Body-Powered and Portable Soft Hydraulic Actuators as Prosthetic Hands

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials and Preparation

2.2. Fabrication of the Fiber-Reinforced Elastomeric Actuator

2.3. Characterization

2.4. Evaluation of Shrugging Force

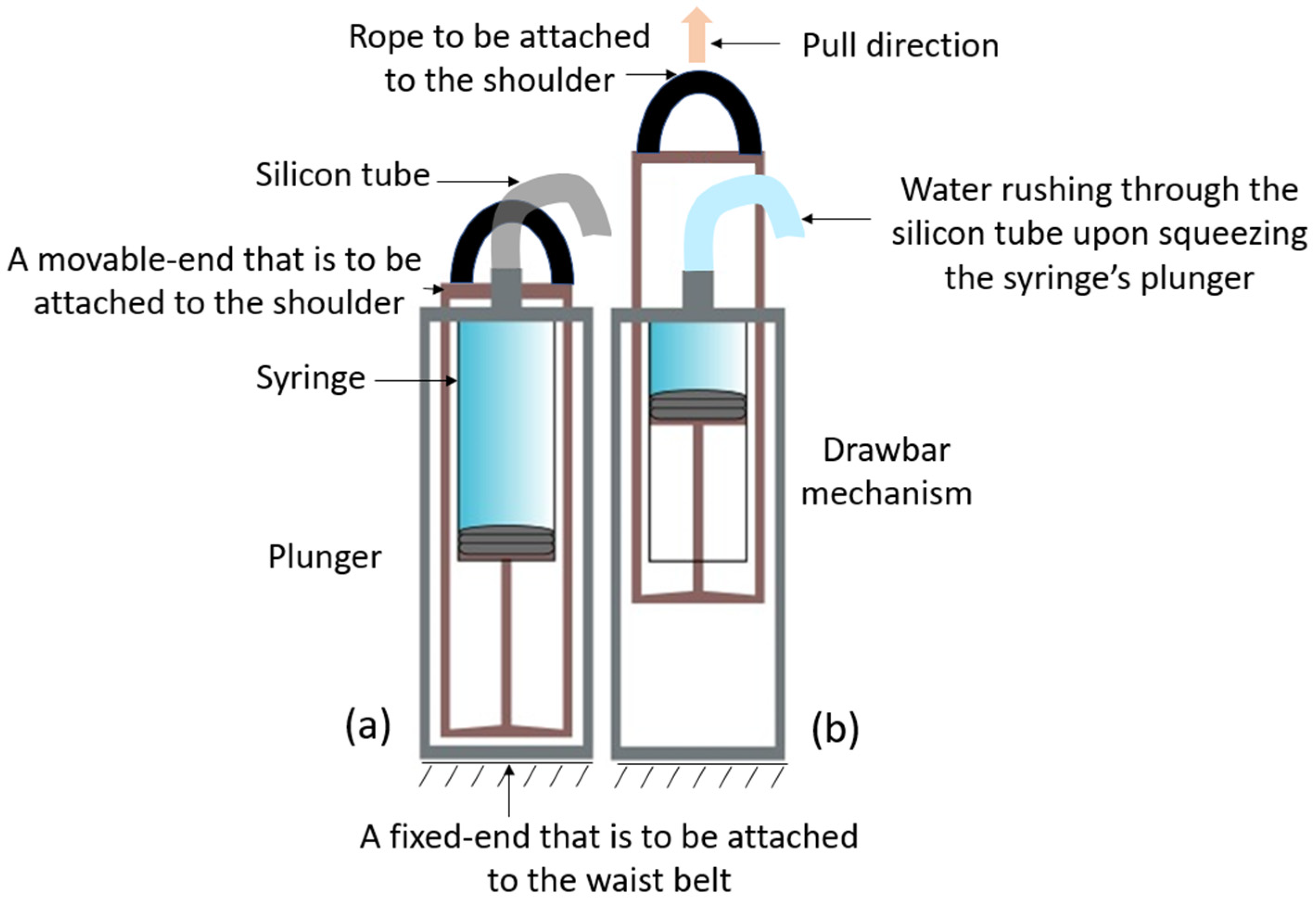

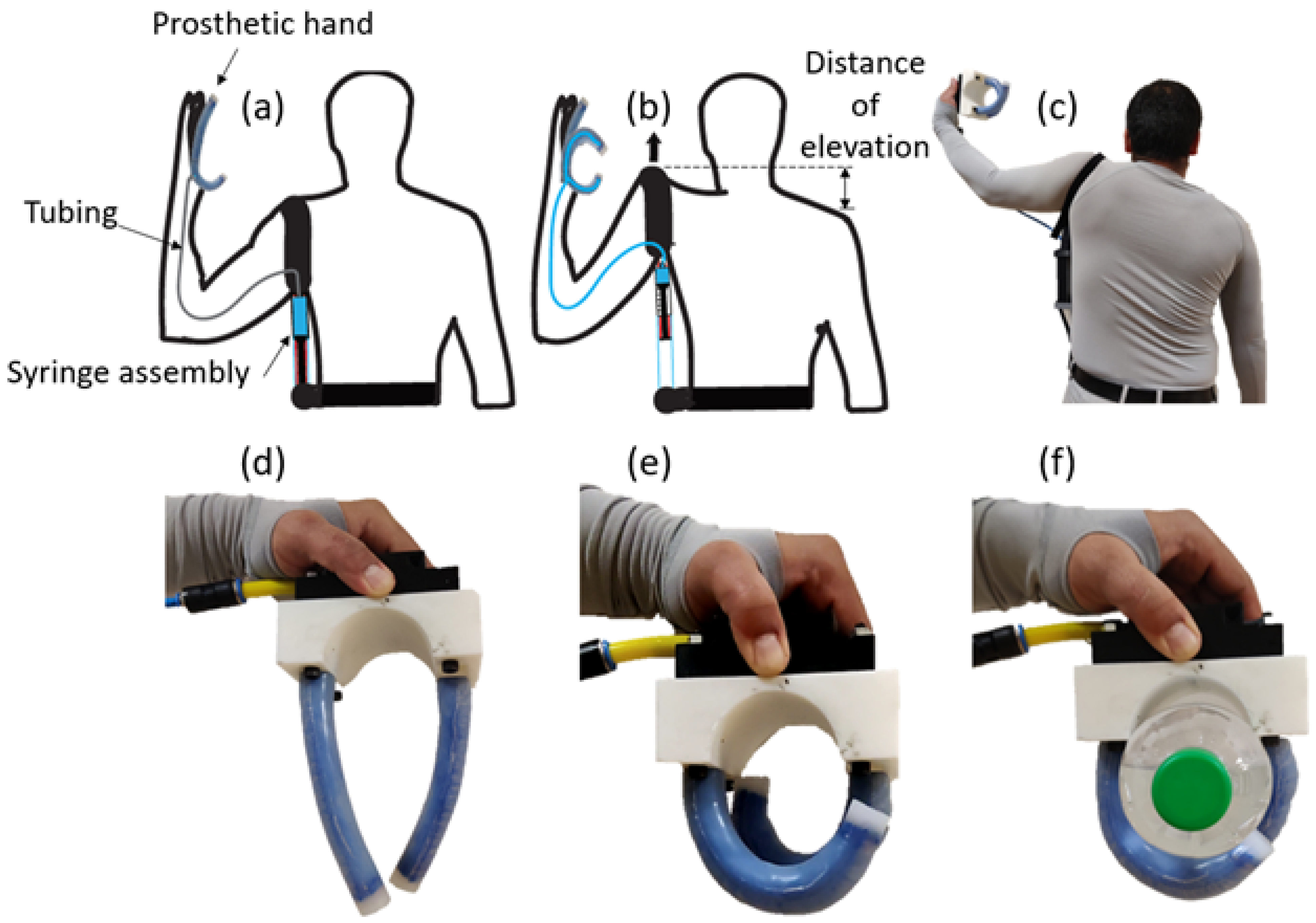

2.5. Draw-Bar Spring Mechanism for Body Power Generation

3. Results and Discussion

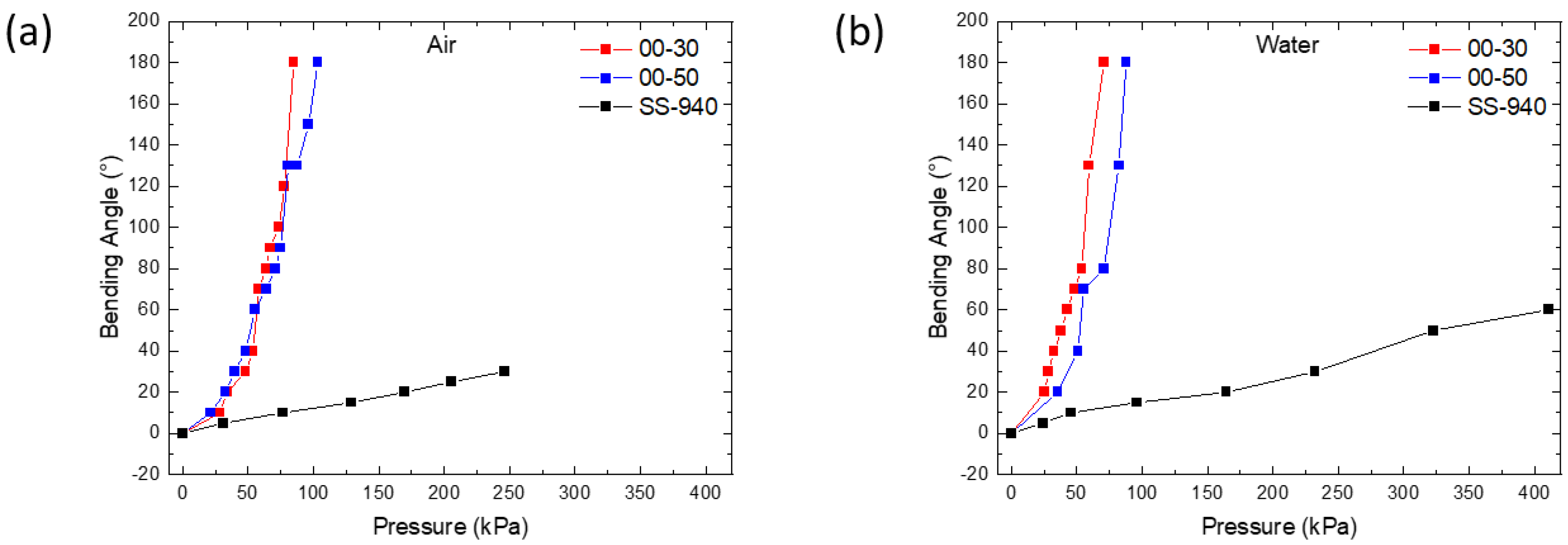

3.1. Bending Characteristics

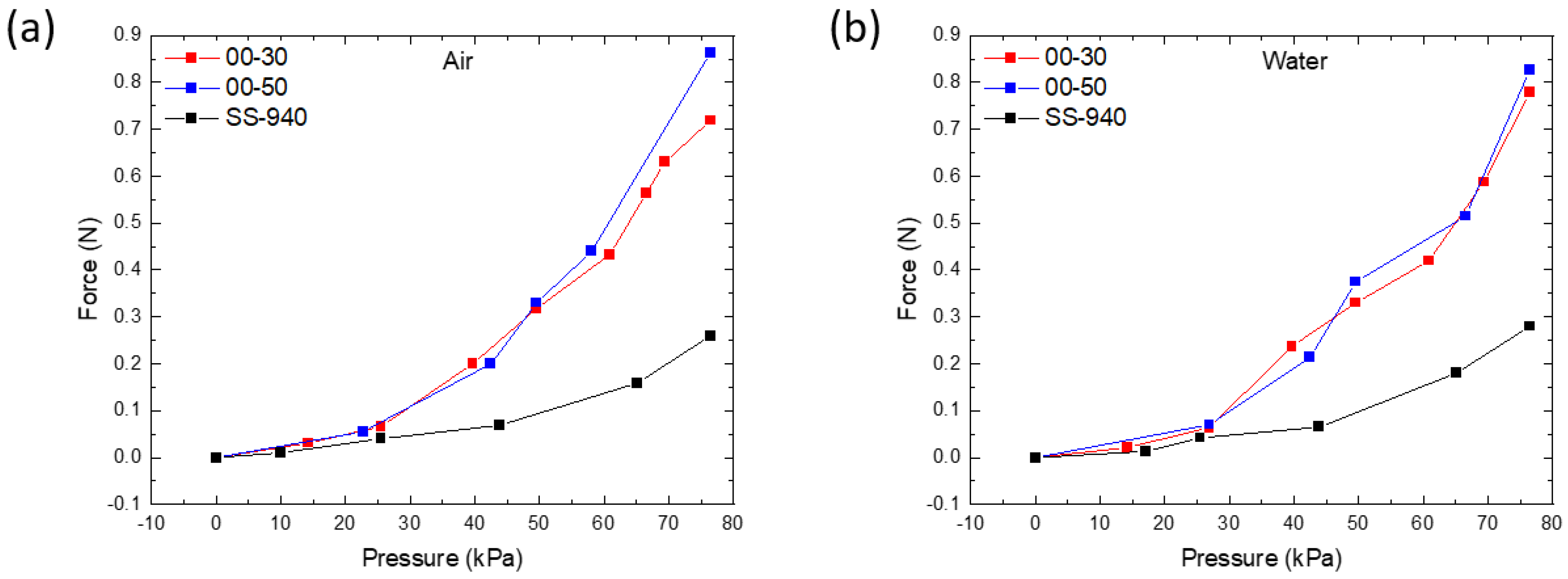

3.2. Force Characteristics

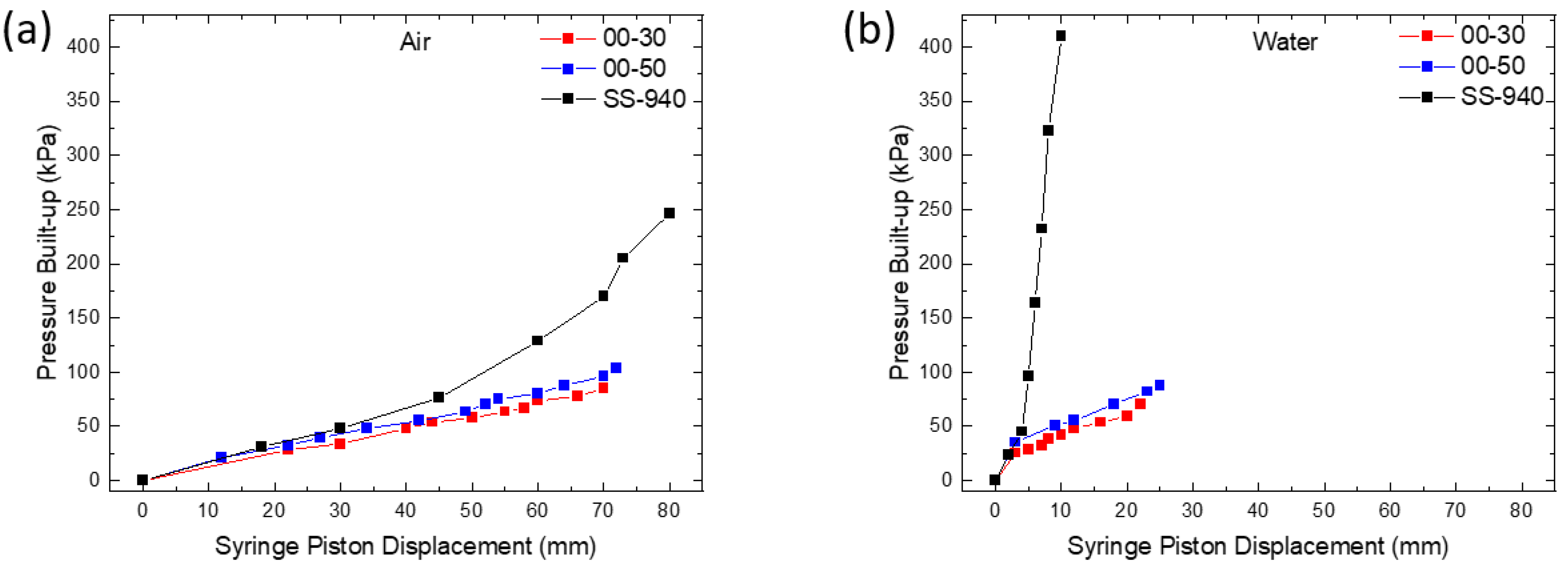

3.3. Syringe Plunger Displacement versus Pressure Built Up in the Actuator

3.4. Application of Body-Powered Actuation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bao, G.; Fang, H.; Chen, L.; Wan, Y.; Xu, F.; Yang, Q.; Zhang, L. Soft Robotics: Academic Insights and Perspectives Through Bibliometric Analysis. Soft Robot. 2018, 5, 229–241. [Google Scholar] [CrossRef] [PubMed]

- Datteri, E. The Logic of Interactive Biorobotics. Front. Bioeng. Biotechnol. 2020, 8, 637. [Google Scholar] [CrossRef] [PubMed]

- Park, Y.-L.; Chen, B.; Pérez-Arancibia, N.O.; Young, D.; Stirling, L.; Wood, R.J.; Goldfield, E.C.; Nagpal, R. Design and control of a bio-inspired soft wearable robotic device for ankle–foot rehabilitation. Bioinspir. Biomim. 2014, 9, 016007. [Google Scholar] [CrossRef]

- Walsh, C. Human-in-the-loop development of soft wearable robots. Nat. Rev. Mater. 2018, 3, 78–80. [Google Scholar] [CrossRef]

- Agarwal, G.; Besuchet, N.; Audergon, B.; Paik, J. Stretchable Materials for Robust Soft Actuators towards Assistive Wearable Devices. Sci. Rep. 2016, 6, 34224. [Google Scholar] [CrossRef] [Green Version]

- Majidi, C. Soft Robotics: A Perspective—Current Trends and Prospects for the Future. Soft Robot. 2014, 1, 5–11. [Google Scholar] [CrossRef]

- Martinez, R.V.; Glavan, A.C.; Keplinger, C.; Oyetibo, A.I.; Whitesides, G.M. Soft actuators and robots that are resistant to mechanical damage. Adv. Funct. Mater. 2014, 24, 3003–3010. [Google Scholar] [CrossRef] [Green Version]

- Amjadi, M.; Kyung, K.U.; Park, I.; Sitti, M. Stretchable, Skin-Mountable, and Wearable Strain Sensors and Their Potential Applications: A Review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

- Guo, J.; Sun, Y.; Liang, X.; Low, J.H.; Wong, Y.R.; Tay, V.S.C.; Yeow, C.H. Design and fabrication of a pneumatic soft robotic gripper for delicate surgical manipulation. In Proceedings of the 2017 IEEE International Conference on Mechatronics and Automation (ICMA), Takamatsu, Japan, 6–9 August 2017; pp. 1069–1074. [Google Scholar] [CrossRef]

- Chappel, E.; Dumont-Fillon, D. Micropumps for drug delivery. In Drug Delivery Devices and Therapeutic Systems; Elsevier: Amsterdam, The Netherlands, 2021; pp. 31–61. [Google Scholar]

- Collie, A. Walking Robot. IEE Colloq. 1985, 19, 339–347. [Google Scholar]

- Yao, J.; Jiao, Z.; Ma, D.; Yan, L. High-accuracy tracking control of hydraulic rotary actuators with modeling uncertainties. IEEE/ASME Trans. Mechatron. 2014, 19, 633–641. [Google Scholar] [CrossRef]

- Coyle, S.; Majidi, C.; LeDuc, P.; Hsia, K.J. Bio-inspired soft robotics: Material selection, actuation, and design. Extrem. Mech. Lett. 2018, 22, 51–59. [Google Scholar] [CrossRef]

- Yap, H.K.; Lim, J.H.; Nasrallah, F.; Low, F.Z.; Goh, J.C.H.; Yeow, R.C.H. MRC-glove: A fMRI compatible soft robotic glove for hand rehabilitation application. In Proceedings of the 2015 IEEE International Conference on Rehabilitation Robotics (ICORR), Singapore, 11–14 August 2015; pp. 735–740. [Google Scholar] [CrossRef]

- Yap, H.K.; Khin, P.M.; Koh, T.H.; Sun, Y.; Liang, X.; Lim, J.H.; Yeow, C.-H. A Fully Fabric-Based Bidirectional Soft Robotic Glove for Assistance and Rehabilitation of Hand Impaired Patients. IEEE Robot. Autom. Lett. 2017, 2, 1383–1390. [Google Scholar] [CrossRef]

- Yap, H.K.; Ng, H.Y.; Yeow, C.-H. High-Force Soft Printable Pneumatics for Soft Robotic Applications. Soft Robot. 2016, 3, 144–158. [Google Scholar] [CrossRef]

- Wang, Z.; Polygerinos, P.; Overvelde, J.T.B.; Galloway, K.C.; Bertoldi, K.; Walsh, C.J. Interaction Forces of Soft Fiber Reinforced Bending Actuators. IEEE/ASME Trans. Mechatron. 2017, 22, 717–727. [Google Scholar] [CrossRef]

- Connolly, F.; Walsh, C.J.; Bertoldi, K. Automatic design of fiber-reinforced soft actuators for trajectory matching. Proc. Natl. Acad. Sci. USA 2017, 114, 51–56. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, B.; Aw, K.C.; Biglari-Abhari, M.; McDaid, A. Design and fabrication of a fiber-reinforced pneumatic bending actuator. In Proceedings of the 2016 IEEE International Conference on Advanced Intelligent Mechatronics (AIM), Banff, AB, Canada, 12–15 July 2016; pp. 83–88. [Google Scholar] [CrossRef]

- Wang, B.; McDaid, A.; Giffney, T.; Biglari-Abhari, M.; Aw, K.C. Design, modelling and simulation of soft grippers using new bimorph pneumatic bending actuators. Cogent Eng. 2017, 4, 1285482. [Google Scholar] [CrossRef]

- Kandasamy, S.; Devaraj, H.; Stuart, L.; McDaid, A.; Aw, K.C. A novel varying angle fiber-reinforced elastomer as a soft pneumatic bending actuator. In Proceedings of the 3rd International Conference on Automation, Control and Robots, Praha, Czech Republic, 11–13 October 2019; pp. 50–54. [Google Scholar]

- Hashemi, S.; Durfee, W. Variable hydraulic transmission to be used in a body-powered wearable Robot. In Proceedings of the 2020 Design of Medical Devices Conference, Minneapolis, MN, USA, 6–9 April 2020; pp. 7–9. [Google Scholar] [CrossRef]

- Gerez, L.; Chen, J.; Liarokapis, M. On the Development of Adaptive, Tendon-Driven, Wearable Exo-Gloves for Grasping Capabilities Enhancement. IEEE Robot. Autom. Lett. 2019, 4, 422–429. [Google Scholar] [CrossRef]

- Trent, L.; Intintoli, M.; Prigge, P.; Bollinger, C.; Walters, L.S.; Conyers, D.; Miguelez, J.; Ryan, T. A narrative review: Current upper limb prosthetic options and design. Disabil. Rehabil. Assist. Technol. 2020, 15, 604–613. [Google Scholar] [CrossRef]

- Gemmell, K.D.; Leddy, M.T.; Belter, J.T.; Dollar, A.M. Investigation of a passive capstan based grasp enhancement feature in a voluntary-closing prosthetic terminal device. In Proceedings of the 38th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Orlando, FL, USA, 16–20 August 2016; pp. 5019–5025. [Google Scholar] [CrossRef]

- Ayub, R.; Villarreal, D.; Gregg, R.D.; Gao, F. Evaluation of transradial body-powered prostheses using a robotic simulator. Prosthet. Orthot. Int. 2017, 41, 194–200. [Google Scholar] [CrossRef]

- Lee, C.-W.; Jeong, S.-Y.; Kwon, Y.-W.; Lee, J.-U.; Cho, S.-C.; Shin, B.-S. Fabrication of laser-induced graphene-based multifunctional sensing platform for sweat ion and human motion monitoring. Sens. Actuators A Phys. 2021, 334, 113320. [Google Scholar] [CrossRef]

- Hashemi, S.; Bentivegna, D.; Durfee, W. Bone-Inspired Bending Soft Robot. Soft Robot. 2021, 8, 387–396. [Google Scholar] [CrossRef] [PubMed]

- Montagnani, F.; Smit, G.; Controzzi, M.; Cipriani, C.; Plettenburg, D.H. A passive wrist with switchable stiffness for a body-powered hydraulically actuated hand prosthesis. In Proceedings of the International Conference on Rehabilitation Robotics (ICORR), London, UK, 17–20 July 2017; pp. 1197–1202. [Google Scholar] [CrossRef]

- Yap, H.K.; Lim, J.H.; Nasrallah, F.; Cho Hong Goh, J.; Yeow, C.H. Characterisation and evaluation of soft elastomeric actuators for hand assistive and rehabilitation applications. J. Med. Eng. Technol. 2016, 40, 199–209. [Google Scholar] [CrossRef] [PubMed]

- Galloway, K.C.; Polygerinos, P.; Walsh, C.J.; Wood, R.J. Mechanically programmable bend radius for fiber-reinforced soft actuators. In Proceedings of the 2013 16th International Conference on Advanced Robotics (ICAR), Montevideo, Uruguay, 25–29 November 2013; pp. 1–6. [Google Scholar]

- Polygerinos, P.; Lyne, S.; Wang, Z.; Nicolini, L.F.; Mosadegh, B.; Whitesides, G.M.; Walsh, C.J. Towards a Soft Pneumatic Glove for Hand Rehabilitation. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013; pp. 1512–1517. [Google Scholar] [CrossRef]

- Mosadegh, B.; Polygerinos, P.; Keplinger, C.; Wennstedt, S.; Shepherd, R.F.; Gupta, U.; Shim, J.; Bertoldi, K.; Walsh, C.J.; Whitesides, G.M. Pneumatic Networks for Soft Robotics That Actuate Rapidly. Adv. Funct. Mater. 2014, 24, 2163–2170. [Google Scholar] [CrossRef]

- Shintake, J.; Sonar, H.; Piskarev, E.; Paik, J.; Floreano, D. Soft Pneumatic Gelatin Actuator for Edible Robotics. In Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; pp. 6221–6226. [Google Scholar] [CrossRef] [Green Version]

- Allmendinger, A.; Fischer, S. Tissue Resistance during Large-Volume Injections in Subcutaneous Tissue of Minipigs. Pharm. Res. 2020, 37, 184. [Google Scholar] [CrossRef]

- Veilleux, J.C.; Shepherd, J.E. Pressure and Stress Transients in Autoinjector Devices. Drug Deliv. Transl. Res. 2018, 8, 1238–1253. [Google Scholar] [CrossRef] [Green Version]

- Jackson, D.P.; Laws, P.W. Syringe Thermodynamics: The Many Uses of a Glass Syringe. Am. J. Phys. 2006, 74, 94–101. [Google Scholar] [CrossRef]

| Material | Experimental Young’s Modulus (MPa) |

|---|---|

| Ecoflex 00-30 | 0.15 |

| Ecoflex 00-50 | 0.21 |

| Smooth Sil-940 | 0.90 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kandasamy, S.; Teo, M.; Ravichandran, N.; McDaid, A.; Jayaraman, K.; Aw, K. Body-Powered and Portable Soft Hydraulic Actuators as Prosthetic Hands. Robotics 2022, 11, 71. https://doi.org/10.3390/robotics11040071

Kandasamy S, Teo M, Ravichandran N, McDaid A, Jayaraman K, Aw K. Body-Powered and Portable Soft Hydraulic Actuators as Prosthetic Hands. Robotics. 2022; 11(4):71. https://doi.org/10.3390/robotics11040071

Chicago/Turabian StyleKandasamy, Sivakumar, Meiying Teo, Narrendar Ravichandran, Andrew McDaid, Krishnan Jayaraman, and Kean Aw. 2022. "Body-Powered and Portable Soft Hydraulic Actuators as Prosthetic Hands" Robotics 11, no. 4: 71. https://doi.org/10.3390/robotics11040071

APA StyleKandasamy, S., Teo, M., Ravichandran, N., McDaid, A., Jayaraman, K., & Aw, K. (2022). Body-Powered and Portable Soft Hydraulic Actuators as Prosthetic Hands. Robotics, 11(4), 71. https://doi.org/10.3390/robotics11040071