Assessment of the Competitiveness and Effectiveness of an Open Business Model in the Industry 4.0 Environment

Abstract

:1. Introduction

2. Literature Review

2.1. The Open Business Model of the Industry 4.0 Era

- Interoperability—the creation of communication standards between businesses, cyber–physical systems and human teams;

- Virtualization—creating virtual work/collaboration/cooperation models and simulation models;

- Decentralization—devolving manufacturing decisions to intelligent products, with full electronic traceability throughout the value chain;

- Real-time decision-making capability—access to all key process information automatically, based on data collected from machines and equipment;

- Service orientation—opening the use of assets (factory, technology, human teams) for service use in other factories, as well as for servitization;

- Orientation to personalization of production—providing the customer with the product maximally adapted to their needs;

- Orientation to servitization—increasing the proportion of services in the enterprise’s portfolio;

- Orientation on sustainable production—production connected with the concept of limiting the use of resources and the environmental impact of the product, from its design to the end of its life.

- Pushing the boundaries of existing business models;

- Extending the bottom-up framework of the modern business model;

- Cultivating the front neighborhood of the modern business model;

- Cultivating the back neighborhood of the new business model. Existing companies can implement open innovation into the modern business model by cultivating the neighborhood and value of change. The important actors in this concept are engineers, technology, customers and social entrepreneurs [21].

2.2. Balanced Scorecard (BSC)

- refining the vision and strategy;

- clarification of strategic objectives and metrics and their integration into management systems;

- planning, setting objectives and undertaking strategic initiatives;

- improving the organization’s monitoring, strategy execution and learning systems.

- Financial perspective—How should we be perceived by shareholders to be considered financially successful?

- Development perspective—How to maintain the ability to change and improve efficiency in order to achieve our vision?

- Internal processes perspective—What internal processes do we need to improve to keep the owners and customers of the company happy?

- Customer perspective—How should customers perceive us so that we achieve our vision?

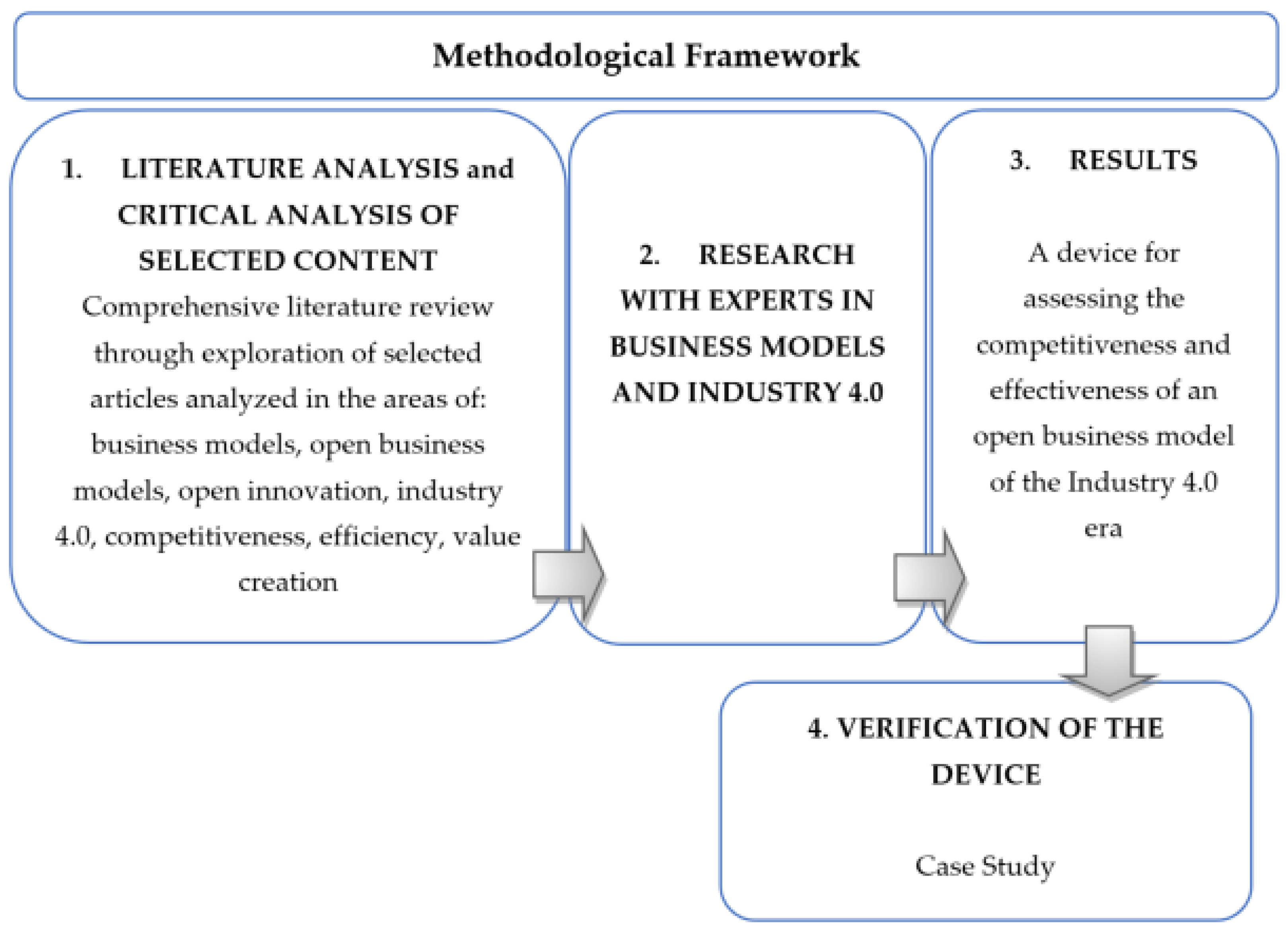

3. Materials and Methods

4. Results and Case Study

4.1. Results

- organizational perspective,

- business process perspective,

- technical architecture process perspective,

- knowledge and learning perspective.

4.2. Case Study

5. Discussion

- Collaboration and projects—collaboration between people, teams and partners inside and outside the company. It is defined by how projects are managed, how interdisciplinary teams are formed and how partners work together to achieve common goals. Teams build a shared knowledge base that allows lessons to be learned for all teams in the future for continuous improvement. Teams can be formed in a flexible and agile way to solve problems as they arise. Risk, responsibility and rewards are shared [64,65].

- Strategy—involves identifying priorities, developing a system of rules, practices and processes to transform vision into business value. A long-term strategy and an appropriately aligned business model should be implemented in all areas of the company and remain constantly evolving, taking into account changes in the latest trends in technology, management and consumer preferences.

- Leadership—leadership competencies refer to the readiness of the management to use the potential of the latest management trends and technological solutions in order to maintain the competitiveness and effectiveness of the company’s business model [39]. Management should have an established knowledge of the latest solutions, be able to implement them on their own in key business areas, and in complementary areas, use an integrated network with external partners [66]. Such cooperation is enabled by an open business model that absorbs open innovations [29].

- Networking—the company is capable of building cyber–physical networks, sharing knowledge, competencies, spare capacity but also risks with network partners during joint production and/or service projects [64].

- Internal integration—vertical integration of processes within the company. All data should be comprehensively integrated with related digital tools and systems. Their real-time analysis will allow autonomous decision making by systems (which are the pillars of Industry 4.0) [23]. The processes inside the company and the IT systems connected to them will be comprehensively integrated and automated. All systems will be able to actively analyze data in real time and make autonomous decisions based on them, which will enable the optimization of processes integrated with them [26].

- Integration with the environment—horizontal integration of processes across the company and across the value chain. Data will be comprehensively integrated with related digital tools and systems, and real-time analytics will allow systems to make autonomous decisions. Supply chain processes and related IT systems will be comprehensively integrated and automated. The systems will be able to proactively analyze data in real time and make autonomous decisions based on those data to optimize their integrated processes [65,66].

- Product life cycle integration—an integrated product life cycle will involve the integration of people, processes and systems across the entire product life cycle, spanning the design and development, engineering, manufacturing, customer service, service and sales stages. Data will be comprehensively integrated with related digital tools and systems, and real-time analytics will allow systems to make autonomous decisions. Product life cycle management processes and related information systems will be comprehensively integrated and automated [67]. The systems will be able to actively analyze data in real time and make autonomous decisions based on them, allowing for optimization of the integrated processes [68].

- Standardization of technology purchasing—total cost of ownership (TCO) over the life cycle of the investment will be a key bidding criterion for companies. Machines and technologies will be selected in tenders where total cost of ownership (TCO) over the planned technology life cycle will be a key consideration. The purchase specification will include requirements for open communication interfaces of the machines, allowing for real-time data reading [1]. The machine will immediately become part of the industrial Internet of Things infrastructure when installed in the plant [2].

- Energy efficiency standardization and optimization—the company will use machine-learning algorithms to support energy cost optimization and recommend changes [52].

- Cooperation with the customer—in the open business model of the Industry 4.0 era, cooperation with the customer takes on the dimension of a partnership and requires deep communication, interaction and personalization of communication [69]. As part of the cooperation with the company, the customer has the opportunity to personalize the product and to co-create it from the very beginning of its creation. Co-creation and communication will be possible through the use of digital tools and channels. Communication with customers will take place through online and offline channels and will be personalized and automated [70].

- Product personalization—will be achieved through online configurators. The customer will be involved in co-creating the product by providing information and guidance for product development and new product design [71]. Digital technological solutions and the adopted competitive strategy will enable customer involvement in product co-creation through dialog, active provision of guidance for its development and design of new products and testing of prototypes [72,73].

- Process automation—in the scope of production, together with internal logistics, it will be characterized by implementation of technologies for monitoring, controlling and automation of production processes. The processes will be fully automated, flexible, not requiring the intervention of employees. This will enable collaboration and dynamic interactions within highly autonomous networks (between departments and between partners). Automation within the administration and management of the company will be characterized by the implementation of technology for monitoring and control, and automation of administrative processes of the company, e.g., product sales, demand planning, marketing, order processing, human resources planning and management. Automation within the building infrastructure will be characterized by the implementation of technology to monitor, control and automate processes inside buildings and rooms where production takes place, e.g., management of heat, ventilation and air conditioning (HVAC), chillers, refrigeration, security and lighting systems [63].

- Connectivity in the area of production execution and internal logistics will be characterized by connectivity, ability to communicate and freely exchange data between devices, machines and computer systems [3]. Systems and equipment will be secured, able to interact in real time and to be quickly and easily reconfigured. Information exchange and interactions within the network will be conducted in real time, while maintaining data security. There will be the ability to quickly and easily reconfigure the network to accommodate any modifications, enabling scalability [7].

- Smart technologies—will be used to process and analyze data to optimize existing manufacturing processes and create new smart systems. Applied IT systems will be able to predict and diagnose potential deviations and make autonomous and intelligent decisions to optimize productivity and resource efficiency. Systems will make autonomous decisions to optimize productivity and resource efficiency [24].

- A smart product—the vision of a smart product in the open business model of the Industry 4.0 era is characterized by the ability to make autonomous, intelligent decisions based on real-time data from sensors embedded in the product. It will also have its digital counterpart, the so-called digital twin, enabling simulation of processes using the product [25].

- Employee satisfaction—job satisfaction is a priority of the social architecture area of the open business model of the Industry 4.0 era, which seeks to provide employees with a work–life balance. It is an indispensable element to achieving high performance by an enterprise [28].

- Staff qualifications—a number of employees with specialist education, including engineering/technical education. The level of staff qualifications reflects the level of knowledge of the company, affecting its competitiveness and attractiveness from the point of view of the customer and business partners [74,75].

- Talent—talent management will be a set of activities aimed at finding, recruiting, developing, valuing and empowering individuals with above-average intellectual skills, as well as being aimed at the effective use of these abilities by the company for the implementation of its strategy [28].

- Employee competence management—a system of training aimed at improving the skills of employees. The company will acquire well-trained professional staff and will thus increase the effectiveness and efficiency of their work and their profits. Training will make the staff increase their ingenuity, innovation, gain a new perspective on the tasks performed routinely [29].

- Innovativeness of employees—indicates the creativity of employees. It will allow the company to achieve success on the market and strive for progress by stimulating and supporting creative and active employees. Innovativeness increases company’s competitive advantages and abilities, thanks to the need for constant observation of competitors’ actions and customers’ reactions, as well as the necessity for permanent implementation of novelties [28,32].

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hermann, M.; Pentek, T.; Otto, B. Design Principles for Industrie 4.0 Scenarios, A Literature Review; Working Paper; Technische Universität: Dortmund, Germany, 2015. [Google Scholar]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inf. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Beier, G.; Ullrich, A.; Niehoff, S.; Reißig, M.; Habich, M. Industry 4.0: How it is defined from a sociotechnical perspective and how much sustainability it includes—A literature review. J. Clean. Prod. 2020, 259, 120856. [Google Scholar] [CrossRef]

- Birkel, H.; Veile, J.W.; Müller, J.M.; Hartmann, E.; Voigt, K.-I. Development of a Risk Framework for Industry 4.0 in the Context of Sustainability for Established Manufacturers. Sustainability 2019, 11, 384. [Google Scholar] [CrossRef] [Green Version]

- Kagermann, H. Industrie 4.0: Mit dem Internet der Dinge auf dem Weg zur 4. Industriellen Revolution. In Proceedings of the VDI-Nachrichten, Berlin, Germany, 1 April 2011. [Google Scholar]

- Kagermann, H.; Helbig, J.; Hellinger, A.; Wahlster, W. Recommendations for Implementing the Strategic Initiative Industry 4.0: Securing the Future of German Manufacturing Industry. Final Report of the Industry 4.0 Working Group. Forschungsunion 2013. Available online: http://www.acatech.de/fileadmin/user_upload/Baumstruktur_nach_Website/Acatech/root/de/Material_fuer_Sonderseiten/Industrie_4.0/Final_reportIndustrie_4.0_accessible.pdf (accessed on 6 February 2021).

- Azmi, A.N.; Kamin, Y.; Noordin, M.K.; Nasir, A.N.M. Towards industrial revolution 4.0: ‘employers’ expectations on fresh engineering graduates. Int. J. Eng. Technol. 2018, 7, 267–272. [Google Scholar]

- Bauernhansl, T.; Hompel, M.; Vogel-Henser, B. Industrie 4.0 in Produkten. Automatisierung und Logistik; Springer: Fachmedien/Wiesbaden, Germany, 2014. [Google Scholar]

- Berger, R. The Industrie 4.0 Transition Quantified. In How the Fourth Industrial Revolution Is Reshuffling the Economic, Social and Industrial Model; Roland Berger: Munich, Germany, 2016. [Google Scholar]

- Grabowska, S. Business model metallurgical company built on the competitive advantage. In Proceedings of the 25th International Conference on Metallurgy and Materials, METAL 2016, Brno, Czech Republic, 25–27 May 2016; pp. 1800–1807. [Google Scholar]

- Schneider, S.; Spieth, P. Business model innovation: Towards an integrated future research agenda. Int. J. Innov. Manag. 2013, 17, 1340001. [Google Scholar] [CrossRef]

- Teece, D.J. Business models, business strategy and innovation. Long Range Plan. 2010, 43, 172–194. [Google Scholar] [CrossRef]

- Wirtz, B.W.; Pistoia, A.; Ullrich, S.; Gottel, V. Business model innovation: Development, concept and future research directions. J. Bus. Models 2016, 4, 1–28. [Google Scholar]

- Zott, C.; Amit, R. The business model: A theoretically anchored robust construct for strategic analysis. Strateg. Organ. 2013, 11, 403–411. [Google Scholar] [CrossRef] [Green Version]

- Stewart, A.C.; Carpenter-Hubin, J. The balanced scorecard. Plan. High. Educ. 2001, 29, 37–42. [Google Scholar]

- Kaplan, R.S.; Norton, D.P. Balanced scorecard. In Das Summa Summarum des Management; Springer Gabler: Wiesbaden, Germany, 2007; pp. 137–148. [Google Scholar]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Olsen, T.L.; Tomlin, B. Industry 4.0: Opportunities and challenges for operations management. Manuf. Serv. Oper. Manag. 2020, 22, 113–122. [Google Scholar] [CrossRef]

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: State of the art and future trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef] [Green Version]

- Lele, A. Industry 4.0. In Disruptive Technologies for the Militaries and Security; Springer: Singapore, 2019; pp. 205–215. [Google Scholar]

- Yun, J.J.; Zhao, X. Business Model Innovation through a Rectangular Compass: From the Perspective of Open Innovation with Mechanism Design. J. Open Innov. Technol. Mark. Complex. 2020, 6, 131. [Google Scholar] [CrossRef]

- Arnold, C.; Kiel, D.; Voigt, K.I. How industry 4.0 changes business models in different manufacturing industries. In Proceedings of the International Society for Professional Innovation Management (ISPIM), Boston, MA, USA, 13–16 March 2016; p. 1. [Google Scholar]

- Pilloni, V. How Data Will Transform Industrial Processes: Crowdsensing, Crowdsourcing and Big Data as Pillars of Industry 4.0. Future Internet 2018, 10, 24. [Google Scholar] [CrossRef] [Green Version]

- Strozzi, F.; Colicchia, C.; Creazza, A.; Noè, C. Literature review on the ‘Smart Factory’ concept using bibliometric tools. Int. J. Prod. Res. 2017, 55, 6572–6591. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing Smart Factory of Industrie 4.0: An Outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 3159805. [Google Scholar] [CrossRef] [Green Version]

- Müller, J.M.; Kiel, D.; Voigt, K.-I. What Drives the Implementation of Industry 4.0? The Role of Opportunities and Challenges in the Context of Sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef] [Green Version]

- Müller, J.M.; Buliga, O.; Voigt, K.I. Fortune favors the prepared: How SMEs approach business model innovations in Industry 4.0. Technol. Forecast. Soc. Chang. 2018, 132, 2–17. [Google Scholar] [CrossRef]

- Dobrowolska, M.; Knop, L. Fit to Work in the Business Models of the Industry 4.0 Age. Sustainability 2020, 12, 4854. [Google Scholar] [CrossRef]

- Bawany, S. The Future of Leadership in the Fourth Industrial Revolution. 2017. Available online: https://strategicleaders.com/future-leadership-fourth-industrial-revolution/ (accessed on 12 February 2022).

- Weking, J.; Stocker, M.; Kowalkiewicz, M.; Bohm, M.; Krcmar, H. Archetypes for industry 4.0 business model innovations. In Proceedings of the 24th Americas Conference on Information Systems (AMCIS), New Orleans, LA, USA, 16 August 2018; Bush, A., Grover, V., Schiller, S., Eds.; Association for Information Systems (AIS): Atlanta, GA, USA, 2018; pp. 1–10. [Google Scholar]

- Śledziewska, K.; Włoch, R. Jakich kompetencji wymaga rewolucja przemysłowa 4.0? Pomor. Prz. Gospod. 2020, 2, 1–4. [Google Scholar]

- Hu, B.; Zhang, T.; Yan, S. How Corporate Social Responsibility Influences Business Model Innovation: The Mediating Role of Organizational Legitimacy. Sustainability 2020, 12, 2667. [Google Scholar] [CrossRef] [Green Version]

- Brzóska, J. Model biznesowy–współczesna forma organizacyjnego zarza˛dzania przedsie˛biorstwem; Kwartalnik Naukowy Organizacja i Zarza˛dzanie: Gliwice, Poland, 2009; Volume 2, pp. 5–23. [Google Scholar]

- DaSilva, C.M.; Trkman, P. Business model: What it is and what it is not. Long Range Plan. 2004, 47, 379–389. [Google Scholar] [CrossRef]

- Magretta, J. Why Business Models Matter? 2002. Available online: https://hbr.org/2002/05/why-business-models-matter (accessed on 3 February 2022).

- Prahalad, C.K.; Krishnan, M.S. New Age of Innovation; Mc Graw Hill: New York, NY, USA, 2010. [Google Scholar]

- Frank, A.G.; Mendes, G.H.; Ayala, N.F.; Ghezzi, A. Servitization and Industry 4.0 convergence in the digital transformation of product firms: A business model innovation perspective. Technol. Forecast. Soc. Chang. 2019, 141, 341–351. [Google Scholar] [CrossRef]

- Afuah, A. Business Models: A Strategic Management Approach; McGraw-Hill Irwin: New York, NY, USA, 2004. [Google Scholar]

- Moradi, E.; Jafari, S.M.; Doorbash, Z.M.; Mirzaei, A. Impact of organizational inertia on business model innovation, open innovation and corporate performance. Asia Pac. Manag. Rev. 2021, 26, 171–179. [Google Scholar] [CrossRef]

- Kaplan, R.S.; Norton, P.D. The Balanced Scorecard–Measures That Drive Performance. 1992. Available online: https://hbr.org/1992/01/the-balanced-scorecard-measures-that-drive-performance-2 (accessed on 12 February 2022).

- Kaplan, R.S.; Norton, P.D. Putting the Balanced Scorecard to Work. Available online: https://hbr.org/1993/09/putting-the-balanced-scorecard-to-work?cm_sp=Article-_-Links-_-Comment (accessed on 12 February 2022).

- Kaplan, R.S.; Norton, P.D. Balanced Scorecard: Translating Strategy into Action; Harvard Business School Press: Boston, MA, USA, 1996. [Google Scholar]

- Kaplan, R.S.; Norton, P.D. Norton: Strategy Maps: Converting Intangible Assets into Tangible Outcomes; Harvard Business School Press: Boston, MA, USA, 2004. [Google Scholar]

- Hansen, E.G.; Schaltegger, S. The Sustainability Balanced Scorecard: A Systematic Review of Architectures. J. Bus. Ethics 2016, 133, 193–221. [Google Scholar] [CrossRef]

- Cabrita, M.R.; Machado, V.C.; Grilo, A. Leveraging knowledge management with the balanced scorecard. In Proceedings of the IEEM2010—IEEE International Conference on Industrial Engineering and Engineering Management, Macao, China, 7–10 December 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 1066–1071. [Google Scholar]

- Zhou, S.S.; Zhou, A.J.; Feng, J.; Jiang, S. Dynamic capabilities and organizational performance: The mediating role of innovation. J. Manag. Organ. 2019, 25, 731–747. [Google Scholar] [CrossRef] [Green Version]

- Silva, R.; Oliveira, C. The Influence of Innovation in Tangible and Intangible Resource Allocation: A Qualitative Multi Case Study. Sustainability 2020, 12, 4989. [Google Scholar] [CrossRef]

- García-Valderrama, T.; Mulero-Mendigorri, E.; Revuelta-Bordoy, D. A Balanced Scorecard framework for R&D. Eur. J. Innov. Manag. 2008, 11, 241–281. [Google Scholar]

- Poll, R. Performance, Processes and Costs: Managing Service Quality with the Balanced Scorecard. Libr. Trends 2001, 49, 709–717. [Google Scholar]

- Lesáková, Ľ.; Dubcová, K. Knowledge and Use of the Balanced Scorecard Method in the Businesses in the Slovak Republic. Procedia Soc. Behav. Sci. 2016, 230, 39–48. [Google Scholar] [CrossRef] [Green Version]

- Mooraj, S.; Oyon, D.; Hostettler, D. The balanced scorecard: A necessary good or an unnecessary evil? Eur. Manag. J. 1999, 17, 481–491. [Google Scholar] [CrossRef]

- Cooper, D.J.; Ezzamel, M.; Qu, S. Creating and Poularizing a Management Accounting Idea: The Case of the Balanced Scorecard; Alberta School of Business: Edmonton, AB, Canada, 2011; Unpublished Paper. [Google Scholar]

- Frigo, M.L.; Krumwiede, K.R. The balanced scorecard: A winning performance measurement system. Strateg. Financ. 2000, 81, 50–54. [Google Scholar]

- Męczyńska, A. Grupowa Ocena Ekspertów w Procesach Decyzyjnych Zarządzania; Zeszyty Naukowe Politechniki Śląskiej, seria Organizacja i Zarządzanie z. 40; Wydawnictwo Politechniki Śląskiej: Gliwice, Poland, 2007. [Google Scholar]

- Helmer, O. Korzystanie z ocen ekspertów. In Analiza Systemowa-Podstawy i Metodologia; Findeisen, W., Ed.; PWN: Warszawa, Poland, 1985; pp. 235–289. [Google Scholar]

- Męczyńska, A. Metoda heurystyczna-grupowa ocena ekspertów w zastosowaniu do analizy procesów, produktów. In Komputerowo Zintegrowane Zarządzanie; Knosala, R., Ed.; WNT: Warszawa, Poland, 1999; pp. 275–286. [Google Scholar]

- Alling, S.; Knoesen, A. Introduction of Students to Engineering Design Practices of Remote and Distributed Collaboration: Lessons Learnt from COVID-19. Adv. Eng. Educ. 2020, 8, n4. [Google Scholar]

- Orzeł, B.; Wolniak, R. Digitization in the Design and Construction Industry—Remote Work in the Context of Sustainability: A Study from Poland. Sustainability 2022, 14, 1332. [Google Scholar] [CrossRef]

- Riyanti, B.P.D.; Suryani, A.O.; Sandroto, C.W.; Soeharso, S.Y. The construct and predictive validity testing of Indonesian entrepreneurial competence inventory-situational judgment test model. J. Innov. Entrep. 2020, 11. [Google Scholar] [CrossRef]

- Giannnopoulos, G.; Holt, A.; Khansalar, E.; Cleanthous, S. The use of the balanced scorecard in small compa-nies. Int. J. Bus. Manag. 2013, 8, 1–22. [Google Scholar] [CrossRef] [Green Version]

- Gumbus, A.; Lussier, R. Entrepreneurs use a balanced scorecard to translate strategy into performance meas-ures. J. Small Bus. Manag. 2006, 44, 407–425. [Google Scholar] [CrossRef]

- Stalmachova, K.; Chinoracky, R.; Strenitzerova, M. Changes in Business Models Caused by Digital Transformation and the COVID-19 Pandemic and Possibilities of Their Measurement—Case Study. Sustainability 2022, 14, 127. [Google Scholar] [CrossRef]

- Narzędzie Oceny Dojrzałości Cyfrowej. 2009. Available online: https://przemyslprzyszlosci.gov.pl/narzedzie-oceny-dojrzalosci-cyfrowej-firm/ (accessed on 3 February 2022).

- Saniuk, S.; Saniuk, A.; Cagánˇová, D. Cyber Industry Networks as an Environment of the Industry 4.0 Implementation. Wirel. Netw. 2021, 27, 1649–1655. [Google Scholar] [CrossRef] [Green Version]

- Chesbrough, H. Managing open innovation. Res.-Technol. Manag. 2004, 47, 23–26. [Google Scholar] [CrossRef]

- Wang, J.-J.; Chen, H.; Rogers, D.S.; Ellram, L.M.; Grawe, S.J. A bibliometric analysis of reverse logistics research (1992–2015) and opportunities for future research. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 666–687. [Google Scholar] [CrossRef] [Green Version]

- Kaur, R.; Awasthi, A. City logistics: A review and bibliometric analysis. Int. J. Bibliometr. Bus. Manag. 2018, 1, 160–188. [Google Scholar] [CrossRef]

- Grzybowska, K.; Awasthi, A. Literature review on sustainable logistics and sustainable production for Industry 4.0. In Sustainable Logistics and Production in Industry 4.0 New Opportunities and Challenges; Grzybowska, K., Awasthi, A., Sawhney, R., Eds.; Springer: New York, NY, USA, 2020; pp. 1–19. [Google Scholar]

- Saniuk, S.; Grabowska, S. The Concept of Cyber-Physical Networks of Small and Medium Enterprises under Personalized Manufacturing. Energies 2021, 14, 5273. [Google Scholar] [CrossRef]

- Saniuk, S.; Grabowska, S.; Gajdzik, B. Personalization of Products in the Industry 4.0 Concept and Its Impact on Achieving a Higher Level of Sustainable Consumption. Energies 2020, 13, 5895. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, H.-S.; Yang, J.-H.; Wang, K.-S. Industry 4.0: A way from mass customization to mass personalization production. Adv. Manuf. 2017, 5, 311–320. [Google Scholar] [CrossRef]

- Senanayake, M.M.; Little, T.J. Mass customization: Points and extent of apparel customization. J. Fash. Mark. Manag. 2010, 14, 282–299. [Google Scholar] [CrossRef]

- Hu, S.J. Evolving paradigms of manufacturing: From mass production to mass customization and personalization. Procedia CIRP 2013, 7, 3–8. [Google Scholar] [CrossRef] [Green Version]

- Blom, J.; Monk, A. Theory of personalisation of appearance: Why people personalise their mobile phones and PCs. Hum. Comput. Interact. 2003, 18, 193–228. [Google Scholar] [CrossRef]

- Saniuk, S.; Caganova, D.; Saniuk, A. Knowledge and Skills of Industrial Employees and Managerial Staff for the Industry 4.0 Implementation. Mob. Netw. Appl. 2021. [Google Scholar] [CrossRef]

- Salgado, C.; Maciel, R. Exploring a Three-Dimensional, Requirements-Based, Balanced Scorecard Business Model. In Proceedings of the IEEE 17th Conference on Business Informatics, Lisbon, Portugal, 13–16 July 2015. [Google Scholar]

- Soderberg, M.; Kalagnanam, S.; Sheehan, N.T.; Vaidyanathan, G. When is a balanced scorecard a balanced scorecard? Int. J. Product. Perform. Manag. 2011, 60, 688–708. [Google Scholar] [CrossRef]

- Chytas, P.; Glykas, M.; Valiris, G. A proactive balanced scorecard. Int. J. Inf. Manag. 2011, 31, 460–468. [Google Scholar] [CrossRef]

- Chavan, M. The balanced scorecard: A new challenge. J. Manag. Dev. 2009, 28, 393–406. [Google Scholar] [CrossRef] [Green Version]

| Goal | Measure | Size of the Measure during the Measurement Period |

|---|---|---|

| Organizational perspective | ||

| Cooperation and projects | Projects carried out | Number |

| Strategy | Assessment of strategy implementation | Scale 1–5 |

| Employees | Qualitative assessment of employees | Scale 1–5 |

| Leadership | Qualitative assessment of leadership | Scale 1–5 |

| Networking | Execution of projects within cyber–physical networks | Number of completed projects |

| Business process perspective | ||

| Internal process integration | Degree of integration of processes within the enterprise | % |

| Process integration with the environment | Degree of process integration with the environment | % |

| Degree of process integration in the product life cycle | Degree of integration of processes in the product life cycle area | % |

| Service life cycle process integration | Degree of process integration in the service life cycle area | % |

| Standardization of technology purchasing | Degree of standardization of technology purchasing | % |

| Standardization and optimization of energy efficiency | Degree of standardization and optimization of energy efficiency | % |

| Customer cooperation | Degree of customer cooperation | % |

| Product personalization | Range of product personalization | % |

| Personalized products, their number in the company’s offer | Number | |

| Personalization of service | Scope of service personalization | % |

| Personalized services, their number in the company’s offer | Number | |

| A technical architecture process perspective | ||

| Automation | Degree of process automation | % |

| Connectivity | Quantity of data exchange between devices, machines and computer systems | Quantity of data |

| Smart technologies | Number of smart technologies | Number |

| Smart product | Number of smart products | Number |

| Smart service | Number of smart services | Number |

| A knowledge and learning perspective | ||

| Employee satisfaction | Percentage of satisfied employees according to surveys | % |

| Staff qualifications | Percentage of employees who have a degree, license or credential | % |

| Talents | Number of employees covered by talent management program | Number |

| Employee competence management | Training costs per employee | EUR |

| Innovation of employees | Number of reported innovative solutions | Number |

| Elements of the Model | Description |

|---|---|

| Customer value | High-quality products, guarantee of realization of orders in a short time (within Poland—within two working days), wide range of assortment, professional consulting. |

| Social Architecture | |

| Human resources | 71% of employees have a university degree, including 45% in engineering, 26% in economics (mainly trade and finance). |

| Organizational structure | Dominated by a line structure, characterized by process management with elements of a virtual organization (which enables cooperation with a network of over a thousand distributors in 45 countries around the world). |

| Decision-making authority | The decision-making authority is held by those responsible for the implementation of specific processes in the company and those who manage the various departments of the company. |

| Enterprise performance management systems | In the enterprise, all data are stored in the cloud and processed/analyzed by an externally designed system. Significantly increased scope of formalized information and knowledge (training, postgraduate studies, extensive information systems). Information and knowledge acquired individually by employees (broader scope). Less importance of using tacit knowledge. |

| Processes and Activities | |

| Business processes | Production of sausage industry packaging, customer training, purchasing, sales, sausage market marketing, consulting with business partners and customers, HR process, risk management. |

| Type and structure of the value chain | Developed value chain adapted to customer needs—a source of value creation based on professional consulting. |

| Information and knowledge resources | Strong support of business processes by information systems. Intensive development of the use of information resources to build explicit knowledge resources. |

| Achieved competitive advantage and its sources | Advantage in the quality of offered products obtained thanks to implemented pillars of Industry 4.0 and well-trained employees. Advantage due to flexibility of production and reduction in unit costs. Advantage due to localization and e-business. |

| Technical Architecture | |

| ICT resources | Controlling information system, CRM system, production planning and control systems, digitalization of business processes (industrial scanners), automatic identification of customer order fulfillment. |

| Industry 4.0 pillars supporting the use of open innovation | Manufacturing automation (at 45%), systems integration (at 60%), industrial Internet of Things (15%), technologies supporting cyber security, big data, cloud computing. |

| Goal | Measure | Size of the Measure during the Measurement Period | Year I | Year II | Year III |

|---|---|---|---|---|---|

| Organizational perspective | |||||

| Strategy | Assessment of strategy implementation | Scale 1–5 | 3 | 3 | 3 |

| Employees | Qualitative assessment of employees | Scale 1–5 | 3 | 3 | 4 |

| Leadership | Qualitative assessment of leadership | Scale 1–5 | 3 | 3 | 4 |

| Networking | Execution of projects within cyber–physical networks | Number of completed projects | 0 | 5 | 12 |

| Business process perspective | |||||

| Internal process integration | Degree of integration of processes within the enterprise | % | 45% | 60% | 65% |

| Process integration with the environment | Degree of process integration with the environment | % | 5% | 15% | 15% |

| Degree of process integration in the product life cycle | Degree of integration of processes in the product life cycle area | % | 42% | 43% | 44% |

| Standardization and optimization of energy efficiency | Degree of standardization and optimization of energy efficiency | % | 42% | 43% | 44% |

| Customer cooperation | Degree of customer cooperation | % | 46% | 50% | 52% |

| A technical architecture process perspective | |||||

| Automation | Degree of process automation | % | 25% | 45% | 45% |

| Connectivity | Quantity of data exchange between devices, machines and computer systems | Quantity of data | 10 T | 12 T | 13 T |

| Smart technologies | Number of smart technologies | Number | 6 | 7 | 7 |

| A knowledge and learning perspective | |||||

| Staff qualifications | Percentage of employees who have a degree, license or credential | % | 69% | 69% | 71% |

| Talents | Number of employees covered by talent management program | Number | 6 | 7 | 5 |

| Employee competence management | Training costs per employee | EUR | 120 | 120 | 150 |

| Innovation of employees | Number of reported innovative solutions | Number | 21 | 19 | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grabowska, S.; Saniuk, S. Assessment of the Competitiveness and Effectiveness of an Open Business Model in the Industry 4.0 Environment. J. Open Innov. Technol. Mark. Complex. 2022, 8, 57. https://doi.org/10.3390/joitmc8010057

Grabowska S, Saniuk S. Assessment of the Competitiveness and Effectiveness of an Open Business Model in the Industry 4.0 Environment. Journal of Open Innovation: Technology, Market, and Complexity. 2022; 8(1):57. https://doi.org/10.3390/joitmc8010057

Chicago/Turabian StyleGrabowska, Sandra, and Sebastian Saniuk. 2022. "Assessment of the Competitiveness and Effectiveness of an Open Business Model in the Industry 4.0 Environment" Journal of Open Innovation: Technology, Market, and Complexity 8, no. 1: 57. https://doi.org/10.3390/joitmc8010057

APA StyleGrabowska, S., & Saniuk, S. (2022). Assessment of the Competitiveness and Effectiveness of an Open Business Model in the Industry 4.0 Environment. Journal of Open Innovation: Technology, Market, and Complexity, 8(1), 57. https://doi.org/10.3390/joitmc8010057