Development and Usability Testing of a Finger Grip Enhancer for the Elderly

Abstract

1. Introduction

2. Literature Review

2.1. Conceptual Design

- Wrist is in slight extension.

- Metacarpophalangeal flexion with slight phalangeal flexion.

- Flexion of the thumb’s interphalangeal (IP) joint and index finger’s distal interphalangeal (DIP) joint [29].

- Each finger has a limited motion range due to the mechanical limitation of hand anatomy.

- In each finger, the DIP joint and proximal interphalangeal (PIP) joint always move together.

- People have a habit of making standard gestures, where they usually bend all the fingers at the same time to make a fist, instead of one by one.

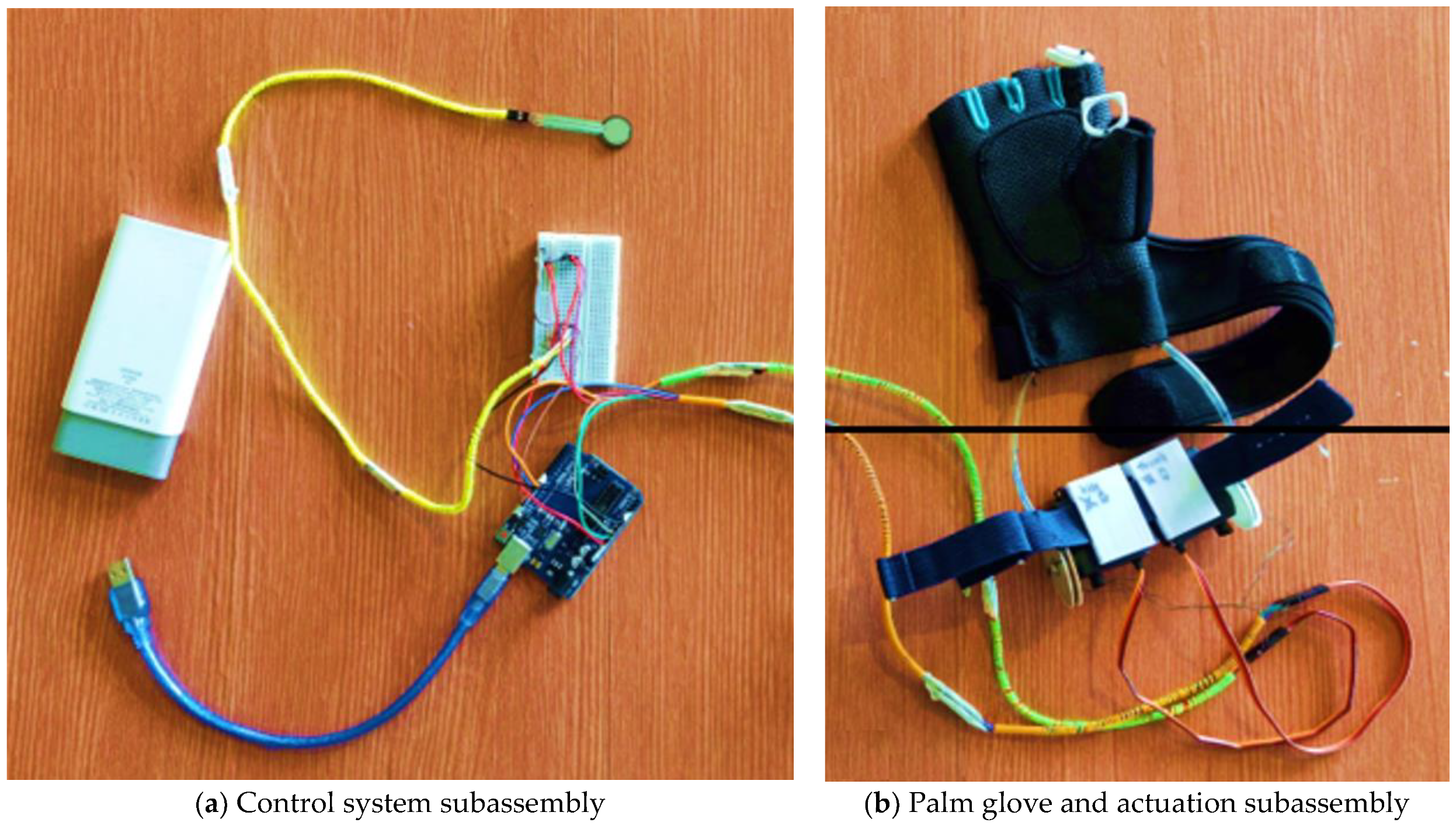

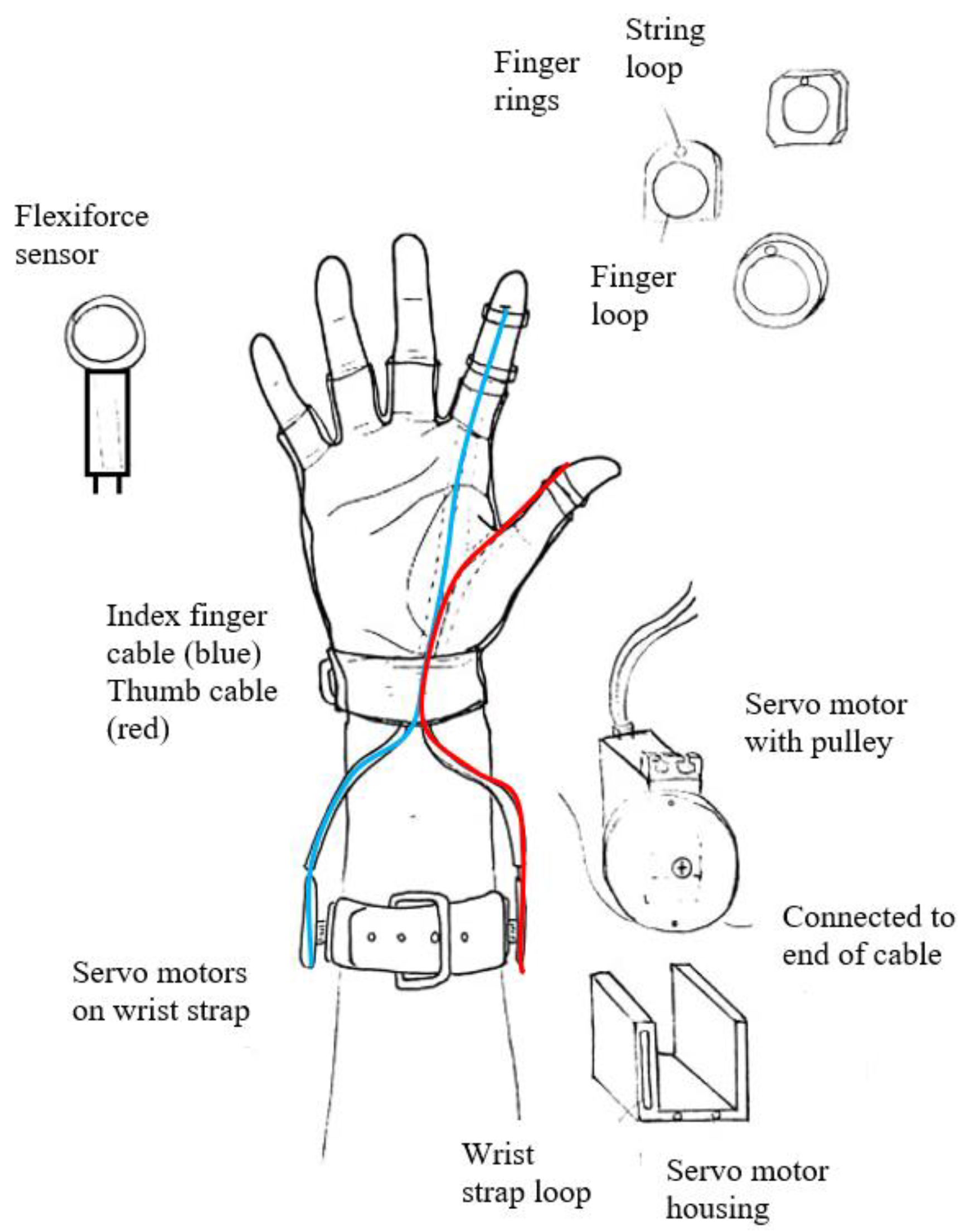

2.2. Design Subassembly

2.3. Actuation

2.4. Servo Unit

2.5. Control System

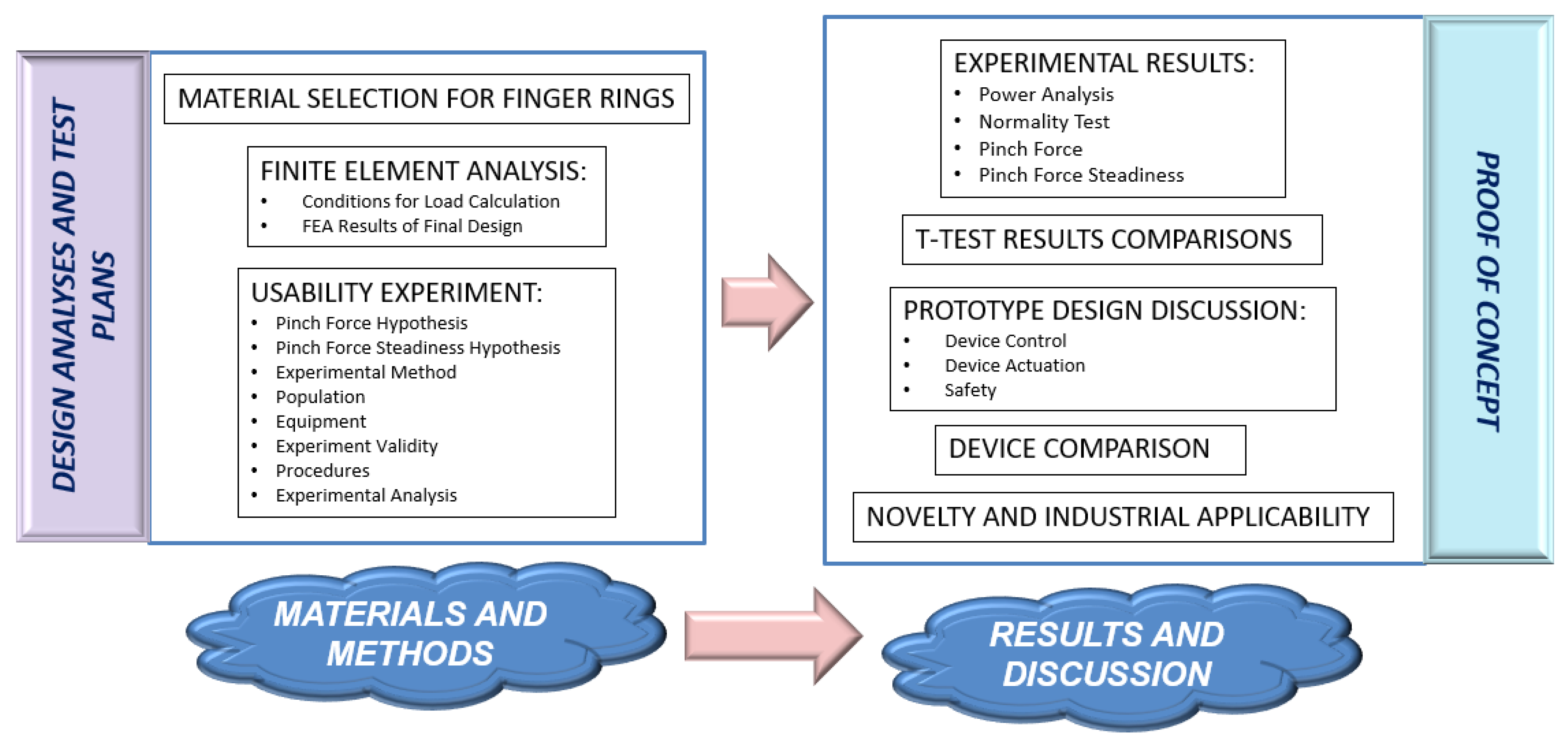

3. Materials and Methods

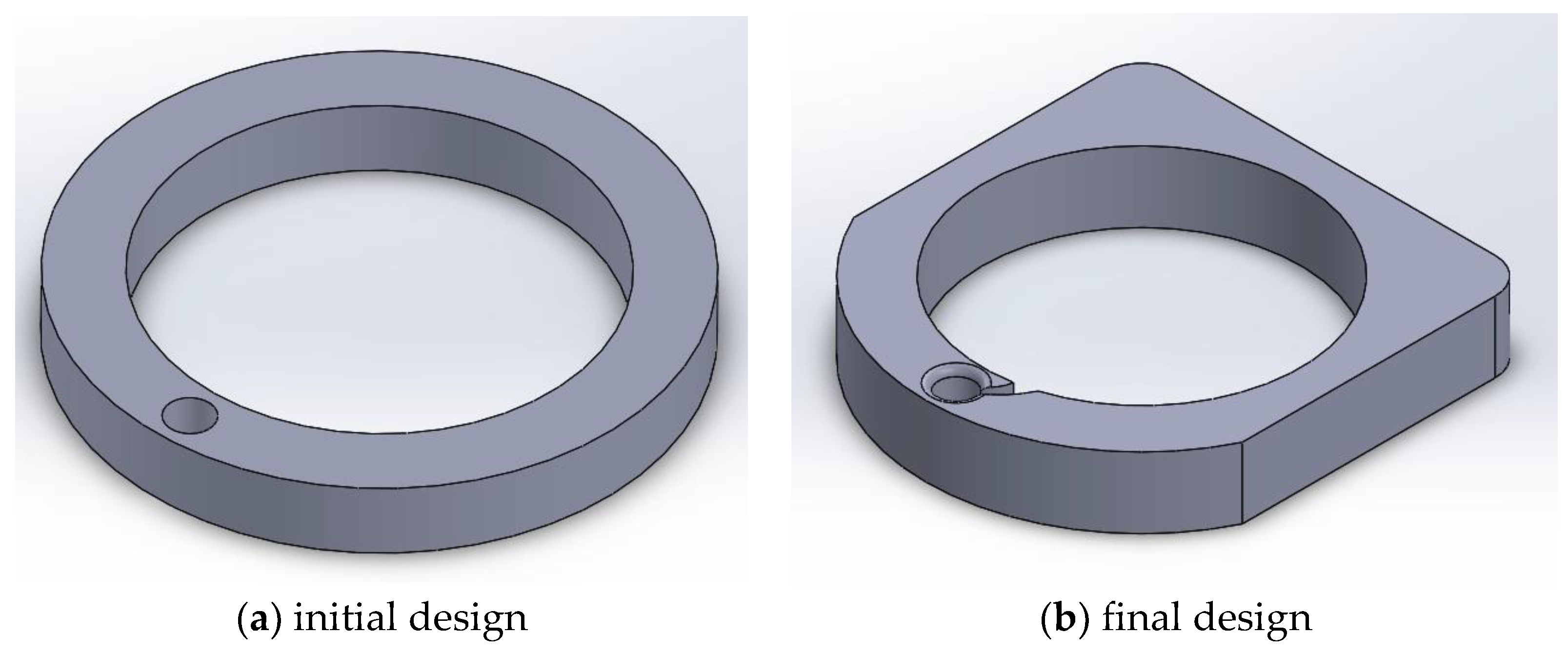

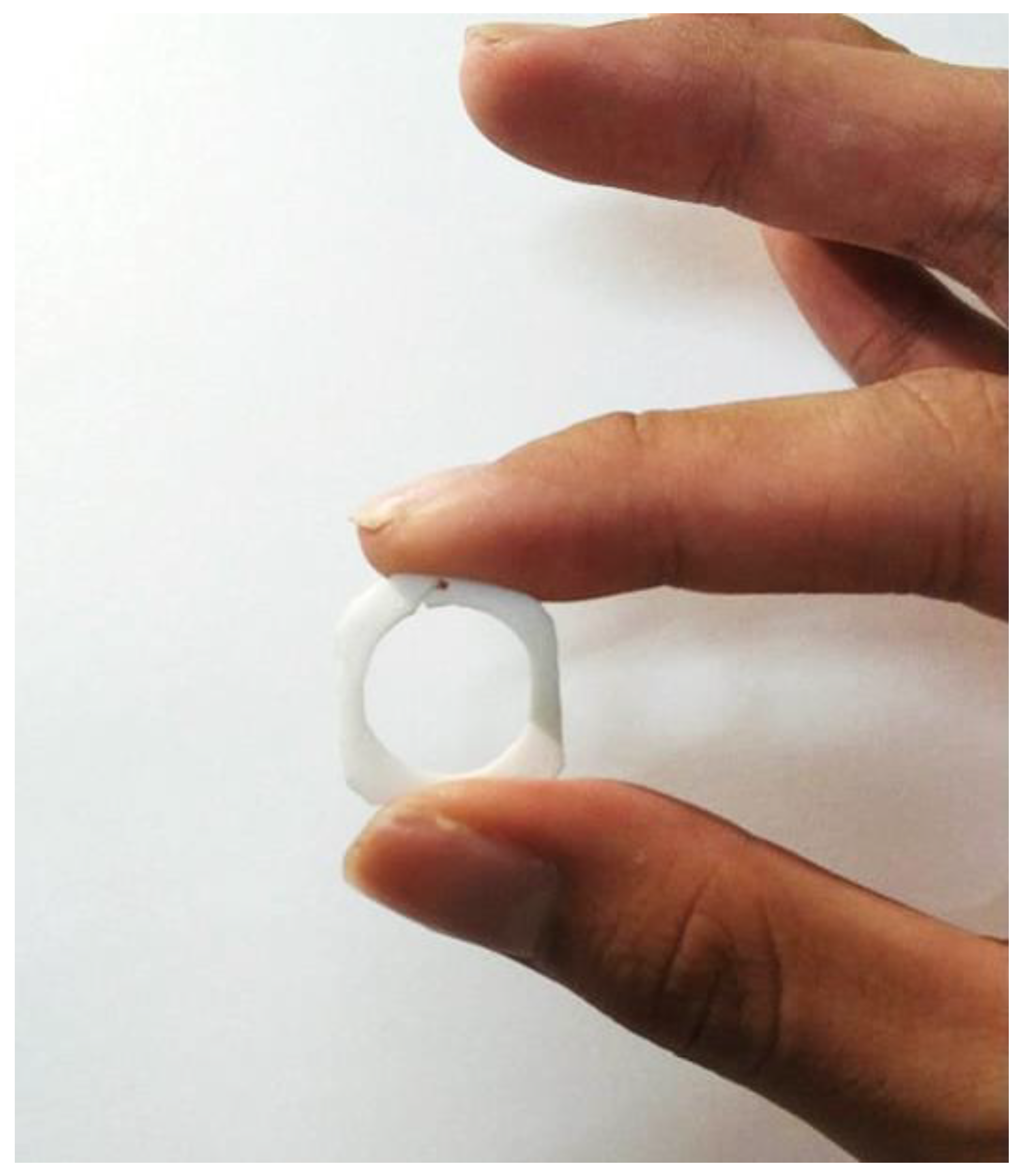

3.1. Material Selection Finger Rings

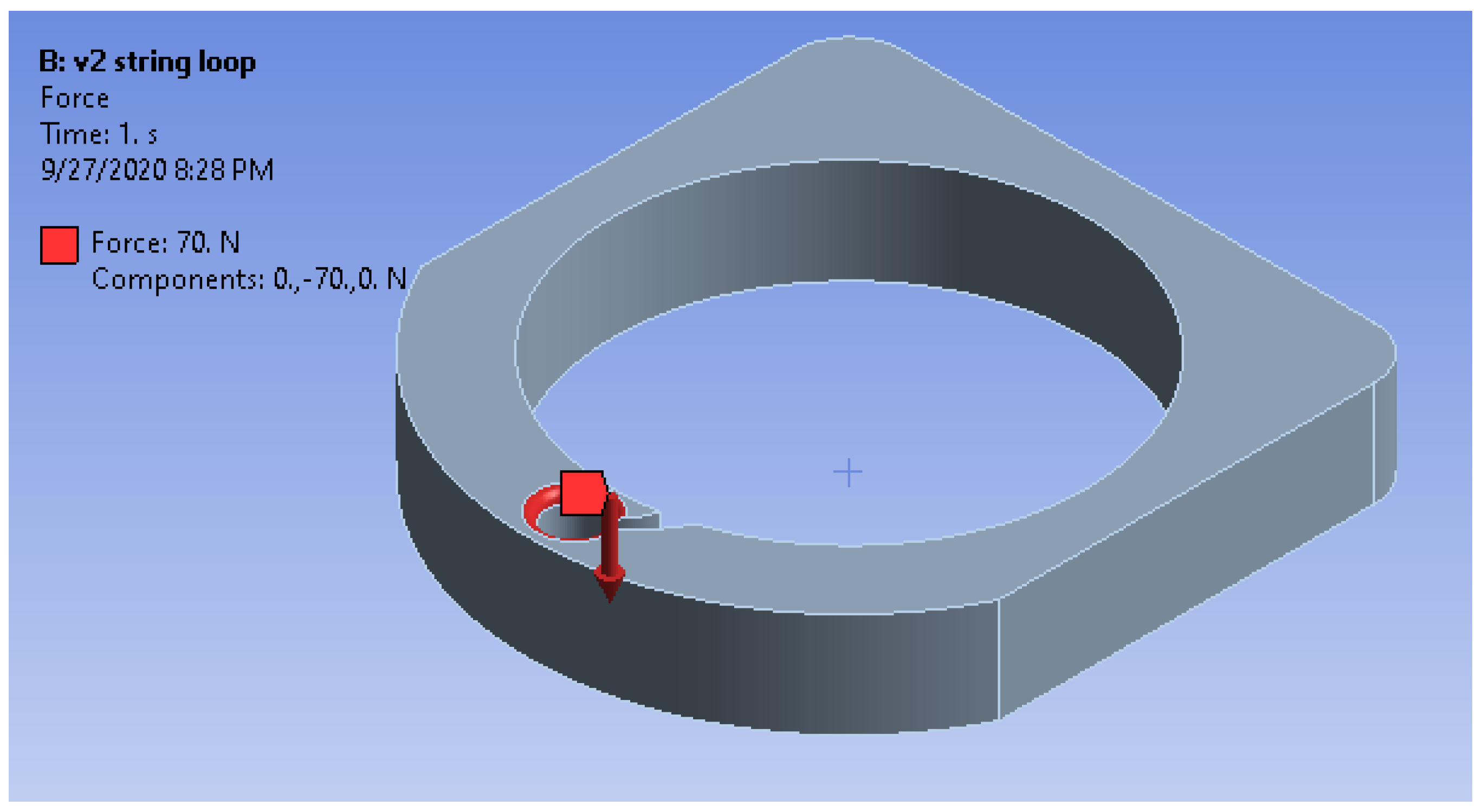

3.2. Finite Element Analysis

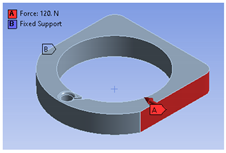

3.2.1. Conditions for Load Calculation

- Axial load of 120 N acting across a single surface of the ring.

- Fixed support at the outer surface opposite of the axial load.

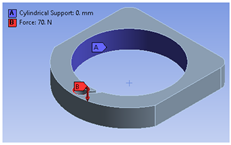

- Axial load of 70 N acting around the edge of the string loop.

- Fixed cylindrical support at the inner surface of the finger loop.

- Axial load of 70 N acting around the edge of the string loop.

- Axial load of 120 N acting across a single surface of the ring.

- Fixed cylindrical support at the inner surface of the finger loop.

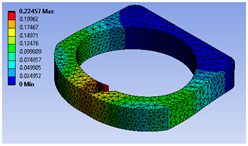

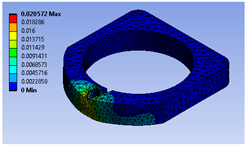

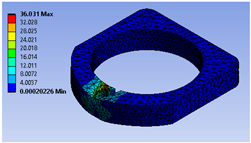

3.2.2. FEA Results of Final Design

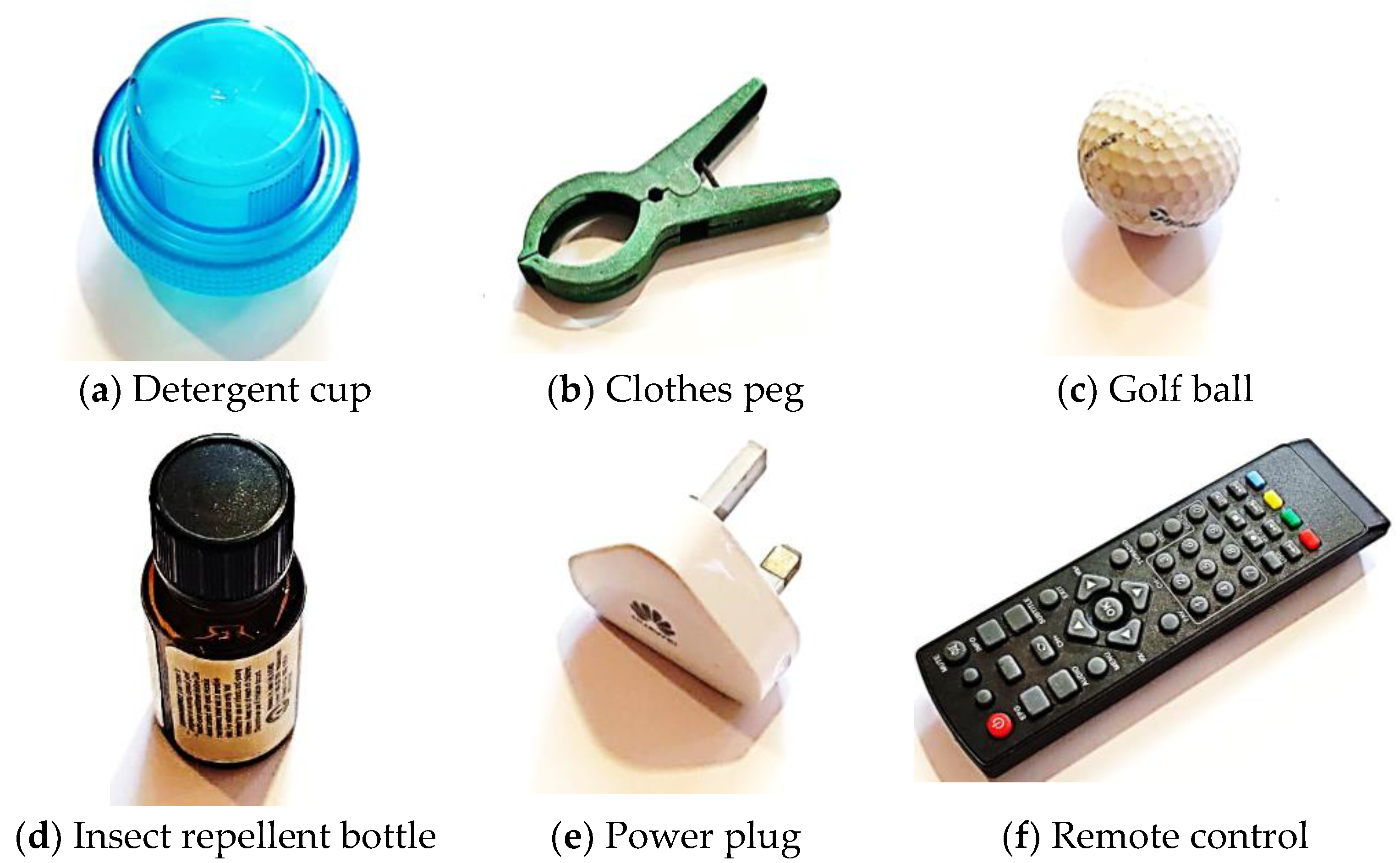

3.3. Usability Experiment

3.3.1. Pinch Force Hypotheses

3.3.2. Pinch Force Steadiness Hypotheses

3.3.3. Experimental Method

3.3.4. Population

3.3.5. Equipment

3.3.6. Experiment Validity

3.3.7. Procedures

3.3.8. Experimental Analysis

4. Results and Discussion

4.1. Experimental Results

4.1.1. Power Analysis

4.1.2. Normality Test

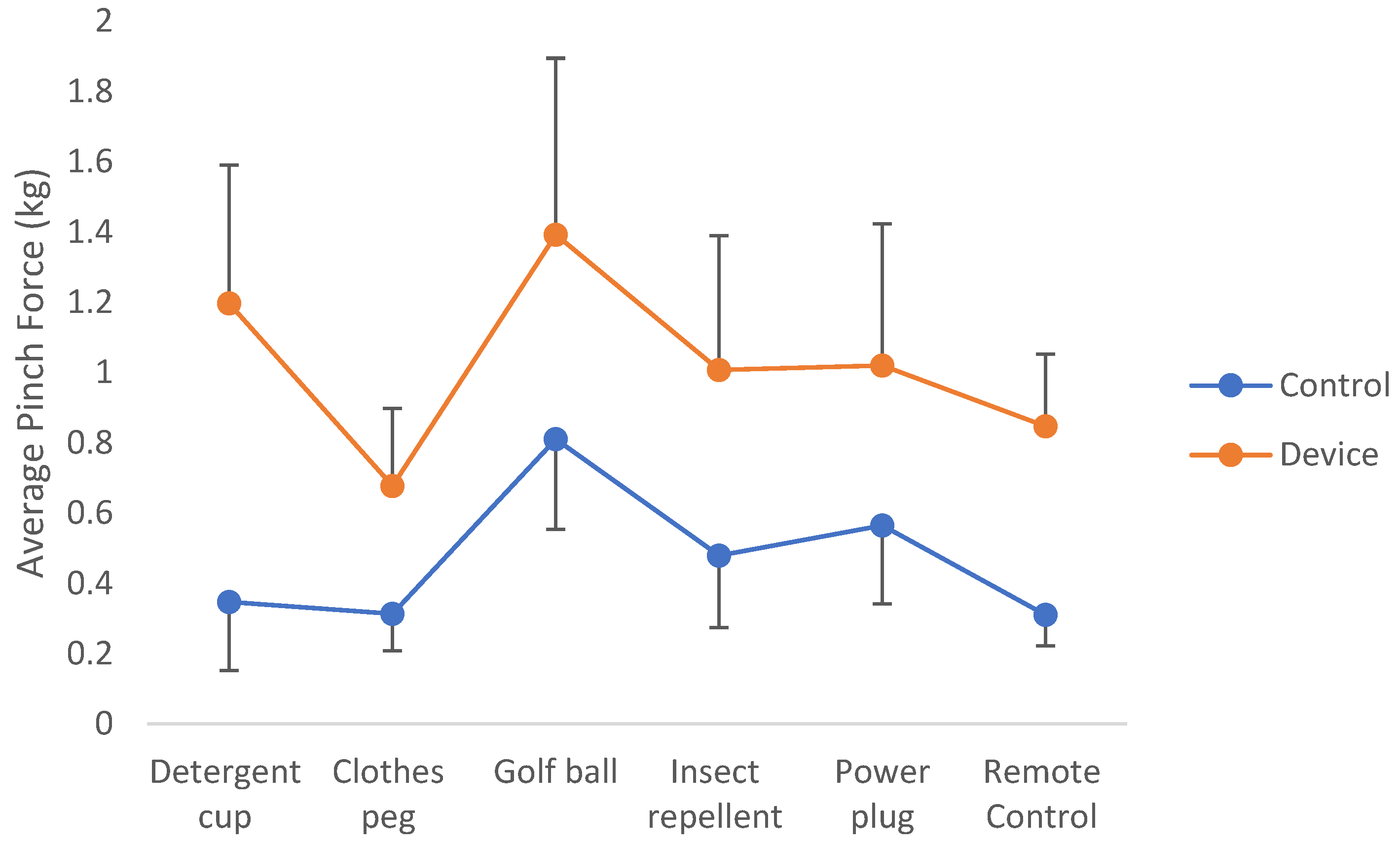

4.1.3. Pinch Force

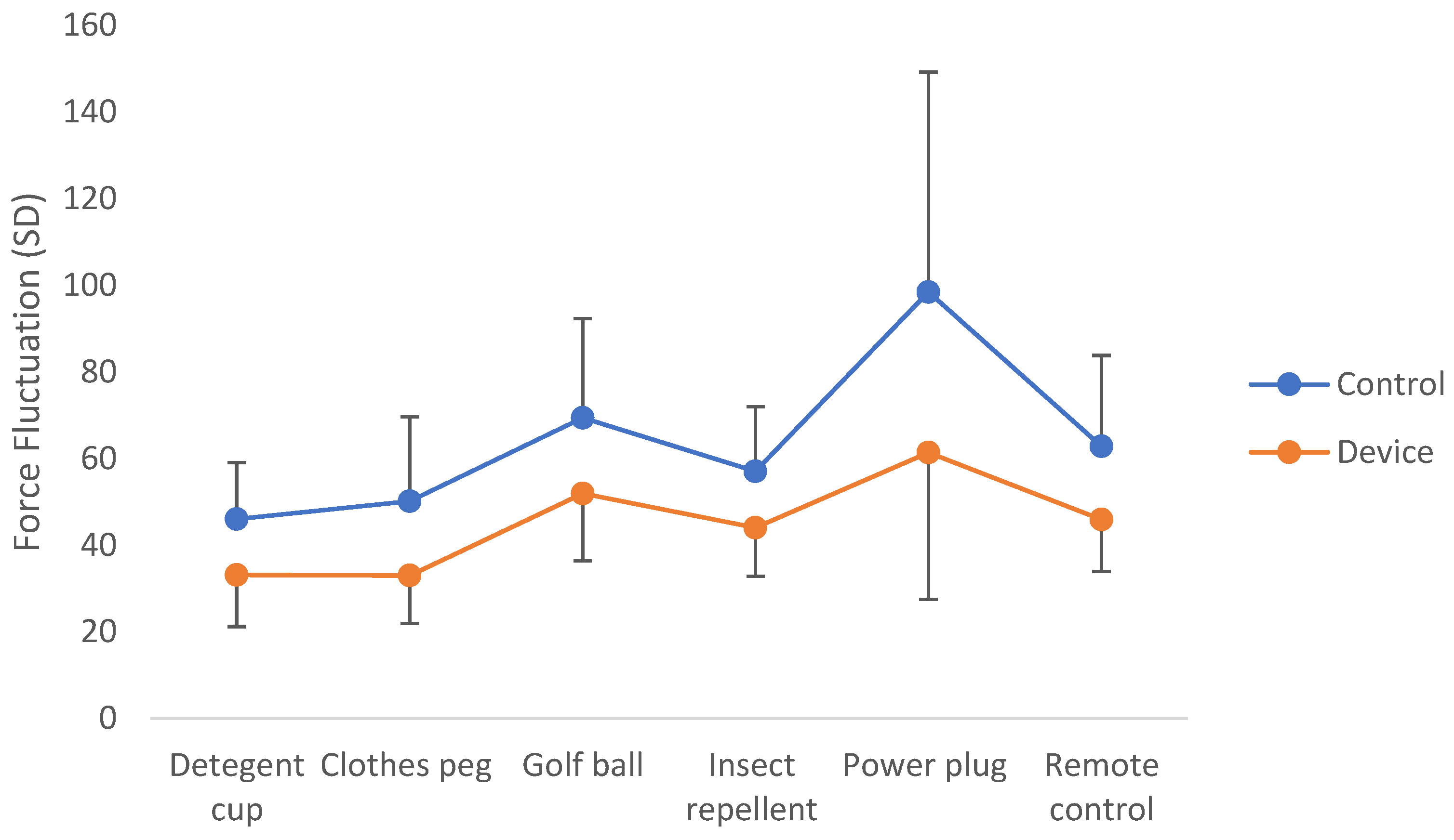

4.1.4. Pinch Force Steadiness

4.2. T-Test Results Comparison

4.3. Prototype Design Discussion

4.3.1. Device Control

4.3.2. Device Actuation

4.3.3. Safety

4.4. Device Comparison

4.5. Novelty and Industrial Applicability

5. Conclusions

5.1. Contribution of Study

5.2. Limitations of Research

5.3. Research Challenges

5.4. Recommendation for Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gul, R.; Alam, I.; Ibrar, A.; Saleem, K.; Pervez, I.P. Aging Affects the Number of WBC and Its Subsets in A Pakistani Cohort of Young and Elderly Women. ARPN J. Eng. Appl. Sci. 2013, 8, 638–641. [Google Scholar]

- Kurnianingsih, K.; Nugroho, L.; Widyawan, W.; Lazuardi, L. Reflective Sensing and Conditioning System in Ubiquitous Home Care for Elderly People. ARPN J. Eng. Appl. Sci. 2015, 10, 998–1007. [Google Scholar]

- Seidler, R.; Bernard, J.; B Burutolu, T.; Fling, B.; Gordon, M.; Gwin, J.; Kwak, Y.; Lipps, D. Motor Control and Aging: Links to Age-Related Brain Structural, Functional, and Biochemical Effects. Neurosci. Biobehav. Rev. 2009, 34, 721–733. [Google Scholar] [CrossRef]

- Young Hoogendam, Y.; van der Lijn, F.; Vernooij, M.W.; Hofman, A.; Niessen, W.J.; Lugt, A.; Arfan Ikram, M.; van der Geest, J.N. Older Age Relates to Worsening of Fine Motor Skills: A Population-Based Study of Middle-Aged and Elderly Persons. Front. Aging Neurosci. 2014, 6, 259. [Google Scholar] [CrossRef]

- Rahman, N.; Thomas, J.J.; Rice, M.S. The Relationship between Hand Strength and the Forces Used to Access Containers by Well Elderly Persons. Am. J. Occup. Ther. 2002, 56, 78–85. [Google Scholar] [CrossRef]

- Rice, M.S.; Leonard, C.; Carter, M. Grip strengths and required forces in accessing everyday containers in a normal population. Am. J. Occup. Ther. 1998, 52, 621–626. [Google Scholar] [CrossRef]

- Chen, X.P.; Lu, Y.M.; Zhang, J. Intervention study of finger-movement exercises and finger weight-lift training for improvement of handgrip strength among the very elderly. Int. J. Nurs. Sci. 2014, 1, 165–170. [Google Scholar] [CrossRef][Green Version]

- Ranganathan, V.K.; Siemionow, V.; Sahgal, V.; Liu, J.Z.; Yue, G.H. Skilled Finger Movement Exercise Improves Hand Function. J. Gerontol. Ser. A 2001, 56, 518–522. [Google Scholar] [CrossRef]

- Ellegaard, K.; von Bülow, C.; Røpke, A.; Bartholdy, C.; Hansen, I.S.; Rifbjerg-Madsen, S.; Henriksen, M.; Wæhrens, E.E. Hand exercise for women with rheumatoid arthritis and decreased hand function: An exploratory randomized controlled trial. Arthritis Res. Ther. 2019, 21, 158. [Google Scholar] [CrossRef]

- Rodríguez-Sánchez-Laulhé, P.; Luque-Romero, L.G.; Blanquero, J.; Suero-Pineda, A.; Biscarri-Carbonero, Á.; Barrero-García, F.J.; Heredia-Rizo, A.M. A mobile app using therapeutic exercise and education for self-management in patients with hand rheumatoid arthritis: A randomized controlled trial protocol. Trials 2020, 21, 777. [Google Scholar] [CrossRef]

- Liu, B.; Chen, X.; Li, Y.; Liu, H.; Guo, S.; Yu, P. Effect of passive finger exercises on grip strength and the ability to perform activities of daily living for older people with dementia: A 12-week randomized controlled trial. Clin. Interv. Aging 2018, 13, 2169–2177. [Google Scholar] [CrossRef]

- Cole, T.; Robinson, L.; Romero, L.; O’Brien, L. Effectiveness of interventions to improve therapy adherence in people with upper limb conditions: A systematic review. J. Hand Ther. Off. J. Am. Soc. Hand Ther. 2019, 32, 175–183.e7. [Google Scholar] [CrossRef]

- Hepple, R.T.; Rice, C.L. Innervation and neuromuscular control in ageing skeletal muscle. J. Physiol. 2016, 594, 1965–1978. [Google Scholar] [CrossRef] [PubMed]

- Rahim, A.A.; Patar, M.N.A.A.; Amin, A.M.; Mahmud, J. The Development of Finger Rehabilitation Device for Stroke Patients. Appl. Mech. Mater. 2013, 393, 604–610. [Google Scholar] [CrossRef]

- Rahman, M.A.; Al-Jumaily, A. Design and Development of a Hand Exoskeleton for Rehabilitation Following Stroke. Procedia Eng. 2012, 41, 1028–1034. [Google Scholar] [CrossRef]

- Cempini, M.; De Rossi, S.M.M.; Lenzi, T.; Cortese, M.; Giovacchini, F.; Vitiello, N.; Carrozza, M.C. Kinematics and design of a portable and wearable exoskeleton for hand rehabilitation. In Proceedings of the 2013 IEEE 13th International Conference on Rehabilitation Robotics (ICORR), Seattle, WA, USA, 24–26 June 2013; pp. 1–6. [Google Scholar] [CrossRef]

- Zaid, A.; Tee, C.C.; Sukor, J.A.; Hanafi, D. Development of hand exoskeleton for rehabilitation of post-stroke patient. AIP Conf. Proc. 2017, 1891, 020103. [Google Scholar] [CrossRef]

- Rudd, G.; Daly, L.; Jovanovic, V.; Cuckov, F. A Low-Cost Soft Robotic Hand Exoskeleton for Use in Therapy of Limited Hand–Motor Function. Appl. Sci. 2019, 9, 3751. [Google Scholar] [CrossRef]

- Wege, A.; Hommel, G. Development and Control of A Hand Exoskeleton for Rehabilitation of Hand Injuries. In Proceedings of the 2005 IEEE/RSJ International Conference on Intelligent Robots and Systems, Edmonton, AB, Canada, 2–6 August 2005; pp. 3046–3051. [Google Scholar]

- In, H.; Cho, K.-J.; Kim, K.; Lee, B. Jointless structure and under-actuation mechanism for compact hand exoskeleton. In Proceedings of the 2011 IEEE International Conference on Rehabilitation Robotics, Zurich, Switzerland, 29 June–1 July 2011; Volume 2011, pp. 1–6. [Google Scholar]

- Polygerinos, P.; Wang, Z.; Galloway, K.C.; Wood, R.J.; Walsh, C.J. Soft robotic glove for combined assistance and at-home rehabilitation. Robot. Auton. Syst. 2015, 73, 135–143. [Google Scholar] [CrossRef]

- DiCicco, M.; Lucas, L.; Matsuoka, Y. Comparison of Control Strategies for an EMG Controlled Orthotic Exoskeleton for the Hand. In Proceedings of the IEEE International Conference on Robotics and Automation 2004, New Orleans, LA, USA, 26 April–1 May 2004; pp. 1622–1627. [Google Scholar] [CrossRef]

- Hasegawa, Y.; Mikami, Y.; Watanabe, K.; Firouzimehr, Z.; Sankai, Y. Wearable Handling Support System for Paralyzed Patient. In Proceedings of the 2008 IEEE/RSJ International Conference on Intelligent Robots and Systems, Nice, France, 22–26 September 2008; pp. 741–746. [Google Scholar] [CrossRef]

- Mahmud, N.A.; Yoep, N.; Paiwai, F.; Shahein, N.A.; Tan, M.P.; Yusof, M.; Muhamad, N.A. Functional Limitations and Falls. In National Health and Morbidity Survey 2018: Elderly Health; Chan, Y.Y., Tan, L., Ahmad, F.H., Yusoff, M.F.M., Lodz, N.A., Shawal, N., Sooryanarayana, R., Aris, T., Robert, T., Saminathan, T.A., Eds.; Institute for Public Health, National Institutes of Health (NIH), Ministry of Health: Selangor, Malaysia, 2018; Volume 2, pp. 8–13. [Google Scholar]

- Tan, D.; Ng, P.; Noor, E. A TRIZ-driven conceptualisation of finger grip enhancer designs for the elderly [version 1; peer review: 1 approved, 1 approved with reservations]. F1000Research 2021, 10, 392. [Google Scholar] [CrossRef]

- Garrett, J.W. The adult human hand: Some anthropometric and biomechanical considerations. Hum. Factors 1971, 13, 117–131. [Google Scholar] [CrossRef] [PubMed]

- Greiner, T.M. Hand Anthropometry of US Army Personnel; Army Natick Reseach Development and Engineering Center: Natick, MA, USA, 1991. [Google Scholar]

- Taylor, C.L.; Schwarz, R.J. The anatomy and mechanics of the human hand. Artif. Limbs 1955, 2, 22–35. [Google Scholar]

- Duncan, S.F.M.; Saracevic, C.E.; Kakinoki, R. Biomechanics of the Hand. Hand Clin. 2013, 29, 483–492. [Google Scholar] [CrossRef]

- Lin, J.; Wu, Y.; Huang, T.S. Modeling the constraints of human hand motion. Proc. Workshop Hum. Motion 2000, 121–126. [Google Scholar] [CrossRef]

- Sarac, M.; Solazzi, M.; Frisoli, A. Design Requirements of Generic Hand Exoskeletons and Survey of Hand Exoskeletons for Rehabilitation, Assistive or Haptic Use. IEEE Trans. Haptics 2019, 12, 400–413. [Google Scholar] [CrossRef]

- Tanaka, T.; Amadio, P.C.; Zhao, C.; Zobitz, M.E.; An, K.-N. Flexor digitorum profundus tendon tension during finger manipulation. J. Hand Ther. 2005, 18, 330–338. [Google Scholar] [CrossRef]

- ElKoura, G.; Singh, K. Handrix: Animating the human hand. In Proceedings of the 2003 ACM SIGGRAPH/Eurographics Symposium on Computer Animation, San Diego, CA, USA, 26–27 July 2003; pp. 110–119. [Google Scholar] [CrossRef]

- Lisini, T.; Scheggi, S.; Meli, L.; Mohammadi, M.; Prattichizzo, D. GESTO: A Glove for Enhanced Sensing and Touching Based on Inertial and Magnetic Sensors for Hand Tracking and Cutaneous Feedback. IEEE Trans. Hum.-Mach. Syst. 2017, 47, 1066–1076. [Google Scholar] [CrossRef]

- Lince, A.R. A Portable Assistive Rehabilitation Hand Exoskeleton. Ph.D. Thesis, Polytechnic University of Turin, Turin, Italy, 2016. [Google Scholar]

- Imrhan, S.N. The influence of wrist position on different types of pinch strength. Appl. Ergon. 1991, 22, 379–384. [Google Scholar] [CrossRef]

- Worsnopp, T.T.; Peshkin, M.; Colgate, J.; Kamper, D. An Actuated Finger Exoskeleton for Hand Rehabilitation Following Stroke. In Proceedings of the 2007 IEEE 10th International Conference on Rehabilitation Robotics, Noordwijk, The Netherlands, 13–15 June 2007; pp. 896–901. [Google Scholar] [CrossRef]

- Leonardis, D.; Barsotti, M.; Loconsole, C.; Solazzi, M.; Troncossi, M.; Mazzotti, C.; Castelli, V.P.; Procopio, C.; Lamola, G.; Chisari, C.; et al. An EMG-Controlled Robotic Hand Exoskeleton for Bilateral Rehabilitation. IEEE Trans Haptics 2015, 8, 140–151. [Google Scholar] [CrossRef]

- Alexander, B.; Kotiuk, V. Proportions of Hand Segments. Int. J. Morphol. 2010, 28, 755–758. [Google Scholar]

- Richterman, I.E.; DuPree, J.; Thoder, J.; Kozin, S.H. The radiographic analysis of web height. J. Hand Surg. 1998, 23, 1071–1076. [Google Scholar] [CrossRef]

- Hume, M.; Gellman, H.; McKellop, H.; Brumfield, R. Functional range of motion of the joints of the hand. J. Hand Surg. 1990, 15, 240–243. [Google Scholar] [CrossRef]

- Jahn, J.; Janes, W.E.; Saheb-Al-Zamani, M.; Burbank, C.M.; Brown, J.M.; Engsberg, J.R. Identification of three movement phases of the hand during lateral and pulp pinches using video motion capture. Hand 2013, 8, 123–131. [Google Scholar] [CrossRef] [PubMed]

- Brorsson, S. Biomechanical Studies of Finger Extension Function. Analysis with a New Force Measuring Device and Ultrasound Examination in Rheumatoid Arthritis and Healhty Muscles. Ph.D. Thesis, University of Gothenburg, Gothenburg, Sweden, 2008. [Google Scholar]

- Shojaei Barjuei, E.; Caldwell, D.G.; Ortiz, J. Bond Graph Modeling and Kalman Filter Observer Design for an Industrial Back-Support Exoskeleton. Designs 2020, 4, 53. [Google Scholar] [CrossRef]

- Lampman, S.; Dieter, G.E. ASM Handbook: Materials Selection and Design; Taylor & Francis: Abingdon, UK, 1997; Volume 20. [Google Scholar]

- Novakova-Marcincinova, L.; Novak-Marcincin, J.; Barna, J.; Torok, J. Special Materials Used in FDM Rapid Prototyping Technology Application. In Proceedings of the 2012 IEEE 16th International Conference on Intelligent Engineering Systems (INES), Lisbon, Portugal, 13–15 June 2012; pp. 73–76. [Google Scholar] [CrossRef]

- McKeen, L. Elastomers. In The Effect of Sterilization Methods on Plastics and Elastomers, 4th ed.; McKeen, L., Ed.; William Andrew Publishing: Norwich, NY, USA, 2018; pp. 305–351. [Google Scholar]

- Kulkarni, G.S. Introduction to Polymer and Their Recycling Techniques. In Recycling of Polyurethane Foams; Thomas, S., Rane, A.V., Kanny, K., V.K, A., Thomas, M.G., Eds.; William Andrew Publishing: Norwich, NY, USA, 2018; pp. 1–16. [Google Scholar]

- Materialise. 3D Printing Materials. Available online: https://bit.ly/3o4HM03 (accessed on 27 March 2020).

- Camargo, J.; Machado, A.; Almeida, E.; Moura, E. Mechanical properties of PLA-graphene filament for FDM 3D printing. Int. J. Adv. Manuf. Technol. 2019, 103, 2423–2443. [Google Scholar] [CrossRef]

- Rodriguez-Panes, A.; Claver, J.; Camacho, A.M. The Influence of Manufacturing Parameters on the Mechanical Behaviour of PLA and ABS Pieces Manufactured by FDM: A Comparative Analysis. Materials 2018, 11, 1333. [Google Scholar] [CrossRef]

- MatWeb. Overview of Materials for Polylactic Acid (PLA) Biopolymer. Available online: https://bit.ly/2KTcbQy (accessed on 27 March 2020).

- Stratasys. Nylon (Polyamide) Parts on Demand. Available online: https://www.stratasysdirect.com/materials/thermoplastics/nylon#nylon-12 (accessed on 27 March 2020).

- Hyie, K.; Budin, S.; Martinus, N.; Salleh, Z.; Masdek, N. Tensile and flexural investigation on polypropylene recycling. J. Phys. Conf. Ser. 2019, 1174, 012005. [Google Scholar] [CrossRef]

- Mathiowetz, V.; Kashman, N.; Volland, G.; Weber, K.; Dowe, M.; Rogers, S. Grip and Pinch Strength: Normative data for adults. Arch. Phys. Med. Rehabil. 1985, 66, 69–74. [Google Scholar]

- Mohammadian, M.; Choobineh, A.; Haghdoost, A.; Hasheminejad, N. Normative data of grip and pinch strengths in healthy adults of Iranian population. Iran J. Public Health 2014, 43, 1113–1122. [Google Scholar]

- Nilsen, T.; Hermann, M.; Eriksen, C.; Dagfinrud, H.; Mowinckel, P.; Kjeken, I. Grip force and pinch grip in an adult population: Reference values and factors associated with grip force. Scand. J. Occup. Ther. 2011, 19, 288–296. [Google Scholar] [CrossRef]

- Harth, A.; Vetter, W.R. Grip and pinch strength among selected adult occupational groups. Occup. Ther. Int. 1994, 1, 13–28. [Google Scholar] [CrossRef]

- Eliopoulos, G.M.; Harris, A.D.; Bradham, D.D.; Baumgarten, M.; Zuckerman, I.H.; Fink, J.C.; Perencevich, E.N. The Use and Interpretation of Quasi-Experimental Studies in Infectious Diseases. Clin. Infect. Dis. 2004, 38, 1586–1591. [Google Scholar] [CrossRef]

- Maciejewski, M.L. Quasi-experimental design. Biostat. Epidemiol. 2020, 4, 38–47. [Google Scholar] [CrossRef]

- Harris, A.D.; McGregor, J.C.; Perencevich, E.N.; Furuno, J.P.; Zhu, J.; Peterson, D.E.; Finkelstein, J. The use and interpretation of quasi-experimental studies in medical informatics. J. Am. Med Inform. Assoc. 2006, 13, 16–23. [Google Scholar] [CrossRef] [PubMed]

- Campbell, D.T.; Stanley, J.C. Experimental and Quasi-Experimental Designs for Research; Ravenio Books: Cambridge, UK, 2015. [Google Scholar]

- Walukonis, K.; Beasley, J.; Boerema, R.; Powers, J.; Anderson, K. The impact of finger position on pinch strength. Hand Ther. 2018, 23, 70–76. [Google Scholar] [CrossRef]

- Fausset, C.; Kelly, A.; Rogers, W.; Fisk, A. Challenges to Aging in Place: Understanding Home Maintenance Difficulties. J. Hous. Elder. 2011, 25, 125–141. [Google Scholar] [CrossRef] [PubMed]

- Smaby, N.; Baker, B.; Johanson, M.E.; Towles, J.D.; Murray, W.M. Determination of lateral pinch force requirements for six common activities of daily living. In Proceedings of the Third National Meeting for Rehabilitation Research and Development Conference, Arlington, VA, USA, 10–12 February 2002; p. 104. [Google Scholar]

- Stegink Jansen, C.W.; Simper, V.K.; Stuart, H.G., Jr.; Pinkerton, H.M. Measurement of maximum voluntary pinch strength: Effects of forearm position and outcome score. J. Hand Ther. 2003, 16, 326–336. [Google Scholar] [CrossRef]

- Ames, H.; Glenton, C.; Lewin, S. Purposive sampling in a qualitative evidence synthesis: A worked example from a synthesis on parental perceptions of vaccination communication. BMC Med. Res. Methodol. 2019, 19, 26. [Google Scholar] [CrossRef]

- Palinkas, L.A.; Horwitz, S.M.; Green, C.A.; Wisdom, J.P.; Duan, N.; Hoagwood, K. Purposeful Sampling for Qualitative Data Collection and Analysis in Mixed Method Implementation Research. Adm. Policy Ment. Health 2015, 42, 533–544. [Google Scholar] [CrossRef]

- Werle, S.; Goldhahn, J.; Drerup, S.; Simmen, B.R.; Sprott, H.; Herren, D.B. Age- and Gender-Specific Normative Data of Grip and Pinch Strength in a Healthy Adult Swiss Population. J. Hand Surg. 2009, 34, 76–84. [Google Scholar] [CrossRef]

- Parmar, S.; Khodasevych, I.; Troynikov, O. Evaluation of Flexible Force Sensors for Pressure Monitoring in Treatment of Chronic Venous Disorders. Sensors 2017, 17, 1923. [Google Scholar] [CrossRef]

- Mathiowetz, V.; Weber, K.; Volland, G.; Kashman, N. Reliability and validity of grip and pinch strength evaluations. J. Hand Surg. 1984, 9, 222–226. [Google Scholar] [CrossRef]

- Shih, Y.-C.; Ou, Y.-C. Influences of span and wrist posture on peak chuck pinch strength and time needed to reach peak strength. Int. J. Ind. Ergon. 2005, 35, 527–536. [Google Scholar] [CrossRef]

- Hanten, W.P.; Chen, W.-Y.; Austin, A.A.; Brooks, R.E.; Carter, H.C.; Law, C.A.; Morgan, M.K.; Sanders, D.J.; Swan, C.A.; Vanderslice, A.L. Maximum grip strength in normal subjects from 20 to 64 years of age. J. Hand Ther. 1999, 12, 193–200. [Google Scholar] [CrossRef]

- Mathiowetz, V. Effects of three trials on grip and pinch strength measurements. J. Hand Ther. 1990, 3, 195–198. [Google Scholar] [CrossRef]

- Trossman, P.B.; Li, P.-W. The Effect of the Duration of Intertrial Rest Periods on Isometric Grip Strength Performance in Young Adults. Occup. Ther. J. Res. 1989, 9, 362–378. [Google Scholar] [CrossRef]

- Jones, S.R.; Carley, S.; Harrison, M. An introduction to power and sample size estimation. Emerg. Med. J. 2003, 20, 453–458. [Google Scholar] [CrossRef] [PubMed]

- Brysbaert, M. How Many Participants Do We Have to Include in Properly Powered Experiments? A Tutorial of Power Analysis with Reference Tables. J. Cogn. 2019, 2, 16. [Google Scholar] [CrossRef] [PubMed]

- Lakens, D. Calculating and reporting effect sizes to facilitate cumulative science: A practical primer for t-tests and ANOVAs. Front. Psychol. 2013, 4, 863. [Google Scholar] [CrossRef]

- Ghasemi, A.; Zahediasl, S. Normality tests for statistical analysis: A guide for non-statisticians. Int. J. Endocrinol. Metab. 2012, 10, 486–489. [Google Scholar] [CrossRef]

- Nosakhare, U.H.; Bright, A.F. Evaluation of Techniques for Univariate Normality Test Using Monte Carlo Simulation. Am. J. Theor. Appl. Stat. 2018, 6, 51–61. [Google Scholar]

- Kinoshita, H.; Francis, P.R. A comparison of prehension force control in young and elderly individuals. Eur. J. Appl. Physiol. Occup. Physiol. 1996, 74, 450–460. [Google Scholar] [CrossRef]

- De Serres, S.J.; Fang, N.Z. The accuracy of perception of a pinch grip force in older adults. Can. J. Physiol. Pharmacol. 2004, 82, 693–701. [Google Scholar] [CrossRef]

- Spirduso, W.W.; Choi, J. Age and Practice Effects on Force Control of the Thumb and Index Fingers in Precision Pinching and Bilateral Coordination. In Sensorimotor Impairment in the Elderly; Stelmach, G.E., Hömberg, V., Eds.; Springer: Dordrecht, The Netherlands, 1993; pp. 393–412. [Google Scholar]

- Stelmach, G.E.; Hömberg, V. Sensorimotor Impairment in the Elderly; Springer: Heidelberg, Germany, 2012. [Google Scholar]

- Boatright, J.R.; Kiebzak, G.M.; O’Neil, D.M.; Peindl, R.D. Measurement of thumb abduction strength: Normative data and a comparison with grip and pinch strength. J. Hand Surg. 1997, 22, 843–848. [Google Scholar] [CrossRef]

- Carmeli, E.; Patish, H.; Coleman, R. The Aging Hand. J. Gerontol. Ser. A 2003, 58, 146–152. [Google Scholar] [CrossRef]

- Kornatz, K.W.; Christou, E.A.; Enoka, R.M. Practice reduces motor unit discharge variability in a hand muscle and improves manual dexterity in old adults. J. Appl. Physiol. 2005, 98, 2072–2080. [Google Scholar] [CrossRef]

- Portnoy, S.; Halaby, O.; Dekel-Chen, D.; Dierick, F. Effect of an auditory feedback substitution, tactilo-kinesthetic, or visual feedback on kinematics of pouring water from kettle into cup. Appl. Ergon. 2015, 51, 44–49. [Google Scholar] [CrossRef] [PubMed]

- Cole, K.; Rotella, D. Old age affects fingertip forces when restraining an unpredictably loaded object. Exp. Brain Res. 2001, 136, 535–542. [Google Scholar] [CrossRef] [PubMed]

- Keen, D.A.; Yue, G.; Enoka, R. Training-related enhancement in the control of motor output in elderly humans. J. Appl. Physiol. 1995, 77, 2648–2658. [Google Scholar] [CrossRef] [PubMed]

- Hasegawa, Y.; Mikami, Y.; Watanabe, K.; Sankai, Y. Five-fingered assistive hand with mechanical compliance of human finger. In Proceedings of the 2008 IEEE International Conference on Robotics and Automation, Pasadena, CA, USA, 19–23 May 2008; pp. 718–724. [Google Scholar] [CrossRef]

- Nilsson, M.; Ingvast, J.; Wikander, J.; Holst, H. The Soft Extra Muscle system for improving the grasping capability in neurological rehabilitation. In Proceedings of the 2012 IEEE-EMBS Conference on Biomedical Engineering and Sciences, Langkawi, Malaysia, 17–19 December 2012; pp. 412–417. [Google Scholar] [CrossRef]

- An, K.N.; Chao, E.Y.; Cooney, W.P.; Linscheid, R.L. Forces in the normal and abnormal hand. J. Orthop. Res. 1985, 3, 202–211. [Google Scholar] [CrossRef] [PubMed]

- Tjahyono, A.; Aw, K.; Devaraj, H.; Surendra, W.; Hämmerle, E.; Travas-Sejdic, J. A five-fingered hand exoskeleton driven by pneumatic artificial muscles with novel polypyrrole sensors. Ind. Robot 2013, 40, 251–260. [Google Scholar] [CrossRef]

- Smaby, N.; Johanson, M.E.; Baker, B.; Kenney, D.E.; Murray, W.M.; Hentz, V.R. Identification of key pinch forces required to complete functional tasks. J. Rehabil. Res. Dev. 2004, 41, 215–224. [Google Scholar] [CrossRef] [PubMed]

- Belter, J.T.; Segil, J.L.; Dollar, A.M.; Weir, R.F. Mechanical design and performance specifications of anthropomorphic prosthetic hands: A review. J. Rehabil. Res. Dev. 2013, 50, 599–618. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, A.; Lavranos, J.; Zhou, H.; Mutlu, R.; Alici, G.; Tan, Y.; Choong, P.; Oetomo, D. A practical 3D-printed soft robotic prosthetic hand with multi-articulating capabilities. PLoS ONE 2020, 15, e0232766. [Google Scholar] [CrossRef]

- Takahashi, N.; Furuya, S.; Koike, H. Soft Exoskeleton Glove with Human Anatomical Architecture: Production of Dexterous Finger Movements and Skillful Piano Performance. IEEE Trans Haptics 2020, 13, 679–690. [Google Scholar] [CrossRef] [PubMed]

- Wei, W.; Zha, S.; Xia, Y.; Gu, J.; Lin, X. A Hip Active Assisted Exoskeleton That Assists the Semi-Squat Lifting. Appl. Sci. 2020, 10, 2424. [Google Scholar] [CrossRef]

- Webster, A.; Poyade, M.; Rooney, S.; Paul, L. Upper limb rehabilitation interventions using virtual reality for people with multiple sclerosis: A systematic review. Mult. Scler. Relat. Disord. 2021, 47, 102610. [Google Scholar] [CrossRef]

- Sulfikar Ali, A.; Arumugam, A.; Kumaran, D.S. Effectiveness of an intensive, functional, gamified Rehabilitation program in improving upper limb motor function in people with stroke: A protocol of the EnteRtain randomized clinical trial. Contemp. Clin. Trials 2021, 105, 106381. [Google Scholar] [CrossRef] [PubMed]

| Finger | Distal Phalanx (mm) | Medial Phalanx (mm) | Proximal Phalanx (mm) |

|---|---|---|---|

| Thumb | 21.67 ± 1.60 | - | 31.57 ± 3.13 |

| Index Finger | 15.82 ± 2.26 | 22.38 ± 2.51 | 39.78 ± 4.94 |

| Fingers | DIP/IP | PIP | MCP |

|---|---|---|---|

| Max ROM (T) | 5–73 | - | 0–56 |

| Max ROM (I) | 0–85 | 0–105 | 0–100 |

| Pinch ROM (T) | 23 | - | 11.1 |

| Pinch ROM (I) | 11.8 | 25.7 | 38.7 |

| Extension Force of Index Fingers Mean ± SD, N | |

|---|---|

| Men | Women |

| 40.6 ± 2.9 | 17.2 ± 1.6 |

| Input Pins | Output Pins |

|---|---|

| Thumb sensor (analogue) | Thumb servo motor (analogue) |

| Index finger sensor (analogue) | Index finger servo motor (analogue) |

| Criteria | Details |

|---|---|

| Function | Act as Pivot Points to Guide the Finger Movements |

| Constraints | Must not fail under stress |

| Water-resistant | |

| Length | |

| Objective | As small and light as possible |

| Criteria | ABS | Polylactic Acid (PLA) | Polycarbonate (PC) | Polyamides (Nylon) | Polypropylene (PP) |

|---|---|---|---|---|---|

| Tensile strength (MPa) | 22 | 41 | 68 | 53 | 21.4 |

| Flexural modulus (MPa) | 1834 | 2800 | 2234 | 1300 | 698 |

| Flexural strength (MPa) | 41 | 103 | 104 | 69 | 55 |

| IZOD impact (J/m) | 107 | 139 | 53 | 150 | 75 |

| Density (g/cm3) | 1.05 | 1.25 | 1.2 | 1.00 | 0.84 |

| Heat deflection temperature @ 0.45 MPa | 90 | 80.3 | 138 | 97 | 121 |

| Elongation at break (%) | 6 | 4.7 | 4.8 | 9.5 | 529 |

| Sources | [49] | [50,51,52] | [49] | [53] | [49,54] |

| Criteria | Decision Number | Positive Decisions | Weighting Factors | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | |||

| Tensile strength | 2 | 1 | 2 | 2 | 2 | 2 | 11 | 0.17 | |||||||||||||||

| Flexural modulus | 1 | 1 | 1 | 1 | 2 | 2 | 8 | 0.13 | |||||||||||||||

| Flexural strength | 2 | 2 | 2 | 2 | 2 | 2 | 12 | 0.19 | |||||||||||||||

| IZOD impact | 1 | 2 | 1 | 1 | 2 | 2 | 9 | 0.14 | |||||||||||||||

| Density | 1 | 2 | 1 | 2 | 2 | 2 | 10 | 0.16 | |||||||||||||||

| Heat deflection temp. | 1 | 1 | 1 | 1 | 1 | 2 | 7 | 0.11 | |||||||||||||||

| Elongation at break | 1 | 1 | 1 | 1 | 1 | 1 | 6 | 0.10 | |||||||||||||||

| Total Number of Positive Decisions | 63 | 1.00 | |||||||||||||||||||||

| Materials | Tensile Strength | Flexural Modulus | Flexural Strength | IZOD Impact | Density | Heat Deflection Temperature | % Elongation | Weighted Property Index |

|---|---|---|---|---|---|---|---|---|

| 0.17 * | 0.13 * | 0.19 * | 0.14 * | 0.16 * | 0.11 * | 0.1 * | ||

| ABS | 32.35 | 65.5 | 39.42 | 71.33 | 80 | 65.22 | 1.13 | 51.58 |

| PLA | 60.29 | 100 | 99.04 | 92.67 | 67.20 | 58.19 | 0.88 | 72.28 |

| PC | 100 | 79.79 | 100 | 35.33 | 70 | 100 | 0.91 | 73.61 |

| Nylon | 77.94 | 46.43 | 66.35 | 100 | 84 | 70.29 | 1.80 | 67.24 |

| PP | 31.47 | 24.93 | 52.88 | 50 | 100 | 87.68 | 100 | 61.28 |

| Material | Relative Cost | Cost of Unit Strength × 100 | Weighted Property Index | Figure of Merit | Rank |

|---|---|---|---|---|---|

| ABS | 1 | 8.83 | 51.58 | 5.84 | 2 |

| PLA | 1 | 5.69 | 72.28 | 12.70 | 1 |

| PC | 2.80 | 15.19 | 73.61 | 4.84 | 3 |

| Nylon | 2.80 | 16.64 | 67.24 | 4.04 | 4 |

| PP | 3.25 | 18.88 | 61.28 | 3.24 | 5 |

| Parameters | Initial Design | Final Design |

|---|---|---|

| Mass | 0.731 g | 1.035 g |

| Volume | 584.514 mm3 | 828.12 mm3 |

| Top surface area | 194.838 mm2 | 204.28 mm2 |

| Wall thickness | 3 mm | 2–5.73 mm |

| Height | 3 mm | 4 mm |

| Test | Boundary Conditions | Total Deformation Profile | Von Mises Stress Profile |

|---|---|---|---|

| 1a |  |  |  |

| 1b |  |  |  |

| 2 |  |  |  |

| 3 |  |  |  |

| Simulation Conditions | Maximum Deformation (mm) | Maximum von Mises Stress (MPa) | Result |

|---|---|---|---|

| Compression force 1 | 0.2246 | 28.649 | Pass |

| Compression force 2 | 0.3026 | 36.113 | Pass |

| Cable reaction force | 0.0207 | 35.997 | Pass |

| Pinch action simulation | 0.0206 | 36.031 | Pass |

| Device Component | Function |

|---|---|

Servo motor with pulley (Feetech RC Model Co., Ltd., Shenzhen, China) | Main driver unit that provides the required torque to support the thumb and index finger. Servo motor: Fitec FS5115M |

PLA finger rings with tendon cables | Used to transfer tension force from the servo motors to the fingers. |

Flexiforce sensor (Tekscan, Inc., South Boston, MA, USA) | Measures the amount of pressure from the fingers during pinching activity. FSR: Tekscan FlexiForce A201 Sensor |

Power bank (Zhongshan Pineng Battery Co., Ltd., Guangdong, China) | Supplies 5 VDC, 2.1 A to power the Arduino, sensor, and servo motor. |

Arduino Uno and electronic circuit (Arduino SA, Chiasso, Switzerland) | The control unit receives an analog signal from the sensor and instructs the servo motor to rotate accordingly. Control board: Arduino Uno Microcontroller: ATmega328P (part of the Arduino Uno board) |

Glove | Central piece of the device that keeps the tendon cables in place. |

| Characteristic | Device Performance |

|---|---|

| Weight of glove and actuators | 320 g |

| Weight of device | 520 g |

| DOFs for index finger | 3 |

| DOFs for thumb | 2 |

| Bending angle of index finger | ~134° |

| Bending angle of thumb | ~100.76° |

| Force range | 8.5 to 13.9 N |

| Electrical input | 5 V DC 2 A |

| Operating hours | ~3.5 h continuously |

| Cost | ~RM 296.5 |

| Test | Effect Size | Actual Power | Predicted Sample Size |

|---|---|---|---|

| T1 Detergent cup | 1.409 | 0.81 | 4 |

| T2 Clothes peg | 1.364 | 0.98 | 4 |

| T3 Golf ball | 1.038 | 0.91 | 7 |

| T4 Insect repellent | 1.065 | 0.82 | 5 |

| T5 Power plug | 0.843 | 0.95 | 5 |

| T6 Remote control | 1.162 | 0.88 | 5 |

| Test | p-Values | |

|---|---|---|

| With Device | Without Device | |

| T1 Detergent cup | >0.1 | >0.1 |

| T2 Clothes peg | >0.1 | >0.1 |

| T3 Golf ball | 0.056 | >0.1 |

| T4 Insect repellent | >0.1 | >0.1 |

| T5 Power plug | 0.05 | >0.1 |

| T6 Remote control | >0.1 | >0.1 |

| Test | Control | Device | ||

|---|---|---|---|---|

| Mean | SD | Mean | SD | |

| T1 Detergent cup | 0.35 | 0.29 | 1.20 | 0.59 |

| T2 Clothes peg | 0.31 | 0.16 | 0.68 | 0.33 |

| T3 Golf ball | 0.81 | 0.38 | 1.39 | 0.75 |

| T4 Insect repellent | 0.48 | 0.31 | 1.01 | 0.57 |

| T5 Power plug | 0.57 | 0.33 | 1.02 | 0.60 |

| T6 Remote control | 0.31 | 0.13 | 0.85 | 0.31 |

| Paired Sample | Paired Difference | ||

|---|---|---|---|

| Mean | Std. Deviation | T-Value | |

| T1 Detergent cup | 0.85 | 0.42 | 6.71 * |

| T2 Clothes peg | 0.36 | 0.23 | 5.26 * |

| T3 Golf ball | 0.58 | 0.43 | 4.52 ** |

| T4 Insect repellent | 0.53 | 0.35 | 4.96 ** |

| T5 Power plug | 0.46 | 0.40 | 3.80 ** |

| T6 Remote control | 0.54 | 0.35 | 5.10 * |

| Test | Control | Device | ||

|---|---|---|---|---|

| Mean * | SD | Mean * | SD | |

| T1 Detergent cup | 46.01 | 19.46 | 33.09 | 17.71 |

| T2 Clothes peg | 50.14 | 28.99 | 32.96 | 16.47 |

| T3 Golf ball | 69.40 | 34.00 | 51.90 | 23.1 |

| T4 Insect repellent | 57.07 | 22.18 | 44.06 | 16.73 |

| T5 Power plug | 83.40 | 46.20 | 51.40 | 24.10 |

| T6 Remote control | 62.86 | 31.15 | 45.86 | 17.72 |

| Paired Sample | Paired Difference | ||

|---|---|---|---|

| Mean | Std. Deviation | T-Value | |

| T1 Detergent cup | 12.92 | 11.65 | 3.68 * |

| T2 Clothes peg | 17.17 | 15.00 | 3.80 * |

| T3 Golf ball | 17.49 | 16.25 | 3.57 ** |

| T4 Insect repellent | 13.01 | 15.30 | 2.82 *** |

| T5 Power plug | 31.96 | 31.42 | 3.37 ** |

| T6 Remote control | 17.00 | 20.17 | 2.80 *** |

| Output Variables | Ref. [8] | Current Study |

|---|---|---|

| Pinch force | p > 0.05 | p < 0.05 |

| Pinch force steadiness | p > 0.05 | p < 0.05 |

| Output Variables | Ref. [90] | Current Study |

|---|---|---|

| Pinch force | p > 0.05 | p < 0.05 |

| Pinch force steadiness | p > 0.05 | p < 0.05 |

| Devices | Weight (g) | No. of DOFs | No. of Actuators | Pinch Force (N) | |

|---|---|---|---|---|---|

| Current study’s device | 520 | 5 | 2 | 13.9 | |

| Research | SoftHand Pro | 520 | 2 | 2 | 20 |

| X-Limb | 253 | 13 | 5 | 10.2 | |

| Commercial | Bebionic | 539 | 6 | 5 | 12.47 |

| I-limb | 504 | 6 | 5 | 6.54 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, D.W.H.; Ng, P.K.; Noor, E.E.M.; Saptari, A.; Hue, C.C.; Ng, Y.J. Development and Usability Testing of a Finger Grip Enhancer for the Elderly. Robotics 2022, 11, 5. https://doi.org/10.3390/robotics11010005

Tan DWH, Ng PK, Noor EEM, Saptari A, Hue CC, Ng YJ. Development and Usability Testing of a Finger Grip Enhancer for the Elderly. Robotics. 2022; 11(1):5. https://doi.org/10.3390/robotics11010005

Chicago/Turabian StyleTan, Dominic Wen How, Poh Kiat Ng, Ervina Efzan Mhd Noor, Adi Saptari, Chee Chen Hue, and Yu Jin Ng. 2022. "Development and Usability Testing of a Finger Grip Enhancer for the Elderly" Robotics 11, no. 1: 5. https://doi.org/10.3390/robotics11010005

APA StyleTan, D. W. H., Ng, P. K., Noor, E. E. M., Saptari, A., Hue, C. C., & Ng, Y. J. (2022). Development and Usability Testing of a Finger Grip Enhancer for the Elderly. Robotics, 11(1), 5. https://doi.org/10.3390/robotics11010005