A Polydimethylsiloxane (PDMS) Transparent Fresnel Zone Lens Antenna at Ku-Band for Satellite Communication

Abstract

1. Introduction

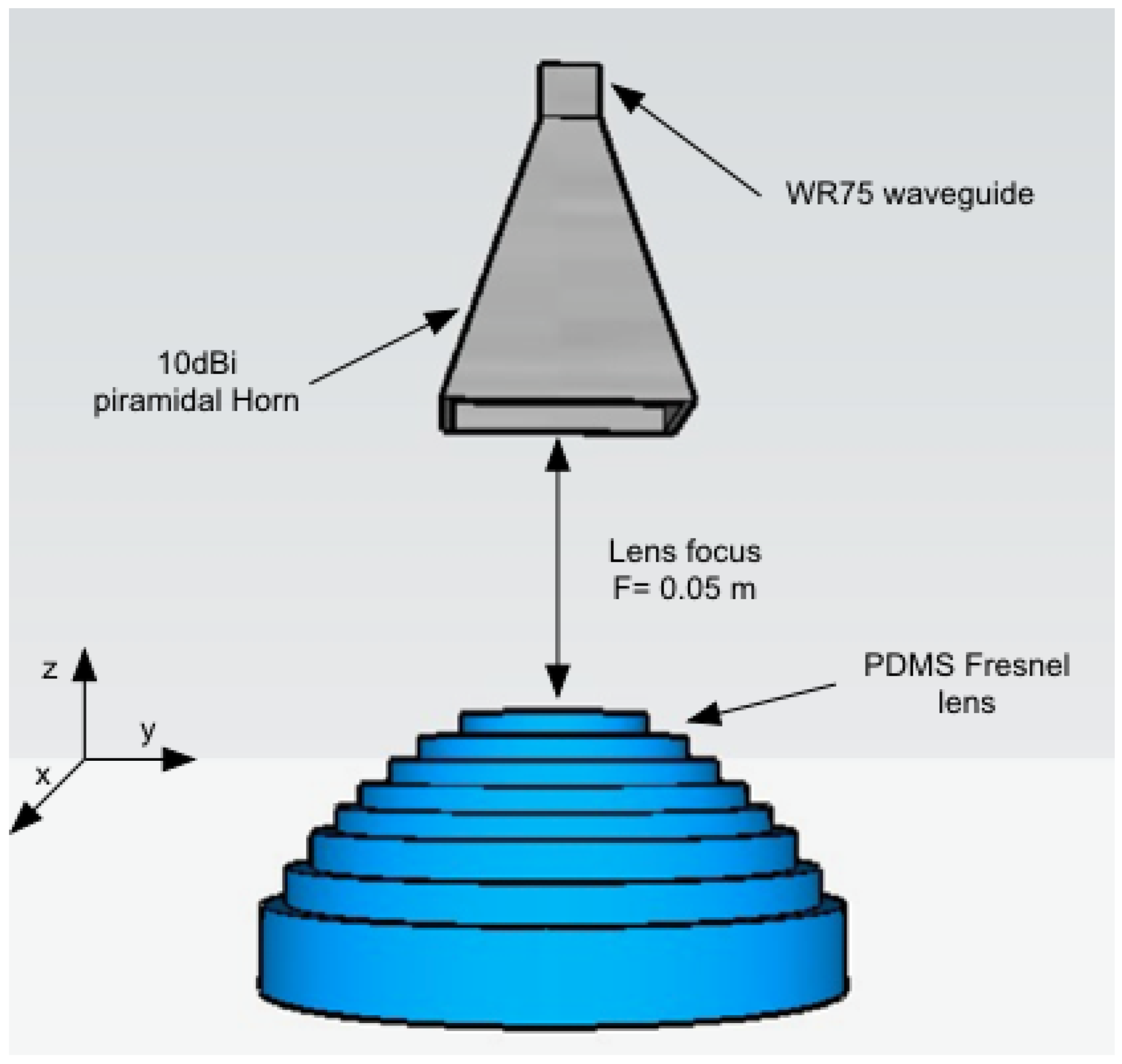

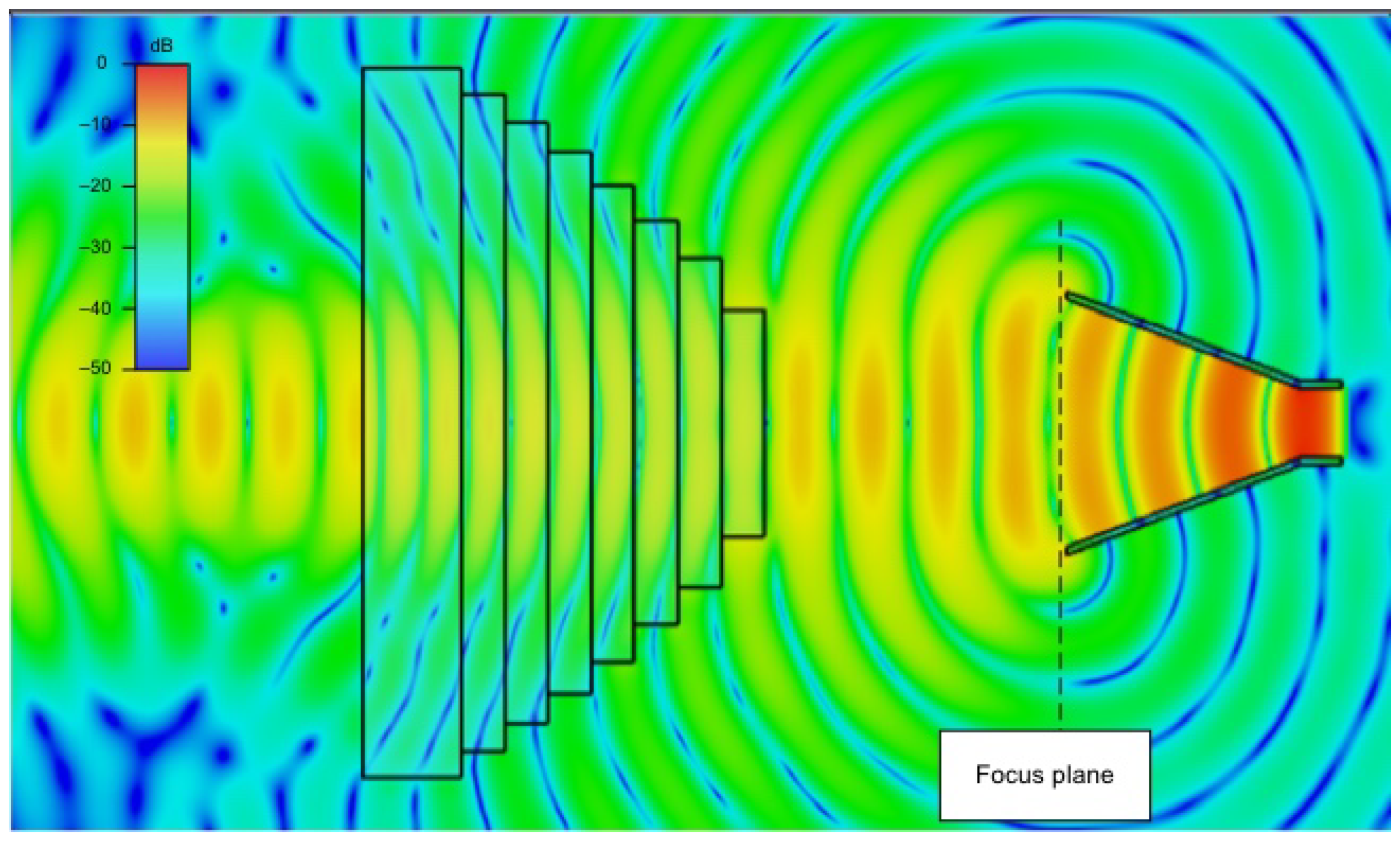

2. Mathematical Formulation

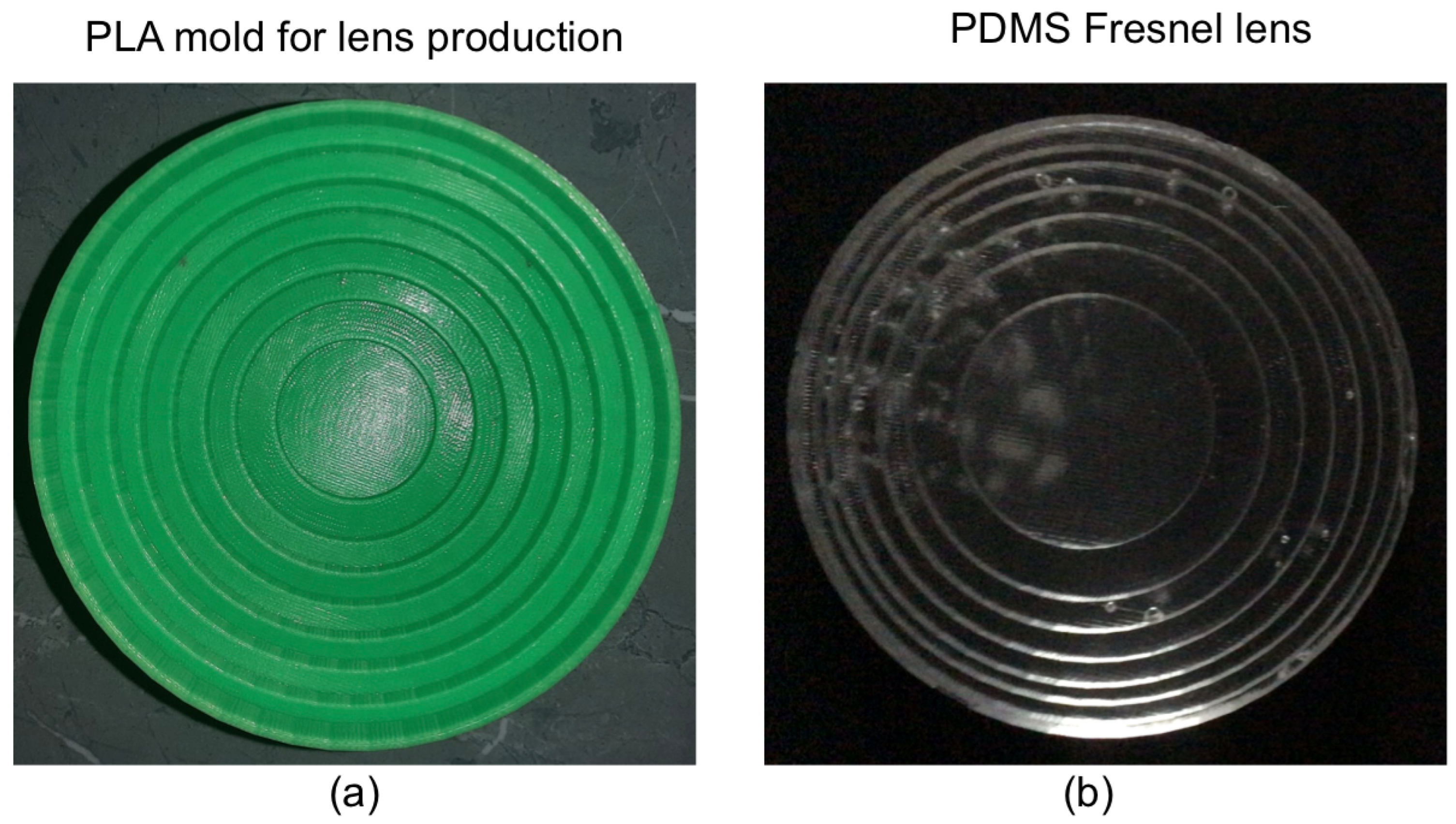

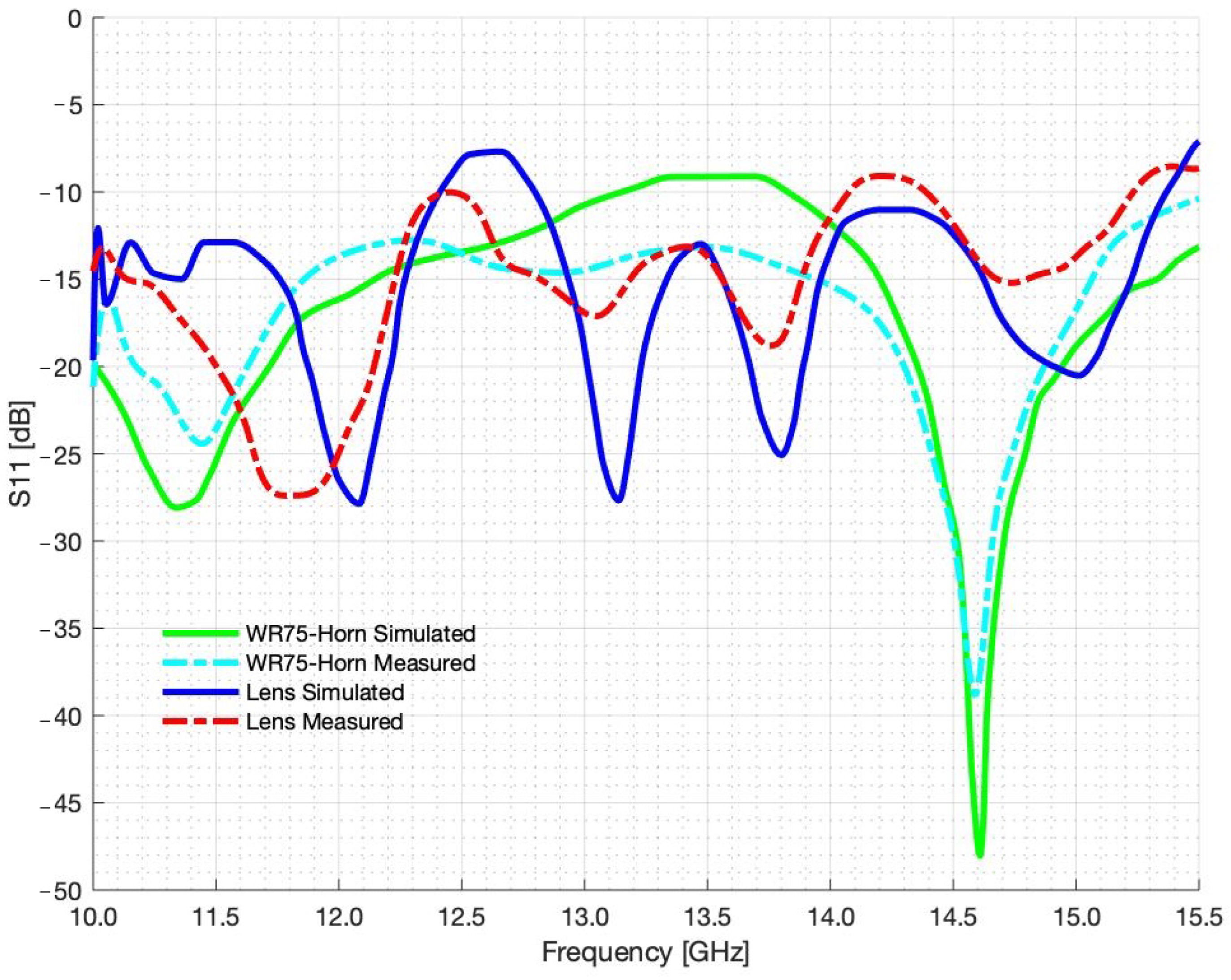

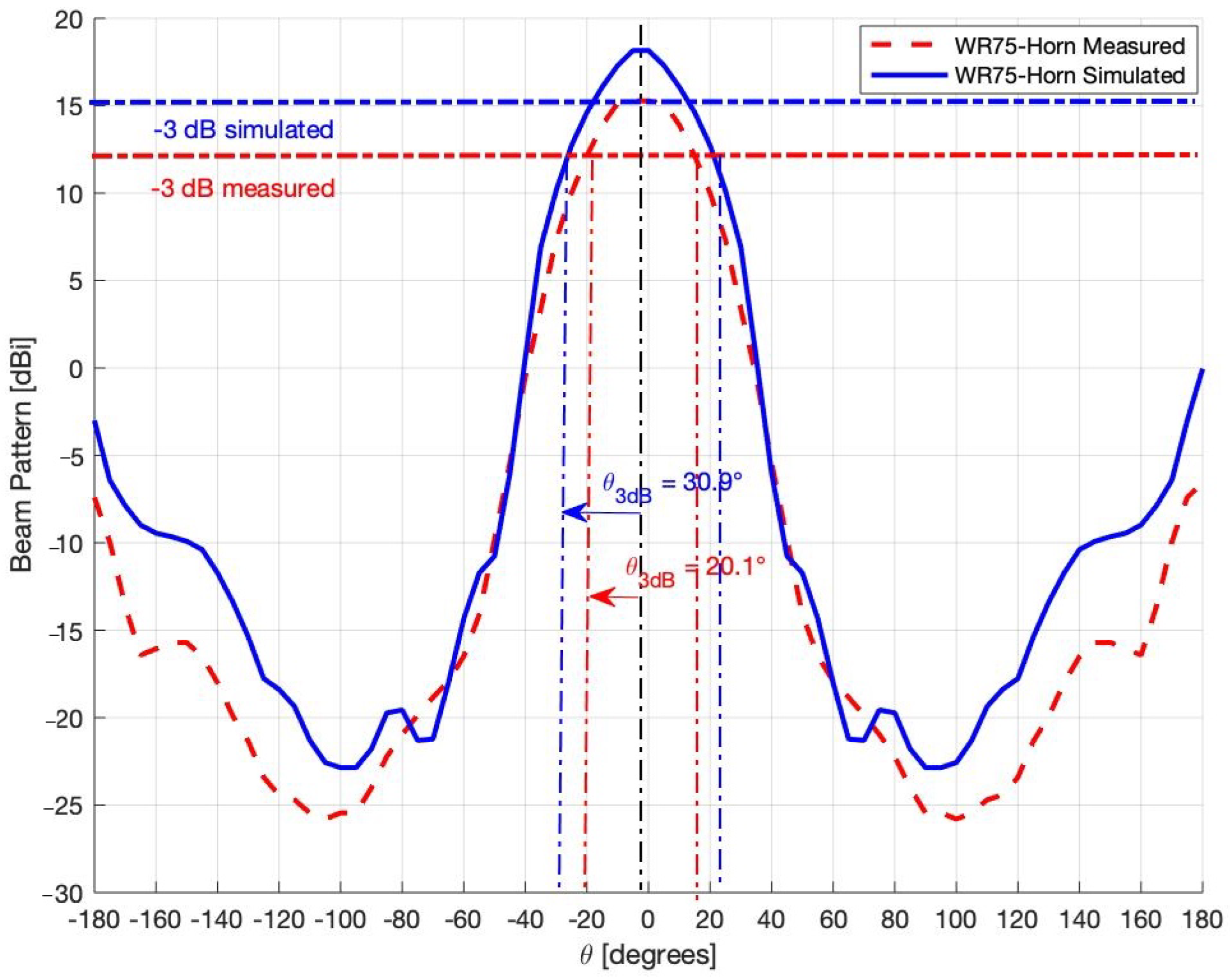

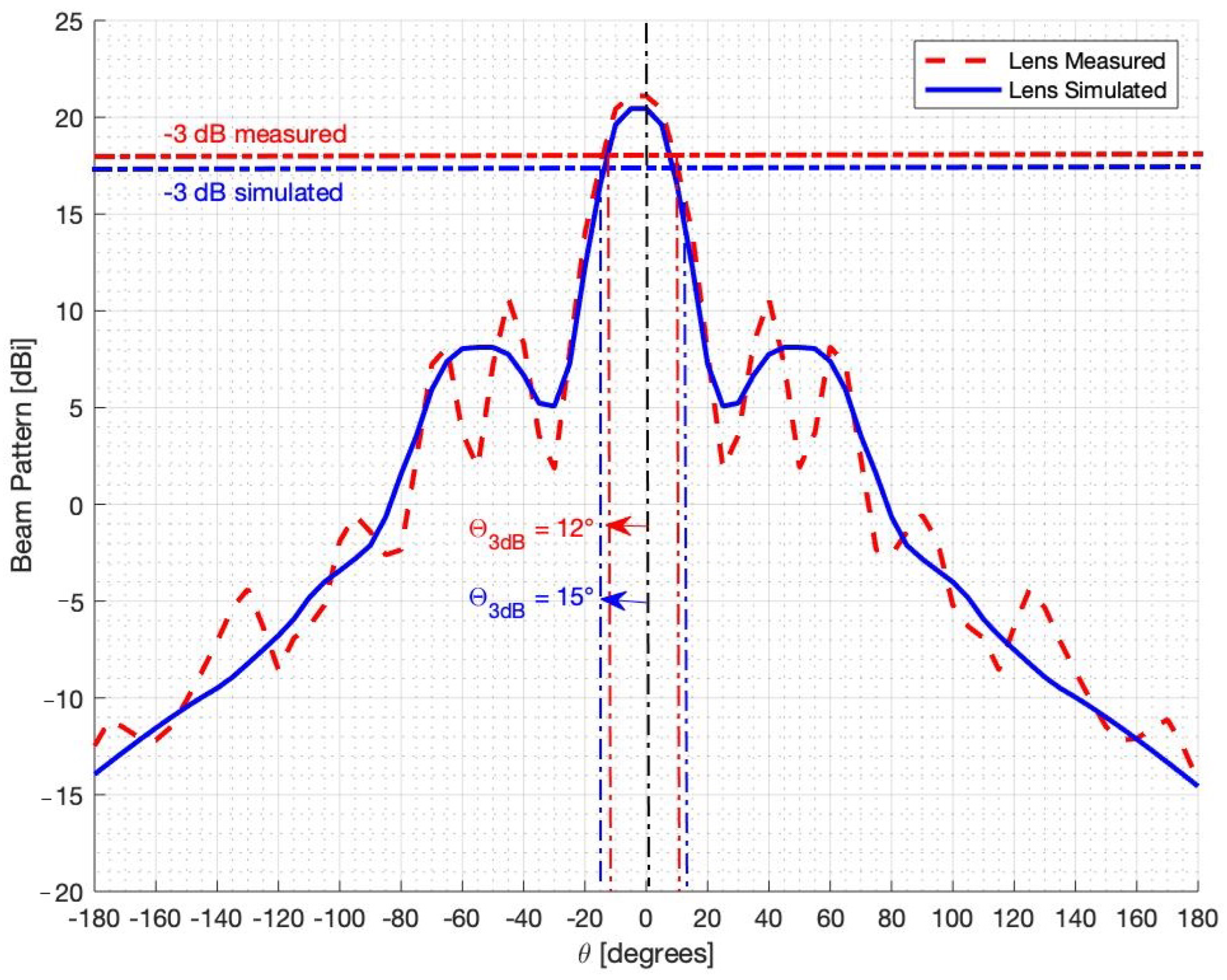

3. Antenna Prototype

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kitsuregawa, T. (Ed.) Advanced Technology in Satellite Communication Antennas: Electrical and Mechanical Design; Artech House: Norwood, MA, USA, 1990. [Google Scholar]

- Sharma, S.K.; Rao, S.; Shafai, L. (Eds.) Handbook of Reflector Antennas and Feed Systems: Volume 1: Theory and Design of Reflectors; Artech House: Norwood, MA, USA, 2013. [Google Scholar]

- Thornton, J.; Huang, K.-C. Modern Lens Antennas for Communications Engineering-MAJ (1. Aufl); Wiley-IEEE Press: Hoboken, NJ, USA, 2012. [Google Scholar]

- Biswas, S. Dual-Polarized Antenna Feed Matrix Design for Multibeam Lens Antenna. IEEE Antennas Wirel. Propag. Lett. 2023, 22, 2760–2764. [Google Scholar] [CrossRef]

- Baharom, B.; Sugimoto, Y.; Rohani, B.; Sakakibara, K.; Kikuma, N.; Yamada, Y.; Abd Rahman, N.H. 2 x 2 Lens Array Antenna Using Square-Bottom Concave-Convex Lens in 300-GHz Band. IEEE Open J. Antennas Propag. 2023, 4, 1074–1086. [Google Scholar] [CrossRef]

- Liu, K.; Zhao, C.; Qu, S.-W.; Chen, Y.; Hu, J.; Yang, S. A 3-D-Printed Multibeam Spherical Lens Antenna with Ultrawide-Angle Coverage. IEEE Antennas Wirel. Propag. Lett. 2021, 20, 411–415. [Google Scholar] [CrossRef]

- Guo, Y.J.; Barton, S.K. Fresnel Zone Antennas; Kluwer Academic Publishers: Boston, MA, USA, 2002. [Google Scholar]

- Kusko, M.; Avram, A.; Apostol, D. Design and fabrication of Fresnel lenses. In Proceedings of the 2008 International Semiconductor Conference, Sinaia, Romania, 13–15 October 2008; pp. 445–448. [Google Scholar] [CrossRef]

- Dutta Roy, S.C. Characteristics of Single-and Multiple-Frequency Impedance Matching Networks. IEEE Trans. Circuits Syst. II Express Briefs 2015, 62, 222–225. [Google Scholar] [CrossRef]

- Hristov, H.D.; Rodriguez, J.M. Design Equation for Multidielectric Fresnel Zone Plate Lens. IEEE Microw. Wirel. Components Lett. 2012, 22, 574–576. [Google Scholar] [CrossRef]

- Hristov, H.D. Fresnel Zones in Wireless Links, Zone Plate Lenses, and Antennas; Artech House: Norwood, MA, USA, 2000. [Google Scholar]

- Ge, Y.; Chen, Y.; Liu, Y.; Chen, L. Designs of flat reflectarray and transmitarray antennas using the Fresnel zone principle. In Proceedings of the 2016 IEEE 5th Asia-Pacific Conference on Antennas and Propagation (APCAP), Kaohsiung, Taiwan, 26–29 July 2016; pp. 351–352. [Google Scholar] [CrossRef]

- Ghaffar, F.A.; Khalid, M.U.; Salama, K.N.; Shamim, A. 24-GHz LTCC Fractal Antenna Array SoP with Integrated Fresnel Lens. IEEE Antennas Wirel. Propag. Lett. 2011, 10, 705–708. [Google Scholar] [CrossRef]

- Gagnon, N.; Petosa, A.; McNamara, D.A. Printed Hybrid Lens Antenna. IEEE Trans. Antennas Propag. 2012, 60, 2514–2518. [Google Scholar] [CrossRef]

- Wang, C.; Yu, W.; Liu, Y.; Peng, L. A 3D printed all dielectric Fresnel zone plate lens with high gain characteristic at the X-band. In Proceedings of the 2021 International Conference on Microwave and Millimeter Wave Technology (ICMMT), Nanjing, China, 23–26 May 2021; pp. 1–3. [Google Scholar] [CrossRef]

- Gong, J.; Dai, X. 3D-Printed Transparent Fresnel Zone Plate Lens with Multi-beams at Ka-band. In Proceedings of the 2023 International Conference on Microwave and Millimeter Wave Technology (ICMMT), Qingdao, China, 14–17 May 2023; pp. 1–3. [Google Scholar] [CrossRef]

- Zhu, J.; Yang, Y.; Li, M.; Mcgloin, D.; Liao, S.; Nulman, J.; Yamada, M.; Iacopi, F. Additively Manufactured Millimeter-Wave Dual-Band Single-Polarization Shared Aperture Fresnel Zone Plate Metalens Antenna. IEEE Trans. Antennas Propag. 2021, 69, 6261–6272. [Google Scholar] [CrossRef]

- Zhang, S. 3D printed dielectric Fresnel lens. In Proceedings of the 2016 10th European Conference on Antennas and Propagation (EuCAP), Davos, Switzerland, 10–15 April 2016; pp. 1–3. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, P.; Whittow, W. Design and Fabrication of 3-D-Printed High-Gain Broadband Fresnel Zone Lens Using Hybrid Groove-Perforation Method for Millimeter-Wave Applications. IEEE Antennas Wirel. Propag. Lett. 2022, 21, 34–38. [Google Scholar] [CrossRef]

- Dorozhkin, K.V.; Teterina, D.D.; Badin, A.V.; Moskalenko, V.D. ABS and PLA sub-terahertz absorbers for 3D-printing technology. J. Phys. Conf. Ser. 2020, 1499, 012008. [Google Scholar] [CrossRef]

- Kuzmanić, I.; Vujović, I.; Petković, M.; Šoda, J. Influence of 3D printing properties on relative dielectric constant in PLA and ABS materials. Prog. Addit. Manuf. 2023, 8, 703–710. [Google Scholar] [CrossRef] [PubMed]

- Cai, H.; Wang, K. A Transparent MMW Liquid Fresnel Lens Antenna for 5G Communication. In Proceedings of the 2021 International Symposium on Antennas and Propagation (ISAP), Taipei, Taiwan, 19–22 October 2021; pp. 1–2. [Google Scholar] [CrossRef]

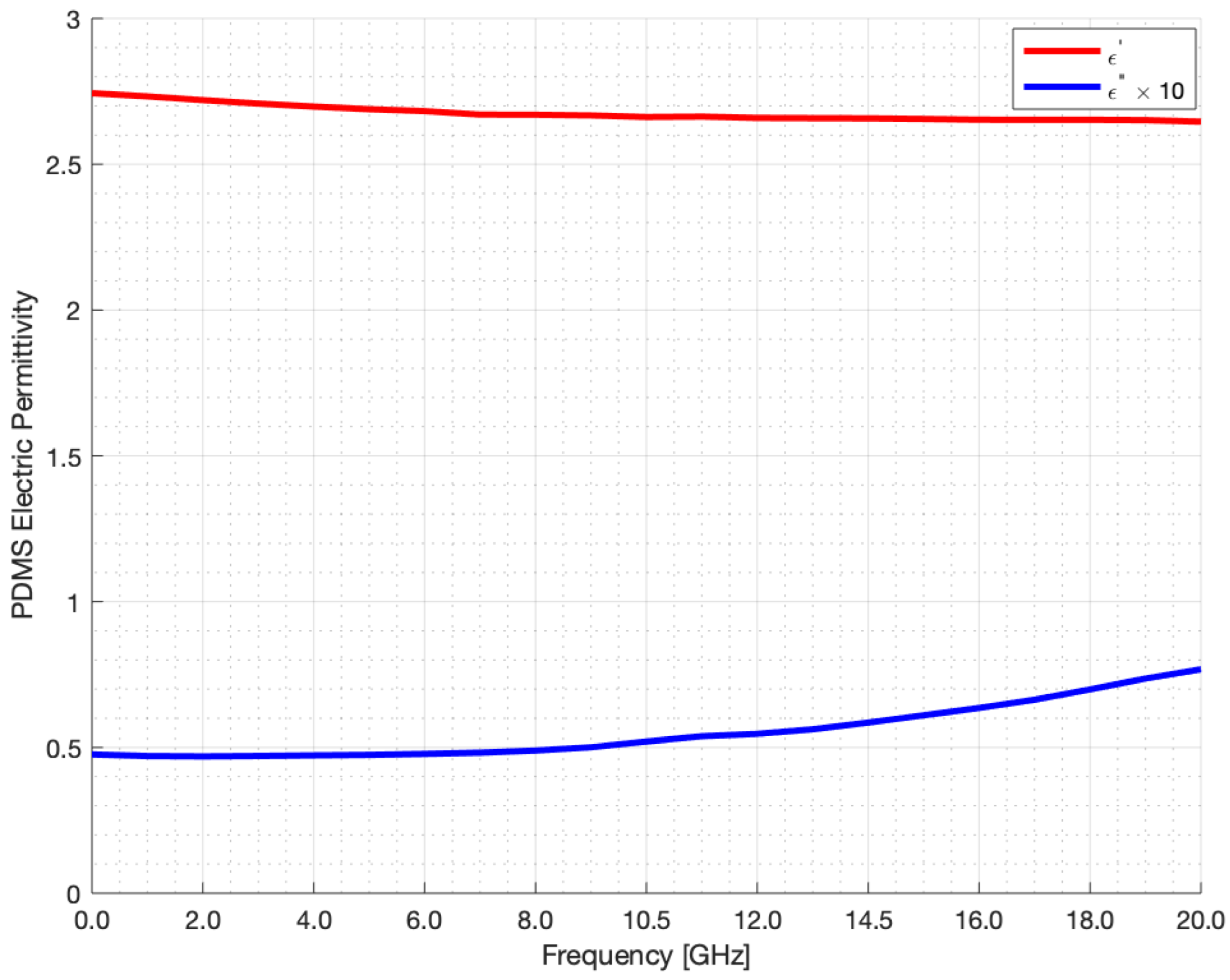

- Sharma, P.K.; Gupta, N.; Dankov, P.I. Analysis of Dielectric Properties of Polydimethylsiloxane (PDMS) as a Flexible Substrate for Sensors and Antenna Applications. IEEE Sens. J. 2021, 21, 19492–19504. [Google Scholar] [CrossRef]

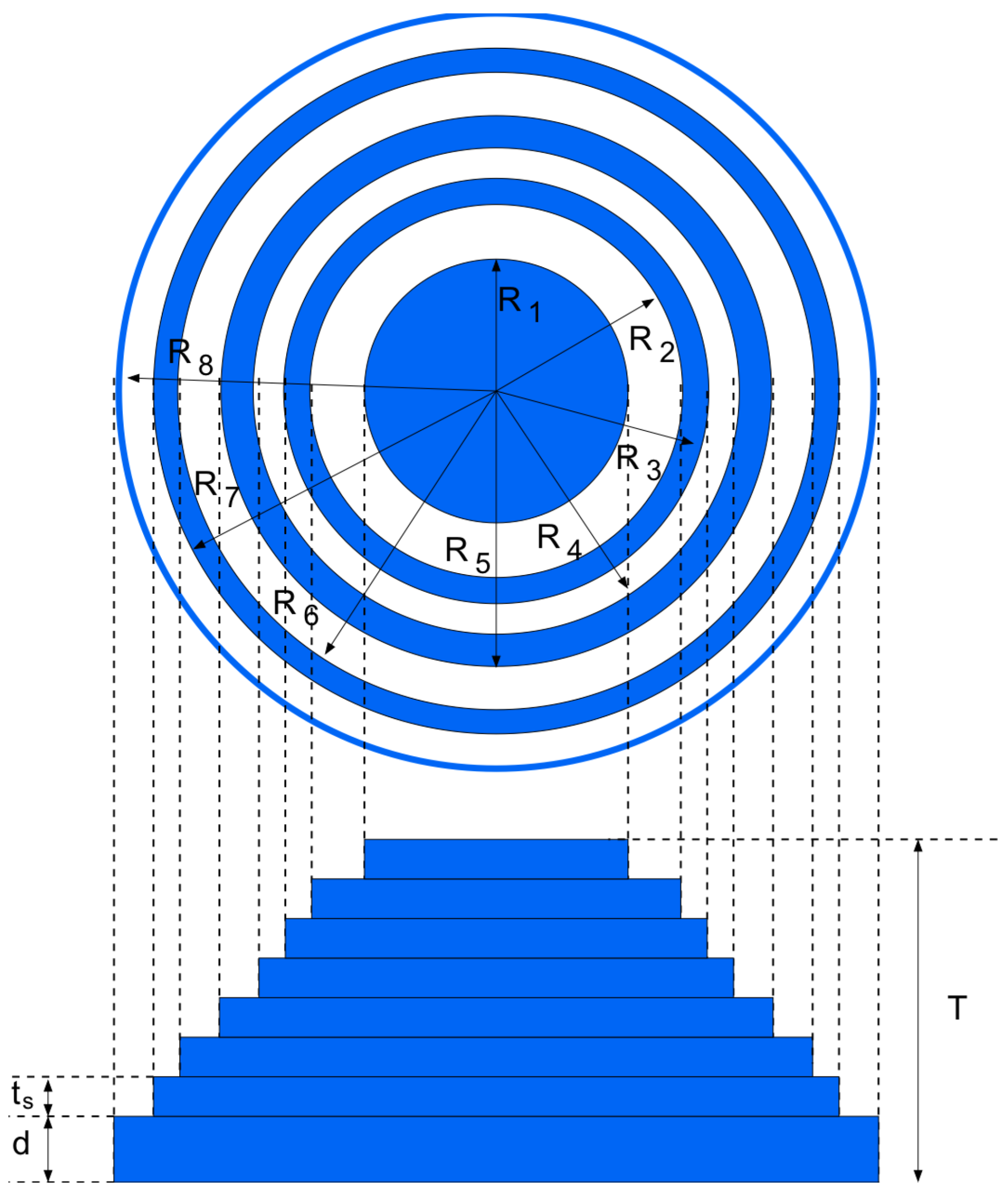

| Parameters | Value [cm] |

|---|---|

| 1.60 | |

| 2.30 | |

| 2.83 | |

| 3.31 | |

| 3.75 | |

| 4.15 | |

| 4.53 | |

| 4.90 | |

| 0.64 | |

| d | 0.82 |

| Technolgies | Mech. Robustness | Cost | Time for Fabrication |

|---|---|---|---|

| Additive Tech. (3D) | Low | High | High |

| CNC Miling. Mach. | Low | High | Medium |

| Company Custom Made | Medium | Very High | Very High |

| Proposed Tech. | Very High | Low | Medium |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Donelli, M.; Menon, S.; Mulloni, V.; Marchi, G.; Dal Chiele, I. A Polydimethylsiloxane (PDMS) Transparent Fresnel Zone Lens Antenna at Ku-Band for Satellite Communication. Electronics 2025, 14, 3766. https://doi.org/10.3390/electronics14193766

Donelli M, Menon S, Mulloni V, Marchi G, Dal Chiele I. A Polydimethylsiloxane (PDMS) Transparent Fresnel Zone Lens Antenna at Ku-Band for Satellite Communication. Electronics. 2025; 14(19):3766. https://doi.org/10.3390/electronics14193766

Chicago/Turabian StyleDonelli, Massimo, Sreedevi Menon, Viviana Mulloni, Giada Marchi, and Irene Dal Chiele. 2025. "A Polydimethylsiloxane (PDMS) Transparent Fresnel Zone Lens Antenna at Ku-Band for Satellite Communication" Electronics 14, no. 19: 3766. https://doi.org/10.3390/electronics14193766

APA StyleDonelli, M., Menon, S., Mulloni, V., Marchi, G., & Dal Chiele, I. (2025). A Polydimethylsiloxane (PDMS) Transparent Fresnel Zone Lens Antenna at Ku-Band for Satellite Communication. Electronics, 14(19), 3766. https://doi.org/10.3390/electronics14193766