Evaluation of Power Requirement for a Self-Propelled Garlic Collector Based on Load Experiments and Variable Impact Analysis Under Various Operating Conditions

Abstract

1. Introduction

2. Materials and Methods

2.1. Self-Propelled Garlic Collector

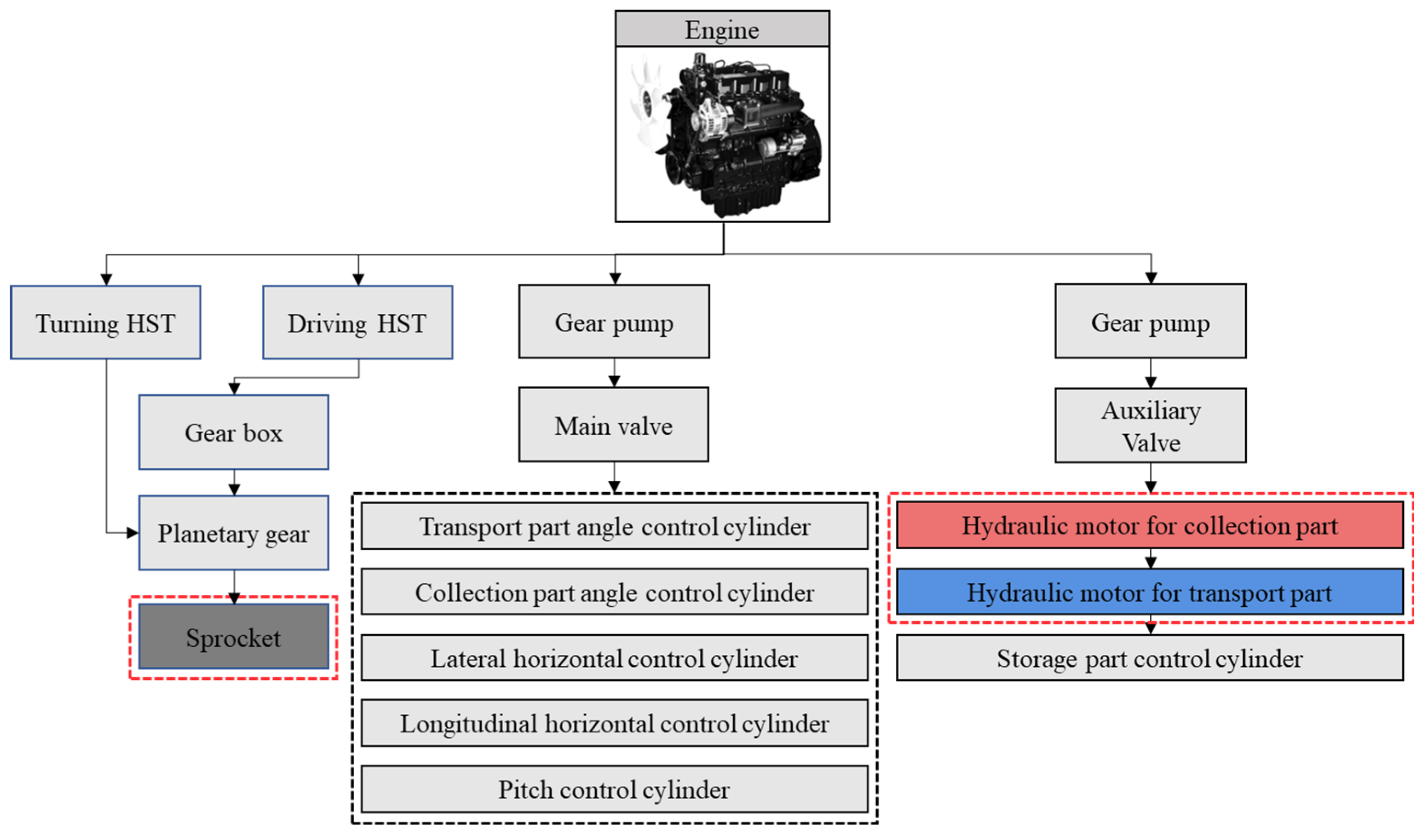

2.2. Power Transmission System of the Garlic Collector

2.3. Power Requirement Measurement System of the Garlic Collector

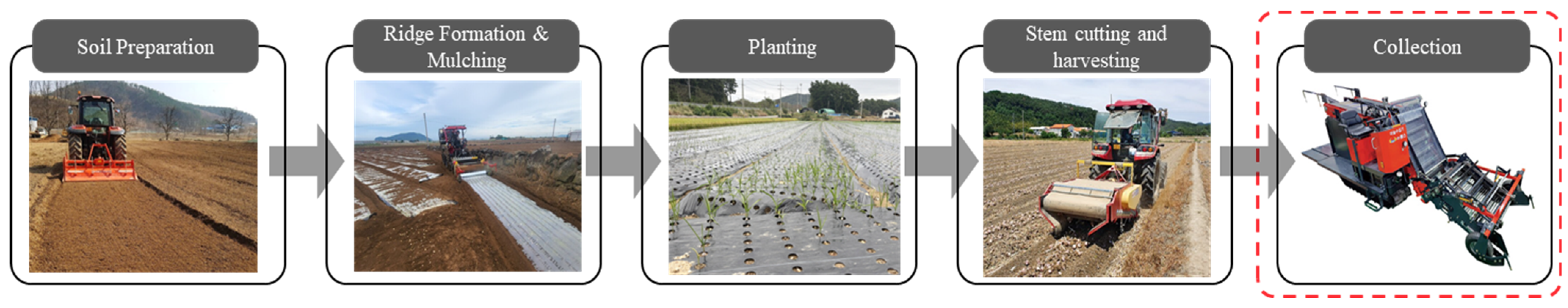

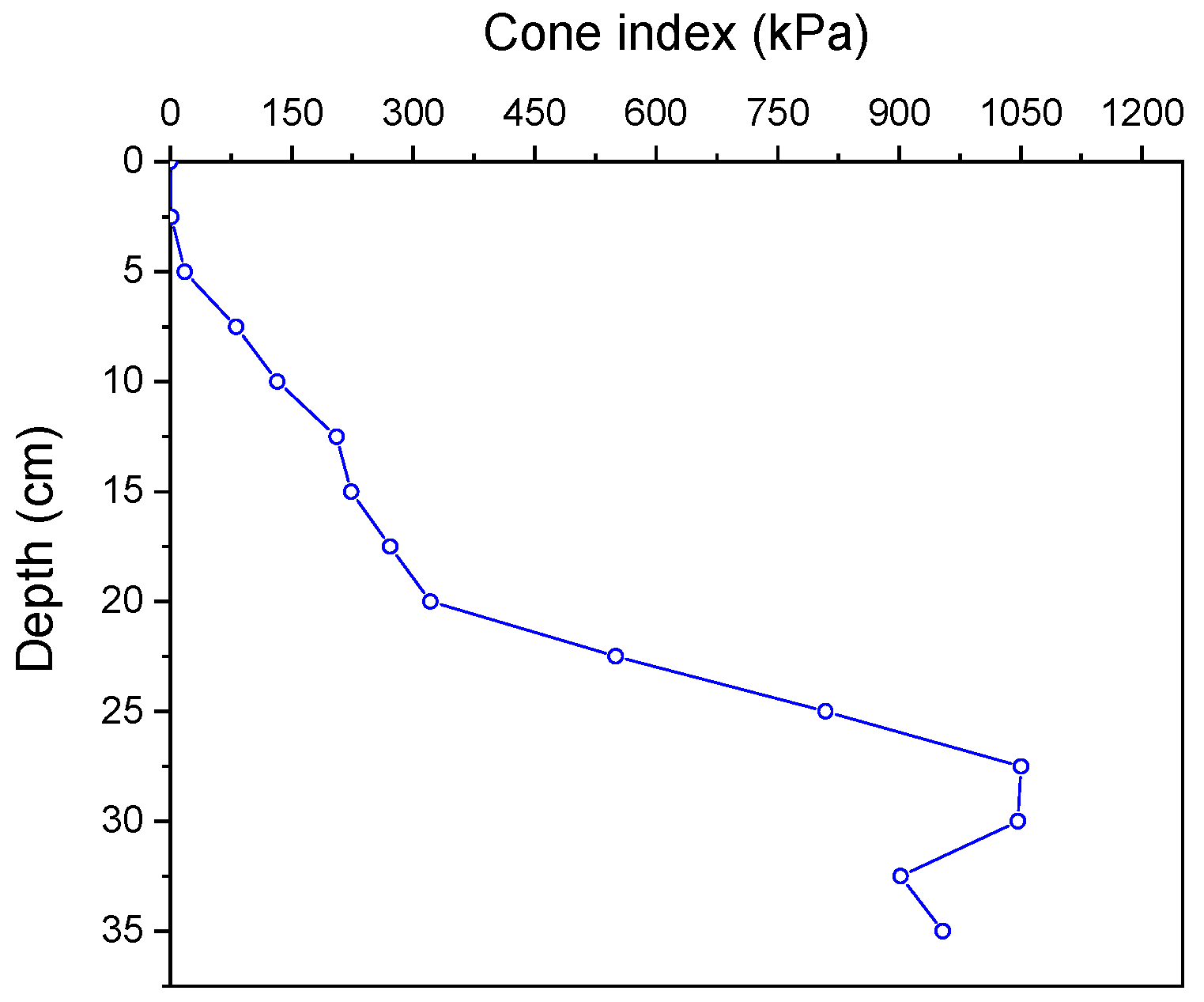

2.4. Field Experiments

2.5. Data Analysis Methods

3. Results

3.1. Analysis of Power Requirements Under Different Operating Conditions

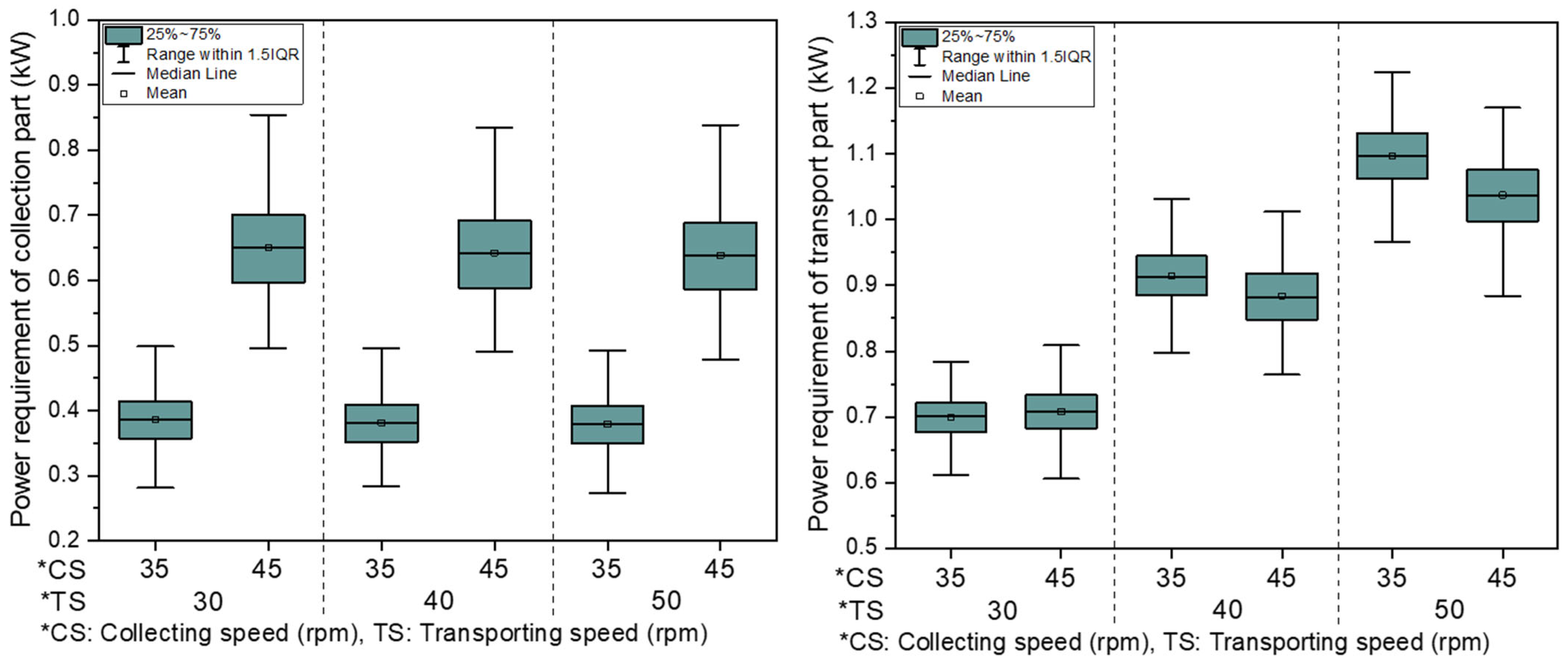

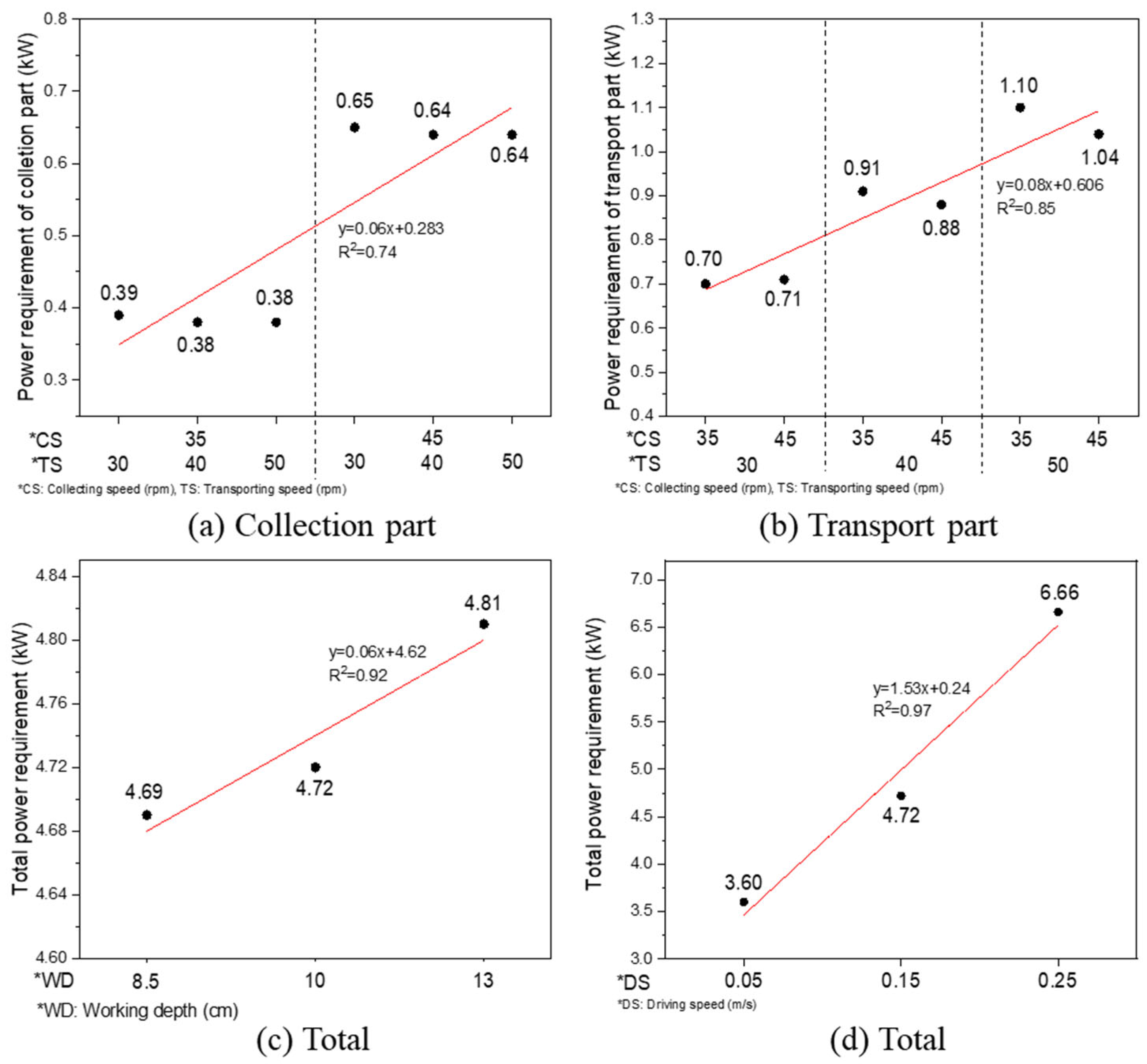

3.1.1. Power Requirements According to Collecting and Transporting Speeds

3.1.2. Power Requirements According to Working Depth

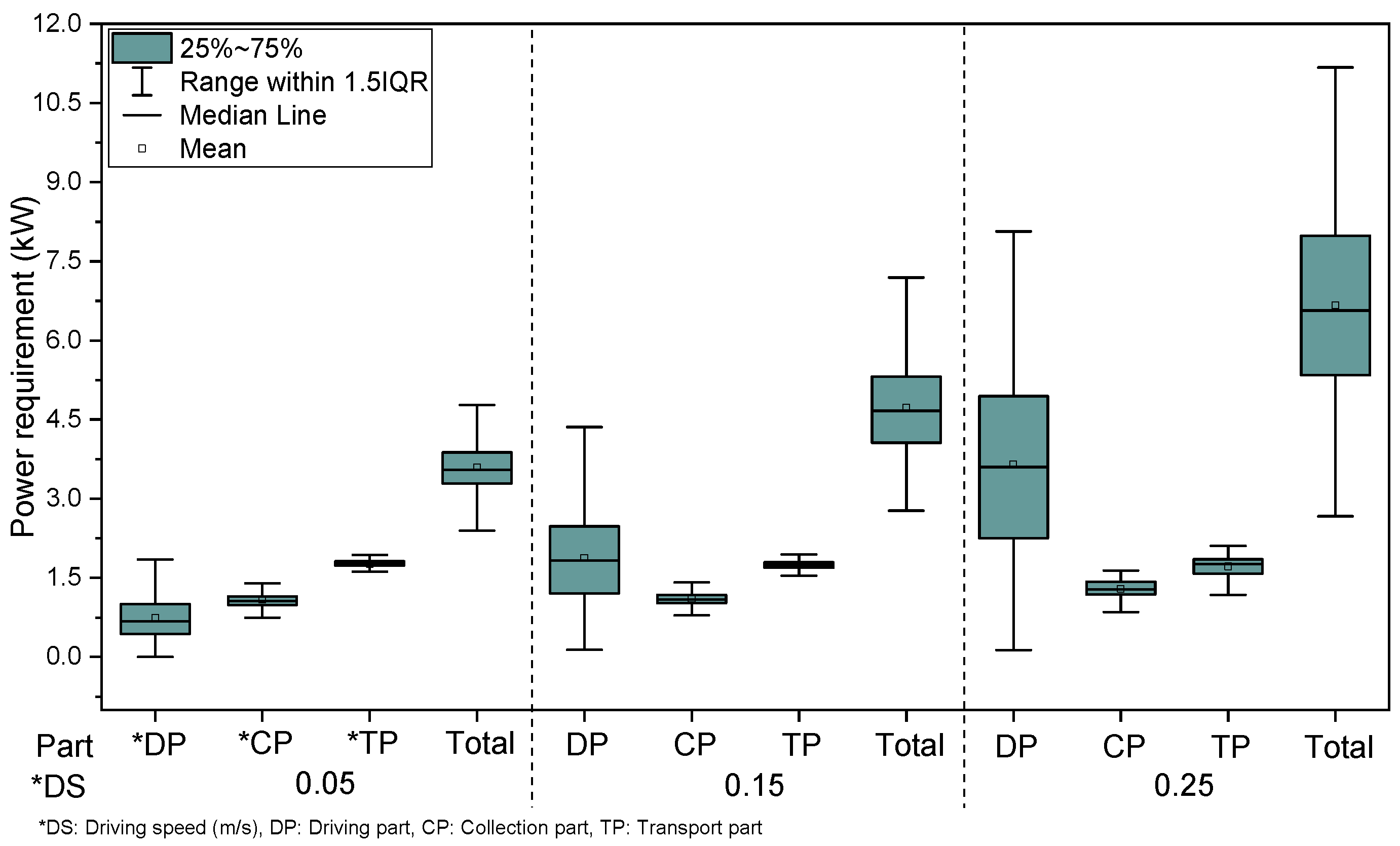

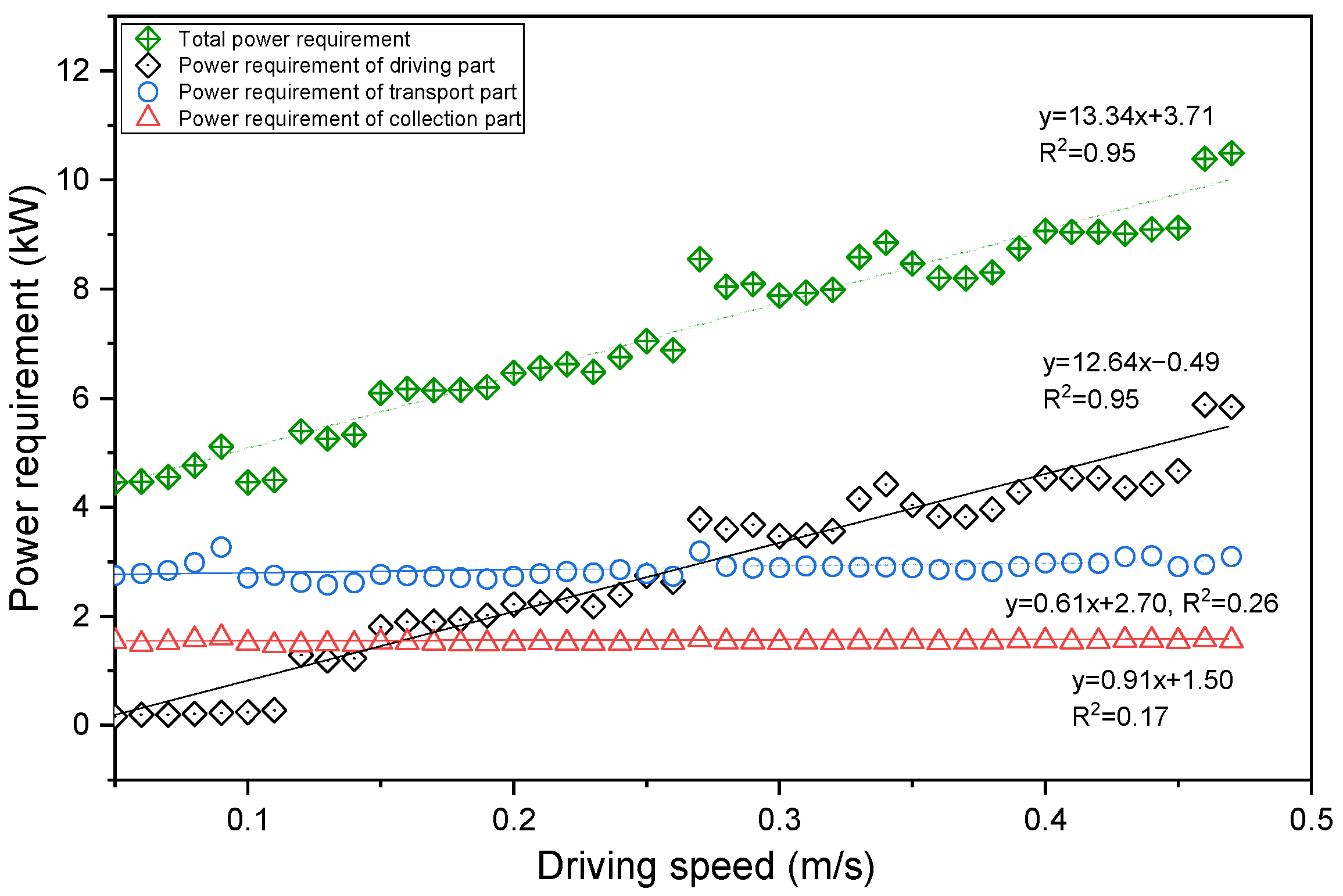

3.1.3. Power Requirements According to Driving Speed

3.2. Variable Impact Assessment

3.2.1. Impact of Transporting and Collecting Speed

3.2.2. Impact of Working Depth

3.2.3. Impact of Driving Speed

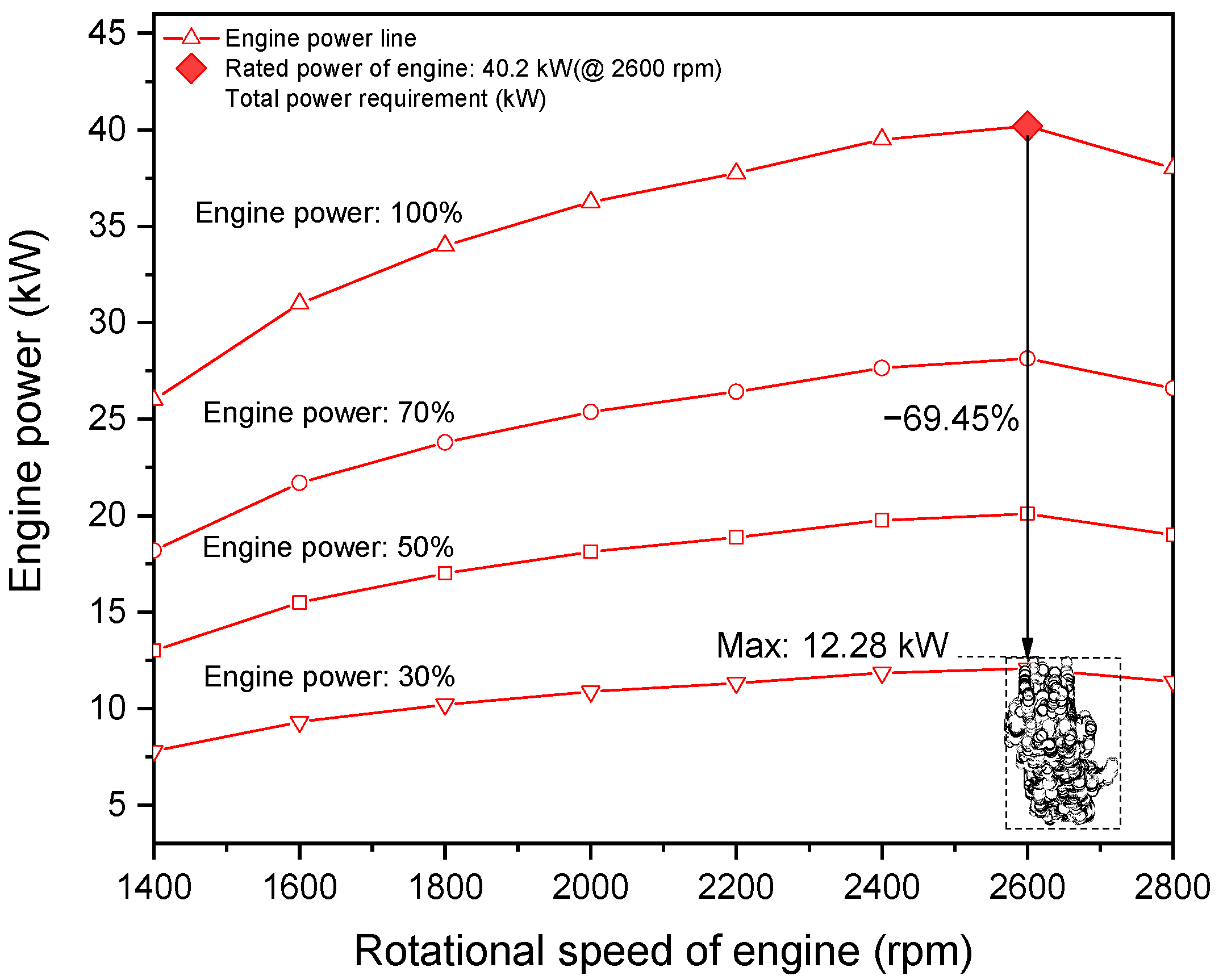

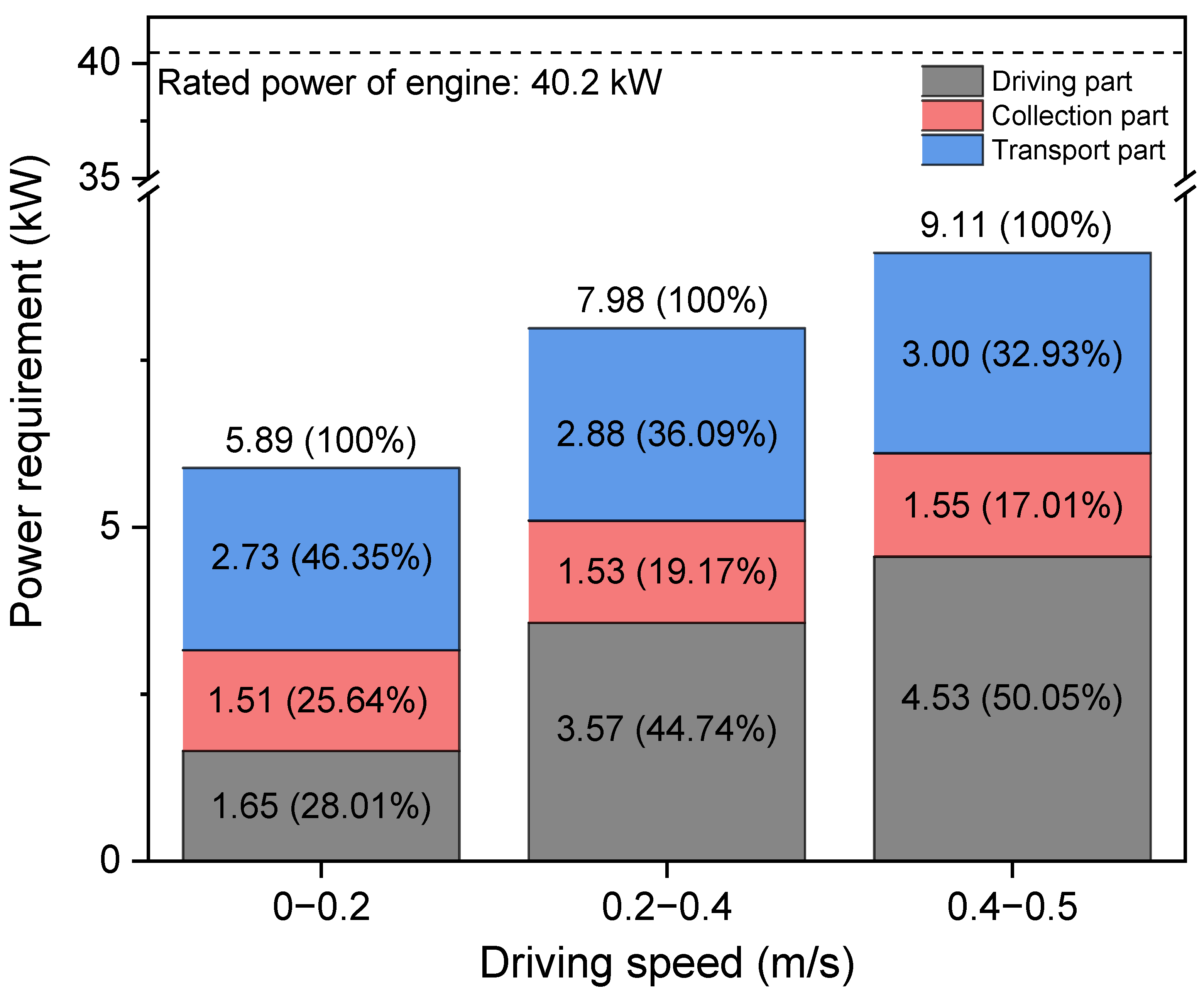

3.3. Analysis of Power Requirements for Main Parts Under Actual Operating Conditions

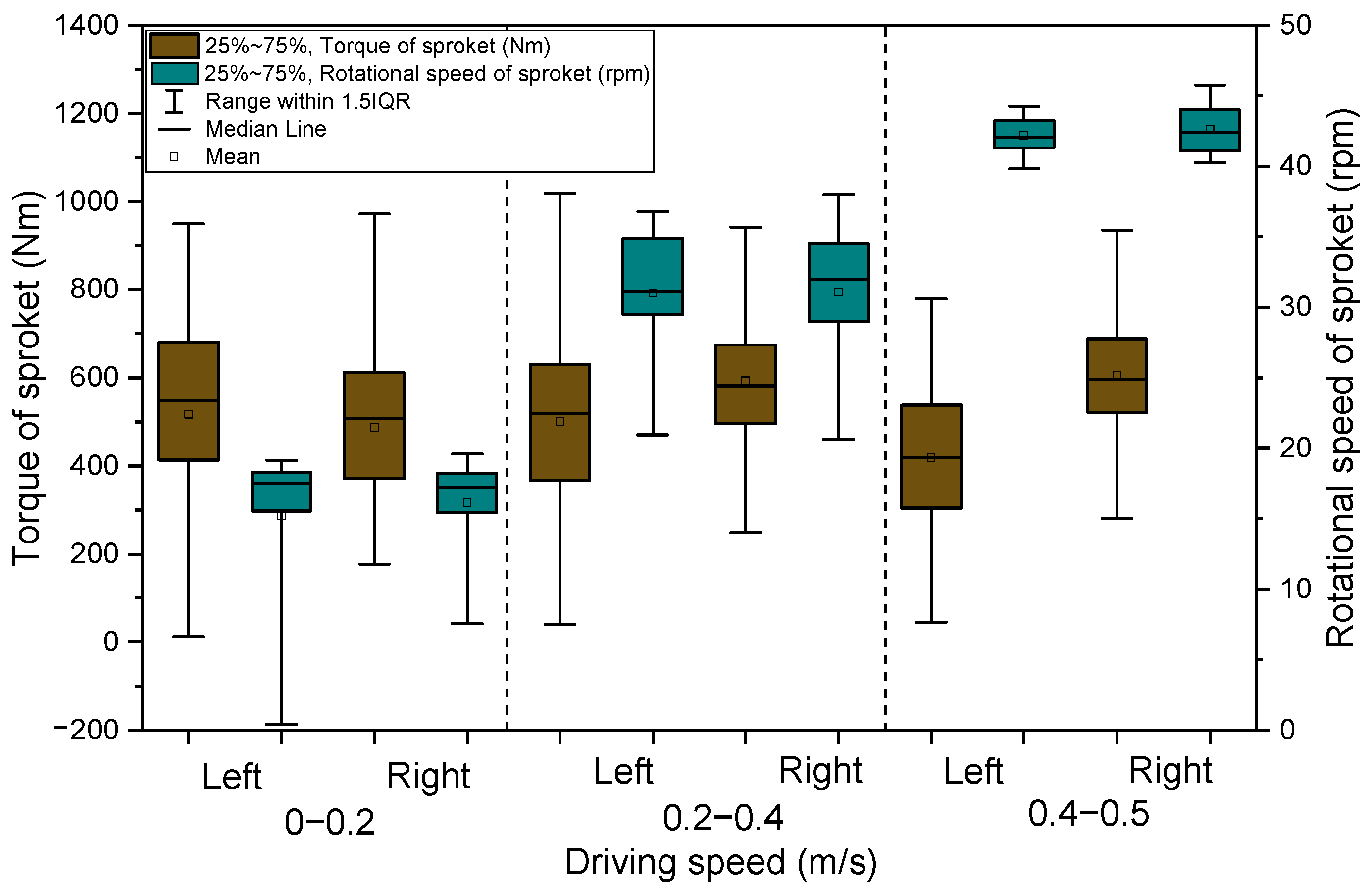

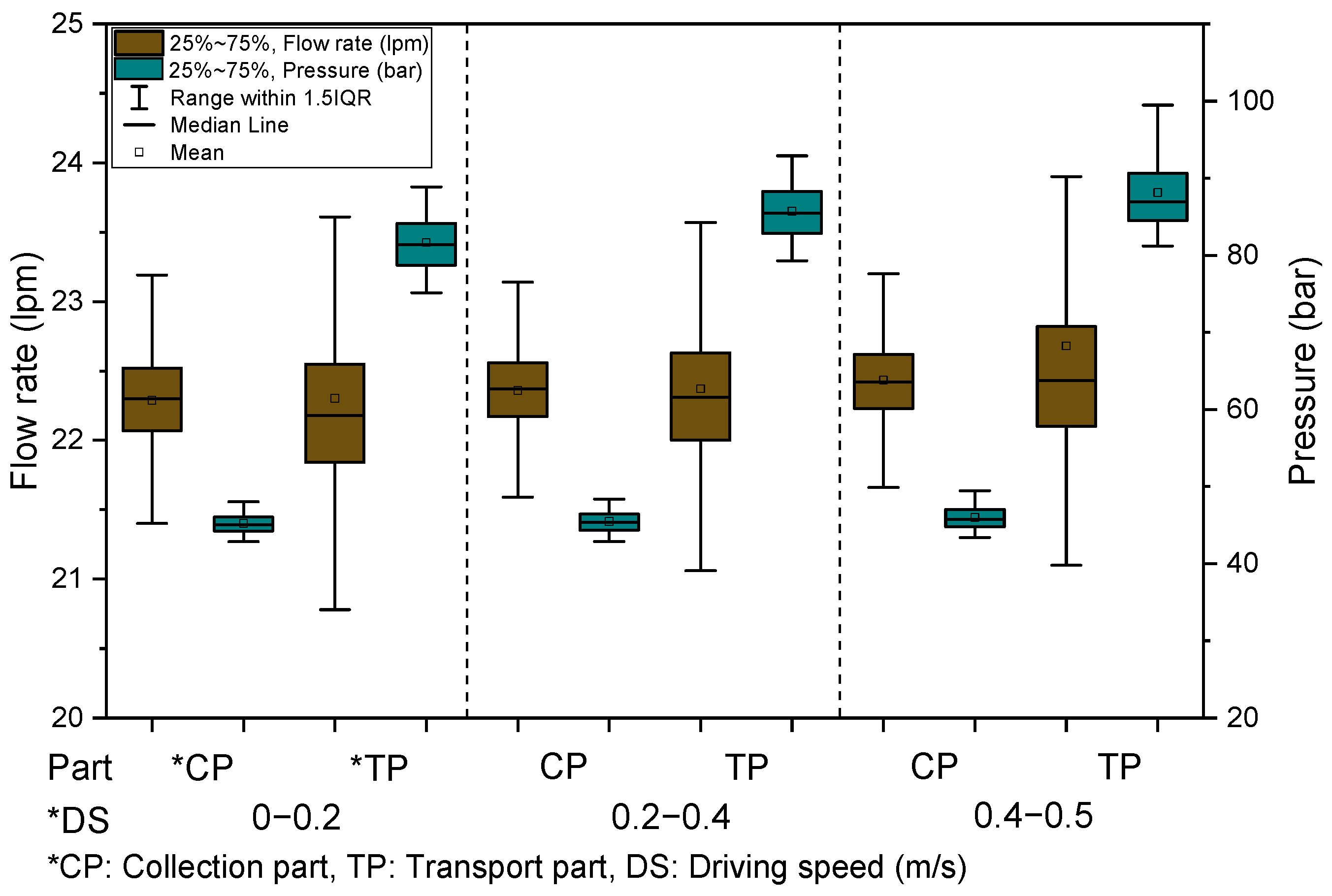

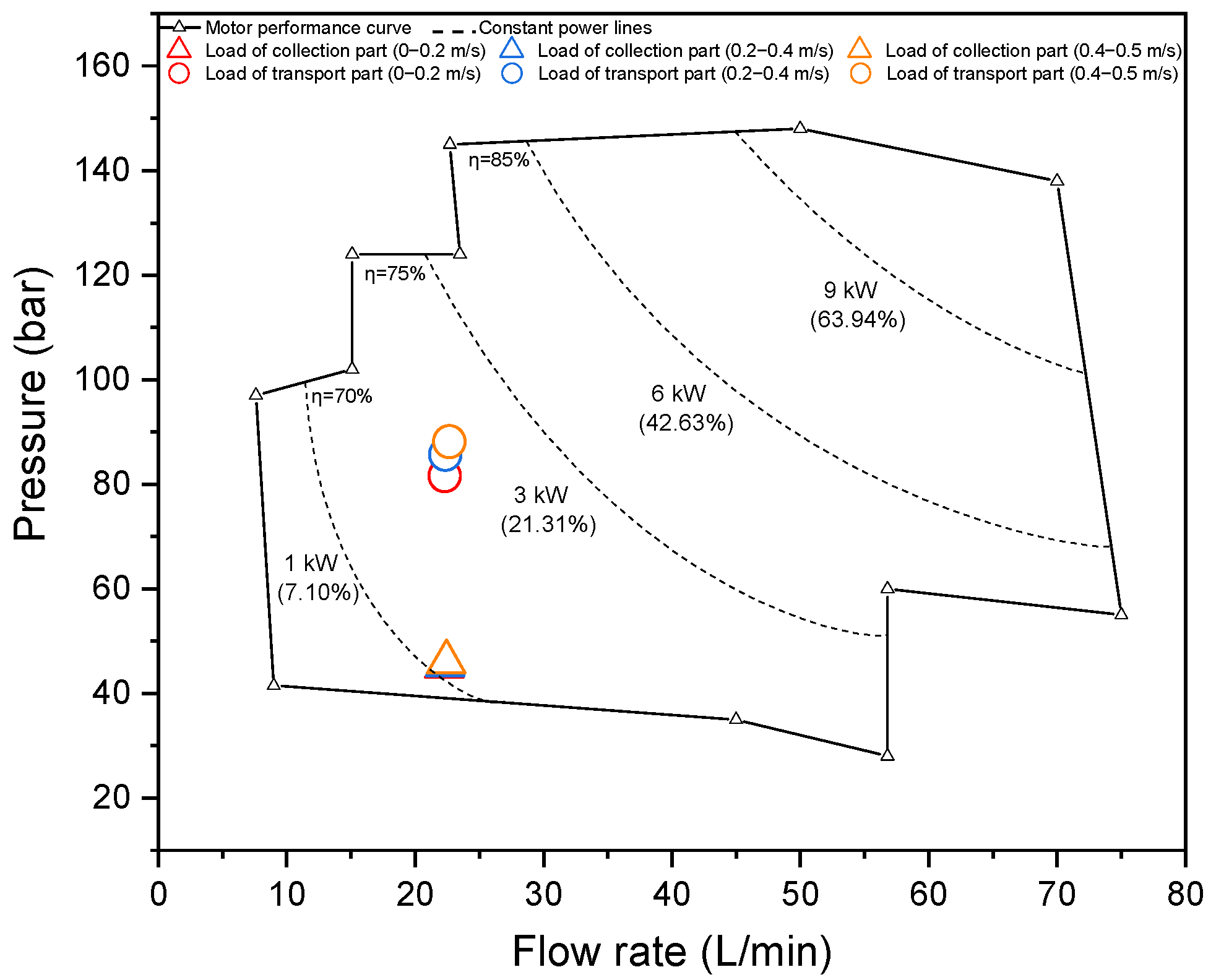

3.3.1. Load Analysis for Main Parts

3.3.2. Analysis of Power Requirements for Main Parts According to Driving Speed

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lee, J.; Oh, Y.-G.; Yoo, S.-H.; Suh, K. Vulnerability assessment of rural aging community for abandoned farmlands in South Korea. Land Use Policy 2021, 108, 105544. [Google Scholar] [CrossRef]

- Happy, K.; Gang, R.; Ban, Y.; Yang, S.; Rahmat, E.; Okello, D.; Komakech, R.; Cyrus, O.; David, K.O.; Kang, Y. Agricultural sustainability through smart farming systems: A comparative analysis between the Republic of Korea and Republic of Uganda. J. Plant Biotechnol. 2024, 51, 167–201. [Google Scholar] [CrossRef]

- Tong, T.; Ye, F.; Zhang, Q.; Liao, W.; Ding, Y.; Liu, Y.; Li, G. The impact of labor force aging on agricultural total factor productivity of farmers in China: Implications for food sustainability. Front. Sustain. Food Syst. 2024, 8, 1434604. [Google Scholar] [CrossRef]

- Emami, M.; Almassi, M.; Bakhoda, H.; Kalantari, I. Agricultural mechanization, a key to food security in developing countries: Strategy formulating for Iran. Agric. Food Secur. 2018, 7, 24. [Google Scholar] [CrossRef]

- Cho, S.; Yoon, H. Evaluating the economic and environmental benefits of rice–soybean diversification in South Korea. Agric. Syst. 2025, 224, 104258. [Google Scholar] [CrossRef]

- Im, D.; Kim, J.H.; Moon, D.J.; Moon, T.I.; Yu, S.H.; Park, Y.J. Optimization of Bucket Size of Garlic Metering Device Using Multibody Dynamics Simulation. J. Biosyst. Eng. 2022, 47, 480–488. [Google Scholar] [CrossRef]

- Lee, C.K.; Choi, D.K. Development of a self-propelled riding garlic clove planter for film mulching: Static falling down angle, center of gravity, seed metering performance. Precis. Agric. Sci. Technol. 2025, 7, 81–94. [Google Scholar] [CrossRef]

- Choi, I.S.; Kang, N.R.; Choi, K.S.; Woo, J.K.; Kim, Y.H.; Yu, S.H.; Choi, Y.; Kim, Y.K. Design·Manufacture and Performance Evaluation of Gathering Type Garlic Harvesting Machine. J. Drive Control 2023, 20, 64–70. [Google Scholar]

- Yu, Z.; Yang, M.; Hu, Z.; Gu, F.; Peng, B.; Zhang, Y.; Yang, K. Kinematic analysis and process optimization of root-cutting systems in field harvesting of garlic based on computer simulation technology. Front. Plant Sci. 2023, 14, 1168900. [Google Scholar] [CrossRef]

- Park, H.G.; Kang, S.H.; Kim, Y.G.; Son, J.H.; Kim, Y.S.; Woo, S.M.; Ha, Y.S. An Investigation of Garlic’s Physical Properties Prior to Collection for the Development of a Garlic Collector. Appl. Sci. 2024, 14, 1644. [Google Scholar] [CrossRef]

- Lee, Y.S.; Kang, N.R.; Kim, Y.H.; Yu, S.H.; Nam, Y.O.; Kwon, S.G.; Hwang, U.S.; Park, H.G. Performance Evaluation of Riding Type Self-Propelled Garlic Collector. J. Korea Acad. Ind. Coop. Soc. 2022, 23, 733–740. [Google Scholar] [CrossRef]

- Jat, D.; Imran, S.; Singh, K.P. Development and Evaluation of Garlic Harvester for Raised Beds. J. Sci. Ind. Res. 2023, 82, 493–503. [Google Scholar] [CrossRef]

- Han, G.; Kim, K.-D.; Ahn, D.-V.; Park, Y.J. Comparative Analysis of Tractor Ride Vibration According to Suspension System Configuration. J. Biosyst. Eng. 2023, 48, 69–78. [Google Scholar] [CrossRef]

- Rahman, M.S.; Fahim, N.S.; Khan, B.; Jubayer, M.F.; Islam, T.; Hossain, M.A. The impact of soil physical properties on combine harvester efficiency: A composite model from correlation trends. Discov. Civil Eng. 2025, 2, 111. [Google Scholar] [CrossRef]

- Do, Y.W.; Moon, S.P.; Nam, Y.J.; Kwon, S.G.; Kim, W.S. Analysis of power requirements for self-propelled garlic collector by travel speed under actual operation condition. J. Drive Control 2024, 21, 135–144. [Google Scholar]

- Pitla, S.K.; Luck, J.D.; Werner, J.; Lin, N.; Shearer, S.A. In-field fuel use and load states of agricultural field machinery. Comput. Electron. Agric. 2016, 121, 290–300. [Google Scholar] [CrossRef]

- Ali, M.; Lee, Y.S.; Chowdhury, M.; Khan, N.A.; Swe, K.M.; Rasool, K.; Kabir, M.S.N.; Lee, D.H.; Chung, S.O. Analysis of driving stability and vibration of a 20-kW self-propelled 1-row Chinese cabbage harvester. J. Biosyst. Eng. 2021, 46, 48–59. [Google Scholar] [CrossRef]

- Kumari, A.; Raheman, H. Development of a Novel Draft Sensing Device with Lower Hitch Attachments for Tractor-Drawn Implements. J. Biosyst. Eng. 2024, 49, 20–28. [Google Scholar] [CrossRef]

- Rodias, E.; Berruto, R.; Busato, P.; Bochtis, D.; Sørensen, C.G.; Zhou, K. Energy Savings from Optimised In-Field Route Planning for Agricultural Machinery. Sustainability 2017, 9, 1956. [Google Scholar] [CrossRef]

- Kwon, D.; Ahn, D.V.; Kim, J.G.; Park, Y.J. Effect Analysis of Motor Power Characteristics on the Energy Consumption of Dual Motor Driven Powertrain for Electric Tractor. J. Biosyst. Eng. 2024, 49, 465–475. [Google Scholar] [CrossRef]

- Kumari, A.; Raheman, H. Tillage Operation with a Tractor Drawn Rotavator Using an Embedded Advisory System for Minimizing Fuel Consumption. J. Biosyst. Eng. 2023, 48, 487–502. [Google Scholar] [CrossRef]

- Zhang, X.; Qiu, L.; Sun, Q.; Jing, Y.; Zhao, Y.; Yao, P. Design and Test of a Single-Row Harvesting and Cutting Integrated Handheld Garlic Harvester. Appl. Sci. 2023, 13, 7077. [Google Scholar] [CrossRef]

- Swe, K.M.; Ali, M.; Chowdhury, M.; Reza, M.N.; Gulandaz, M.A.; Lee, S.H.; Chung, S.O.; Hong, S.J. Theoretical analysis of power requirement of a four-row tractor-mounted radish collector. Korean J. Agric. Sci. 2025, 52, 33–44. [Google Scholar] [CrossRef]

- Oduma, O.; Ugwu, E.C.; Ehiomogue, P.; Igwe, J.E.; Ntunde, D.I.; Agu, C.S. Modelling of the effects of working width, tillage depth and operational speed on draft and power requirements of disc plough in sandy-clay soil in South-East Nigeria. Sci. Afr. 2023, 21, e01815. [Google Scholar] [CrossRef]

- Sun, Q.; Sui, Y.; Zhao, L.; Hou, J.; Wang, C.; Ying, C.; Shangguan, J. Design and Development of Self-Propelled Garlic Harvester. Agric. Res. 2018, 7, 495–505. [Google Scholar] [CrossRef]

- Hou, J.; Chen, Y.; Li, T.; Wang, L.; Zhou, J. Development and Test of 4S-6 Garlic Combine Harvester. J. Eng. Sci. Technol. Rev. 2020, 13, 106–114. [Google Scholar] [CrossRef]

- Zhu, Z.; Li, W.; Wen, F.; Chen, L.; Xu, Y. Towards Optimizing Garlic Combine Harvester Design with Logistic Regression. Appl. Sci. 2022, 12, 6015. [Google Scholar] [CrossRef]

- Lee, G.-H.; Moon, B.-E.; Basak, J.K.; Kim, N.-E.; Paudel, B.; Jeon, S.-W.; Kook, J.; Kang, M.-Y.; Ko, H.J.; Kim, H.T. Assessment of Load on Threshing Bar During Soybean Pod Threshing. J. Biosyst. Eng. 2023, 48, 478–486. [Google Scholar] [CrossRef]

- Kumar, M.; Sahoo, P.K.; Kushwaha, D.K.; Mani, I.; Pradhan, N.C.; Patel, A.; Tariq, A.; Ullah, S.; Soufan, W. Force and power requirement for development of cumin harvester: A dynamic approach. Sci. Rep. 2024, 14, 15366. [Google Scholar] [CrossRef] [PubMed]

- Tekeste, M.Z.; Raper, R.L.; Schwab, E.B. Soil Drying Effects on Soil Strength and Depth of Hardpan Layers as Determined from Cone Index Data. Agric. Eng. Int. CIGR J. 2008, X, 1–17. [Google Scholar]

- Li, J.; Sun, S.; Sun, C.; Liu, C.; Tang, W.; Wang, H. Analysis of Effect of Grouser Height on Tractive Performance of Tracked Vehicle under Different Moisture Contents in Paddy Soil. Agriculture 2022, 12, 1581. [Google Scholar] [CrossRef]

- Shin, S.; Woo, S.I. Three-Dimensional Upper Bound Solution to Estimate Soil Thrust of a Track System on Saturated Clay Slopes under Undrained Conditions. Appl. Sci. 2024, 14, 4335. [Google Scholar] [CrossRef]

- Kim, W.S.; Kim, Y.S.; Kim, T.J.; Park, S.E.; Choi, I.S.; Kim, Y.K.; Kim, Y.J.; Kim, Y.J. Analysis of Power Requirement of 78 kW Class Agricultural Tractor According to the Major Field Operation. Trans. Korean Soc. Mech. Eng. A 2019, 43, 911–922. [Google Scholar] [CrossRef]

- Li, Z.; Wang, C.; Quan, L.; Hao, Y.; Ge, L.; Xia, L. Study on energy efficiency characteristics of the heavy-duty manipulator driven by electro-hydraulic hybrid active-passive system. Autom. Constr. 2021, 125, 103646. [Google Scholar] [CrossRef]

- Siddique, M.A.A.; Jeon, H.H.; Park, J.D.; Lee, S.H.; Kim, Y.J. Power Requirement Analysis and Performance Evaluation Using a Self-Propelled Harvester Simulation Model for Potato Harvesting. J. Drive Control 2025, 22, 1–7. [Google Scholar]

- Park, M.J.; Yang, C.W.; Jeon, H.H.; Baek, S.Y.; Baek, S.M.; Lee, J.H.; Kim, Y.J. Power Analysis for Silage Formation of 140 kW Self-Propelled Integrated Bale Production Machine. Precis. Agric. Sci. Technol. 2024, 3, 45–56. [Google Scholar]

- Li, Y.; He, Y.; Zhang, K.; Wang, S.; Hu, X.; Chen, J. Design and Performance Evaluation of a Self-Propelled Mugwort Harvester for Hilly and Mountainous Regions. Agriculture 2025, 15, 111. [Google Scholar] [CrossRef]

- Vukovic, M.; Leifeld, R.; Murrenhoff, H. Reducing Fuel Consumption in Hydraulic Excavators—A Comprehensive Analysis. Energies 2017, 10, 687. [Google Scholar] [CrossRef]

| Item | Specification | |

|---|---|---|

| Engine | Type | 4-Cycle, In-line, Diesel, Water-cooled |

| Cylinders | 4 | |

| Length × Width × Height (mm3) | 772 × 531 × 696 | |

| Aspiration | Turbocharged | |

| Rated power (kW) | 40.2 @ 2600 rpm | |

| Max. torque (Nm) | 182.6 @ 1700 rpm | |

| Length × Width × Height (mm3) | 5580 × 2205 × 2100 | |

| Weight (kg) | 3170 | |

| Sensor | Model | Measurement Range | Accuracy (Class) | Resolution | Temperature Drift | Sampling Rate/Applied Filter | Expanded Uncertainty (k = 2) |

|---|---|---|---|---|---|---|---|

| Flow sensor | HySense QG100 (Hydrotechnik, Germany) | 0.7–70 L/min | ±0.4% of reading | 0.01 L/min | ±0.03%/°C | 2 kHz/Low-pass (2nd order) | ±0.6% |

| Pressure sensor | HySense PR130 (Hydrotechnik, Germany) | 0–250 bar | ±0.5% FS @ +22 °C | 0.1 bar | ±0.03%/°C | ≤1 kHz/Low-pass (2nd order) | ±0.7% |

| GNSS receiver | MRP-2000 (MBC RTK, Republic of Korea) | Horizontal ± (10 + 1 × 10−6 D) mm | ±1.0% (RTK mode) | 1 mm | ±0.01%/°C | 10 Hz/Kalman filter | ±15 mm |

| Torque telemetry | Telemetry System (MANNER, Germany) | 0–2000 Nm | ±0.1% FS | 0.5 Nm | ±0.002%/°C (zero drift) | 4 kHz/Bandwidth 1 kHz | ±0.2% |

| Encoder | Autonics E50S8 (Republic of Korea) | 1024 pulse/rev | - | 13-bit (8000 PPR max) | - | ≤300 kHz/Moving average | ±1 pulse |

| Data acquisition (DAQ) | HBM QuantumX MX840B (Germany) | ±10 V | ±0.03% FS | 24 bit | ±0.01%/°C | 40 kHz/ch/Digital Butterworth filter | ±0.05% |

| Transporting Speed (rpm) | Collecting Speed (rpm) | Transport Part | Collection Part | ||||

|---|---|---|---|---|---|---|---|

| Min. | Max. | Avg. ± Std. | Min. | Max. | Avg. ± Std. | ||

| 30 | 35 | 0.58 | 0.78 | 0.70 ± 0.03 f | 0.28 | 0.51 | 0.39 ± 0.04 d |

| 45 | 0.57 | 0.81 | 0.71 ± 0.04 e | 0.50 | 0.88 | 0.65 ± 0.07 a | |

| 40 | 35 | 0.79 | 1.03 | 0.91 ± 0.04 c | 0.28 | 0.52 | 0.38 ± 0.04 e |

| 45 | 0.76 | 1.01 | 0.88 ± 0.05 d | 0.49 | 0.88 | 0.64 ± 0.07 b | |

| 50 | 35 | 0.96 | 1.22 | 1.10 ± 0.05 a | 0.27 | 0.53 | 0.38 ± 0.04 e |

| 45 | 0.88 | 1.17 | 1.04 ± 0.05 b | 0.48 | 0.89 | 0.64 ± 0.07 c | |

| Working Depth (cm) | Item | Power Requirement (kW) | |||||

|---|---|---|---|---|---|---|---|

| Driving Part | Collection Part | Transport Part | Total | ||||

| Left | Right | Total | |||||

| 8.5 | Min. | 0.00 | 0.00 | 0.17 | 0.80 | 1.44 | 2.96 |

| Max. | 2.59 | 4.10 | 6.55 | 1.47 | 2.04 | 9.43 | |

| Avg. ± Std. | 0.71 ± 0.38 b | 1.10 ± 0.61 c | 1.81 ± 0.78 c | 1.10 ± 0.13 c | 1.78 ± 0.07 a | 4.69 ± 0.79 c | |

| 10 | Min. | 0.01 | 0.00 | 0.14 | 0.79 | 1.23 | 2.78 |

| Max. | 2.48 | 4.69 | 5.07 | 1.56 | 2.02 | 8.12 | |

| Avg. ± Std. | 0.70 ± 0.42 c | 1.17 ± 0.65 b | 1.88 ± 0.84 b | 1.11 ± 0.13 b | 1.74 ± 0.08 b | 4.72 ± 0.84 b | |

| 13 | Min. | 0.10 | 0.00 | 0.27 | 0.81 | 1.22 | 2.85 |

| Max. | 2.79 | 3.70 | 5.87 | 1.46 | 1.77 | 8.47 | |

| Avg. ± Std. | 0.95 ± 0.51 a | 1.21 ± 0.71 a | 2.16 ± 1.02 a | 1.12 ± 0.13 a | 1.53 ± 0.09 c | 4.81 ± 1.04 a | |

| Driving Speed (m/s) | Item | Power Requirement (kW) | |||||

|---|---|---|---|---|---|---|---|

| Driving Part | Collection Part | Transport Part | Total | ||||

| Left | Right | Total | |||||

| 0.05 | Min. | 0.00 | 0.00 | 0.00 | 0.74 | 0.23 | 0.97 |

| Max. | 1.38 | 2.45 | 2.74 | 1.60 | 2.06 | 6.40 | |

| Avg. ± Std. | 0.31 ± 0.21 c | 0.44 ± 0.32 c | 0.75 ± 0.42 c | 1.09 ± 0.14 c | 1.77 ± 0.14 b | 3.60 ± 0.71 c | |

| 0.15 | Min. | 0.01 | 0.00 | 0.14 | 0.79 | 1.23 | 2.16 |

| Max. | 2.48 | 4.69 | 5.07 | 1.56 | 2.02 | 8.64 | |

| Avg. ± Std. | 0.70 ± 0.42 b | 1.17 ± 0.65 b | 1.88 ± 0.84 b | 1.11 ± 0.13 b | 1.74 ± 0.08 a | 4.72 ± 1.05 b | |

| 0.25 | Min. | 0.00 | 0.00 | 0.13 | 0.85 | 1.15 | 2.13 |

| Max. | 4.22 | 6.76 | 8.07 | 1.64 | 2.11 | 11.81 | |

| Avg. ± Std. | 1.41 ± 0.78 a | 2.25 ± 1.24 a | 3.65 ± 1.65 a | 1.29 ± 0.16 a | 1.72 ± 0.18 c | 6.66 ± 1.99 a | |

| Variable | Variable | Power Requirement | Variable Increase Rate | Power Requirement Increase Rate | ||

|---|---|---|---|---|---|---|

| Value (a) | Value (b) | Value (a) | Value (b) | |||

| Transporting speed (rpm) | 30 | 40 | 0.71 | 0.91 | 33.33% | 28.17% |

| 40 | 50 | 0.91 | 1.1 | 25.00% | 20.88% | |

| Collecting speed (rpm) | 35 | 45 | 0.39 | 0.65 | 28.57% | 66.67% |

| Working depth (cm) | 8.5 | 10 | 4.69 | 4.72 | 17.65% | 0.64% |

| 10 | 13 | 4.72 | 4.81 | 30.00% | 1.91% | |

| Driving speed (m/s) | 0.05 | 0.15 | 3.6 | 4.72 | 200.00% | 31.11% |

| 0.15 | 0.25 | 4.72 | 6.66 | 66.67% | 41.10% | |

| Driving Speed (m/s) | Item | Driving Part | |||

|---|---|---|---|---|---|

| * TL | * RL | * TR | * RR | ||

| 0–0.2 | Min. | 7 | 0 | 177 | 6 |

| Max. | 949 | 22 | 1065 | 20 | |

| Avg. ± Std. | 517 ± 203 a | 15 ± 6 c | 487 ± 167 c | 16 ± 3 c | |

| 0.2–0.4 | Min. | 40 | 17 | 248 | 20 |

| Max. | 1020 | 44 | 1092 | 40 | |

| Avg. ± Std. | 500 ± 192 b | 31 ± 5 b | 593 ± 148 b | 31 ± 5 b | |

| 0.4–0.5 | Min. | 45 | 38 | 281 | 40 |

| Max. | 778 | 46 | 989 | 47 | |

| Avg. ± Std. | 419 ± 153 c | 42 ± 1 a | 604 ± 125 a | 43 ± 2 a | |

| Driving Speed (m/s) | Item | Collection Part | Transport Part | ||

|---|---|---|---|---|---|

| Flow Rate (L/min) | Pressure (bar) | Flow Rate (L/min) | Pressure (bar) | ||

| 0–0.2 | Min. | 20.81 | 40.09 | 20.39 | 69.43 |

| Max. | 23.44 | 52.29 | 27.14 | 108.21 | |

| Avg. ± Std. | 22.29 ± 0.34 c | 45.20 ± 1.56 c | 22.30 ± 0.83 c | 81.64 ± 4.31 c | |

| 0.2–0.4 | Min. | 21.13 | 39.08 | 20.63 | 69.90 |

| Max. | 23.56 | 52.47 | 26.71 | 106.66 | |

| Avg. ± Std. | 22.36 ± 0.30 b | 45.47 ± 1.65 b | 22.37 ± 0.65 b | 85.71 ± 4.35 b | |

| 0.4–0.5 | Min. | 21.46 | 40.69 | 20.93 | 76.14 |

| Max. | 23.56 | 52.45 | 26.60 | 109.12 | |

| Avg. ± Std. | 22.43 ± 0.29 a | 46.01 ± 1.82 a | 22.68 ± 1.00 a | 88.15 ± 5.51 a | |

| Driving Speed (m/s) | Item | Power Requirement (kW) | |||||

|---|---|---|---|---|---|---|---|

| Driving Part | Collection Part | Transport Part | Total | ||||

| Left | Right | Total | |||||

| 0–0.2 | Min. | 0.01 | 0.12 | 0.14 | 1.29 | 2.24 | 4.08 |

| Max. | 2.34 | 2.23 | 3.78 | 1.82 | 4.07 | 8.50 | |

| Avg. ± Std. | 0.78 ± 0.47 | 0.86 ± 0.39 | 1.65 ± 0.70 c | 1.51 ± 0.07 c | 2.73 ± 0.22 c | 5.89 ± 0.69 c | |

| 0.2–0.4 | Min. | 0.08 | 0.60 | 1.38 | 1.28 | 2.30 | 5.22 |

| Max. | 4.02 | 3.77 | 7.35 | 1.80 | 4.18 | 12.28 | |

| Avg. ± Std. | 1.64 ± 0.71 | 1.94 ± 0.59 | 3.57 ± 0.97 b | 1.53 ± 0.06 b | 2.88 ± 0.19 b | 7.98 ± 1.04 b | |

| 0.4–0.5 | Min. | 0.18 | 1.19 | 2.72 | 1.33 | 2.47 | 7.28 |

| Max. | 3.90 | 4.84 | 7.29 | 1.82 | 4.24 | 11.79 | |

| Avg. ± Std. | 1.85 ± 0.67 | 2.71 ± 0.64 | 4.56 ± 0.85 a | 1.55 ± 0.07 a | 3.00 ± 0.30 a | 9.11 ± 0.85 a | |

| Category | Variable | Levels (Expected Range) | Hypothesized Effect and Objective |

|---|---|---|---|

| Soil conditions | Soil moisture content | Dry (20%)–Moderate (30%)–Wet (40%) | Higher moisture increases crawler driving torque. |

| Soil texture (regional fields) | Sandy loam–Loam–Clay loam | Texture variation affects load stability. | |

| Cone index | 1000–2500 kPa | Higher CI increases driving torque fluctuation. | |

| Crop conditions | Crop density | Low–Medium–High | Higher density increases collection resistance. |

| Terrain conditions | Slope | 0–5–10° | Slope affects left–right torque balance. |

| Operating conditions (interaction) | Driving speed × Working depth | (0.05–0.25 m/s) × (8–13 cm) | Cross-effects alter total power behavior. |

| Machine configuration | Engine capacity | 30–50 kW | Evaluate optimal capacity and downsizing. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Do, Y.-W.; Min, Y.-S.; Moon, S.-P.; Nam, Y.-J.; Kwon, S.-G.; Kim, W.-S. Evaluation of Power Requirement for a Self-Propelled Garlic Collector Based on Load Experiments and Variable Impact Analysis Under Various Operating Conditions. Electronics 2025, 14, 4559. https://doi.org/10.3390/electronics14234559

Do Y-W, Min Y-S, Moon S-P, Nam Y-J, Kwon S-G, Kim W-S. Evaluation of Power Requirement for a Self-Propelled Garlic Collector Based on Load Experiments and Variable Impact Analysis Under Various Operating Conditions. Electronics. 2025; 14(23):4559. https://doi.org/10.3390/electronics14234559

Chicago/Turabian StyleDo, Young-Woo, Yi-Seo Min, Seok-Pyo Moon, Young-Jo Nam, Seung-Gwi Kwon, and Wan-Soo Kim. 2025. "Evaluation of Power Requirement for a Self-Propelled Garlic Collector Based on Load Experiments and Variable Impact Analysis Under Various Operating Conditions" Electronics 14, no. 23: 4559. https://doi.org/10.3390/electronics14234559

APA StyleDo, Y.-W., Min, Y.-S., Moon, S.-P., Nam, Y.-J., Kwon, S.-G., & Kim, W.-S. (2025). Evaluation of Power Requirement for a Self-Propelled Garlic Collector Based on Load Experiments and Variable Impact Analysis Under Various Operating Conditions. Electronics, 14(23), 4559. https://doi.org/10.3390/electronics14234559