Abstract

Semiconductor wafer manufacturing is one of the most complex and data-intensive industrial processes, comprising 500–1000 tightly interdependent steps, each requiring nanometer-level precision. As device nodes approach 3 nm and beyond, even minor deviations in parameters such as oxide thickness or critical dimensions can lead to catastrophic yield loss, challenging traditional physics-based control methods. In response, the industry has increasingly adopted regression analysis and predictive modeling as essential analytical frameworks. Classical regression, long used to support design of experiments (DOE), process optimization, and yield analysis, has evolved to enable multivariate modeling, virtual metrology, and fault detection. Predictive modeling extends these capabilities through machine learning and AI, leveraging massive sensor and metrology data streams for real-time process monitoring, yield forecasting, and predictive maintenance. These data-driven tools are now tightly integrated into advanced process control (APC), digital twins, and automated decision-making systems, transforming fabs into agile, intelligent manufacturing environments. This review synthesizes foundational and emerging methods, industry applications, and case studies, emphasizing their role in advancing Industry 4.0 initiatives. Future directions include hybrid physics–ML models, explainable AI, and autonomous manufacturing. Together, regression and predictive modeling provide semiconductor fabs with a robust ecosystem for optimizing performance, minimizing costs, and accelerating innovation in an increasingly competitive, high-stakes industry.

1. Introduction

Semiconductor wafer manufacturing is widely recognized as one of the most intricate, multivariate, and data-intensive industrial processes in existence [1]. The fabrication of a single wafer involves 500 to 1000 sequential process steps, each one interdependent and highly sensitive to variation [2,3]. Semiconductor fabrication involves photolithography, thin-film deposition, ion implantation, etching, cleaning, CMP, metrology, inspection, and electrical testing [4]. Engineers analyze vast data—such as film thickness, line widths, critical dimensions (CD), overlay accuracy, defect counts, and electrical parameters—to ensure wafer quality [2]. Each layer requires sub-nanometer precision; even minor deviations can compound across hundreds of steps, resulting in significant yield loss [2,4].

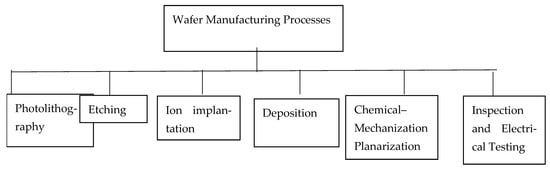

The overall classification of the wafer manufacturing processes is shown in Figure 1.

Figure 1.

The overall classification of the wafer manufacturing processes.

As technology nodes shrink toward 3 nm and beyond, manufacturing tolerances have become incredibly stringent [5]. Variations as minor as a few angstroms in oxide thickness or a few nanometers in CD can have profound impacts on device performance and overall yield [6]. These tight margins are further challenged by factors such as tool-to-tool variability, recipe drift, environmental fluctuations, consumable wear, and raw material lot differences [5]. In earlier technology nodes, engineers often relied on physics-based heuristics and empirical control strategies. Still, these traditional approaches struggle to provide sufficient precision and adaptability in the face of modern manufacturing complexity [7,8]. The semiconductor industry has therefore embraced advanced statistical modeling and machine learning techniques to manage this growing variability and maintain competitiveness [7,9].

Wafer fabrication aims to maximize yield, minimize variability, detect process excursions early, and sustain high tool uptime and throughput [10]. Achieving these goals requires proactive, data-driven control rather than reactive troubleshooting [5,6]. Regression analysis and predictive modeling now underpin semiconductor manufacturing, empowering engineers to monitor, forecast, and optimize processes with exceptional precision and efficiency [11].

Regression, a long-standing staple of semiconductor data analytics, is used to quantify the relationships between process inputs and outputs [11,12,13]. Inputs may include recipe parameters, tool settings, consumable lifetimes, or incoming material characteristics, while outputs encompass key metrics like wafer yield, defect density, and device electrical performance [12]. Regression models, including linear, polynomial, and multivariate regression [11,13], have historically underpinned the design of experiments, helping process engineers identify critical factors, model process interactions, and fine-tune recipes [4,14]. However, regression has evolved well beyond its traditional role, now serving as a foundation for high-dimensional analysis, fault detection models, and virtual metrology systems [4,7,13,14]. Wan et al. [14] evaluate the performance of four typical regression methods for VM: multiple linear regression (MLR), least absolute shrinkage and selection operator (LASSO), neural networks (NN), and Gaussian process regression (GPR) on the virtual metrology.

Predictive modeling represents a natural extension of regression-based analytics [13], incorporating machine learning (ML) and artificial intelligence (AI) to handle large-scale, nonlinear, and high-dimensional data streams [15]. For example, virtual metrology models predict measurements, such as film thickness or CD, using upstream sensor data, allowing fabs to reduce reliance on time-consuming or destructive physical metrology steps [1,16,17]. Dreyfus et al. [17] reported a detailed review of the development of virtual metrology (VM). Similarly, fault detection and classification (FDC) systems integrate predictive algorithms to detect subtle deviations in process signals before they escalate into yield-impacting issues [6,8]. By embedding predictive models into run-to-run (R2R) control loops, fabs can achieve real-time adjustments and minimize process drift [6,14].

Another critical application of predictive modeling is yield forecasting, which enables proactive decision-making by predicting wafer-level or lot-level yield distributions [2,18]. These forecasts inform engineering teams about potential risks and guide preventive measures, such as equipment calibration or recipe modification, before failures occur [19]. Machine learning models trained on sensor and maintenance logs can anticipate tool failures, optimize maintenance schedules, and minimize costly downtime [15]. This proactive approach represents a paradigm shift from reactive troubleshooting to autonomous optimization, aligning with the semiconductor industry’s vision of “lights-out” manufacturing. In this future, fabs run continuously with minimal human intervention [17,19].

Device complexity, market pressures, and rapid innovation cycles require fabs to maintain agility while ensuring uncompromising quality [8]. Regression and predictive modeling not only enhance process visibility but also provide a framework for continuous improvement, where insights from historical and real-time data feed into iterative optimization cycles [2,8]. By integrating these models with advanced process control, fabs achieve tighter control limits, faster ramp-to-yield for new technology nodes, and significant cost savings [16].

This article reviews regression and predictive modeling in semiconductor wafer manufacturing, covering classical regression, multivariate statistics, machine learning, AI, and predictive maintenance frameworks. It examines how these methods enhance understanding of process interactions, failure prediction, and efficiency optimization. Emphasizing integration with SPC, DOE, virtual metrology, digital twins, and analytics platforms, the review positions these tools as pillars of smart fabs—where data-driven intelligence enables highly efficient, predictive, and scalable wafer production.

In this review of applications of regression and predictive modeling in wafer manufacturing, the background is introduced in the first section. The application of regression and predictive modeling in wafer manufacturing is described in Section 2 and Section 3. The fourth and fifth sections describe the regression and predictive modeling methods. The sixth section is the integration with machine learning. The seventh section describes the challenges of regression and predictive modeling. The future trends are discussed in Section 8. Finally, there is Section 9, the conclusion.

1.1. Role of Regression and Predictive Modeling

Wafer manufacturing is a highly complex, multi-step process (including lithography, etching, deposition, CMP, implantation, etc.) with thousands of controllable parameters [2,10]. The variability in these parameters strongly affects critical dimension uniformity, overlay accuracy, film thickness, electrical test performance (parametric yield), and overall yield and reliability [2].

Wafer fabrication is highly multivariate, with each step involving numerous controllable factors such as etch time, gas flow, and pressure [3]. Massive, nonlinear, and correlated datasets emerge from metrology, inspection, testing, and in-tool sensors capturing temperature, pressure, and plasma signals [14]. Statistical modeling and machine learning—particularly regression and predictive modeling—enable fabs to convert these complex, high-dimensional data streams into actionable insights, driving process optimization and accelerated technology scaling [20,21].

Regression models serve as a bridge to quantify relationships between process inputs and outputs. They help engineers answer the following questions:

- How do process conditions (e.g., etch time, temperature, pressure) influence wafer characteristics (e.g., film thickness, CD uniformity)? That is, how do we quantify complex relationships between inputs (recipes, tool settings, material properties) and outputs (film thickness, line width, yield) [4,14]?

- What is the impact of multiple interacting factors on yield and defect density [4,8]?

Predictive modeling aims to transform these large, noisy datasets into actionable predictions for wafer yield, defect density, process excursions, and equipment health and maintenance needs [22]. Therefore, the intermediate in-line data can be used to predict wafer and die-level outcomes without destructive measurement (virtual metrology) [20]. This helps fabs reduce cycle time, improve yield, and detect deviations and anomalies early in real time (fault detection and classification), without the need for exhaustive measurement [23]. Therefore, it could forecast the health of the forecast tool and wafer yield distributions well before the final test [15,18].

The key differences and complementarity of regression and predictive modeling in semiconductor wafer manufacturing are listed in Table 1.

Table 1.

Key differences and complementarity of regression and predictive modeling in semiconductor wafer manufacturing.

1.2. The Applications in the Process Steps of Wafer Manufacturing

Some typical examples of the applications in wafer manufacturing are introduced as follows:

- Lithography: This includes regression models for predicting CD uniformity, focus-exposure process windows, and overlay error [24] and regression models for overlay error prediction based on stage temperature, wafer bow, and lens aberration [24].

- Etching and Deposition: This predicts etch depth and film thickness uniformity from tool sensor signals [25], optimizing plasma etching by integrating precise three-dimensional etching simulation and machine learning [26].

- Chemical–Mechanical Polishing (CMP): Predicting the wafer material removal rate for semiconductor chemical–mechanical polishing is performed by a regression model [27]. Five regression models were proposed to predict the material removal of a wafer [28]. Yu et al. [29] used models to predict the material removal rate (MRR) in the chemical–mechanical planarization process, with the asperity radius and asperity density of the polishing pad as the responses.

- Metrology Data Correlation: Regression links in-line inspection data with final wafer yield [8]. Rana et al. [22] showed that predictive metrology and analytics, which rely on multivariate, nonlinear, and correlated data, are difficult to model mathematically but can be effectively learned by computing machines for process prediction and control.

- Electrical Test Data: Regression can be used for predicting die pass/fail before final test [30]. Skinner et al. [11] selected two traditional multivariate statistical methods—principal component methods and regression-based methods—and a classification and regression tree (CART) method to study the effects of the wafer fabrication process on the quality or yield of the wafers.

1.3. Benefits of Regression and Predictive Modeling

The benefits of regression and predictive modeling are listed below.

1.3.1. Early Yield Estimation: Predicts Outcomes Before Wafers Reach the Testing Stage

Wang et al. [31] developed a discrete spatial Bayesian model using wafer map defect data. They employed a hierarchical generalized linear mixed framework to capture global trends and spatial correlations, enabling improved analysis and prediction of wafer yield across spatially clustered die locations.

Ahmadi et al. [32] analyzed production data from two 65 nm RF transceivers to validate a yield estimation method based on wafer measurements, suitable for fab or design migrations. Kumar et al. [33] reviewed probabilistic yield models addressing spatial defects, radial yield loss, and complex process variations, highlighting techniques for accurately modeling interconnected wafer manufacturing processes.

1.3.2. Process Optimization: Identifies Critical Parameters with the Most Significant Impact

Kim et al. [34] introduced an ROI-based productivity model that uses deep neural networks to predict yields from wafer map configurations and employs differential evolution to optimize wafer dimensions. Comparative results demonstrated significant improvements in fab productivity and wafer production capacity [2,34].

1.3.3. Cost Reduction: Reduces Metrology Steps and Wafer Scrap and Enables Predictive Maintenance and Fewer Reworks

Pfitzner et al. [35] proposed two cost-reduction strategies for wafer fabrication: integrating metrology directly into processing tools and expanding wafer recycling. Standardized hardware and software interfaces enable seamless metrology integration, reducing testing costs, transport, and handling while improving tool utilization. Application-specific recycling models with graded wafer quality further enhance material efficiency and overall manufacturing sustainability [35].

1.3.4. Improved Reliability: Detects Subtle Drifts Before They Cause Widespread Failures

Kuo and Kim [36] introduce the realities of yield, reliability, aging, cost factors, and fault coverage in semiconductor manufacturing. They discuss the advantages and disadvantages of various yield models. Establishing a model that encompasses both reliability and yield can serve as a foundation for developing effective stress management strategies to ensure high-quality semiconductor products [36].

Chou et al. [37] combined artificial intelligence (AI) and simulation techniques to evaluate the long-term reliability of wafer-level packages (WLPs). This study applied artificial neural network (ANN) theory to analyze an extensive database of WLP structural reliability data to develop a regression model that correlates WLP structure with reliability. Once the regression model was validated, reliability results could be instantly obtained by simply inputting the geometric parameters of the WLP.

1.3.5. Shorter Ramp-Up: Accelerates Development of New Technology Nodes and Accelerates Learning Cycles for New Nodes

Xu et al. [38] establish a fast-ramp-up framework for the yield improvement model, which enables rapid yield improvements for new products and provides design companies with prompt feedback on failure analysis results. Tirkel [39] applied machine learning (ML) and data mining (DM) methods to develop a cycle time prediction model. Historical production line data from the fab’s manufacturing execution system (MES) contained detailed wafer batch processing for various operations.

1.3.6. Higher Yield: Early Detection of Yield Excursions

Dong et al. [40] developed a wafer yield prediction model that integrates spatial defect clustering into functional testing. Using a fusion LASSO algorithm, spatial covariates were derived and combined with test data via logistic regression. Incorporating defect cluster characteristics improved prediction accuracy and enabled reliable yield forecasting for new wafers using historical production data [41,42].

Kumar et al. [43] reviewed the literature on key yield modeling issues, including simple probabilistic yield models and models that incorporate key characteristics such as spatial defects and radial yield loss. The authors emphasized the importance of systematically integrating various factors in yield modeling.

1.3.7. Reduced Scrap: Predict Failing Wafers Before Packaging

Dimaculangan et al. [30] identified the final test as a frequent source of low yield. Using three years of production data, they applied regression analysis with continuous and categorical front- and back-end variables (excluding WAT) to train, validate, and evaluate 11 regressors for predicting final test yield in semiconductor manufacturing.

1.4. Data Landscape in Wafer Manufacturing

Before addressing regression and predictive modeling, it is crucial to understand the nature of data in wafer fabs [41]:

- Process parameters: The tool settings data are temperature, pressure, RF power, gas flow, and rotation speed. The recipe variables are bake times, etch durations, and polish rates [42,43,44].

- In situ sensor data: These time-series signals from plasma optical emission, chamber pressure traces, and motor current profiles often include thousands of correlated variables per wafer run [45,46].

- Metrology data: This includes critical dimensions (CD-SEM, scatterometry) and film thickness (ellipsometry, X-ray Reflectivity (XRR)) [44,45].

- Overlay, flatness, defects: They include defect and inspection data and defect counts, wafer maps, defect types (particles, pattern defects, scratches) [42,44].

- Electrical test and yield data: They include wafer acceptance test (WAT), parametric tests (threshold voltage, leakage currents), final test yield at the die and wafer level, etc. [42,44].

Such data is high-volume, high-dimensional, and hierarchical (wafer-within-lot, die-within-wafer). Regression and predictive modeling are essential for extracting insights and deploying run-to-run control, yield learning, and predictive maintenance [41,45].

2. The Application of Regression in Wafer Manufacturing

Regression models quantify the mathematical relationships between process variables (inputs) and wafer outcomes (outputs) [4,8,14]. They are often the foundation for predictive modeling.

2.1. Process–Parameter Relationship Modeling

It is necessary to establish the relationship between the process variables (etch time, plasma power, deposition rate, temperature, etc.) and wafer-level metrics (oxide thickness, line width, dopant concentration, etc.) [47]. Based on the process–parameter relationships, these critical process parameters are identified [11]. A typical example is the use of multiple linear regression to predict film thickness variation from tool settings [13].

2.2. Metrology Correlation

Metrology correlation in wafer manufacturing leverages regression and predictive modeling to relate inline and end-of-line measurements, minimizing costly inspections [11]. Regression models quantify relationships between process parameters, metrology readings, and product quality, while predictive analytics forecast unseen measurements [48]. This enables virtual metrology, rapid feedback, and proactive control, improving yield, reducing cycle time, and enhancing tool performance monitoring in advanced semiconductor fabrication [14].

Zeng [6] used regression to correlate in-line metrology (critical dimension, overlay, thickness) with end-of-line electrical test results. For example, partial least squares (PLS) regression is used to relate spectra from scatterometry with actual CD measurements [6].

Krueger et al. [49] proposed a method to identify which data should be collected, integrated, and summarized, and to predict yield using a generalized linear model based on defect metrology data. This technique identifies important factors driving process improvement. It allows the model to account for the nested structure of the process, thereby improving predictive power and enabling its application to situations where assumptions are violated.

2.3. Fault Detection and Excursion Analysis

Regression models can be used to reveal abnormal deviations between expected and actual performance, aiding in the identification of root causes. A typical example is to use regression residuals to highlight when a chamber drifts out of calibration [50].

Lee and Kim [51] defined fault detection (FD) in semiconductor manufacturing processes as a feature extraction, feature selection, and classification algorithm. They tested FD models on six datasets using 117 possible algorithm combinations. Statistical analysis was conducted from both an algorithmic perspective and an FD model perspective. Multiple comparisons of algorithms were conducted to evaluate the performance of competing algorithms in the three modeling steps, and the strengths and weaknesses of each algorithm were discussed [51]. Chen et al. [52] used statistical metrics to convert physical data from state variable identification (SVID) into fault detection and classification parameters (FDC parameters). The authors developed a multivariate analysis model to identify key factors that may cause process deviations from a large amount of FDC data. The proposed two-stage multivariate analysis framework included applying the least absolute shrinkage and selection operator (LASSO) for key operation screening and using random forest (RF) to rank the FDC parameters based on the key operations [50,52].

A summary of the applications of regression in wafer manufacturing is listed in Table 2.

Table 2.

Applications of regression in wafer manufacturing.

3. The Application of Predictive Modeling in Wafer Manufacturing

Predictive modeling expands beyond regression to include advanced machine learning and statistical forecasting. The focus is on anticipating wafer quality, yield, or tool health before issues arise.

3.1. Yield Prediction

Regression helps identify which variables most significantly affect wafer yield and supports real-time yield monitoring. It involves predicting wafer/die yield using defect density, metrology data, and test parameters [33,53].

Predicting the final wafer yield could optimize yield and ensure optimal results early.

Logistic regression is an example to classify wafers as pass/fail based on defect density and parametric test data [54].

Because early detection of low yields related to wafer materials is crucial for effectively controlling cost and quality, Jiang et al. [53] proposed using a Gaussian mixture model (GMM) clustering approach to develop a weighted ensemble regressor to predict back-end final test (FT) yield during the wafer fabrication (WF) stage. This approach was validated on actual production data from a new wafer product line, demonstrating significant improvement in prediction performance [53].

3.2. Equipment Health Monitoring and Predictive Maintenance

Predictive models are used to anticipate tool failures before they occur using sensor logs and historical maintenance data. Some examples are the prediction of chamber clean frequency based on RF power stability and endpoint signal drift; predictive models forecast tool drift and failures and are used in predictive maintenance (PdM) to avoid costly downtime [55,56].

Equipment health monitoring and predictive maintenance in wafer manufacturing use predictive modeling to track tool performance, detect anomalies, and prevent failures. By analyzing sensor data, vibration signals, and historical maintenance records, machine learning models identify degradation patterns and predict component lifetimes [57]. This approach enables condition-based maintenance, reduces unplanned downtime, extends equipment life, and ensures process stability, supporting higher yield, cost efficiency, and reliability in advanced semiconductor manufacturing environments [56,58].

3.3. Defect Density and Pattern Prediction

Defect density and pattern prediction in wafer manufacturing leverage predictive modeling to identify defect sources, spatial patterns, and yield risks early [23]. Using inspection data, wafer maps, and process parameters, machine learning detects correlations and recurring defect signatures [59]. This enables rapid root cause analysis, targeted corrective actions, and reduced variability, improving yield, quality, and manufacturing efficiency [60].

It is possible to use predictive models to generate wafer defect maps based on lithography, CMP, or etch parameters, predict wafer-level defect hotspots using tool/process data, and correlate equipment signals with their impact on wafer-level yield [23]. The primary techniques are machine learning classifiers and spatial predictive models [59,60].

3.4. Process Control and Run-to-Run Optimization

Process control and run-to-run (R2R) optimization in wafer manufacturing leverage predictive modeling to maintain stability, reduce variability, and improve yield across complex process steps [61,62]. Predictive models analyze metrology data, tool parameters, and historical trends to adjust recipes dynamically between wafer runs. Machine learning enhances fault detection, drift compensation, and excursion prevention, enabling fabs to respond proactively to process changes [62]. Integrated with advanced process control systems, these models optimize throughput, minimize scrap, and ensure consistent device performance, supporting high-volume manufacturing at advanced technology nodes [62].

Wan et al. [63] proposed that integrating virtual metrology (VM) with batch-to-batch (R2R) control can maintain the advantages of R2R control while avoiding the negative impact of physical metrology on cost and cycle time. They proposed using a Gaussian process regression (GPR) model in VM-enabled R2R control to provide this information in an integrated manner. They also demonstrated the effectiveness of the GPR-enabled VM R2R control approach using a case study of a chemical–mechanical polishing process.

3.5. Reliability and Lifetime Forecasting

Reliability and lifetime forecasting in wafer manufacturing applies predictive modeling to anticipate equipment wear, process drift, and product degradation over time [64]. By analyzing sensor data, maintenance logs, and historical failure patterns, models such as survival analysis, Weibull modeling, and machine learning predict tool replacement intervals and product reliability [65,66]. These insights enable proactive maintenance, minimize downtime, and extend the lifespan of equipment [67]. Integrated forecasting improves process stability, reduces costs, and ensures consistent wafer quality, supporting advanced-node manufacturing with higher efficiency, yield, and operational resilience [64,66]. The typical application is to predict transistor/device degradation based on process variations and test data and improve design-for-reliability (DfR) strategies [68].

Lenhard et al. [69] introduce a screening method for wafer-level inline defect detection. This method utilizes an advanced prediction engine to generate wafer-level failure probabilities, screening out wafers with higher reliability risks when the predicted probability exceeds a predefined limit. A saliency graph clustering algorithm is employed to increase the granularity of latent defect detection beyond supervised defect classification.

3.6. Virtual Fabrication and Digital Twin

Digital twin models replicate semiconductor processes by integrating physical models, sensor data, and AI-based analytics for real-time monitoring and optimization. Model construction involves synchronizing virtual and physical systems through continuous data streams [20,21,22,23]. Validation is achieved via historical data matching, real-time feedback, and performance benchmarking. However, limitations arise from data latency, model drift, computational demands, and incomplete physics-to-data coupling, which can reduce accuracy and scalability in complex, multistage wafer fabrication environments [20,21,22,23].

Virtual fabrication and digital twin technology in wafer manufacturing leverages predictive modeling to create high-fidelity simulations of processes, tools, and wafer behavior [2]. These digital replicas integrate physics-based models with machine learning to optimize recipes, predict yield outcomes, and evaluate process changes without physical trials [70]. Engineers can run “what-if” scenarios, accelerating development and reducing costly experiments [71]. Real-time data feeds continuously update the twin, enabling adaptive control, early fault detection, and process optimization, ultimately improving efficiency, product quality, and fab decision-making [71,72].

Nguyen et al. [73] proposed a physical model at a characteristic scale that uses the roughness and elastic deformation of the polishing pad to calculate the pressure distribution. This topography simulation module is coupled with various tools, including process simulators and electrical characterization modules. This allows for integrated 3D simulation of barrier and copper deposition, making it suitable for dam scenes. Graves et al. [74] identified plasma–tool digital twins to track reactor state, guide control, and predict maintenance, which is crucial for equipment-level twins in fabs.

3.7. Design–Technology Co-Optimization (DTCO)

Design–technology co-optimization (DTCO) in wafer manufacturing uses predictive modeling to align chip design and process technology for optimal performance, power, and cost [75]. By integrating layout-aware simulations, process variability models, and manufacturing constraints early in the design process, DTCO identifies trade-offs between design rules, materials, and device architectures [76]. Machine learning enhances the prediction of yield, performance, and manufacturability, reducing design iterations [77]. This synergy accelerates technology node development, improves yield ramp, and ensures robust designs that fully leverage advanced lithography and process innovations, driving efficient semiconductor scaling [75,77].

Chen and Chen [78] explore the application of generative adversarial networks (GANs) in the chip manufacturing process to generate wafer-level wafer acceptance test (WAT) and wafer probe (CP) test data, emphasizing design–technology co-optimization (DTCO). The generated virtual silicon wafer data contains essential performance characteristics, physical electrical properties, wafer-level process parameter distributions, and implicit information about wafer-level uniformity and defects. This enables the collaborative optimization of the manufacturing and chip design processes [78].

A summary of the applications of predictive modeling in wafer manufacturing is listed in Table 3.

Table 3.

Applications of predictive modeling in wafer manufacturing.

4. Regression Methods in Wafer Manufacturing

4.1. Regression Models

4.1.1. Linear Regression

Ordinary Least Squares (OLS) regression is the simplest and historically most widely used tool. It models a dependent variable (e.g., oxide thickness) as a linear combination of predictors (e.g., deposition time, temperature, gas flows) [5]. While easy to interpret, linear regression assumes independence and homoscedasticity, which are often violated in real fab data (due to wafer-to-wafer correlation, tool drifts, and hierarchical nesting) [12]. It is frequently used for DOE and initial process modeling [11].

The deposition rate is modeled as a function of chamber pressure and power, allowing for control of film thickness [79]. Critical dimensions (CDs) in lithography are modeled as a function of exposure dose and focus, which helps define the process window using a crucial dimension linear model [80]. Defect counts or parametric yield can be regressed against process settings across lots with a yield loss correlation equation [12,49].

Krueger et al. [49] proposed a modeling strategy for yield prediction using generalized linear models based on defect metrology data. This technique can identify important factors that drive process improvements. Purwins et al. [79] evaluated the use of high-dimensional multivariate input data against a small parameter set, comparing simple linear regression, multiple linear regression, partial least squares regression, and ridge linear regression. Regression parameter optimization and model selection were performed and evaluated using root mean square error (RMSE) through cross-validation and grid search. The results suggest that virtual metrology can benefit from regression methods that exploit collinearity and incorporate process expertise [79].

4.1.2. Multiple Regression

As wafers involve multi-factor interactions, multiple regression is widely adopted. The functions of multiple regression include incorporating multiple input variables simultaneously [13,81], helping capture multi-factor interactions in processes such as lithography focus/exposure or etch gas composition, capturing interactions between multiple parameters, and being used for process window analysis (e.g., lithography focus × dose) [13].

Mahandran et al. [82] investigated factors contributing to oxide thickness instability. The coefficient of determination, R2, was used to indicate a good model prediction. Significant influencing factors were gas flow rate, oxidation time, and temperature. Multiple regression was used to determine the optimal operating factor. Shumate et al. [83] investigated the characteristics of SF6/sub6He plasmas for TiW etching using fractional factors and a mixed response surface model. Factors influencing the process included RF power, reactor pressure, and the SF6/He gas ratio. A quadratic/cubic model captured the interaction between the gas ratio and pressure. The model employed both quadratic and special cubic response surface models. Contour lines of this empirical model were used for joint analysis to optimize the process. Liu et al. [84] developed a chemical–mechanical polishing process at low downforce. They employed response surface methodology (RSM) to optimize the slurry composition, which included silica sol, H2O2, and an FA/O chelating agent. A central composite design (the standard design for RSM) was used to evaluate the influence and interaction of the three factors. Ultimately, the optimal conditions for silica sol concentration, H2O2 concentration, and FA/O chelating agent concentration were determined [84].

4.1.3. Polynomial Regression

Because semiconductor processes are rarely purely linear, polynomial regression is used to approximate nonlinear relationships. For example, the photoresist CD shrinkage during baking is nonlinear with respect to time and temperature, and the ion implantation dose–response curves follow quadratic-like patterns [85,86]. For example, plasma etch rate is modeled as a function of RF power, gas mixture ratios, and pressure, and interaction terms reveal synergies (e.g., pressure × gas ratio) [87].

Polynomial regression is suitable for nonlinear processes such as chemical vapor deposition (CVD) or CMP dishing [88]. Polynomial regression improves accuracy over simple linear models but risks overfitting without careful validation [84]. Liu et al. [84] employ RSM with second-order polynomial models to capture nonlinear CMP behavior and optimize slurry composition for a route commonly used to control planarization metrics like dishing/erosion.

4.1.4. Logistic Regression

Logistic regression in wafer manufacturing predicts binary or categorical outcomes, such as the presence of defects, pass/fail classification, or yield risk. It identifies key process variables that influence defects, supports early decision-making, and optimizes quality control by modeling the relationships between process parameters and product quality, thereby enhancing predictive maintenance and excursion detection [40].

Bae et al. [89] used models based on Poisson regression, negative binomial regression, and zero-inflated Poisson (ZIP) regression, with the spatial location of each IC die and the corresponding number of defects in the wafer map as dependent variables. Their model significantly improved yield prediction accuracy by capturing the spatial distribution of defects on the wafer map. Jizat et al. [90] established and evaluated the best machine learning classifier for wafer defect inspection applications. Logistic regression was one of the evaluated models, achieving high accuracy in classifying pass/fail defects.

4.1.5. Nonlinear Regression

Nonlinear regression in wafer manufacturing models involves complex, nonlinear relationships between process variables and outputs such as critical dimensions, film thickness, and yield. It enables accurate process optimization, virtual metrology, and root cause analysis, capturing intricate tool–material interactions, improving parameter tuning, and supporting predictive control for advanced technology nodes [91]. It is suitable for highly nonlinear processes (e.g., plasma etch rate vs. gas flow). Typical examples include diffusion processes, where dopant concentration profiles follow error function shapes [92].

Jia et al. [93] employed a nonlinear polynomial neural network VM model for CMP removal rate prediction, which supports adaptive feature and model selection. They found that the highly nonlinear CMP dynamics were well-suited for the virtual metrology in semiconductor manufacturing. Nami et al. [94] measured the deposition rate under a range of deposition conditions using statistically designed experiments. A semi-empirical metal–organic chemical vapor deposition (MOCVD) model based on a “hybrid” neural network is proposed to characterize the MOCVD properties of titanium dioxide (TiO2) thin films. They demonstrate a nonlinear neural network regression for CVD film growth, capturing intricate process–material interactions beyond linear models [94].

Huang et al. [95] derived a relationship between the polar component of film stress and the polar component of system curvature in the presence of arbitrary radial inhomogeneities, inferring such stresses from full-field curvature measurements. The relations linking film stress to temperature fields and resulting curvature (bow) were modeled in a nonlinear equation [95].

4.1.6. Principal Component Regression (PCR)

Principal component regression (PCR) in wafer manufacturing reduces multicollinearity among highly correlated process variables by transforming them into orthogonal principal components [25,96]. It enables robust modeling of yield, defect density, and critical dimensions, enhances virtual metrology, improves fault detection, and supports process optimization in high-dimensional, data-rich semiconductor fabrication environments [25,96].

Phatak et al. [97] showed that PCR models relating sensor features to CMP material removal rate outperform alternatives and demonstrated robust modeling and process optimization with many correlated inputs. Jeong et al. [98] built plasma etch prediction models using PCR on high-dimensional data, compared them with neural networks, and illustrated VM and multicollinearity reduction in practice.

4.1.7. Partial Least Squares Regression (PLSR)

PLSR is particularly important in wafer manufacturing because it handles collinear and high-dimensional input spaces and extracts latent variables linking tool signatures to outputs [99,100]. Some applications include spectroscopic ellipsometry, which models film refractive indices and thickness from multichannel spectra, and plasma emission monitoring, which is used to predict etch profiles from thousands of spectral intensities [99]. Pan et al. [100] proposed a robust linear regression method based on variable selection for predicting final quality variables required in complex industrial processes. Initial model coefficients were generated using partial least squares regression, and then the non-negative Gallot method was used to shrink the original coefficients, implicitly eliminating irrelevant variables. This method significantly improved both the accuracy and robustness of variable selection. Khan et al. [101] applied partial least squares (PLS) modeling techniques to develop a linear regression model for the underlying process of VM. They also created a recursive moving window method to update the VM model as metrology data became available. Then they employed batch-by-batch control techniques to develop W2W process control capabilities.

4.1.8. Regularized Regression (Ridge, Lasso, Elastic Net)

Regularized regression methods, such as ridge, Lasso, and Elastic Net, are vital in wafer manufacturing for handling high-dimensional, collinear process data. Ridge stabilizes models by shrinking coefficients, Lasso performs feature selection to identify critical parameters, and Elastic Net combines the benefits of both [102].

These techniques enhance defect prediction, virtual metrology, yield modeling, and fault detection, enabling the development of robust and interpretable models that generalize well, support advanced process control, and optimize performance in data-intensive semiconductor fabrication environments [103].

Ridge regression stabilizes coefficients by shrinking them toward zero [102]. Lasso regression performs variable selection, identifying critical tool signals among thousands [39,104,105].

Chen and Leclair [106] proposed using kernel ridge regression (KRR) to tune multi-input and multi-output dry etching recipes, thereby generating optimal recipes for multiple-input, multiple-output (MIMO) systems. They also developed a KRR parameter optimization method. Lee et al. [107] proposed an Elastic Net regularization that enforces sparsity in latent factors to reduce multicollinearity and improve variable selection.

4.1.9. Hierarchical and Mixed-Effect Regression

Hierarchical and mixed-effect regression models variability in wafer manufacturing across nested structures, such as wafers, lots, and tools, capturing both fixed process effects and random variations [108]. This approach improves yield prediction, process optimization, and equipment health monitoring by accounting for batch-to-batch and tool-to-tool variability. It enhances root cause analysis, enables more accurate virtual metrology, and supports advanced control strategies in high-volume manufacturing environments where multi-level data structures and correlated measurements are common [109]. Yuan et al. [110] proposed hierarchical Bayesian regression models to predict yield for wafer map defects within and across wafers. Wang et al. [31] propose a hierarchical generalized linear mixed model to incorporate global trends and spatially correlated random effects on wafer maps. They found that the proposed model provides a better fit for spatially correlated wafer map data.

Liu et al. [111] developed a profile-based statistical process control scheme to monitor wafer thickness profiles with abnormal distributions during industrial wafer slicing. The authors propose a mixed-effect profile monitoring (MEPM) scheme that adaptively groups profile data into clusters and models inter-cluster variation, resulting in a robust statistical process control scheme for detecting abnormal profile data. The comparison of these regression models is listed in Table 4.

Table 4.

Comparative overview of regression methods in semiconductor wafer manufacturing.

4.2. Generalization of the Regression Model

Regression models—whether linear, polynomial, or regularized—generalize only moderately well across heterogeneous fab datasets without deliberate harmonization and adaptation. The challenge arises because wafer manufacturing data are not identically distributed: they vary by tool, time, and context. These datasets are characterized by data heterogeneity, non-stationarity, multicollinearity, and confounding due to measurement system differences, sampling bias, and domain mismatch. The most effective treatments combine hierarchical regression, domain adaptation, and physics-constrained learning, augmented by digital twin calibration and drift-aware retraining. This layered approach maintains interpretability while achieving robustness—turning regression from a static estimator into a dynamic, transferable model aligned with real fab variability.

Some regression models that transfer robustly are introduced as follows:

Lynn et al. [91] investigated the application of global and local virtual metrology from an industrial plasma etch chamber and found that the Gaussian process regression models provided accurate results, capable of producing valid estimates of plasma etch rates over multiple chamber maintenance events and many thousands of wafers. Some regression cases achieved robust transferability. Melhem et al. [102] presented a survey of regularized linear regression methods that utilize feature reduction and variable selection to address multicollinearity in high-dimensional input data. These methods could predict wafer quality based on production equipment data, demonstrating model robustness and prediction accuracy. Yu et al. [29] introduced a novel physics-informed machine learning approach, developing physics-based and data-driven regression models to predict the material removal rate (MRR) in the CMP process. Experimental results revealed that the physics-informed model could predict MRR with high accuracy. Miyaguchi et al. [112] presented a novel framework, partial trajectory regression (PTR, to address the limitations of conventional vector-based regression models for wafer defect root cause analysis. This model was validated for its effectiveness using real wafer history data from the NY CREATES fab in Albany.

Some regression cases that failed to generalize are introduced as follows:

Orji et al. [113] proposed that barriers to virtual metrology (VM) adoption include low confidence in regression models, poor data quality, limited process understanding, weak metrology correlation, high maintenance costs, and IP concerns. Key solutions emphasize developing standardized data and model quality metrics, improving data completeness and communication, and establishing model maintenance frameworks to ensure robustness under process drift. Regression models remain central to VM by linking process parameters to wafer outcomes; however, their reliability depends on transparent quality evaluation, validated metrology correlation, and adaptive retraining. Kim and Kang [114] investigated the effect of irrelevant variables on three learning algorithms for regression tasks—artificial neural network, decision tree (DT), and k-nearest neighbors (k-NN)—and collected datasets from a semiconductor manufacturer to examine how the number of irrelevant variables affects the performance of prediction models. The results indicate that higher model complexity of learning algorithms leads to a higher sensitivity to irrelevant variables. However, low sensitivities are preferred as a first trial for building prediction models.

Maitra et al. [16] surveyed the state-of-the-art VM works for prominent processes involved in semiconductor manufacturing, and the unique contributions of those VM predictive works are summarized. They found that the VM models were significant hurdles that prevent VM implementation and acceptance in the semiconductor industry. These VM models need to be trained faster and be more compatible with the existing VM models in the factory.

4.3. Demonstration of the Regression Methods

4.3.1. Virtual Metrology

Wan and McLoone [63] introduced a Gaussian process regression (GPR) technique that consistently surpasses classic linear/NN baselines on benchmark VM datasets and provides uncertainty bands useful for R2R. Comparative studies and CMP-focused work show that this GPR tracked drifts well. Ishikawa et al. [115] applied recursive PLS to a plasma etcher with time-varying endpoint characteristics, showing improved prediction of etch rate and uniformity under continuous process drift. The model is updated via exponentially weighted recursive least squares, emphasizing recent runs while gradually discounting outdated samples. Similarly, Lee et al. [116] employed LW-PLS in oxide and poly-etch VM, using local similarity weighting to adapt to process condition changes across different chambers, achieving more stable residuals and reduced RMSE over extended production periods.

4.3.2. Yield Prediction

Lee and Roh [117] establish an expandable machine learning framework for semiconductor yield prediction that integrates heterogeneous process data. After data preprocessing, multiple regression models were optimized and compared to identify the most effective predictor, with random forest (RF) regression achieving the best performance. The model captures complex, nonlinear dependencies among fabrication variables and demonstrates strong generalization across diverse process stages. It provides actionable insights for adaptive process optimization and data-driven production management across scalable semiconductor fabrication environments.

Amato et al. [43] established a data-driven framework to optimize semiconductor testing by predicting final yield from Scanning Electron Microscope (SEM)-detected defects. Two modeling approaches were developed: an Odds Ratio-based model to rank wafer layers most correlated with electrical failures, guiding targeted SEM inspections, and a gradient boosting regression/classification model to predict device yield from defect distributions. The gradient boosting model validated the Odds Ratio findings and demonstrated strong predictive capability despite sparse data. Both models were validated on two STMicroelectronics datasets, enhancing inspection efficiency and yield prediction accuracy.

4.3.3. Excursion Detection

Puggini and McLoone [118] proposed a variable selection and Isolation Forest–based anomaly detection model for analyzing high-dimensional optical emission spectroscopy (OES) data in semiconductor manufacturing. The framework could perform dimensionality reduction while retaining critical isolated variables often missed by conventional PCA methods. By validating through simulated and industrial plasma etch case studies, the approach demonstrates strong capability for efficient, interpretable, and data-driven anomaly diagnosis in production environments.

Kazemi et al. [119] established an adaptive neural-based Principal Component Analysis (PCA) framework for fault detection and diagnosis in time-varying industrial processes. This model recursively updates the correlation matrix, the number of principal components, and confidence limits for the monitoring indices, enabling dynamic adaptation to process variations, and is validated through three studies. The result indicated that the model exhibits superior detection accuracy and diagnostic reliability compared to conventional PCA, enhancing real-time monitoring and fault isolation in complex dynamic systems.

5. Predictive Modeling in Wafer Manufacturing

5.1. Virtual Metrology (VM) Models

Virtual metrology models predict wafer properties without physical measurement, using tool sensor data and regression models. VM reduces costly metrology steps, enables 100% wafer monitoring, and improves run-to-run control [7]. It predicts metrology outcomes (e.g., CD, thickness, overlay) using statistical or machine learning regression models trained on tool/sensor data, thereby reducing reliance on time-consuming and expensive inline metrology [9]. The application examples include predicting post-etch CD from chamber pressure, RF power, and in situ spectral data [120], and predicting CMP film thickness from platen pressure and slurry parameters [121,122].

5.2. Yield Prediction Models

Yield is the ultimate KPI in wafer manufacturing [110]. Predictive models forecast yield before wafers finish processing and enable adaptive lot dispositioning (deciding early whether to scrap or continue wafers) [53,89].

Some examples include the wafer acceptance test (WAT) parametrics regressed against final test yield [123], defect density mapping to predict die yield distributions [124], and hierarchical regression modeling of wafer-within-lot correlations [49].

Spatial covariates are obtained from the fused LASSO on the wafer map, and logistic regression is used to combine these derived spatial covariates with functional test values to predict the final yield, thereby improving accuracy by exploiting the clustered defect structure [40].

5.3. Fault Detection and Classification (FDC) Models

Fault detection and classification (FDC) models in wafer manufacturing monitor tool sensors and process data to detect anomalies early, classify fault types, and prevent excursions [125]. They enable predictive maintenance, improve process stability, and reduce scrap by identifying subtle deviations in real time, supporting higher yields, equipment reliability, and robust manufacturing control in semiconductor fabs [126,127].

Some models of the FDC systems include the regression residuals to signal deviations (e.g., predicted CD differs significantly from the measured CD); machine learning classifiers predict whether a tool run will be “normal” or “abnormal”, and time-series predictive models anticipate drifts before out-of-control events [128].

Kim et al. [128] evaluated seven novelty-detection machine learning methods applied to real-world FDC data for wafer fabrication and tackled challenges such as high-dimensional input (150+ variables) through dimensionality reduction, achieving high true-positive rates in detecting faulty wafers. Fan et al. [129] used traditional and multivariate ML techniques to build predictive models for equipment fault detection in wafer fabrication. They emphasized real-time predictive maintenance to maintain high yields through rapid anomaly detection.

5.4. Time-Series Predictive Models

Time-series predictive models in wafer manufacturing analyze sequential process and sensor data to forecast tool performance, process drift, and yield trends [130]. They enable proactive fault detection, predictive maintenance, and run-to-run control by capturing temporal patterns and correlations, ensuring process stability, minimizing downtime, and optimizing throughput in highly automated, data-intensive semiconductor fabrication environments [131].

Chen and Blue [132] developed a sensor trajectory health metric based on time series and generalized moving variance to predict equipment performance degradation, enabling predictive maintenance. This was validated using case studies of plasma-enhanced chemical vapor deposition and physical vapor deposition tools. A hierarchical, recipe-independent monitoring system based on multi-stream time-series sensor data is developed for proactive fault detection and tool status prediction [133].

5.5. Hybrid Models

Hybrid models integrate physics-based equations with data-driven algorithms to enhance predictive accuracy and interpretability in semiconductor process modeling. Model construction involves coupling physical laws with machine learning structures, enabling generalization beyond the training domain [134,135,136]. Validation typically employs cross-validation, residual analysis, and comparison with physical benchmarks to ensure robustness. However, limitations include high computational cost, complexity in parameter tuning, and challenges in balancing physical fidelity with data flexibility, particularly when process mechanisms or sensor data are incomplete [134,135,136].

Hybrid models in wafer manufacturing combine physics-based simulations with data-driven machine learning to enhance process understanding and prediction [134]. They enable accurate virtual metrology, defect prediction, and yield modeling by leveraging domain knowledge and large datasets [134,135]. This integration improves root cause analysis, accelerates process optimization, and supports advanced control strategies in complex semiconductor fabrication workflows [135].

Deivendran et al. [122] proposed a novel hybrid modeling framework for chemical–mechanical polishing that uses machine learning models (random forest, Lasso, SVM, XGBoost, etc.) to accurately predict slurry temperature, mean abrasive particle size (MAPS), and material removal rate (MRR). Model-based optimization (via particle swarm optimization) is used to determine the optimal operating conditions [136]. Liu introduced a hierarchical modeling approach for virtual wafer metrology based on machine learning [136]. This approach leverages batch-to-batch (RTS) and post-processing quality characteristics to enhance wafer property prediction. The authors propose that this approach can capture the structure of physical information and enable data-driven adaptability, thereby improving the accuracy of virtual metrology [137].

6. Integration with Machine Learning

Machine learning models include decision trees/random forests to capture nonlinear interactions, support vector machines (SVM) to classify wafers/dies as good/bad, and neural networks (NNs) to predict yield from complex multivariate data [138].

Beyond regression, fabs now use machine learning-based predictive models.

Random forests and gradient boosting are used to handle nonlinearities and interactions. Neural networks are used to capture complex sensor–output mappings, while support vector regression (SVR) is effective in high-dimensional metrology data [139]. Deep learning, including CNNs, is applied to wafer map defect classification, and RNNs are used for time-series tool data [140].

Shih et al. [141] used decision trees and random forests to classify and predict white-pixel defects in Complementary Metal–Oxide–Semiconductor (CMOS) wafers. They identified critical process factors (e.g., grinding load/torque) and achieved high predictive accuracy (~97%) using interpretable tree-based models. Choi et al. [142] combined handcrafted features (e.g., radon, geometric, density) with an ensemble approach using a stacking model that included base-level classifiers and extreme gradient boosting (XGBoost) as the meta-level predictor. It is particularly effective in classifying wafer map defect patterns—even under severe class imbalance and limited data—and demonstrates how gradient boosting handles nonlinear interactions well. Jeong et al. [143] review a range of traditional ML methods, including SVM, applied to features such as radon transforms and geometry for wafer map defect classification. They explored how convolutional neural networks (CNNs) are increasingly used for deep learning-based defect pattern classification, showing performance improvements and automation of feature extraction.

The clear advantages of hybrid physics–ML models over purely data-driven or purely physics-based approaches in wafer manufacturing include predictive modeling of material removal rate in chemical–mechanical planarization [29,144], improved accuracy on complex 3D effects of lithography [145], prediction of fan-out wafer-level package [146], plasma etch rate optimization [147], and prediction of Si etch profile [148].

6.1. Support Vector Regression (SVR)

Support vector regression (SVR) is used in wafer manufacturing to predict nonlinear critical dimensions (CD) with high accuracy [3,20]. By mapping process variables into higher-dimensional spaces, SVR captures complex relationships between tool settings and CD variations. It supports virtual metrology, enhances process optimization, and reduces inspection costs, enabling tighter control in advanced technology nodes [25].

Dailey et al. [149] proposed a new approach for virtual metrology (VM) of plasma etch processes. They used full optical emission spectroscopy (OES) signatures and regression analysis, including support vector regression (SVR), to predict post-etch critical dimensions (CDs) for plasma etch VM. The proposed SVD-based OES signature consistently outperformed the baseline VM model signature.

Kang et al. [150] introduced a self-training-based semi-supervised support vector regression (SS-SVR) method. Two probabilistic local reconstruction (PLR) models were used to estimate the label distribution of unlabeled data. Training data was generated by oversampling from the unlabeled data and its estimated label distribution. Results showed that the proposed method improved accuracy by 8% compared to traditional supervised support vector regression (SVR) and reduced training time [150].

6.2. Random Forests/Gradient Boosting

Random forests and gradient boosting are powerful ensemble methods for yield prediction in wafer manufacturing, excelling with noisy, high-dimensional fab data [151]. They capture nonlinear relationships, rank critical features, and provide robust predictions despite measurement variability. These models support root cause analysis, defect classification, and process optimization, driving higher yield and reliability in advanced semiconductor production [152,153].

Lee et al. [117] developed a complete yield prediction system. They compared multiple machine learning models, including gradient boosting, using various types of manufacturing data from wafer fabrication processes to determine the model with the best predictive performance [117]. They also integrated SHAP (Shapley Additive exPlanations) to explain feature importance and illuminate the relationship between yield and features. This approach can analyze a scalable range of manufacturing conditions, understand the influencing factors, and optimize the process [117]. Mohammed’s research describes an integrated model using random forests, XGBoost (a form of gradient boosting), LightGBM, and stacking to predict defect density (a key yield driver) [154]. Performance evaluation using metrics such as RMSE shows that the stacking model outperforms traditional single models. This integrated approach can be applied to complex, high-dimensional fab data, improving robustness and prediction accuracy [154]. Kalir et al. [155] applied long short-term memory (LSTM) networks and optimized random forests (RF) to address productivity and cost challenges for predictive maintenance, forecasting equipment behavior, and unplanned downtime. They demonstrated the robustness of RF on noisy fab data and how reliability indirectly supports yield by reducing downtime [155].

6.3. Neural Networks

Neural networks in wafer manufacturing model highly nonlinear relationships between process parameters and outputs, such as yield, defects, and critical dimensions [45]. They learn complex patterns from large fab datasets, enabling virtual metrology, predictive maintenance, and early detection of anomalies [103]. Their adaptability supports advanced nodes, optimizing process control and decision-making in data-rich semiconductor fabrication environments [156].

Choi et al. [157] proposed a multivariate virtual metrology (VM) model based on a convolutional neural network. This model uses process data from multiple sensors to predict various physical metrology results, capturing the complex nonlinear mapping between device signals and outputs within a single deep learning framework. The model was evaluated using VM modeling of the etch process in wafer fabrication as a real-world example. Bao et al. [158] combined autoencoder-based data augmentation techniques with a CNN classifier to process a noisy and unbalanced dataset of wafer defect images. This deep learning approach significantly improved defect pattern classification accuracy, outperforming traditional classifiers such as random forests and support vector machines (SVMs) [158].

Jeong et al. [143] proposed a rotation- and flip-invariant method. This method is based on labeling rules and is insensitive to the rotation and flipping of labels. Therefore, it could improve class discrimination performance even without data by utilizing a convolutional neural network backbone, combined with radon transforms and kernel flipping, to achieve geometric invariance. Qualitative applications suggest using multi-branch layer-by-layer correlation propagation to explain model decisions. Quantitative applications validate the superiority of this method through ablation studies [143].

6.4. Deep Learning (CNNs, LSTMs)

Deep learning models, including CNNs and LSTMs, enable the recognition of wafer map patterns and temporal prediction in semiconductor manufacturing [151]. CNNs excel at identifying spatial defect patterns, while LSTMs capture time-dependent process trends [139]. Together, they support early excursion detection, root cause analysis, and predictive control, enhancing yield, equipment reliability, and process optimization in advanced wafer fabrication [159].

Hybrid approaches often combine statistical regression + machine learning to balance interpretability and predictive power [139].

Tsai et al. [160] designed a compact convolutional neural network for wafer image classification, using depth-wise separable convolutions. They also utilized encoder–decoder enhancement techniques to achieve fast and accurate spatial defect recognition. The results showed that lightweight deep convolutions can reduce model parameters and computational complexity, making them highly effective for high-volume test fabs [160]. Yoon et al. [161] proposed a semi-automated wafer image pattern classification method that selectively utilizes a convolutional neural network to classify new wafer images. The convolutional neural network classifier incorporates uncertainty perception and engineer-in-the-loop (EIL) decision logic, improving the practicality and interpretability of wafer fab deployments [161].

Kim et al. [162] employed a long short-term memory (LSTM) network in conjunction with a feedforward neural network (FFNN) for temporal modeling. The LSTM utilizes time-series data, whereas the FFNN employs non-time-series data. They predicted edge yield trends based on fab time series, enabling early deviation detection and predictive control [162].

A summary of the integration of machine learning in wafer manufacturing is listed in Table 5.

Table 5.

Integration of machine learning in wafer manufacturing.

7. Challenges of Regression and Predictive Modeling

7.1. Regression

7.1.1. Multicollinearity

Tool parameters are often strongly correlated, inflating the variance of estimates in the regression application of wafer manufacturing [47].

Chang et al. [163] noted that predictive modeling in semiconductor processes often faces multicollinearity due to causal relationships among numerous variables. To address this, they proposed two algorithmic variable elimination methods and compared them with principal component and ridge regression. Their study, focused on high-dimensional EUV lithography models, demonstrated improved handling of multicollinearity [163]. Magklaras et al. [164] proposed a ridge regression method using a machine learning (ML) algorithm to adapt to datasets with high multicollinearity. They applied this method to perturbed data from a 300 mm wafer fab. Kim et al. [12] developed an outlier detection technique using multivariate partial least squares regression with dimensionality reduction and function-based independent component analysis. The method captures OES data continuity, extracts structural components, and enhances prediction accuracy for wafer performance during plasma etching, demonstrating strong applicability to optical emission spectroscopy-based process monitoring [12].

7.1.2. Nonlinear and Dynamic Processes

Many interactions are highly nonlinear and time-dependent in the regression application of wafer manufacturing [165]. Advanced models (deep learning, Gaussian processes) outperform linear regression [53].

Wu et al. [166] proposed a hybrid CNN–Gaussian process regression (GPR) model for virtual metrology, combining deep learning feature extraction with probabilistic GPR yield prediction, outperforming linear models in accuracy and uncertainty. Chan et al. [167] introduced a just-in-time GPR framework that adapts to time-varying nonlinear process data, enhancing predictive accuracy. Zhou et al. [168] developed a recursive GPR model for dynamic batch processes, enabling online updates and robust handling of process uncertainty and nonstationarity.

7.1.3. High-Dimensional Data

Modern sensors produce thousands of signals, requiring dimension reduction before regression [169]. Thousands of parameters per wafer make overfitting a risk. Hundreds of variables per wafer step need dimensionality reduction (PLS, PCA, autoencoders) [169,170].

Serani and Diez [171] compared linear (PCA) and nonlinear (autoencoder) methods for functional surface and shape optimization, showing how dimensionality reduction improves tractability and mitigates overfitting in high-dimensional engineering models. Ghojogh et al. [172] presented sufficient dimensionality reduction (SDR) for high-dimensional regression, detailing SIR, SAVE, and MAVE techniques to address overfitting and parameter redundancy. Ajana et al. [173] demonstrated that combining dimensionality reduction with penalized regressions, such as LASSO and ridge, enhances predictive performance and reduces overparameterization, improving model generalization in complex semiconductor process data.

7.1.4. Concept Drift

Regression coefficients change as processes age, requiring frequent recalibration.

Lima et al. [174] reviewed regression coefficient drift, proposing ensemble and neural drift detection methods to address nonstationarity, with a focus on the effects of batch size and drift location on model calibration. Igual et al. [175] explored proactive concept drift strategies, introducing adaptive linear filtering to maintain model accuracy during gradual or sudden process changes, ideal for real-time applications. Samuel and Ahmed [176] developed a continuous learning approach that achieves complete retraining accuracy while efficiently adapting models over time, effectively managing concept drift in dynamic engineering systems.

7.1.5. Interpretability vs. Accuracy

Engineers prefer interpretable regression models, but AI/ML often provides higher predictive accuracy [177]. Alangari et al. [178] compared seven generalized additive model (GAM) variants with seven machine learning models using 20 benchmark datasets. After extensive hyperparameter tuning and cross-validation, advanced GAMs—particularly interpretable boosting machines (EBMs)—achieved predictive accuracy comparable to black-box models while maintaining transparency [178]. Muckley et al. [179] contrasted simple linear regression with black-box methods, finding that despite higher interpolation error, the simple model performed within 5% of complex models during extrapolation and even outperformed them in 40% of cases [179]. Nazir et al. [180] proposed a framework to balance interpretability and accuracy using the Simulatable Operation Count (SOC) metric. They demonstrated that interpretability can improve by 97% with only a 2.5% loss in accuracy, offering a practical trade-off between explainability and performance [180].

A summary of the challenges associated with regression in wafer manufacturing is listed in Table 6.

Table 6.

Challenges of regression in wafer manufacturing.

7.2. Predictive

7.2.1. Data Quality and Integration

Sensor data is often noisy, missing, or unaligned across tools. Missing, loud, or inconsistent fab data complicates regression accuracy [181].

Teh et al. [182] discussed key sensor data challenges, including error types, detection, quantification, and correction, providing theoretical and practical strategies for engineers. Siang et al. [183] emphasized that reliable industrial modeling relies on substantial data collection and preprocessing rather than algorithmic complexity, offering guidelines for preparing noisy or incomplete time series for soft sensors. Halder et al. [184] combined physics-informed neural networks with energy-based modeling and Fisher fraction regularization to embed physical knowledge for real-time noise reduction in laser powder bed fusion (LPBF) systems [184].

7.2.2. Model Interpretability

Black-box AI models are more complex for engineers to trust in high-stakes manufacturing [185].

Sofianidis et al. [185] emphasized explainable AI (XAI) to enhance operator trust by increasing transparency in industrial AI systems, which are often viewed as opaque “black boxes.” Lisboa et al. [186] argued that manufacturing decisions require ethically cautious use of interpretable, inherently transparent models over opaque ones. Kusiak [187] highlighted that while digital manufacturing leverages predictive models for optimization and simulation, challenges remain in balancing interpretability, complexity, and reusability. This underscores the persistent trade-off between model performance and operator trust in adopting advanced machine learning systems.

7.2.3. Tool-to-Tool Variation

Models may not generalize across different equipment sets [110]. Models must adapt to new tools, recipes, and products [188].

Shim et al. [189] observed that recipe changes in semiconductor manufacturing often shift sensor data distributions, degrading existing fault detection and classification (FDC) model performance. To address this, they developed an adaptive FDC framework employing unsupervised adaptation to limit degradation and semi-supervised adaptation using partial inspection results for new recipes. Chien et al. [190] proposed a CNN-based intelligent FDC strategy that analyzes SVID data to detect wafer status, enabling rapid redefinition of monitoring rules and self-learning, which significantly reduces cycle time. Li et al. [191] introduced the causal mechanism transfer network (CMTN), a domain-adaptive model for multivariate time series that captures invariant causal mechanisms across tools and timescales, allowing effective adaptation with limited new data and improving reliability in tool-to-tool model transfer within semiconductor and mechanical systems.

7.2.4. Computational Efficiency

Real-time predictions require fast inference at fab scale in wafer manufacturing [192].

Horr [193] explored reduced-order modeling (ROM) for wire arc additive manufacturing (WAAM), comparing hybrid ML-ROM approaches that enable fast, reliable, real-time predictions for dynamic manufacturing environments. Horr et al. [194] extended this within a digital twin framework, integrating data-driven, physical, and machine learning models for efficient real-time monitoring and control in additive and extrusion processes. Chen et al. [195] proposed a time-series dense encoder (TiDE) surrogate model to accelerate model predictive control in digital twin systems, enabling multi-step predictions per execution and significantly reducing computational latency for real-time fab-scale decision-making.

7.2.5. Imbalanced Data

Defective wafers/dies are rare and require advanced classification methods [54].

Kim et al. [196] developed an oversampling strategy to balance wafer image data by generating synthetic samples, improving rare defect detection [196]. Choi et al. [142] addressed severe class imbalance with a framework combining a convolutional autoencoder-based data augmentation and a stacked ensemble classifier, enhancing robustness when defect samples are limited [142]. Taha [139] reviewed machine learning methods for wafer defect classification, noting that ResNet achieves about 99% accuracy. At the same time, XGBoost balances strong accuracy (~94.8%) with high computational efficiency, making it suitable for practical industrial applications [139]. A summary of the challenges associated with predictive modeling in wafer manufacturing is listed in Table 7.

Table 7.

Challenges of predictive modeling in wafer manufacturing.

8. Future Trends

8.1. Hybrid Physics–ML Models

Process physics may be combined with regression/AI for more robust predictions in wafer manufacturing. Kasilingam et al. [134] provide an overview of various hybrid modeling strategies in manufacturing, combining physics-based models with machine learning methods. They describe the different components and architectures of hybrid models, providing a taxonomy and practical insights. This engineering-oriented framework is used to incorporate physics-based knowledge into predictive models, with potential applications in wafer processing [134]. Yu et al. [29] proposed a physics-based machine learning approach to predict material removal rate (MRR) during chemical–mechanical polishing (CMP). This approach combines a multiscale mechanical physics model, including contact mechanics and abrasive wear, with a data-driven model for predicting pad topology variables. Experimental validation demonstrates that the hybrid model achieves extremely high prediction accuracy. This result illustrates how hybrid models can improve regression accuracy and reliability by embedding physical process understanding [29]. Han et al. [197] reviewed the application of physical information neural networks (PINNs) in semiconductor thin-film deposition. They analyzed how to embed physical laws and governing equations into neural network architectures to improve interpretability, robustness, and data efficiency. They also proposed future research directions for integrating PINNs into semiconductor manufacturing [197].

8.2. Real-Time Predictive Analytics