Abstract

Cleanrooms are widely used in various industries, where the precise control of parameters such as CO2 concentration is crucial for optimal production. Most cleanrooms utilize variable air volume (VAV) air conditioning systems, but existing proportional–integral–derivative (PID) controllers in VAV systems often suffer from long response delays, excessive overshoot, and difficulties in handling dynamic changes in occupant conditions. This study introduces an Improved Crested Porcupine Optimizer (ICPO) to optimize PID controller parameters, aiming to enhance the control of VAV air supply. Additionally, a CO2 concentration control system for cleanrooms was designed based on an STM32 microcontroller. The results demonstrate that the Improved Crested Porcupine Optimizer PID (ICPO-PID) controller outperforms traditional PID, Fuzzy-PID, and Crested Porcupine Optimizer PID (CPO-PID) controllers in control accuracy, response speed, and robustness. In simulation, ICPO-PID achieves a settling time of just 59 s and an overshoot of only 5.14%. In real-world performance evaluations, ICPO-PID outperforms other controllers in terms of the Integral Absolute Error (IAE) and Integral Squared Error (ISE). Furthermore, ICPO-PID reduces energy consumption by approximately 40% during air volume adjustment compared to traditional PID. These results indicate that ICPO-PID is an efficient and reliable solution for maintaining cleanroom environments with precise CO2 concentration control.

1. Introduction

Cleanrooms are critical environments used in high-precision industries, such as semiconductor manufacturing, biotechnology, and pharmaceuticals, where maintaining strict control over environmental parameters is essential for both product quality and personnel health [1,2,3]. Parameters such as air quality, temperature, humidity, and CO2 concentration are all extremely crucial. Among them, the regulation of CO2 concentration is especially significant because it directly affects indoor air quality, the health of workers, and the accuracy of experiments. Excessively high or low CO2 levels can lead to health issues for workers and adversely impact the precision of experiments, making the regulation of CO2 concentration a significant challenge in cleanroom air quality control [4,5,6,7].

Currently, the most widely used systems for regulating indoor air quality in cleanrooms are Variable Air Volume (VAV) air conditioning systems [8,9]. These systems adjust the volume of air supplied to different areas of a cleanroom based on real-time fluctuations in environmental loads, such as changes in temperature, humidity, and CO2 concentration. While these systems are effective in maintaining the desired air quality, controlling CO2 concentration efficiently remains a challenge due to the system’s complexity and varying environmental conditions.

Traditional PID (Proportional–Integral–Derivative) controllers are commonly used in VAV systems for CO2 concentration regulation. However, PID controllers may exhibit slow response times, low control accuracy, and high energy consumption under varying disturbance conditions. Moreover, maintaining a balance between control precision and energy efficiency is a critical concern in VAV air conditioning systems. Although numerous studies have explored the optimization of PID controllers using techniques such as Genetic Algorithms (GAs) [10], Particle Swarm Optimization (PSO) [11], and Firefly Algorithms [12], these methods still face limitations, especially in the real-time control of complex systems like VAV air conditioning. Additionally, there is a lack of practical validation of these optimized controllers on hardware platforms [13,14,15,16].

This research aims to address the shortcomings of traditional PID control in VAV air conditioning systems, particularly in regulating the CO2 concentration. An intelligent CO2 concentration control method based on an improved Crested Porcupine Optimizer (ICPO) algorithm is proposed. The primary objectives of this study are:

- Designing a robust PID control algorithm that enhances the performance of VAV air conditioning systems by optimizing the PID parameters using the ICPO algorithm.

- Improving the response speed and control accuracy of the CO2 concentration regulation while reducing energy consumption.

- Validating the proposed control method through both simulation and experimental tests under varying environmental conditions, demonstrating its practical applicability in cleanroom environments.

The main contributions of this study are as follows:

- The ICPO-PID technique has been proposed for the first time in the PID controller design of a VAV control system, marking the most significant aspect of the originality of this study.

- A mathematical model for indoor CO2 concentration variation has been established, incorporating the control function of the Variable Air Volume (VAV) air conditioning system’s air valve. By constructing the model, the changes in CO2 concentration can be simulated in real time, and the adjustment of the air valve can be analyzed in response to fluctuations in indoor CO2 levels, thereby enhancing the precision and response speed of the air conditioning system.

- A hardware control platform has been developed for real-time CO2 concentration regulation. This platform utilizes CO2 sensors for data collection and integrates cloud-based analysis to optimize system performance.

- The demonstration of the ICPO-PID controller’s effectiveness in improving control precision and energy efficiency in cleanroom air conditioning systems.

The rest of the paper is organized as follows. Section 2 provides an overview of related work in CO2 concentration control in cleanrooms, highlighting existing PID control methods and optimization techniques. Section 3 details the methodology used to develop a VAV air conditioning control system for regulating CO2 concentration, including modeling the system’s CO2 dynamics, designing the VAV air damper control function, and developing a hardware platform for real-time data acquisition and PID control. Section 4 focuses on the improvements made to the Crested Porcupine Optimizer (CPO) algorithm, comparing it with three other intelligent algorithms while evaluating their performance and computational cost. This section also discusses the traditional PID and Fuzzy-PID methods. Section 5 outlines the simulation and experimental setup used to evaluate the proposed method, presenting the results of the performance tests. Finally, Section 6 concludes the paper and suggests directions for future work.

2. Related Work

A VAV terminal unit control method based on the indoor CO2 concentration was proposed in [17], which regulates indoor air quality by controlling the airflow. In recent years, VAV air conditioning systems [18,19,20] have integrated CO2 sensors to assist in regulating fresh air supply by monitoring indoor CO2 concentrations in real time. Previous authors [21] designed a hardware platform incorporating machine vision to intelligently adjust ventilation rates based on the infection risks of occupants. This system automatically adjusts ventilation outputs according to needs, effectively optimizing air quality and enhancing energy efficiency. Other research [22] utilized the differences in CO2 concentration and moisture content between the exhaust and outdoor air to control the airflow of VAV systems in single-family houses, achieving a 23% reduction in thermal energy consumption and a 35% reduction in fan energy usage. Demand-controlled ventilation (DCV) strategies have been widely investigated for their potential to enhance energy efficiency while maintaining indoor air quality. A CO2-based DCV strategy proposed in [23] dynamically adjusts the CO2 concentration in the supply air and regulates airflow by incorporating a PID control loop. This approach allows more precise ventilation tailored to each zone’s requirements, demonstrating significant potential for energy savings. Furthermore, reference [24] introduced a testing method for DCV controllers, assessing the CO2 tracking and damper movement performance of six DCV controllers and a PI controller. Their results showed that the PI controller delivered enhanced performance without requiring parameter adjustments.

Although CO2 demand-controlled ventilation systems have demonstrated energy-saving benefits, the response speed and accuracy of PID controllers under complex conditions still need improvement. To overcome these limitations, researchers have explored nonlinear theories to optimize PID control performance. For instance, ref. [13] developed an online intelligent tuning fuzzy PID controller based on a robust extended Kalman filter, which significantly improved pressure control accuracy. Similarly, ref. [14] designed an intelligent PID controller using Particle Swarm Optimization to fine-tune PID parameters for electro-hydraulic system position controllers, achieving superior performance compared to traditional PID controllers under diverse conditions. In [15], a method combining genetic algorithms and fuzzy PID control was proposed to enhance the stability of temperature regulation in high-precision accelerometers. Additionally, ref. [16] introduced a novel online PID tuning method using a Structured Artificial Neural Network (S-ANN) and propagation matrix, effectively improving control performance. Table 1 summarizes the control strategies, optimization methods, and corresponding results from these studies, highlighting their contributions to specific fields and performance improvements.

Table 1.

Comparison of control strategies and optimization methods in various applications.

In this research, the ICPO algorithm is proposed to optimize the PID parameters in a VAV air conditioning system. The improved ICPO algorithm introduces an average fitness mechanism and a variable neighborhood search to enhance its optimization efficiency and global search ability. This approach significantly improves the performance of PID controllers in CO2 concentration regulation, addressing the shortcomings of traditional PID control methods.

A hardware control platform is constructed and tested under various environmental conditions. The ICPO-PID control is used to adjust the opening degree of the supply air valve of the VAV air conditioning system, so as to change the supply air volume and regulate the indoor air. Moreover, a hardware method for collecting the indoor CO2 concentration and outputting the control voltage of the VAV air valve is proposed. The more complex parts of the software are executed on a separate computer, thus reducing the software load of the Microcontroller Unit (MCU).

3. Materials and Methods

3.1. Modeling of the VAV Air Conditioning System in Cleanrooms

For the purpose of analysis, the cleanroom is modeled as a single-capacity CO2 model, with the air mixing delay ignored. The following assumptions are made:

- The sources of CO2 include the CO2 generated by indoor personnel respiration and the CO2 content in the outdoor fresh air introduced.

- The CO2 concentration generated by indoor personnel respiration is constant, the outdoor CO2 concentration remains relatively stable, and the indoor air is well-mixed.

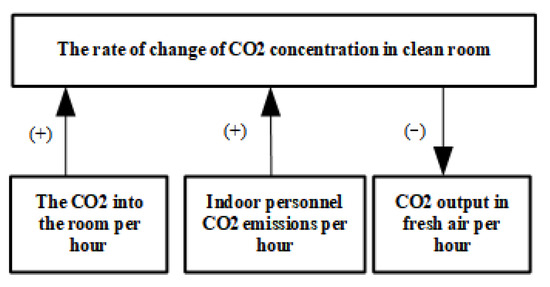

According to the mass balance equation, the change in CO2 concentration within the ultra-clean room is equal to the sum of the CO2 amount in the supplied air and the CO2 generated by indoor personnel respiration, minus the CO2 amount in the exhaust air. The factors influencing the indoor CO2 concentration are illustrated in Figure 1.

Figure 1.

CO2 capacity in a single room.

According to the mass balance formula, the variation in CO2 concentration within the cleanroom can be expressed by:

where represents the actual room volume of the cleanroom, measured at 50 m3; denotes the indoor CO2 concentration, with units of mol/m3; represents the CO2 concentration of the fresh air, also in mol/m3; is the fresh air volume flow rate, measured in m3/s; and is the CO2 emission rate from indoor personnel.

The CO2 concentration in the fresh air is set at 4.5 × 10−4, and the CO2 emission rate per person in the room is 5.5 × 10−6 m3/s. Substituting the relevant parameters into the mass balance equation results in:

As shown in Equation (2), it is assumed that the indoor air is uniformly mixed, the activities of the occupants are consistent, and the CO2 variation rate remains steady.

3.2. Modeling of the Air Supply Valve

The VAV air conditioning system is a high-order system with a relatively complex model. To simplify the analysis, a first-order inertia element with a time delay is selected to approximate the dynamic characteristics of the air supply system. The least squares method is employed to process the data of the VAV air conditioning damper position and the corresponding output airflow, yielding the transfer function of the fresh air damper:

In Equation (3), = 3.6, = 10.1, and = 3.

3.3. Integration of the Air Supply Valve Model with CO2 Concentration Model

According to Equation (2), the airflow rate is used as the input, and the variation of the indoor CO2 concentration is the output. After applying the Laplace transform, the transfer function for indoor CO2 concentration can be obtained as follows:

In Equation (4), = 9, = 1.2.

To establish a unified control system, the air supply valve model is integrated with the CO2 concentration model. The dynamics of the CO2 concentration are primarily influenced by the airflow, which is regulated by the air supply valve. The transfer function can be expressed as the product of the individual transfer functions and , as shown in Equation (5):

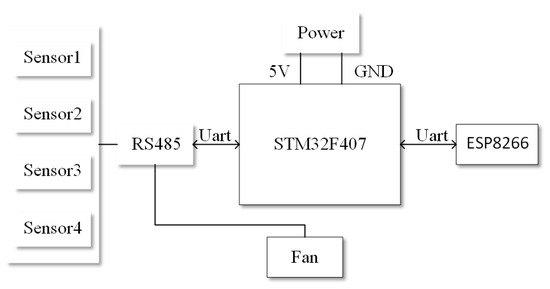

3.4. Design of the Hardware Platform

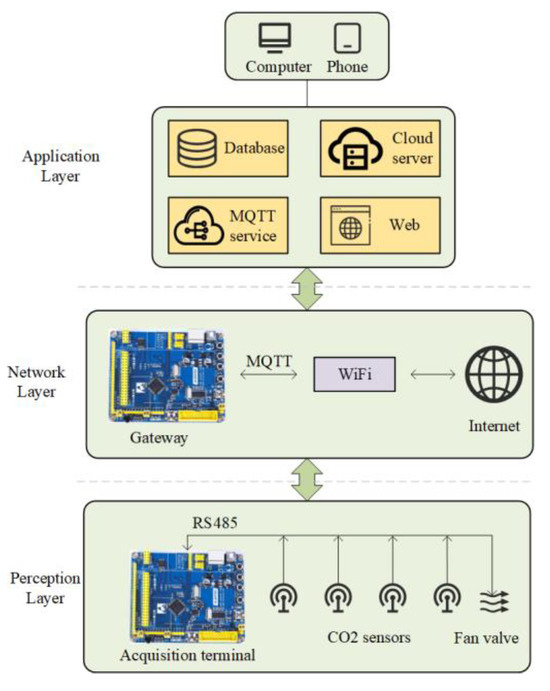

The design of the acquisition system’s hardware is based on a three-layer IoT architecture, enabling the system to meet the requirements for CO2 concentration data acquisition, analysis, transmission, and real-time monitoring. The overall architecture of the acquisition system is shown in Figure 2.

Figure 2.

Overall framework of the VAV control system.

The Perception Layer is responsible for the real-time acquisition and preprocessing of indoor and outdoor CO2 concentration data, providing essential support for subsequent control and optimization. The system uses an indoor CO2 sensor to continuously measure the current CO2 concentration, with the data transmitted via an RS485 interface to the core control unit, the STM32F407ZET6 microcontroller. The STM32 processes the received data and uses the measured CO2 concentration as feedback, comparing it with the target CO2 concentration (reference value) to provide input for the PID control algorithm.

The Transmission Layer ensures efficient and reliable data transfer while optimizing control parameters via the cloud. The STM32 packages the preprocessed CO2 concentration data and transmits them to the cloud server using an ESP8266 WiFi module. Data transmission is conducted through the efficient MQTT protocol, ensuring low latency and high reliability. Upon receiving the data, the cloud server runs the Improved Crested Porcupine Optimization (ICPO) algorithm to optimize the PID control parameters. The optimized parameters are updated every 6 s and sent back to the STM32 via MQTT. The STM32 dynamically updates the PID parameters in the next control cycle and adjusts the system’s operation based on the new parameters, ensuring precise and real-time control.

The Application Layer provides a monitoring interface for users and improves air quality through the ICPO-PID control algorithm. The cloud server parses and stores the uploaded CO2 concentration data, building a database for further analysis and optimization. The system offers a user-friendly client interface, allowing real-time monitoring of the indoor air quality. Based on the deviation between the actual indoor CO2 concentration and the target value, as well as the rate of change of the deviation, the STM32 controls the airflow of the fresh air system. By utilizing the ICPO-PID control algorithm, the STM32 dynamically adjusts the variable air volume (VAV) air conditioning system, optimizing airflow and ensuring stable indoor air quality. Users can visually monitor air quality data through the client interface, ensuring that the air quality meets the desired targets.

The system combines cloud-based ICPO-PID optimization with local real-time PID control on the STM32 for efficient and reliable operation. Locally, the STM32 executes the PID control algorithm, making real-time adjustments using the current PID parameters, thereby avoiding delays caused by cloud processing. Meanwhile, the cloud continuously receives CO2 data from the STM32 and uses the ICPO algorithm to globally optimize PID parameters every 6 s. These optimized parameters are transmitted back to the STM32 for integration into the control cycle. This hybrid approach ensures both the responsiveness of local control and the adaptability of cloud-based optimization, maintaining system stability and achieving precise CO2 concentration regulation.

3.5. Evaluation Criteria for Cleanroom Carbon Dioxide Concentration Control System

The paper uses stability, control accuracy, and fluctuations as the main criteria for evaluating the PID control system [28,29]. Nominal performance is used to assess how much ICPO-PID improves the performance of the closed-loop system compared to the traditional PID control. Stability is used to determine whether the trained closed-loop system remains stable. Perturbation to the system aims to quantify how much disturbance is needed to achieve satisfactory performance. The Integral Absolute Error (IAE), Integral Squared Error (ISE), and Total Variation (TV) are used to quantify the evaluation, as is shown in Equations (6)–(8).

All of these equations are computed by approximating the summation using discrete time samples in the system.

4. Design of PID Controllers

4.1. PID Controller Based on the Improved Crested Porcupine Algorithm

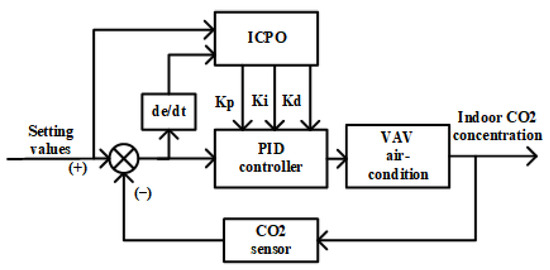

The CPO algorithm [30] exhibits strong local search capabilities by simulating the porcupine’s defensive mechanisms, enabling rapid convergence to favorable regions within the solution space. However, its limited global exploration ability often leads to premature convergence to local optima, restricting its application in PID controller optimization. To address this limitation, the improved CPO algorithm incorporates a nonlinear adaptive adjustment mechanism and the Variable Neighborhood Search (VNS) algorithm. The nonlinear adaptive mechanism dynamically adjusts individual fitness according to real-time system changes, enhancing the algorithm’s adaptability. Meanwhile, the VNS algorithm strengthens global search capabilities, avoiding local optima traps and ensuring comprehensive PID parameter optimization. Consequently, the improved algorithm enhances the stability and control performance of PID controllers in complex and dynamic environments. The framework for optimizing PID control systems using the improved CPO algorithm is illustrated in Figure 3.

Figure 3.

The PID controller based on ICPO.

4.1.1. Design for Improving Individual Fitness

In the CPO algorithm, the fitness of each individual determines the quality of its current solution. The fitness value of an individual is calculated using a fitness function. When the fitness value of a particular individual falls significantly below the average fitness of the population, it may lead to an over-selection of that individual, neglecting other potential solutions. This process accelerates convergence toward a local optimum, diminishing population diversity and limiting the algorithm’s ability to fully explore the solution space. To address this issue, the average fitness of the population is incorporated into the fitness adjustment of individuals within the CPO algorithm. This adjustment enhances the population diversity and helps prevent the algorithm from becoming trapped in local minima. The improved formula for calculating individual fitness is as follows:

In the formula, represents the fitness value of an individual, denotes the fitness value of the individual in the population, and refers to the average fitness value of the population. The parameters and are adjustment coefficients used to control the magnitude of fitness value modifications. Different values of and are set based on the iteration count , as defined by the following formula:

In the formula, represents the maximum number of iterations and is the control parameter. As the number of iterations increases, the intensity of fitness adjustment gradually increases. From Equation (9), it can be inferred that when , the selection probability should be reduced to avoid premature convergence. Conversely, when , the individual fitness can be appropriately increased to enhance the selection probability, thereby promoting population diversity and improving the algorithm’s exploration capability.

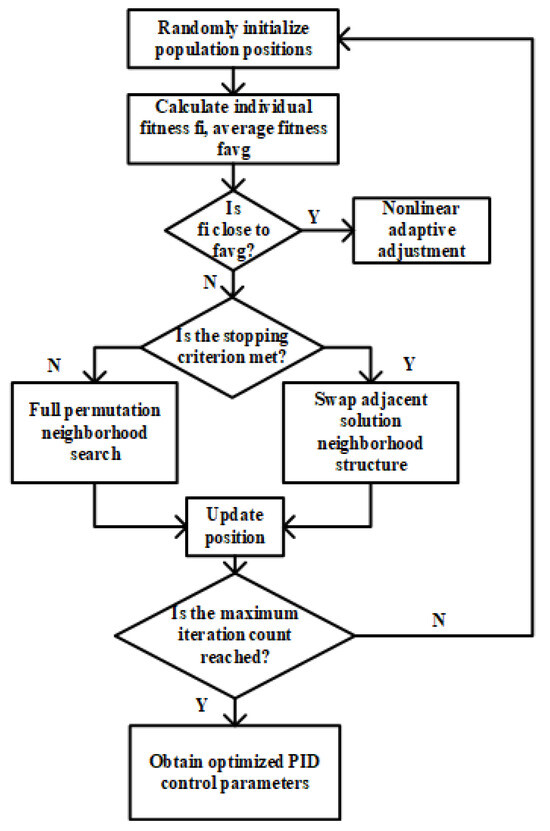

4.1.2. Improvement of the Design of Variable Neighborhood Search

To enhance the local search capability of the CPO and ensure effective search performance in the later stages of iteration, the VNS algorithm was incorporated. VNS is an effective local search algorithm that explores the solution space by progressively altering the neighborhood structure, thereby avoiding local optima. The neighborhood structure includes a series of fine-tuning operations on the current solution, such as insertion, swapping, and reversal. During each iteration, CPO adopts different neighborhood structures to seek improved solutions, with the strategy for using neighborhood structures dynamically adjusted based on the search outcomes.

When an individual’s fitness is significantly lower than the average fitness of the population, shallow search methods are unlikely to help the individual escape from a local optimum. In such cases, a deeper search is required to induce substantial changes and assist the individual in breaking free from the local optimum. On the other hand, when the fitness of an individual is very close to the average fitness of the population, it may already be near the optimal solution. In this scenario, large adjustments could disrupt the proximity to the optimal solution, leading to a decrease in fitness. Therefore, only a shallower neighborhood search structure is needed to further optimize the solution. Based on this, a domain search depth is introduced in this study to control the local search range of each individual, and the update formula for is as follows:

In the formula, is a constant used to adjust the scale of the search depth; is the sensitivity parameter for the search depth, which is typically set to 1. represents the difference between the individual’s fitness and the average fitness. When is large, the neighborhood search depth increases and a more complex permutation-based neighborhood structure is selected for local search. In the permutation neighborhood structure, multiple solution parameter positions are randomly selected, and a full permutation is performed to generate a series of new solutions. Conversely, when is small, the local search depth is reduced, and a simpler adjacent swap neighborhood structure is chosen for fine-tuning. An adjacent swap involves selecting two neighboring positions in the current solution and exchanging their elements to obtain a new neighboring solution.

The improved process of the porcupine optimization algorithm is shown in Figure 4.

Figure 4.

The process of the ICPO algorithm.

4.2. Algorithm Verification and Performance Analysis

4.2.1. Comparison of Algorithm Performance

In this study, the performance of the ICPO is compared to three other well-established optimization algorithms: the Grey Wolf Optimizer (GWO), the Football Team Training Optimization Algorithm (FTTA), and the Crested Porcupine Optimizer (CPO). These algorithms were selected due to their demonstrated effectiveness in optimizing PID control systems in previous research. In order to conduct these experiments, MATLAB R2018a was installed on a computer with the following specifications: an Intel Core i7-12700H CPU operating at 2.70 GHz, 16 GB RAM, and 64-bit Windows 11 Pro. All algorithms used in these experiments were independently executed 30 times, and the maximum cycle number in each experiment was set to 500. The fitness values obtained from those runs were analyzed in terms of the average fitness value, and the convergence curve is used to show which algorithm can arrive at the best fitness value faster.

This study investigates the performance of the ICPO algorithm on the CEC 2017 benchmark suite. The CEC 2017 suite consists of four categories of mathematical functions: unimodal functions (F1–F2), multimodal functions (F3–F9), composition functions (F10–F19), and hybrid functions (F20–F29). The study selects F1-F6 for evaluation. The parameter settings are shown in Table 2. The results of all competing algorithms are assessed based on the average (Avg) and standard deviation (SD) obtained from 30 independent runs for each function, with detailed results presented in Table 3.

Table 2.

Parameter settings of the competitors and proposed ICPO.

Table 3.

Results of ICPO and classical metaheuristics for CEC2017 test functions.

From an overall perspective, the performance ranking of algorithms in Table 3 reveals that, for the CEC2017 test problems, the ICPO algorithm is demonstrated to perform well in multiple functions, achieving better results than other algorithms. The best solutions are obtained in four out of six samples (F1, F4, F5, and F6). For functions F2 and F3, the second-best solutions are achieved. In this regard, the ICPO algorithm is ranked as the best overall, with an average rank of 1.33.

4.2.2. Convergence Analysis in the Unified Control System

The PID control parameters play a crucial role in determining the system’s response speed, error stability, and dynamic performance. Selecting appropriate parameter ranges is essential to ensuring effective optimization. By using the ITAE (Integral of Time-weighted Absolute Error) performance index as the fitness function, the algorithm can more accurately evaluate the effectiveness of different PID parameter combinations.

Equation (13) defines the ITAE, which comprehensively evaluates the system’s dynamic behavior by minimizing time-weighted errors, thus emphasizing both rapid error reduction and stability. Furthermore, it provides a reliable basis for verifying the algorithm’s convergence and assessing whether the final parameters achieve satisfactory performance in practical control applications.

In the equation, represents the error value.

In the optimization process, the number of individuals in the porcupine population is set to 30, with a dimension of 3, corresponding to the three PID controller parameters. Four algorithms are employed for comparison: GWO, FTTA, CPO, and the proposed ICPO. The parameter ranges for the PID controller were selected based on extensive engineering experience: , , and .

To ensure a fair comparison, only the population size and dimensionality are modified, with all other parameters remaining consistent with those outlined in Table 2. This approach enables a controlled evaluation of each algorithm’s performance under the same experimental conditions.

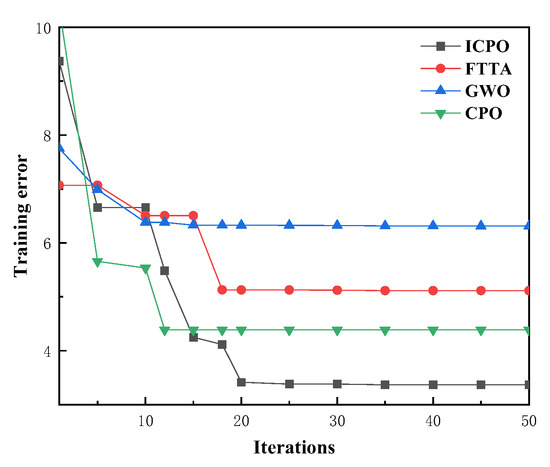

Figure 5 illustrates the convergence behavior of the ICPO algorithm compared to other methods. The ICPO achieved a minimum objective function value of 3.35 and exhibited faster error reduction and greater stability during optimization. The optimized PID parameters were = 1.72, , and , demonstrating the algorithm’s effectiveness in dynamic adjustment.

Figure 5.

Training error curve.

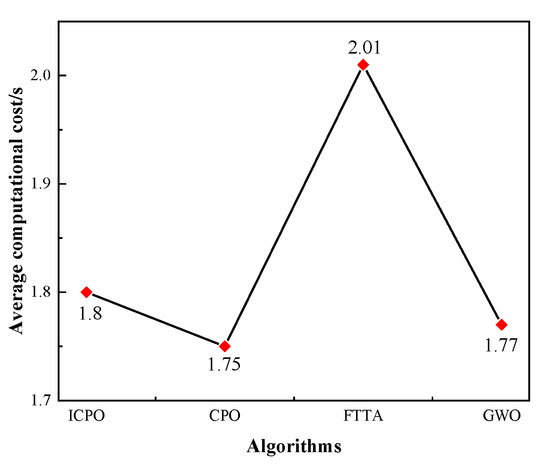

4.2.3. Computational Cost Analysis

This section estimates the average computational cost for completing the optimization process of each algorithm on the CEC2017 test suite, as shown in Figure 6. The results indicate that the ICPO algorithm has an average runtime of approximately 1.8 s, slightly higher than that of the CPO algorithm. However, ICPO performs excellently on multiple test functions, with optimization results significantly outperforming the other algorithms.

Figure 6.

Comparison among algorithms in terms of computational cost.

The introduction of VNS significantly improves the stability and accuracy of the optimization process. The reduction in SD and the decrease in Avg shown in Table 3 indicate that VNS enhances the stability of the algorithm and improves the precision of finding the global optimum. Although the computation time is not significantly reduced, the improvement in optimization accuracy and stability suggests that VNS plays a crucial role in balancing precision and efficiency.

4.3. Traditional PID Controller

The PID [31,32] controller operates as a closed-loop feedback control system, which adjusts based on the error between the measured value and the setpoint, incorporating the proportional gain , integral gain , and derivative gain . The governing equation is:

In the formula, represents the control output at time ; is the error input; , , and are the proportional, integral, and derivative coefficients, respectively. The typical PID controller parameters are set as , , and .

4.4. Fuzzy PID Controller

Fuzzy-PID [33,34] control is a control method that utilizes fuzzy algorithms to tune the PID parameters. The control model design process is as follows: the input variables for the fuzzy controller are the error between the target CO2 concentration and the current monitored CO2 concentration, and the rate of change of the error , while the output variables are , , and . The domain of the inputs and outputs is defined, fuzzy sets are established, and the corresponding membership functions are determined. A fuzzy inference table is constructed, and the centroid method is used for defuzzification to determine the values of , , and .

The domain of the deviation within the range of is selected as the control subset. Elements in the domain less than minus 2 are assigned a value of −2, corresponding to a CO2 concentration less than half of the set CO2 concentration. Conversely, elements greater than 2 are assigned a value of 2, representing a CO2 concentration more than twice the set CO2 concentration. The domains of , , , , and are uniformly divided into five levels , with the corresponding fuzzy subsets defined as .

5. Experimental Evaluation

Cleanroom environments are highly sensitive to fluctuations in environmental parameters, such as CO2 concentration, which can impact both product quality and personnel health. Consequently, a single experiment may not fully capture the complexity of real-world operations. To address this, multiple experimental analyses are conducted to evaluate the performance of the ICPO-PID controller under varying conditions and compare its effectiveness with other commonly used control methods (e.g., traditional PID, Fuzzy-PID).

In the simulation phase, four PID control strategies were tested in an indoor CO2 concentration variation model, and disturbances were introduced to simulate real-world conditions, observing the system’s response under each control method. Meanwhile, to validate the simulation results and assess the practical applicability of the control strategies, the ICPO-PID control method was implemented in an actual cleanroom environment. During the real-world experiment, the CO2 concentration was continuously monitored, and the air supply volume was adjusted based on concentration fluctuations. Additionally, energy consumption was monitored in real time during the adjustment process to provide a comprehensive evaluation of the ICPO-PID control method’s performance in a real environment.

5.1. Analysis of Simulation Results

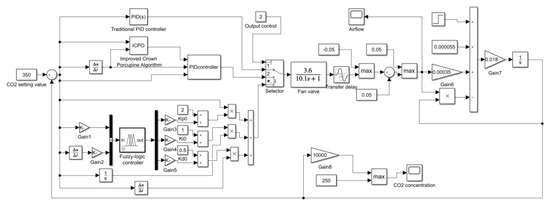

A cleanroom CO2 concentration control model was developed using the MATLAB simulation platform (Figure 7), focusing on real-time regulation of indoor CO2 levels. To ensure scientific validity and consistency, the simulation setup was based on the single-capacity CO2 model proposed in Section 3.1, with parameters unified across all experiments.

Figure 7.

Model of cleanroom CO2 concentration under different PID controls.

The model employs specific control strategies: when the CO2 concentration is below 350 ppm, the fresh air valve output is fixed at 0.05 m3/s. For concentrations exceeding 350 ppm, PID control dynamically adjusts the fresh air output to stabilize the CO2 concentration at the target level. Simulation experiments evaluated four control methods: PID, Fuzzy-PID, CPO-PID, and ICPO-PID. Parameter settings for CPO and ICPO are detailed in Table 2 of Section 4.2.1, while explanations for PID and Fuzzy-PID are provided in Section 4.3 and Section 4.4. To test the robustness of these strategies, a disturbance scenario was simulated at 950 s by introducing 10 individuals into the experimental room.

The PID parameters determined by the ICPO algorithm were implemented in the simulation to adjust the fresh air valve output dynamically, ensuring the CO2 concentration stabilized at the target level. The resulting PID parameters, derived from the ICPO optimization process, were integrated into the control system, and their effectiveness was assessed in the simulation, comparing the CO2 concentration and airflow variation curves under different control methods.

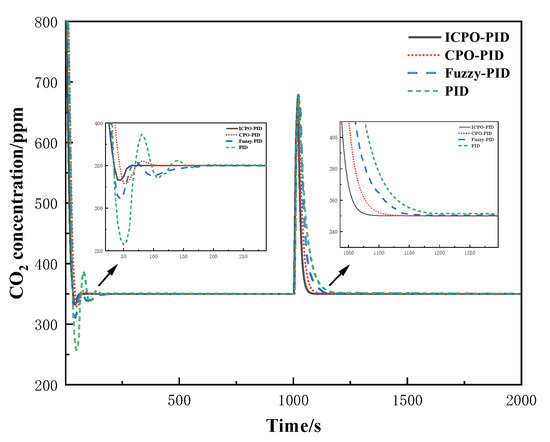

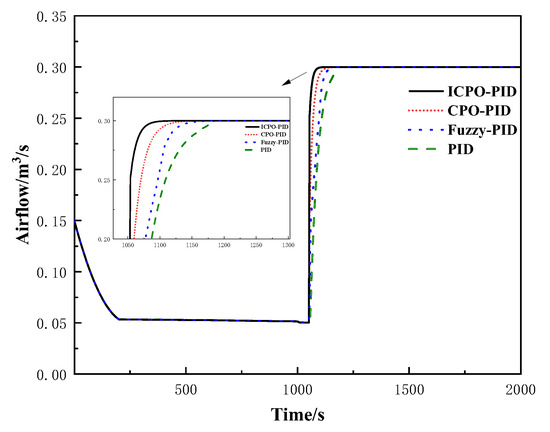

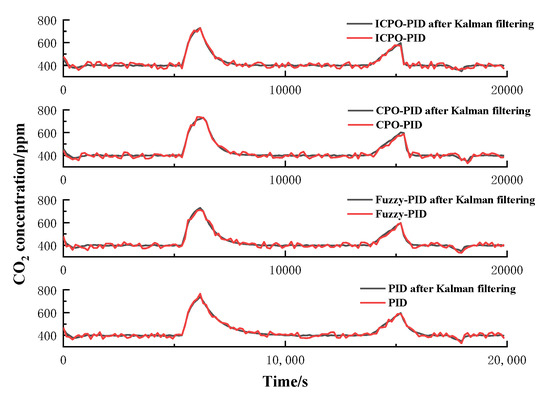

The simulation results illustrate the CO2 concentration variation curves under different control strategies (Figure 8) and the corresponding VAV airflow variation curves (Figure 9). The performance metrics of the controller are presented in Table 4. Specifically, the rise time refers to the time required for the system to reach 90% of the steady-state value for the first time; control time indicates the time taken for the system to stabilize at the setpoint; and overshoot represents the ratio of the maximum transient deviation to the steady-state value under step input.

Figure 8.

CO2 concentration change curve.

Figure 9.

Airflow change curve.

Table 4.

Performance of different PID controllers.

It can be observed in Figure 8 and Table 4 that while the traditional PID controller exhibits a faster response speed, it generates significant oscillations during the initial adjustment phase, resulting in a prolonged settling time of 185 s and an overshoot as high as 26.8%. In contrast, the Fuzzy-PID controller integrates adaptive features of fuzzy control into the traditional PID framework. Although its response time slightly increases to 21 s, the settling time is reduced to 176 s, and the overshoot is decreased to 9.71%.

The performance of the CPO-PID controller was further optimized. Compared with traditional PID and Fuzzy-PID controllers, its settling time was significantly reduced to 88 s, and the overshoot was decreased to 6%. The ICPO-PID controller demonstrated the best dynamic performance. Its response time (24 s) was slightly longer than that of traditional PID and Fuzzy-PID controllers but shorter than that of the CPO-PID controller, striking a favorable balance between response speed and system stability. The ICPO-PID controller achieved a settling time of only 59 s, significantly shorter than the other three controllers, with an overshoot reduced to 5.14% during the adjustment process.

As shown in Figure 8 and Figure 9, the ICPO-PID controller demonstrates excellent performance in suppressing CO2 concentration fluctuations under disturbances. It optimally adjusts fresh air volume, rapidly increasing air supply while effectively controlling CO2 levels. Overall, the ICPO algorithm efficiently identifies optimal control parameters in the system’s initial phase, significantly reducing the adjustment time and overshoot while ensuring a smoother and faster system response.

5.2. Analysis of Experimental Results

5.2.1. Experimental Environment Setup

Figure 10 illustrates the hardware design of the acquisition system. This system consists of several key components integrated to monitor and control CO2 concentration in the environment. The experimental environment is set up in a clean room, where the system achieves real-time CO2 concentration monitoring and control through hardware design. The CO2 sensor (model S8-0053) is used to measure the indoor CO2 concentration, with a measurement range of 0–2000 ppm and an accuracy of ±40 ppm. The data are transmitted to the STM32F407ZET6 microcontroller via an RS485 interface for processing. The system’s fan has a rated airflow of 2000 m3/h and a rated power of 0.55 kW, which is used to adjust the airflow. The processed data are sent to the cloud server via the ESP8266 WiFi module, using the MQTT protocol to ensure low latency and high reliability. The cloud server optimizes the PID parameters using the ICPO algorithm, and the optimized parameters are updated every 6 s and sent back to the STM32. The microcontroller, based on the received data, applies the PID control algorithm for real-time adjustments, controlling the air valve to regulate airflow and achieve precise air quality control.

Figure 10.

Hardware design of acquisition system.

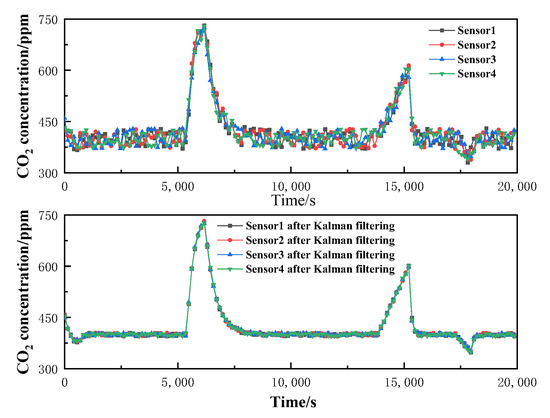

5.2.2. Measured Results

This paper uses the CO2 concentration in the cleanroom as the control parameter, with the target CO2 concentration set at 400 ppm. A CO2 cylinder is used as the CO2 generator, and the valve opening of the cylinder is adjusted to control the CO2 release.

Figure 11 illustrates the variation in CO2 concentration within the cleanroom under ICPO-PID control. Upon activation of the CO2 cylinder, the released CO2 causes an initial increase in concentration, which is subsequently reduced as the system adjusts the fresh air volume, ultimately stabilizing near the target value. Figure 12 illustrates the variation in fresh air volume in response to fluctuations in CO2 concentration. As CO2 concentration increases, the fresh air volume rises rapidly to dilute the CO2 and then gradually decreases and stabilizes at an appropriate level.

Figure 11.

The variation of CO2 concentration under ICPO-PID control.

Figure 12.

The variation in air volume under ICPO-PID control.

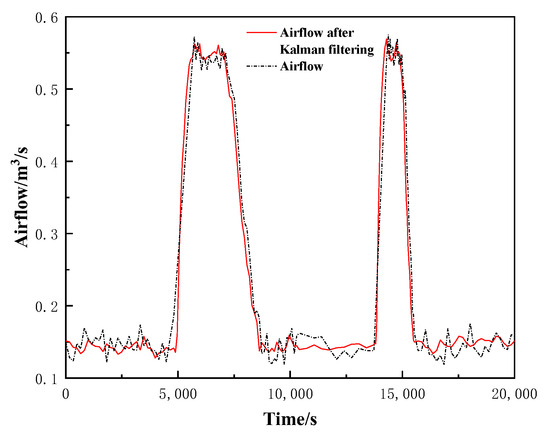

As shown in Figure 11, significant fluctuations are observed in the sensor data, primarily due to the limitations in the measurement accuracy of the sensors and the influence of environmental interference during the signal acquisition process. In order to improve system stability, the Kalman filtering algorithm [35] was introduced into the ICPO-PID control system. The system noise covariance was set to 0.003, the measurement noise covariance to 0.02, and the variance of the estimated values to 0.004. A comparison of the sensor data before and after filtering reveals that the Kalman filter effectively enhanced the robustness and stability of the system, thereby providing a more reliable basis for precise control.

Figure 12 illustrates the dynamic response of the fresh air volume to changes in the CO2 concentration. As the CO2 concentration increases, the VAV air conditioning system responds quickly by increasing the fresh air volume. After a decrease in the CO2 concentration, the output air volume gradually reduces and stabilizes at the minimum airflow. This process demonstrates the rapid response capability of the ICPO-PID algorithm in dynamic environments. Meanwhile, the Kalman filter significantly enhances the smoothness of the fresh air volume data, effectively eliminating abrupt fluctuations. This validates the key role of the filtering algorithm in improving system stability and operational reliability.

Figure 13 illustrates the dynamic response of the fresh air volume to variations in the CO2 concentration. As the CO2 concentration increases, the VAV air conditioning system responds rapidly by increasing the fresh air output. Following a decrease in the CO2 concentration, the output air volume gradually reduces and stabilizes at the minimum airflow. This process reflects the rapid response capability of the ICPO-PID algorithm in dynamic environments. Meanwhile, the Kalman filter reduces oscillations during the adjustment process, resulting in smoother fresh air output. This confirms that the filtering algorithm can significantly enhance the dynamic performance of the control system.

Figure 13.

The variation of CO2 concentration under different PID controls.

For each of these evaluation experiments, the average normalized IAE, ISE, and TV are calculated. This helps to intuitively show the relative performance of each controller across different metrics. Table 5 presents the normalized performance evaluation of PID controllers. The ICPO-PID algorithm performs best in IAE and ISE, meaning it accumulates the least error compared to the other three control algorithms, resulting in more precise system control. Although the TV value is slightly higher, indicating larger output fluctuations, the output variation is still relatively acceptable given its excellent performance in error control. The fluctuations in output may be attributed to the natural variation in indoor CO2 concentration.

Table 5.

Normalized performance evaluation of PID controllers.

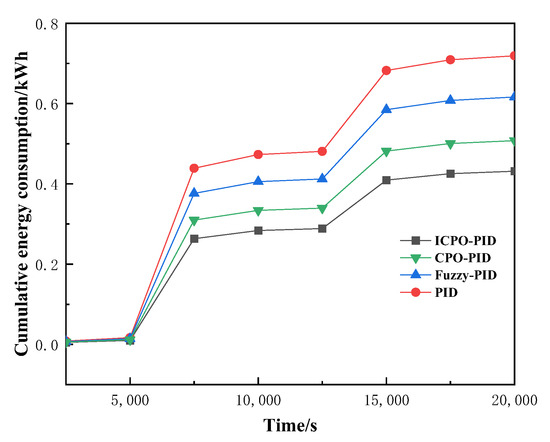

5.2.3. Energy Consumption Analysis of the System

The control strategy proposed in this study was validated through the intelligent regulation of ventilation rates. In terms of energy consumption, differences among various PID control schemes were reflected in the adjustment speed of air supply rates. Ventilation energy consumption was composed of two parts: the air conditioning process and the air delivery process. In this study, indoor environmental variables were set as the CO2 concentration. Since the energy consumed during the air conditioning process remained essentially constant, it was excluded from consideration, with the focus placed solely on the energy consumption of the air delivery process. The energy consumption of the air delivery process refers to the energy required to drive the airflow within the ventilation system, which can be calculated as:

In the formula, represents the air delivery energy consumption (kW) and is the proportionality coefficient.

The outdoor air ventilation rate has been identified as a key factor influencing energy consumption under different ventilation strategies, given the specified air conditions and associated equipment. Figure 14 illustrates the energy consumption of a VAV air conditioning system under different PID control strategies. Compared to traditional PID control, Fuzzy-PID control, and CPO-PID control, the ICPO-PID control system based on Kalman filtering demonstrates the most significant energy-saving performance, reducing energy consumption by approximately 40% compared to traditional PID control.

Figure 14.

VAV energy consumption under different PID controllers.

5.3. Discussion

The experimental results demonstrate that the ICPO-PID-based CO2 concentration control system for cleanrooms exhibits excellent performance in both simulation and real-world environments. Compared to traditional PID, Fuzzy-PID, and CPO-PID controllers, ICPO-PID shows significant advantages in control accuracy, response speed, system stability, and energy efficiency. In our simulation, the ICPO-PID control achieved a settling time of only 59 s and an overshoot of just 5.14%, showing a faster response and higher system stability. In the performance evaluation of real-world results, ICPO-PID outperforms other control methods in IAE and ISE. The introduction of the Kalman filtering algorithm in the real environment significantly enhances system stability and improves the smoothness of fresh air volume and CO2 concentration data. The ICPO-PID control system reduces energy consumption by approximately 40% in air volume adjustment compared to traditional PID, indicating that it not only provides precise control and a quick response but also improves energy efficiency. Overall, the ICPO-PID control system outperforms other control methods across various performance metrics and has broad practical application potential.

6. Conclusions

In conclusion, this paper presents a PID controller based on the ICPO algorithm, validated through simulation experiments. When applied to the intelligent CO2 concentration control system in cleanrooms, the results show that the ICPO-PID system outperforms traditional PID, Fuzzy-PID, and CPO-PID controllers in terms of regulation speed, stability, and energy efficiency. The system effectively integrates real-time monitoring with cloud-based optimization, combining local PID control with cloud-driven ICPO adjustments to enhance responsiveness, improve air quality regulation, and further reduce energy consumption.

While the intelligent CO2 concentration control system for cleanrooms has partially met the expected objectives, there is still potential for further optimization. Future research could focus on the following areas:

- Optimizing the sensor layout: Given the slow diffusion rate of CO2 concentration, the placement of sensors significantly influences the measurement accuracy. To enhance precision, sensor positions should be determined based on indoor airflow direction and specific usage scenarios, ensuring both data accuracy and representativeness.

- Improving indoor air quality regulation: This study only considers CO2 concentration control; however, comprehensive air quality regulation requires monitoring multiple gases. Future work could incorporate additional gas sensors, such as PM2.5 and volatile organic compounds (VOCs), enabling more comprehensive air quality control and increasing the system’s adaptability.

These improvements will enhance the system’s accuracy, flexibility, and applicability, contributing to the broader adoption of intelligent cleanroom control systems.

Author Contributions

Conceptualization, T.C. and W.W.; methodology, T.C. and Y.Y.; software, T.C.; validation, T.C., W.W. and Y.Y.; formal analysis, Y.Y.; investigation, W.W.; resources, Y.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

All data that support the findings of this study are included within this article. Other related data associated with this study can be made available upon request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Liu, J.; Zhang, L.; Yang, J.; Chen, Y.; Zhang, X. Study on Pressure Control and Energy Saving of Cleanroom in Purification Air Conditioning System. Energy Build. 2021, 253, 111502. [Google Scholar] [CrossRef]

- Yang, Z.; Hao, Y.; Shi, W.; Shao, X.; Dong, X.; Cheng, X.; Li, X.; Ma, X. Field test of pharmaceutical cleanroom cleanliness subject to multiple disturbance factors. J. Build. Eng. 2021, 42, 103083. [Google Scholar] [CrossRef]

- Ma, Z.; Liu, X.; Zhang, T. Measurement and optimization on the energy consumption of fans in semiconductor cleanrooms. Build. Environ. 2021, 197, 107842. [Google Scholar] [CrossRef]

- Xu, Y.; Han, X.; Cao, X.E. Comprehensive performance evaluation of HVAC systems integrated with direct air capture of CO2 in various climate zones. Build. Environ. 2024, 266, 112048. [Google Scholar] [CrossRef]

- Lu, X.; Pang, Z.; Fu, Y.; O’Neill, Z. The nexus of the indoor CO2 concentration and ventilation demands underlying CO2-based demand-controlled ventilation in commercial buildings: A critical review. Build. Environ. 2022, 218, 109116. [Google Scholar] [CrossRef]

- Poirier, B.; Guyot, G.; Woloszyn, M.; Geoffroy, H.; Ondarts, M.; Gonze, E. Development of an assessment methodology for IAQ ventilation performance in residential buildings: An investigation of relevant performance indicators. J. Build. Eng. 2021, 43, 103140. [Google Scholar] [CrossRef]

- Faulkner, C.A.; Castellini, J.E.; Lou, Y.; Zuo, W.; Lorenzetti, D.M.; Sohn, M.D. Tradeoffs among indoor air quality, financial costs, and CO2 emissions for HVAC operation strategies to mitigate indoor virus in U.S. office buildings. Build. Environ. 2022, 221, 109282. [Google Scholar] [CrossRef] [PubMed]

- Cheng, X.; Li, C.; Ma, X.; Shao, X. Differential pressure control method for pharmaceutical cleanrooms under variable air supply conditions. Build. Environ. 2022, 213, 108849. [Google Scholar] [CrossRef]

- Shao, X.; Liang, S.; Zhao, J.; Wang, H.; Fan, H.; Zhang, H.; Cao, G.; Li, X. Experimental investigation of particle dispersion in cleanrooms of electronic industry under different area ratios and speeds of fan filter units. J. Build. Eng. 2021, 43, 102590. [Google Scholar] [CrossRef]

- Feng, H.; Yin, C.-B.; Weng, W.-W.; Ma, W.; Zhou, J.-J.; Jia, W.-H.; Zhang, Z.-L. Robotic excavator trajectory control using an improved GA based PID controller. Mech. Syst. Signal Process. 2018, 105, 153–168. [Google Scholar] [CrossRef]

- Wang, X.; Tang, Y.; Li, Z.; Xu, C. Research on charging strategy based on improved particle swarm optimization PID algorithm. Complex Intell. Syst. 2024, 10, 6421–6433. [Google Scholar] [CrossRef]

- Rajesh, K.S.; Dash, S.S.; Rajagopal, R. Hybrid improved firefly-pattern search optimized fuzzy aided PID controller for automatic generation control of power systems with multi-type generations. Swarm Evol. Comput. 2019, 44, 200–211. [Google Scholar] [CrossRef]

- Truong, D.Q.; Ahn, K.K. Force control for press machines using an online smart tuning fuzzy PID based on a robust extended Kalman filter. Expert Syst. Appl. 2011, 38, 5879–5894. [Google Scholar] [CrossRef]

- Coskun, M.Y.; İtik, M. Intelligent PID control of an industrial electro-hydraulic system. ISA Trans. 2023, 139, 484–498. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Lu, Q.; Bai, J.; Xu, X.; Yao, Y.; Fang, W. A Temperature Control Method for Micro-accelerometer Chips Based on Genetic Algorithm and Fuzzy PID Control. Micromachines 2021, 12, 1511. [Google Scholar] [CrossRef]

- Moura, J.P.; Fonseca Neto, J.V.; Ferreira, E.F.M.; Araujo Filho, E.M. On the Design and Analysis of Structured-ANN for Online PID-Tuning to Bulk Resumption Process in Ore Mining System. Neurocomputing 2020, 402, 266–282. [Google Scholar] [CrossRef]

- Kim, H.-J.; Cho, Y.-H. A study on a control method with a ventilation requirement of a VAV system in multi-zone. Sustainability 2017, 9, 2066. [Google Scholar] [CrossRef]

- Yang, X.-B.; Jin, X.-Q.; Du, Z.-M.; Fan, B.; Chai, X.-F. Evaluation of four control strategies for building VAV air-conditioning systems. Energy Build. 2011, 43, 414–422. [Google Scholar] [CrossRef]

- Zucker, G.; Sporr, A.; Garrido-Marijuan, A.; Ferhatbegovic, T.; Hofmann, R. A ventilation system controller based on pressure-drop and CO2 models. Energy Build. 2017, 155, 378–389. [Google Scholar] [CrossRef]

- Okochi, G.S.; Yao, Y. A review of recent developments and technological advancements of variable-air-volume (VAV) air-conditioning systems. Renew. Sustain. Energy Rev. 2016, 59, 784–817. [Google Scholar] [CrossRef]

- Wang, H.; Wang, J.; Feng, Z.; Haghighat, F.; Cao, S.-J. An intelligent anti-infection ventilation strategy: From occupant-centric control and computer vision perspectives. Energy Build. 2023, 296, 113403. [Google Scholar] [CrossRef]

- Nielsen, T.R.; Drivsholm, C. Energy efficient demand controlled ventilation in single family houses. Energy Build. 2010, 42, 1995–1998. [Google Scholar] [CrossRef]

- Nassif, N. A robust CO2-based demand-controlled ventilation control strategy for multi-zone HVAC systems. Energy Build. 2012, 45, 72–81. [Google Scholar] [CrossRef]

- Cao, S.; Zhao, W.; Zhu, A. Research on intervention PID control of VAV terminal based on LabVIEW. Case Stud. Therm. Eng. 2023, 45, 103002. [Google Scholar] [CrossRef]

- Pistochini, T.; Ellis, M.; Meyers, F.; Frasier, A.; Cappa, C.; Bennett, D. Method of test for CO2-based demand control ventilation systems: Benchmarking the state-of-the-art and the undervalued potential of proportional-integral control. Energy Build. 2023, 301, 113717. [Google Scholar] [CrossRef]

- Chen, J. Design and Analysis of Home Control Complex System Based on PLC Technology. Mob. Inf. Syst. 2022, 2022, 6830120. [Google Scholar] [CrossRef]

- Rana, K.P.S.; Kumar, V.; Sehgal, N.; George, S. A Novel dP/dI Feedback Based Control Scheme Using GWO-Tuned PID Controller for Efficient MPPT of PEM Fuel Cell. ISA Trans. 2019, 93, 312–324. [Google Scholar] [CrossRef]

- Pradhan, R.; Majhi, S.K.; Pradhan, J.K.; Pati, B.B. Optimal Fractional Order PID Controller Design Using Ant Lion Optimizer. Ain Shams Eng. J. 2020, 11, 281–291. [Google Scholar] [CrossRef]

- Babu, D.C.; Kumar, D.B.S.; Sree, R.P. Tuning of PID Controllers for Unstable Systems Using Direct Synthesis Method. Indian Chem. Eng. 2016, 59, 215–241. [Google Scholar] [CrossRef]

- Abdel-Basset, M.; Mohamed, R.; Abouhawwash, M. Crested Porcupine Optimizer: A New Nature-Inspired Metaheuristic. Knowl.-Based Syst. 2024, 284, 111257. [Google Scholar] [CrossRef]

- Skogestad, S. Simple Analytic Rules for Model Reduction and PID Controller Tuning. J. Process Control. 2003, 13, 291–309. [Google Scholar] [CrossRef]

- Ziegler, J.G.; Nichols, N.B. Optimum Settings for Automatic Controllers. ASME Trans. ASME Novemb. 1942, 64, 759–765. [Google Scholar] [CrossRef]

- Miccio, M.; Cosenza, B. Control of a Distillation Column by Type-2 and Type-1 Fuzzy Logic PID Controllers. J. Process Control 2014, 24, 475–484. [Google Scholar] [CrossRef]

- Zadeh, L.A. Fuzzy Sets. Inf. Control 1965, 8, 338–353. [Google Scholar] [CrossRef]

- Chui, C.K.; Chen, G. Kalman Filtering with Real-Time Applications, 5th ed.; Springer: Cham, Switzerland, 2017. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).