Precision Position Servo PMSM Fast-Response Control Based on Trajectory Planning and ADRC

Abstract

1. Introduction

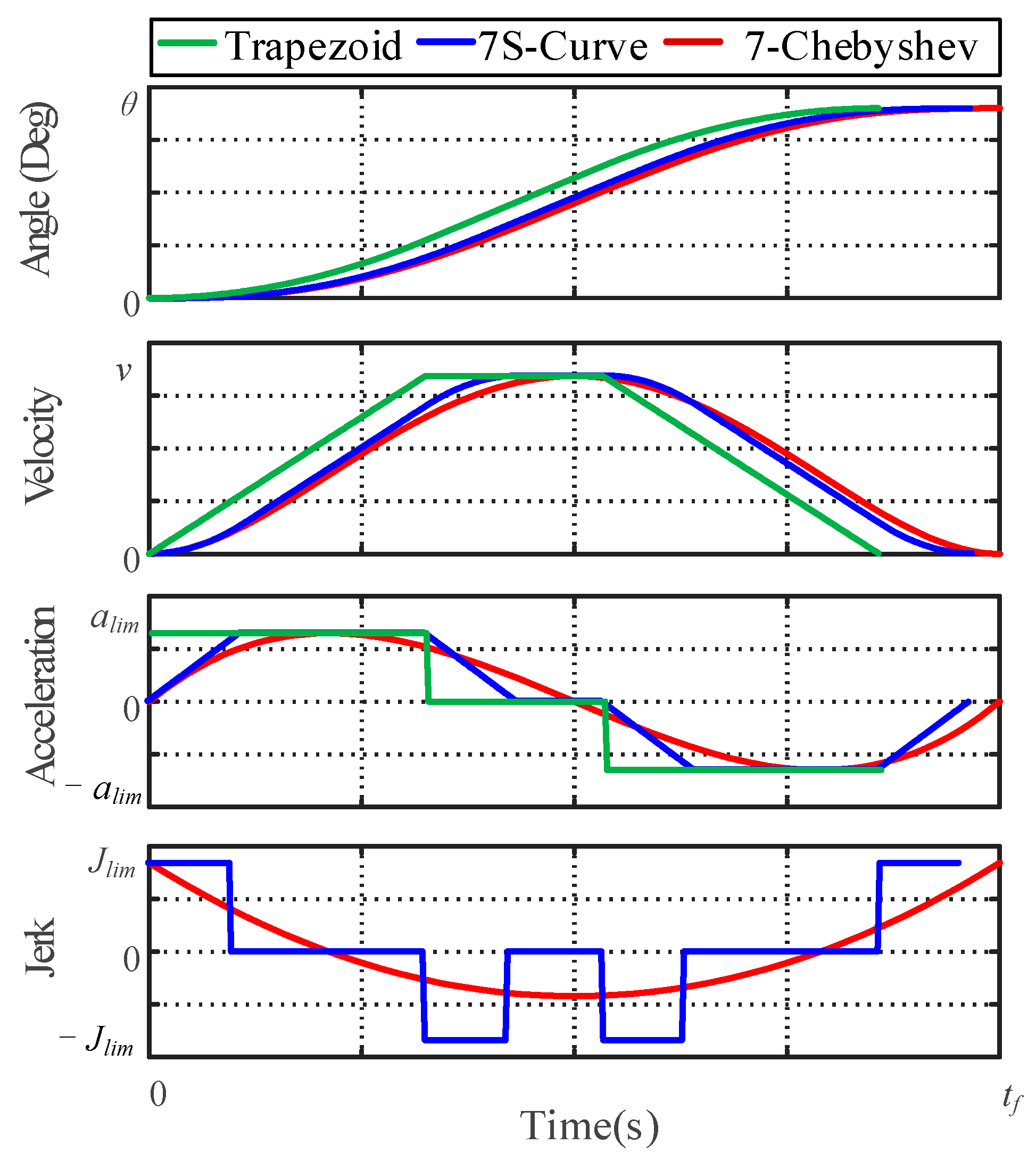

2. Smooth and Time-Optimal Trajectory Planning

2.1. Chebyshev Polynomials

2.2. Servo Pmsm Short-Term Overload Constraints

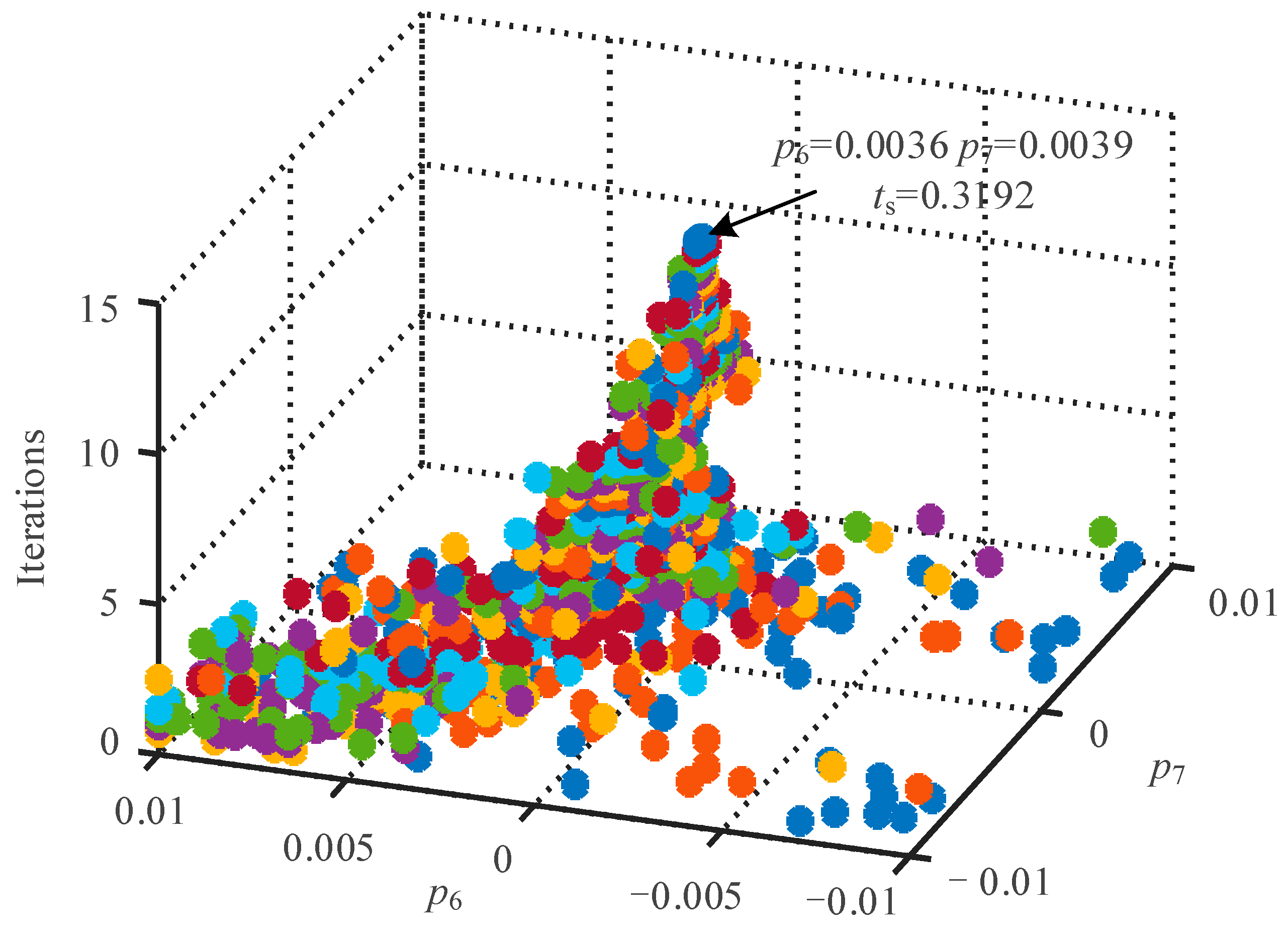

2.3. Optimal Trajectory Solution Based on FPSO Algorithm

- (1)

- The algorithm parameters are initialized, k = 0 is set, and the iteration parameters such as the inertia factor and learning factor are set;

- (2)

- N initial particles are randomly generated within the given parameter range, and the particles are distributed within the constraint conditions;

- (3)

- The local optimal solutions and global optimal solutions Pbi(k) and Pg(k) for each particle are updated;

- (4)

- The dynamic learning factor parameters are calculated, the particle velocity vector is calculated, and the position information of the next iteration of the particle is updated according to the particle velocity and the current position of the particle;

- (5)

- After the maximum number of iterations or the global optimal solution remains unchanged after many operations, the calculation is terminated and the CPMT is constructed according to the particle coordinate parameters.

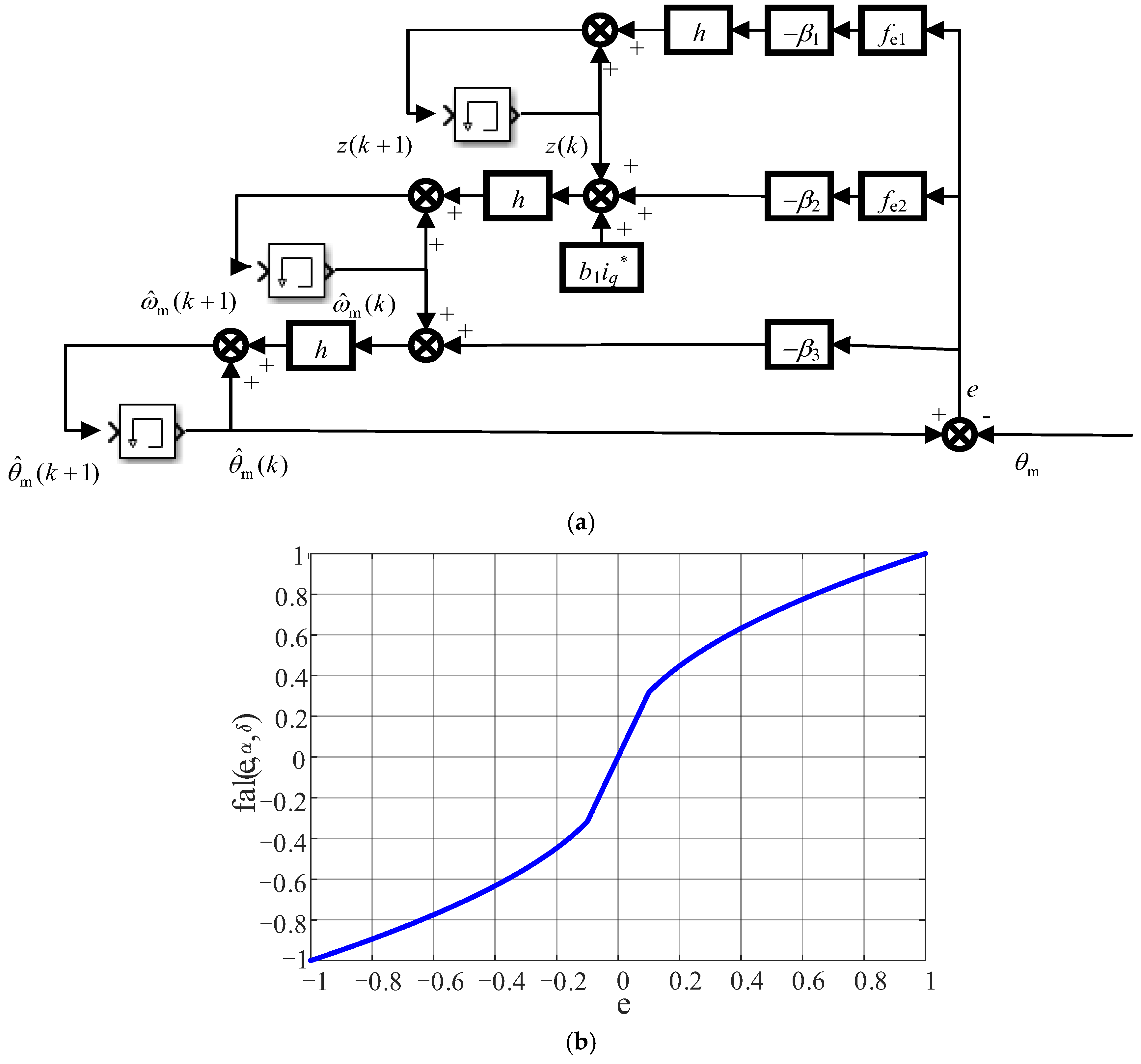

3. ADRC Trajectory Tracking Control Strategy

3.1. Analysisi of Cascading PI Outer-Loop Control

3.2. Tracking Control Based on Non-Cascading ADRC

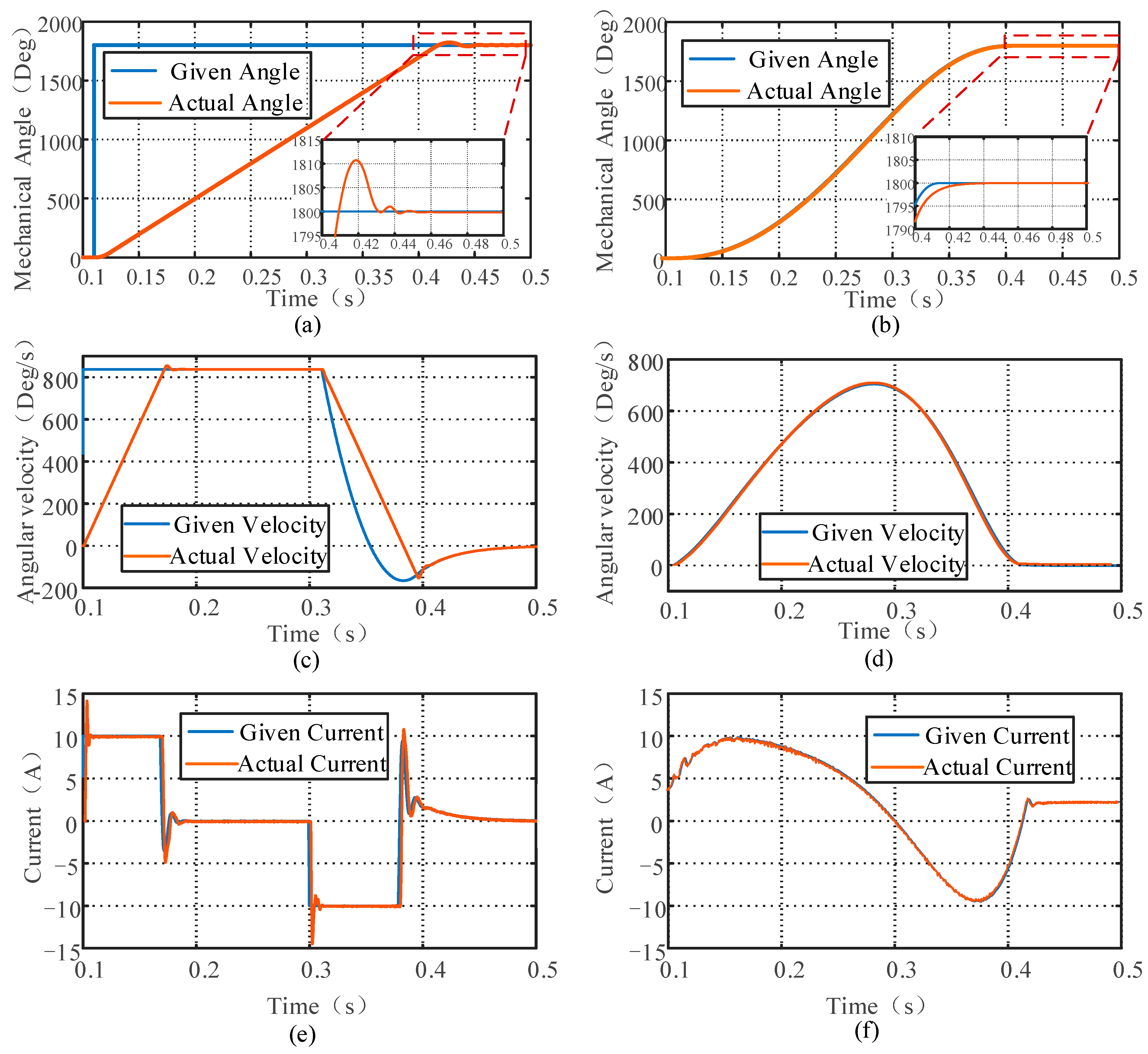

3.3. Simulation Verification of Proposed Control Strategy

4. Experiment Verification

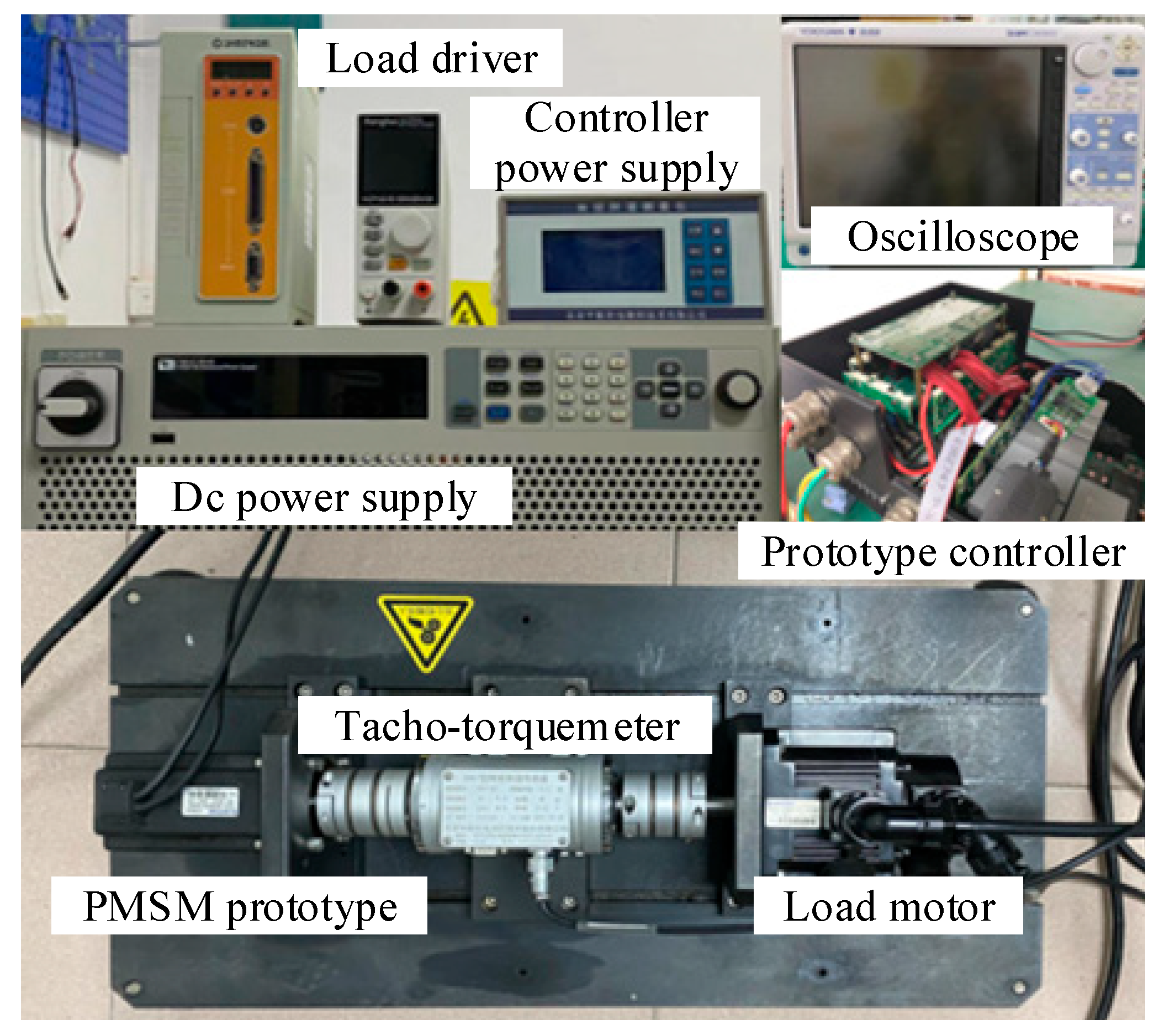

4.1. Prototype Test Platform

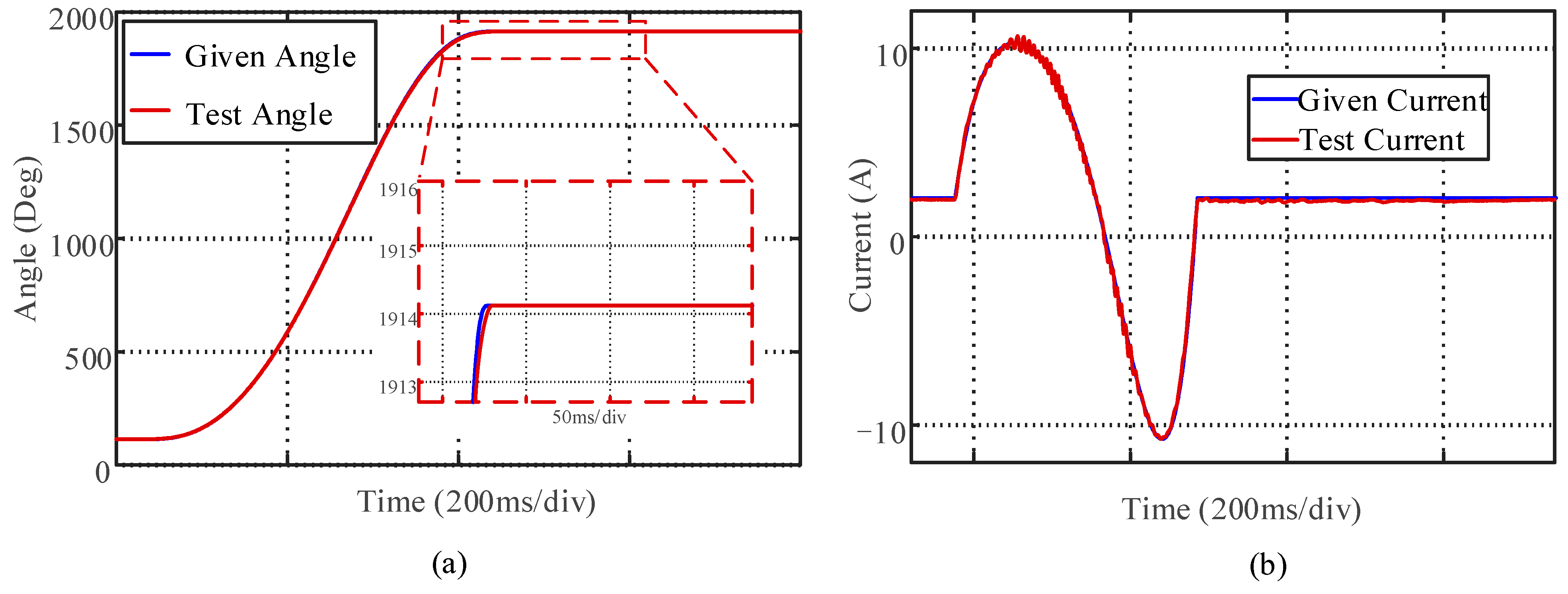

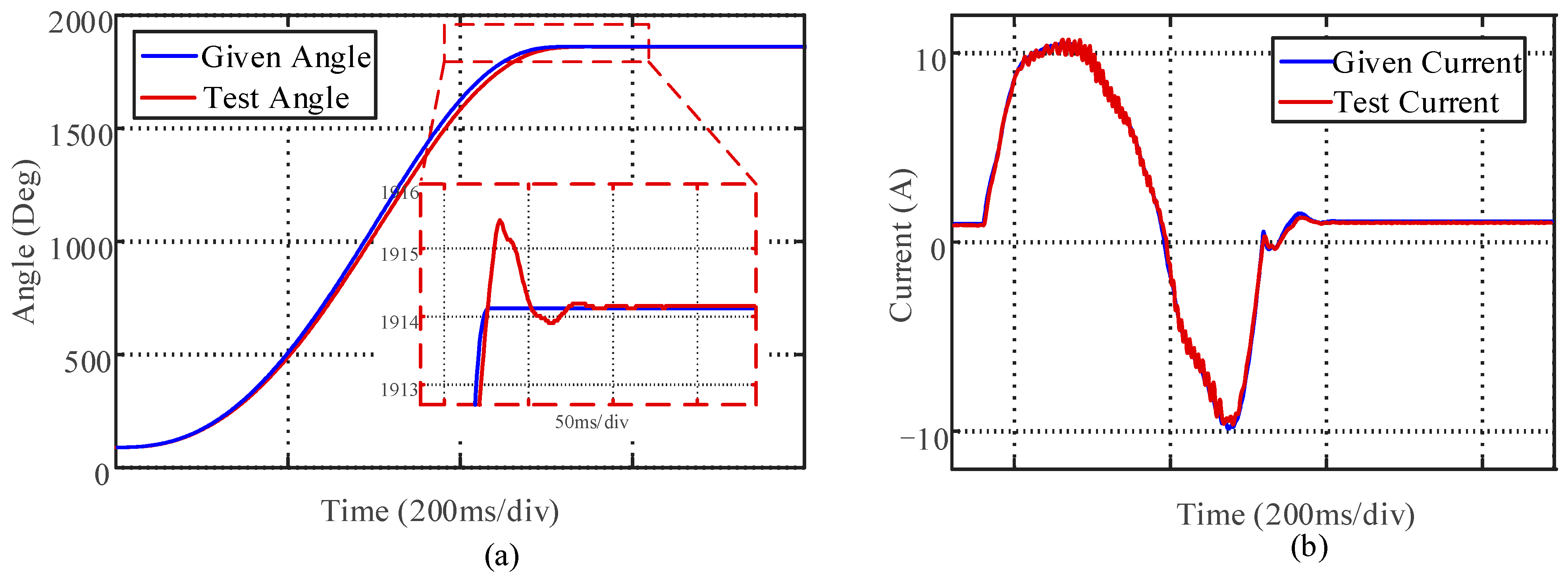

4.2. Trajectory Planning and Control Strategy Test Results

5. Conclusions

- (1)

- Based on the seventh-degree Chebyshev polynomial and the dynamic boundary conditions under the short-term overload of the PMSM, it is possible to take into account the fast-response performance while ensuring the continuous impact during the motion of the high-precision position servo system. Meanwhile, the FPSO algorithm can quickly solve the trajectory planning function and realize the online application of the impact-time-optimal trajectory planning.

- (2)

- By introducing the ADRC strategy, the problem of the decline in trajectory tracking performance of the servo PMSM system caused by internal and external interference errors is avoided. Directly applying CPMT to the design of the ADRC can fully take into account both smooth and fast-response performance. Through the prototype experiment test, the steady-state positioning time can be reduced to 0.35 s during the positioning process at 1800°. Compared with the traditional S-shaped trajectory curve or PI closed-loop control strategies, the positioning time can be reduced by more than 12.5%, and the smoothness of the trajectory has also been greatly improved.

- (3)

- The method proposed in this paper, through the integrated coordination of trajectory planning and control strategies, can achieve smooth and rapid response operation of high-precision position servo PMSM systems and can be widely applied in point-to-point position servo systems, such as in aerospace, industrial automation production lines, and multi-axis systems. Meanwhile, in future research, it is also necessary to take into account the computing power requirements of FPSO and the complexity of ADRC parameters, and continue to carry out research on the structure of FPSO algorithms, the adjustment and optimization of ADRC parameters, etc., in order to improve the applicability and practicability of the proposed method.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shi, S.; Dai, L.; Min, H.; Yang, J.; Li, S. Prescribed-Time Nonsingular Terminal Sliding Mode Control and Its Application in PMSM Servo Systems. IEEE Trans. Ind. Electron. 2025, 72, 3072–3081. [Google Scholar] [CrossRef]

- Cui, P.; Zheng, Z.; Fu, J.; Zhang, Q.; An, L. A Fault-Tolerant Control Method for a PMSM Servo Drive System with a Four-Leg Inverter. Electronics 2023, 12, 3857. [Google Scholar] [CrossRef]

- Lv, C.; Wang, B.; Chen, J.; Zhang, R.; Dong, H.; Wan, S. Research on a Torque Ripple Suppression Method of Fuzzy Active Disturbance Rejection Control for a Permanent Magnet Synchronous Motor. Electronics 2024, 13, 1280. [Google Scholar] [CrossRef]

- Wang, P.; Tang, J.; Lin, H.W.; Zhang, F.; Wang, C.; Wang, J.; Shi, L.; Meng, M.Q.-H. MINER-RRT*: A Hierarchical and Fast Trajectory Planning Framework in 3D Cluttered Environments. IEEE Trans. Autom. Sci. Eng. 2025, 22, 10973–10985. [Google Scholar] [CrossRef]

- Chen, Z.; Helian, B.; Zhou, Y.; Geimer, M. An Integrated Trajectory Planning and Motion Control Strategy of a Variable Rotational Speed Pump-Controlled Electro-Hydraulic Actuator. IEEE/ASME Trans. Mechatron. 2023, 28, 588–597. [Google Scholar] [CrossRef]

- Wang, M.; Xiao, J.; Zhao, W.; Liu, H. A Real-Time Trajectory Generator With 3rd-Order Constraints Satisfaction Through Velocity Mode Evolution. IEEE Trans. Ind. Electron. 2025, 72, 6205–6214. [Google Scholar] [CrossRef]

- Bai, Y.; Chen, X.; Sun, H.; Yang, Z. Time-Optimal Freeform S-Curve Profile Under Positioning Error and Robustness Constraints. IEEE/ASME Trans. Mechatron. 2018, 23, 1993–2003. [Google Scholar] [CrossRef]

- Biagiotti, L.; Melchiorri, C. Optimization of Generalized S-Curve Trajectories for Residual Vibration Suppression and Compliance With Kinematic Bounds. IEEE/ASME Trans. Mechatron. 2021, 26, 2724–2734. [Google Scholar] [CrossRef]

- Fang, S.; Cao, J.; Zhang, Z.; Zhang, Q.; Cheng, W. Study on High-Speed and Smooth Transfer of Robot Motion Trajectory Based on Modified S-Shaped Acceleration/Deceleration Algorithm. IEEE Access 2020, 8, 199747–199758. [Google Scholar] [CrossRef]

- Su, T.; Cheng, L.; Wang, Y.; Liang, X.; Zheng, J.; Zhang, H. Time-Optimal Trajectory Planning for Delta Robot Based on Quintic Pythagorean-Hodograph Curves. IEEE Access 2018, 6, 28530–28539. [Google Scholar] [CrossRef]

- Huang, M.S.; Hsu, Y.L.; Fung, R.F. Minimum-Energy Point-to-Point Trajectory Planning for a Motor-Toggle Servomechanism. IEEE/ASME Trans. Mechatron. 2012, 17, 337–344. [Google Scholar] [CrossRef]

- Deng, J.; Cui, X.; Tang, W.; Chen, W.; Sun, J. Research on Climbing Motion Planning of Inchworm Robot Based on Improved PSO. In Proceedings of the 2024 3rd International Conference on Service Robotics (ICoSR), Hangzhou, China, 26–28 July 2024; pp. 43–48. [Google Scholar]

- Wang, W.; Liu, C.; Liu, S.; Song, Z.; Zhao, H.; Dai, B. Current Harmonic Suppression for Permanent-Magnet Synchronous Motor Based on Chebyshev Filter and PI Controller. IEEE Trans. Magn. 2021, 57, 1–6. [Google Scholar] [CrossRef]

- He, X. Hybrid ADRC and PI Controller Design for Three-Phase Inverter with Nonlinear Loads. IEEE Access 2024, 12, 130857–130864. [Google Scholar] [CrossRef]

- Lixian, A.S.; Rahiman, W. A Compound Control for Hybrid Stepper Motor Based on PI and Sliding Mode Control. IEEE Access 2024, 12, 163536–163550. [Google Scholar] [CrossRef]

- Xia, C.; Ji, B.; Yan, Y. Smooth Speed Control for Low-Speed High-Torque Permanent-Magnet Synchronous Motor Using Proportional–Integral–Resonant Controller. IEEE Trans. Ind. Electron. 2015, 62, 2123–2134. [Google Scholar] [CrossRef]

- Mohamed, M.; Alaas, Z.M.; Al Faiya, B.; Hegazy, H.Y.; Mohamed, W.I.; Abdelwahab, S.A.M. Performance Improvement of Grid-Connected PV-Wind Hybrid Systems Using Adaptive Neuro-Fuzzy Inference System and Fuzzy FOPID Advanced Control With OPAL-RT. IEEE Access 2025, 13, 55996–56020. [Google Scholar] [CrossRef]

- Tarkhani, R.; Krim, S.; Mansouri, M.; Mimouni, M.F. Robust Current Sensor Fault-Tolerant Controller Using Third Order Super-Twisting Sliding Mode Observer and Controller for Induction Motors. IEEE Access 2025, 13, 52841–52862. [Google Scholar] [CrossRef]

- Yin, Y.; Liu, L.; Vazquez, S.; Xu, R.; Dong, Z.; Liu, J.; Leon, J.I.; Wu, L.; Franquelo, L.G. Disturbance and Uncertainty Attenuation for Speed Regulation of PMSM Servo System Using Adaptive Optimal Control Strategy. IEEE Trans. Transp. Electrif. 2023, 9, 3410–3420. [Google Scholar] [CrossRef]

- Tian, S.; Liu, K.-Z.; Zhang, M.; Lu, C.; Wu, M.; She, J. Improved Equivalent-Input-Disturbance Method for Nonlinear Repetitive-Control Systems: Integration With High-Order Sliding-Mode Control. IEEE/ASME Trans. Mechatron. 2025, 30, 692–702. [Google Scholar] [CrossRef]

- Liu, Z.-H.; Nie, J.; Wei, H.-L.; Chen, L.; Li, X.-H.; Lv, M.-Y. Switched PI Control Based MRAS for Sensorless Control of PMSM Drives Using Fuzzy-Logic-Controller. IEEE Open J. Power Electron. 2022, 3, 368–381. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Nguyen, T.T.; Nguyen, V.Q.; Le, K.M.; Tran, H.N.; Jeon, J.W. An Adaptive Sliding-Mode Controller with a Modified Reduced-Order Proportional Integral Observer for Speed Regulation of a Permanent Magnet Synchronous Motor. IEEE Trans. Ind. Electron. 2022, 69, 7181–7191. [Google Scholar] [CrossRef]

- Fang, Q.; Zhou, Y.; Ma, S.; Zhang, C.; Wang, Y.; Huangfu, H. Electromechanical Actuator Servo Control Technology Based on Active Disturbance Rejection Control. Electronics 2023, 12, 1934. [Google Scholar] [CrossRef]

- Liu, G.; Fang, L.; Liu, Z.; Chen, Q.; Zhang, J. Active Disturbance Rejection Control of a Magnetic Screw Motor for High Tracking Performance. IEEE Trans. Power Electron. 2022, 37, 9641–9651. [Google Scholar] [CrossRef]

- Zhu, M.; Wu, Y. ChevOpt: Continuous-Time State Estimation by Chebyshev Polynomial Optimization. IEEE Trans. Signal Process. 2022, 70, 3136–3147. [Google Scholar] [CrossRef]

- NChen, N.; Yang, S.; An, S. A New Hybrid Algorithm Based on PSO and Fireworks Algorithm for Optimal Design of Metasurface Absorber in RF Energy Harvesting. IEEE Trans. Magn. 2025, 61, 1–4. [Google Scholar]

| Parameter | Value |

|---|---|

| Armature resistance (Ω) | 1.92 |

| D-axis inductance (mH) | 8.5 |

| Q-axis inductance (mH) | 11.7 |

| Magnet flux linkage (Wb) | 0.036 |

| Pole pairs | 4 |

| Rated torque (Nm) | 3 |

| Peak torque (Nm) | 6 |

| Output power (W) | 750 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, B.; Li, H.; Xiang, X.; Zhou, T. Precision Position Servo PMSM Fast-Response Control Based on Trajectory Planning and ADRC. Electronics 2025, 14, 2062. https://doi.org/10.3390/electronics14102062

Yuan B, Li H, Xiang X, Zhou T. Precision Position Servo PMSM Fast-Response Control Based on Trajectory Planning and ADRC. Electronics. 2025; 14(10):2062. https://doi.org/10.3390/electronics14102062

Chicago/Turabian StyleYuan, Bin, Hui Li, Xuewei Xiang, and Tong Zhou. 2025. "Precision Position Servo PMSM Fast-Response Control Based on Trajectory Planning and ADRC" Electronics 14, no. 10: 2062. https://doi.org/10.3390/electronics14102062

APA StyleYuan, B., Li, H., Xiang, X., & Zhou, T. (2025). Precision Position Servo PMSM Fast-Response Control Based on Trajectory Planning and ADRC. Electronics, 14(10), 2062. https://doi.org/10.3390/electronics14102062