Multi-Layered Carbon-Black/Elastomer-Composite-Based Shielded Stretchable Capacitive Sensors for the Underactuated Robotic Hand

Abstract

:1. Introduction

2. Materials and Methods

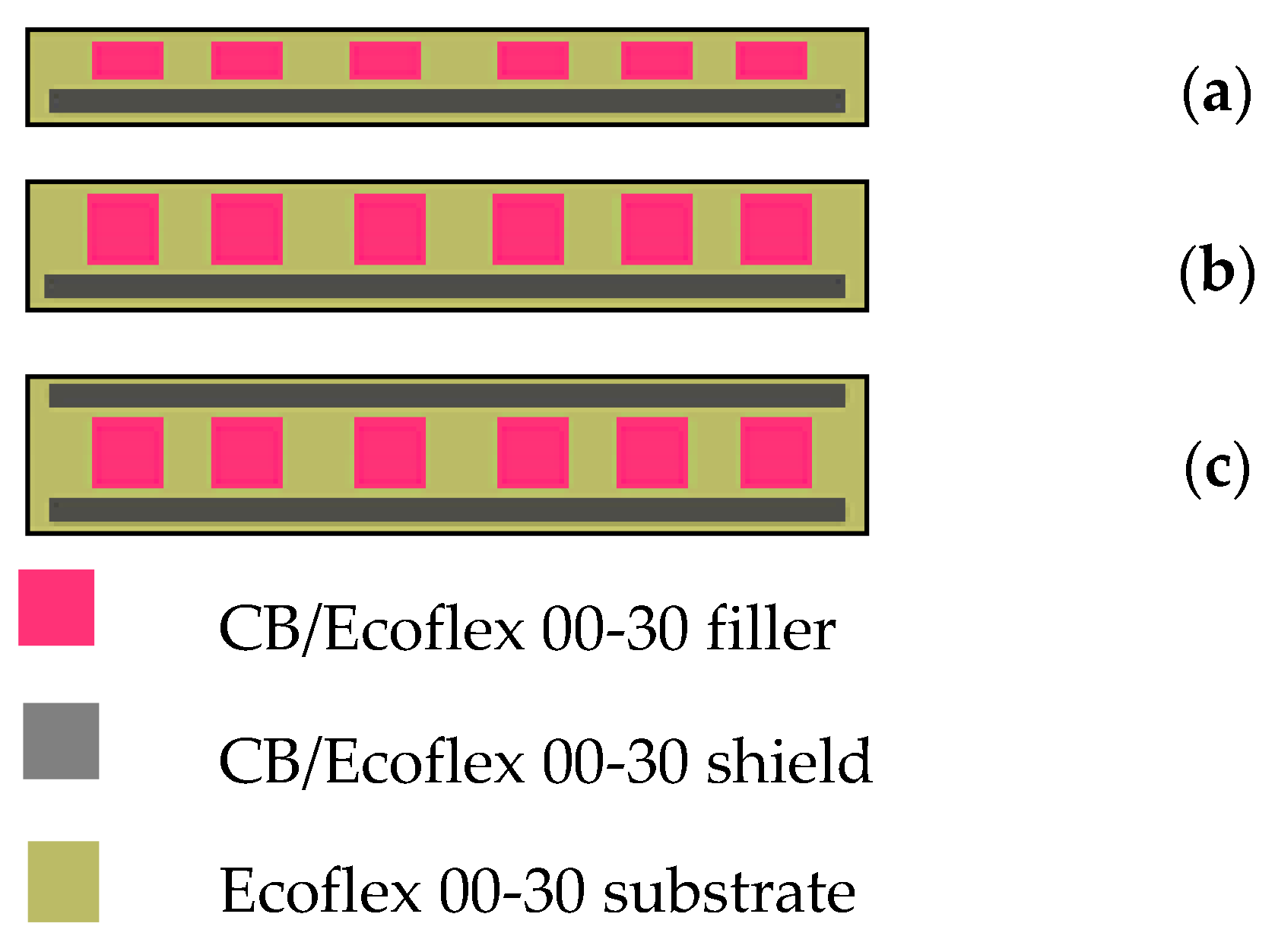

2.1. The Architecture of the Sensors

2.2. The Material and Schematic of the Sensors

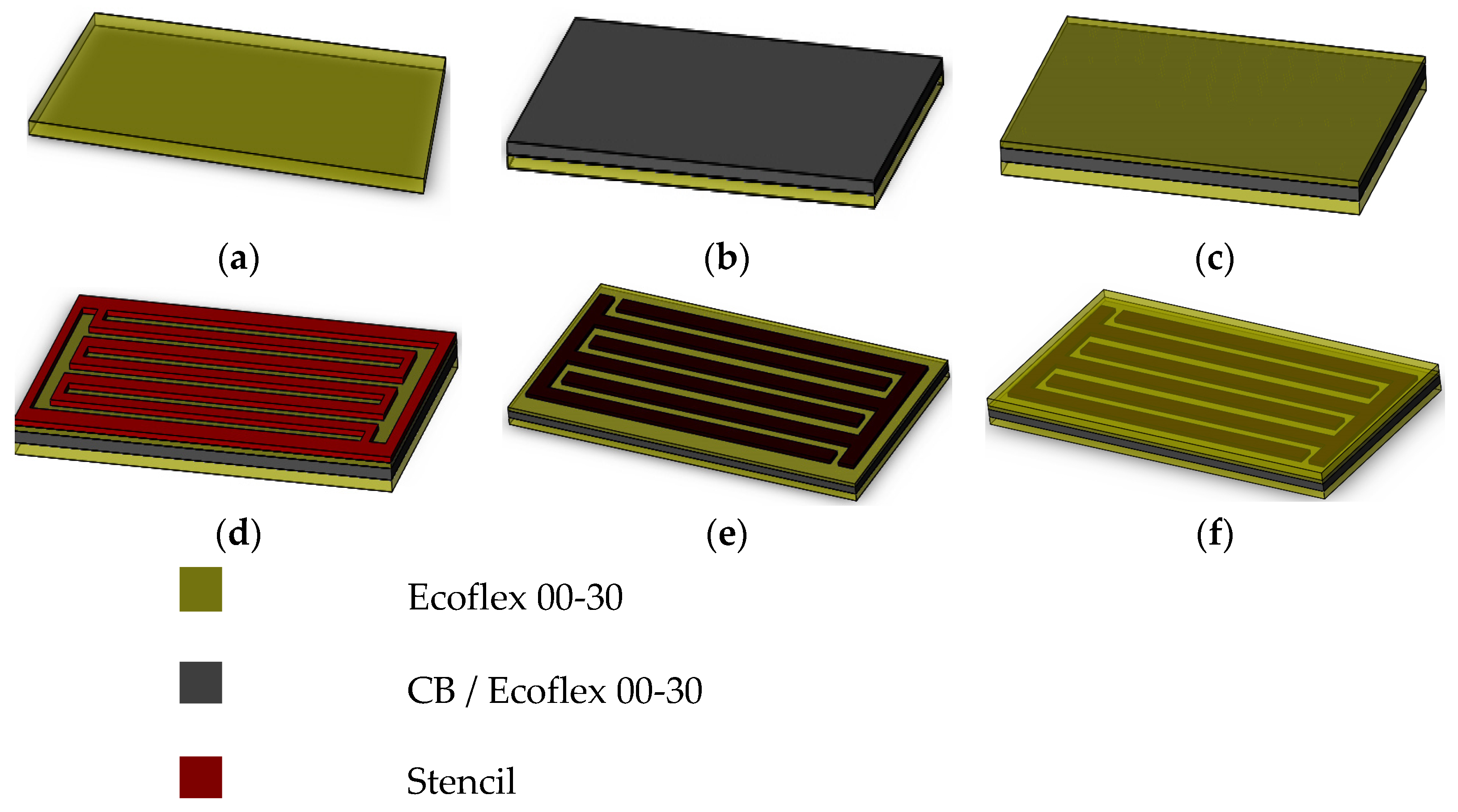

2.3. The Fabrication of the Sensors

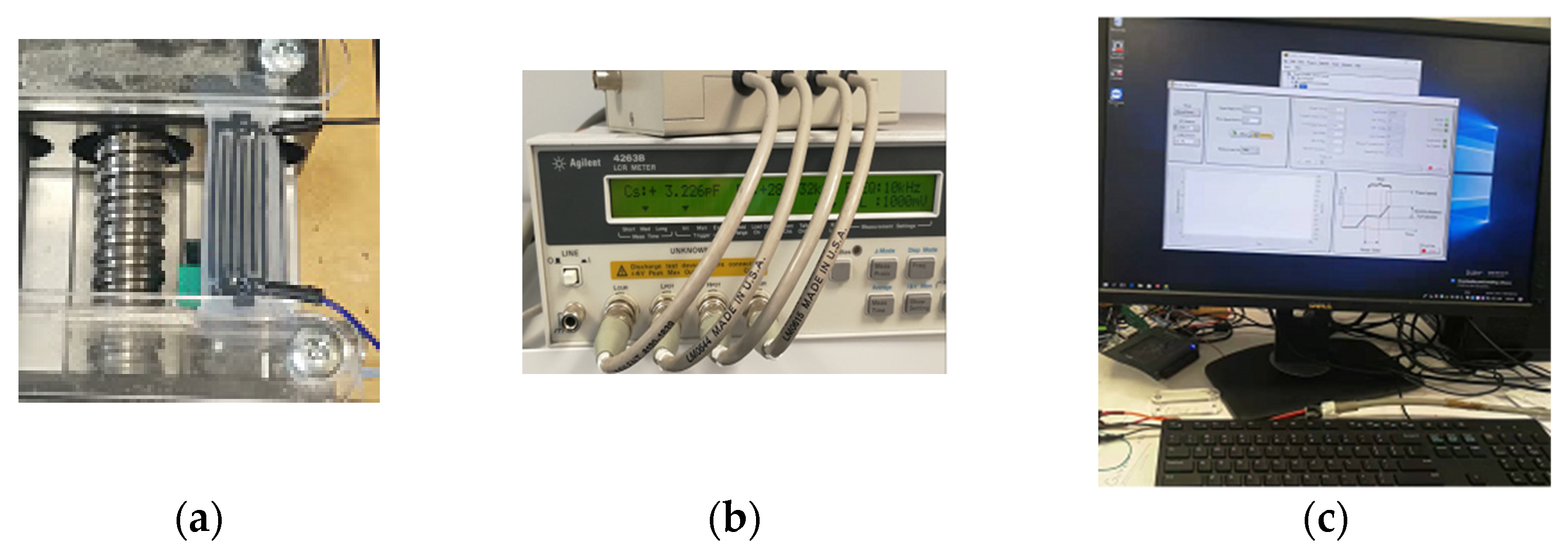

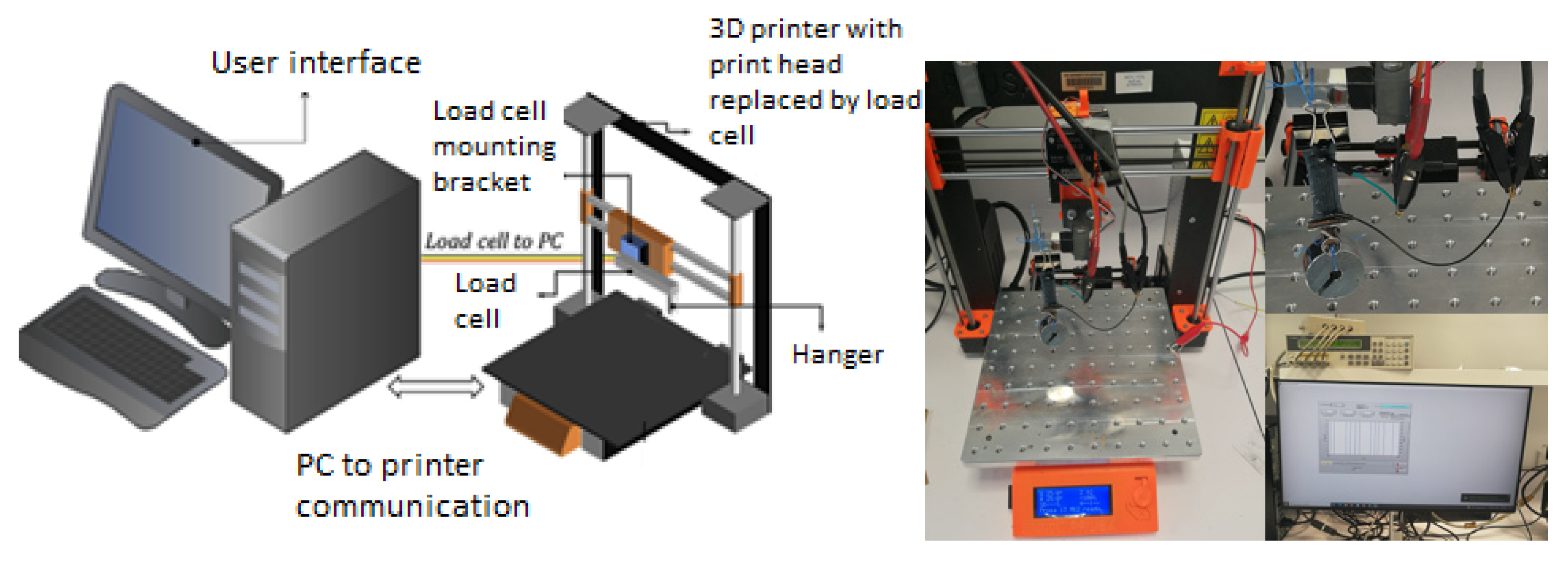

2.4. The Data Collection and Testing Rigs

3. Results and Discussion

3.1. Sensor Characteristics

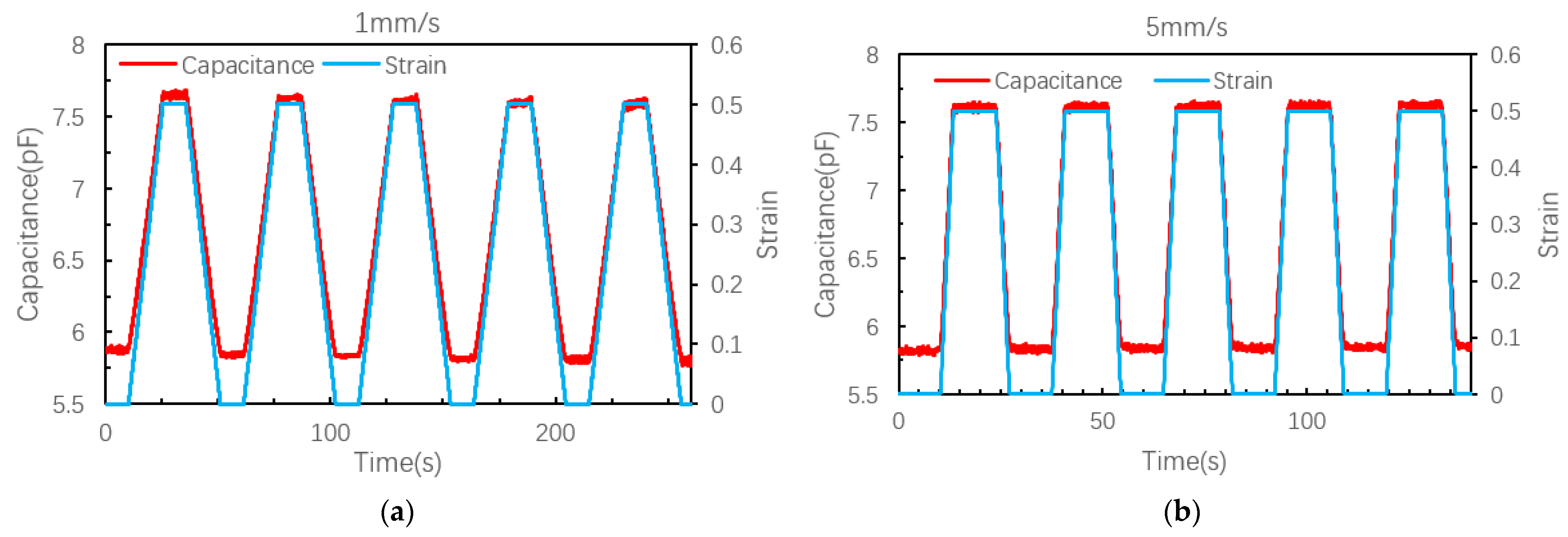

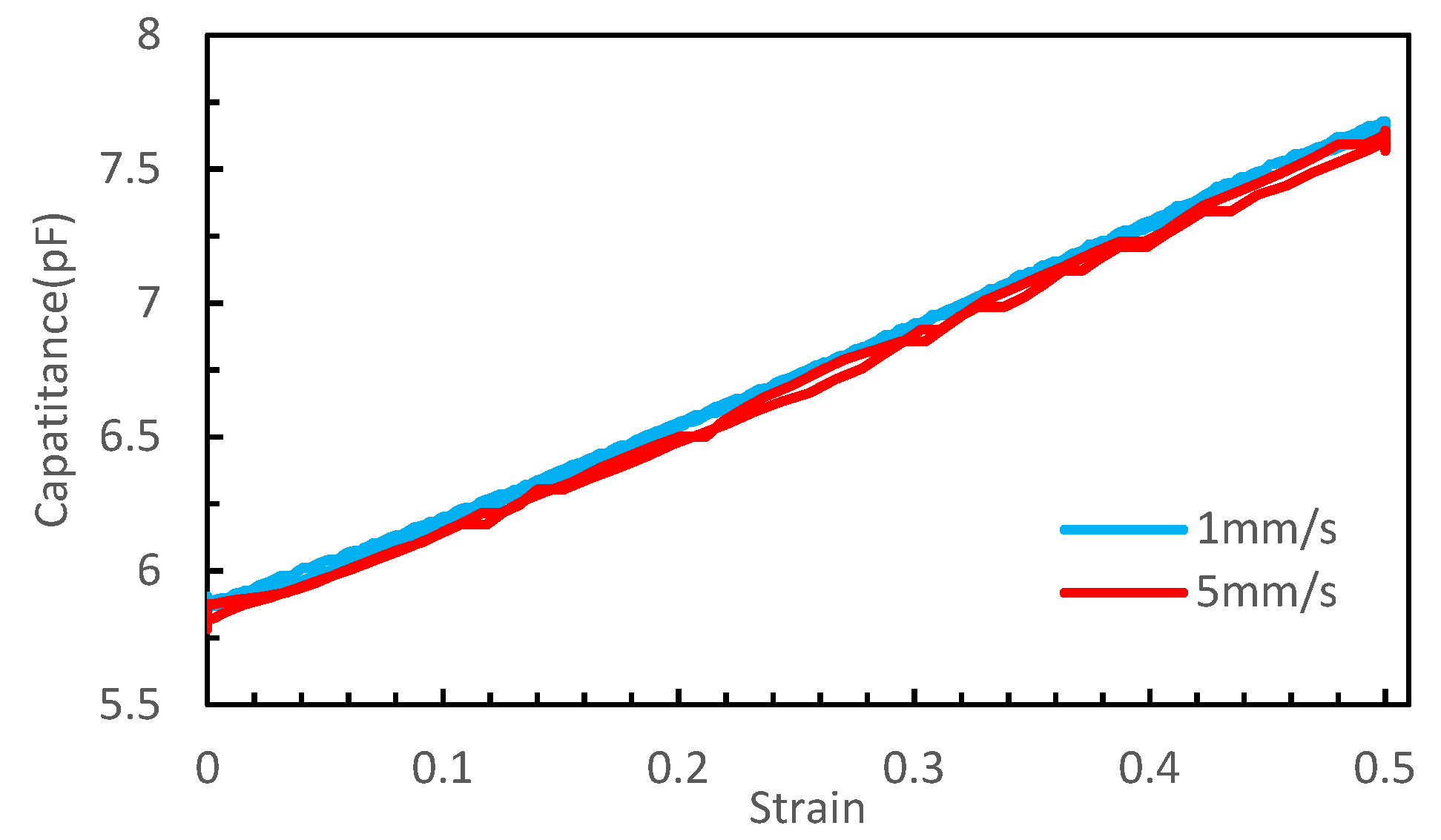

3.1.1. The Characteristics of LIDC Sensor with One-Layer IDC and One-Layer Shield

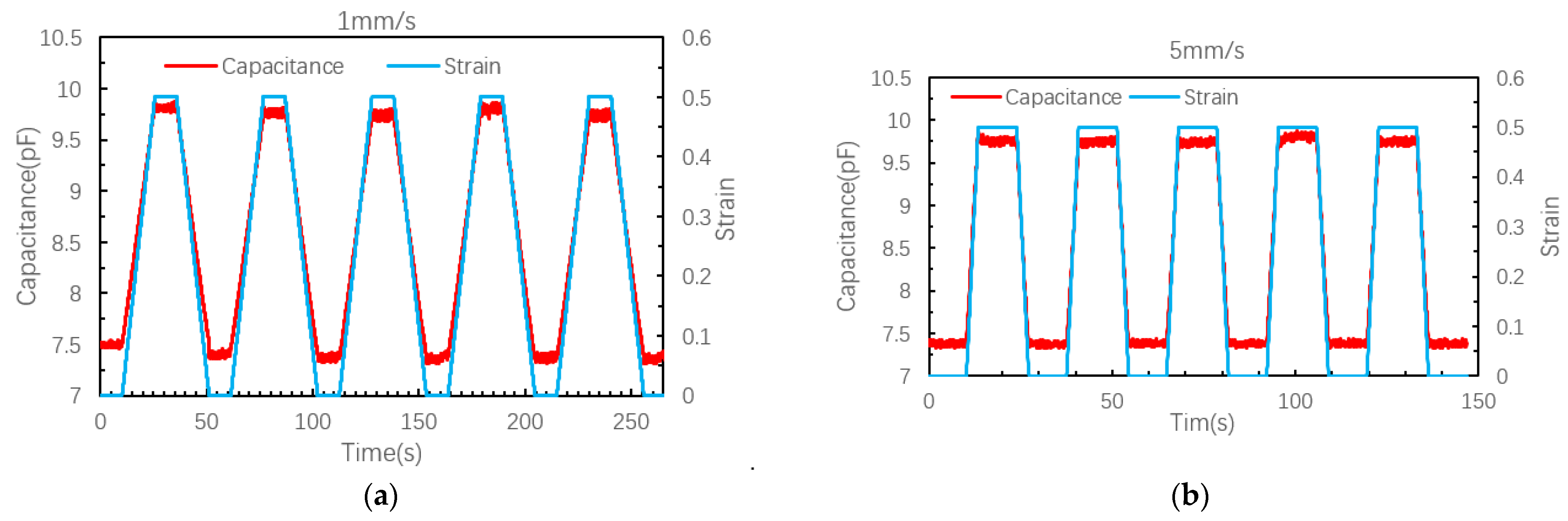

3.1.2. The Characteristics of LIDC Sensor with Two Layers IDC and One-Layer Shield

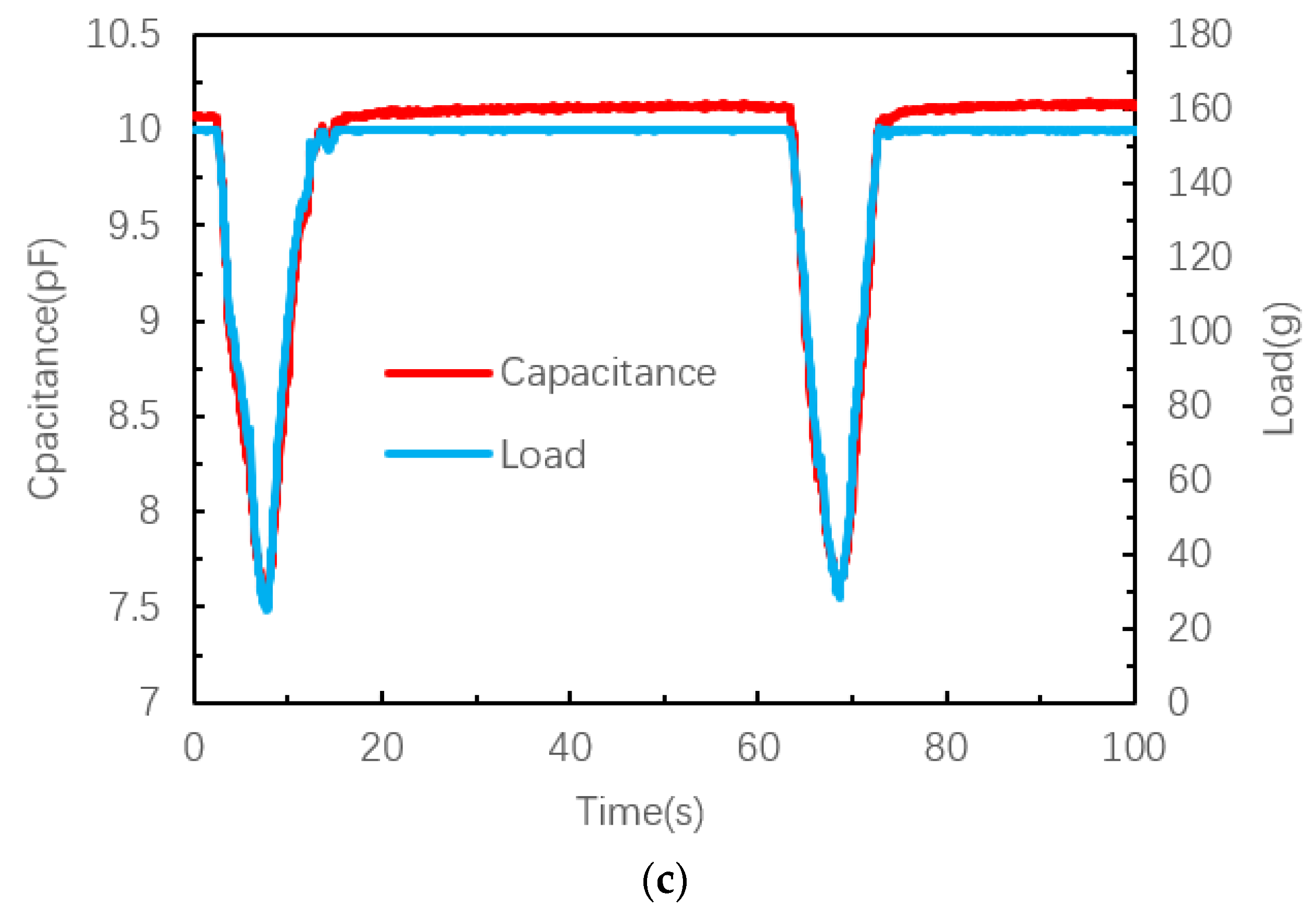

3.1.3. The Creep Behavior of LIDC Sensors with Two Layers of IDC and One Layer Shield

3.1.4. The Shielding Configuration Experiment of LIDC Sensors

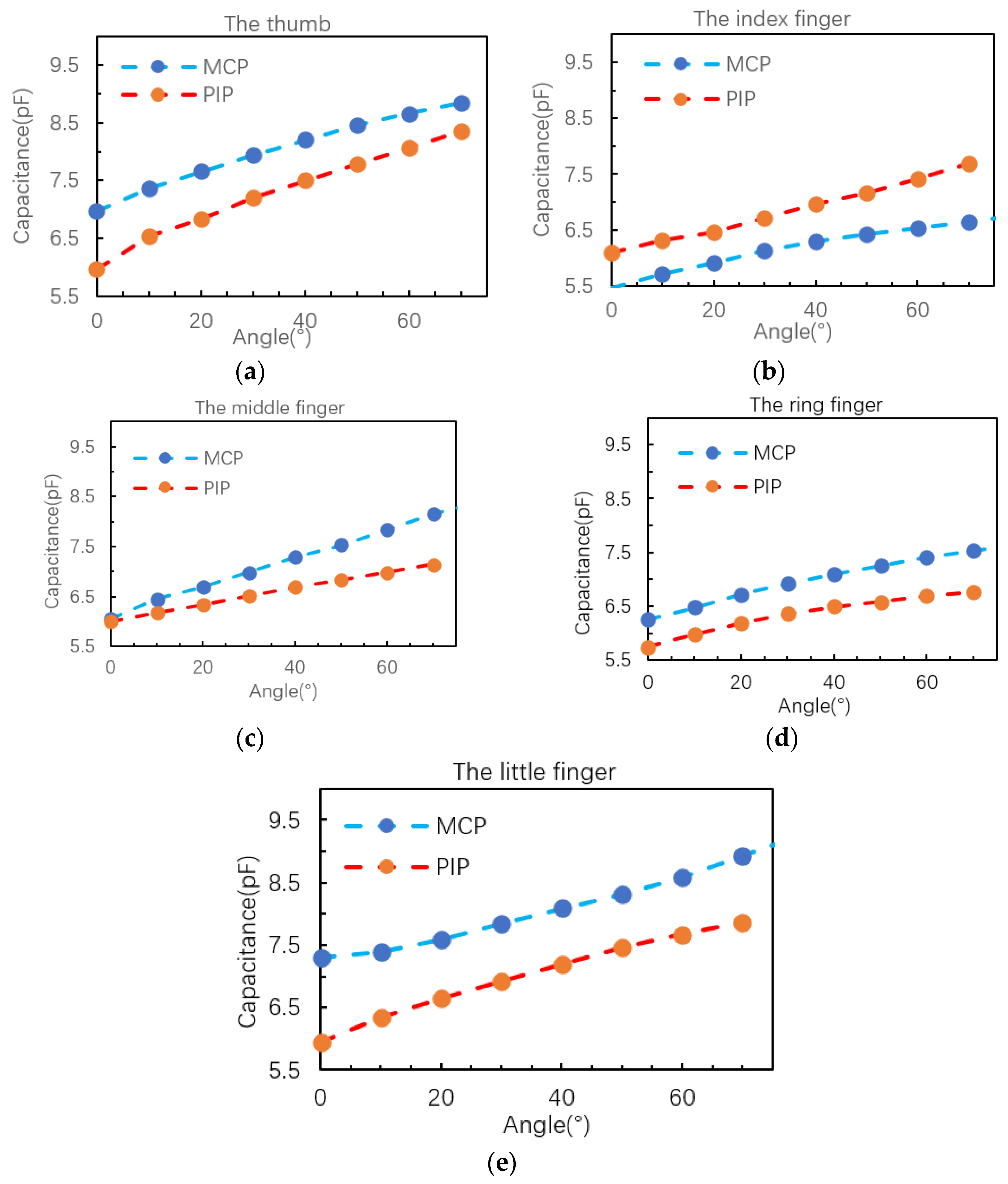

3.2. The Application of the Sensors

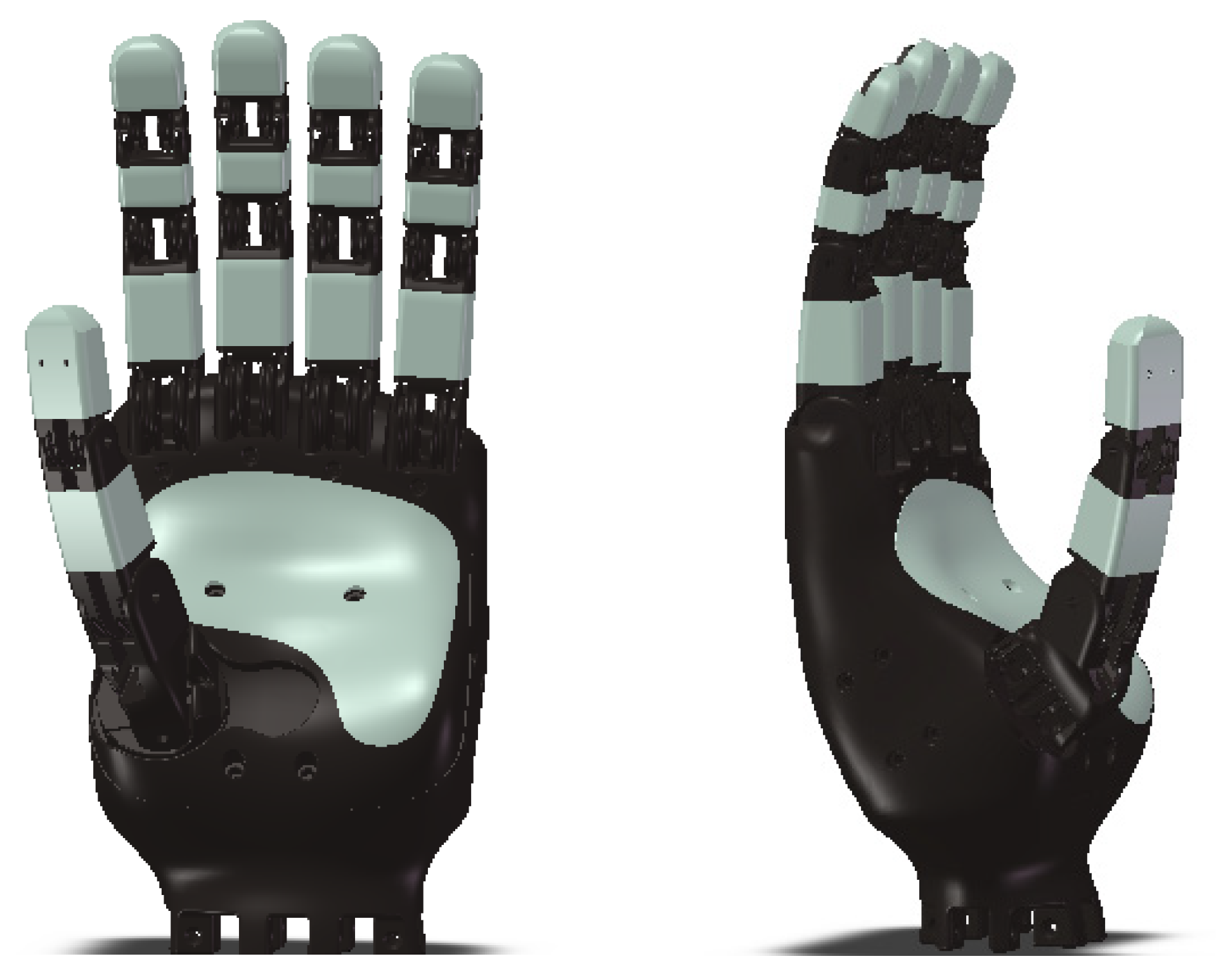

3.2.1. The Underactuated Robotic Hand

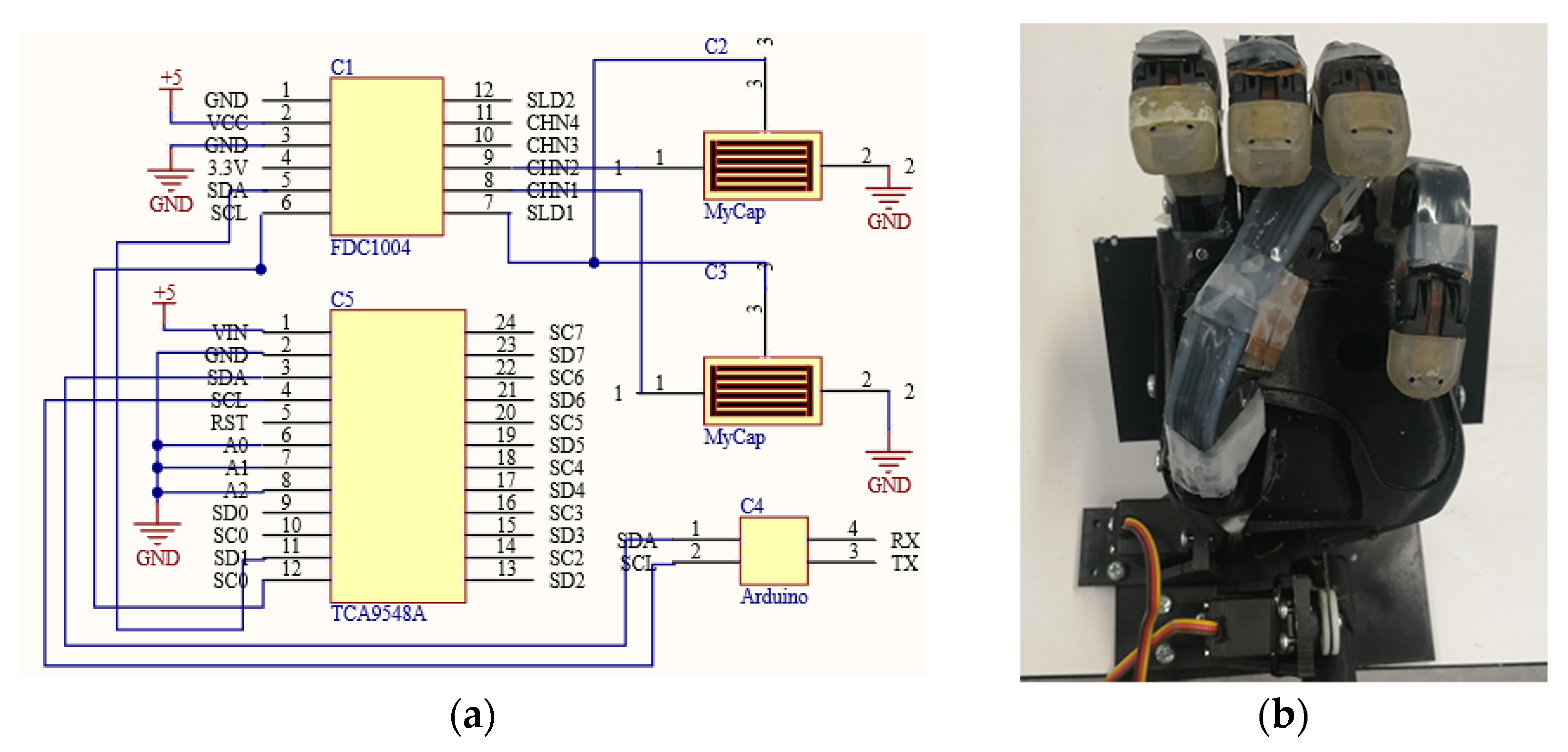

3.2.2. The Measuring Circuits and the Hand with the Sensors

3.3. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Klatzky, R.L.; Lederman, S.J.; Metzger, V.A. Identifying objects by touch: An expert system. Percept. Psychophys. 1985, 37, 299–302. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vasquez, A.; Kappassov, Z.; Perdereau, V. In-hand Object Shape Identification Using Invariant Proprioceptive Signatures. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Deajeon, Korea, 9–14 October 2016; pp. 965–970. [Google Scholar] [CrossRef]

- Lyubova, N.; Ivaldi, S.; Filliat, D. From passive to interactive object learning and recognition through self-identification on a humanoid robot. Auton. Robot. 2016, 40, 33–57. [Google Scholar] [CrossRef] [Green Version]

- Khasnobish, A.; Singh, G.; Jati, A.; Konar, A.; Tibarewala, D.N. Object-shape recognition and 3D reconstructi on from tactile sensor images. Med. Biol. Eng. Comput. 2014, 52, 353–362. [Google Scholar] [CrossRef] [PubMed]

- Rebollo, D.R.R.; Pedro, P.; Molina, A. From 3 fingers to 5 fingers dexterous hands. Adv. Robot. 2017, 31, 1051–1070. [Google Scholar] [CrossRef]

- Neha, E.; Suhaib, M.; Mukherjee, S.; Shrivastava, Y. Kinematic analysis of four-fingered tendon actuated robotic hand. Aust. J. Mech. Eng. 2021, 3, 1–11. [Google Scholar] [CrossRef]

- Kontoudis, G.P.; Liarokapis, M.; Vamvoudakis, K.G.; Furukawa, T. An Adaptive Actuation Mechanism for Anthropomorphic Robotic hands. Front. Robot. AI 2019, 6, 47. [Google Scholar] [CrossRef] [Green Version]

- Ryu, W.; Choi, Y.; Choi, Y.J.; Lee, Y.G.; Lee, S. Development of an Anthropomorphic Prosthetic Hand with Underactuated Mechanism. Appl. Sci. 2020, 10, 4384. [Google Scholar] [CrossRef]

- Spiers, A.J.; Liarokapis, M.V.; Calli, B.; Dollar, A.M. Single-Grasp Object Classification and Feature Extraction with Simple Robot Hands and Tactile Sensors. IEEE Trans. Haptics 2016, 9, 207–222. [Google Scholar] [CrossRef]

- Hao, Z.; Charbel, T.; Gursel, A. A 3D Printed Soft Robotic Hand With Embedded Soft Sensors for Direct Transition Between Hand Gestures and Improved Grasping Quality and Diversity. IEEE Trans. Neural Syst. Rehabil. Eng. 2022, 30, 550–558. [Google Scholar] [CrossRef]

- Kappassov, Z.; Corrales, J.A.; Perdereau, V. Tactile sensing in dexterous robot hands- Review. Robot. Auton. Syst. 2015, 74, 195–220. [Google Scholar] [CrossRef] [Green Version]

- Hanna, Y.; Mehdi, B.; Kaspar, A. Tactile sensing for dexterous in-hand manipulation in robotics—A review. Sens. Actuators A. Phys. 2011, 167, 171–187. [Google Scholar] [CrossRef]

- Luo, S.; Bimbo, J.; Dahiya, R.; Liu, H. Robotic tactile perception of object properties: A review. Mechatronic 2017, 48, 54–67. [Google Scholar] [CrossRef] [Green Version]

- Senthil, K.K.; Chen, P.Y.; Ren, H. A review of printable flexible and stretchable tactile sensors. Research 2019, 2019, 3018568. [Google Scholar] [CrossRef] [Green Version]

- Obaid, N.; Kortschot, M.T.; Sain, M. Modeling and predicting the stress relaxation of composites with short and randomly oriented fibers. Materials 2017, 10, 1207. [Google Scholar] [CrossRef] [PubMed]

- Ding, H.; Chen, J.K. Research on the resistivity attenuation law of cementitious conductive composites induced by stress relaxation. Constr. Build. Mater. 2019, 206, 347. [Google Scholar] [CrossRef]

- Reis, P.N.B.; Neto, M.A.; Amaro, A.M. Amaro.Effect of hostile solutions on stress relaxation of carbon/epoxy composites. Polym. Degrad. Stab. 2019, 165, 60–67. [Google Scholar] [CrossRef]

- Sousa, A.M.F.; Furtado, C.R.G. Stress relaxation of nitrile rubber composites filled with a hybrid metakaolin/carbon black filler under tensile and compressive forces. Appl. Clay Sci. 2018, 151, 81–188. [Google Scholar] [CrossRef]

- Reis, P.N.B.; Silva, M.P.; Santos, P. Stress Relaxation in Delaminated Carbon/Epoxy Composites. Fibers Polym. 2019, 20, 1284–1289. [Google Scholar] [CrossRef]

- Chang, X.; Chen, L.; Chen, J.; Zhu, Y.; Guo, Z. Advances in transparent and stretchable strain sensors. Adv. Compos. Hybrid Mater. 2021, 4, 435–450. [Google Scholar] [CrossRef]

- Heo, J.S.; Hossain, M.F.; Kim, I. Challenges in Design and Fabrication of Flexible/Stretchable Carbon- and Textile-Based Wearable Sensors for Health Monitoring: A Critical Review. Sensors 2020, 20, 3927. [Google Scholar] [CrossRef]

- Kanoun, O.; Bouhamed, A.; Ramalingame, R.; Bautista-Quijano, J.R.; Rajendran, D.; Ammar, A.H. Review on Conductive Polymer/C.N.T.s Nanocomposites Based Flexible and Stretchable Strain and Pressure Sensors. Sensors 2021, 21, 341. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.W.; Yu, Q.L.; Cui, X.H.; Dong, M.Y.; Zhang, J.X.; Wang, C.; Fan, J.C.; Zhu, Y.T.; Guo, Z.H. An overview of stretchable strain sensors from conductive polymer nanocomposites. J. Mater. Chem. C Mater. Opt. Electron. Devices 2019, 7, 1171–1173. [Google Scholar] [CrossRef]

- Cholleti, E.R.; Stringer, J.; Kelly, P.; Bowen, C.; Aw, K. Studying the creep behaviour of stretchable capacitive sensor with barium titanate silicone elastomer composite. Sens. Actuators A Phys. 2021, 319, 112560. [Google Scholar] [CrossRef]

- Devaraj, H.D.; Schober, R.; Picard, M.; Teo, M.Y.; Lo, C.Y.; Gan, W.C.; Aw, K.C. Highly elastic and flexible multi-layered carbon black/elastomer composite-based capacitive sensor arrays for soft robotics. Meas. Sens. 2019, 2, 100004. [Google Scholar] [CrossRef]

- Haberman, M.; Cassino, A.; Spinelli, E. Estimation of stray coupling capacitances in biopotential measurements. Med. Biol. Eng. Comput. 2011, 49, 1067–1071. [Google Scholar] [CrossRef]

- Wang, D. Capacitive Sensing: Ins and Outs of Active Shielding. Application Report. February 2015. Available online: https://www.ti.com/lit/an/snoa926a/snoa926a.pdf?ts=1645237565469&ref_url=https%253A%252F%252Fwww.google.com.hk%252F (accessed on 1 March 2022).

- Devaraj, H.; Giffney, T.; Petit, A.; Assadian, M.; Aw, K. The Development of Highly Flexible Stretch Sensors for a Robotic Hand. Robotics 2018, 7, 54. [Google Scholar] [CrossRef] [Green Version]

- Cholleti, E.R.; Stringer, J.; Kelly, P.; Bowen, C.; Aw, K. Mechanical Behaviour of Large Strain Capacitive Sensor with Barium Titanate Ecoflex Composite Used to Detech Human Motion. Robotics 2021, 10, 69. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, Y.; Li, Y.; Hao, Q. Development and Application of Resistance Strain Force Sensors. Sensors 2020, 20, 582. [Google Scholar] [CrossRef]

- Li, J.; Fang, L.C.; Sun, B.; Li, X.X.; Kang, S.H.K. Review-Recent Progress in Flexible and Stretchable Piezoresistive Sensors and Their Applications. J. Electrochem. Soc. 2020, 167, 37561. [Google Scholar] [CrossRef]

- Wang, W.; Yang, S.; Ding, K.; Jiao, L.; Yan, J.; Zhao, W.; Ma, Y.Y.; Wang, T.Y.; Cheng, B.; Ni, Y.H. Biomaterials- and biostructures Inspired high-performance flexible, stretchable strain sensors: A review. Chem. Eng. J. 2021, 425, 129949. [Google Scholar] [CrossRef]

- Yan, T.; Wang, Z.; Pan, Z.J. Flexible strain sensors fabricated using carbon-based nanomaterials: A review. Curr. Opin. Solid State Mater. Sci. 2018, 22, 213–228. [Google Scholar] [CrossRef]

- Amjadi, M.; Yoon, Y.J.; Park, I. Ultra-stretchable and skin-mountable strain sensors using carbon nanotubes-Ecoflex nanocomposites. Nanotechnology 2015, 26, 37550. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wang, H.; Zhao, W.; Zhang, M.; Qin, H.; Xie, Y. Flexible, Stretchable Sensors for Wearable Health Monitoring: Sensing Mechanisms, Materials, Fabrication Strategies and Features. Sensors 2018, 18, 645. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kidner, N.J.; Homrighaus, Z.J.; Mason, T.O.; Garboczi, E.J. Modeling interdigital electrode structures for the dielectric characterization of electroceramic thin films. Thin Solid Films 2006, 496, 539–545. [Google Scholar] [CrossRef]

- Gao, G.; Shahmohammadi, M.; Gerez, L.; Kontoudis, G.; Liarokapis, M. On Differential Mechanisms for Underactuated, Lightweight, Adaptive Prosthetic Hands. Front. Neurorobot. 2021, 15, 702031. [Google Scholar] [CrossRef] [PubMed]

- Gao, G.; Chapman, J.; Matsunaga, S.; Maruyama, T. A Dexterous, Reconfigurable, Adaptive Robot Hand Combining Anthropomorphic and Interdigitated Configurations. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Prague, Czech Republic, 27–31 September 2021; pp. 7209–7215. [Google Scholar] [CrossRef]

| Finger Name | Joint Name | Capacitance Range (pF) | Sensitivity (pF/°) | R2 |

|---|---|---|---|---|

| The thumb | MCP | 1.87 | 0.026714 | 0.9885 |

| PIP | 2.38 | 0.034 | 0.9884 | |

| The index finger | MCP | 1.29 | 0.018429 | 0.9753 |

| PIP | 1.6 | 0.022857 | 0.9962 | |

| The middle Finger | MCP | 2.38 | 0.02975 | 0.9981 |

| PIP | 1.14 | 0.016286 | 0.9993 | |

| The ring finger | MCP | 1.39 | 0.017375 | 0.9851 |

| PIP | 1.02 | 0.014571 | 0.9658 | |

| The little finger | MCP | 1.97 | 0.024625 | 0.9838 |

| PIP | 1.92 | 0.027429 | 0.9896 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yong, S.; Aw, K. Multi-Layered Carbon-Black/Elastomer-Composite-Based Shielded Stretchable Capacitive Sensors for the Underactuated Robotic Hand. Robotics 2022, 11, 58. https://doi.org/10.3390/robotics11030058

Yong S, Aw K. Multi-Layered Carbon-Black/Elastomer-Composite-Based Shielded Stretchable Capacitive Sensors for the Underactuated Robotic Hand. Robotics. 2022; 11(3):58. https://doi.org/10.3390/robotics11030058

Chicago/Turabian StyleYong, Shi, and Kean Aw. 2022. "Multi-Layered Carbon-Black/Elastomer-Composite-Based Shielded Stretchable Capacitive Sensors for the Underactuated Robotic Hand" Robotics 11, no. 3: 58. https://doi.org/10.3390/robotics11030058

APA StyleYong, S., & Aw, K. (2022). Multi-Layered Carbon-Black/Elastomer-Composite-Based Shielded Stretchable Capacitive Sensors for the Underactuated Robotic Hand. Robotics, 11(3), 58. https://doi.org/10.3390/robotics11030058