Abstract

Solar panels play a crucial role in producing renewable electricity power for the grid, and this role grows more significant each year. However, defects in solar panels can significantly drop power output, leading to grid instability. Therefore, employing an efficient Artificial Intelligence (AI) algorithm to autonomously detect defects in solar panels is crucial. In this study, we employ the You Only Look Once (YOLO) v9, v10, and v11 algorithms to detect defects in solar panels. To this end, we examined their performance results via training on three datasets. The first dataset includes 191 thermal images with an image size of 200 × 160 pixels to identify a cell, multi-cell levels, and shadow defects. The second dataset consists of 792 optical images of solar panels with an image size of 244 × 244 to identify dust, snow, bird droppings, physical damage, and electrical defects. The third dataset includes 316 thermal images with an image size of 200 × 160 pixels, an enhanced version of the first dataset. Moreover, we examined the training and test performance results of YOLO v5, v9, v10, and v11. We achieved improved performance in detecting defects in solar panels compared to existing solutions by using the YOLO v10 and v11 algorithms. Additionally, we compared their performance results against Support Vector Machine (SVM) and Faster Region-based Convolutional Neural Network (R-CNN) to demonstrate the efficiency of the YOLO v10 algorithm. In conclusion, YOLO v11-X delivered the best performance among the algorithms tested. It reached a precision rate, recall rate, mean average precision, and F1 score of about 89.7%, 87.7%, 92.7%, and 90%, respectively.

1. Introduction

The role of solar panels in the electricity grid has increased by 50% to nearly 510 gigawatts (GW) in 2023, the fastest growth rate during the past two decades [1]. Solar panels play a crucial role in generating power. However, defects in solar panels can lead to significant power loss. These faults can be either electrical or nonelectrical. Nonelectrical defects can have poor construction and incorrect panels utilizing roots, settling of dirt and dust over solar panels, browning, shading, discoloration, delamination, soiling, moisture, humidity, and clamping-induced failures. Most of these defects cause hotspots. Electrical defects include line-to-line, ground, and open circuit faults, which usually occur because of massive connections and soldering points [2]. Autonomously monitoring solar panels is an effective method for localizing and detecting defects, allowing for timely interventions [2]. According to the literature, some traditional image processing and Artificial Intelligence (AI) algorithms have been developed for real-time defect detection in solar panels. However, their performance needs to be improved, as higher accuracy in defect detection can lead to a reduction in overall expenses and save resources [3,4,5,6,7,8].

Monicka et al. [9] proposed the innovative Otsu-Canny operator method, which is a traditional image processing algorithm. Artificial neural networks require many potential samples from pictures of the dataset for pre-training. However, the proposed method does not need massive numbers of potential images. Moreover, this method removes the impact of grids on detection and employs a double threshold to enhance edge detection performance for microcracks. A 92.83% precision rate was achieved in microcrack detection. Bordihn et al. [10] reported a hybrid model, a combination of the principle component analysis (PCA) algorithm and the k-nearest neighbor (kNN) classifier. They used this method to detect potential-induced degradation (PID) and light- and temperature-induced degradation (LeTID) using electroluminescence (EL) images.

Deep learning algorithms usually employ a Convolution Neural Network (CNN) to detect and classify objects. Le et al. [11], suggested a custom-designed CNN to detect 11 types of anomalies in solar panels. Moreover, the model was quantized and implemented on Jetson Nano (a low-resource platform) for real-time defect detection. This method reached an accuracy of 85.35% with 1.04 ms latency to process one image on average. Park et al. [12] proposed a method that combines a pre-trained attention mechanism and statistical feature extraction. A pre-trained attention mechanism recycles spatial features and feeds them into CNN. This method reached an accuracy of 94.31%. Vlaminck et al. [13] suggested an algorithm for the analysis of thermal images. During the pre-processing stage, the thermal images are normalized, and the solar panels are identified. The identified panels are then processed using the Simple Linear Iterative Clustering (SLIC) segmentation algorithm to produce positive samples of hotspots. These samples are subjected to manual verification, and the images are enhanced via various operations such as rotations, cropping, and contrast adjustments. The training process utilizes a region-based CNN, employing a Feature Pyramid Network (FPN) as the region proposal network and ResNet-50 as the backbone architecture. In the final post-processing phase, non-maximum suppression is applied to eliminate redundant detections.

Chen et al. [14] suggested a visual defect detection method based on multi-spectral deep CNN. Experimental results and K-fold cross-validation indicate that the multi-spectral deep CNN model can successfully identify surface defects in solar cells with enhanced accuracy and adaptability, achieving a defect recognition accuracy of 94.30%.

Duranay et al. [15] utilized the Efficientb0 model. From this model, a total of 17,000 features were identified using the Neighborhood Component Analysis (NCA) feature selection process. Following this, classification was executed using a Support Vector Machine (SVM) classifier. The proposed technique, when applied to a dataset comprising 12 distinct classes, demonstrated commendable performance across various metrics, including accuracy, F1 score, precision, and sensitivity. The average results achieved were 93.93% for accuracy, 89.82% for F1 score, 91.50% for precision, and 88.28% for sensitivity. Tommaso et al. [16] introduced an innovative automatic multi-stage model designed to identify panel defects in aerial images obtained by uncrewed aerial vehicles, utilizing the YOLOv3 algorithm alongside computer vision methods. They achieved an impressive Average Precision (AP) of over 98% for panel detection and approximately 66.9% for hotspots identified through infrared thermography. Additionally, the model attained a mean Average Precision (mAP) of nearly 70% in the visible spectrum for detecting various anomalies, including shading of panels caused by soiling and bird droppings, delamination, the presence of puddles, and elevated rooftop panels.

Hassan et al. [17] introduced an automated method for defect detection in photovoltaic (PV) systems, utilizing a custom-designed CNN that varies in the number of convolutional layers and pooling architectures. The proposed system demonstrates an impressive validation accuracy of 98.07%, which significantly reduces the need for manual inspections, improves quality standards, and lowers costs. In a case study of PV installations affected by PID, the system successfully identified all defective modules, achieving an impressive precision rate of 96.6%. Cao et al. [18] introduced an enhanced and efficient YOLOv8-GD (You Only Look Once v8 with Group Depthwise Convolution) algorithm. This improvement builds upon YOLOv8 by incorporating Depthwise Convolution (DW-Conv) into its backbone network. Additionally, the standard convolution is replaced with GSConv (Group-shuffle Convolution), and a BiFPN (Bidirectional Feature Pyramid Network) is integrated into the architecture. The final experimental results demonstrate that YOLOv8-GD achieves map@0.5 and map@0.5~0.95 scores of 92.8% and 63.1%, respectively, marking improvements of 4.2% and 5.7% over the original algorithm while also reducing the model size by 16.7%.

According to the literature, we require a fast and efficient algorithm to conduct real-time defect detection in solar panels. You Only Look Once (YOLO) algorithms are one of the efficient algorithms developed for image analysis that can quickly and reliably detect objects as they have a good balance of speed and accuracy. Several versions of YOLO have been presented, and their performance enhanced significantly. The transfer learning approach, architectural improvements, training techniques, and dataset augmentation are critical factors in the YOLO algorithms for object detection tasks. The YOLO models have been employed in many object detection projects such as crops, pests, and diseases in agriculture, face recognition in security, and biometrics [19].

The novelty of this manuscript is as follows: application of the latest YOLO architecture released in September 2024 to solar panel defect detection for the first time. This is the first time this architecture has been trained and tested using thermal and optical images of solar panels from the Roboflow and Kaggle datasets, respectively. Additionally, the contributions of this manuscript are as follows: improvement in fault detection performance on solar panels by employing YOLO v11-X, YOLO v10-X, and YOLO v9 algorithms for detecting defects on solar panels and providing an augmented version of the Roboflow dataset to achieve enhanced performance results. We first discussed the architectures of YOLO v9, v10, and v11 algorithms. Secondly, we optimized them to detect defects in solar panels and conducted experiments on Google Colaboratory. We used a random search method to optimize critical hyperparameters, aiming to achieve the best performance results. Finally, we compared YOLO’s performance results with SVM and Faster Region-based Convolutional Neural Network (R-CNN). The datasets used are discussed in Section 2, the YOLO models in Section 3, the methodology in Section 4, the results in Section 5, the discussion in Section 6, and the conclusions in Section 7.

2. Datasets

We used three datasets for our experiments: the Roboflow dataset, the Kaggle dataset, and the augmented Roboflow dataset. The Roboflow dataset is composed of 191 thermal images of solar panels with an image size of 200 × 160 pixels, as thermal images can provide deeper vision into solar panels, especially in detecting hotspot defects. Additionally, some images include several solar panels. Overall, 70% of the dataset was employed for training, 19% for validation, and 11% for testing. This dataset was downloaded from the Roboflow website [20]. To ensure a fair comparison, we used the same number of images for training, validation, and testing as those specified in the referenced website. The purpose of this dataset is to examine the accuracy of various machine learning classifiers in identifying hotspots in cell and multi-cell levels and shadows on the surface of solar panels.

The Kaggle dataset is composed of 792 optical images of solar panels with the image size of 244 × 244. Additionally, some images include several solar panels. 70% of the dataset was employed for training, 20% for validation, and 10% for testing. This dataset was downloaded from the Kaggle website provided by Afroz. The purpose of this dataset is to examine the accuracy of various machine learning classifiers in identifying dust, snow, bird droppings, physical damage, and electrical issues on the surfaces of solar panels [21].

The augmented Roboflow dataset consists of 316 thermal images of solar panels, each with a resolution of 200 × 160 pixels. This dataset is an enhanced version of the first dataset. Augmentation techniques applied include horizontal and vertical flips, as well as 90° rotations in clockwise, counterclockwise, and upside-down orientations. Approximately 75% of the dataset was employed for training, 15% for validation, and 10% for testing.

This project was implemented on the Google Colaboratory servers with T4 GPU and 15360MiB memory.

3. YOLO Model

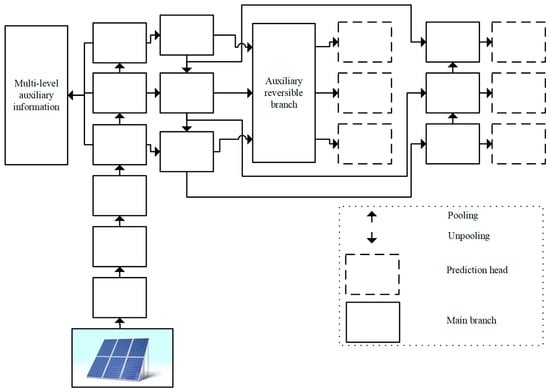

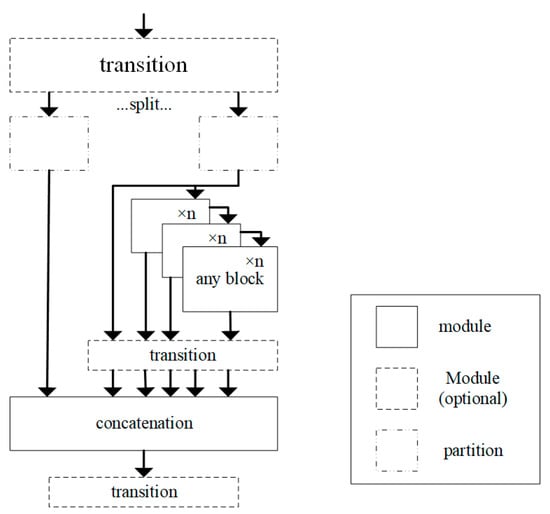

YOLO algorithms present a primary model for real-time object detection due to their impressive balance between detection performance and computational complexity. However, there are some challenges that new versions of YOLOs have attempted to overcome. The YOLO v9 algorithm represents a notable progression to address spatial transformation and layer-by-layer feature extraction that can lead to significant information loss by utilizing Programmable Gradient Information (PGI) and the Generalized Efficient Layer Aggregation Network (GELAN) in real-time object detection. The PGI structure is shown in Figure 1. This structure enables the detection of multiple objects. Moreover, it reduces information loss during feature extraction. The PGI includes three main components: main branch, auxiliary reversible branch, and multi-level auxiliary information. The main branch is utilized for inference. The auxiliary reversible branch provides reliable gradients to assist deep features in preserving key characteristics. The multi-level auxiliary information handles the broken information issue caused by deep supervision. The GELAN architecture, illustrated in Figure 2, is a novel, lightweight network designed with gradient path planning in mind. The YOLO v9e model exhibits 15% smaller parameters, 25% less computational requirement, and a 1.7% improvement in comparison with the YOLO v8x [22,23].

Figure 1.

Programmable Gradient Information (PGI) structure.

Figure 2.

Generalized Efficient Layer Aggregation Network (GELAN) structure [22].

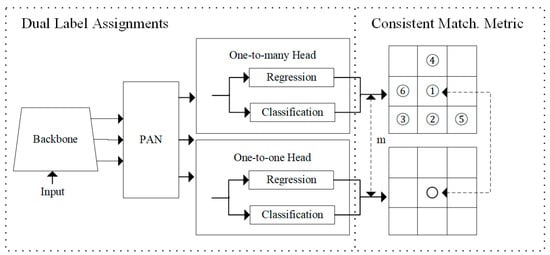

YOLOs employ Non-Maximum Suppression (NMS) as a post-processing stage, and this leads to inference latency. Additionally, various components in YOLOs result in significant computational costs and constrain the model’s potential. The YOLO v10 algorithm has been presented to improve the model architecture and enhance the performance of YOLOs. The YOLO v10 utilizes dual assignments for NMS-free training, which improves the performance results and decreases the inference latency. The structure of consistent dual assignments for NMS-free training is shown in Figure 3, in which m is a consistent matching metric and can be derived from the following equation:

where â and a refer to the bounding box of prediction and instance, p is the classification score, s shows the spatial prior, and α and ẞ are two hyperparameters that balance the impact of the location regression task and the semantic prediction task.

m (α, ẞ) = s.pα . IOU (â, a) ẞ

Figure 3.

Consistent dual assignments structure for NMS-free training [24].

Moreover, various components of the model have been optimized to reach better efficiency and accuracy. For instance, the YOLO v10-S is 1.8× quicker than the RT-DETR-R18, and it has 2.8× fewer parameters and Floating-Point Operations Per Second (FLOPs), with a comparable AP on COCO. The YOLO v10-B model exhibits 46% less latency and 25% smaller parameters in comparison with the YOLO v9-C model [24].

YOLO v11 builds upon the advancements of YOLO v8, introducing new architectural features and optimized parameters that boost detection performance. While YOLO v11 retains the Spatial Pyramid Pooling-Fast (SPPF) block from earlier versions, it also adds a Cross Stage Partial with Spatial Attention (C2PSA) block directly after it. The C2PSA block is a key improvement, enhancing spatial attention in the feature maps, which allows the model to concentrate more effectively on critical regions within an image. This spatial attention helps YOLO v11 focus on areas of interest, potentially enhancing detection accuracy for objects of various sizes and positions. Additionally, YOLO v11 replaces the C2f block in the neck with a new C3k2 block, which is faster and more efficient, thereby improving the feature aggregation process. After up-sampling and concatenation, this updated neck structure enhances both speed and performance in YOLO v11 [25].

4. Methodology

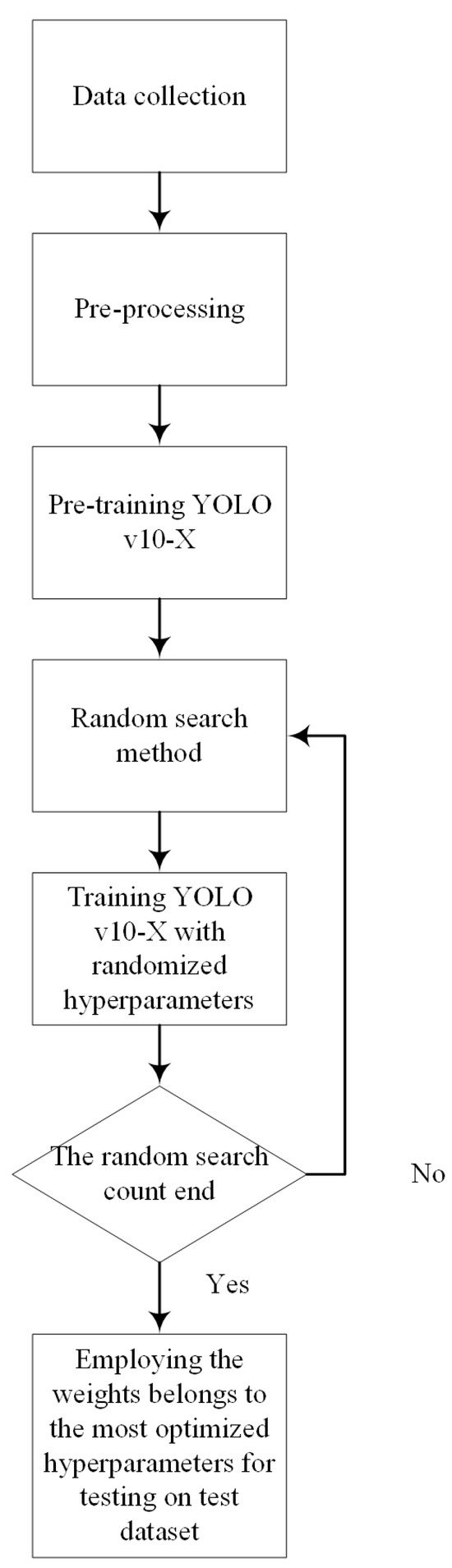

Figure 4 shows the flowchart for training and testing the YOLO v10-X algorithm to detect defects in solar panels. First, we prepared the dataset, and since it was already pre-processed, we skipped the second stage. Next, we pre-trained the algorithm on the COCO dataset to aid in the localization of solar panels. Then, we applied the random search method to optimize hyperparameters such as batch size and the number of epochs. Random search is a method for optimizing hyperparameters in AI models by randomly selecting combinations from a predefined range. Unlike grid search, it does not test all possible combinations, making it more efficient when the hyperparameter space is large. It is useful when some parameters have minimal effect on performance or when exploring complex relationships between hyperparameters [26]. We defined a range for each parameter, randomly selected combinations of values, trained the model, and evaluated its performance. We repeated this for a set number of trials and chose the best-performing combination. Afterwards, we trained the algorithm on the dataset, evaluated the results, and repeated the process until optimal performance was achieved. Finally, we tested the algorithm on the test dataset to assess its performance.

Figure 4.

The flowchart of employing the YOLO v10-X to detect defects.

5. Experimental Evaluation

Our experiments have two main stages, including training and validation and test phases. The training and validation phase provides and updates weights to have a better performance in detecting defects, and the test phase assists us in evaluating the real-time performance of our algorithm and system.

5.1. Training and Validation Results

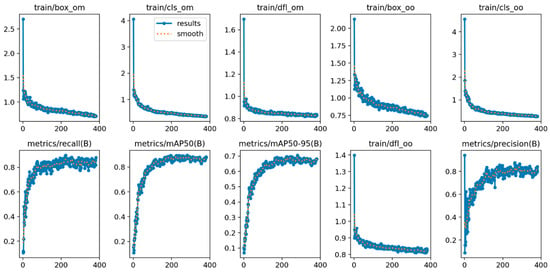

Table 1 presents the performance results, while Figure 5 shows the training outcomes after 370 epochs with a batch size of 8. As shown in Figure 5, the algorithm decreases the error between bounding boxes and grounded boxes or labels as the number of epochs increases.

Table 1.

Summary of training performance metrics.

Figure 5.

The results of YOLO v10-X training on the Roboflow dataset.

5.2. Test Results

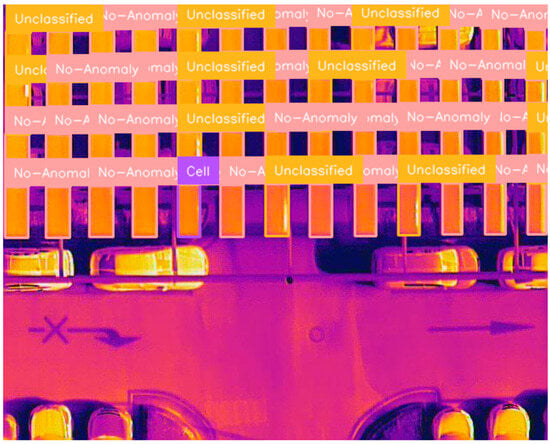

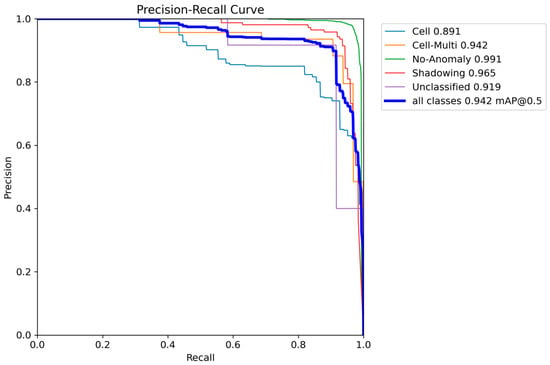

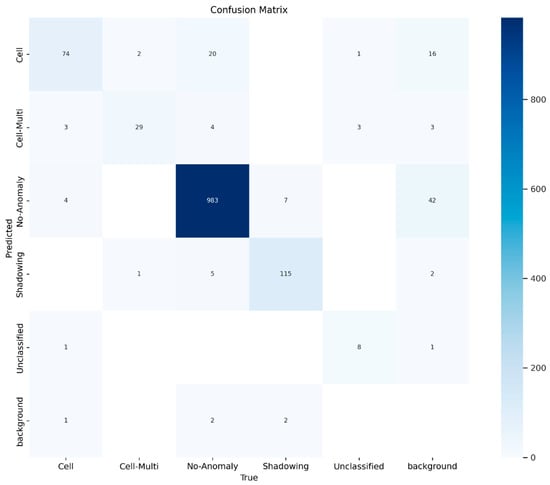

The test results of the YOLO v10-X algorithm are shown in Table 2. Figure 6, Figure 7 and Figure 8 include the test results, the defect detection on the test dataset, the PR curve, and the confusion matrix, respectively. The YOLO v10-X models achieved better performance results in comparison with the YOLO v5s and YOLO v9 models, as shown in Table 2. Moreover, the YOLO v9 model obtained better precision in detecting defects in solar panels. However, the YOLO v10-X model achieved a significantly better recall rate and F1 score in comparison with the YOLO v9 model. Therefore, the total performance of the YOLO v10-X algorithm was better than previous YOLOs.

Table 2.

The results of test experiments.

Figure 6.

The object detection of YOLO v10-X on the Roboflow test dataset.

Figure 7.

The PR curve of the object detection of YOLO v10-X on the Roboflow test dataset.

Figure 8.

The confusion matrix of YOLO v10-X for the test phase.

6. Discussion

We used three datasets to test the performance of YOLO v11-X and YOLO v10-X: the first and third dataset consists of thermal images, while the second dataset consists of optical images. Our experiments show that the YOLO v10-X model has lower inference latency and better accuracy on first and second datasets. However, YOLO v11-X showed better performance results on the third dataset. These enhancements in object detection performance and reduced computational complexity make the YOLO v11 model highly efficient for real-time solar panel defect detection, and the YOLO v11-X algorithm has a better performance compared to previous versions of YOLO based on Table 2. YOLO v11 has lower computational costs than previous versions. However, techniques like quantization and pruning can further optimize the model, facilitating its deployment on edge devices or in low-power environments. Additionally, the YOLO v11-X model achieved better performance results on datasets in comparison with a traditional algorithm, SVM, and Faster R-CNN, as shown in Table 3. It obtained a 90% F1 score, which is a significant enhancement in comparison with the YOLO v5 model, which gives a 43.4% F1 score; SVM, which reached a 71.8% F1 score; and Faster R-CNN, which reached a 72.3% F1 score. The performance enhancements of YOLO v11 can lead to significant cost savings and efficiency improvements in real-world solar panel maintenance by quickly and accurately identifying faults and assisting maintenance teams in inspecting and assessing more solar panels in less time. Moreover, the smaller model size of YOLO v11 makes it easier to deploy it on edge devices, and this by itself reduces the need for expensive hardware devices and allows for real-time monitoring in remote locations, leading to the further lowering of operational costs.

Table 3.

Comparison table of the YOLO v10-X, YOLO v11-X, Fater R-CNN, and SVM algorithms.

7. Conclusions and Outlook

The YOLO v11-X algorithm was employed to enhance the performance of real-time solar panel defect detection compared to previous versions of YOLOs. The YOLO v11-X algorithm showed better performance results in comparison with the previous versions of YOLOs on the third dataset. Additionally, we compared its performance against a traditional algorithm, SVM, and Faster R-CNN, in which the YOLO v11-X model demonstrated a better performance. The algorithm achieved precision, recall, mean average precision (mAP), and F1 scores of 89.7%, 87.7%, 92.7%, and 90%, respectively, for detecting hot spots and shadow issues on solar panel surfaces. As a future work, combining YOLO v11-X and power anticipation algorithms such as LSTM can provide a comprehensive algorithm for detecting defects and forecasting power. This integration uses YOLO for feature extraction, while LSTM identifies patterns from historical data, providing a comprehensive approach to both defect detection and power forecasting. This approach can optimize maintenance schedules, reduce downtime, and ensure consistent energy efficiency, resulting in smarter and more cost-effective solar panel management.

Author Contributions

Conceptualization, A.G., S.D.A., M.N., S.Y.K., and A.Z.K.; methodology, A.G., S.D.A., M.N., S.Y.K., and A.Z.K.; formal analysis, A.G.; investigation, A.G.; writing—original draft preparation, A.G.; writing—review and editing, A.G., S.D.A., M.N., S.Y.K., and A.Z.K.; visualization, A.G.; supervision, S.D.A., M.N., S.Y.K., and A.Z.K.; resources, A.Z.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

All data analyzed during this study are included in this published article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- IEA. Renewables 2023; IEA: Paris, France, 2023.

- Meribout, M.; Tiwari, V.K.; Herrera, J.P.P.; Baobaid, A.N.M.A. Solar panel inspection techniques and prospects. Measurement 2023, 209, 112466. [Google Scholar] [CrossRef]

- Mohammad, A.; Mahjabeen, F. Revolutionizing solar energy with AI-driven enhancements in photovoltaic technology. BULLET J. Multidisiplin Ilmu 2023, 2, 1174–1187. [Google Scholar]

- Youssef, A.; El-Telbany, M.; Zekry, A. The role of artificial intelligence in photo-voltaic systems design and control: A review. Renew. Sustain. Energy Rev. 2017, 78, 72–79. [Google Scholar] [CrossRef]

- Kermadi, M.; Berkouk, E.M. Artificial intelligence-based maximum power point tracking controllers for Photovoltaic systems: Comparative study. Renew. Sustain. Energy Rev. 2017, 69, 369–386. [Google Scholar] [CrossRef]

- Chine, W.; Mellit, A.; Lughi, V.; Malek, A.; Sulligoi, G.; Pavan, A.M. A novel fault diagnosis technique for photovoltaic systems based on artificial neural networks. Renew. Energy 2016, 90, 501–512. [Google Scholar] [CrossRef]

- Herraiz, Á.H.; Marugán, A.P.; Márquez, F.P.G. Photovoltaic plant condition monitoring using thermal images analysis by convolutional neural network-based structure. Renew. Energy 2020, 153, 334–348. [Google Scholar] [CrossRef]

- Premkumar, M.; Sowmya, R. Certain study on MPPT algorithms to track the global MPP under partial shading on solar PV module/array. Int. J. Comput. Digit. Syst. 2019, 8, 405–416. [Google Scholar] [CrossRef] [PubMed]

- Monicka, S.G.; Manimegalai, D.; Karthikeyan, M. Detection of microcracks in silicon solar cells using Otsu-Canny edge detection algorithm. Renew. Energy Focus 2022, 43, 183–190. [Google Scholar] [CrossRef]

- Bordihn, S.; Fladung, A.; Schlipf, J.; Köntges, M. Machine learning based identification and classification of field-operation caused solar panel failures observed in electroluminescence images. IEEE J. Photovolt. 2022, 12, 827–832. [Google Scholar] [CrossRef]

- Le, M.; Le, D.; Vu, H.H.T. Thermal inspection of photovoltaic modules with deep convolutional neural networks on edge devices in AUV. Measurement 2023, 218, 113135. [Google Scholar] [CrossRef]

- Park, Y.; Kim, M.J.; Gim, U.; Yi, J. Boost-up efficiency of defective solar panel detection with pre-trained attention recycling. IEEE Trans. Ind. Appl. 2023, 59, 3110–3120. [Google Scholar] [CrossRef]

- Vlaminck, M.; Heidbuchel, R.; Philips, W.; Luong, H. Region-based CNN for anomaly detection in PV power plants using aerial imagery. Sensors 2022, 22, 1244. [Google Scholar] [CrossRef]

- Chen, H.; Pang, Y.; Hu, Q.; Liu, K. Solar cell surface defect inspection based on multispectral convolutional neural network. J. Intell. Manuf. 2020, 31, 453–468. [Google Scholar] [CrossRef]

- Duranay, Z.B. Fault detection in solar energy systems: A deep learning approach. Electronics 2023, 12, 4397. [Google Scholar] [CrossRef]

- Di Tommaso, A.; Betti, A.; Fontanelli, G.; Michelozzi, B. A multi-stage model based on YOLOv3 for defect detection in PV panels based on IR and visible imaging by unmanned aerial vehicle. Renew. Energy 2022, 193, 941–962. [Google Scholar] [CrossRef]

- Hassan, S.; Dhimish, M. Enhancing solar photovoltaic modules quality assurance through convolutional neural network-aided automated defect detection. Renew. Energy 2023, 219, 119389. [Google Scholar] [CrossRef]

- Cao, Y.; Pang, D.; Zhao, Q.; Yan, Y.; Jiang, Y.; Tian, C.; Wang, F.; Li, J. Improved yolov8-gd deep learning model for defect detection in electroluminescence images of solar photovoltaic modules. Eng. Appl. Artif. Intell. 2024, 131, 107866. [Google Scholar] [CrossRef]

- Terven, J.; Córdova-Esparza, D.-M.; Romero-González, J.-A. A comprehensive review of yolo architectures in computer vision: From yolov1 to yolov8 and yolo-nas. Mach. Learn. Knowl. Extr. 2023, 5, 1680–1716. [Google Scholar] [CrossRef]

- Solar Panels Computer Vision Project. Available online: https://universe.roboflow.com/roboflow-100/solar-panels-taxvb (accessed on 12 January 2025).

- Afroz. Solar Panel Images Clean and Faulty Images. Available online: https://www.kaggle.com/datasets/pythonafroz/solar-panel-images (accessed on 12 January 2025).

- Wang, C.; Yeh, I.; Liao, H. YOLOv9: Learning what you want to learn using programmable gradient information. arXiv 2024, arXiv:2402.13616. [Google Scholar]

- Jocher, G.; Mattioli, F.; Qaddoumi, B.; Laughing, Q.; Munawar, M.R. YOLOv9: A Leap Forward in Object Detection Technology. Available online: https://docs.ultralytics.com/models/yolov9/ (accessed on 12 January 2025).

- Wang, A.; Chen, H.; Liu, L.; Chen, K.; Lin, Z.; Han, J.; Ding, G. YOLOv10: Real-Time End-to-End Object Detection. arXiv 2024, arXiv:2405.14458. [Google Scholar]

- Khanam, R.; Hussain, M. YOLOv11: An Overview of the Key Architectural Enhancements. arXiv 2024, arXiv:2410.17725. [Google Scholar]

- Bergstra, J.; Bengio, Y. Random search for hyper-parameter optimization. J. Mach. Learn. Res. 2012, 13, 281–305. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).