Low-Loss Multicore FIFO Device Based on Chemically Etched Optical Fibers

Abstract

1. Introduction

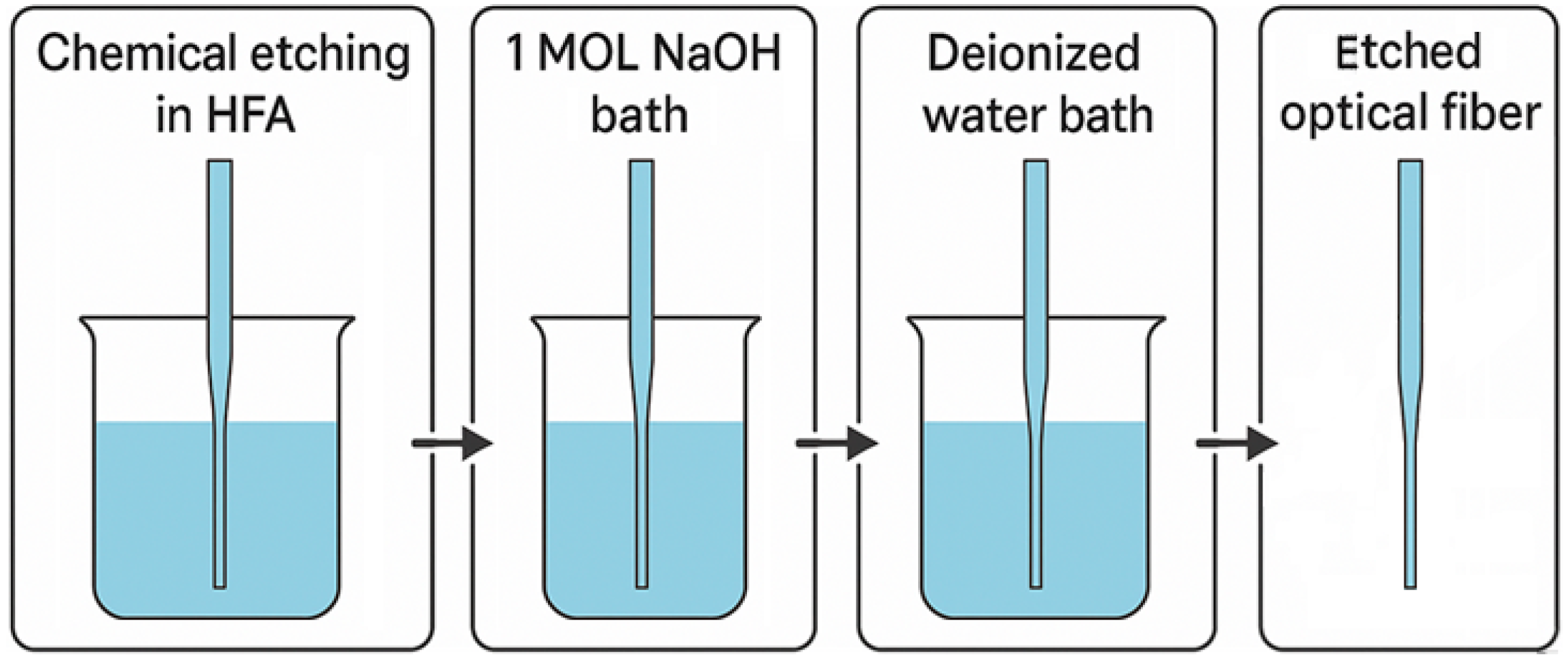

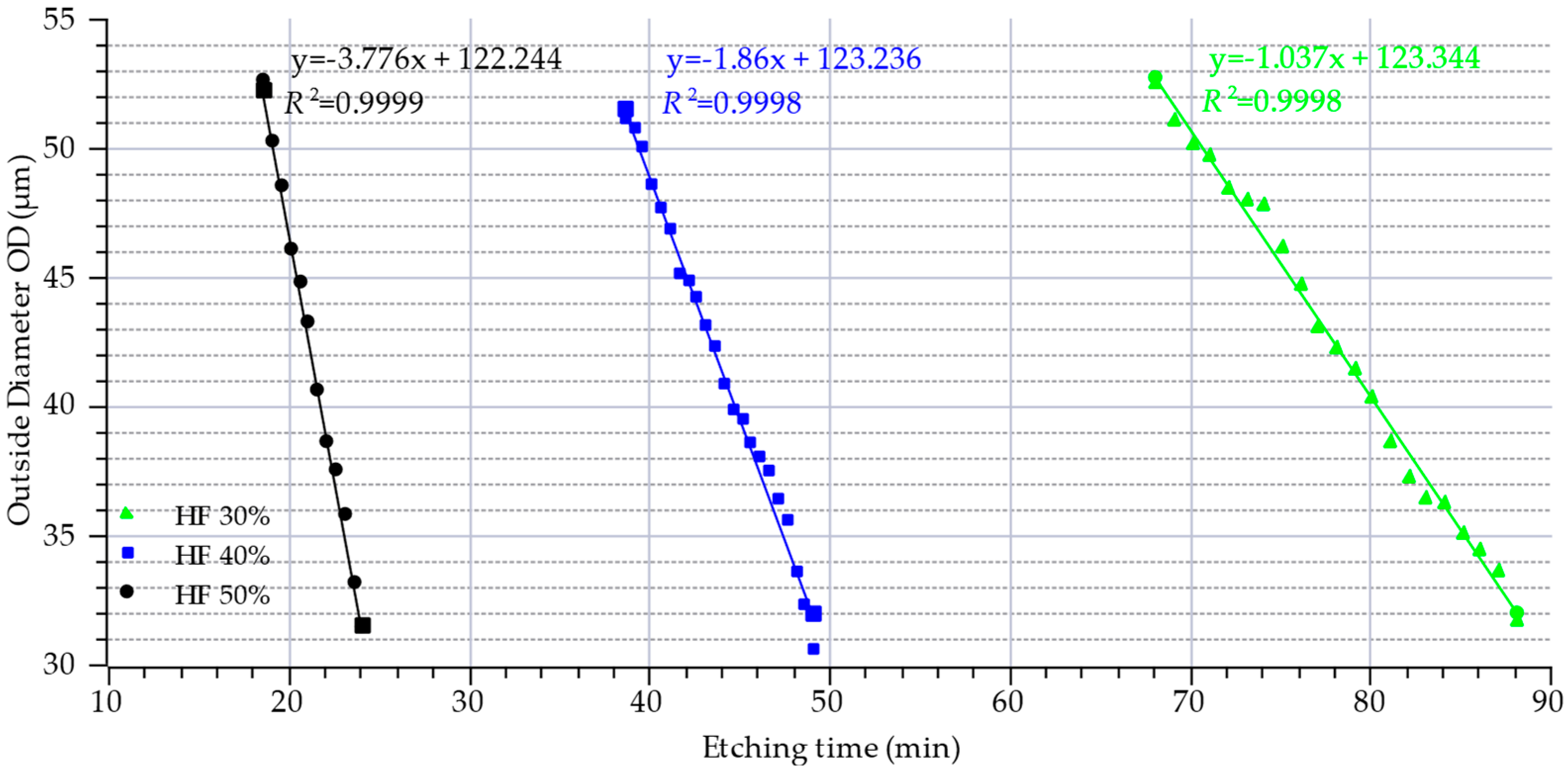

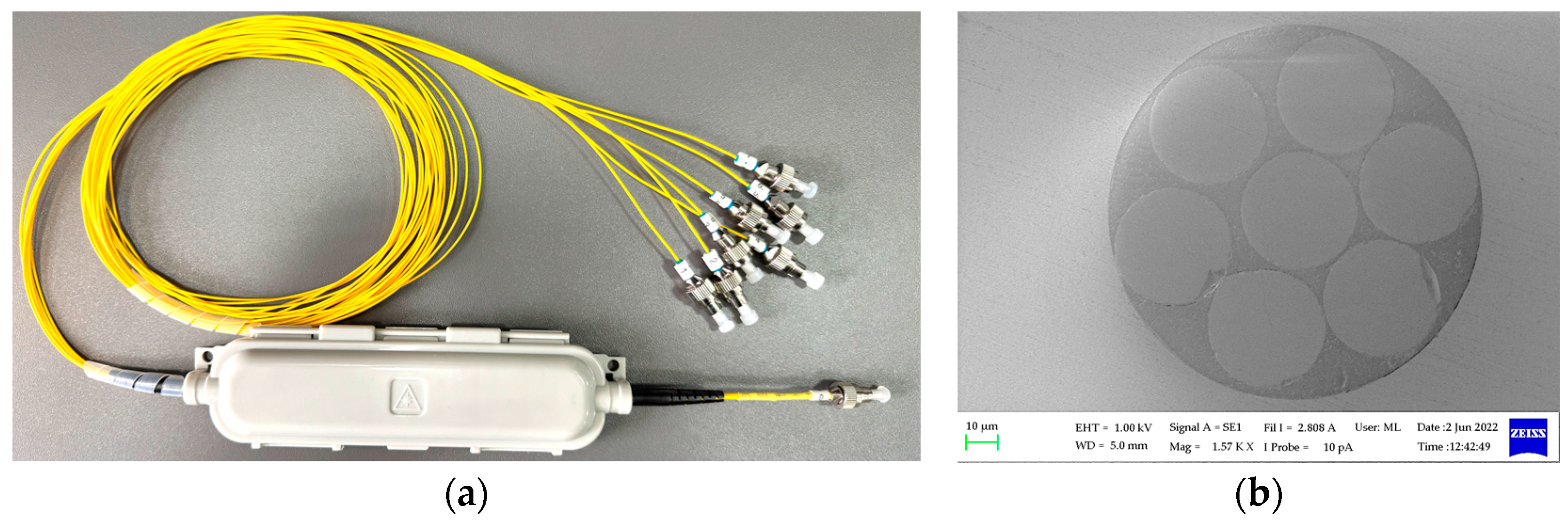

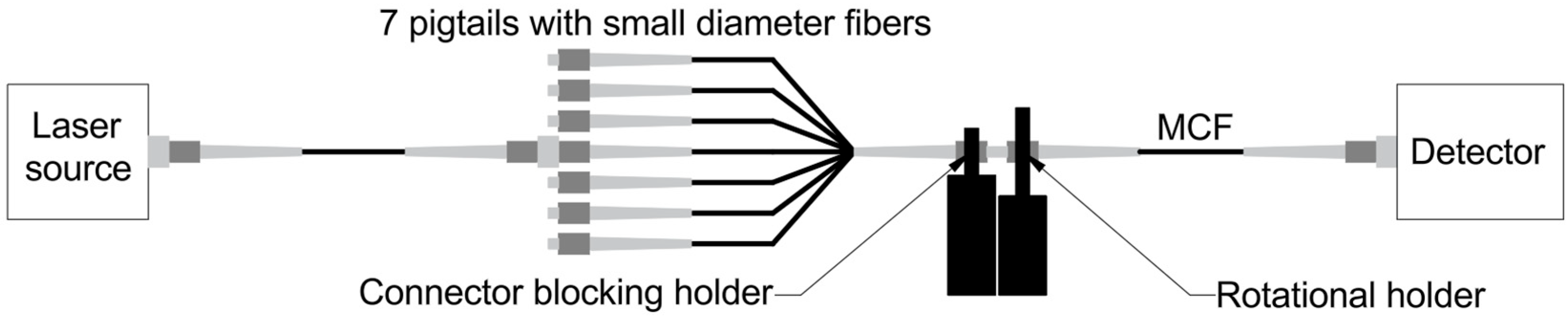

2. Materials and Methods

3. Results

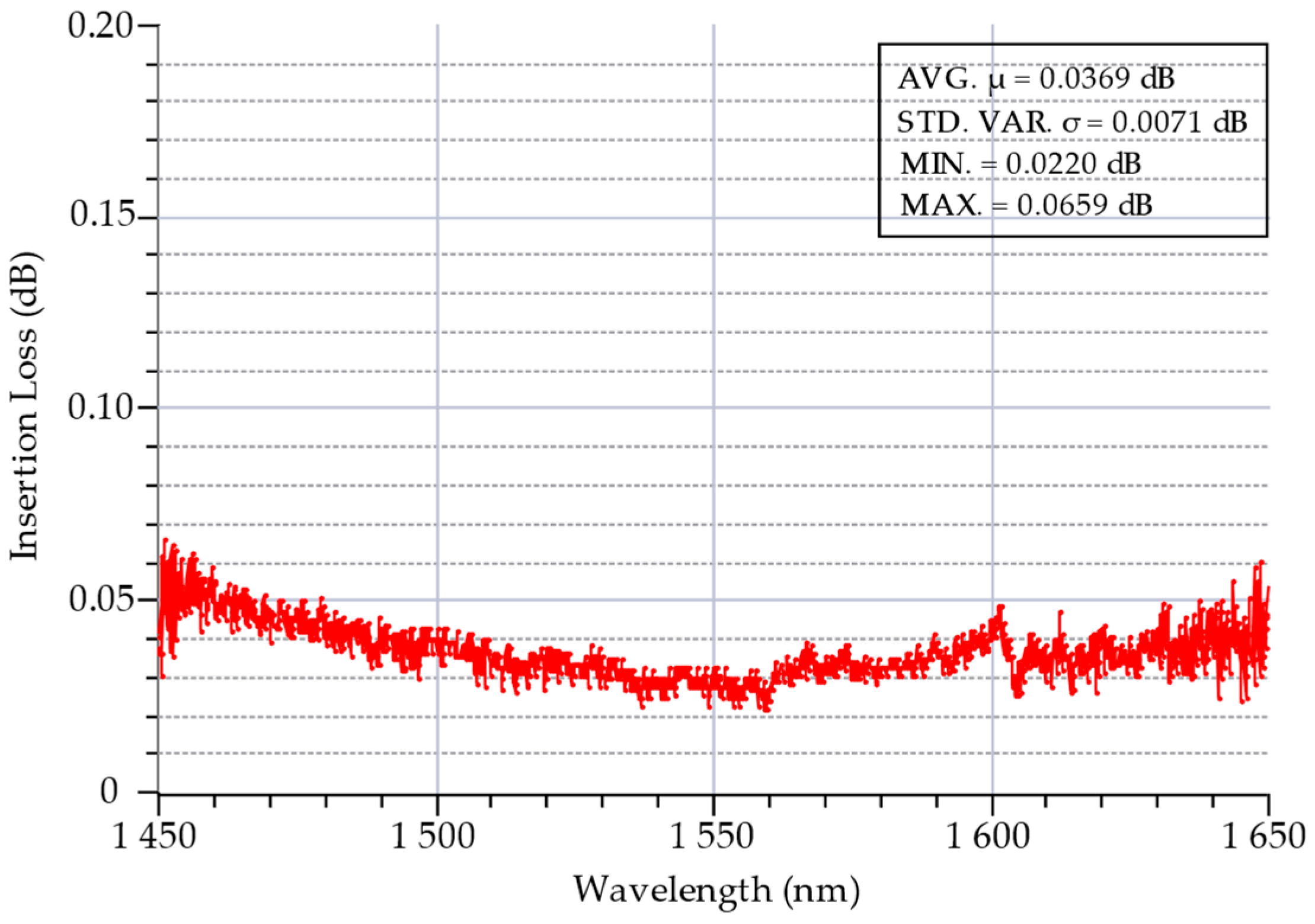

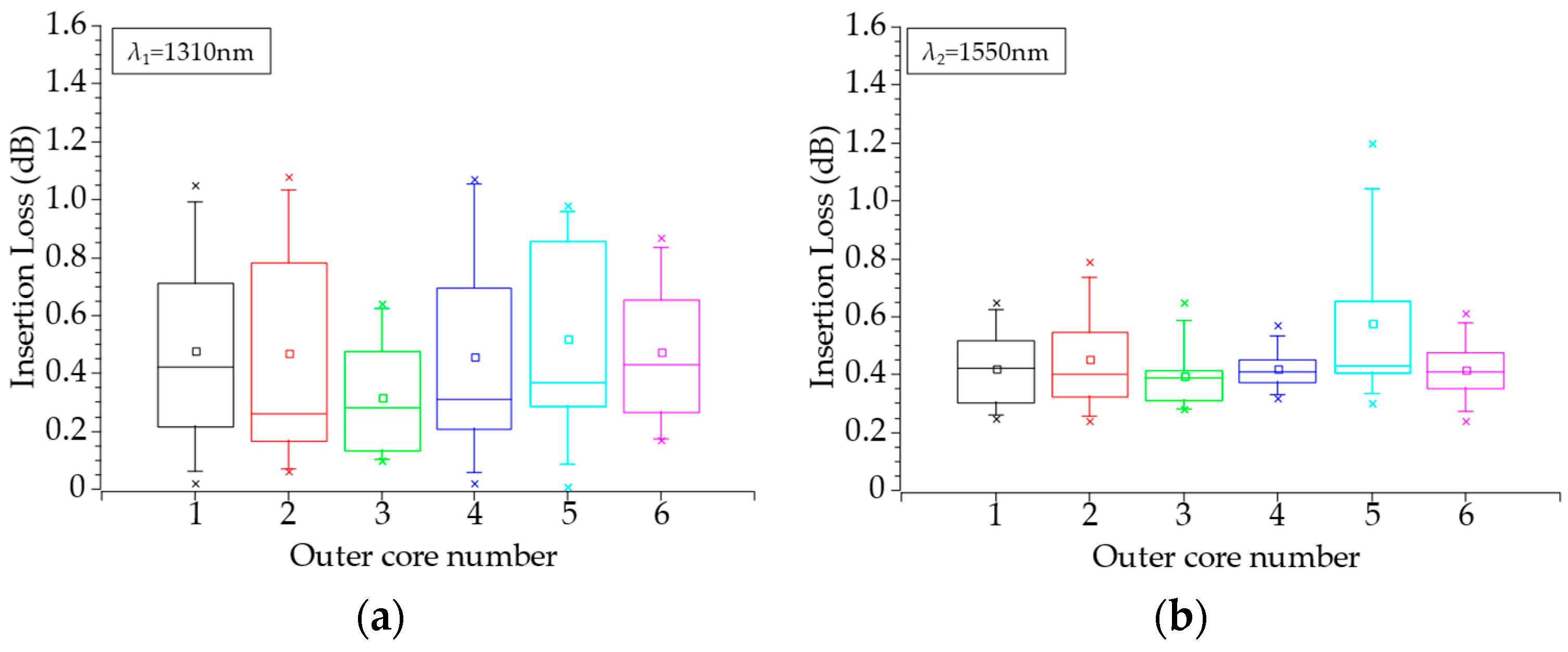

3.1. Coupling Loss

3.2. Crosstalk

3.3. Return Loss

4. Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| FIFO | Fan-in/Fan-out device |

| SMF | Single-mode optical fiber |

| MCF | Multicore fiber |

| HFA | Hydrofluoric acid |

| EOF | Etched optical fiber |

| TOF | Tapered optical fiber |

| MFD | Mode field diameter |

| SEM | Scanning electron microscopy |

| AVG | Average |

| STD DEV | Standard deviation |

References

- Gan, L.; Zhou, J.; Shen, L.; Guo, X.; Wang, Y.; Yang, C.; Tong, W.; Xia, L.; Fu, S.; Tang, M.; et al. Ultra-Low Crosstalk Fused Taper Type Fan-In/Fan-Out Devices for Multicore Fibers. In Proceedings of the 2019 Optical Fiber Communications Conference and Exhibition (OFC), San Diego, CA, USA, 3–7 March 2019; pp. 1–3. [Google Scholar]

- Watanabe, K.; Saito, T. Compact fan-out for 19-core multicore fiber, with high manufacturability and good optical properties. In Proceedings of the 2015 Opto-Electronics and Communications Conference (OECC), Shanghai, China, 28 June–2 July 2015. [Google Scholar]

- Kopp, V.I.; Park, J.; Singer, J.; Neugroschl, D.; Gillooly, A. Low Return Loss Multicore Fiber-Fanout Assembly for SDM and Sensing Applications. In Proceedings of the Optical Fiber Communication Conference (OFC) 2020, San Diego, CA, USA, 8–12 March 2020. [Google Scholar]

- Cui, J.; Zhu, S.; Feng, K.; Hong, D.; Li, J.; Tan, J. Fan-out device for multicore fiber coupling application based on capillary bridge self-assembly fabrication method. Opt. Fiber Technol. 2015, 26, 234–242. [Google Scholar] [CrossRef]

- Watanabe, K.; Saito, T.; Imamura, K.; Shiino, M. Development of fiber bundle type fan-out for multicore fiber. In Proceedings of the 2012 17th Opto-Electronics and Communications Conference, Busan, Republic of Korea, 2–6 July 2012; pp. 475–476. [Google Scholar]

- Uemura, H.; Takenaga, K.; Ori, T.; Matsuo, S.; Saitoh, K.; Koshiba, M. Fused taper type fan-in/fan-out device for multicore EDF. In Proceedings of the 2013 18th OptoElectronics and Communications Conference Held Jointly with 2013 International Conference on Photonics in Switching (OECC/PS), Kyoto, Japan, 30 June–4 July 2013; pp. 1–2. [Google Scholar]

- Abe, Y.; Shikama, K.; Yanagi, S.; Takahashi, T. Low-loss physical-contact-type fan-out device for 12-core multicore fiber. In Proceedings of the 39th European Conference and Exhibition on Optical Communication (ECOC 2013), London, UK, 22–26 September 2013; IET Conference Publications: Stevenage, UK, 2013; pp. 861–863. [Google Scholar]

- Qiao, G.; Yang, Y.; Ji, H.; Huang, S.; Long, C.; Gao, Y.; Zuo, M.; Zhang, J.; Xu, Z.; Wu, Q.; et al. 205.8Tb/s Weakly-Coupled 2-Mode 7-Core Transmission Over 1170-km FM-MCF Only Using 2×2 MIMO-DSP. In Proceedings of the 2024 Optical Fiber Communications Conference and Exhibition (OFC), San Diego, CA, USA, 24–28 March 2024; pp. 1–3. [Google Scholar]

- Tottori, Y.; Kobayashi, T.; Watanabe, M. Low loss optical connection module for seven-core multicore fiber and seven single-mode fibers. IEEE Photonics Technol. Lett. 2012, 24, 1926–1928. [Google Scholar] [CrossRef]

- Klaus, W.; Sakaguchi, J.; Puttnam, B.J.; Awaji, Y.; Wada, N.; Kobayashi, T.; Watanabe, M. Free-Space Coupling Optics for Multicore Fibers. IEEE Photonics Technol. Lett. 2012, 24, 1902–1905. [Google Scholar] [CrossRef]

- Lee, Y.; Tanaka, K.; Hiruma, K.; Nomoto, E.; Sugawara, T.; Arimoto, H. Experimental Demonstration of a Highly Reliable Multicore-Fiber-Based Optical Network. IEEE Photonics Technol. Lett. 2014, 26, 538–540. [Google Scholar] [CrossRef]

- Shimakawa, O.; Arao, H.; Harumoto, M.; Sano, T.; Inoue, A. Compact multi-core fiber fan-out with GRIN-lens and micro-lens array. In Proceedings of the OFC 2014, San Francisco, CA, USA, 9–13 March 2014. [Google Scholar]

- Oh, J.; Yang, J.; Marra, L.; Dorrah, A.H.; Palmieri, A.; Dainese, P.; Capasso, F. Metasurfaces for Free-Space Coupling to Multicore Fibers. J. Light. Technol. 2024, 42, 2385–2396. [Google Scholar] [CrossRef]

- Suganuma, D.; Ishigure, T. Fan-in/out polymer optical waveguide for a multicore fiber fabricated using the Mosquito method. Opt. Express 2015, 23, 1585–1593. [Google Scholar] [CrossRef] [PubMed]

- Thomson, R.R.; Bookey, H.T.; Psaila, N.D.; Fender, A.; Campbell, S.; Macpherson, W.N.; Barton, J.S.; Reid, D.T.; Kar, A.K.; Gander, M.J.; et al. Ultrafast-laser inscription of a three dimensional fan-out device for multicore fiber coupling applications. Opt. Express 2007, 15, 11691–11697. [Google Scholar] [CrossRef] [PubMed]

- Watanabe, T.; Hikita, M.; Kokubun, Y. Laminated polymer waveguide fan-out device for uncoupled multicore fibers. Opt. Express 2012, 20, 26317. [Google Scholar] [CrossRef] [PubMed]

- Ams, M.; Marshall, G.D.; Withford, M.J. Study of the influence of femtosecond laser polarisation on direct writing of waveguides. Opt. Express 2006, 14, 13158–13163. [Google Scholar] [CrossRef] [PubMed]

- Shikama, K.; Abe, Y.; Ono, H.; Aratake, A. Low-Loss and Low-Mode-Dependent-Loss Fan-In/Fan-Out Device for 6-Mode 19-Core Fiber. J. Light. Technol. 2018, 36, 302–308. [Google Scholar] [CrossRef]

- Zhu, B.; Taunay, T.F.; Yan, M.F.; Fini, J.M.; Fishteyn, M.; Monberg, E.M.; Dimarcello, F.V. Seven-core multi-core fiber transmissions for passive optical network. Opt. Express 2010, 18, 11117. [Google Scholar] [CrossRef] [PubMed]

- Matsui, T.; Pondillo, P.L.; Nakajima, K. Weakly Coupled Multicore Fiber Technology, Deployment, and Systems. Proc. IEEE 2022, 110, 1772–1785. [Google Scholar] [CrossRef]

- Anderson, G.P.; Golden, J.P.; Ligler, F.S. A fiber optic biosensor: Combination tapered fibers designed for improved signal acquisition. Biosens. Bioelectron. 1993, 8, 249–256. [Google Scholar] [CrossRef]

- Zhong, N.; Liao, Q.; Zhu, X.; Wang, Y.; Chen, R. High-quality fiber fabrication in buffered hydrofluoric acid solution with ultrasonic agitation. Appl. Opt. 2013, 52, 1432–1440. [Google Scholar] [CrossRef] [PubMed]

- Spierings, G.A.C.M. Wet chemical etching of silicate glasses in hydrofluoric acid based solutions. J. Mater. Sci. 1993, 28, 6261–6273. [Google Scholar] [CrossRef]

- Zhang, E.J.; Sacher, W.D.; Poon, J.K.S. Hydrofluoric acid flow etching of low-loss subwavelength-diameter biconical fiber tapers. Opt. Express 2010, 18, 22593–22598. [Google Scholar] [CrossRef] [PubMed]

- Xiao, H.; Wang, H.; Fu, G.; Chen, Z. Surface roughness and morphology evolution of optical glass with microcracks during chemical etching. Appl. Opt. 2017, 56, 702–711. [Google Scholar] [CrossRef] [PubMed]

- Kurkjian, C.R.; Matthewson, M.J.; Rooney, J.M. Effects of heat treatment and HF etching on the strength of silica lightguides. In Reliability of Optical Fiber Components, Devices, Systems, and Networks II; Limberger, H.G., Matthewson, M.J., Eds.; SPIE: Pune, India, 2004; Volume 5465, pp. 223–229. [Google Scholar]

- Machavaram, V.R.; Badcock, R.A.; Fernando, G.F. Fabrication of intrinsic fibre Fabry–Perot sensors in silica fibres using hydrofluoric acid etching. Sens. Actuators A Phys. 2007, 138, 248–260. [Google Scholar] [CrossRef]

- Orbray Co., Ltd. Available online: https://orbray.com/en/ (accessed on 1 August 2025).

- Domaille Engineering. Available online: https://www.domailleengineering.com/ (accessed on 1 August 2025).

- Ye, F.; Ono, H.; Abe, Y.; Yamada, M.; Morioka, T. Novel Crosstalk Measurement Method for Multi-Core Fiber Fan-In/Fan-Out Devices. IEEE Photonics Technol. Lett. 2016, 28, 2269–2272. [Google Scholar] [CrossRef]

| Coupling Loss λ = 1310 nm [dB] | ||||

|---|---|---|---|---|

| FIFO Aligned to Outer Core | AVG | STD DEV | MAX | MIN |

| 1 | 0.48 | 0.37 | 1.05 | 0.02 |

| 2 | 0.47 | 0.41 | 1.08 | 0.06 |

| 3 | 0.32 | 0.22 | 0.64 | 0.10 |

| 4 | 0.46 | 0.42 | 1.07 | 0.02 |

| 5 | 0.52 | 0.37 | 0.98 | 0.01 |

| 6 | 0.47 | 0.27 | 0.87 | 0.17 |

| Coupling Loss λ = 1550 nm [dB] | ||||

|---|---|---|---|---|

| FIFO Aligned to Outer Core | AVG | STD DEV | MAX | MIN |

| 1 | 0.42 | 0.15 | 0.65 | 0.25 |

| 2 | 0.45 | 0.19 | 0.79 | 0.24 |

| 3 | 0.40 | 0.13 | 0.65 | 0.28 |

| 4 | 0.42 | 0.08 | 0.57 | 0.32 |

| 5 | 0.58 | 0.30 | 1.20 | 0.30 |

| 6 | 0.42 | 0.12 | 0.61 | 0.24 |

| Crosstalk [dB] | |||||||

|---|---|---|---|---|---|---|---|

| Core 0 | Core 1 | Core 2 | Core 3 | Core 4 | Core 5 | Core 6 | |

| Core 0 | - | −48.5 | −46.3 | −45.8 | −43.2 | −43.4 | −42.6 |

| Core 1 | −46.5 | - | −49.5 | −54.2 | −56.7 | −55.4 | −51.4 |

| Core 2 | −53.7 | −44.7 | - | −48.7 | −51.4 | −58.2 | −54.8 |

| Core 3 | −51.5 | −49.3 | −47.2 | - | −44.4 | −52.6 | −55.1 |

| Core 4 | −41.8 | −53.4 | −49.7 | −44.3 | - | −47.1 | −48.6 |

| Core 5 | −47.1 | −50.2 | −48.5 | −48.1 | −47.9 | - | −45.8 |

| Core 6 | −45.8 | −48.7 | −52.4 | −51.7 | −50.7 | −47.5 | - |

| Return Loss [dB] | ||

|---|---|---|

| 1310 nm | 1550 nm | |

| Core 0 | −55.5 | −56.5 |

| Core 1 | −52.1 | −53.4 |

| Core 2 | −51.9 | −52.4 |

| Core 3 | −51.3 | −52.7 |

| Core 4 | −54.4 | −55.8 |

| Core 5 | −52.4 | −52.9 |

| Core 6 | −53.1 | −53.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Woźniak, A.; Łakomski, M.; Lisik, Z. Low-Loss Multicore FIFO Device Based on Chemically Etched Optical Fibers. Electronics 2025, 14, 3479. https://doi.org/10.3390/electronics14173479

Woźniak A, Łakomski M, Lisik Z. Low-Loss Multicore FIFO Device Based on Chemically Etched Optical Fibers. Electronics. 2025; 14(17):3479. https://doi.org/10.3390/electronics14173479

Chicago/Turabian StyleWoźniak, Arkadiusz, Mateusz Łakomski, and Zbigniew Lisik. 2025. "Low-Loss Multicore FIFO Device Based on Chemically Etched Optical Fibers" Electronics 14, no. 17: 3479. https://doi.org/10.3390/electronics14173479

APA StyleWoźniak, A., Łakomski, M., & Lisik, Z. (2025). Low-Loss Multicore FIFO Device Based on Chemically Etched Optical Fibers. Electronics, 14(17), 3479. https://doi.org/10.3390/electronics14173479