Tunable Adhesion of Shape Memory Polymer Dry Adhesive Soft Robotic Gripper via Stiffness Control †

Abstract

1. Introduction

2. Methods

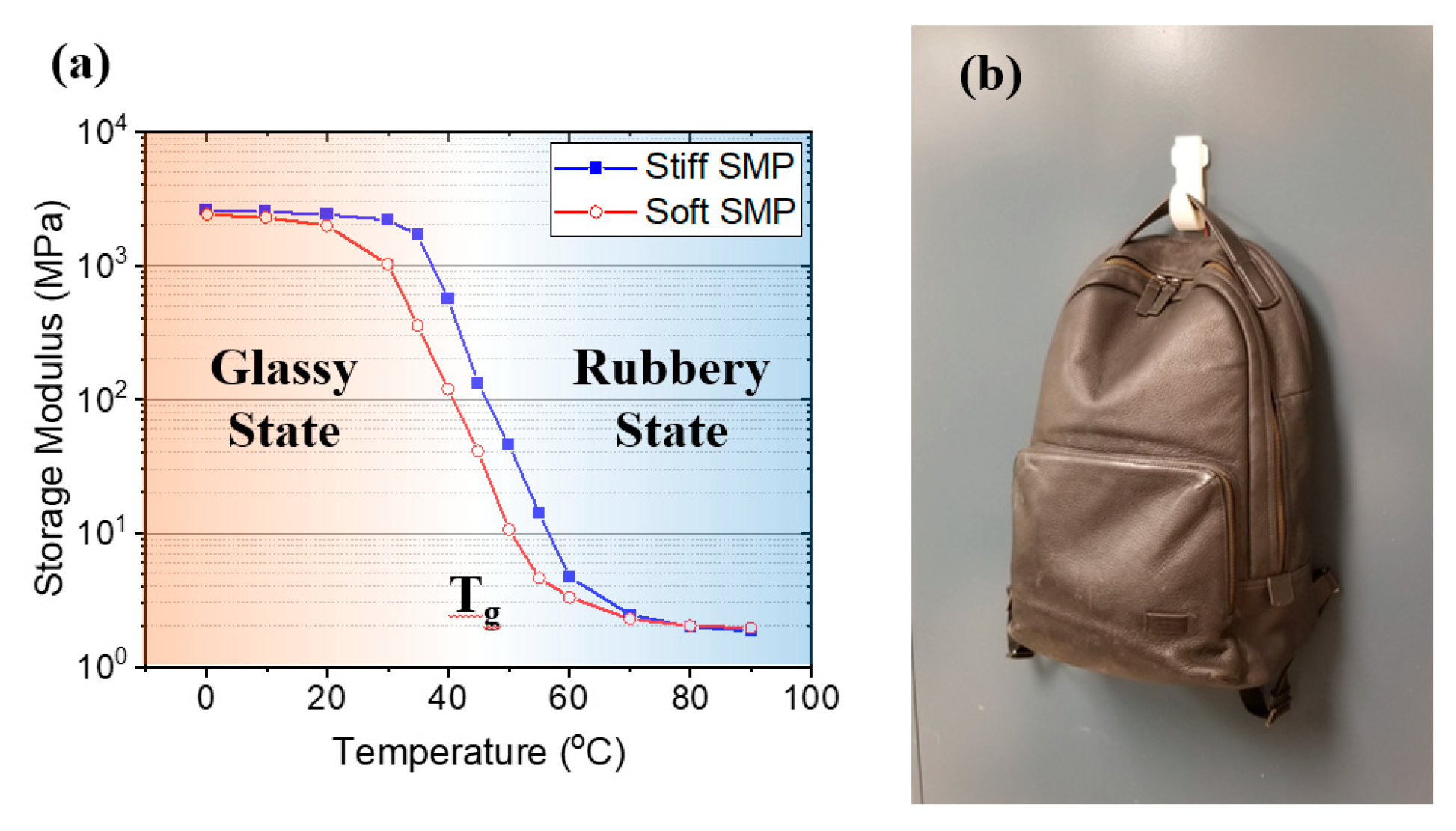

2.1. Fabrication of the SMP

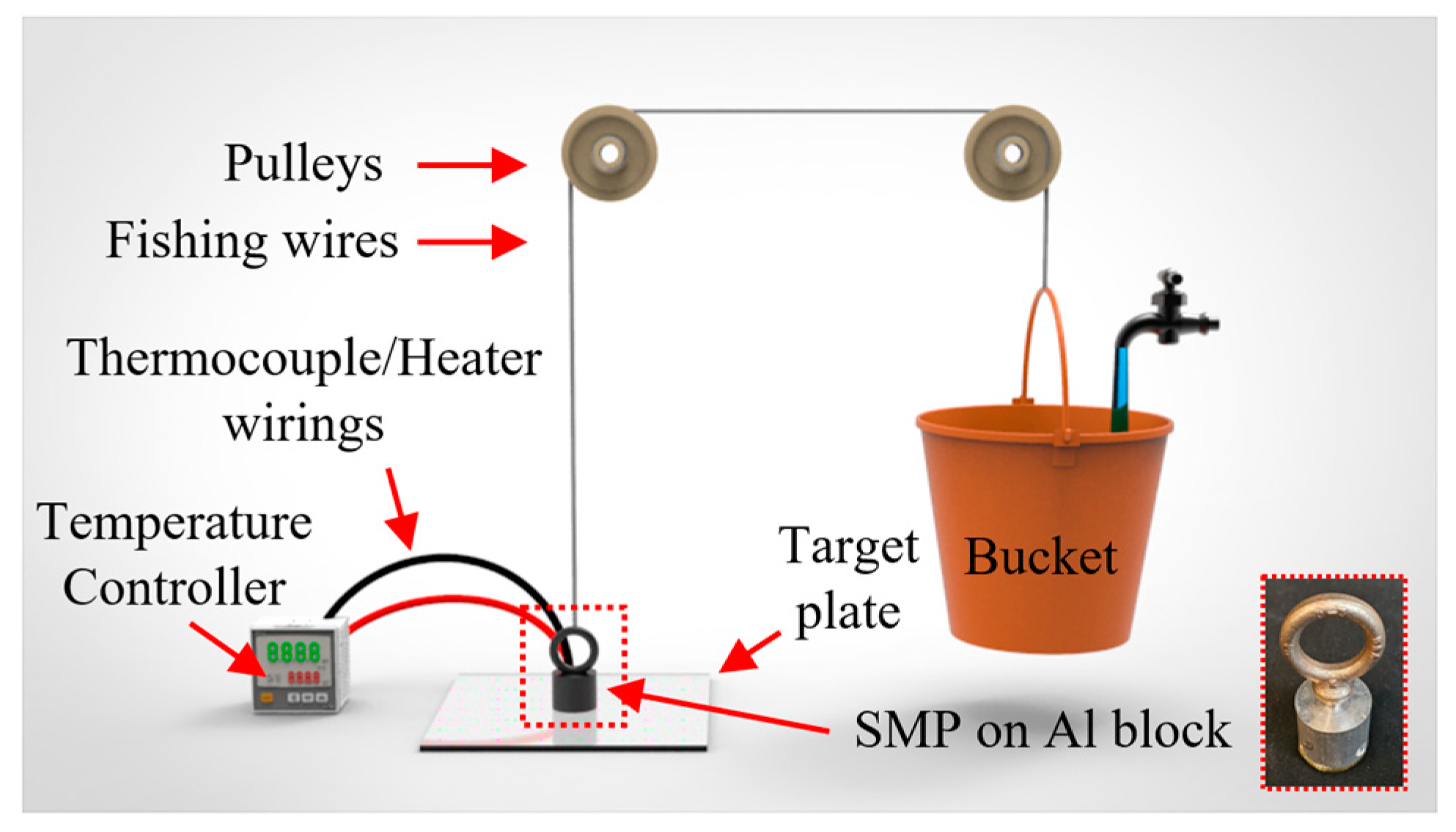

2.2. Adhesion Test Setup

3. Dual SMP and Release Tip SMP

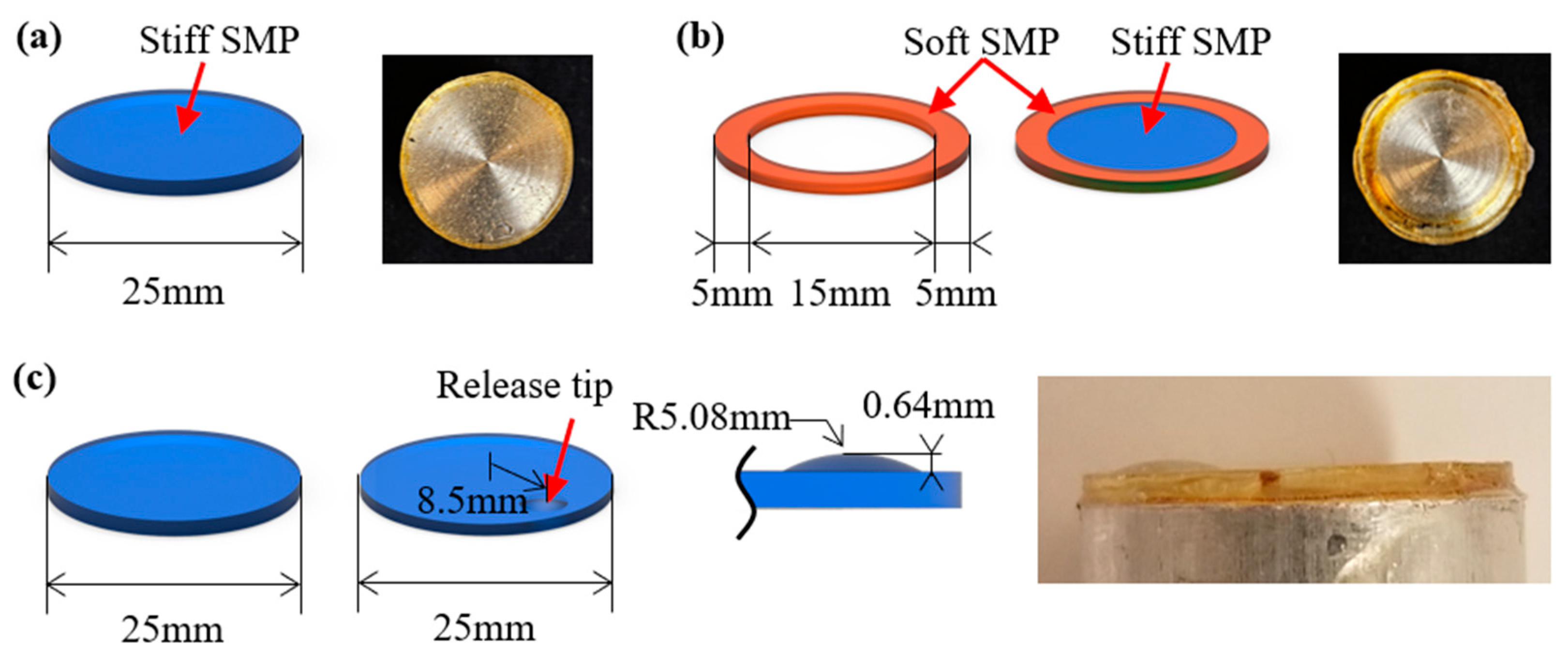

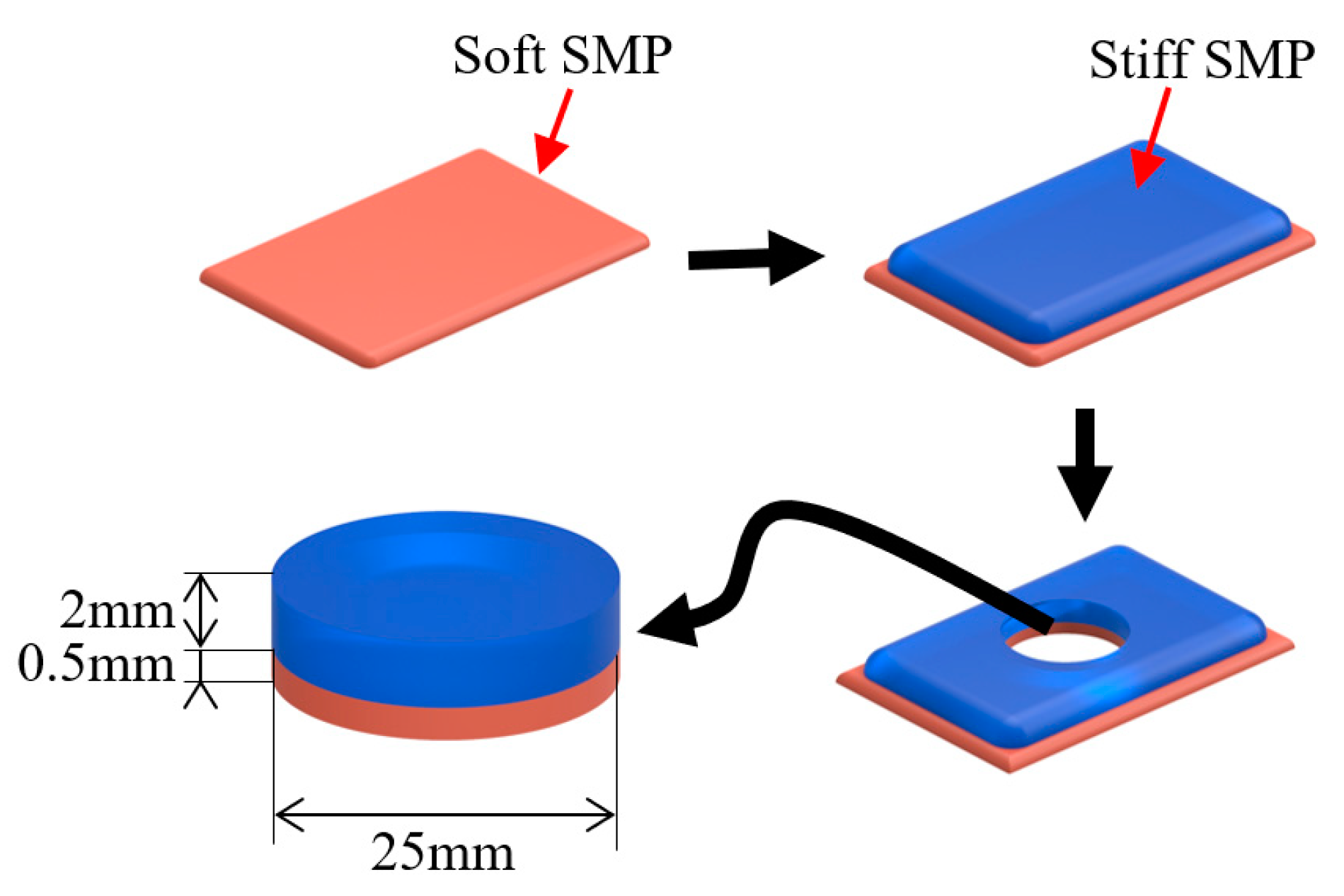

3.1. Fabrication of Dual SMP and Release Tip SMP

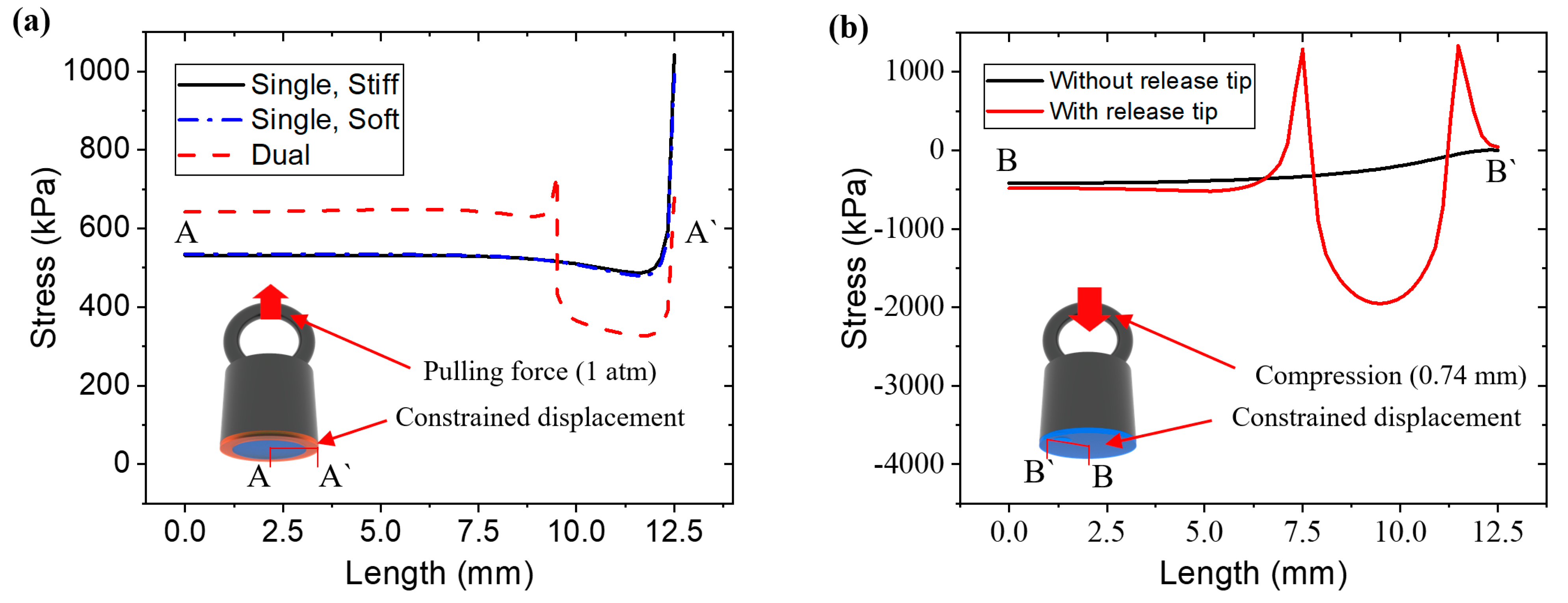

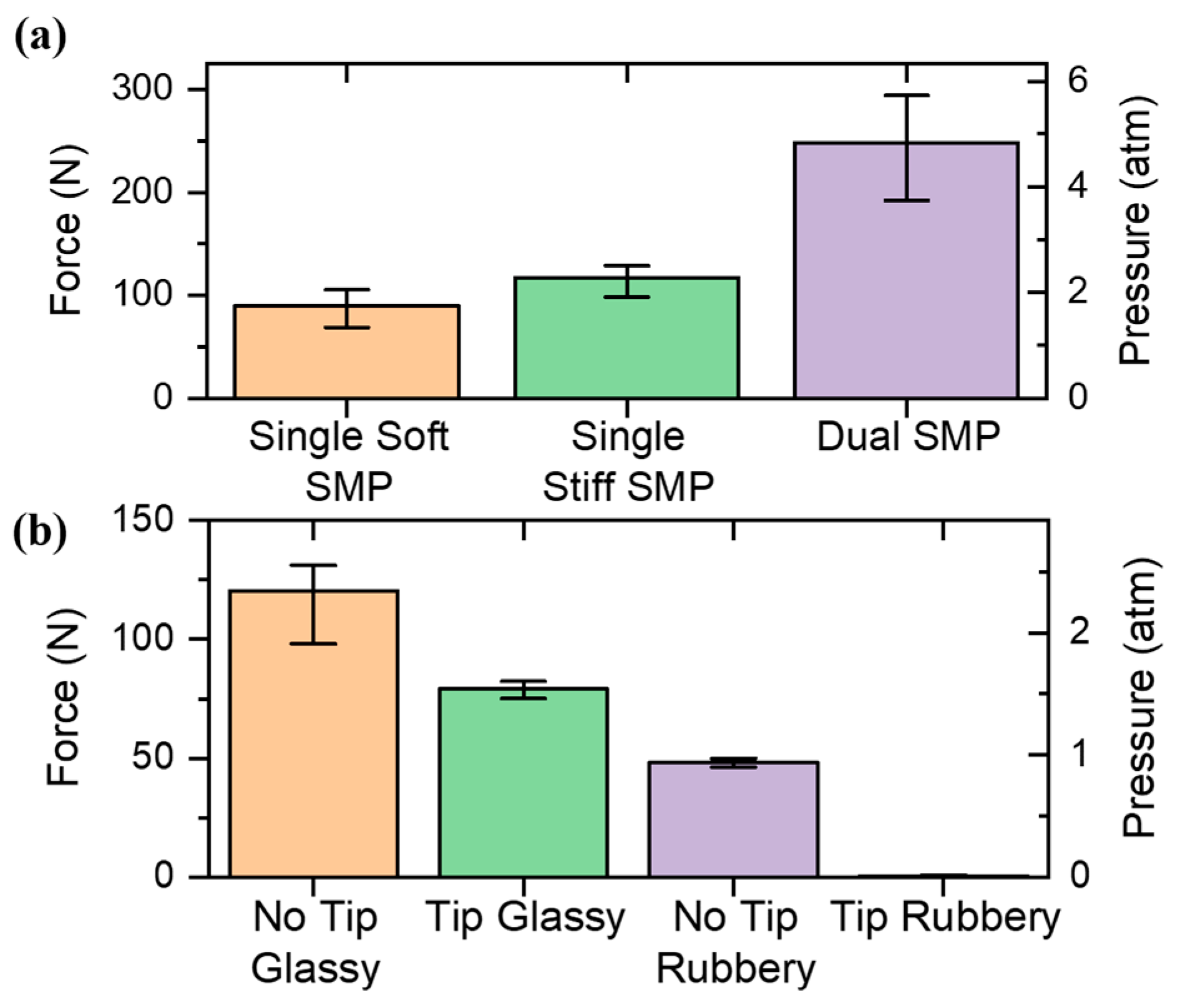

3.2. Numerical Results of Dual SMP and Release Tip SMP

3.3. Experimental Results of Dual SMP and Release Tip SMP

4. Bi-Layer SMP

4.1. Fabrication of Bi-Layer SMP

4.2. Experimental Results of Bi-Layer SMP

5. Thermoelectric Peltier Module

5.1. Schematics of Thermoelectric Peltier Module

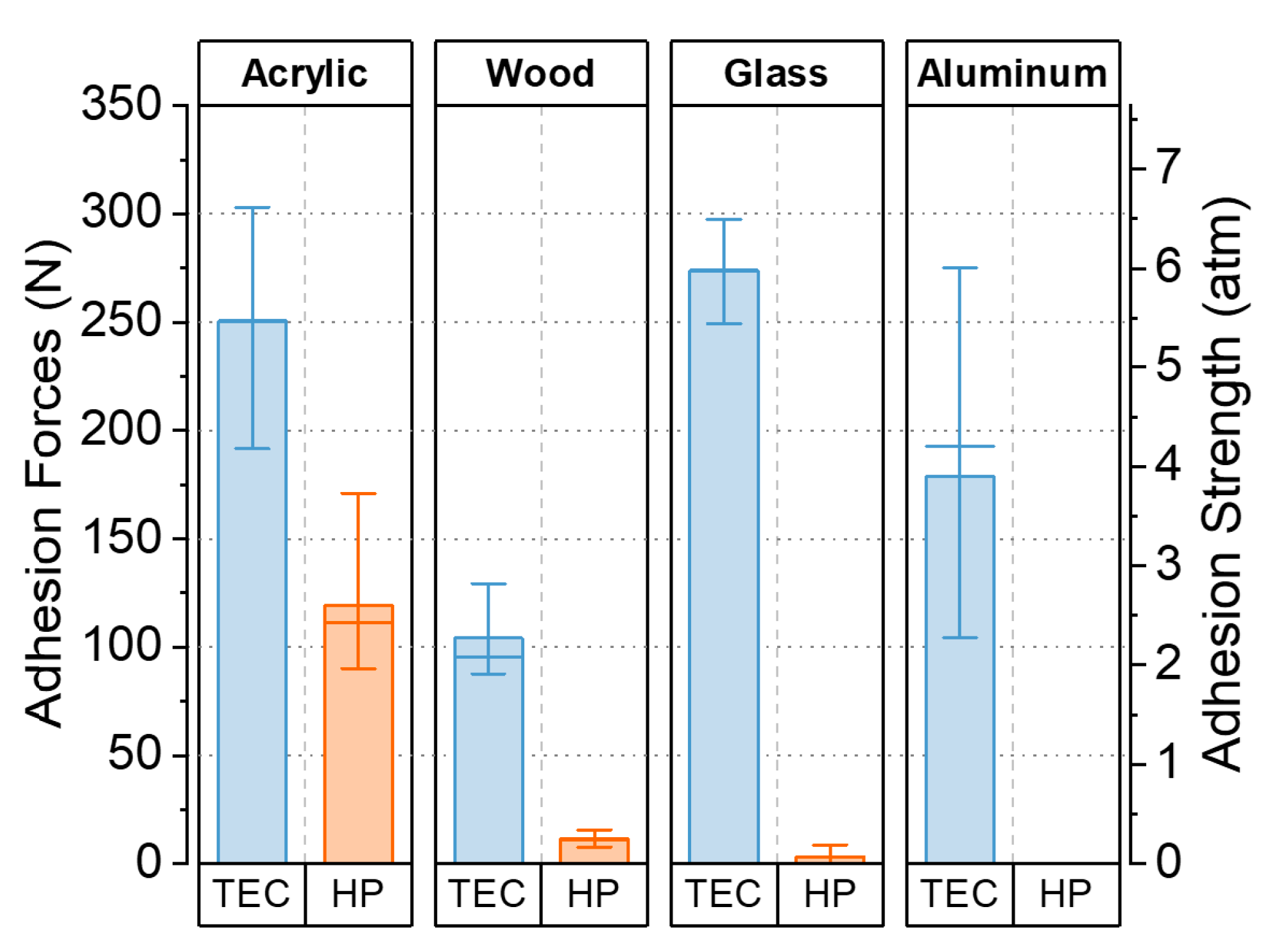

5.2. Adhesion Strength and Temperature Profile

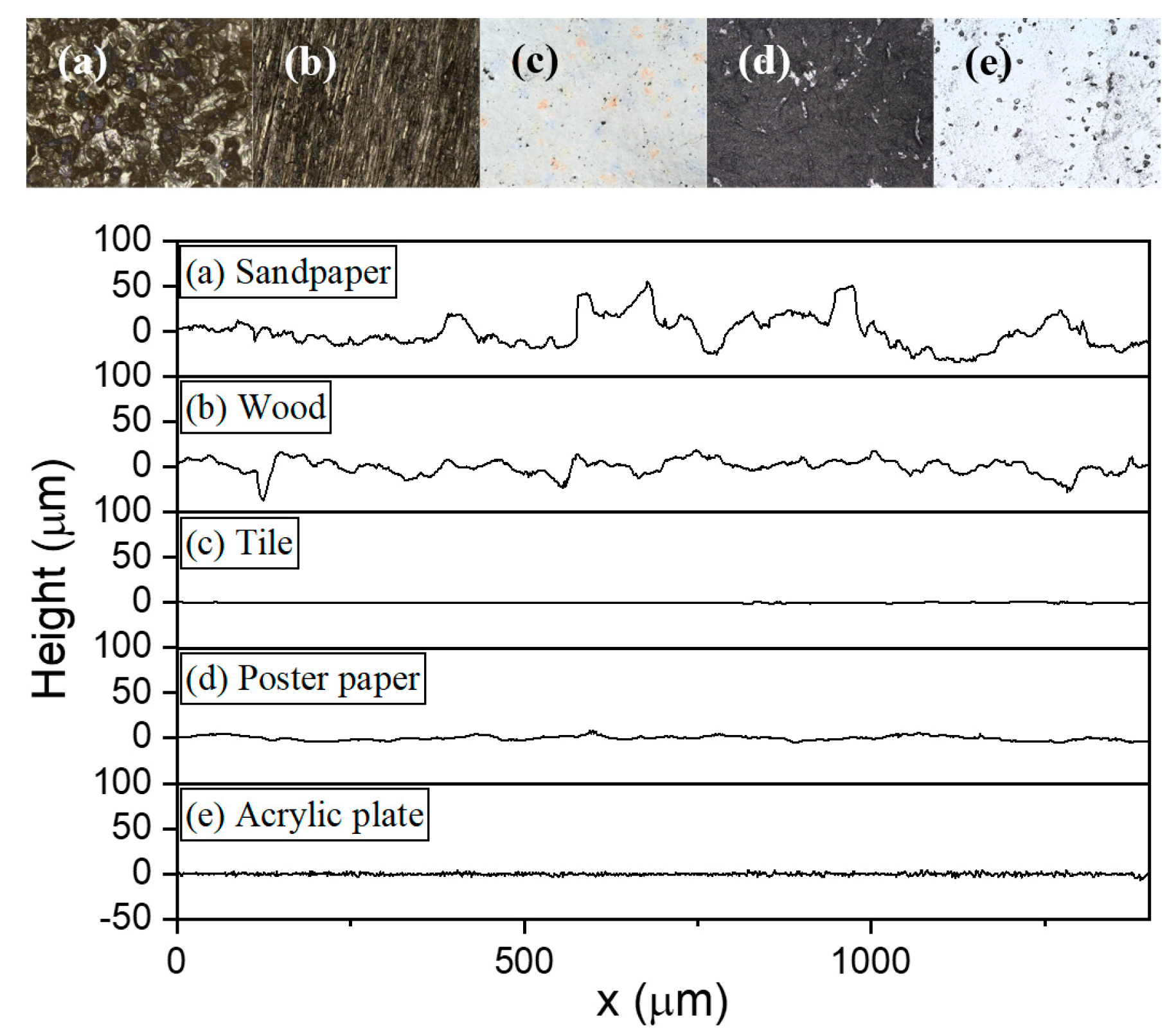

5.3. Radially Averaged Power Spectral Density for Surface Profiles

6. SMP Adhesive Gripper

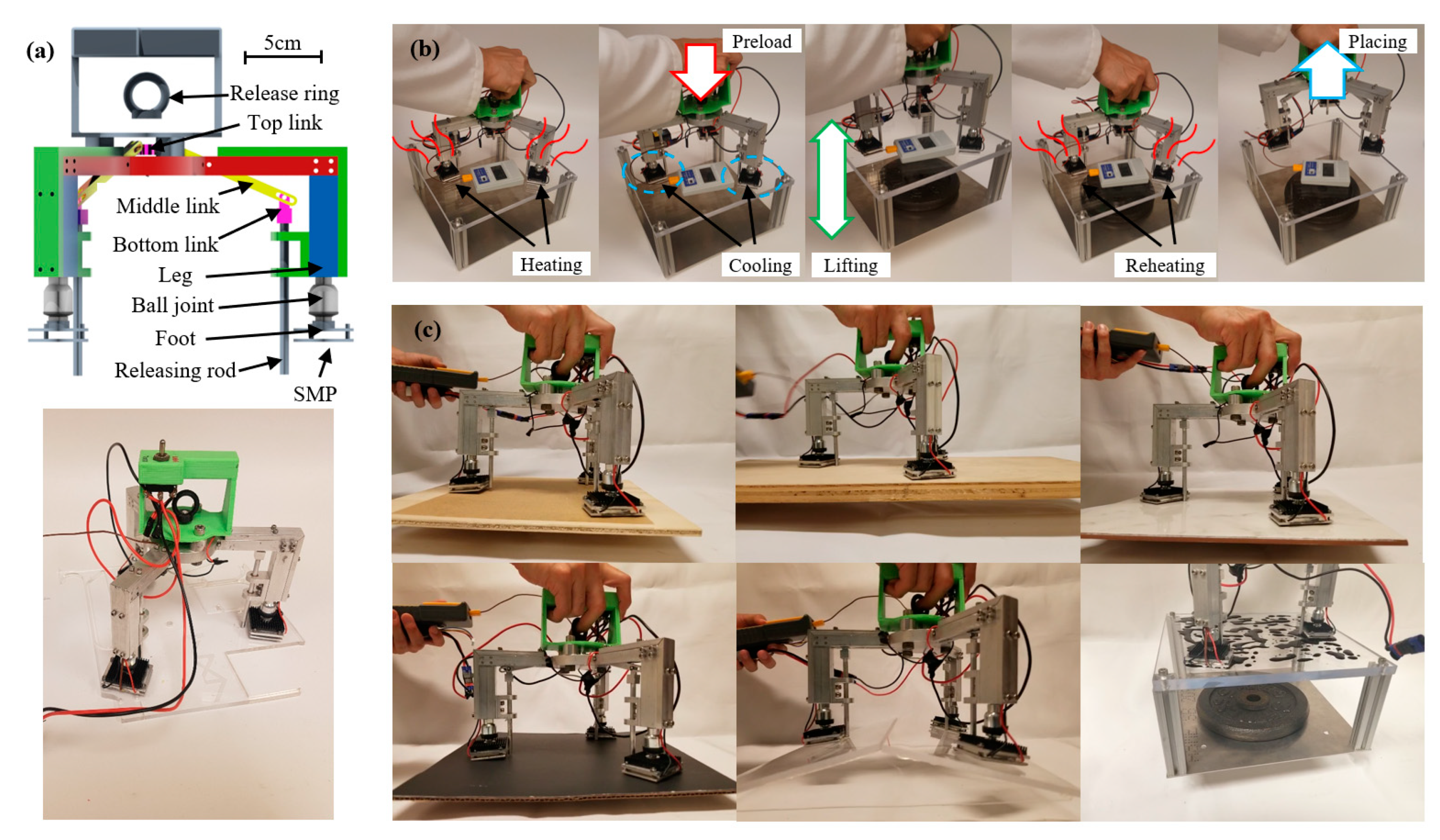

6.1. Schematic of an SMP Gripper

6.2. Pick-and-Place Procedure

6.3. SMP Gripper Demonstration

6.4. Picking Mechanism of the SMP Gripper

6.5. Placing Mechanism of the SMP Gripper

6.6. Temperature Analysis

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Farinelli, A.; Boscolo, N.; Zanotto, E.; Pagello, E. Advanced Approaches for Multi-Robot Coordination in Logistic Scenarios. Robot. Auton. Syst. 2017, 90, 34–44. [Google Scholar] [CrossRef]

- Stoyanov, T.; Vaskevicius, N.; Mueller, C.A.; Fromm, T.; Krug, R.; Tincani, V.; Mojtahedzadeh, R.; Kunaschk, S.; Mortensen Ernits, R.; Canelhas, D.R.; et al. No More Heavy Lifting: Robotic Solutions to the Container Unloading Problem. IEEE Robot. Autom. Mag. 2016, 23, 94–106. [Google Scholar] [CrossRef]

- Jiang, H.; Hawkes, E.W.; Fuller, C.; Estrada, M.A.; Suresh, S.A.; Abcouwer, N.; Han, A.K.; Wang, S.; Ploch, C.J.; Parness, A.; et al. A Robotic Device Using Gecko-Inspired Adhesives Can Grasp and Manipulate Large Objects in Microgravity. Sci. Robot. 2017, 2, 28. [Google Scholar] [CrossRef]

- Parness, A.; Frost, M.; Thatte, N.; King, J.P.; Witkoe, K.; Nevarez, M.; Garrett, M.; Aghazarian, H.; Kennedy, B. Gravity-Independent Rock-Climbing Robot and a Sample Acquisition Tool with Microspine Grippers. J. Field Robot. 2013, 30, 897–915. [Google Scholar] [CrossRef]

- Kuriyama, Y.; Okino, Y.; Wang, Z.; Hirai, S. A Wrapping Gripper for Packaging Chopped and Granular Food Materials. In Proceedings of the 2019 2nd IEEE International Conference on Soft Robotics (RoboSoft), Seoul, Korea, 14–18 April 2019; pp. 114–119. [Google Scholar] [CrossRef]

- Wang, Z.; Furuta, H.; Hirai, S.; Kawamura, S. A Scooping-Binding Robotic Gripper for Handling Various Food Products. Front. Robot. AI 2021, 8, 43. [Google Scholar] [CrossRef]

- Wang, Z.; Or, K.; Hirai, S. A Dual-Mode Soft Gripper for Food Packaging. Rob. Auton. Syst. 2020, 125, 103427. [Google Scholar] [CrossRef]

- Lien, T.K. Gripper Technologies for Food Industry Robots. In Robotics and Automation in the Food Industry Current and Future Technologies; Woodhead Publishing: Sawston, UK, 2013; pp. 143–170. [Google Scholar] [CrossRef]

- Zhang, H.; Kumar, A.S.; Chen, F.; Fuh, J.Y.H.; Wang, M.Y. Topology Optimized Multimaterial Soft Fingers for Applications on Grippers, Rehabilitation, and Artificial Hands. IEEE/ASME Trans. Mechatron. 2019, 24, 120–131. [Google Scholar] [CrossRef]

- Rateni, G.; Cianchetti, M.; Ciuti, G.; Menciassi, A.; Laschi, C. Design and Development of a Soft Robotic Gripper for Manipulation in Minimally Invasive Surgery: A Proof of Concept. Meccanica 2015, 50, 2855–2863. [Google Scholar] [CrossRef]

- Galloway, K.C.; Becker, K.P.; Phillips, B.; Kirby, J.; Licht, S.; Tchernov, D.; Wood, R.J.; Gruber, D.F. Soft Robotic Grippers for Biological Sampling on Deep Reefs. Soft Robot. 2016, 3, 23–33. [Google Scholar] [CrossRef]

- Licht, S.; Collins, E.; Mendes, M.L.; Baxter, C. Stronger at Depth: Jamming Grippers as Deep Sea Sampling Tools. Soft Robot. 2017, 4, 305–316. [Google Scholar] [CrossRef] [PubMed]

- Cecil, J.; Vasquez, D.; Powell, D. A Review of Gripping and Manipulation Techniques for Micro-Assembly Applications. Int. J. Prod. Res. 2007, 43, 819–828. [Google Scholar] [CrossRef]

- Keum, H.; Yang, Z.; Han, K.; Handler, D.E.; Nguyen, T.N.; Schutt-Aine, J.; Bahl, G.; Kim, S. Microassembly of Heterogeneous Materials Using Transfer Printing and Thermal Processing. Sci. Rep. 2016, 6, 29925. [Google Scholar] [CrossRef] [PubMed]

- Kim, S. Micro-LEGO for MEMS. Micromachines 2019, 10, 267. [Google Scholar] [CrossRef]

- Becedas, J.; Payo, I.; Feliu, V. Two-Flexible-Fingers Gripper Force Feedback Control System for Its Application as End Effector on a 6-DOF Manipulator. IEEE Trans. Robot. 2011, 27, 599–615. [Google Scholar] [CrossRef]

- Li, X.; Chen, W.; Lin, W.; Low, K.H. A Variable Stiffness Robotic Gripper Based on Structure-Controlled Principle. IEEE Trans. Autom. Sci. Eng. 2018, 15, 1104–1113. [Google Scholar] [CrossRef]

- El-Atab, N.; Mishra, R.B.; Al-Modaf, F.; Joharji, L.; Alsharif, A.A.; Alamoudi, H.; Diaz, M.; Qaiser, N.; Hussain, M.M. Soft Actuators for Soft Robotic Applications: A Review. Adv. Intell. Syst. 2020, 2, 2000128. [Google Scholar] [CrossRef]

- Shintake, J.; Cacucciolo, V.; Floreano, D.; Shea, H. Soft Robotic Grippers. Adv. Mater. 2018, 30, 1707035. [Google Scholar] [CrossRef] [PubMed]

- Petković, D.; Pavlović, N.D.; Shamshirband, S.; Anuar, N.B. Development of a New Type of Passively Adaptive Compliant Gripper. Ind. Rob. 2013, 40, 610–623. [Google Scholar] [CrossRef]

- Ilievski, F.; Mazzeo, A.D.; Shepherd, R.F.; Chen, X.; Whitesides, G.M. Soft Robotics for Chemists. Angew. Chem. 2011, 123, 1930–1935. [Google Scholar] [CrossRef]

- Do, T.N.; Phan, H.; Nguyen, T.-Q.; Visell, Y.; Do, T.N.; Visell, Y.; Phan, H.; Nguyen, T.-Q. Miniature Soft Electromagnetic Actuators for Robotic Applications. Adv. Funct. Mater. 2018, 28, 1800244. [Google Scholar] [CrossRef]

- Kofod, G.; Wirges, W.; Paajanen, M.; Bauer, S. Energy Minimization for Self-Organized Structure Formation and Actuation. Appl. Phys. Lett. 2007, 90, 081916. [Google Scholar] [CrossRef]

- Lau, G.K.; Heng, K.R.; Ahmed, A.S.; Shrestha, M. Dielectric Elastomer Fingers for Versatile Grasping and Nimble Pinching. Appl. Phys. Lett. 2017, 110, 182906. [Google Scholar] [CrossRef]

- Shian, S.; Bertoldi, K.; Clarke, D.R. Dielectric Elastomer Based “Grippers” for Soft Robotics. Adv. Mater. 2015, 27, 6814–6819. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Zhang, J.; Zong, G.; Wang, W.; Liu, R. Sky Cleaner 3. IEEE Robot. Autom. Mag. 2006, 13, 32–41. [Google Scholar] [CrossRef]

- Miyake, T.; Ishihara, H.; Tomino, T. Vacuum-Based Wet Adhesion System for Wall Climbing Robots -Lubricating Action and Seal Action by the Liquid-. In Proceedings of the 2008 IEEE Int. Conf. Robot. Biomimetics, ROBIO 2008, Bangkok, Thailand, 22–25 February 2009; pp. 1824–1829. [Google Scholar] [CrossRef]

- Shintake, J.; Rosset, S.; Schubert, B.; Floreano, D.; Shea, H. Versatile Soft Grippers with Intrinsic Electroadhesion Based on Multifunctional Polymer Actuators. Adv. Mater. 2016, 28, 231–238. [Google Scholar] [CrossRef]

- Glick, P.; Suresh, S.A.; Ruffatto, D.; Cutkosky, M.; Tolley, M.T.; Parness, A. A Soft Robotic Gripper with Gecko-Inspired Adhesive. IEEE Robot. Autom. Lett. 2018, 3, 903–910. [Google Scholar] [CrossRef]

- Hawkes, E.W.; Christensen, D.L.; Han, A.K.; Jiang, H.; Cutkosky, M.R. Grasping without Squeezing: Shear Adhesion Gripper with Fibrillar Thin Film. In Proceedings of the 2015 IEEE International Conference on Robotics and Automation (ICRA), Seattle, WA, USA, 26–30 May 2015; pp. 2305–2312. [Google Scholar] [CrossRef]

- Hawkes, E.W.; Jiang, H.; Cutkosky, M.R. Three-Dimensional Dynamic Surface Grasping with Dry Adhesion. Int. J. Rob. Res. 2016, 35, 943–958. [Google Scholar] [CrossRef]

- Song, S.; Drotlef, D.M.; Majidi, C.; Sitti, M. Controllable Load Sharing for Soft Adhesive Interfaces on Three-Dimensional Surfaces. Proc. Natl. Acad. Sci. USA 2017, 114, E4344–E4353. [Google Scholar] [CrossRef]

- Song, S.; Sitti, M. Soft Grippers Using Micro-Fibrillar Adhesives for Transfer Printing. Adv. Mater. 2014, 26, 4901–4906. [Google Scholar] [CrossRef]

- Hu, Q.; Dong, E.; Sun, D. Soft Gripper Design Based on the Integration of Flat Dry Adhesive, Soft Actuator, and Microspine. IEEE Trans. Robot. 2021, 37, 1065–1080. [Google Scholar] [CrossRef]

- Hao, Y.; Biswas, S.; Hawkes, E.W.; Wang, T.; Zhu, M.; Wen, L.; Visell, Y. A Multimodal, Enveloping Soft Gripper: Shape Conformation, Bioinspired Adhesion, and Expansion-Driven Suction. IEEE Trans. Robot. 2021, 37, 350–362. [Google Scholar] [CrossRef]

- Liu, C.; Qin, H.; Mather, P.T. Review of Progress in Shape-Memory Polymers. J. Mater. Chem. 2007, 17, 1543–1558. [Google Scholar] [CrossRef]

- Mohd Jani, J.; Leary, M.; Subic, A.; Gibson, M.A. A Review of Shape Memory Alloy Research, Applications and Opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- McCoul, D.; Rosset, S.; Besse, N.; Shea, H. Multifunctional Shape Memory Electrodes for Dielectric Elastomer Actuators Enabling High Holding Force and Low-Voltage Multisegment Addressing. Smart Mater. Struct. 2017, 26, 025015. [Google Scholar] [CrossRef]

- Wang, W.; Ahn, S.H. Shape Memory Alloy-Based Soft Gripper with Variable Stiffness for Compliant and Effective Grasping. Soft Robot. 2017, 4, 379–389. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.H.; Chung, Y.S.; Rodrigue, H. Long Shape Memory Alloy Tendon-Based Soft Robotic Actuators and Implementation as a Soft Gripper. Sci. Rep. 2019, 9, 11251. [Google Scholar] [CrossRef]

- Xing, S.; Wang, P.; Liu, S.; Xu, Y.; Zheng, R.; Deng, Z.; Peng, Z.; Li, J.; Wu, Y.; Liu, L. A Shape-Memory Soft Actuator Integrated with Reversible Electric/Moisture Actuating and Strain Sensing. Compos. Sci. Technol. 2020, 193, 108133. [Google Scholar] [CrossRef]

- Li, W.; Liu, Y.; Leng, J. Light-Actuated Reversible Shape Memory Effect of a Polymer Composite. Compos. Part A Appl. Sci. Manuf. 2018, 110, 70–75. [Google Scholar] [CrossRef]

- Xu, Z.; Ding, C.; Wei, D.W.; Bao, R.Y.; Ke, K.; Liu, Z.; Yang, M.B.; Yang, W. Electro and Light-Active Actuators Based on Reversible Shape-Memory Polymer Composites with Segregated Conductive Networks. ACS Appl. Mater. Interfaces 2019, 11, 30332–30340. [Google Scholar] [CrossRef]

- Linghu, C.; Zhang, S.; Wang, C.; Yu, K.; Li, C.; Zeng, Y.; Zhu, H.; Jin, X.; You, Z.; Song, J. Universal SMP Gripper with Massive and Selective Capabilities for Multiscaled, Arbitrarily Shaped Objects. Sci. Adv. 2020, 6, eaay5120. [Google Scholar] [CrossRef]

- Brown, E.; Rodenberg, N.; Amend, J.; Mozeika, A.; Steltz, E.; Zakin, M.R.; Lipson, H.; Jaeger, H.M. Universal Robotic Gripper Based on the Jamming of Granular Material. Proc. Natl. Acad. Sci. USA 2010, 107, 18809–18814. [Google Scholar] [CrossRef]

- Li, L.; Liu, Z.; Zhou, M.; Li, X.; Meng, Y.; Tian, Y. Flexible Adhesion Control by Modulating Backing Stiffness Based on Jamming of Granular Materials. Smart Mater. Struct. 2019, 28, 115023. [Google Scholar] [CrossRef]

- Zhu, T.; Yang, H.; Zhang, W. A Spherical Self-Adaptive Gripper with Shrinking of an Elastic Membrane. In Proceedings of the 2016 International Conference on Advanced Robotics and Mechatronics (ICARM), Macau, China, 18–20 August 2016; pp. 512–517. [Google Scholar] [CrossRef]

- Son, C.H.; Kim, S. A Shape Memory Polymer Adhesive Gripper for Pick-and-Place Applications. In Proceedings of the Proceedings-IEEE International Conference on Robotics and Automation, Paris, France, 15 September 2020; pp. 10010–10016. [Google Scholar]

- Park, J.K.; Eisenhaure, J.D.; Kim, S. Reversible Underwater Dry Adhesion of a Shape Memory Polymer. Adv. Mater. Interfaces 2019, 6, 1801542. [Google Scholar] [CrossRef]

- Eisenhaure, J.; Kim, S. High-Strain Shape Memory Polymers as Practical Dry Adhesives. Int. J. Adhes. Adhes. 2018, 81, 74–78. [Google Scholar] [CrossRef]

- Eisenhaure, J.D.; Rhee, S., II; Al-Okaily, A.M.; Carlson, A.; Ferreira, P.M.; Kim, S. The Use of Shape Memory Polymers for MEMS Assembly. J. Microelectromechan. Syst. 2016, 25, 69–77. [Google Scholar] [CrossRef]

- Seo, J.; Eisenhaure, J.; Kim, S. Micro-Wedge Array Surface of a Shape Memory Polymer as a Reversible Dry Adhesive. Extrem. Mech. Lett. 2016, 9, 207–214. [Google Scholar] [CrossRef]

- Patil, S.; Malasi, A.; Majumder, A.; Ghatak, A.; Sharma, A. Reusable Antifouling Viscoelastic Adhesive with an Elastic Skin. Langmuir 2011, 28, 42–46. [Google Scholar] [CrossRef]

- Shahsavan, H.; Zhao, B. Bioinspired Functionally Graded Adhesive Materials: Synergetic Interplay of Top Viscous-Elastic Layers with Base Micropillars. Macromolecules 2014, 47, 353–364. [Google Scholar] [CrossRef]

- Dharmawan, A.G.; Xavier, P.; Hariri, H.H.; Soh, G.S.; Baji, A.; Bouffanais, R.; Foong, S.; Low, H.Y.; Wood, K.L. Design, Modeling, and Experimentation of a Bio-Inspired Miniature Climbing Robot With Bilayer Dry Adhesives. J. Mech. Robot. 2019, 11, 020902. [Google Scholar] [CrossRef]

- Minsky, H.K.; Turner, K.T. Composite Microposts with High Dry Adhesion Strength. ACS Appl. Mater. Interfaces 2017, 9, 18322–18327. [Google Scholar] [CrossRef]

- Dong, W.P.; Stout, K.J. Two-Dimensional Fast Fourier Transform and Power Spectrum for Surface Roughness in Three Dimensions. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 1995, 209, 381–391. [Google Scholar] [CrossRef]

- Eisenhaure, J.; Kim, S. An Internally Heated Shape Memory Polymer Dry Adhesive. Polymers 2014, 6, 2274–2286. [Google Scholar] [CrossRef]

- Astin, A.D. Finger Force Capability: Measurement and Prediction Using Anthropometric and Myoelectric Measures; Virginia Tech: Blacksburg, VA, USA, 1999. [Google Scholar]

| Material | Thermal Conductivity | Surface Roughness Sa (μm) |

|---|---|---|

| Acrylic | 0.18 | 0.327 |

| Wood | 0.1 | 7.52 |

| Glass | 1.38 | 0.266 |

| Aluminum | 237 | 1.49 |

| Parameter | Symbol | Magnitude |

|---|---|---|

| Weight of the device | FM | 12.7 N |

| Minimum preload pressure | Ppre | 15 N/cm2 [51] |

| Total SMP area | A | 48 cm2 |

| Angle between the middle link and the leg | θ | 0–33.6° |

| Length from pivot point O to top link | La | 25 mm |

| Length from pivot point O to bottom link | Lb | 50 mm |

| Release ring pulling force | FH | 60 N [59] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Son, C.; Jeong, S.; Lee, S.; Ferreira, P.M.; Kim, S. Tunable Adhesion of Shape Memory Polymer Dry Adhesive Soft Robotic Gripper via Stiffness Control. Robotics 2023, 12, 59. https://doi.org/10.3390/robotics12020059

Son C, Jeong S, Lee S, Ferreira PM, Kim S. Tunable Adhesion of Shape Memory Polymer Dry Adhesive Soft Robotic Gripper via Stiffness Control. Robotics. 2023; 12(2):59. https://doi.org/10.3390/robotics12020059

Chicago/Turabian StyleSon, ChangHee, Subin Jeong, Sangyeop Lee, Placid M. Ferreira, and Seok Kim. 2023. "Tunable Adhesion of Shape Memory Polymer Dry Adhesive Soft Robotic Gripper via Stiffness Control" Robotics 12, no. 2: 59. https://doi.org/10.3390/robotics12020059

APA StyleSon, C., Jeong, S., Lee, S., Ferreira, P. M., & Kim, S. (2023). Tunable Adhesion of Shape Memory Polymer Dry Adhesive Soft Robotic Gripper via Stiffness Control. Robotics, 12(2), 59. https://doi.org/10.3390/robotics12020059