Simulation of Eddy Current Suppression and Efficiency Recovery in Mining MCR-WPT Systems Based on Explosion-Proof Slotting

Abstract

1. Introduction

2. Model of Mining MCR-WPT System

2.1. Introduction of Mining MCR-WPT System

2.2. Influence of Metal Explosion-Proof Enclosure on the System

2.3. Equivalent Circuit Model of the System

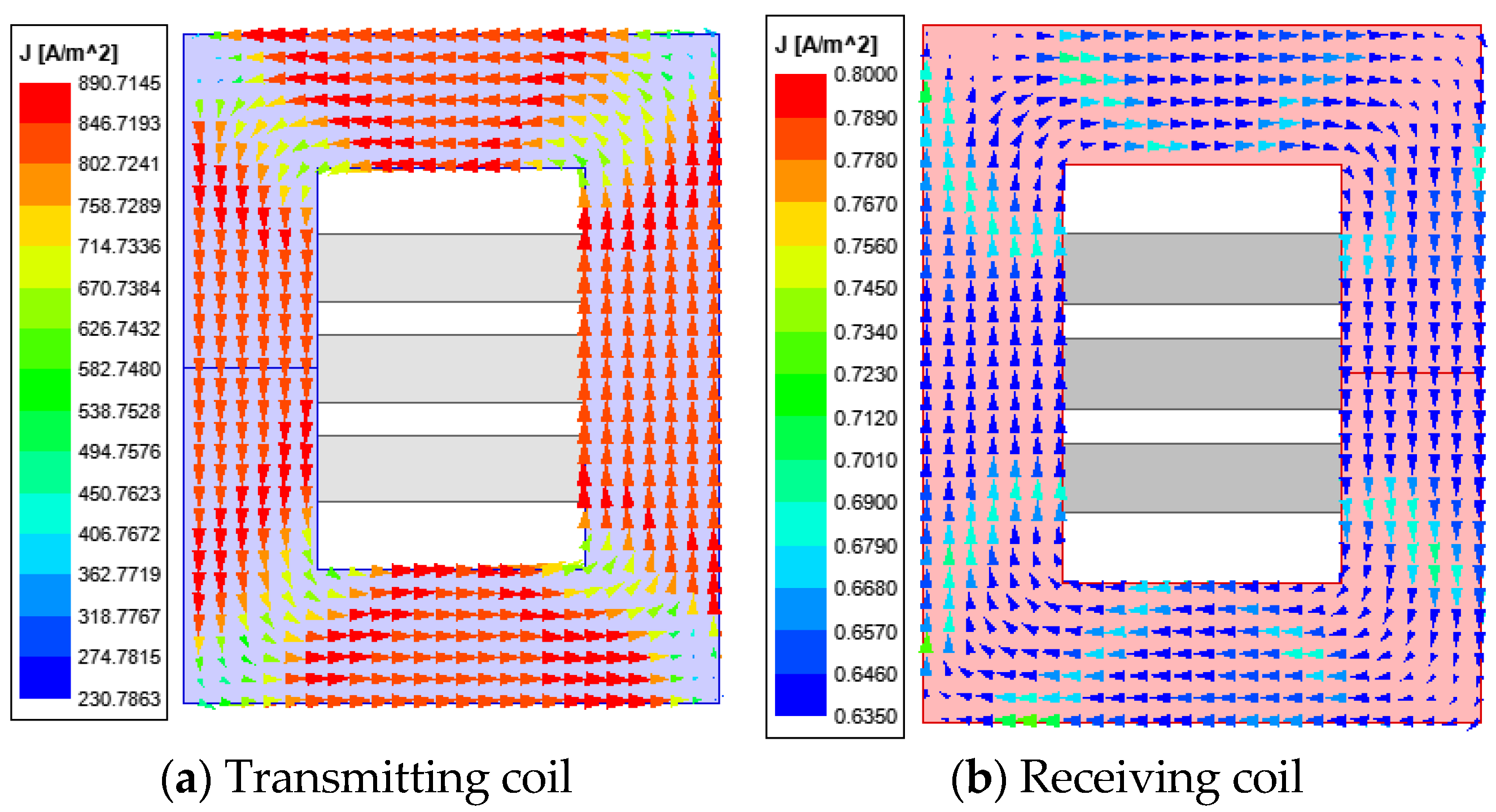

3. Modeling and Simulation

3.1. Scenario Description and Model Establishment

3.2. Simulation and Results Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Mohamed, A.A.; Shaier, A.A.; Metwally, H.; Selem, S.I. Wireless charging technologies for electric vehicles: Inductive, capacitive, and magnetic gear. IET Power Electron. 2024, 17, 3139–3165. [Google Scholar] [CrossRef]

- Chen, L.; Li, Y.; Silamu, W.; Li, Q.; Ge, S.; Wang, F.-Y. Smart mining with autonomous driving in industry 5.0: Architectures, platforms, operating systems, foundation models, and applications. IEEE Trans. Intell. Veh. 2024, 9, 4383–4393. [Google Scholar] [CrossRef]

- Xue, H. Modeling and Analysis of Wireless Power Transfer System Based on Magnetic Coupling Resonance. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2015. [Google Scholar]

- Liu, F. Research on Magnetic Coupled Resonance Wireless Power Transmission in Coal Mine. Ph.D. Thesis, China University of Mining and Technology, Beijing, China, 2020. [Google Scholar]

- Imura, T. Wireless Power Transfer; Springer: Singapore, 2020. [Google Scholar]

- Agbinya, J.I. Wireless Power Transfer; River Publishers: Frederiksberg, Denmark, 2022. [Google Scholar]

- He, X.; Liu, S.; Wu, J.; Feng, Y.; Wang, R.; Li, W.; Weng, W. Wireless power and information dual transfer system via magnetically coupled resonators. Commun. Eng. 2024, 3, 8. [Google Scholar] [CrossRef]

- Hiep, L.T.H.; Bui, H.N.; Tung, B.S.; Lam, V.D.; Khuyen, B.X.; Pham, T.S. Enhanced efficiency of magnetic resonant wireless power transfer system using rollable and foldable metasurface based on polyimide substrate. Appl. Phys. A 2024, 130, 521. [Google Scholar] [CrossRef]

- Namiki, H.; Imura, T.; Hori, Y. Unified Theory of Non-Resonant and Resonant Circuits in Inductive Power Transfer and Capacitive Power Transfer. IEEJ J. Ind. Appl. 2024, 13, 633–644. [Google Scholar] [CrossRef]

- Su, T.; Meng, X.; Fan, X. Impedance matching design of magnetically coupled resonant wireless power transmission based on class E power amplifier. In Proceedings of the Fourth International Conference on Mechanical Engineering, Intelligent Manufacturing, and Automation Technology (MEMAT 2023), Guilin, China, 20–22 October 2023; Volume 13082, pp. 269–275. [Google Scholar]

- Liu, F.; Yang, Y.; Jiang, D.; Ruan, X.; Chen, X. Modeling and optimization of magnetically coupled resonant wireless power transfer system with varying spatial scales. IEEE Trans. Power Electron. 2016, 32, 3240–3250. [Google Scholar] [CrossRef]

- Barman, S.D.; Reza, A.W.; Kumar, N.; Karim, M.E.; Munir, A.B. Wireless powering by magnetic resonant coupling: Recent trends in wireless power transfer system and its applications. Renew. Sustain. Energy Rev. 2015, 51, 1525–1552. [Google Scholar] [CrossRef]

- Namiki, H.; Imura, T.; Hori, Y. Unified Theory of Series, Parallel and LCL/CLC Resonant Circuits in Inductive Power Transfer and Capacitive Power Transfer. IEEJ J. Ind. Appl. 2024, 13, 655–668. [Google Scholar] [CrossRef]

- Liao, Z.J.; Sun, Y.; Ye, Z.H.; Tang, C.S.; Wang, P.Y. Resonant analysis of magnetic coupling wireless power transfer systems. IEEE Trans. Power Electron. 2018, 34, 5513–5523. [Google Scholar] [CrossRef]

- Wei, X.; Wang, Z.; Dai, H. A critical review of wireless power transfer via strongly coupled magnetic resonances. Energies 2014, 7, 4316–4341. [Google Scholar] [CrossRef]

- Cannon, B.L.; Hoburg, J.F.; Stancil, D.D.; Goldstein, S.C. Magnetic resonant coupling as a potential means for wireless power transfer to multiple small receivers. IEEE Trans. Power Electron. 2009, 24, 1819–1825. [Google Scholar] [CrossRef]

- Lai, C.-M.; Liu, H.-E.; Mishima, T. Validation and Design of a Modular Three-Phase WPT System with Improved Misalignment Tolerance by Using an Effective Resonant Frequency Stabilization Technique. IEEJ J. Ind. Appl. 2024, 13, 669–682. [Google Scholar] [CrossRef]

- Kim, J.; Kim, J.; Kong, S.; Kim, H.; Suh, I.S.; Suh, N.P.; Cho, D.H.; Kim, J.; Ahn, S. Coil design and shielding methods for a magnetic resonant wireless power transfer system. Proc. IEEE 2013, 101, 1332–1342. [Google Scholar] [CrossRef]

- Wang, Q.; Li, H. Research on the wireless power transmission system based on coupled magnetic resonances. In Proceedings of the 2011 International Conference on Electronics, Communications and Control (ICECC), Ningbo, China, 9–11 September 2011; pp. 2255–2258. [Google Scholar]

- Hu, Y.; Heng, T.; Zhang, T.; Zhou, W.; Chen, Q. An Improved Magnetic Coupling Resonant Wireless Power Transfer System Based on Ferrite–Nanocrystalline Hybrid Shielding Method. Int. J. Circuit Theory Appl. 2024, 53, 3592–3605. [Google Scholar] [CrossRef]

- Guo, Z.; Chen, Y.; Liu, J.; Wang, Y.; Chen, K.; Wang, W.; Ye, H. Enhancing multi-resonant MCR WPT systems: A novel multi-frequency transmission approach with unipolar PWM and QEP-based analysis. J. Phys. Conf. Ser. 2024, 2823, 012052. [Google Scholar] [CrossRef]

- Gao, P. Research on Magnetically Coupled Resonant Wireless Power Transfer System with Asymmetric Coil Structure for Mining Applications. Ph.D. Thesis, China University of Mining and Technology, Beijing, China, 2019. [Google Scholar]

- Xia, C.; Zhuang, Y.; Jia, N.; Wu, X. Modeling research on wireless safe power supply system in high gas and dust mine. J. China Coal Soc. 2014, 39, 279–284. [Google Scholar]

- Zhang, G. Research on Key Technologies of Underground Mobile Wireless Power Transfer. Master’s Thesis, China University of Mining and Technology, Xuzhou, China, 2017. [Google Scholar]

- Zhang, L.; Yang, H.; Jing, T.; Li, T.; Zhang, L. Analysis on the full resonance characteristics of the underground magnetic-coupled wireless power transfer system. Ind. Mine Autom. 2022, 48, 83–92. [Google Scholar]

- Liu, X.W.; Wang, X.; Chen, D.; Zhao, D.; Yang, Y.F.; Ding, E.J. Optimal Design of Magnetically-coupled Resonant WPT System in Underground Coal Mines. J. China Coal Soc. 2016, 41, 2889–2896. [Google Scholar]

- Kianfar, A.E.; Sherikar, M.; Gilerson, A.; Skora, M.; Stankiewicz, K.; Mitra, R.; Clausen, E. Designing a monitoring system to observe the innovative single-wire and wireless energy transmitting systems in explosive areas of underground mines. Energies 2022, 15, 576. [Google Scholar] [CrossRef]

- Skóra, M.; Hylla, P.; Stankiewicz, K.; Polnik, B.; Kasprzak, M.; Kaczmarczyk, Z.; Kierepka, K.; Przybyła, K. Wireless Capacitive Energy Transfer System for Mining Applications—Preliminary Results. Energies 2023, 16, 6120. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, X.; Zou, X.; Xue, H.; Zhao, D.; Ding, E. Research on wireless power transmission system for coal mine wireless sensor networks. Metall. Min. Ind. 2015, 9, 1151–1156. [Google Scholar]

- Wu, X.; Gong, W.; Xiao, J.; Chen, S.; Mo, Y.; Deng, R. A Multi-Channel Wireless Power Transfer Method for Electric Vehicles Based on Magnetic Field Coupling. In Proceedings of the IEEE 3rd International Conference on Data Science and Computer Application (ICDSCA) 2023, Dalian, China, 27–29 October 2023; pp. 230–235. [Google Scholar]

- Huang, X.; Wang, W.; Tan, L. Technical Progress and Application Development of Magnetic Coupling Resonant Wireless Power Transfer. Autom. Electr. Power Syst. 2017, 41, 2–14. [Google Scholar]

- Xie, W.; Chen, W. Research Progress of Omnidriectional Wireless Power Transfer Technology. Autom. Electr. Power Syst. 2020, 44, 202–215. [Google Scholar]

- Zakerian, A.; Vaez-Zadeh, S.; Babaki, A. A Dynamic WPT System with High Efficiency and High Power Factor for Electric Vehicles. IEEE Trans. Power Electron. 2020, 35, 6732–6740. [Google Scholar] [CrossRef]

- Corti, F.; Intravaia, M.; Reatti, A.; Grasso, F.; Grasso, E.; Cabrera, A.T. Component design procedure for LCC-S wireless power transfer systems based on genetic algorithms and sensitivity analysis. IET Power Electron. 2024, 17, 906–918. [Google Scholar] [CrossRef]

- Liang, C.; Yuan, H.; Zhang, R.; Yang, A.; Wang, X.; Rong, M. Analysis and design of a novel cubic WPT system in a metal environment for an enclosed sensor scenario. IET Power Electron. 2023, 16, 1305–1319. [Google Scholar] [CrossRef]

- GB/T 3836.1-2021; Explosive Atmospheres—Part 1: Equipment General Requirements. State Administration for Market Regulation (SAMR) and Standardization Administration of China (SAC): Beijing, China, 2021.

| Parameters | The Field-Circuit Coupling Simulation Parameters of the Mining MCR-WPT System |

|---|---|

| US | 220 sin(2π × 105 t + 90°) V |

| RS | 0.1 Ω |

| RT | 0.5 Ω |

| RR | 0.5 Ω |

| RL | 99.5 Ω |

| CT | 1.88 nF |

| CR | 1.93 nF |

| Model | Mutual Inductance (mH) | Transmission Efficiency (%) | Average Input Power (W) | Average Output Power (W) |

|---|---|---|---|---|

| I (No enclosure) | 0.5155 | 68.03 | 30.61 | 20.81 |

| II (Enclosure) | 0.0076 | ≈0 | 1.11 | ≈0 |

| III (Slitted) | 0.4017 | 62 | 92.55 | 47.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Yu, J.; Pang, J.; Chen, S.; Wang, Y. Simulation of Eddy Current Suppression and Efficiency Recovery in Mining MCR-WPT Systems Based on Explosion-Proof Slotting. Electronics 2025, 14, 3899. https://doi.org/10.3390/electronics14193899

Wang Y, Yu J, Pang J, Chen S, Wang Y. Simulation of Eddy Current Suppression and Efficiency Recovery in Mining MCR-WPT Systems Based on Explosion-Proof Slotting. Electronics. 2025; 14(19):3899. https://doi.org/10.3390/electronics14193899

Chicago/Turabian StyleWang, Yingying, Jiahui Yu, Jindi Pang, Shuangli Chen, and Yudong Wang. 2025. "Simulation of Eddy Current Suppression and Efficiency Recovery in Mining MCR-WPT Systems Based on Explosion-Proof Slotting" Electronics 14, no. 19: 3899. https://doi.org/10.3390/electronics14193899

APA StyleWang, Y., Yu, J., Pang, J., Chen, S., & Wang, Y. (2025). Simulation of Eddy Current Suppression and Efficiency Recovery in Mining MCR-WPT Systems Based on Explosion-Proof Slotting. Electronics, 14(19), 3899. https://doi.org/10.3390/electronics14193899