A Memory-Efficient Compensation Algorithm for Vertical Crosstalk in 8K LCD Panels

Abstract

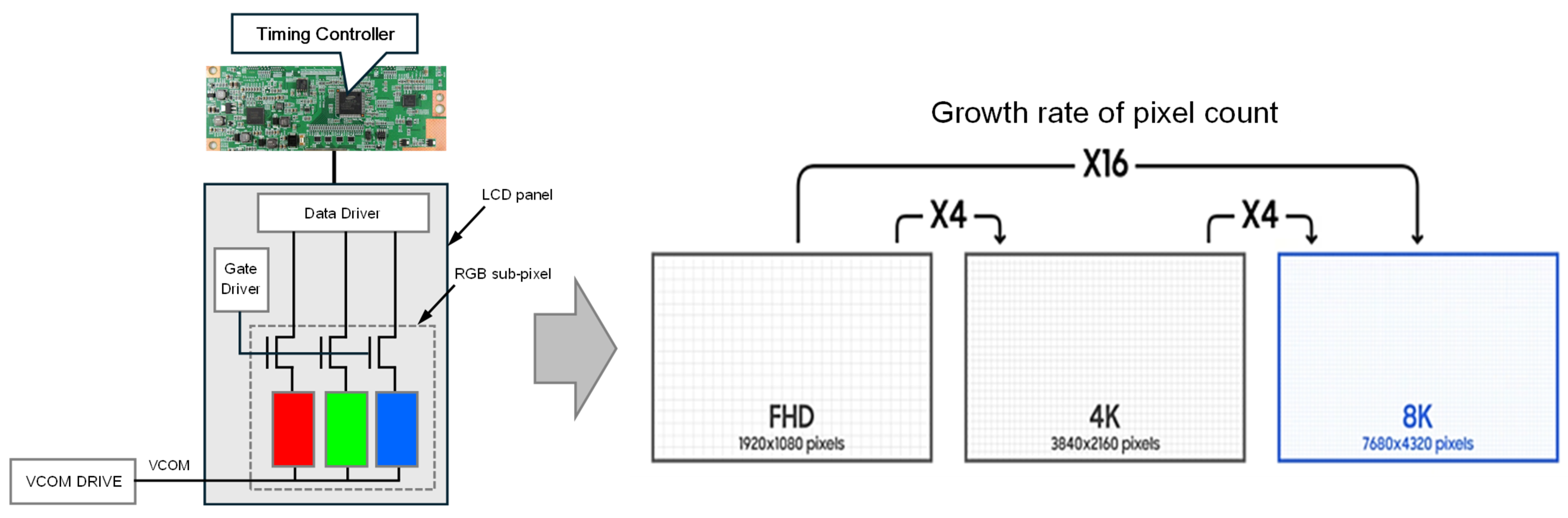

1. Introduction

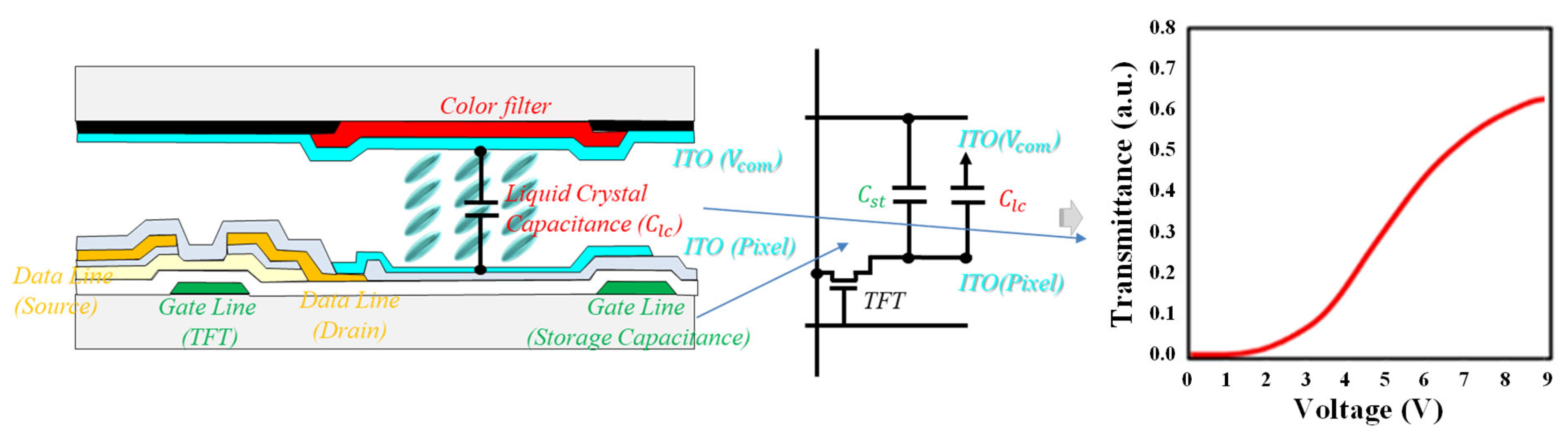

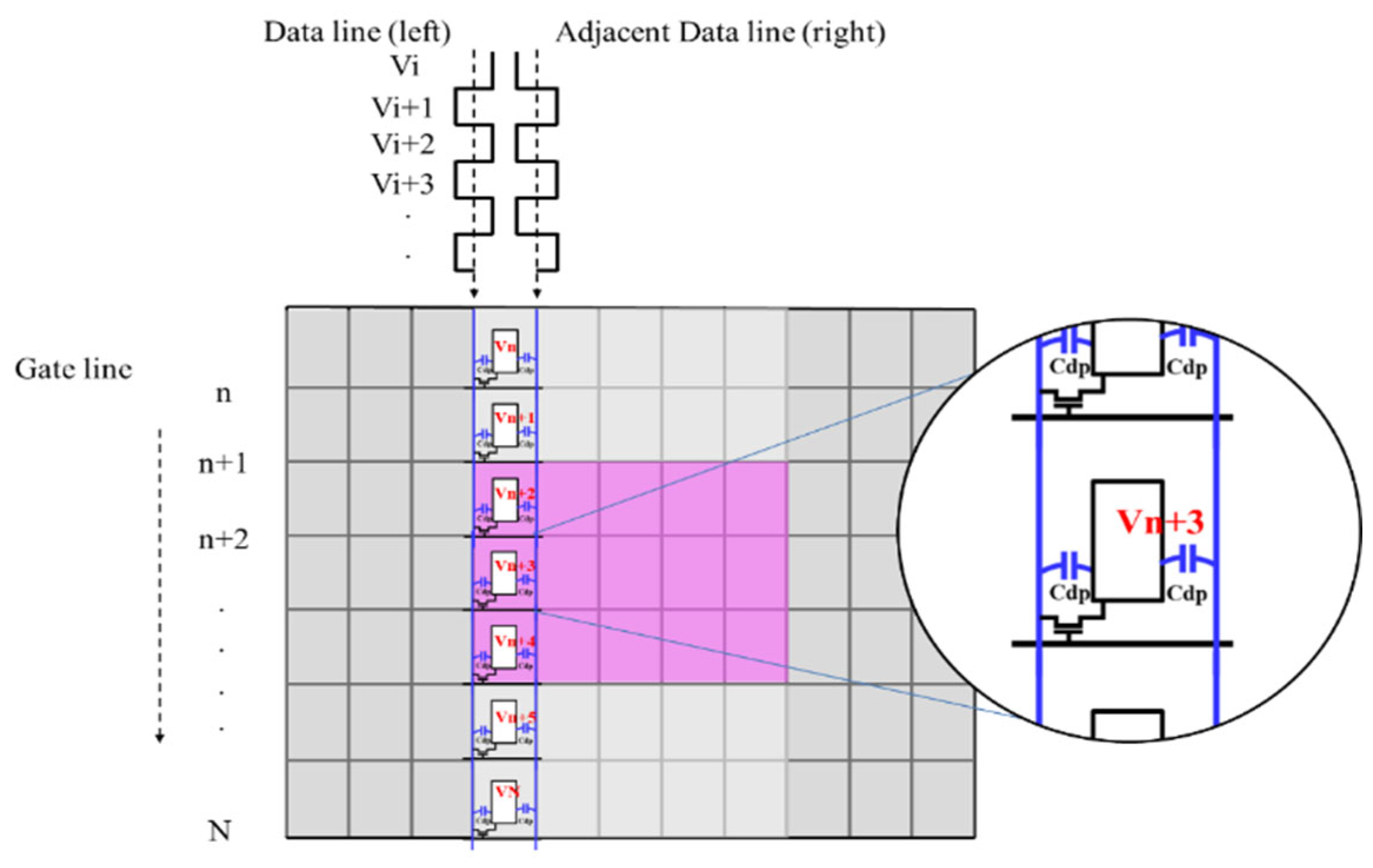

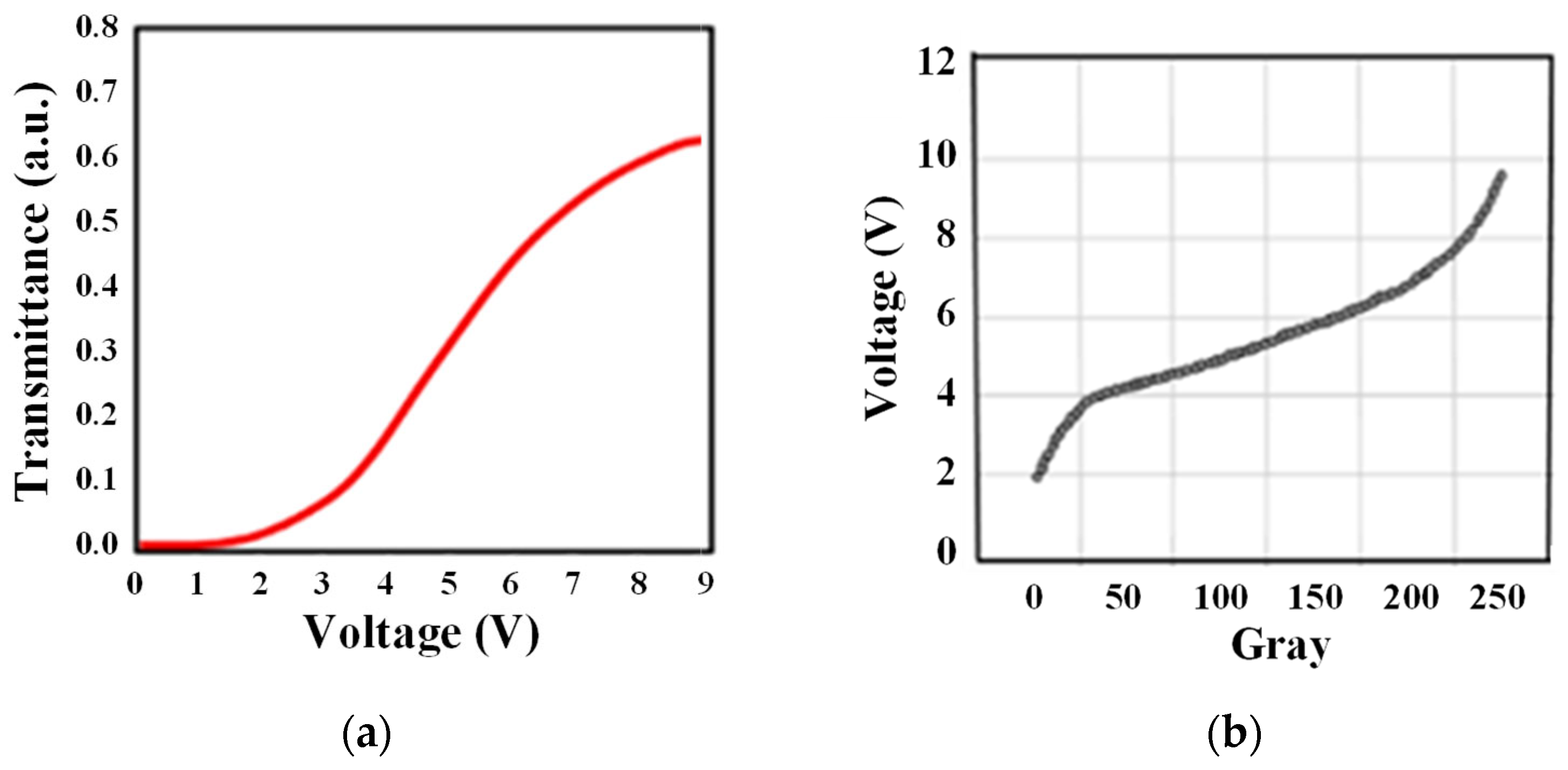

2. Mechanism of Vertical Crosstalk in LCD

- Data line–pixel coupling: The capacitance asymmetry between the data line and pixel electrode (Cdp) can induce undesired variations in the voltages stored in the pixel storage capacitors and the resulting brightness fluctuations.

- Fringing electric fields generated by the data line: Partial overlap between the data line and the pixel electrode produces undesired strong local electric fields that alter the tilt angle of LC molecules, leading to noticeable brightness variations [12,13]. This effect has been identified as the dominant factor in high-resolution LCDs.

- TFT leakage current: Imperfections in TFTs may cause charge loss in pixel storage capacitors. However, under standard operating conditions, this effect is generally less significant and becomes particularly minor at high frequencies.

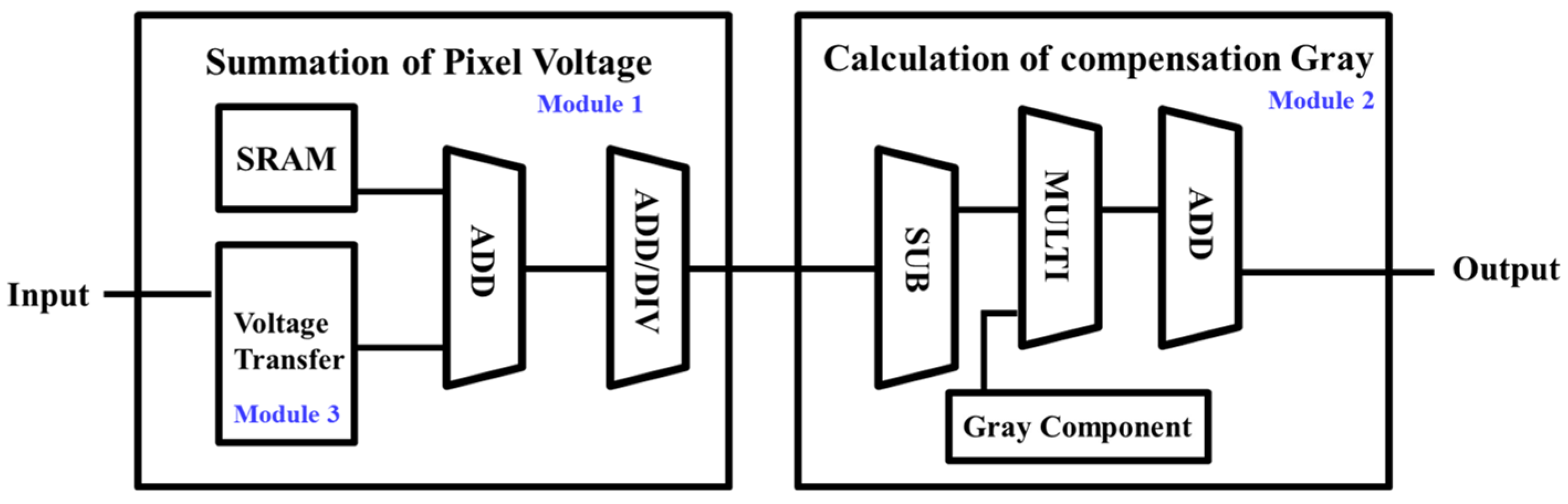

3. Proposed Compensation Method for V-CT

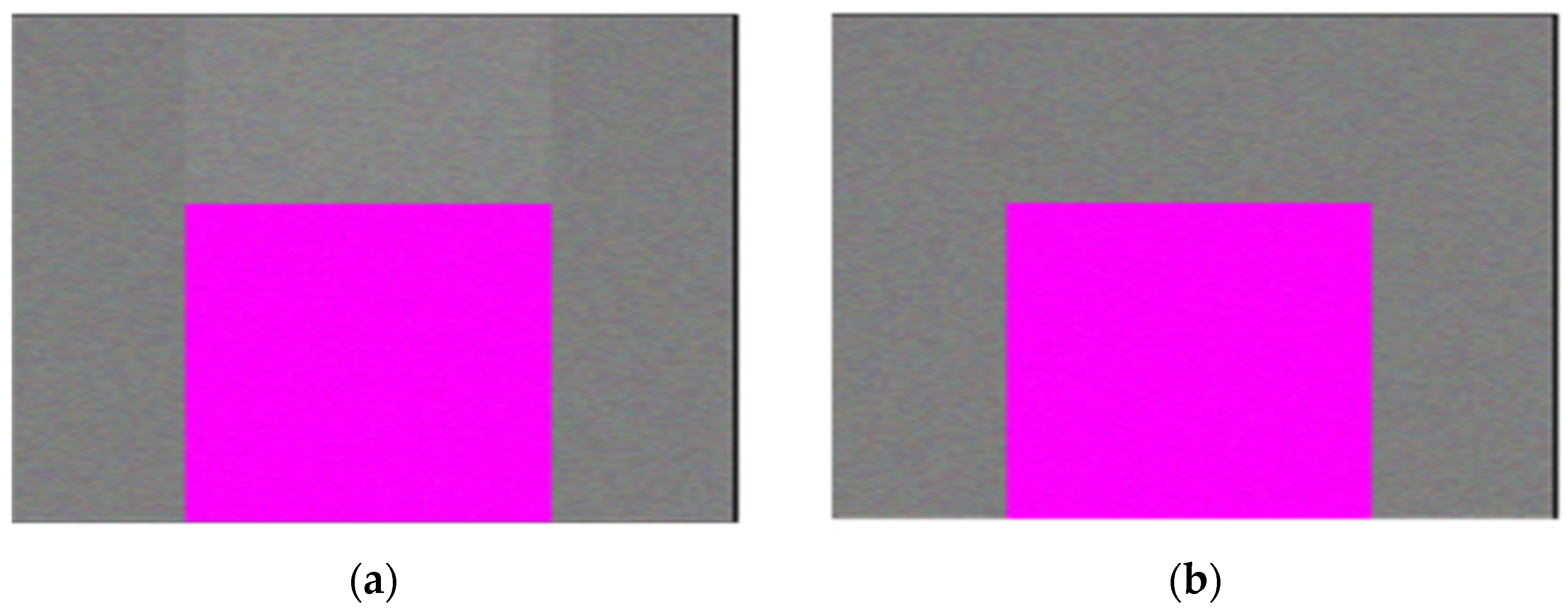

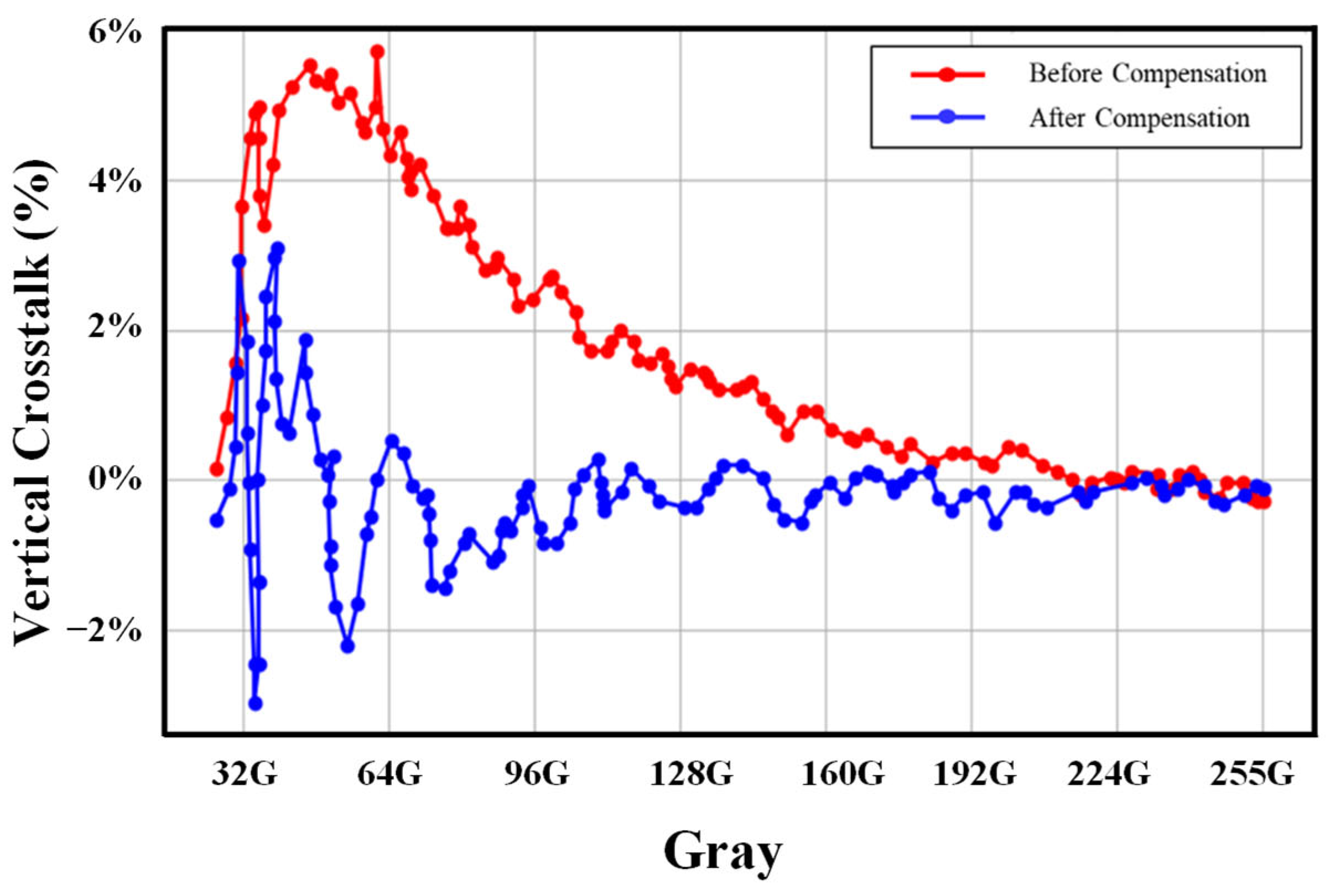

4. Experimental Results and Discussion

4.1. Implementation Methods

4.2. Comparison of the Memory Requirements

4.3. Comparison with the Existing Compensation Methods

4.4. Performance Considerations and Limitations

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bae, K.S.; Oh, M.; Park, B.; Cho, Y.J.; Cho, S.H.; Kim, D. 51-1: Novel pixel structure for 8K QUHD LCD panel with enhanced optical performance. In Proceedings of the SID Symposium Digest of Technical Papers, San Jose, CA, USA, 14–15 May 2019; Wiley: Hoboken, NJ, USA, 2019; Volume 50, pp. 703–706. [Google Scholar] [CrossRef]

- Tan, G.; Huang, Y.; Li, M.-C.; Lee, S.-L.; Wu, S.-T. High dynamic range liquid crystal displays with a mini-LED backlight. Opt. Express 2018, 26, 16572–16584. [Google Scholar] [CrossRef] [PubMed]

- Alt, P.M.; Pleshko, P. Scanning limitations of liquid-crystal displays. IEEE Trans. Electron Devices 1974, 21, 146–155. [Google Scholar] [CrossRef]

- Hara, Y.; Kikuchi, T.; Kitagawa, H. IGZO-TFT technology for large-screen 8K display. J. Soc. Inf. Disp. 2018, 26, 169–177. [Google Scholar] [CrossRef]

- den Boer, W. Active Matrix Liquid Crystal Displays: Fundamentals and Applications, 1st ed.; Elsevier: Oxford, UK, 2005; ISBN 978-0-7506-7813-1. [Google Scholar]

- Chen, R.H. Liquid Crystal Displays: Fundamental Physics and Technology; Wiley: Hoboken, NJ, USA, 2011; ISBN 978-0470930878. [Google Scholar]

- Badano, A.; Kanicki, J. Characterization of crosstalk in high-resolution active-matrix liquid crystal displays for medical imaging. In Flat Panel Display Technology and Display Metrology II, Proceedings of the Photonics West 2001-Electronic Imaging, San Jose, CA, USA, 30 April 2001; SPIE: Bellingham, WA, USA, 2001; Volume 4295, pp. 248–253. [Google Scholar] [CrossRef]

- Xiao, J.; Wu, S. High-transmittance vertical-alignment liquid crystal display with subpixel electrode shielding electric field design. Displays 2021, 68, 102004. [Google Scholar] [CrossRef]

- Lin, J.-S.; Yang, K.-H.; Chen, S.-H. A high-aperture-ratio and low-crosstalk pixel structure design for in-plane-switching-mode TFT-LCDs. J. Soc. Inf. Disp. 2004, 12, 533–537. [Google Scholar] [CrossRef]

- Zhang, Y.; Mao, J.; Wang, Y.; Li, C.; Zhang, H.; Tan, H.; Chen, X.; Liu, Z.; Wu, F. An efficient optical mura compensation system for large liquid-crystal display panels. IEEE Trans. Instrum. Meas. 2022, 71, 1–13. [Google Scholar] [CrossRef]

- Jung, J.; Park, H.B.; Jung, H.Y.; Jung, S.E.; Kim, S.G.; Kim, T.H.; Ku, B.-C.; Kim, M.S.; Lee, S.H. Recent progress in liquid crystal devices and materials of TFT-LCDs. J. Inf. Disp. 2024, 25, 121–142. [Google Scholar] [CrossRef]

- Isomae, Y.; Shibata, Y.; Ishinabe, T.; Fujikake, H. Design of 1-μm-pitch liquid crystal spatial light modulators having dielectric shield wall structure for holographic display with wide field of view. Opt. Rev. 2017, 24, 165–176. [Google Scholar] [CrossRef]

- Vanbrabant, P.J.M.; Beeckman, J.; Neyts, K.; Willman, E.; Fernández, A. Diffraction and Fringing Field Effects in Small Pixel Liquid Crystal Devices with Homeotropic Alignment. J. Appl. Phys. 2010, 108, 083104. [Google Scholar] [CrossRef]

- Xiao, K.; Li, C.; Pointer, M.; Luo, M.R. Visual Gamma Correction for LCD Displays. Displays 2011, 32, 88–94. [Google Scholar] [CrossRef]

- Parraga, C.-A.; Bogdan, C.; Turbatu, A.; Bonnardel, V. Limitations of Visual Gamma Corrections in LCD Displays. Displays 2014, 35, 138–147. [Google Scholar] [CrossRef]

- Smorfa, S.; Olivieri, M.; Mancuso, R.; Lienhard, M. A physical-level LCD driver model and simulator with application to pixel crosstalk suppression. IEEE Trans. Consum. Electron. 2006, 52, 1027–1034. [Google Scholar] [CrossRef]

- Yamada, K.; Noguchi, T.; Sekiguchi, T. A new driving method for an AMLCD using a-Si TFTs. In Proceedings of the International Display Research Conference (IDRC), Nara, Japan, 16–19 October 1995; pp. 339–342. [Google Scholar]

- Dastgeer, G.; Nisar, S.; Rasheed, A.; Akbar, K.; Chavan, V.D.; Kim, D.-K.; Wabaidur, S.M.; Zulfiqar, M.W.; Eom, J. Atomically engineered, high-speed non-volatile flash memory device exhibiting multibit data storage operations. Nano Energy 2024, 119, 109106. [Google Scholar] [CrossRef]

| Types | Factors That Induce Luminance Variation | Factors Related to Manufacturing |

|---|---|---|

| Data line–pixel coupling | Asymmetry between the data line–pixel capacitance on the left and right sides of a pixel | Photomask misalignment during photolithography |

| Fringing electric fields from data line | Undesired distortion of the molecular tilt angle of the LC in the regions adjacent to the pixel’s data lines | Panel design with partial overlap between the data line and the pixel electrode |

| TFT leakage current | Charge loss of pixel storage capacitor due to TFT leakage current | Reduction in the storage capacitor’s capacitance with increasing display resolution |

| Approach | Target Display/Focus | Memory Requirement | Implementation Complexity | Primary Strategy | Notes |

|---|---|---|---|---|---|

| Baseline | LCDs; CT suppression via data compensation | High (full-panel pre-computed maps) | High (large storage) | Pre-stored pixel data +LUT | Effective but scales poorly with resolution |

| Zhang et al., 2022 [10] | Large LCDs; brightness uniformity | High (camera-measured correction maps) | Medium–High (measurement/calibration framework) | Camera-based measurement + correction LUT | Strong uniformity gains; memory and measurement overhead |

| Smorfa et al., 2006 [16] | LCDs; CT analysis and suppression | Low (offline modeling) | Medium (physics-based modeling) | Pre-simulation to optimize drive schemes | Useful for selecting low CT drive conditions (no real-time compensation) |

| Yamada et al., 1995 [17] | High-resolution LCDs; drive scheme-based CT suppression | Low–Medium (no large LUTs) | Medium (drive waveform/mode tuning) | Adjusting driving scheme with inversion | Effective for power optimization (limited high-resolution scalability) |

| Our study | 8K LCDs; CT suppression via data compensation | Low (uses a few pixel data) | Low (small storage) | Streaming implementation on T-con | Memory-efficient, scalable without structural changes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, Y.; Choi, K.; Park, H.; Kim, Y.J.; Choi, K.; Jeon, J.-H.; Ko, M.J. A Memory-Efficient Compensation Algorithm for Vertical Crosstalk in 8K LCD Panels. Electronics 2025, 14, 3965. https://doi.org/10.3390/electronics14193965

Lee Y, Choi K, Park H, Kim YJ, Choi K, Jeon J-H, Ko MJ. A Memory-Efficient Compensation Algorithm for Vertical Crosstalk in 8K LCD Panels. Electronics. 2025; 14(19):3965. https://doi.org/10.3390/electronics14193965

Chicago/Turabian StyleLee, Yongwoo, Kiwon Choi, Hyeryoung Park, Yong Ju Kim, Kookhyun Choi, Jae-Hong Jeon, and Min Jae Ko. 2025. "A Memory-Efficient Compensation Algorithm for Vertical Crosstalk in 8K LCD Panels" Electronics 14, no. 19: 3965. https://doi.org/10.3390/electronics14193965

APA StyleLee, Y., Choi, K., Park, H., Kim, Y. J., Choi, K., Jeon, J.-H., & Ko, M. J. (2025). A Memory-Efficient Compensation Algorithm for Vertical Crosstalk in 8K LCD Panels. Electronics, 14(19), 3965. https://doi.org/10.3390/electronics14193965