A Crop Growth Information Collection System Based on a Solar Insecticidal Lamp

Abstract

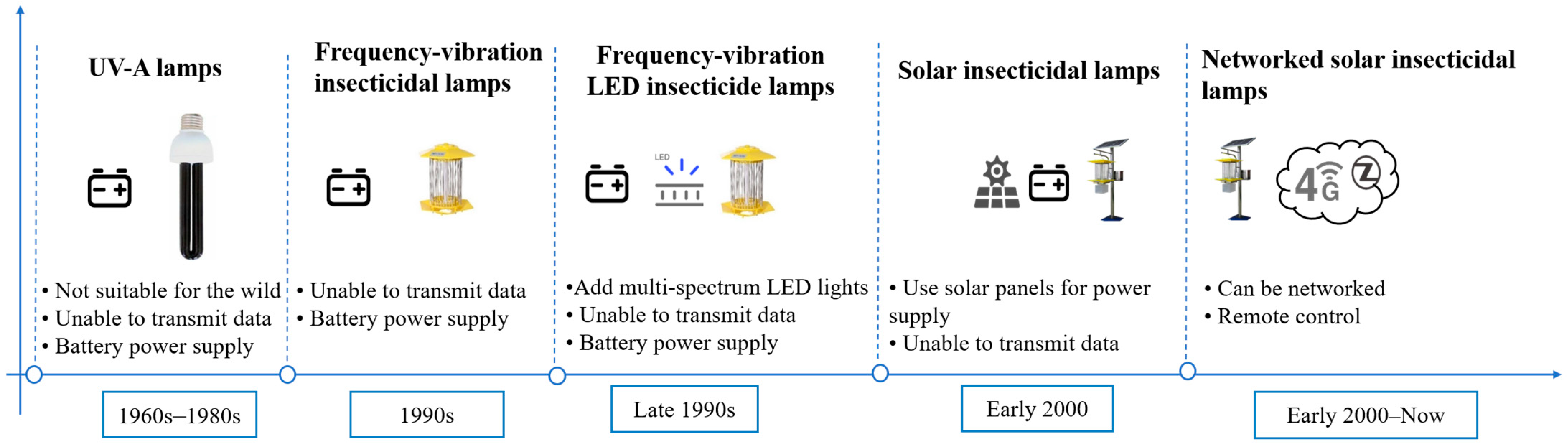

1. Introduction

1.1. Analysis of Agri-Environmental Information Collection Studies

1.2. Analysis of Crop Growth Information Collection Studies

1.3. Analysis of Soil Information Collection Studies

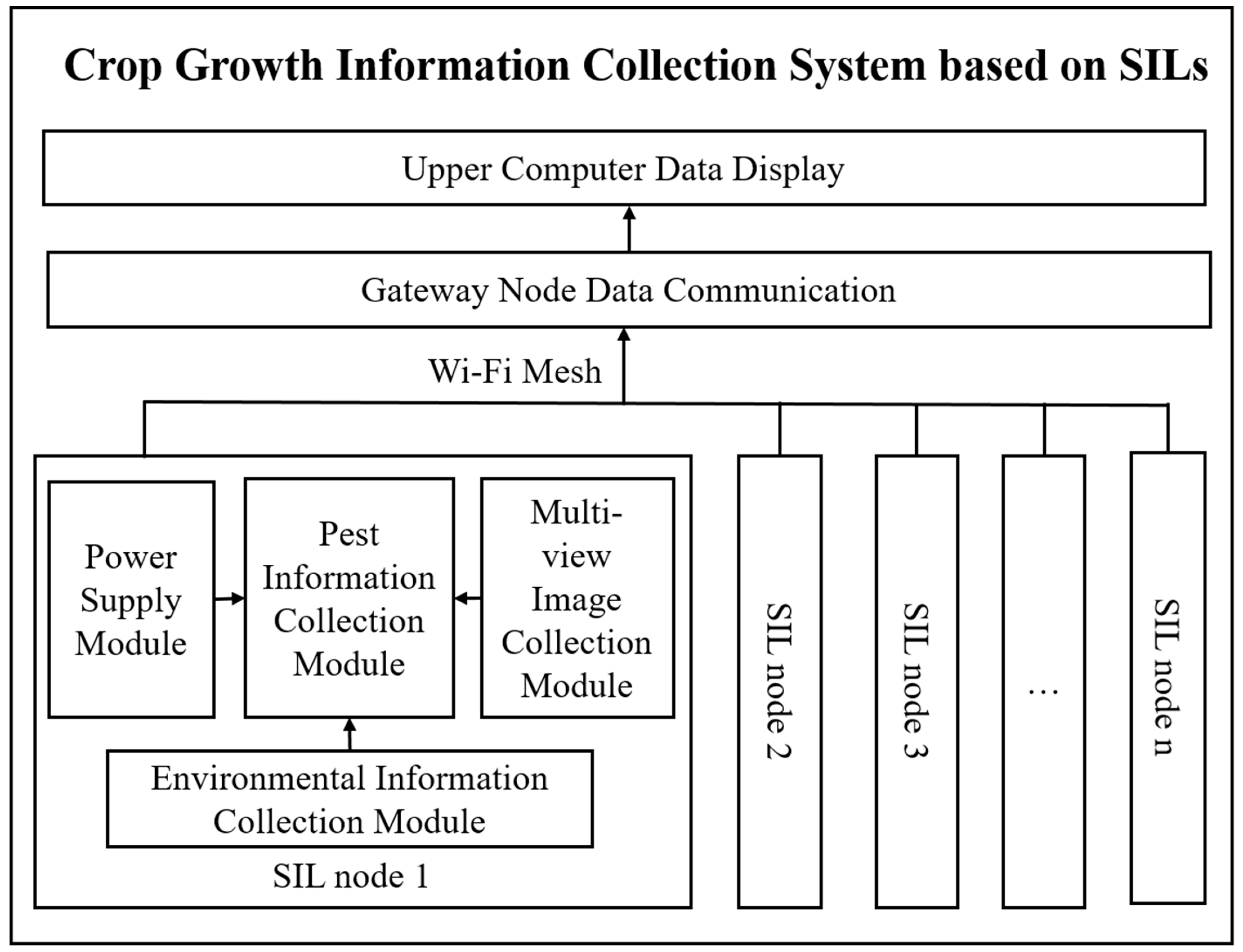

2. System Framework Design and Implementation

2.1. Requirements Analysis and Design Goals

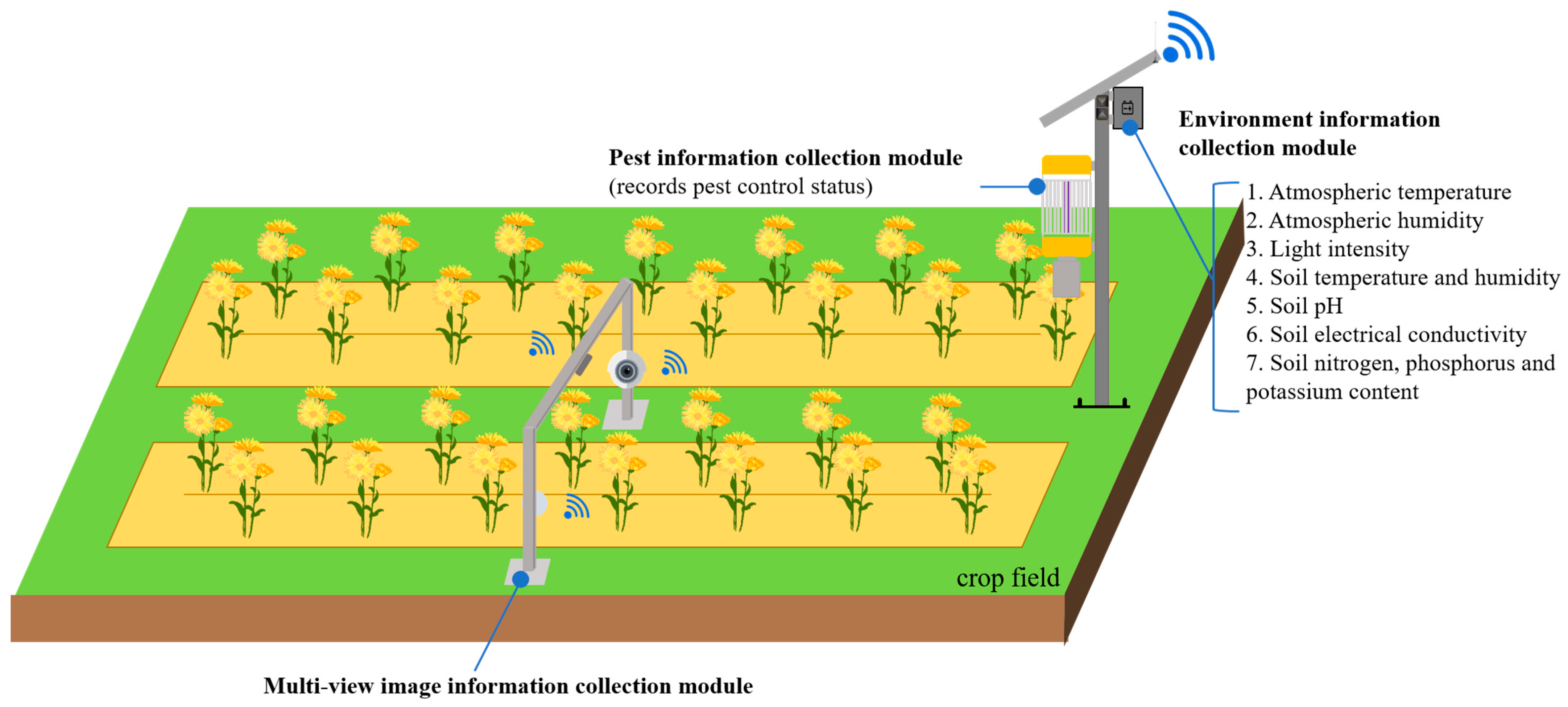

- (1)

- Pest information collection module (PICM): When pests approach the metal mesh, the metal mesh will release high-voltage pulses, and the electrocuted insect corpses will fall into the insect storage box. The sound sensor records the number of insects killed by detecting the level changes.

- (2)

- Environmental information collection module (EICM): Serving as the core platform for collecting environmental data and implementing eco-friendly pest control. It integrates various sensors to monitor conditions, e.g., air temperature and humidity, light intensity, soil temperature and moisture, pH levels, soil conductivity, and the concentrations of nitrogen, phosphorus, and potassium (NPK). This integration supports seamless environmental data acquisition and pest control, contributing to optimal crop growth conditions.

- (3)

- Multi-view image collection module (MICM): This module is equipped with three cameras positioned to capture images from the left, right, and top views. It enables the collection of full-cycle images of the crop growth process and high-frequency images detailing crop morphological characteristics and growth status. The multi-angle approach improves the accuracy of monitoring the crop height, leaf color, and pest and disease conditions.

- (4)

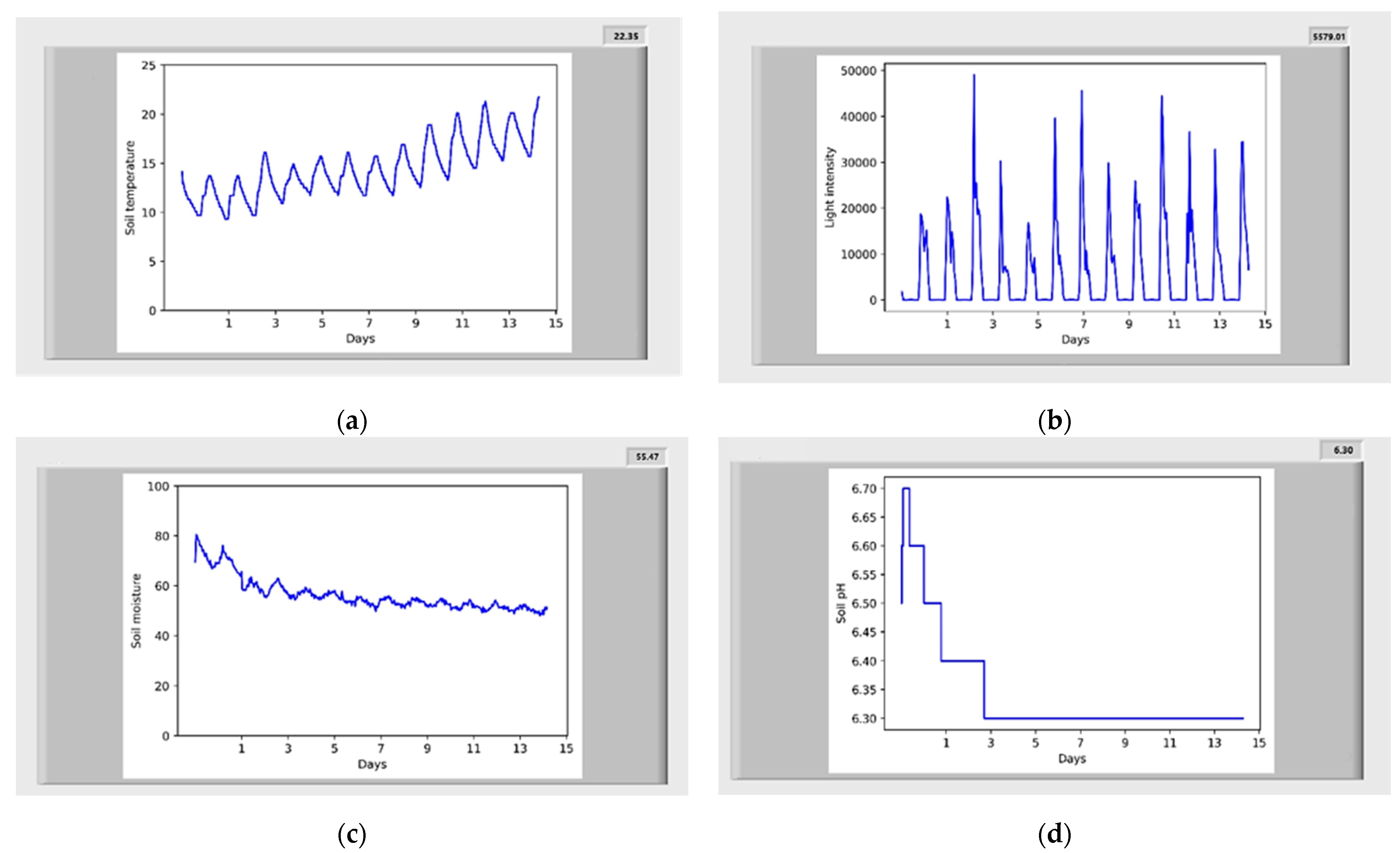

- Visualization software: LabVIEW software (LabVIEW 2022 32-bit) is used to display the collected data in the form of continuous statistical graphs, visually illustrating trends in the air temperature, humidity, light intensity, and soil parameters. This comprehensive visualization aids in monitoring and analyzing fluctuations in crop growth data throughout the growth process.

2.2. System Framework Design

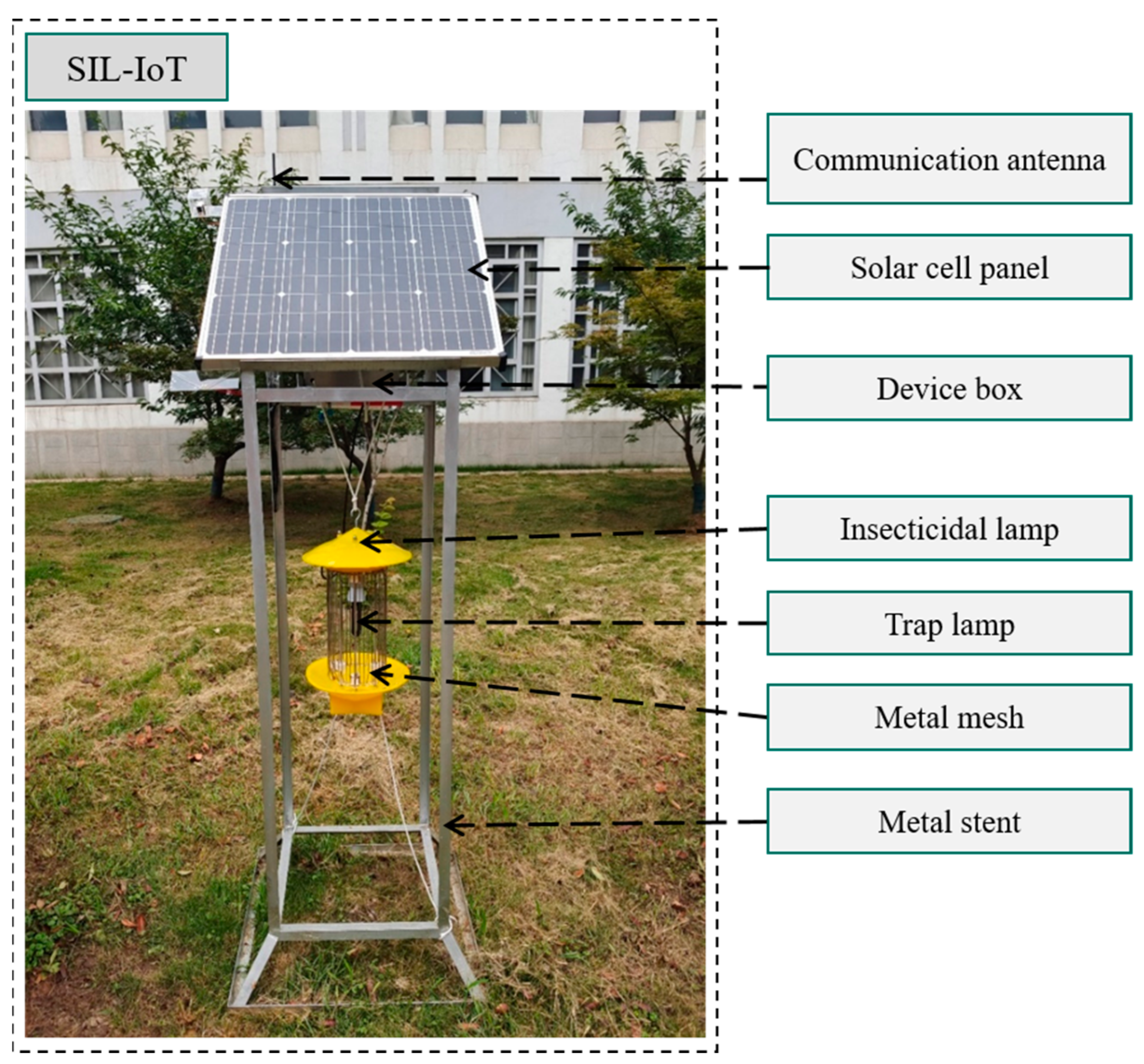

3. Hardware Structure Design

3.1. Pest Information Collection Module Design

3.2. Environmental Information Collection Module Design

3.2.1. Component Selection

3.2.2. Circuit Design

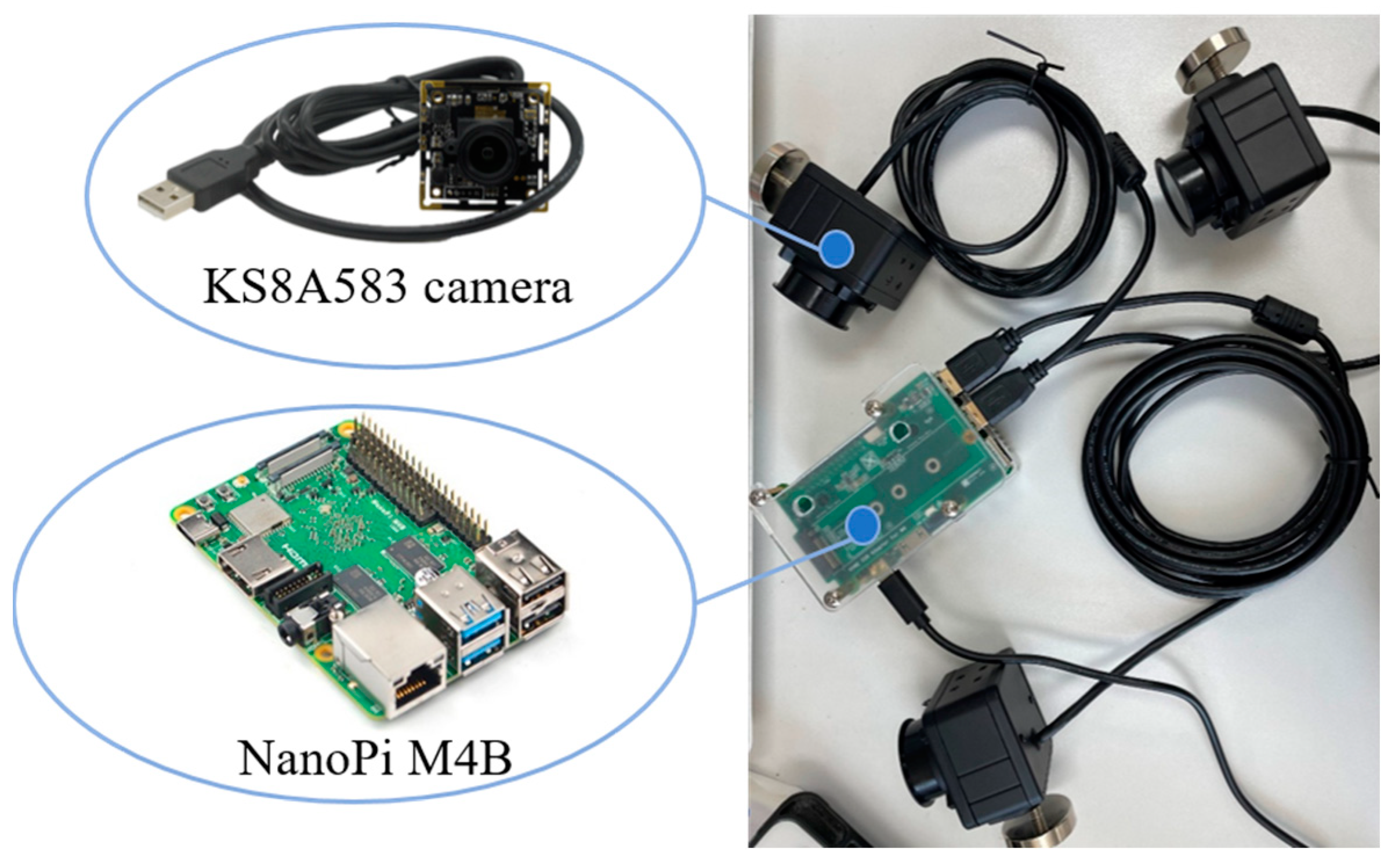

3.3. Multi-View Image Collection Module Design

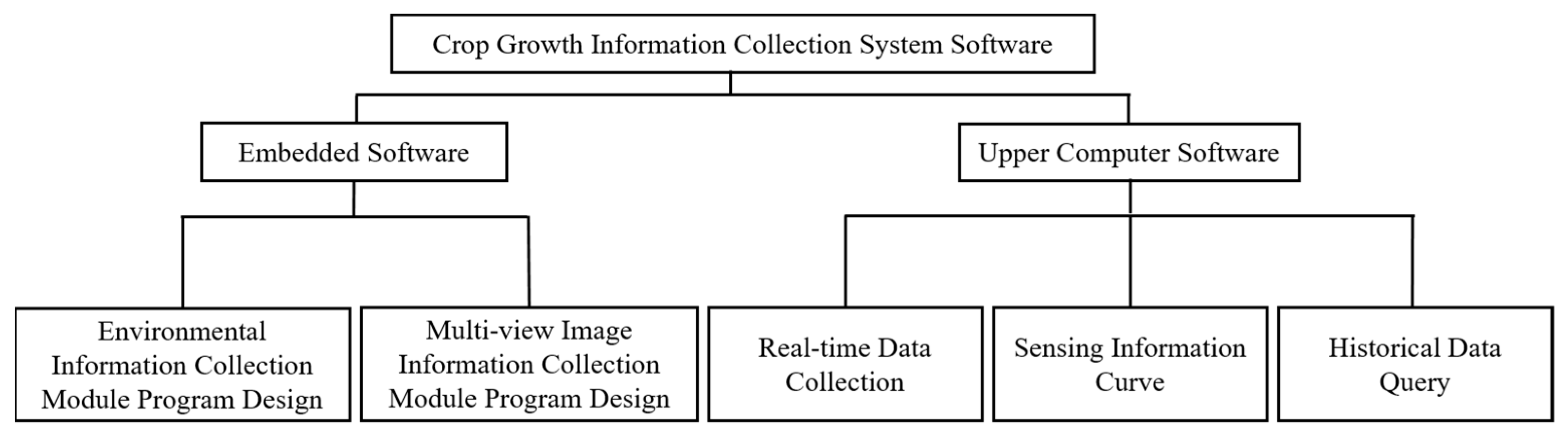

4. Software Framework Design and Implementation

4.1. Environmental Information Collection Module Program Design

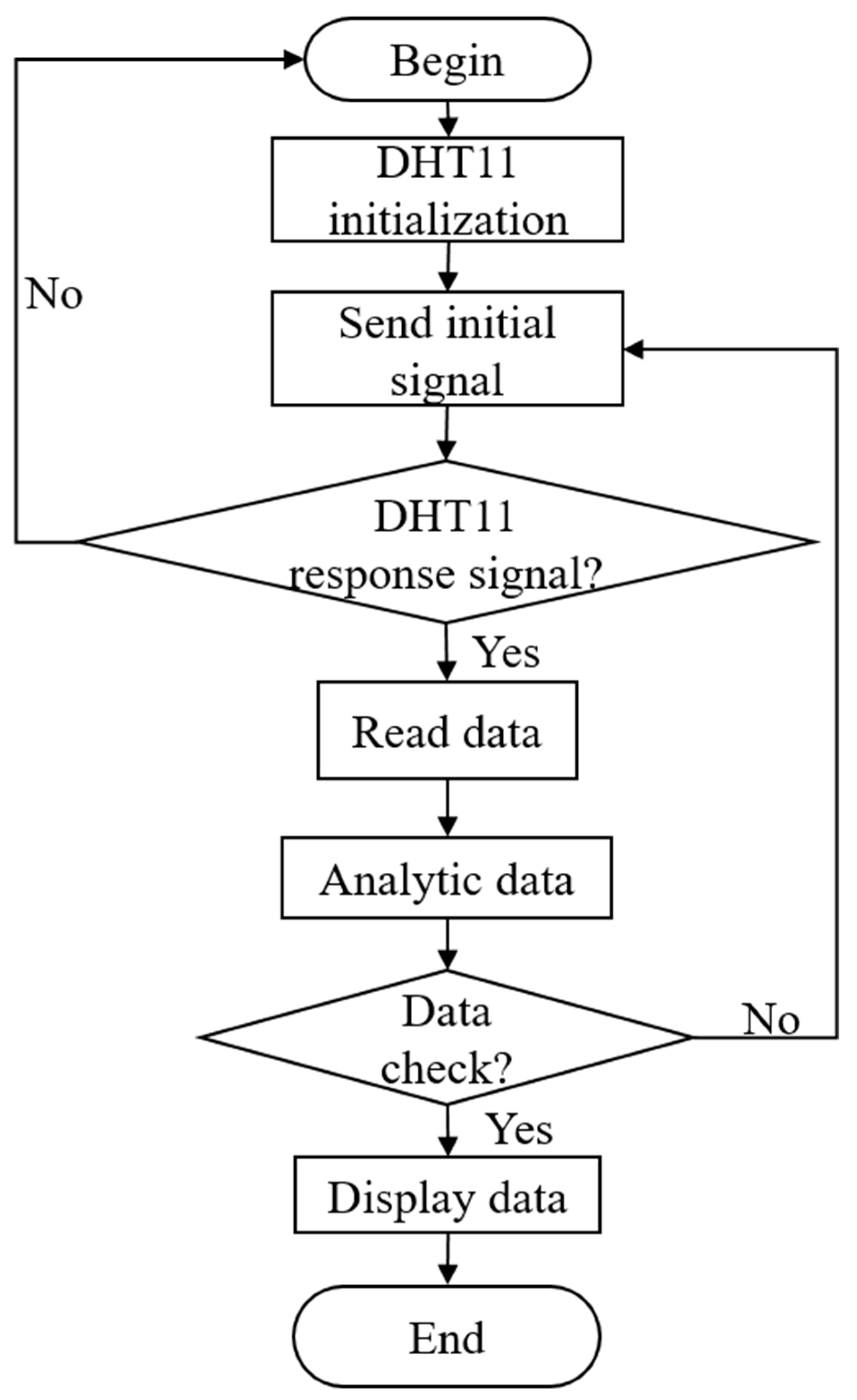

4.1.1. DHT11 Temperature and Humidity Sensor

- (1)

- Initialization: The driver initializes the sensor by setting the GPIO pin mode and communication rate. The ESP32-S3 sends a start signal, pulls down the data line low for over 18 ms, and then pulls it high for 20~40 μs, waiting for the DHT11 to respond.

- (2)

- Response signal: The DHT11 responds to the host’s start signal by pulling the data line down for about 80 μs, and then pulling it up for about 80 μs. Then, the DHT11 sends 40 bits of binary data, where a high level represents a one and a low level represents a zero.

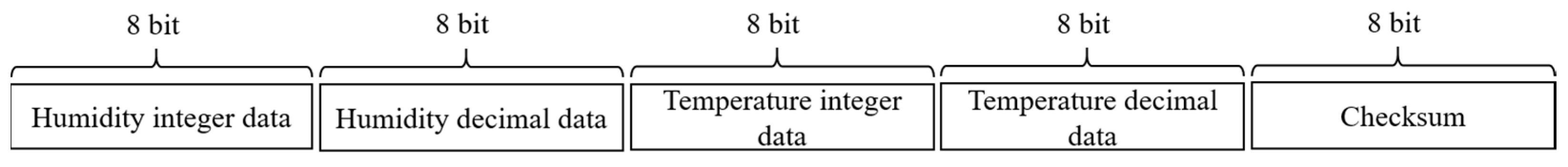

- (3)

- Data parsing: The ESP32-S3 parses the received data packet, including splitting the data segmentation, checksum verification, format conversion, and calculation of the temperature and humidity values. We defined the data packet format as shown in Figure 11, where 16 bits represent the temperature, 16 bits represent the humidity, and the last 8 bits are used for the checksum. The checksum is calculated by summing the first 32 bits and comparing it with the last 8 bits. If the checksum fails, the sensor retransmits the data.

- (4)

- Data output: Once the checksum is verified as correct, the sensor releases the bus. The ESP32-S3 then converts and outputs the temperature and humidity data to the upper computer display.

4.1.2. DS18B20 Temperature Sensor

- (1)

- Reset signal: The ESP32-S3 sends a reset signal to the DS18B20, pulls the data line down for over 480 μs and then pulls it up for about 60 μs. The system waits for the response from the DS18B20. If the response is successful, the DS18B20 pulls the data line low for about 60 μs, and then returns to the high-level state (about 480 μs) at the time of power-on reset.

- (2)

- Send command: The ESP32-S3 sends a “Read ROM” or “Skip ROM” command, prompting the DS18B20 to return its unique ROM code for identification.

- (3)

- Temperature conversion: The ESP32-S3 sends a temperature conversion command, pulling the data line low for at least 1 μs, and then pulling it high again. The DS18B20 starts the temperature conversion and stores the converted data in the internal memory at address 0x44.

- (4)

- Read data: After the temperature conversion is completed, the ESP32-S3 sends a read command that lasts at least 1 μs. Then, the DS18B20 returns 9 bytes of temperature data, where each data bit lasts about 60 μs, and a high level represents one and a low level represents zero.

- (5)

- Data parsing: The ESP32-S3 parses the returned raw temperature data and converts it into standard Celsius format.

- (6)

- CRC checksum: The ESP32-S3 verifies the CRC checksum. If the checksum is correct, it outputs the temperature value to the upper computer for display and closes the program to release the bus.

4.1.3. GY-39 Light Intensity Sensor

- (1)

- Initialization: The I2C address of the GY-39 sensor is defined. The setup function initializes the serial communication and the IIC bus, configuring the ESP32-S3 as the master device.

- (2)

- Send read command: The ESP32-S3 sends a command to read light intensity data from the GY-39, specifying the address of the data to be read. The Wire.requestFrom() function is utilized to request the 2-byte raw light intensity raw data packet.

- (3)

- Receive and parse the data: After receiving the read command, the GY-39 sends a response signal and sends the data back to the ESP32-S3. The Wire.read() function is used to parse the raw data packet byte by byte, combining the high 8 bits and low 8 bits to form the actual 16-bit sensor data through bitwise operations.

- (4)

- Data output: The parsed data are processed and output through the serial port.

4.1.4. FC-04 Sound Sensor

- (1)

- Set I/O Pins: The I/O pins of the FC-04 are configured to output mode. The integrated level comparator within the FC-04 outputs a high-level signal upon detecting surrounding insecticidal sounds.

- (2)

- Read data: The ESP32-S3 continuously monitors the level changes in the I/O pins and records these variations.

- (3)

- Data Processing and Transmission: The system filters and processes the collected insecticidal sound data. The processed data are transmitted to the upper computer through the serial port or other communication methods for user access.

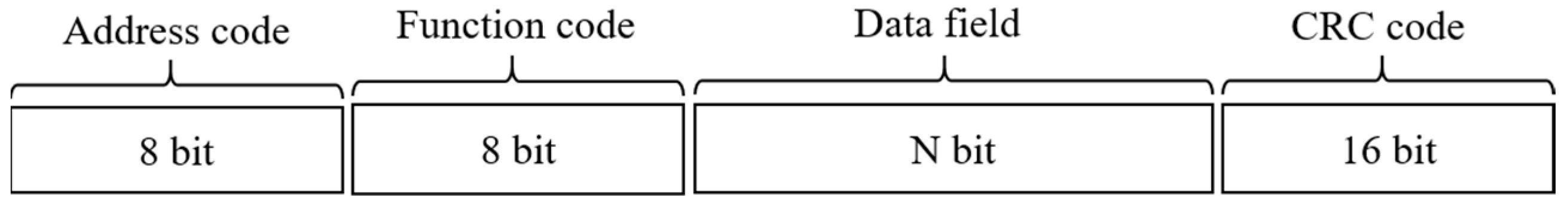

4.1.5. Kenqi-RS485 Soil Sensor

- (1)

- Address code: Indicates the address of the sensor, usually represented as an 8-bit binary number.

- (2)

- Function code: Specifies the type of operation for the communication, also represented as an 8-bit binary number.

- (3)

- Data area: Contains the request or response data. The length of this section depends on the type of communication operation.

- (4)

- Error check: Verifies the integrity of the communication frame using a 16-bit cyclic redundancy check (CRC) code.

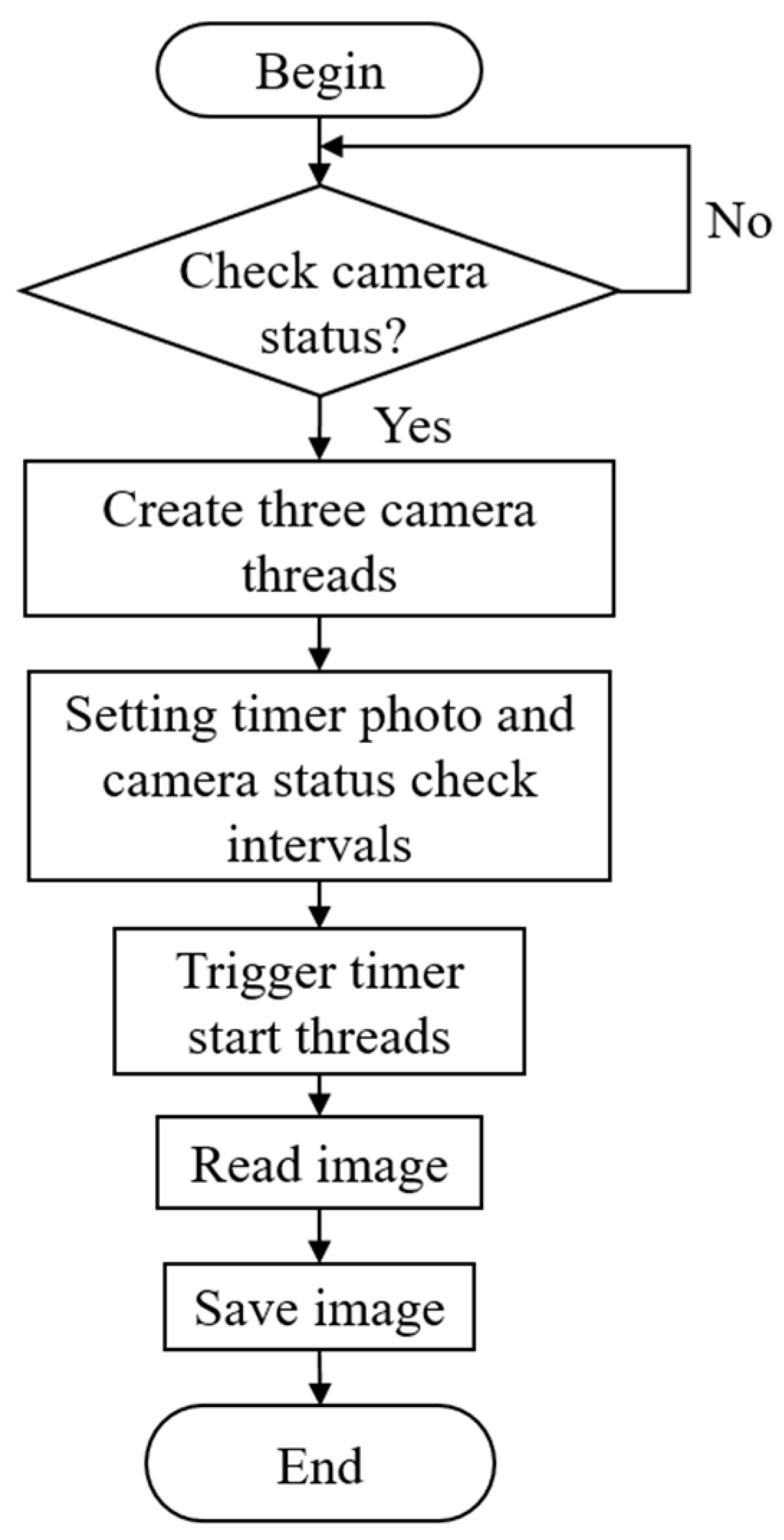

4.2. Multi-View Image Collection Module Program Design

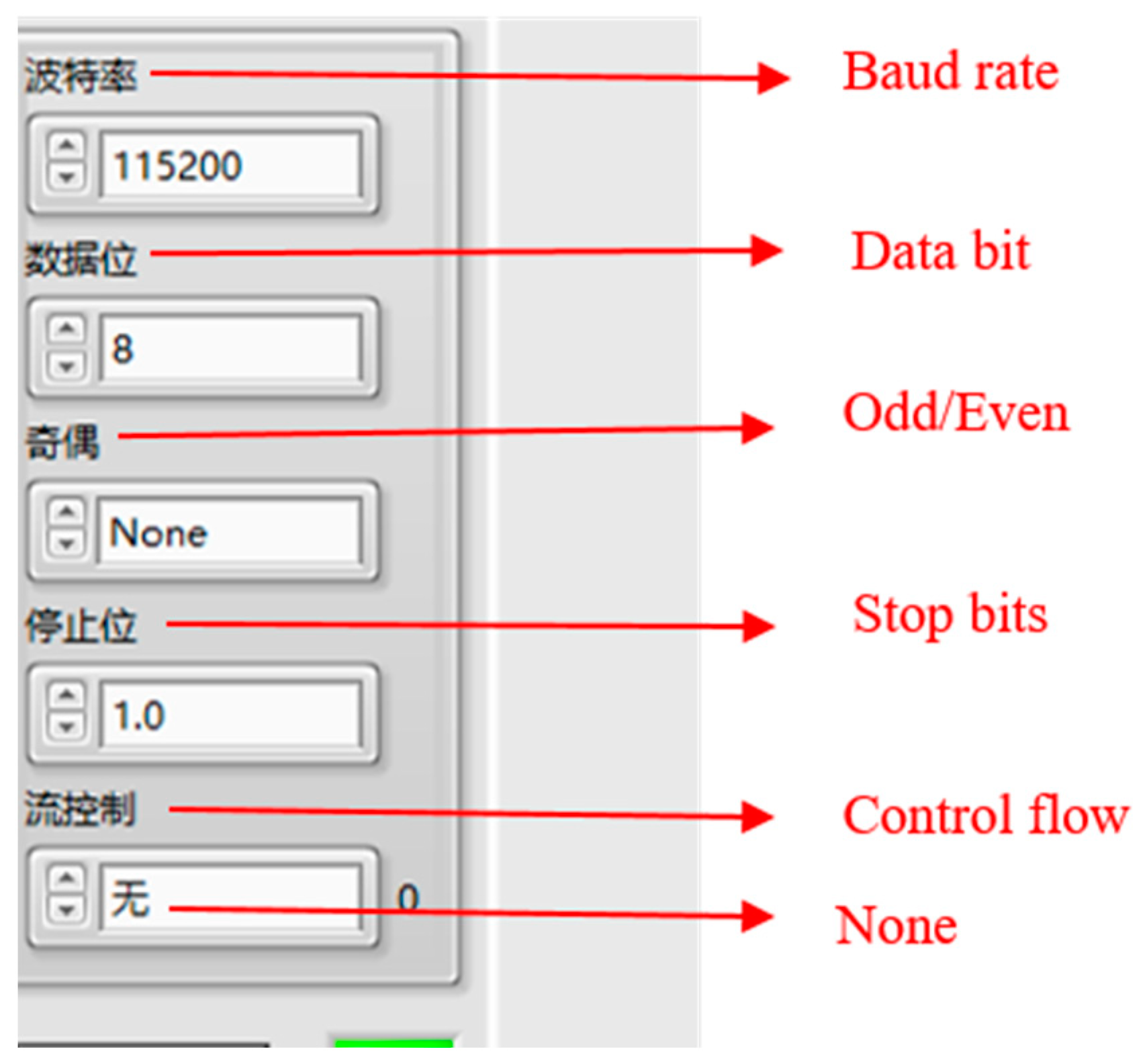

4.3. Upper Computer Software

5. Experimental Implementation and Testing

5.1. Experimental Scenario

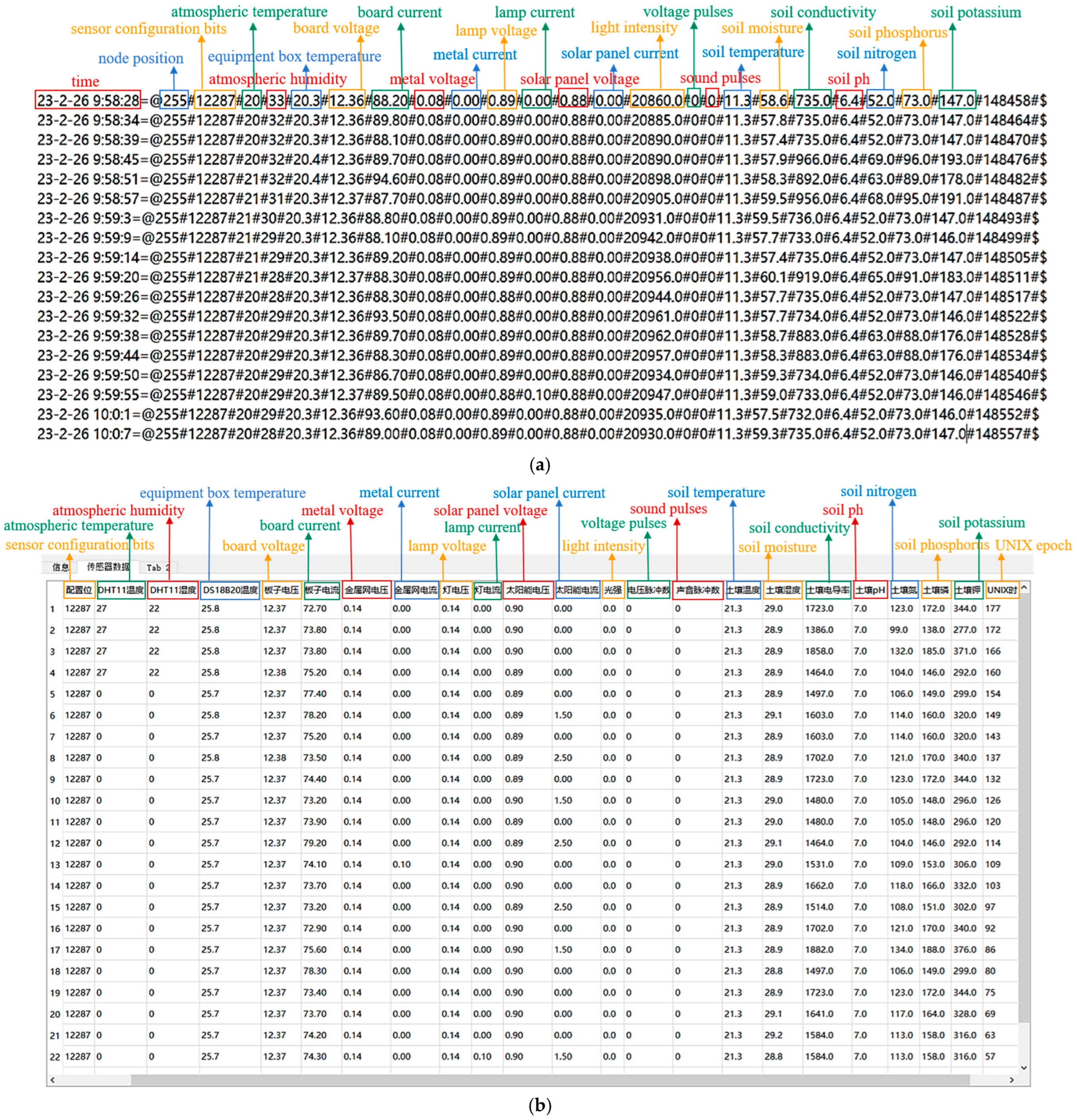

5.2. Experiment on Environmental Information Collection

5.3. Experiment on Multi-View Image Collection

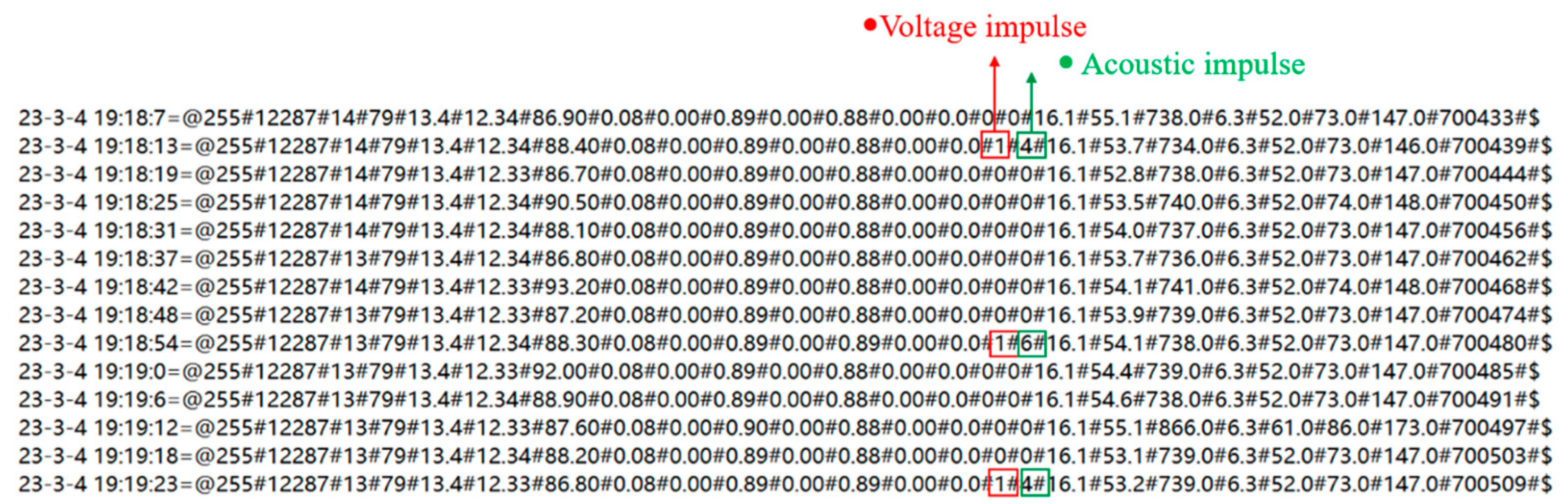

5.4. Experiment on Insecticidal Counting

5.5. Experiment on Upper Computer

5.6. Performance Comparison

6. Conclusions

- (1)

- Hardware maintenance and upgrade: Regular replacement of hardware components such as sensors and insecticidal lamp parts is necessary to ensure the system consistently provides high-quality environmental and crop growth data.

- (2)

- Data acquisition and transmission optimization: Improve data collection modules and refine transmission protocols, e.g., 5G technology, to improve both the accuracy of data collection and the stability of data transmission. Additionally, implement strategies to prevent interference when deploying multiple devices in the field.

- (3)

- Ecological sustainability: Integrating eco-friendly strategies, such as precise control of the operating times and spectral bands for SILs, can minimize the impact on beneficial insects and reduce the environmental burden.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, R.; Yang, W.; Hu, G.; Geng, J. Analysis on the Research, Development and Application of Agricultural Insecticidal Lamps in My Country. Agric. Sci. Eng. China 2022, 34, 68–70. [Google Scholar] [CrossRef]

- Yao, H.; Shu, L.; Lin, W.; Huang, K.; Martínez-García, M.; Zou, X. Pests Phototactic Rhythm Driven Solar Insecticidal Lamp Device Evolution: Mathematical Model Preliminary Result and Future Directions. IEEE Open J. Ind. Electron. Soc. 2024, 5, 236–250. [Google Scholar] [CrossRef]

- Qiu, Z.; Qiu, P.; Zhu, Q.; Wang, R. Insect Trapping Method Based on Progressive Star Network. Int. J. Online Biomed. Eng. (Ijoe) 2015, 11, 56–60. [Google Scholar] [CrossRef][Green Version]

- Tu, H.; Tang, N.; Hu, X.; Yao, Z.; Wang, G.; Wei, H. LED Multispectral Circulation Solar Insecticidal Lamp Application in Rice Field. Trans. Chin. Soc. Agric. Eng. 2016, 32, 193–197. [Google Scholar]

- Ma, Q.; Tian, M.; Tang, W. Research and Design of Distributed Solar Insect Killer Lamp Remote Control System Based on WSN. Internet Things Technol. 2017, 7, 77–79+83. [Google Scholar] [CrossRef]

- Cao, J. The Design and Research of an Intelligent Solar Insect Killing Lamp. Master’s Thesis, Guizhou University, Guiyang, China, 2018. [Google Scholar]

- Zhu, C. Research on Intelligent Management Systemof Plant Protection Insecticide Lamp Basedon Internet of Things Technology. Master’s Thesis, Anhui University, Hefei, China, 2019. [Google Scholar]

- Yang, T. Remote Control System of Solar Insecticidal Lamp Based on NB-IoT. Master’s Thesis, Beijing Forestry University, Beijing, China, 2020. [Google Scholar]

- Wang, X. Study on Effect of Improved Solar Pest-Killing Lamp on Trapping and Killing Field Pests in Liangshan Prefecture. J. Xichang Univ. (Nat. Sci. Ed.) 2020, 34, 9–13+92. [Google Scholar] [CrossRef]

- Han, H.; Zhang, J.; Liu, M.; Zhao, F.; Wang, G.; Lv, Y. The Application of Fan Suction Solar Energy Insecticidal Lamp in Fresh Corn Fields and its Effect on the Biodiversity of Arthropods. J. Plant Prot. 2020, 47, 1234–1243. [Google Scholar] [CrossRef]

- Zhang, Z.; Leng, Z.; Zhu, C.; Zhu, Z.; Su, Y. Design and Implementation of Remote State Monito Ring and Control System for Internet of Things Insecticidal Lamp. Comput. Appl. Softw. 2021, 38, 37–41. [Google Scholar]

- Wang, J.; Yu, G.; Zhang, E. Plant Protection Insecticide Lamp and Environmental Monitoring System Based on Internet of Things. China Sci. Technol. Inf. 2021, 9, 91–92. [Google Scholar]

- Liang, F. Research and Application of Greenhouse Environment Monitoring and Early Warning System. Master’s Thesis, Jilin Agricultural University, Changchun, China, 2016. [Google Scholar]

- López-Martínez, J.; Blanco-Claraco, J.L.; Pérez-Alonso, J.; Callejón-Ferre, Á.J. Distributed Network for Measuring Climatic Parameters in Heterogeneous Environments: Application in A Greenhouse. Comput. Electron. Agric. 2018, 145, 105–121. [Google Scholar] [CrossRef]

- Foughali, K.; Fathallah, K.; Frihida, A. Using Cloud IOT for disease prevention in precision agriculture. Procedia Comput. Sci. 2018, 130, 575–582. [Google Scholar] [CrossRef]

- Wang, X.; Sun, H.; Long, Y.; Zheng, L.; Liu, H.; Li, M. Development of Visualization System for Agricultural UAV Crop Growth Information Collection. IFAC-Pap. 2018, 51, 631–636. [Google Scholar] [CrossRef]

- Kochhar, A.; Kumar, N. Wireless Sensor Networks for Greenhouses: An End-to-end Review. Comput. Electron. Agric. 2019, 163, 104877. [Google Scholar] [CrossRef]

- Wang, J. Design of Low Power Consumption Wireless System for Information Collection of Facility Agriculture. Master’s Thesis, Hebei Agricultural University, Baoding, China, 2020. [Google Scholar]

- Luo, J. Testing and Evaluation of Cgmd302 Crop Growth Monitoring and Diagnosis Instrument. Master’s Thesis, Nanjing Agricultural University, Nanjing, China, 2015. [Google Scholar]

- Xu, R. Remote Monitoring Device for Corn Plant Growth Information. Master’s Thesis, Jilin Agricultural University, Changchun, China, 2017. [Google Scholar]

- Zhou, T. Estimation of Wheat Yield Based on WOFOST Model and Uavimage Assimilation. Master’s Thesis, Yangzhou University, Yangzhou, China, 2019. [Google Scholar]

- Zhou, L. Research on Wheat Phenotypic Information Perception Method Based on Spectrum and Image. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2022. [Google Scholar]

- Wang, W. Study on Rapid Detection Method of Rice Root and Stem Phenotypic Information Under Cadmium Stress. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2021. [Google Scholar]

- Pan, B. Design of Growth Information Detection System for Wheat Plot Breeding Based on Vision. Master’s Thesis, Anhui Agricultural University, Hefei, China, 2022. [Google Scholar]

- Li, S.; Zhang, A.; Zhang, X.; Yang, Z.; Li, M. Method for Extracting Three-Dimensional Phenotypic Information of Corn Seedlings at Leaf Scale. Laser Optoelectron. Prog. 2023, 60, 71–79. [Google Scholar]

- Wang, N.; Suomalainen, J.; Bartholomeus, H.; Kooistra, L.; Masiliūnas, D.; Clevers, J.G.P.W. Diurnal Variation of Sun-Induced Chlorophyll Fluorescence of Agricultural Crops Observed from A Point-Based Spectrometer on A UAV. Int. J. Appl. Earth Obs. Geoinf. 2021, 96, 102276. [Google Scholar] [CrossRef]

- Chamara, N.; Bai, G.; Ge, Y. AICropCAM: Deploying classification, segmentation, detection, and counting deep-learning models for crop monitoring on the edge. Comput. Electron. Agric. 2023, 215, 108420. [Google Scholar] [CrossRef]

- Tesfaye, K.; Takele, R.; Shelia, V.; Lemma, E.; Dabale, A.; Sibiry Traore, P.C.; Solomon, D.; Hoogenboom, G. High Spatial Resolution Seasonal Crop Yield Forecasting for Heterogeneous Maize Environments in Oromia, Ethiopia. Clim. Serv. 2023, 32, 100425. [Google Scholar] [CrossRef]

- Song, Y.; Bi, J.; Wang, X. Design and Implementation of Intelligent Monitoring System for Agricultural Environment in IoT. Internet Things 2024, 25, 101029. [Google Scholar] [CrossRef]

- Chen, T.; Tang, H. Remote Monitoring and Forecasting System of Soil Moisture Based on ARM and GPRS. Trans. CSAE 2012, 28, 162–166. [Google Scholar]

- Qin, Y.; Chen, X.; Zhou, K.; Klenk, P.; Roth, K.; Sun, L.; Dai, H.; Huang, D.; Mao, H. Ground-penetrating Radar for Monitoring theDistribution of Near-surface Soil Water Content in the Gurbantünggüt Desert. Environ. Earth Sci. 2013, 70, 7. [Google Scholar] [CrossRef]

- Tan, Y. Rescarch of Wirelcss Mcasurement Systerm for Soil Moisture. Master’s Thesis, Anhui Agricultural University, Hefei, China, 2013. [Google Scholar]

- Xue, F. Study on Intelligent Acquisition System of Farmland Soil Information. Master’s Thesis, Nanjing University of Information Science and Technology, Nanjing, China, 2014. [Google Scholar]

- Gao, Z.; Liu, X. Chinese Herbal Medicine Soil Detection System Based on ZigBee. J. Jingchu Univ. Technol. 2014, 29, 37–41. [Google Scholar] [CrossRef]

- Xiao, Y.; Li, H.; Wang, X. Soil Moisture Monitoring System. In Proceedings of the Exploring Science Academic Seminar (2016), Changsha, China, 18–20 March 2016; p. 1. [Google Scholar]

- Qin, L.; Mu, Y.; Liu, S.; Shang, M. Design and Implementation of A Multi-Parameter Monitoring Station for Soil Moisture and Environmental Information In Winter Wheat Production. Internet Things Technol. 2019, 9, 13–15+18. [Google Scholar] [CrossRef]

- Cao, Y.; Zhou, H.; Yin, F. Design of Multi-purpose Soil Moisture Collection Device. Wirel. Internet Technol. 2022, 19, 116–118. [Google Scholar]

- Zhu, W.; Feng, Z.; Wu, S.; Mei, H.; Cui, B.; Wei, X.; Luo, J. Development of An Airborne Non-contact Near-infrared Soil Moisture Detection System. Trans. Chin. Soc. Agric. Eng. 2022, 38, 73–80. [Google Scholar]

- Ji, W.; Wang, J.; Wang, X. Design of Multi-parameter Monitoring System of Agricultural Field Soil Based on LoRa. Radio Eng. 2023, 53, 456–464. [Google Scholar]

- Kang, M.; Wang, F.-Y. From Parallel Plants to Smart Plants: Intelligent Control and Management for Plant Growth. IEEE/CAA J. Autom. Sin. 2017, 4, 161. [Google Scholar] [CrossRef]

- Friha, O.; Ferrag, M.A.; Shu, L.; Maglaras, L.; Wang, X. Internet of Things for the Future of Smart Agriculture: A Comprehensive Survey of Emerging Technologies. IEEE/CAA J. Autom. Sin. 2021, 8, 718. [Google Scholar] [CrossRef]

- Yang, X.; Shu, L.; Li, K.; Huo, Z.; Shu, S.; Nurellari, E. SILOS: An Intelligent Fault Detection Scheme for Solar Insecticidal Lamp IoT with Improved Energy Efficiency. IEEE Internet Things J. 2023, 10, 920–939. [Google Scholar] [CrossRef]

| Year | Researcher | Research Content | Camera Function | Crop Growth Detection |

|---|---|---|---|---|

| 2015 | Qiu et al. [3] | Design a “star net” composed of different types of insecticidal lamps | No | No |

| 2016 | Tu et al. [4] | Design an LED multispectral SIL that uses light of different wavelengths to kill corresponding insects | No | No |

| 2017 | Ma et al. [5] | Collect the working environment data of insecticidal lamps and capture insecticidal pictures in real time, and upload them in real time through WSN technology | Pest identification, pest monitoring, insecticidal lamp control | No |

| 2019 | Cao [6] | Design a solar self-luminous multi-mode insecticidal lamp using luminescent materials | No | No |

| 2019 | Zhu [7] | Use IoT technology to realize remote control of insecticidal lamps | Insecticidal lamp working status monitoring | No |

| 2019 | Yang [8] | Use NB-IoT technology to realize remote monitoring of insecticidal lamps | No | No |

| 2020 | Wang [9] | Improve light spectrum to increase pest killing rate | No | No |

| 2020 | Han et al. [10] | Analyze the effectiveness of fan-suction SILs in corn fields | No | No |

| 2021 | Zhang et al. [11] | Design a system for remote status monitoring and control of IoT-based SILs | Insecticidal lamp working status monitoring | No |

| 2021 | Wang et al. [12] | Design an insecticidal lamp that can change the color of the light and monitor the surrounding environment | No | No |

| Company Name | Product Model | Camera | Environmental Information Collection | Crop Growth Environment Monitoring |

|---|---|---|---|---|

| Zhejiang Longhao Agricultural Technology Co., Ltd., Taizhou, China. | Solar frequency-vibration insecticidal lamp GP-LH18B | No | Atmospheric temperature and humidity | No |

| Changzhou Jinhe New Energy Technology Co., Ltd., Changzhou, China. | Electric shock insecticidal lamp 3S-SPX-JH-DJ01 | No | Light intensity, temperature and humidity | No |

| Chengdu Bion Technology Co., Ltd., Chengdu, China. | Solar insecticidal lamp BA-T/RL | No | Atmospheric temperature | No |

| Shandong Wanxiang Environmental Technology Co., Ltd., Weifang, China. | Solar pest monitoring lamp WX-CQD6 | Yes | Light intensity, weather conditions | No |

| Shandong Tianhe Environmental Technology Co., Ltd., Weifang, China. | Pest monitoring lamp TH-CQ1 | Yes | Light intensity, weather conditions | No |

| Year | Researcher | Data Collection | Image Collection Function | Related to Growth Information Collection |

|---|---|---|---|---|

| 2016 | Liang [13] | Temperature and humidity, light intensity, CO2 concentration | No | No |

| 2018 | López-Martínez et al. [14] | Atmospheric temperature and humidity, soil temperature and humidity, light intensity | No | No |

| 2018 | Foughali et al. [15] | Air humidity, CO2 concentration, light intensity | No | No |

| 2018 | Xu Wang [16] | Light intensity, UAV information collection, remote system | No | No |

| 2019 | Kochhar et al. [17] | / | No | No |

| 2020 | Wang [18] | Air temperature and humidity, CO2 concentration, light intensity, soil temperature and humidity | No | No |

| Year | Researcher | Environmental Parameters | Image Collection Device | Related to SILs |

|---|---|---|---|---|

| 2015 | Luo [19] | Leaf area, leaf dry weight and nitrogen content | CGMD302 crop growth monitor (National Engineering and Technology Center for Information Agriculture, Nanjing, China.) | No |

| 2017 | Xu [20] | Corn growth image | CMOS image sensor (OmniVision Technologies, Inc., Santa Clara, CA, USA.) | No |

| 2019 | Zhou [21] | Wheat growth image | UAVs | No |

| 2021 | Zhou [22] | Wheat seed, leaf moisture content and canopy information | Hyperspectral instrument and UAVs | No |

| 2021 | Wang [23] | Rice rhizome information | Hyper-spectrometer | No |

| 2022 | Pan [24] | Wheat growth image | HT SUA502-T (Shenzhen Huateng Vision Technology Co., Ltd., Shenzhen, China.) | No |

| 2022 | Li et al. [25] | Corn seedling image, plant height and leaf perimeter | HUAWEI P30 (Huawei Technologies Co., Ltd., Shenzhen, China.) | No |

| 2021 | Wang et al. [26] | Crop traits, day and night patterns | UAVs | No |

| 2023 | Nipuna et al. [27] | Crop classification, plant type identification and counting | Meidas SL122 trail cameras, OV5642 imaging sensors with ArduCAM camera, Raspberry Pi camera | No |

| 2023 | Kindie et al. [28] | Soil, temperature, humidity, climate | No | No |

| 2024 | Song et al. [29] | Temperature, humidity, light intensity | Cloud big screen | No |

| Year | Researcher | Collection Device | Soil Data | Related to SILs |

|---|---|---|---|---|

| 2013 | Qin et al. [31] | Radar | Soil moisture content | No |

| 2013 | Tan [32] | Soil temperature and humidity sensor, DS18B20 temperature sensor (Dallas Semiconductor Corporation, Dallas, TX, USA.) | Soil moisture content | No |

| 2014 | Xue [33] | SHT11 temperature and humidity sensor (SENSIRION, Zurich, Switzerland.) | Soil temperature and humidity | No |

| 2014 | Gao et al. [34] | Soil moisture sensor, pH sensor | Soil moisture, pH value | No |

| 2016 | Xiao et al. [35] | Soil temperature and humidity sensor | Soil temperature, moisture content | No |

| 2019 | Qin et al. [36] | Soil moisture sensor | Soil moisture content | No |

| 2022 | Cao et al. [37] | Soil temperature and humidity sensor, conductivity sensor | Soil moisture content | No |

| 2022 | Zhu et al. [38] | Near-infrared spectrum | Soil temperature and humidity | No |

| 2023 | Ji et al. [39] | MS10 soil temperature and humidity sensor, VMS-3000-TR-PH-N01 nitrogen, phosphorus and potassium sensor | Soil temperature and humidity, nutrient content | No |

| Parameter Name | Parameter Value |

|---|---|

| Working voltage | 3–5.5 V |

| Humidity measurement range | 20~90% RH |

| Temperature measurement range | 0~50 °C |

| Humidity accuracy | ±5% RH |

| Temperature accuracy | ±2 °C |

| Output signal | Digital signal |

| Parameter Name | Parameter Value |

|---|---|

| Working voltage | 3–5.5 V |

| Measurement range | −55 °C~125 °C |

| Temperature accuracy | ±0.5 °C |

| Data transmission method | Digital signal |

| Parameter Name | Parameter Value |

|---|---|

| Working voltage | 3.3 V~5 V |

| Working current | 5 mA |

| Temperature measurement range | −40 °C~85 °C |

| Humidity measurement range | 0~100% |

| Light intensity measurement range | 0.045 lux~188,000 lux |

| Light intensity accuracy | ±5% |

| Data transmission method | Digital signal |

| Parameter Name | Parameter Value |

|---|---|

| Working voltage | 12 V~24 V DC |

| Working temperature range | −40 °C~85 °C |

| Response time | ≤1 s |

| Soil temperature accuracy | ±0.5 °C |

| Soil moisture accuracy | ±3% (0~53 °C) |

| ±5% (53~100 °C) | |

| Soil conductivity accuracy | ±3% |

| Soil PH accuracy | ±0.3 pH |

| Soil NPK accuracy | ±2% F·s |

| Component | Model | Advantages |

|---|---|---|

| NanoPi | NanoPi M4B | Fast data processing speed, rich interfaces |

| Industry camera | KS8A583 | High resolution, high frame rate, low noise |

| System | Pest Control | Cost | Long-Term Monitoring | Data Acquisition Interval | Multi-View Image Collection |

|---|---|---|---|---|---|

| Sensor-based [20] | No | Low | No | No | No |

| UAV-based [22] | No | High | No | No | Top view |

| Hyperspectral-based [23] | No | High | No | 5 days | No |

| UAV- and hyperspectral-based [26] | No | Very high | No | About 25 min | Top view |

| Proposed system | Yes | Low | Yes | Real time | Top, left and right view |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, N.; Hu, T.; Shu, L.; Zang, H.; Li, K.; Han, R.; Yang, X. A Crop Growth Information Collection System Based on a Solar Insecticidal Lamp. Electronics 2025, 14, 370. https://doi.org/10.3390/electronics14020370

Jin N, Hu T, Shu L, Zang H, Li K, Han R, Yang X. A Crop Growth Information Collection System Based on a Solar Insecticidal Lamp. Electronics. 2025; 14(2):370. https://doi.org/10.3390/electronics14020370

Chicago/Turabian StyleJin, Naiyun, Tingting Hu, Lei Shu, Hecang Zang, Kailiang Li, Ru Han, and Xing Yang. 2025. "A Crop Growth Information Collection System Based on a Solar Insecticidal Lamp" Electronics 14, no. 2: 370. https://doi.org/10.3390/electronics14020370

APA StyleJin, N., Hu, T., Shu, L., Zang, H., Li, K., Han, R., & Yang, X. (2025). A Crop Growth Information Collection System Based on a Solar Insecticidal Lamp. Electronics, 14(2), 370. https://doi.org/10.3390/electronics14020370