Maxwell Points of Dynamical Control Systems Based on Vertical Rolling Disc—Numerical Solutions

Abstract

:1. Introduction

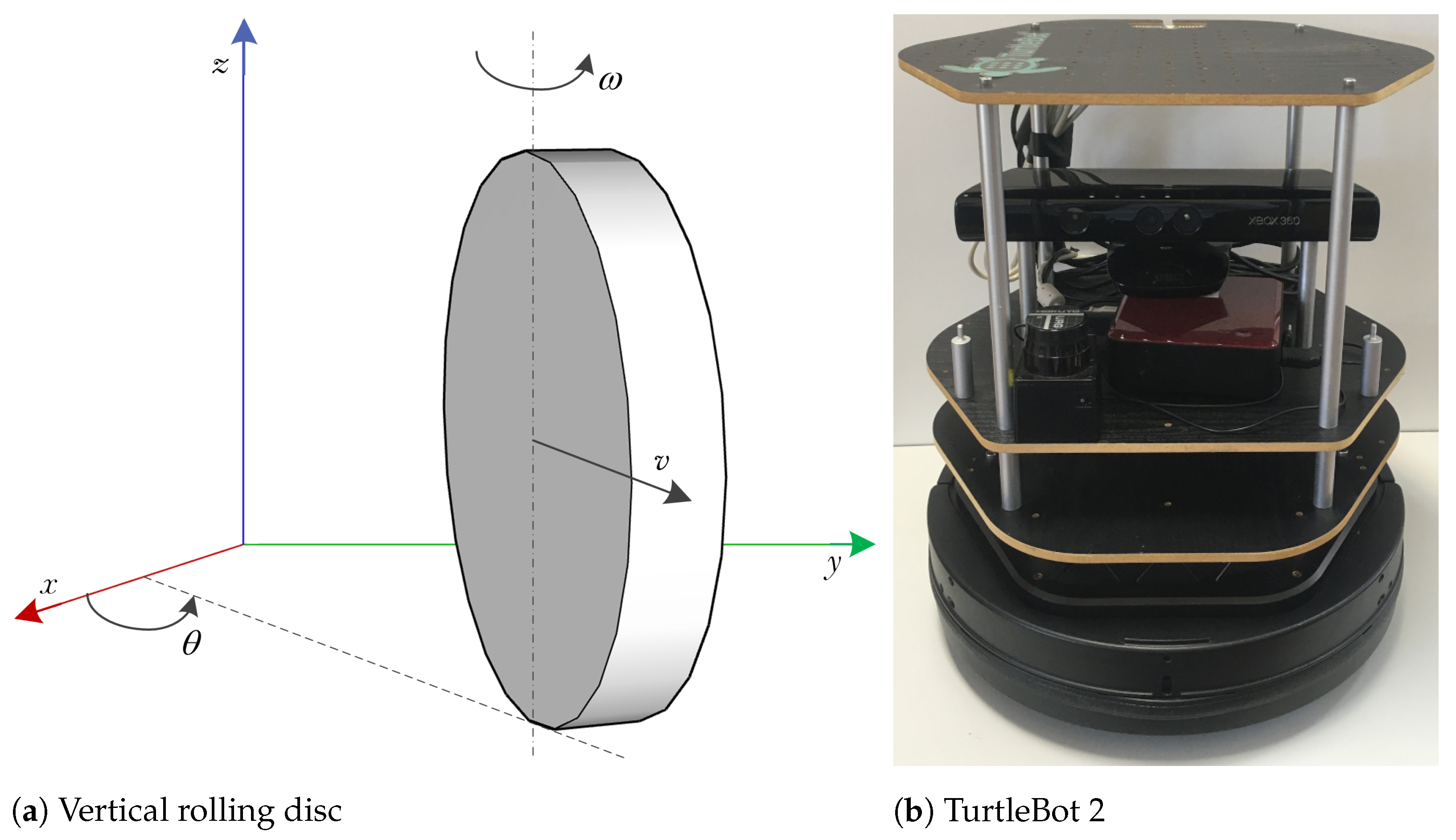

2. Description of the Mechanism

2.1. Differential Kinematics of the Mechanism

2.2. Dynamics of the Mechanism

3. Approximation of Vector Fields Using Taylor Polynomial

3.1. Optimal Control Problem

4. Nilpotent Approximation Using Bellaïche’s Algorithm

- Choose an adapted frame at p.In our case we choose frame at .

- Choose coordinates centered at p such that .For our adapted frame we choose the coordinates

- For setwhere, forwith First notice that for coordinates of degree the transformation degenerates [12]. Thus, we will focus on the evaluation of The sum yieldsNotice that , and furthermore , , . So, the transformations are of the formin original coordinatesWe can see that for the choice of the transformation degenerates, and hence from now on let us introduce a substitution Now, express the base of tangent bundle of old coordinates in terms of new coordinates

4.1. Optimal Control Problem

5. Numerical Analysis

5.1. Finding Trajectories Leading to Known MPs

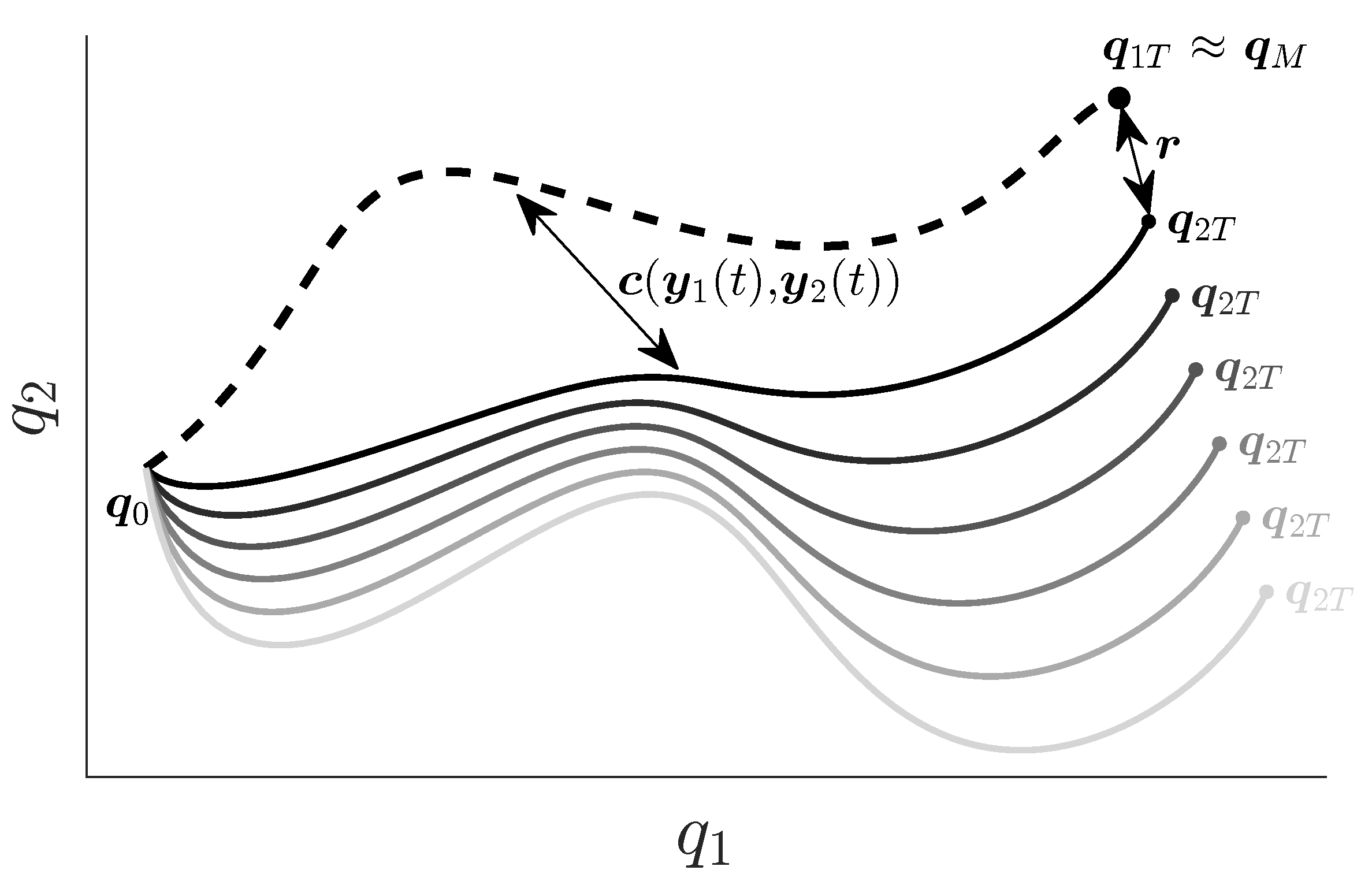

- Find the first trajectoryAssuming the MP position is invariant to the actual trajectory length in time, we can fix the initial configuration of the system to the origin () and choose a final time as any positive real number (affecting only how fast the system passes through the optimal trajectory). We can now optimise the end point of the trajectory to be equal to the suspected Maxwell point . This means we choose such that drives the system to in time T. This is a straightforward convex minimisation task deduced from (17), since now depends only on the choice of and no constraints are required. The cost function will take the form of a euclidean distance result in an optimisation task defined aswhere is the optimal solution. The whole situation is depicted in Figure 2.

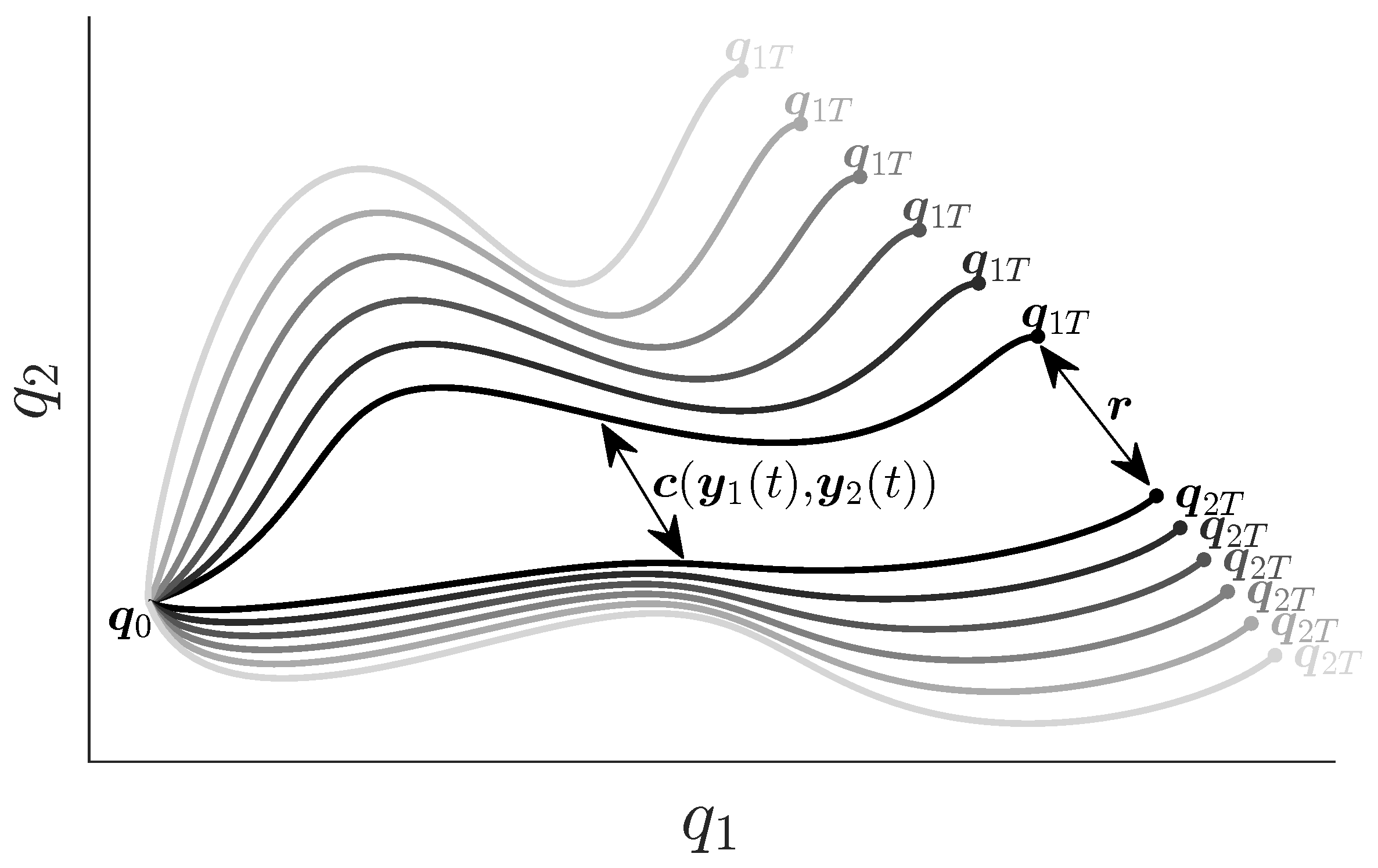

- Find the second trajectoryNow we need to find for a second trajectory, which is different from and drives the system towards the same point , as shown in Figure 3. We can formulate our constrained minimisation problem as (19) with constraints (20) and (21). The equality constraint (20) is meant to satisfy the same functional (9) for both trajectories.The parameter is a tuning parameter which specifies the minimal distance between the vectors and , which are normalized so that the choice of this parameter is independent of their respective scales.

- Review resultsThere are multiple termination conditions to the interior point algorithm. These include:

- First-order optimality;

- Iteration step size;

- Number of iterations.

Any of these can cause the algorithm to stop, but the main concern is the case where the termination occurs due to a local minimum (first-order optimality reached). If this happens, we may need to return to step 2 and restart the algorithm, giving it a different initial guess.To decide whether our result is valid, or if we need to restart the optimisation with a different initial guess, we can compare the value of the optimisation cost function with a numerical tolerance parameter. If the value is smaller than our chosen numerical tolerance, the result is valid and the Maxwell point has been confirmed.

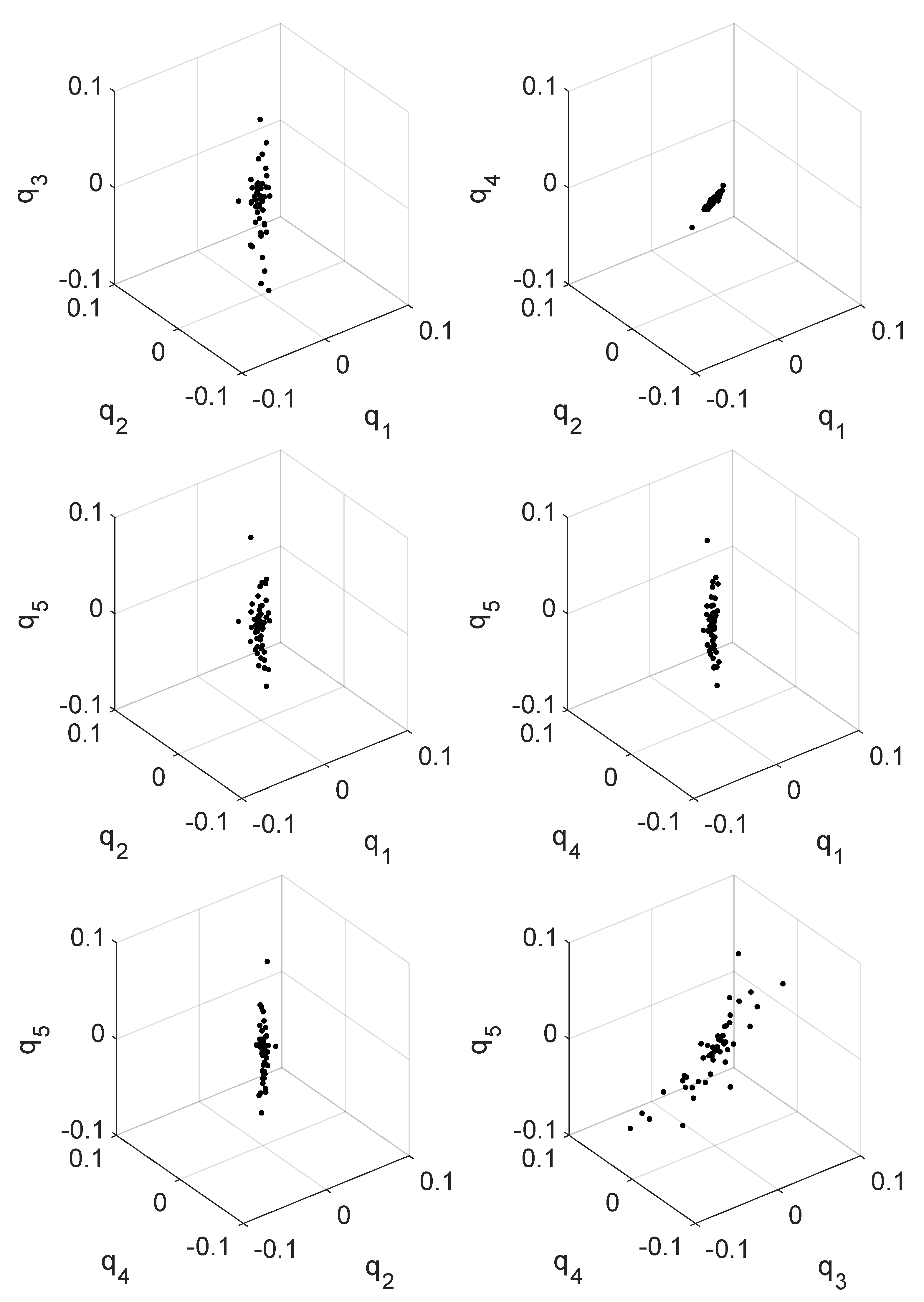

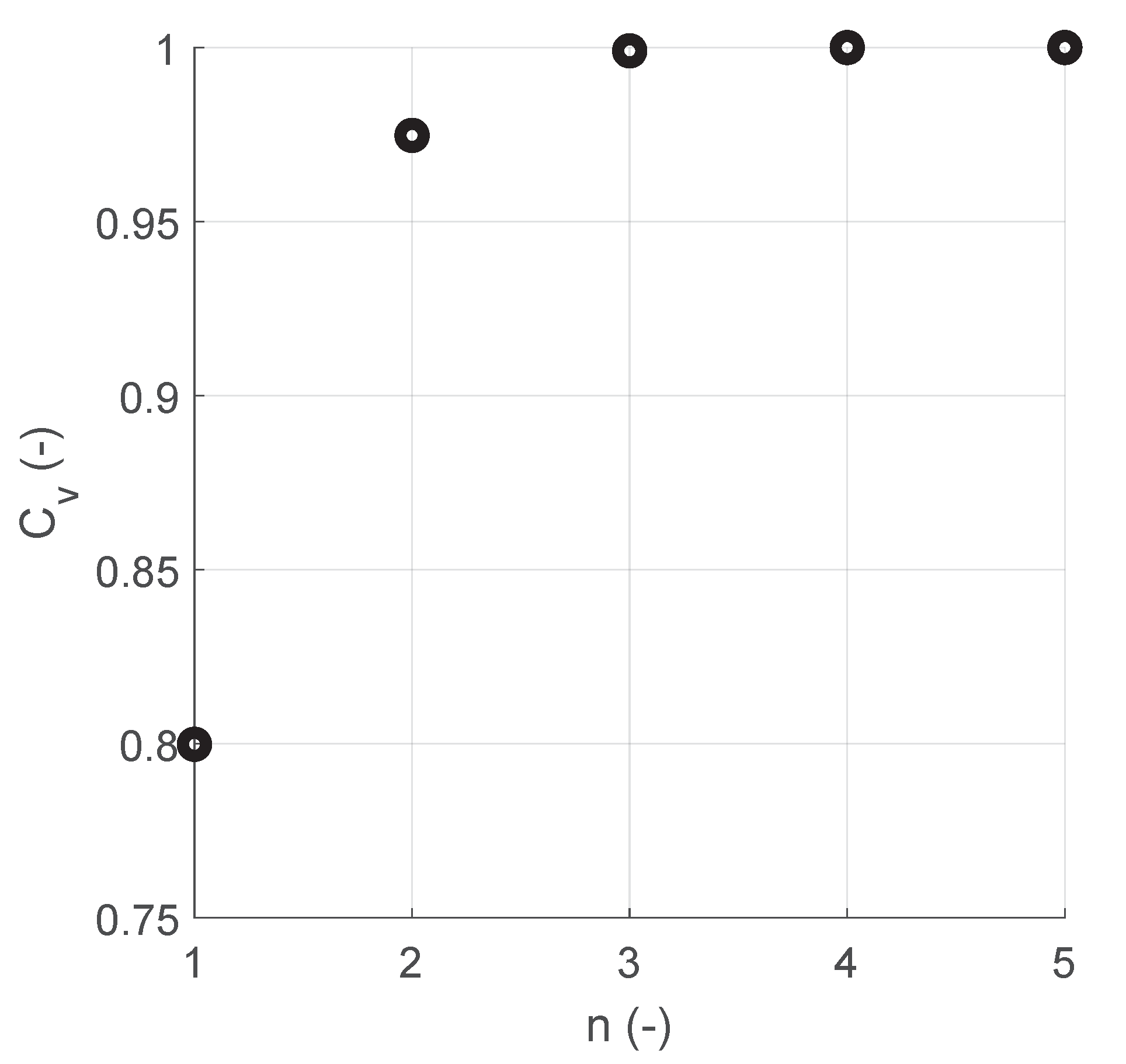

5.2. Finding MPs

6. Numerical Experiments

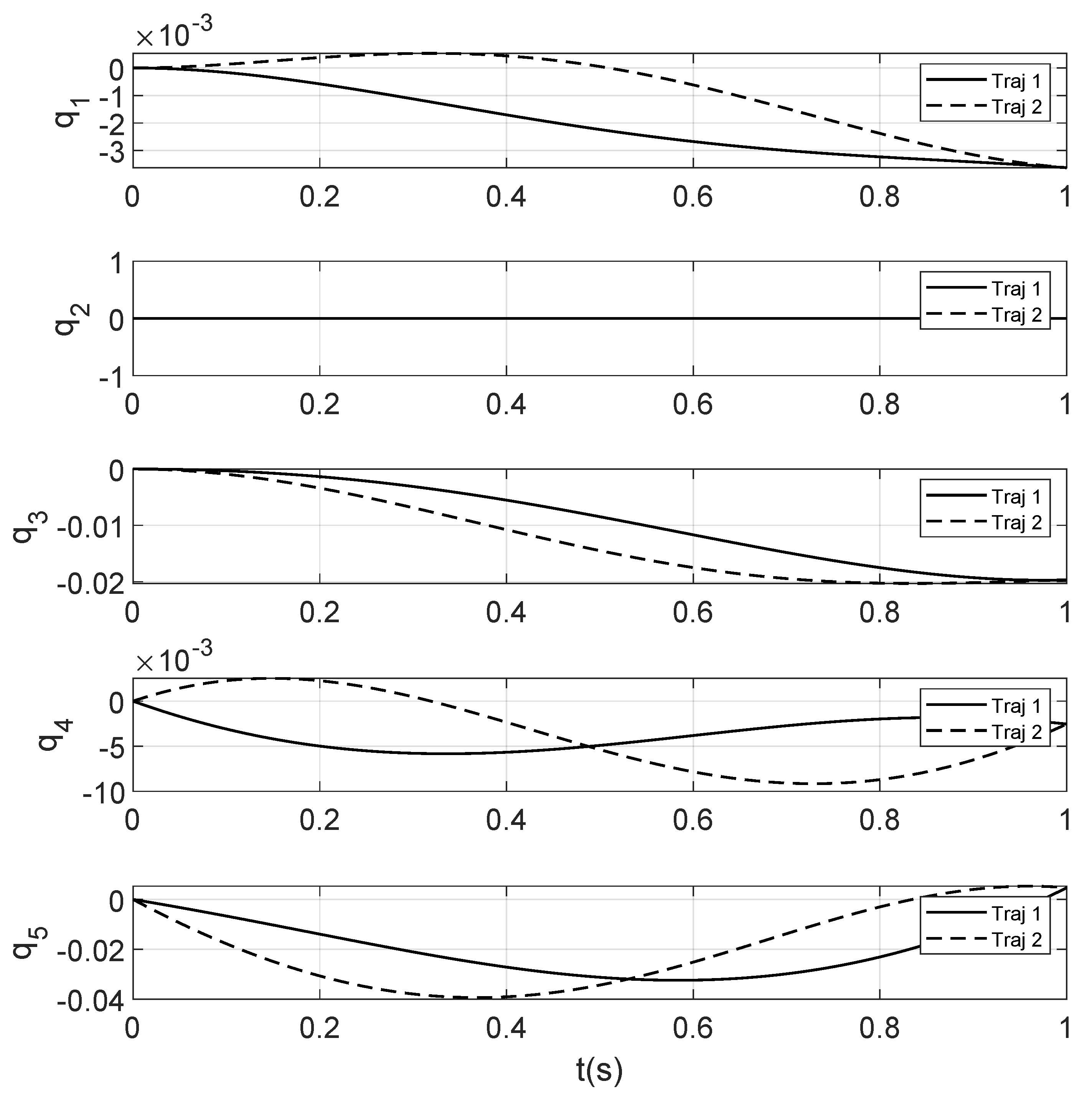

6.1. Rolling Disc—Nilpotent Approximation with Drift

6.2. Rolling Disc—Approximation Based on Taylor Linearisation

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bloch, A.M. Nonholonomic Mechanics and Control; Springer: Cham, Switzerland, 2015; p. 565. [Google Scholar]

- Frolík, S. Note on signature of trident mechanisms with distribution growth vector (4,7). In Lecture Notes in Computer Science (Including Subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics); Springer: Cham, Switzerland, 2019; Volume 11472, pp. 82–89. [Google Scholar]

- Hildenbrand, D.; Hrdina, J.; Návrat, A.; Vašík, P. Local Controllability of Snake Robots Based on CRA, Theory and Practice. Adv. Appl. Clifford Algebras 2020, 30. [Google Scholar] [CrossRef]

- Hrdina, J.; Zalabová, L. Local geometric control of a certain mechanism with the growth vector (4,7). J. Dyn. Control Syst. 2020, 26, 199–216. [Google Scholar] [CrossRef] [Green Version]

- Hrdina, J.; Vašík, P.; Návrat, A.; Matoušek, R. Geometric Control of the Trident Snake Robot Based on CGA. Adv. Appl. Clifford Algebras 2017, 27, 633–645. [Google Scholar] [CrossRef]

- Hrdina, J.; Vašík, P.; Návrat, A.; Matoušek, R. CGA-based robotic snake control. Adv. Appl. Clifford Algebras 2016, 27, 621–632. [Google Scholar] [CrossRef]

- Hůlka, T.; Matoušek, R.; Dobrovský, L.; Dosoudilová, M. Optimization of snake-like robot locomotion using GA: Serpenoid design. Mendel 2020, 26, 1–6. [Google Scholar] [CrossRef]

- Návrat, A.; Vašík, P. On geometric control models of a robotic snake. Note Mat. 2017, 37, 119–129. [Google Scholar]

- Jurdjevic, V.; Sussmann, H.J. Control systems on Lie groups. J. Differ. Equ. 1972, 12, 313–329. [Google Scholar] [CrossRef] [Green Version]

- Agrachev, A.A.; Sachkov, Y.L. Control Theory from the Geometric Viewpoint. Encyclopaedia of Mathematical Sciences, Control Theory and Optimization; Springer: Cham, Switzerland, 2006. [Google Scholar]

- Agrachev, A.A.; Barilari, D.; Boscain, U. A Comprehensive Introduction to Sub-Riemannian Geometry; Cambridge Studies in Advanced Mathematics; Cambridge University Press: Cambridge, UK, 2019. [Google Scholar]

- Bellaïche, A.; Risler, J.J. Sub-Reimannian Geometry; Birkhäuser: Basel, Switzerland, 1996; ISBN 3034899468. [Google Scholar]

- Jean, F. Control of Nonholonomic Systems: From Sub-Riemannian Geometry to Motion Planning; Springer: New York, NY, USA, 2014; ISBN 9783319086897. [Google Scholar]

- Frolík, S.; Rajchl, M.; Stodola, M. Numerical Experiment on Optimal Control for the Dubins Car Model. In Modelling and Simulation for Autonomous Systems; Mazal, J., Fagiolini, A., Vasik, P., Turi, M., Eds.; MESAS 2020. Lecture Notes in Computer Science; Springer: Cham, Switzerland, 2021; Volume 12619. [Google Scholar] [CrossRef]

- Sachkov, Y.L.; Moiseev, I. Maxwell strata in sub-Riemannian problem on the group of motions of a plane. ESAIM Control Optim. Calc. Var. 2010, 16, 380–399. [Google Scholar] [CrossRef]

- Hrdina, J.; Návrat, A.; Zalabová, L. Symmetries in geometric control theory using Maple. Math. Comput. Simul. 2021, 190, 474–493. [Google Scholar] [CrossRef]

- Rizzi, L.; Serres, U. On the cut locus of free, step two Carnot groups. Proc. Am. Math. Soc. 2017, 145, 5341–5357. [Google Scholar] [CrossRef]

- Monroy-Pérez, F.; Anzaldo-Meneses, A. Optimal Control on the Heisenberg Group. J. Dyn. Control. Syst. 1999, 5, 473–499. [Google Scholar] [CrossRef]

- Bucolo, M.; Buscarino, A.; Famoso, C.; Fortuna, L.; Frasca, M. Control of imperfect dynamical systems. Nonlinear Dyn. 2019, 98, 2989–2999. [Google Scholar] [CrossRef]

- Najman, J.; Brablc, M.; Rajchl, M.; Bastl, M.; Spáčil, T.; Appel, M. Monte Carlo Based Detection of Parameter Correlation in Simulation Models. In Mechatronics 2019: Recent Advances towards Industry 4.0; Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2020; ISBN 978-3-030-29992-7. [Google Scholar] [CrossRef]

- Rubes, O.; Brablc, M.; Hadas, Z. Nonlinear vibration energy harvester: Design and oscillating stability analyses. Mech. Syst. Signal Process. 2019, 125, 170–184. [Google Scholar] [CrossRef]

- Bloch, E.D. A First Course in Geometric Topology and Differential Geometry; Birkhauser: Boston, MA, USA, 1997; ISBN 3764338407. [Google Scholar]

- Hrdina, J.; Vašík, P. Notes on differential kinematics in conformal geometric algebra approach. In Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2015; Volume 378, pp. 363–374. [Google Scholar] [CrossRef]

- Štefek, A.; Pham, V.T.; Křivánek, V.; Pham, K.L. Energy comparison of controllers used for a differential drive wheeled mobile robot. IEEE Access 2020, 8, 170915–170927. [Google Scholar] [CrossRef]

- Dubins, L.E. On curves of minimal Length with a constraint on average curvature, and with prescribed initial and terminal positions and tangents. Am. J. Math. 1957, 79, 497–516. [Google Scholar] [CrossRef]

- Ascher, U.M.; Petzold, L.R. Computer Methods for Ordinary Differential Equations and Differential-Algebraic Equations; Society for Industrial and Applied Mathematics: Philadelphia, PA, USA, 1998; ISBN 978-0-89871-412-8. [Google Scholar]

- Press, W.H.; Teukolsky, S.A.; Vetterling, W.T.; Flannery, B.P. Section 18.1. The Shooting Method. In Numerical Recipes: The Art of Scientific Computing, 3rd ed.; Cambridge University Press: New York, NY, USA, 2007; ISBN 978-0-521-88068-8. [Google Scholar]

- Boyd, S.; Vandenberghe, L. Convex Optimization; Cambridge University Press: Cambridge, UK, 2004. [Google Scholar]

- MathWorks, Constrained Nonlinear Optimization Algorithms. Available online: https://www.mathworks.com/help/optim/ug/constrained-nonlinear-optimization-algorithms.html (accessed on 13 March 2021).

- Jolliffe, I.T. Principal Component Analysis; Springer Series in Statistics; Springer: New York, NY, USA, 2002; ISBN 978-0-387-95442-4. [Google Scholar] [CrossRef]

| 0 | 0 | ||

| 0 | |||

| 0 | 0 |

| 0 | 0 | 0 | 0 | |||||

| 0 | 0 | 0 | 0 | 0 | 0 | |||

| 0 | 0 | 0 | 0 | 0 | 0 | |||

| 0 | 0 | 0 | 0 | 0 | 0 | |||

| 0 | 0 | 0 | 0 | 0 | 0 | |||

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 0 | 0 | 0 | |||

| 0 | 0 | 0 | 0 | 0 | |

| 0 | 0 | 0 | 0 | ||

| 0 | 0 | 0 | 0 | ||

| 0 | 0 | 0 | 0 | 0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stodola, M.; Rajchl, M.; Brablc, M.; Frolík, S.; Křivánek, V. Maxwell Points of Dynamical Control Systems Based on Vertical Rolling Disc—Numerical Solutions. Robotics 2021, 10, 88. https://doi.org/10.3390/robotics10030088

Stodola M, Rajchl M, Brablc M, Frolík S, Křivánek V. Maxwell Points of Dynamical Control Systems Based on Vertical Rolling Disc—Numerical Solutions. Robotics. 2021; 10(3):88. https://doi.org/10.3390/robotics10030088

Chicago/Turabian StyleStodola, Marek, Matej Rajchl, Martin Brablc, Stanislav Frolík, and Václav Křivánek. 2021. "Maxwell Points of Dynamical Control Systems Based on Vertical Rolling Disc—Numerical Solutions" Robotics 10, no. 3: 88. https://doi.org/10.3390/robotics10030088

APA StyleStodola, M., Rajchl, M., Brablc, M., Frolík, S., & Křivánek, V. (2021). Maxwell Points of Dynamical Control Systems Based on Vertical Rolling Disc—Numerical Solutions. Robotics, 10(3), 88. https://doi.org/10.3390/robotics10030088