Fiber Jamming of Magnetorheological Elastomers as a Technique for the Stiffening of Soft Robots

Abstract

1. Introduction

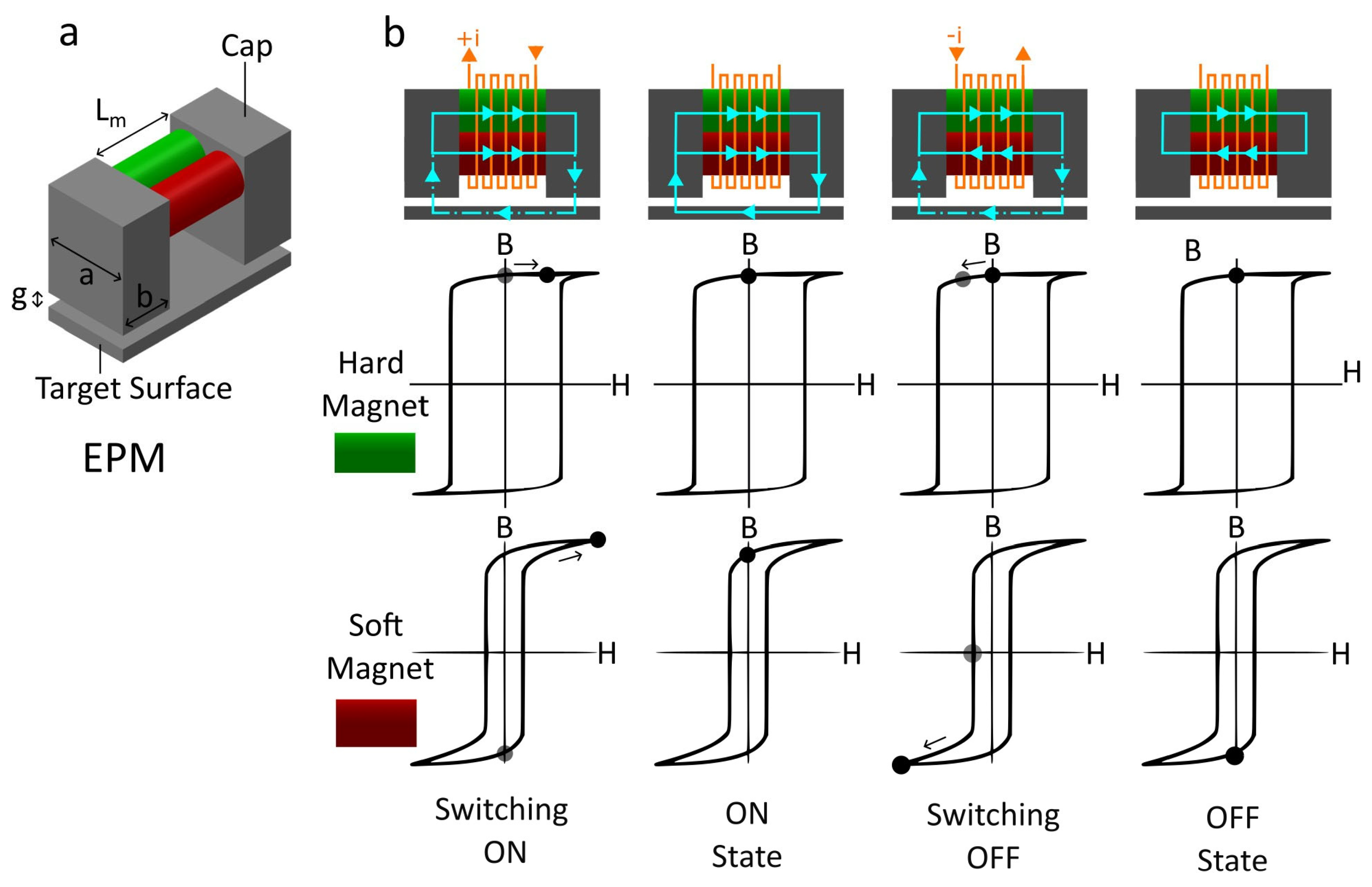

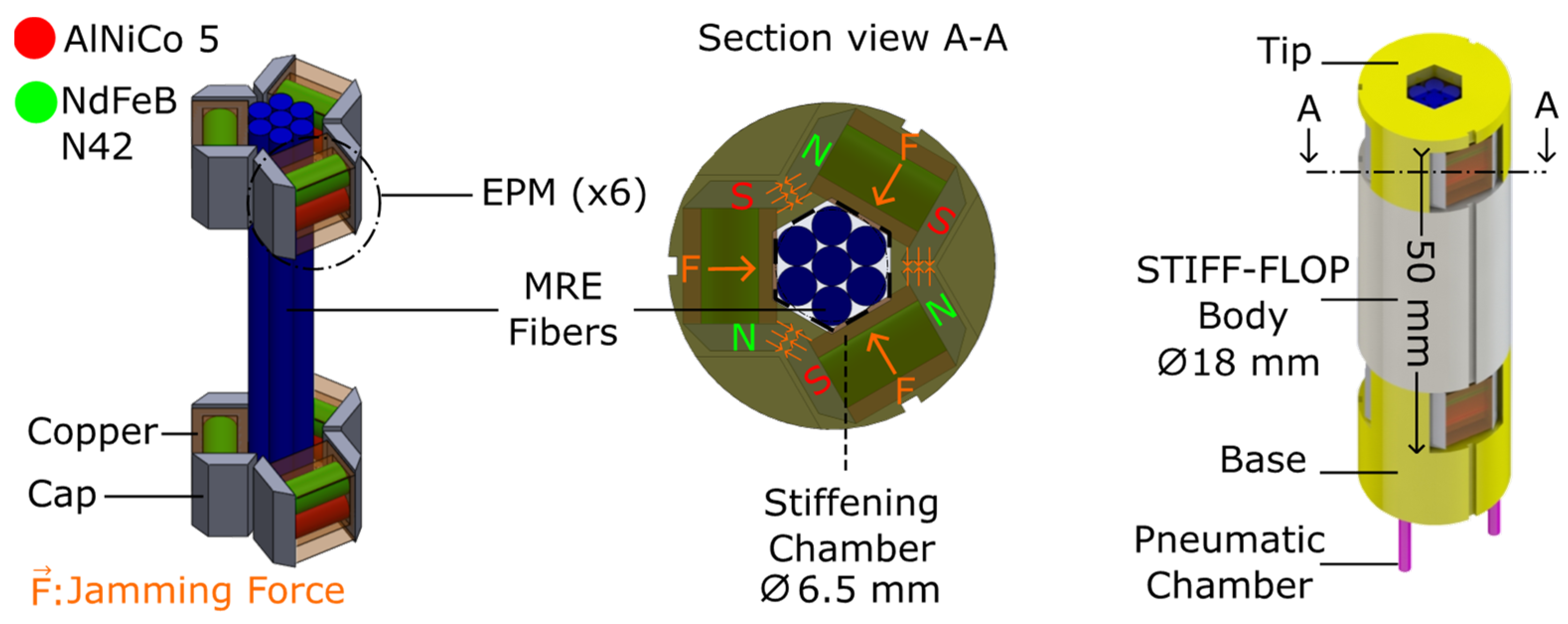

2. Variable Stiffness Device Based on Magnetic Fiber Jamming

2.1. Design

2.2. Proof-of-Concept Test Setup for the Jamming of MRE Fibers

2.3. Fabrication

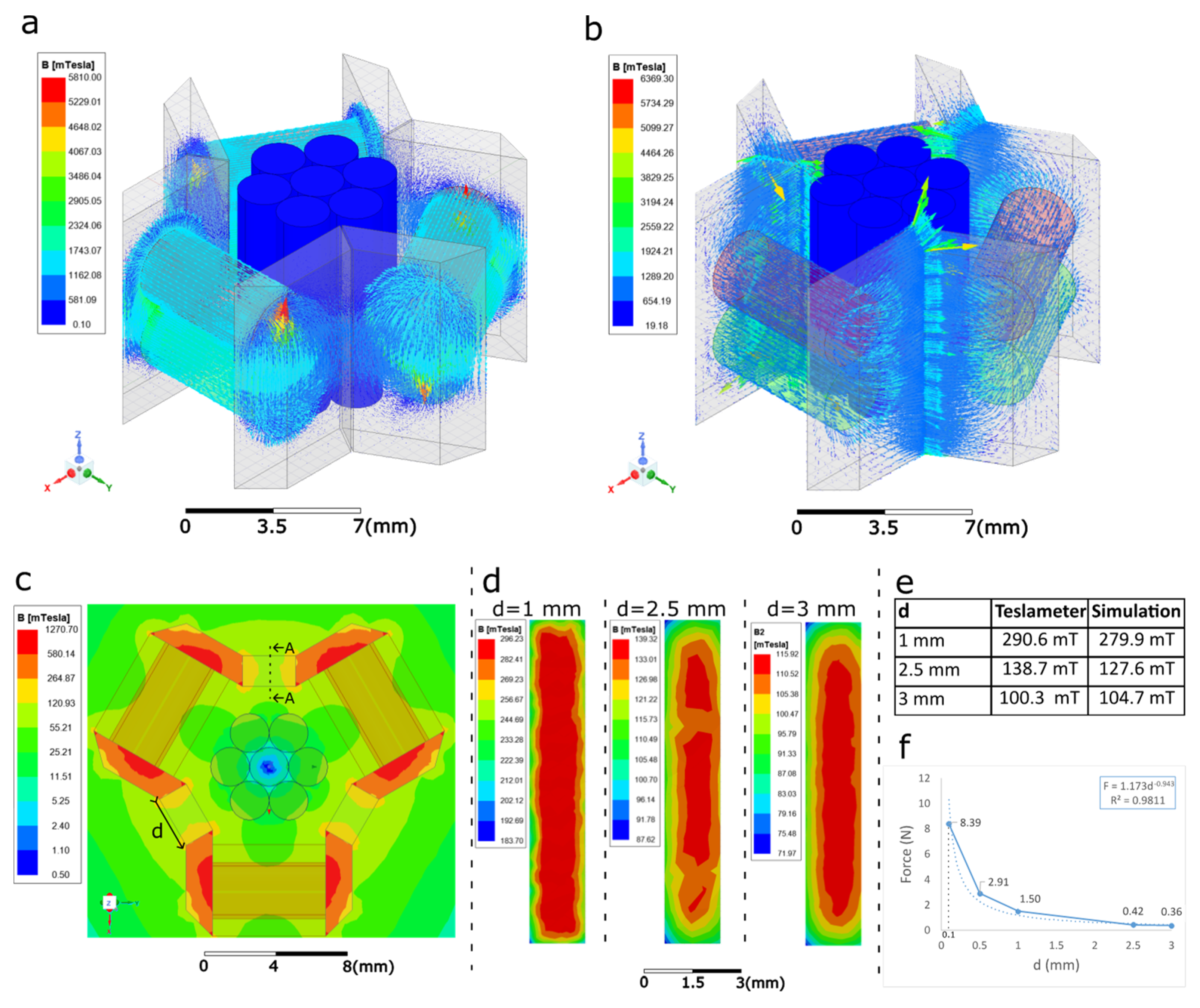

2.4. Modeling

3. Experimental Evaluation

3.1. Proof-of-Concept Magnetic Fiber Jamming Tests

3.2. Electronically Controlled Variable Stiffness Tests

3.3. Bending Angle Tests

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CIP | Carbonyl Iron Particle |

| EPM | Electro-permanent magnet |

| FFA | Flexible Fluidic Actuator |

| MIS | Minimally Invasive Surgery |

| MR | Magnetorheological |

| MRE | Magnetorheological Elastomers |

Appendix A

References

- Trivedi, D.; Rahn, C.D.; Kier, W.M.; Walker, I.D. Soft robotics: Biological inspiration, state of the art, and future research. Appl. Bionics Biomech. 2008, 5, 99–117. [Google Scholar] [CrossRef]

- Majidi, C. Soft robotics: A perspective—Current trends and prospects for the future. Soft Robot. 2014, 1, 5–11. [Google Scholar] [CrossRef]

- Manti, M.; Cacucciolo, V.; Cianchetti, M. Stiffening in soft robotics: A review of the state of the art. IEEE Robot. Autom. Mag. 2016, 23, 93–106. [Google Scholar] [CrossRef]

- Gong, X.; Xie, F.; Liu, L.; Liu, Y.; Leng, J. Electro-active variable-stiffness corrugated structure based on shape-memory polymer composite. Polymers 2020, 12, 387. [Google Scholar] [CrossRef] [PubMed]

- Fras, J.; Althoefer, K. A fluidic actuator with an internal stiffening structure inspired by mammalian erectile tissue. In Proceedings of the 2023 IEEE International Conference on Robotics and Automation (ICRA), London, UK, 29 May–2 June 2023; pp. 662–668. [Google Scholar]

- Hu, J.; Liu, T.; Zeng, H.; Chua, M.X.; Katupitiya, J.; Wu, L. Static Modeling of a Class of Stiffness-Adjustable Snake-like Robots with Gravity Compensation. Robotics 2022, 12, 2. [Google Scholar] [CrossRef]

- Mawah, S.C.; Park, Y.J. Tendon-Driven Variable-Stiffness Pneumatic Soft Gripper Robot. Robotics 2023, 12, 128. [Google Scholar] [CrossRef]

- Pagliarani, N.; Arleo, L.; Albini, S.; Cianchetti, M. Variable Stiffness Technologies for Soft Robotics: A Comparative Approach for the STIFF-FLOP Manipulator. Actuators 2023, 12, 96. [Google Scholar] [CrossRef]

- Chenal, T.P.; Case, J.C.; Paik, J.; Kramer, R.K. Variable stiffness fabrics with embedded shape memory materials for wearable applications. In Proceedings of the 2014 IEEE/RSJ International Conference on Intelligent Robots and Systems, Chicago, IL, USA, 14–18 September 2014; pp. 2827–2831. [Google Scholar]

- Childs, J.A.; Rucker, C. Leveraging geometry to enable high-strength continuum robots. Front. Robot. AI 2021, 8, 629871. [Google Scholar] [CrossRef]

- Sun, Y.; Lueth, T.C. Enhancing Torsional Stiffness of Continuum Robots Using 3-D Topology Optimized Flexure Joints. IEEE/ASME Trans. Mechatron. 2023, 28, 1844–1852. [Google Scholar] [CrossRef]

- Fitzgerald, S.G.; Delaney, G.W.; Howard, D. A review of jamming actuation in soft robotics. Actuators 2020, 9, 104. [Google Scholar] [CrossRef]

- Liu, A.J.; Nagel, S.R. Jamming is not just cool any more. Nature 1998, 396, 21–22. [Google Scholar] [CrossRef]

- van Hecke, M. Jamming of soft particles: Geometry, mechanics, scaling and isostaticity. J. Phys. Condens. Matter 2009, 22, 033101. [Google Scholar] [CrossRef]

- Bi, D.; Zhang, J.; Chakraborty, B.; Behringer, R.P. Jamming by shear. Nature 2011, 480, 355–358. [Google Scholar] [CrossRef]

- Aktaş, B.; Narang, Y.S.; Vasios, N.; Bertoldi, K.; Howe, R.D. A modeling framework for jamming structures. Adv. Funct. Mater. 2021, 31, 2007554. [Google Scholar] [CrossRef]

- Zhou, Y.; Headings, L.M.; Dapino, M.J. Discrete layer jamming for variable stiffness co-robot arms. J. Mech. Robot. 2020, 12, 015001. [Google Scholar] [CrossRef]

- Jiang, Y.; Chen, D.; Liu, C.; Li, J. Chain-like granular jamming: A novel stiffness-programmable mechanism for soft robotics. Soft Robot. 2019, 6, 118–132. [Google Scholar] [CrossRef]

- Tanaka, K.; Karimi, M.A.; Busque, B.P.; Mulroy, D.; Zhou, Q.; Batra, R.; Srivastava, A.; Jaeger, H.M.; Spenko, M. Cable-driven jamming of a boundary constrained soft robot. In Proceedings of the 2020 3rd IEEE International Conference on Soft Robotics (RoboSoft), New Haven, CT, USA, 15 May–15 July 2020; pp. 852–857. [Google Scholar]

- Santiago, J.L.C.; Godage, I.S.; Gonthina, P.; Walker, I.D. Soft robots and kangaroo tails: Modulating compliance in continuum structures through mechanical layer jamming. Soft Robot. 2016, 3, 54–63. [Google Scholar] [CrossRef]

- Diller, S.B.; Collins, S.H.; Majidi, C. The effects of electroadhesive clutch design parameters on performance characteristics. J. Intell. Mater. Syst. Struct. 2018, 29, 3804–3828. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, J.; Li, Y.; Hong, J.; Wang, M.Y. Electrostatic layer jamming variable stiffness for soft robotics. IEEE/ASME Trans. Mechatron. 2019, 24, 424–433. [Google Scholar] [CrossRef]

- Okatani, Y.; Nishida, T.; Tadakuma, K. Development of universal robot gripper using MRα fluid. In Proceedings of the IEEE 2014 Joint 7th International Conference on Soft Computing and Intelligent Systems (SCIS) and 15th International Symposium on Advanced Intelligent Systems (ISIS), Kitakyushu, Japan, 3–6 December 2014; pp. 231–235. [Google Scholar]

- Gaeta, L.T.; McDonald, K.J.; Kinnicutt, L.; Le, M.; Wilkinson-Flicker, S.; Jiang, Y.; Atakuru, T.; Samur, E.; Ranzani, T. Magnetically induced stiffening for soft robotics. Soft Matter 2023, 19, 2623–2636. [Google Scholar] [CrossRef] [PubMed]

- Brown, E.; Rodenberg, N.; Amend, J.; Mozeika, A.; Steltz, E.; Zakin, M.R.; Lipson, H.; Jaeger, H.M. Universal robotic gripper based on the jamming of granular material. Proc. Natl. Acad. Sci. USA 2010, 107, 18809–18814. [Google Scholar] [CrossRef]

- Wei, Y.; Chen, Y.; Ren, T.; Chen, Q.; Yan, C.; Yang, Y.; Li, Y. A novel, variable stiffness robotic gripper based on integrated soft actuating and particle jamming. Soft Robot. 2016, 3, 134–143. [Google Scholar] [CrossRef]

- Cheng, N.G.; Lobovsky, M.B.; Keating, S.J.; Setapen, A.M.; Gero, K.I.; Hosoi, A.E.; Iagnemma, K.D. Design and analysis of a robust, low-cost, highly articulated manipulator enabled by jamming of granular media. In Proceedings of the 2012 IEEE International Conference on Robotics and Automation, Saint Paul, MN, USA, 14–18 May 2012; pp. 4328–4333. [Google Scholar]

- Yamane, S.; Wakimoto, S. Development of a flexible manipulator with changing stiffness by granular jamming. In Proceedings of the IEEE 2017 24th International Conference on Mechatronics and Machine Vision in Practice (M2VIP), Auckland, New Zealand, 21–23 November 2017; pp. 1–5. [Google Scholar]

- Karimi, M.A.; Alizadehyazdi, V.; Jaeger, H.M.; Spenko, M. A self-reconfigurable variable-stiffness soft robot based on boundary- constrained modular units. IEEE Trans. Robot. 2021, 38, 810–821. [Google Scholar] [CrossRef]

- Stanley, A.A.; Gwilliam, J.C.; Okamura, A.M. Haptic jamming: A deformable geometry, variable stiffness tactile display using pneumatics and particle jamming. In Proceedings of the IEEE 2013 World Haptics Conference (WHC), Daejeon, Republic of Korea, 14–17 April 2013; pp. 25–30. [Google Scholar]

- Baines, R.; Yang, B.; Ramirez, L.A.; Kramer-Bottiglio, R. Kirigami layer jamming. Extrem. Mech. Lett. 2023, 64, 102084. [Google Scholar] [CrossRef]

- Narang, Y.S.; Aktaş, B.; Ornellas, S.; Vlassak, J.J.; Howe, R.D. Lightweight highly tunable jamming-based composites. Soft Robot. 2020, 7, 724–735. [Google Scholar] [CrossRef]

- Brancadoro, M.; Manti, M.; Tognarelli, S.; Cianchetti, M. Preliminary experimental study on variable stiffness structures based on fiber jamming for soft robots. In Proceedings of the 2018 IEEE International Conference on Soft Robotics (RoboSoft), Livorno, Italy, 24–28 April 2018; pp. 258–263. [Google Scholar]

- Brancadoro, M.; Manti, M.; Grani, F.; Tognarelli, S.; Menciassi, A.; Cianchetti, M. Toward a variable stiffness surgical manipulator based on fiber jamming transition. Front. Robot. AI 2019, 6, 12. [Google Scholar] [CrossRef]

- Arleo, L.; Lorenzon, L.; Cianchetti, M. Variable stiffness linear actuator based on differential drive fiber jamming. IEEE Trans. Robot. 2023, 39, 4429–4442. [Google Scholar] [CrossRef]

- Rabinow, J. The magnetic fluid clutch. Electr. Eng. 1948, 67, 1167. [Google Scholar] [CrossRef]

- Rigbi, Z.; Jilken, L. The response of an elastomer filled with soft ferrite to mechanical and magnetic influences. J. Magn. Magn. Mater. 1983, 37, 267–276. [Google Scholar] [CrossRef]

- Jolly, M.R.; Carlson, J.D.; Muñoz, B.C.; Bullions, T.A. The magnetoviscoelastic response of elastomer composites consisting of ferrous particles embedded in a polymer matrix. J. Intell. Mater. Syst. Struct. 1996, 7, 613–622. [Google Scholar] [CrossRef]

- Ginder, J.M.; Nichols, M.E.; Elie, L.D.; Tardiff, J.L. Magnetorheological elastomers: Properties and applications. In Proceedings of the Smart Structures and Materials 1999: Smart Materials Technologies. SPIE 1999, 3675, 131–138. [Google Scholar]

- Bica, I. Compressibility modulus and principal deformations in magneto-rheological elastomer: The effect of the magnetic field. J. Ind. Eng. Chem. 2009, 15, 773–776. [Google Scholar] [CrossRef]

- Boczkowska, A.; Awietjan, S. Microstructure and properties of magnetorheological elastomers. In Advanced Elastomers—Technology, Properties and Applications; InTech: London, UK, 2012; Volume 595. [Google Scholar] [CrossRef]

- Li, W.; Zhang, X.; Du, H. Magnetorheological elastomers and their applications. In Advances in Elastomers I: Blends and Interpene-Trating Networks; Springer: Berlin, Germany, 2013; pp. 357–374. [Google Scholar]

- Schubert, G. Manufacture, Characterisation and Modelling of Magneto-Rheological Elastomers. Ph.D. Thesis, University of Glasgow, Glasgow, UK, 2014. [Google Scholar]

- Popp, K.M.; Kröger, M.; Li, W.h.; Zhang, X.Z.; Kosasih, P.B. MRE properties under shear and squeeze modes and applications. J. Intell. Mater. Syst. Struct. 2010, 21, 1471–1477. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Li, W.; Du, H. A state-of-the-art review on magnetorheological elastomer devices. Smart Mater. Struct. 2014, 23, 123001. [Google Scholar] [CrossRef]

- McDonald, K.; Rendos, A.; Woodman, S.; Brown, K.A.; Ranzani, T. Magnetorheological fluid-based flow control for soft robots. Adv. Intell. Syst. 2020, 2, 2000139. [Google Scholar] [CrossRef]

- McDonald, K.J.; Kinnicutt, L.; Moran, A.M.; Ranzani, T. Modulation of magnetorheological fluid flow in soft robots using electropermanent magnets. IEEE Robot. Autom. Lett. 2022, 7, 3914–3921. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Tian, T.; Li, W. A highly adjustable magnetorheological elastomer base isolator for applications of real-time adaptive control. Smart Mater. Struct. 2013, 22, 095020. [Google Scholar] [CrossRef]

- Bira, N.; Dhagat, P.; Davidson, J.R. A review of magnetic elastomers and their role in soft robotics. Front. Robot. AI 2020, 7, 588391. [Google Scholar] [CrossRef]

- Kashima, S.; Miyasaka, F.; Hirata, K. Novel soft actuator using magnetorheological elastomer. IEEE Trans. Magn. 2012, 48, 1649–1652. [Google Scholar] [CrossRef]

- Kim, J.; Chung, S.E.; Choi, S.E.; Lee, H.; Kim, J.; Kwon, S. Programming magnetic anisotropy in polymeric microactuators. Nat. Mater. 2011, 10, 747–752. [Google Scholar] [CrossRef]

- Böse, H.; Rabindranath, R.; Ehrlich, J. Soft magnetorheological elastomers as new actuators for valves. J. Intell. Mater. Syst. Struct. 2012, 23, 989–994. [Google Scholar] [CrossRef]

- Joyee, E.B.; Pan, Y. A fully three-dimensional printed inchworm-inspired soft robot with magnetic actuation. Soft Robot. 2019, 6, 333–345. [Google Scholar] [CrossRef] [PubMed]

- Qi, S.; Guo, H.; Fu, J.; Xie, Y.; Zhu, M.; Yu, M. 3D printed shape-programmable magneto-active soft matter for biomimetic applications. Compos. Sci. Technol. 2020, 188, 107973. [Google Scholar] [CrossRef]

- Hellebrekers, T.; Chang, N.; Chin, K.; Ford, M.J.; Kroemer, O.; Majidi, C. Soft magnetic tactile skin for continuous force and location estimation using neural networks. IEEE Robot. Autom. Lett. 2020, 5, 3892–3898. [Google Scholar] [CrossRef]

- Kitano, S.; Komatsuzaki, T.; Suzuki, I.; Nogawa, M.; Naito, H.; Tanaka, S. Development of a rigidity tunable flexible joint using magneto-rheological compounds—Toward a multijoint manipulator for laparoscopic surgery. Front. Robot. AI 2020, 7, 59. [Google Scholar] [CrossRef]

- Cianchetti, M.; Ranzani, T.; Gerboni, G.; De Falco, I.; Laschi, C.; Menciassi, A. STIFF-FLOP surgical manipulator: Mechanical design and experimental characterization of the single module. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013; pp. 3576–3581. [Google Scholar]

- Abidi, H.; Gerboni, G.; Brancadoro, M.; Fras, J.; Diodato, A.; Cianchetti, M.; Wurdemann, H.; Althoefer, K.; Menciassi, A. Highly dexterous 2-module soft robot for intra-organ navigation in minimally invasive surgery. Int. J. Med. Robot. Comput. Assist. Surg. 2018, 14, e1875. [Google Scholar] [CrossRef]

- Graham, R.L.; Lubachevsky, B.D.; Nurmela, K.J.; Östergård, P.R. Dense packings of congruent circles in a circle. Discret. Math. 1998, 181, 139–154. [Google Scholar] [CrossRef]

- Knaian, A.N. Electropermanent Magnetic Connectors and Actuators: Devices and Their Application in Programmable Matter. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2010. [Google Scholar]

- Abeywardana, D.K.; Hu, A.P.; Salcic, Z. Pulse controlled microfluidic actuators with ultra low energy consumption. Sens. Actuators A Phys. 2017, 263, 8–22. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atakuru, T.; Kocabaş, F.; Pagliarani, N.; Cianchetti, M.; Samur, E. Fiber Jamming of Magnetorheological Elastomers as a Technique for the Stiffening of Soft Robots. Robotics 2024, 13, 16. https://doi.org/10.3390/robotics13010016

Atakuru T, Kocabaş F, Pagliarani N, Cianchetti M, Samur E. Fiber Jamming of Magnetorheological Elastomers as a Technique for the Stiffening of Soft Robots. Robotics. 2024; 13(1):16. https://doi.org/10.3390/robotics13010016

Chicago/Turabian StyleAtakuru, Taylan, Fatih Kocabaş, Niccolò Pagliarani, Matteo Cianchetti, and Evren Samur. 2024. "Fiber Jamming of Magnetorheological Elastomers as a Technique for the Stiffening of Soft Robots" Robotics 13, no. 1: 16. https://doi.org/10.3390/robotics13010016

APA StyleAtakuru, T., Kocabaş, F., Pagliarani, N., Cianchetti, M., & Samur, E. (2024). Fiber Jamming of Magnetorheological Elastomers as a Technique for the Stiffening of Soft Robots. Robotics, 13(1), 16. https://doi.org/10.3390/robotics13010016