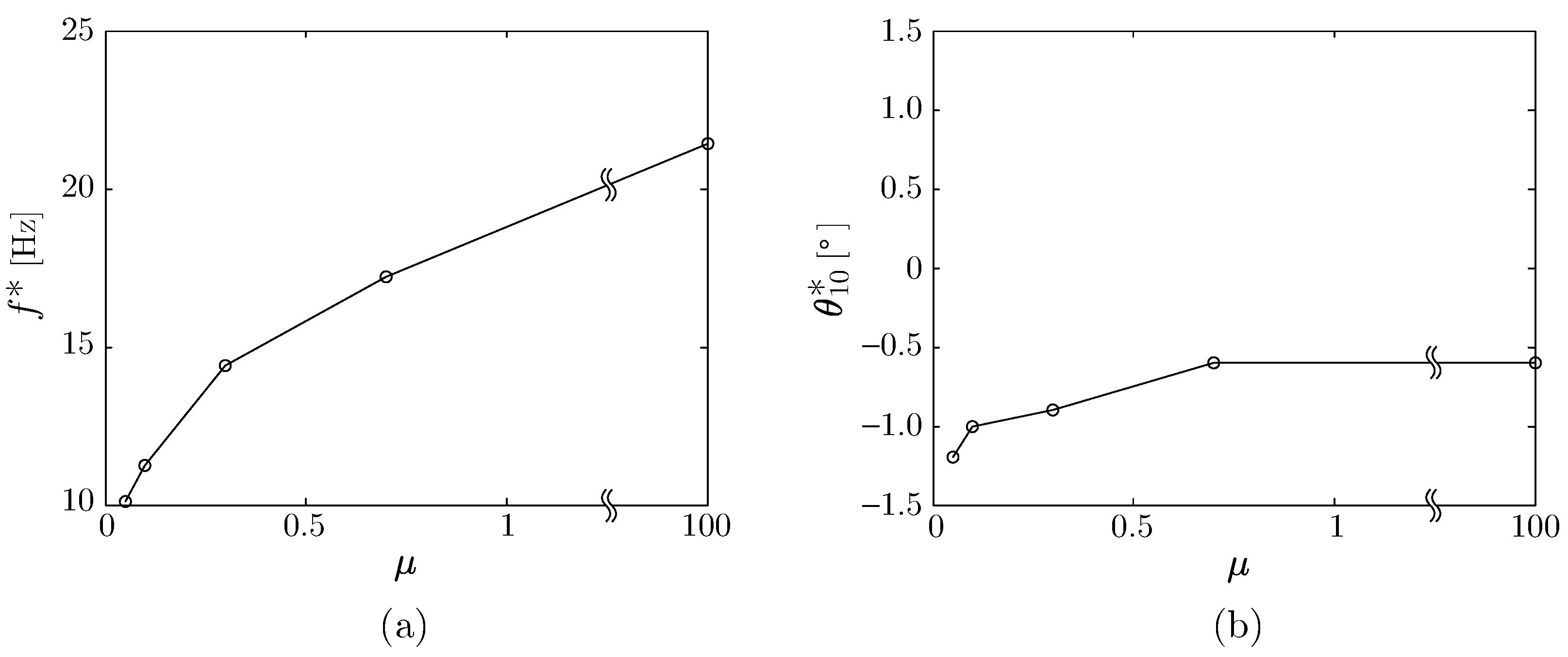

- In the neighborhood of a zero velocity point, there exists an orthogonality between the effects of the frequency and offset angle on the induced velocity. Based on the characteristics, a visual feedback control for manipulating the part was designed.

- The proposed approach was validated via experiments. The feasibility was confirmed and an application to a four-way part-feeding task was demonstrated.

Supplementary Materials

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Bicchi, A. Hands for Dexterous Manipulation and Robust Grasping: A Difficult Road Toward Simplicity. IEEE Trans. Rob. Autom. 2000, 16, 652–662. [Google Scholar] [CrossRef]

- Arai, H.; Khatib, O. Experiments with Dynamic Skills. In Proceedings of the 1994 Japan-USA Symposium on Flexible Automation : A Pacific Rim conference, Kobe, Japan, 11–18 July 1994; pp. 81–84. [Google Scholar]

- Amagai, A.; Takase, K. Implementation of Dynamic Manipulation with Visual Feedback and Its Application to Pick and Place Task. In Proceedings of the 2001 IEEE International Symposium on Assembly and Task Planning (ISATP2001), Fukuoka, Japan, 29–29 May 2001; pp. 344–350. [Google Scholar]

- Reznik, D.; Canny, J. A Flat Rigid Plate is a Universal Planar Manipulator. In Proceedings of the 1998 IEEE International Conference on Robotics and Automation, Leuven, Belgium, 20–20 May 1998; pp. 1471–1477. [Google Scholar]

- Reznik, D.; Canny, J. C’mon Part, Do the Local Motion! In Proceedings of the 2001 ICRA. IEEE International Conference on Robotics and Automation, Seoul, South Korea, 21–26 May 2001; pp. 2235–2242. [Google Scholar]

- Vose, T.H.; Umbanhowar, P.; Lynch, K.M. Vibration-Induced Frictional Force Fields on a Rigid Plate. In Proceedings of the 2007 IEEE International Conference on Robotics and Automation, Roma, Italy, 10–14 April 2007; pp. 660–667. [Google Scholar]

- Vose, T.H.; Umbanhowar, P.; Lynch, K.M. Friction-Induced Velocity Fields for Point Parts Sliding on a Rigid Oscillated Plate. Int. J. Rob. Res. 2009, 28, 1020–1039. [Google Scholar] [CrossRef]

- Vose, T.H.; Umbanhowar, P.; Lynch, K.M. Friction-Induced Lines of Attraction and Repulsion for Parts Sliding on a Oscillated Plate. IEEE Trans. Autom. Sci. Eng. 2009, 6, 685–699. [Google Scholar] [CrossRef]

- Vose, T.H.; Umbanhowar, P.; Lynch, K.M. Toward the Set of Frictional Velocity Fields Generable by 6-Degree-of-Freedom Oscillatory Motion of a Rigid Plate. In Proceedings of the 2010 IEEE International Conference on Robotics and Automation, Anchorage, AK, USA, 3–7 May 2010; pp. 540–547. [Google Scholar]

- Vose, T.H.; Umbanhowar, P.; Lynch, K.M. Sliding Manipulation of Rigid Bodies on a Controlled 6-DoF Plate. Int. J Rob. Res. 2012, 31, 819–838. [Google Scholar] [CrossRef]

- Mitani, A.; Sugano, N.; Hirai, S. Microparts Feeding by a Saw-Tooth Surface. IEEE/ASME Trans. Mechatron. 2006, 11, 671–681. [Google Scholar] [CrossRef]

- Mitani, A.; Hirai, S. Submillimeter Micropart Feeding Along an Asymmetric Femtosecond-Laser- Microfabricated Surface. Int. J. Autom. Technol. 2009, 3, 151–156. [Google Scholar] [CrossRef]

- Le, P.H.; Dinh, T.X.; Mitani, A.; Hirai, S. A Study on the Motion of Micro-Parts on a Saw-Tooth Surface by the PTV Method. J. Syst. Des. Dyn. 2012, 6, 73–80. [Google Scholar] [CrossRef]

- Le, P.H.; Dinh, T.X.; Mitani, A.; Hirai, S. Effect of Geometry Parameters of Saw-tooth Surface on the Feeding Velocity of Micro-parts. IEEJ Trans. Electr. Electron. Eng. 2013, 8, S102–S105. [Google Scholar] [CrossRef]

- Umbanhowar, P.; Vose, T.H.; Mitani, A.; Hirai, S.; Lynch, K.M. The Effect of Anisotropic Friction on Vibratory Velocity Fields. In Proceedings of the IEEE International Conference on Robotics and Automation, Saint Paul, MN, USA, 14–18 May 2012; pp. 2584–2591. [Google Scholar]

- Higashimori, M.; Utsumi, K.; Omoto, Y.; Kaneko, M. Dynamic Manipulation Inspired by the Handling of a Pizza Peel. IEEE Trans. Rob. 2009, 25, 829–838. [Google Scholar] [CrossRef]

- Ramirez-Alpizar, I.G.; Higashimori, M.; Kaneko, M.; Tsai, C.; Kao, I. Dynamic Nonprehensile Manipulation for Rotating a Thin Deformable Object: An Analogy to Bipedal Gaits. IEEE Trans. Rob. 2012, 28, 607–618. [Google Scholar] [CrossRef]

- Ramirez-Alpizar, I.G.; Higashimori, M.; Kaneko, M. Identification of a Thin Flexible Object with Bipedal Gaits. In Proceedings of the 8th IEEE International Conference on Automation Science and Engineering, Seoul, Korea, 20–24 August 2012; pp. 952–957. [Google Scholar]

- Lynch, K.; Mason, M.T. Dynamic Nonprehensile Manipulation: Controllability, Planning and Experiments. Int. J. Rob.Res. 1999, 18, 64–92. [Google Scholar] [CrossRef]

- Böhringer, K.F.; Bhatt, V.; Goldberg, K. Sensorless Manipulation Using Transverse Vibrations of a Plate. In Proceedings of the IEEE International Conference on Robotics and Automation, Nagoya, Japan, 21–27 May 1995; pp. 1989–1996. [Google Scholar]

- Böhringer, K.F.; Donald, B.R.; MadDonald, N.C. What Programmable Vector Fields Can (and Cannot) Do: Force Field Algorithms for MEMS and Vibratory Plate Parts Feeders. In Proceedings of the IEEE International Conference on Robotics and Automation, Minneapolis, MN, USA, 22–28 April 1996; pp. 822–930. [Google Scholar]

- Böhringer, K.F.; Donald, B.R.; Bhatt, V.; Goldberg, K. Algorithms for Sensorless Manipulation Using a Vibrating Surface. Algorithmica 2000, 26, 389–429. [Google Scholar] [CrossRef]

- Natsuhara, H.; Higashimori, M. Dynamic Nonprehensile Manipulation by Using Active-passive Hybrid Joint with Nonparallel Axes. In Proceedings of the IEEE International Conference on Robotics and Automation, Seattle, WA, USA, 26–30 May 2015; pp. 2502–2507. [Google Scholar]

- Sakashita, R.; Higashimori, M. 1-Actuator 3-DoF Parts Feeding Using Hybrid Joint Mechanism with Twisted Axis Layout. In Proceedings of the IEEE International Conference on Robotics and Automation, Singapore, 29 May–3 June 2017; pp. 2335–2342. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Higashimori, M.; Yamaguchi, K.; Shibata, A. Omnidirectional Nonprehensile Manipulation Using Only One Actuator. Robotics 2018, 7, 34. https://doi.org/10.3390/robotics7030034

Higashimori M, Yamaguchi K, Shibata A. Omnidirectional Nonprehensile Manipulation Using Only One Actuator. Robotics. 2018; 7(3):34. https://doi.org/10.3390/robotics7030034

Chicago/Turabian StyleHigashimori, Mitsuru, Kohei Yamaguchi, and Akihide Shibata. 2018. "Omnidirectional Nonprehensile Manipulation Using Only One Actuator" Robotics 7, no. 3: 34. https://doi.org/10.3390/robotics7030034

APA StyleHigashimori, M., Yamaguchi, K., & Shibata, A. (2018). Omnidirectional Nonprehensile Manipulation Using Only One Actuator. Robotics, 7(3), 34. https://doi.org/10.3390/robotics7030034