Smart Water ATM with Arduino Integration, RFID Authentication, and Dynamic Dispensing for Enhanced Hydration Practices

Abstract

1. Introduction

- Most of the water coolers in Singapore are the Point of Use (POU) type, which must be attached to existing water lines. Hence, there are concerns about hygiene and proximity to the bathroom.

- At eating establishments such as food centers, water coolers may face hygiene issues caused by individuals spitting saliva or phlegm. This contamination can compromise the cleanliness of the water dispenser. This might discourage potential users who are put off by its unappealing appearance.

- Existing water coolers in Singapore function in a conventional manner where users need to press a button to regulate the water flow from the nozzle. This increases the likelihood of spillage and scalding.

- Traditional water coolers only dispense water without tracking the user’s water intake. Therefore, it does not monitor and remind individual users to drink up.

2. Literature Review

2.1. Types of Smart Water ATMs

2.2. Various Ways of Monitoring Water Level

2.3. Various Ways of Measuring Water Flow

2.4. Case Studies of Implemented Water ATMs

2.5. Summary

3. Proposed Work

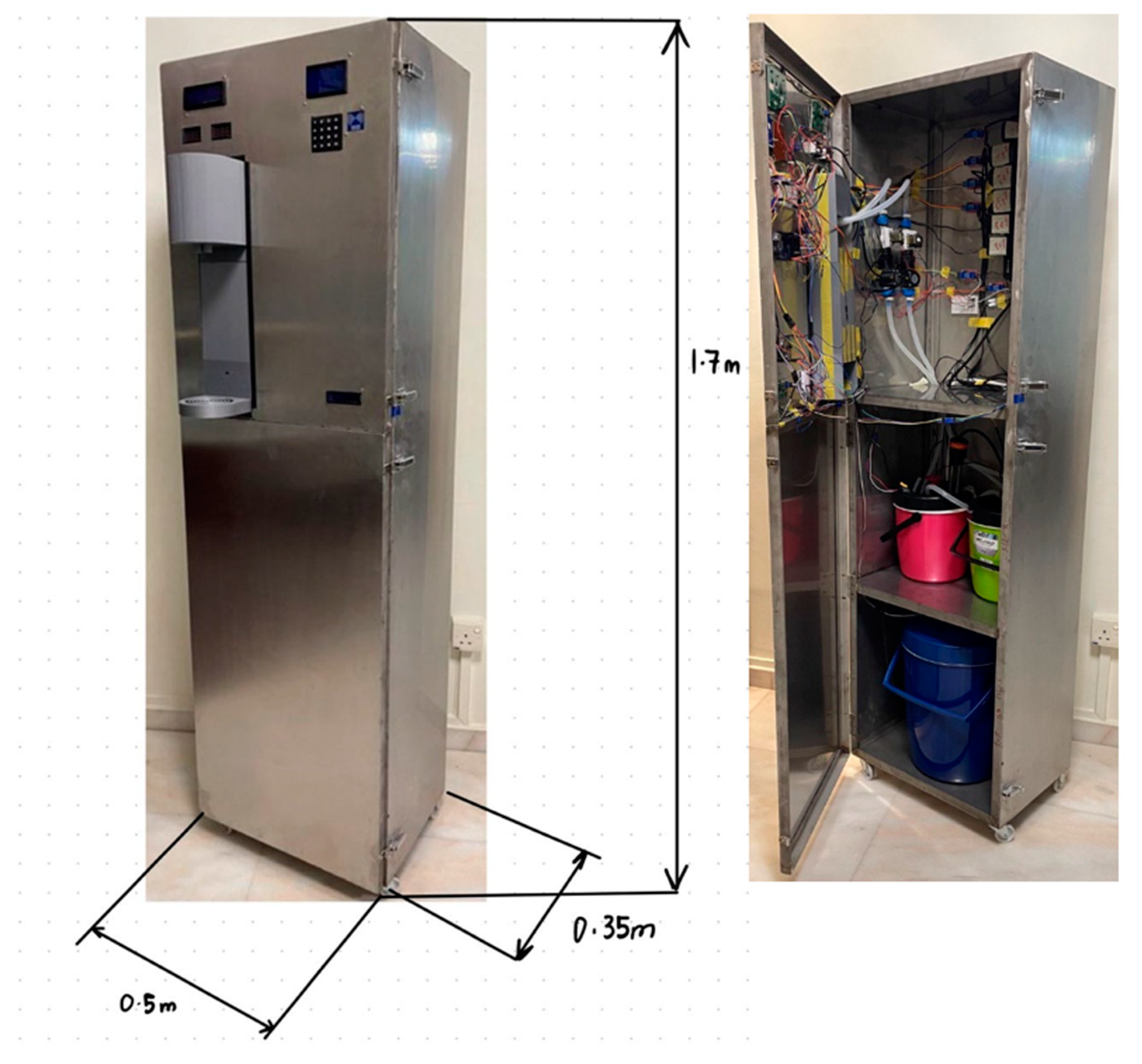

Mechanical Design

4. Method

4.1. Overall Frame Fabrication

4.2. Water Dispensing Unit

4.3. Assembly of Electronic Components

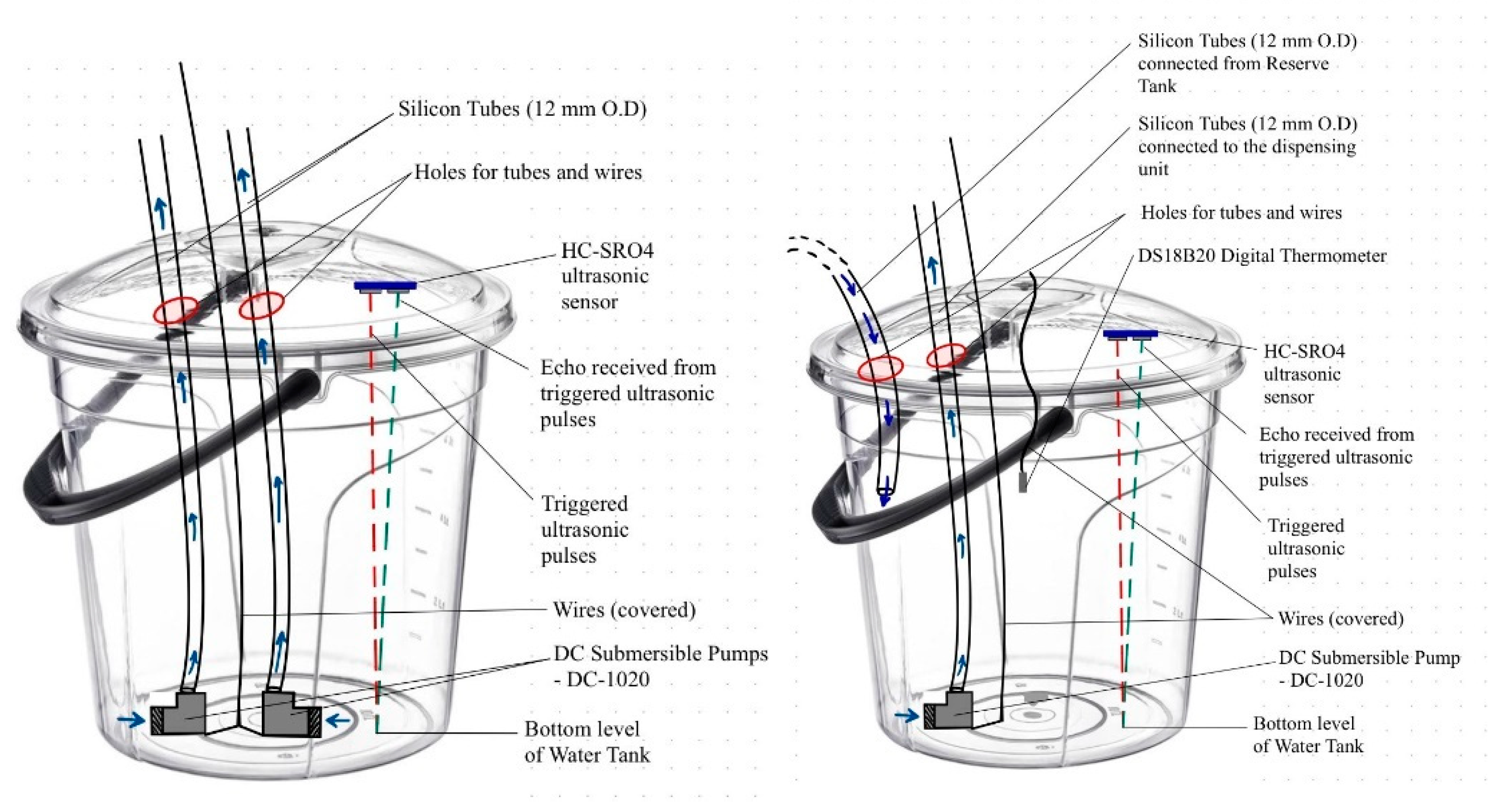

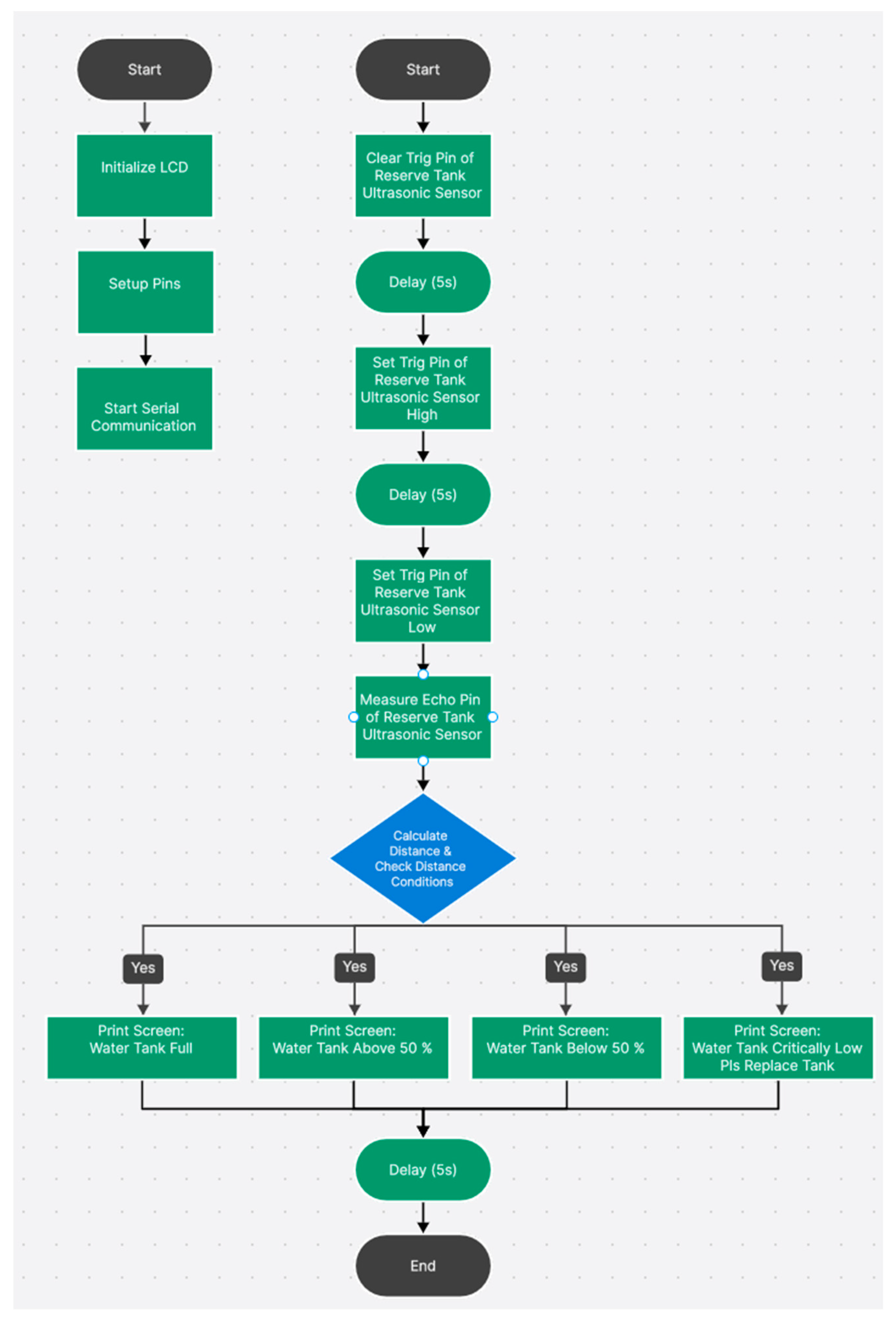

4.4. Water Level Monitoring System

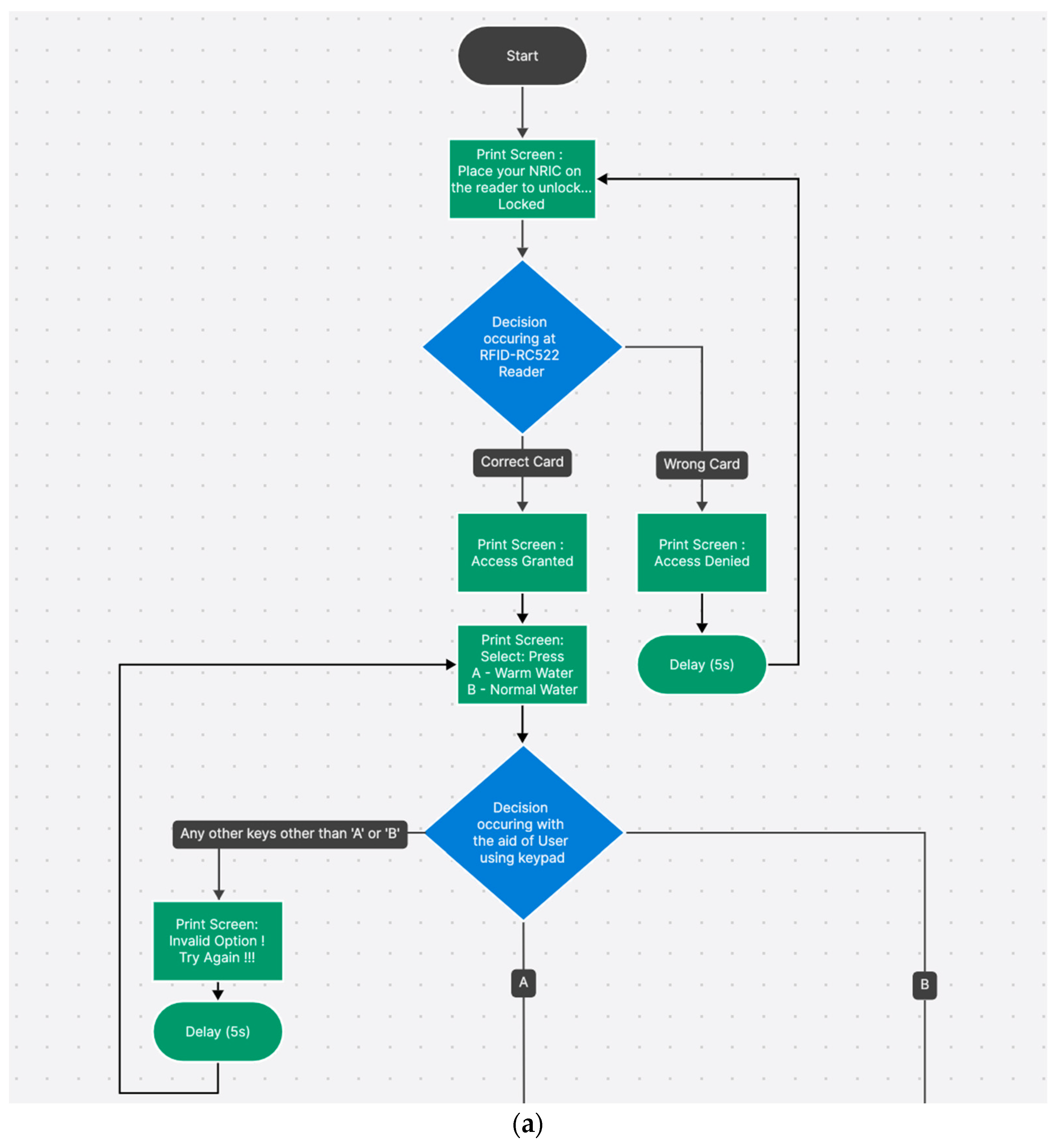

| 1. Start 2. Display “Place NRIC Card on RFID Scanner” 3. Wait for NRIC Card to be placed on RFID Scanner 4. If NRIC Card detected 5. Display “Access Granted” for 5 s 6. Display “Select Option: A—Warm Water, B—Normal Water” 7. Wait for user input 8. If user input is ‘A’ or ‘B’ 9. Wait for user to press ‘*’ 10. If user presses ‘*’ 11. Dispense selected water (Warm Water or Normal Water) 12. Else 13. Display “Invalid Option! Try Again!!!” for 5 s 14. Go to step 6 15. Else 16. Display “Invalid Option! Try Again!!!” for 5 s 17. Go to step 6 18. Else 19. Display “Access Denied!” for 5 s 20. Go to step 2 21. End |

| 1. Start 2. If Option A is selected 3. Display “Option A Selected” 4. Display “Enter amount (001–999 mL) followed by ‘*’ to confirm:” 5. Wait for user input 6. If user input is within range 001–999 7. If user presses ‘*’ 8. Display chosen amount on screen 9. If chosen amount is within range 250–999 10. Display “Place the bottle on the dispenser” 11. Wait for bottle detection by infrared sensor 12. If bottle detected 13. Display “Dispensing” on screen 14. Dispense water using water flow sensor 1, solenoid 1, and water pump 1 15. Display amount dispensing on screen 16. If dispensing complete 17. Display “Completed!” 18. End sequence 19. Else 20. Display “Bottle not detected! Pls Place Bottle!” 21. Go to step 11 22. Else 23. Display “Invalid entry! Key Within Range! 250~999 mL” 24. Go to step 4 25. Else 26. Go to step 4 27. Else 28. Display “Invalid entry! Key Within Range! 001~999 mL” 29. Go to step 4 30. End |

| 1. Start 2. If Option B is selected 3. Display “Option B Selected” 4. Display “Enter amount (001–999 mL) followed by ‘*’ to confirm:” 5. Wait for user input 6. If user input is within range 001–999 7. If user presses ‘*’ 8. Display chosen amount on screen 9. If chosen amount is within range 250–999 10. Display “Place the bottle on the dispenser” 11. Wait for bottle detection by infrared sensor 12. If bottle detected 13. Display “Dispensing” on screen 14. Dispense water using water flow sensor 2, solenoid 2, and water pump 2 15. Display amount dispensing on screen 16. If dispensing complete 17. Display “Completed!” 18. End sequence 19. Else 20. Display “Bottle not detected! Pls Place Bottle!” 21. Go to step 11 22. Else 23. Display “Invalid entry! Key Within Range! 250~999 mL” 24. Go to step 4 25. Else 26. Go to step 4 27. Else 28. Display “Invalid entry! Key Within Range! 001~999 mL” 29. Go to step 4 30. End |

| 1. Start 2. After each dispensing operation 3. Check water level in Tank 1 (Warm Water) using ultrasonic sensor 4. If water level is lowered 5. Signal Mega Board to trigger specific pump at Reserve Tank 6. Pump water until water level reaches targeted line 7. Stop water pump 8. Check water level in Tank 2 (Normal Water) using ultrasonic sensor 9. If water level is lowered 10. Signal Mega Board to trigger specific pump at Reserve Tank 11. Pump water until water level reaches targeted line 12. Stop water pump 13. Measure water level in Reserve Tank using ultrasonic sensor 14. If water level is full 15. Display “Water Tank Full” on smaller LCD Screen 16. Else if water level is above 50% 17. Display “Water Tank Above 50%” on smaller LCD Screen 18. Else if water level is below 50% 19. Display “Water Tank Below 50%” on smaller LCD Screen 20. Else 21. Display “Water Tank Critically Low, Pls Replace Tank” on smaller LCD Screen 22. End |

5. Result and Conclusions

6. Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Toh, C.M.; Cutter, J.; Chew, S.K. School based intervention has reduced obesity in Singapore. BMJ 2002, 324, 427. [Google Scholar] [CrossRef] [PubMed]

- Gunasinghe, A.; Tharmaseelan, J. Smart Water Dispenser. Int. J. Innov. Sci. Res. Technol. 2019, 4, 365–368. Available online: https://www.researchgate.net/publication/348832527_Smart_Water_Dispenser (accessed on 8 January 2024).

- Nag, A.; Nag, S. Smart Water Dispensing System: A New Approach of Monitoring, Controlling and Dispensing. Res. Appl. Emerg. Technol. 2020, 2, 5–13. [Google Scholar]

- Mujawar, S.; Gawade, S.; Shinde, M.; Udage, K.; Bhandari, M. RFID Card and Coin operated Water ATM. Open Access Int. J. Sci. Eng. 2020, 5, 4–6. Available online: http://oaijse.com/VolumeArticles/FullTextPDF/450_1.RFID_CARD_AND_COIN_OPERATED_WATER_ATM.pdf (accessed on 13 December 2023).

- Singh, P.; Lohani, M.K.; Nagarkoti, R.; Chakrabarti, S.; Karandikar, P.B. Development of Secure Integrated Water ATM as a smart system. In Proceedings of the 2021 International Conference on Artificial Intelligence and Smart Systems (ICAIS), Coimbatore, India, 25–27 March 2021. [Google Scholar] [CrossRef]

- Wahyuni, R.; Sentana, J.T.; Muhardi, M.; Irawan, Y. Water level control monitoring based on Arduino Uno R3 Atmega 238P using LM016L LCD at Stmik Hang Tuah Pekanbaru. J. Robot. Control. (JRC) 2021, 2, 265–269. [Google Scholar] [CrossRef]

- Anuradha, T.; Jadhav, S.; Mahamani, S. Smart water dispenser and monitoring water level in IOT and Android Environment. Int. J. Comput. Sci. Eng. 2019, 7, 810–814. [Google Scholar] [CrossRef]

- Syed Haidzir, S.H.H.; Hisham, O.A.H.; Omar, M. Smart Water Dispenser Monitoring System. In Proceedings of the International Jasin Multimedia & Computer Science Invention & Innovation Exhibition, Melaka, Malaysia, 17–28 February 2020; pp. 32–35. [Google Scholar]

- Tahir, M. Measuring Water Flow Rate and Volume Using Arduino and Flow Sensor; Department of Irrigation & Drainage Faculty of Agricultural Engineering: Faisalabad, Pakistan, 2021. [Google Scholar]

- Sarkar, A. Smart technology to serve urban poor: A case study of water ATMs in a Nairobi slum. Water Util. J. 2019, 22, 1–12. [Google Scholar]

- Kumar, A. Water ATMs of Indian Railways: Causing a Silent Revolution. Vikalpa 2018, 43, 106–114. [Google Scholar] [CrossRef]

- Schmidt, J.J. Pop-up infrastructure: Water ATMs and new delivery networks in India. Water Altern. 2020, 13, 119–140. [Google Scholar]

- Amankwaa, G.; Heeks, R.; Browne, A.L. Water ATMs and access to water: Digitalisation of off-grid water infrastructure in peri-urban Ghana. Water Altern. 2022, 15, 733–753. [Google Scholar]

- Jovanov, E.; Nallathimmareddygari, V.R.; Pryor, J. SmartStuff: A Case Study of a Smart Water Bottle. In Proceedings of the 38th Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Orlando, FL, USA, 16–20 August 2016; pp. 6307–6310. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koh, Y.Y.; Kok, C.L.; Ibraahim, N.; Lim, C.G. Smart Water ATM with Arduino Integration, RFID Authentication, and Dynamic Dispensing for Enhanced Hydration Practices. Electronics 2024, 13, 1657. https://doi.org/10.3390/electronics13091657

Koh YY, Kok CL, Ibraahim N, Lim CG. Smart Water ATM with Arduino Integration, RFID Authentication, and Dynamic Dispensing for Enhanced Hydration Practices. Electronics. 2024; 13(9):1657. https://doi.org/10.3390/electronics13091657

Chicago/Turabian StyleKoh, Yit Yan, Chiang Liang Kok, Navas Ibraahim, and Chin Guan Lim. 2024. "Smart Water ATM with Arduino Integration, RFID Authentication, and Dynamic Dispensing for Enhanced Hydration Practices" Electronics 13, no. 9: 1657. https://doi.org/10.3390/electronics13091657

APA StyleKoh, Y. Y., Kok, C. L., Ibraahim, N., & Lim, C. G. (2024). Smart Water ATM with Arduino Integration, RFID Authentication, and Dynamic Dispensing for Enhanced Hydration Practices. Electronics, 13(9), 1657. https://doi.org/10.3390/electronics13091657