Design and Analysis of an H-Type Pickup for Multi-Segment Wireless Power Transfer Systems

Abstract

1. Introduction

2. Analysis of Electrical and Magnetic Circuits

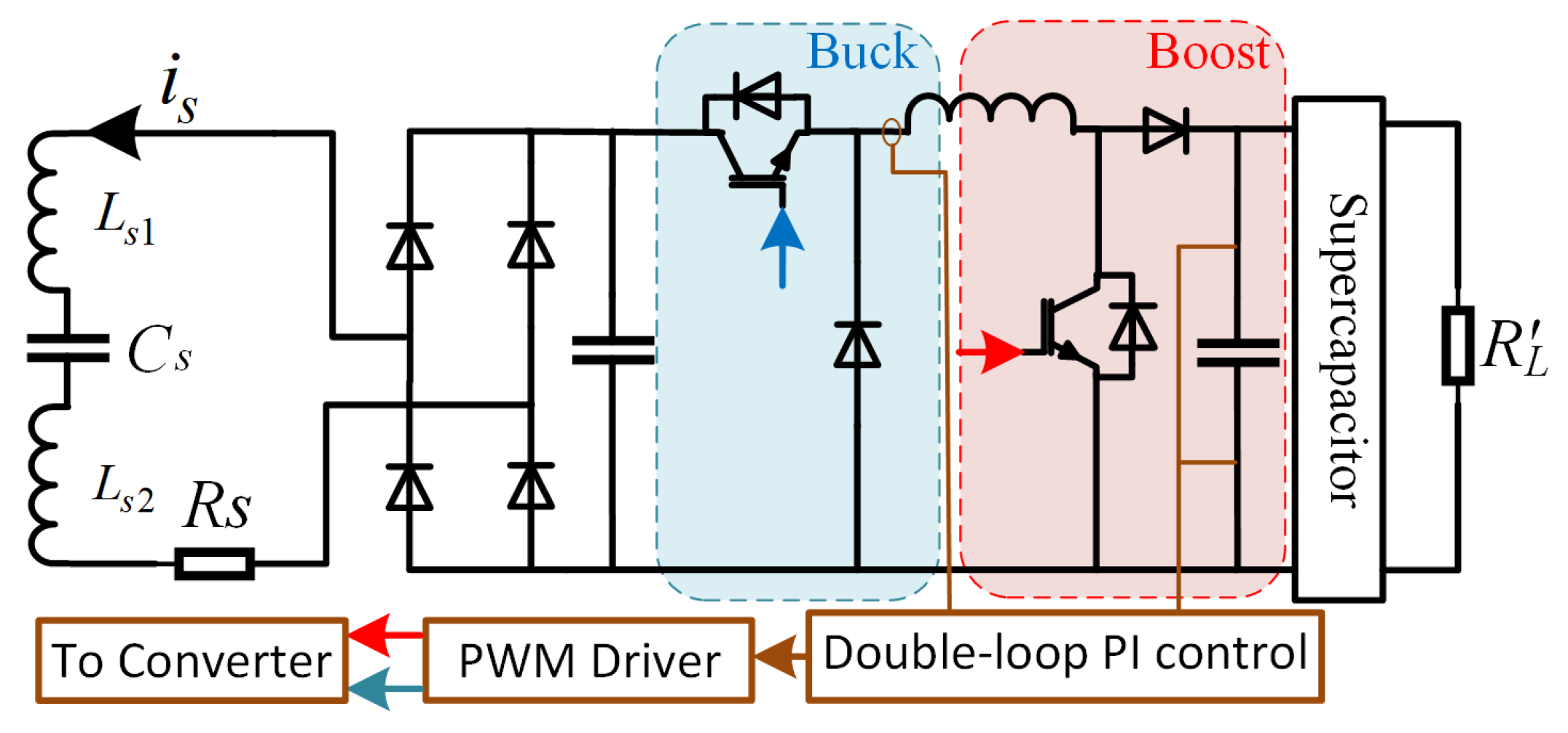

2.1. Multi-Tx LCC-S System Circuit Analysis

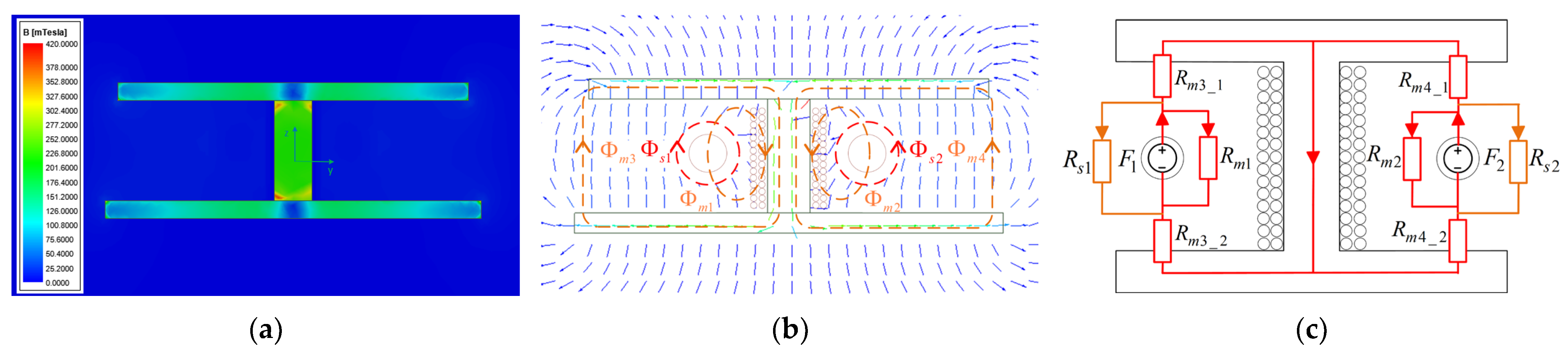

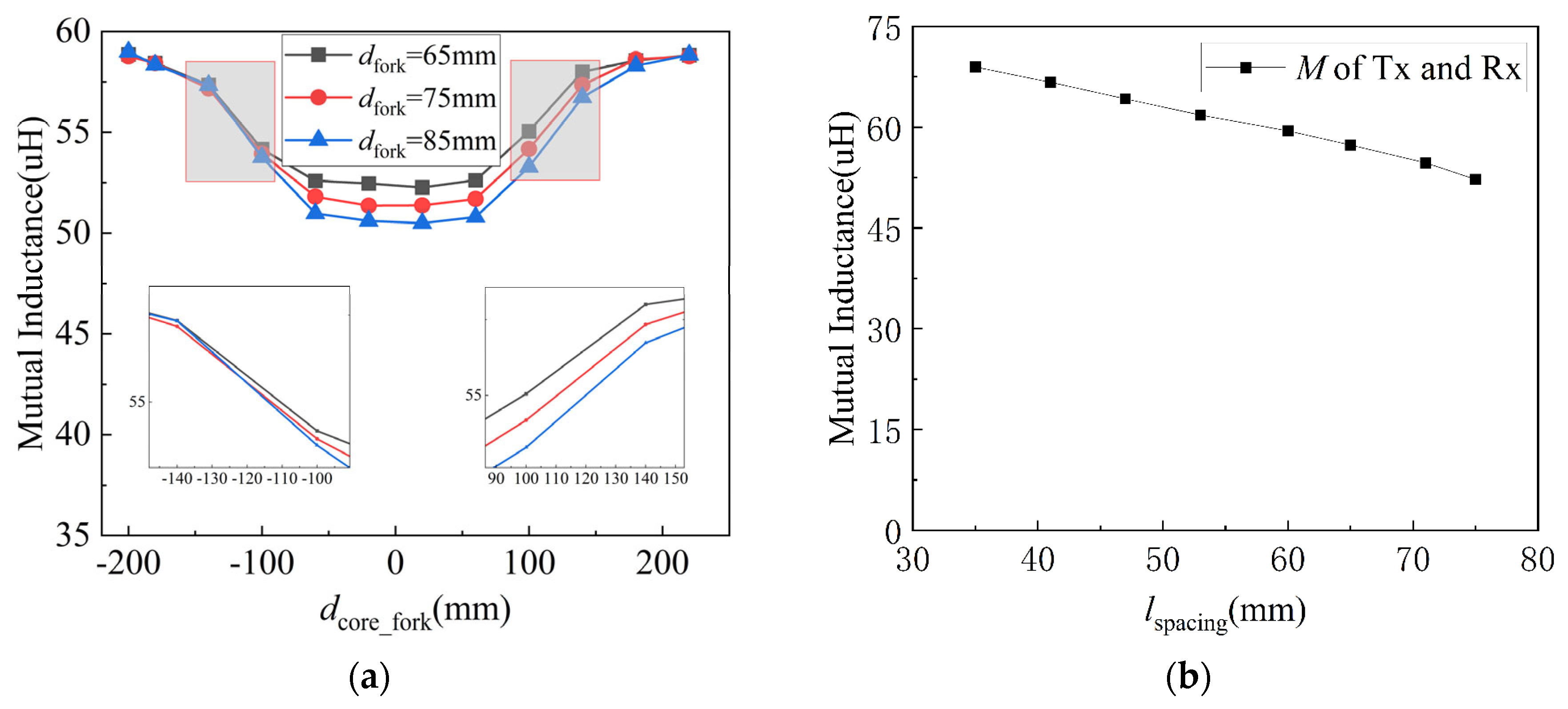

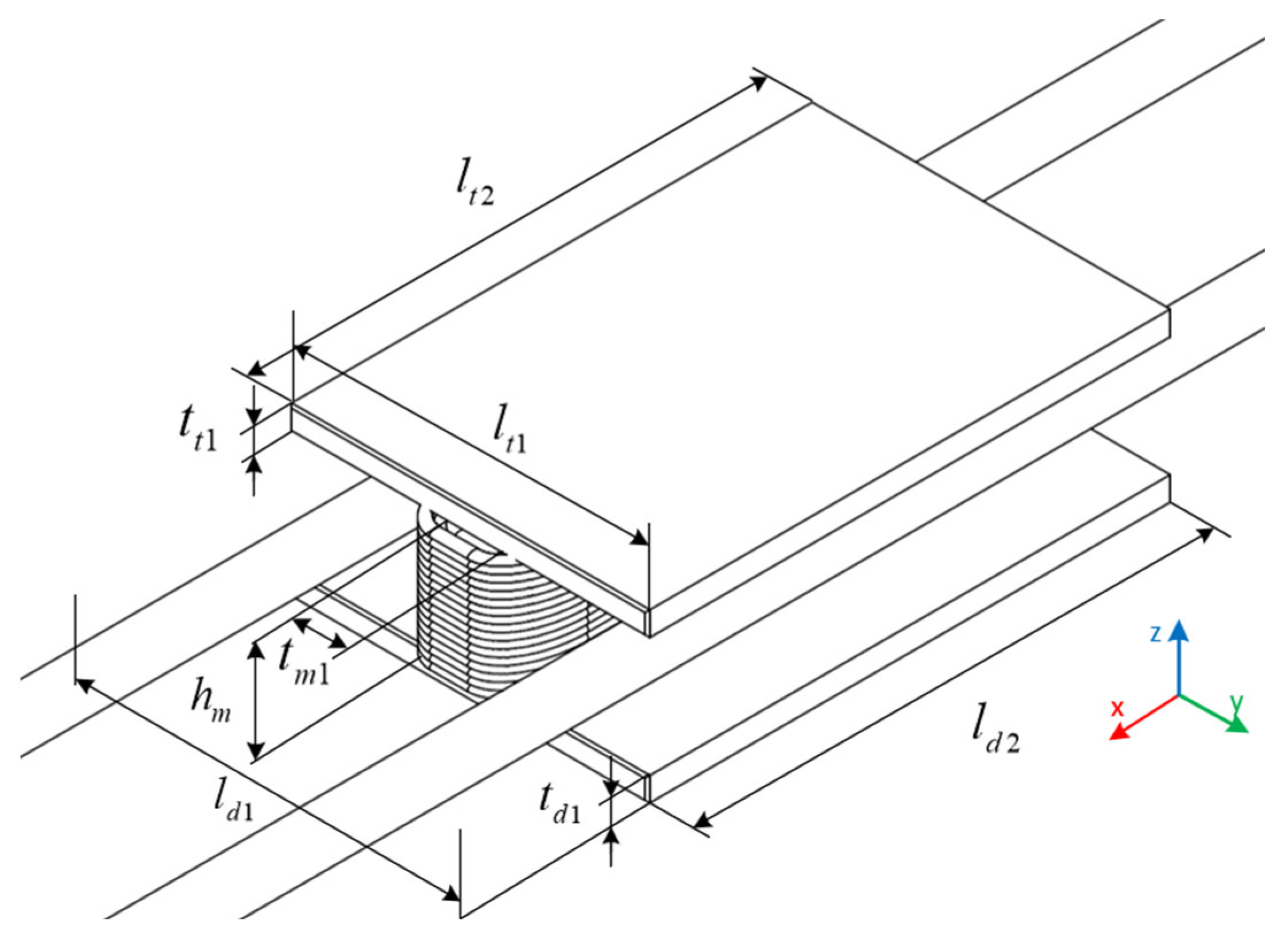

2.2. Magnetic Circuit Analysis of the Coupling Mechanism

2.3. Method of Double Coil Winding

3. Analysis of Track Switching Methods for OHT

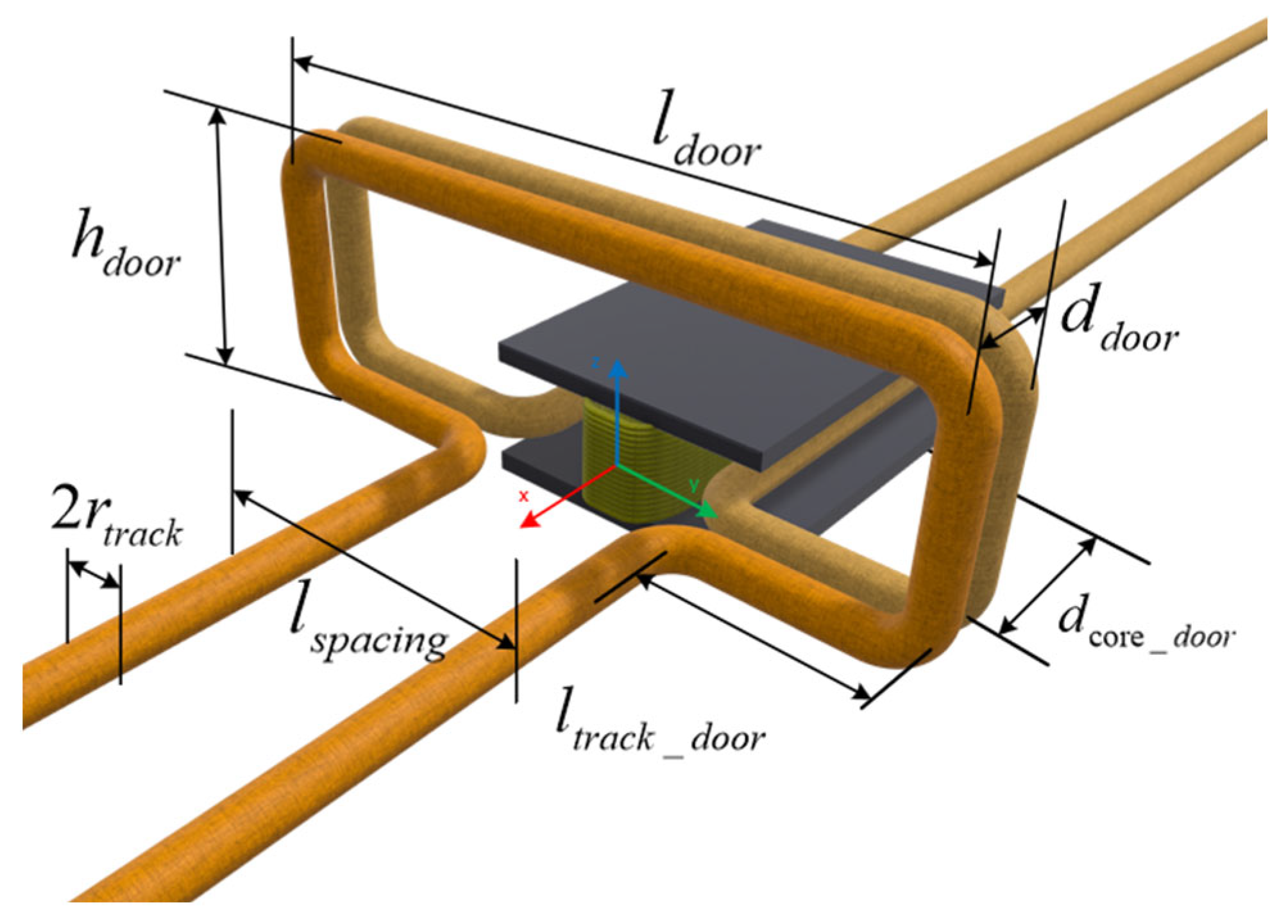

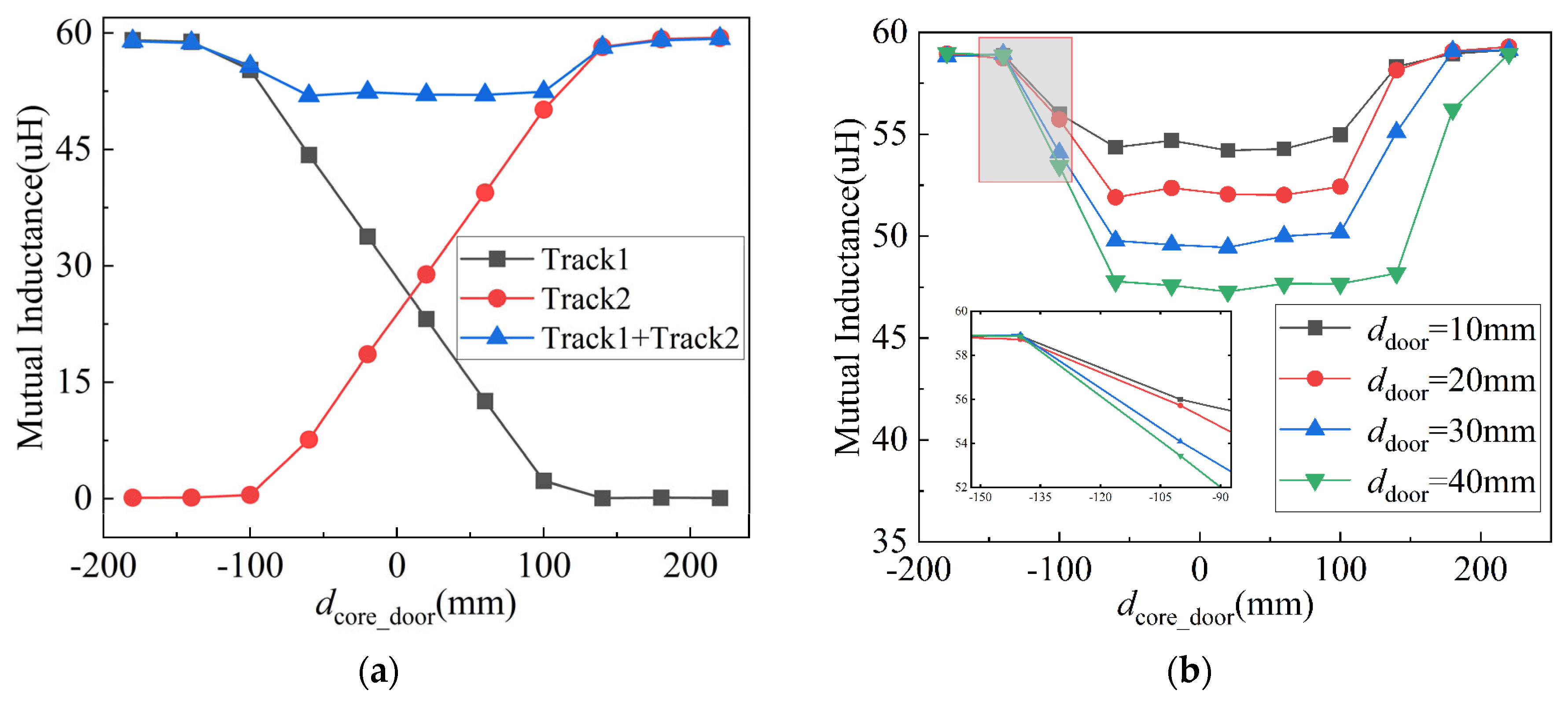

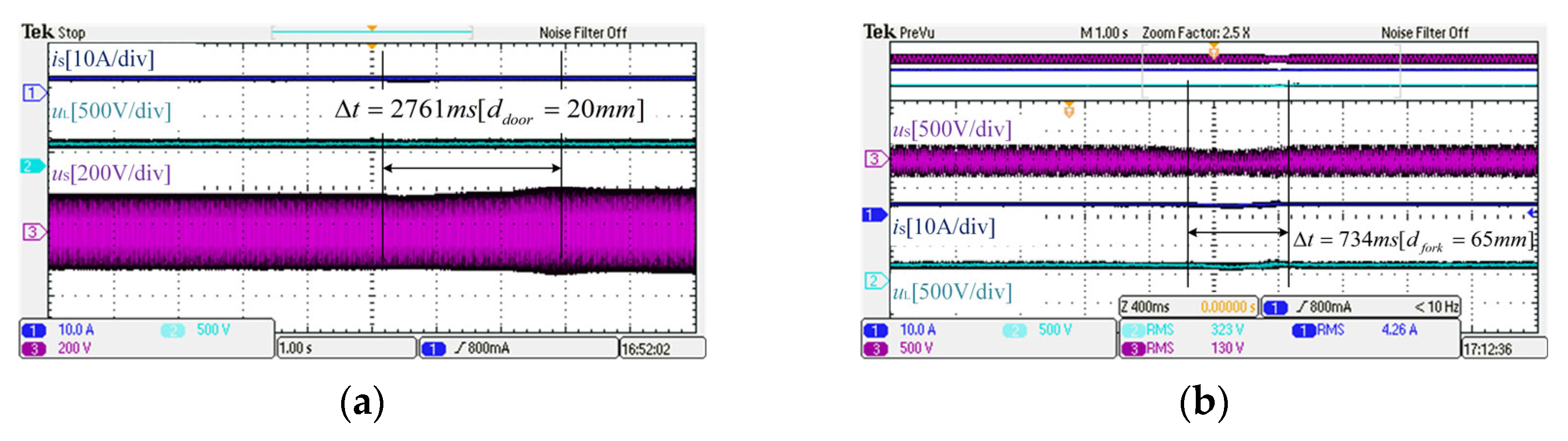

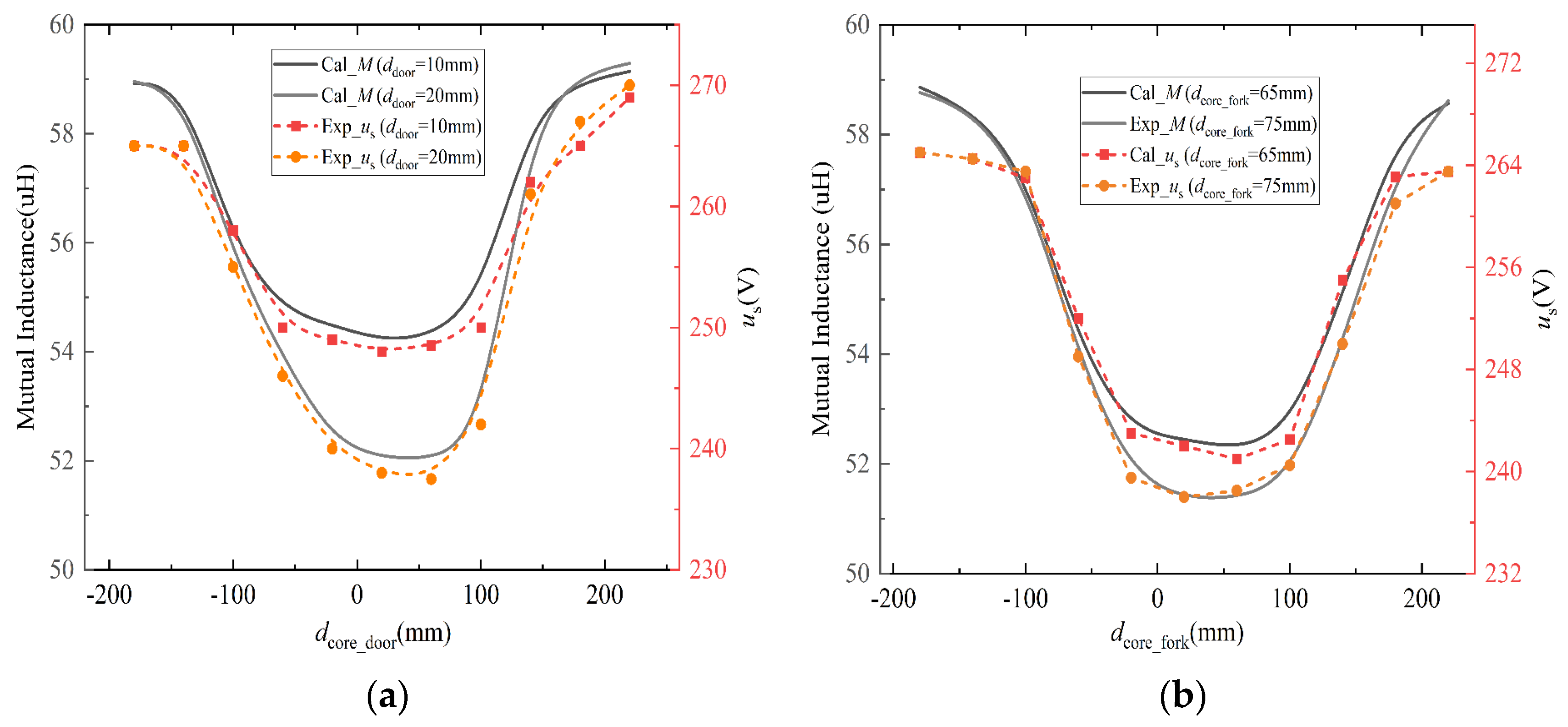

3.1. Cross-Track Operation

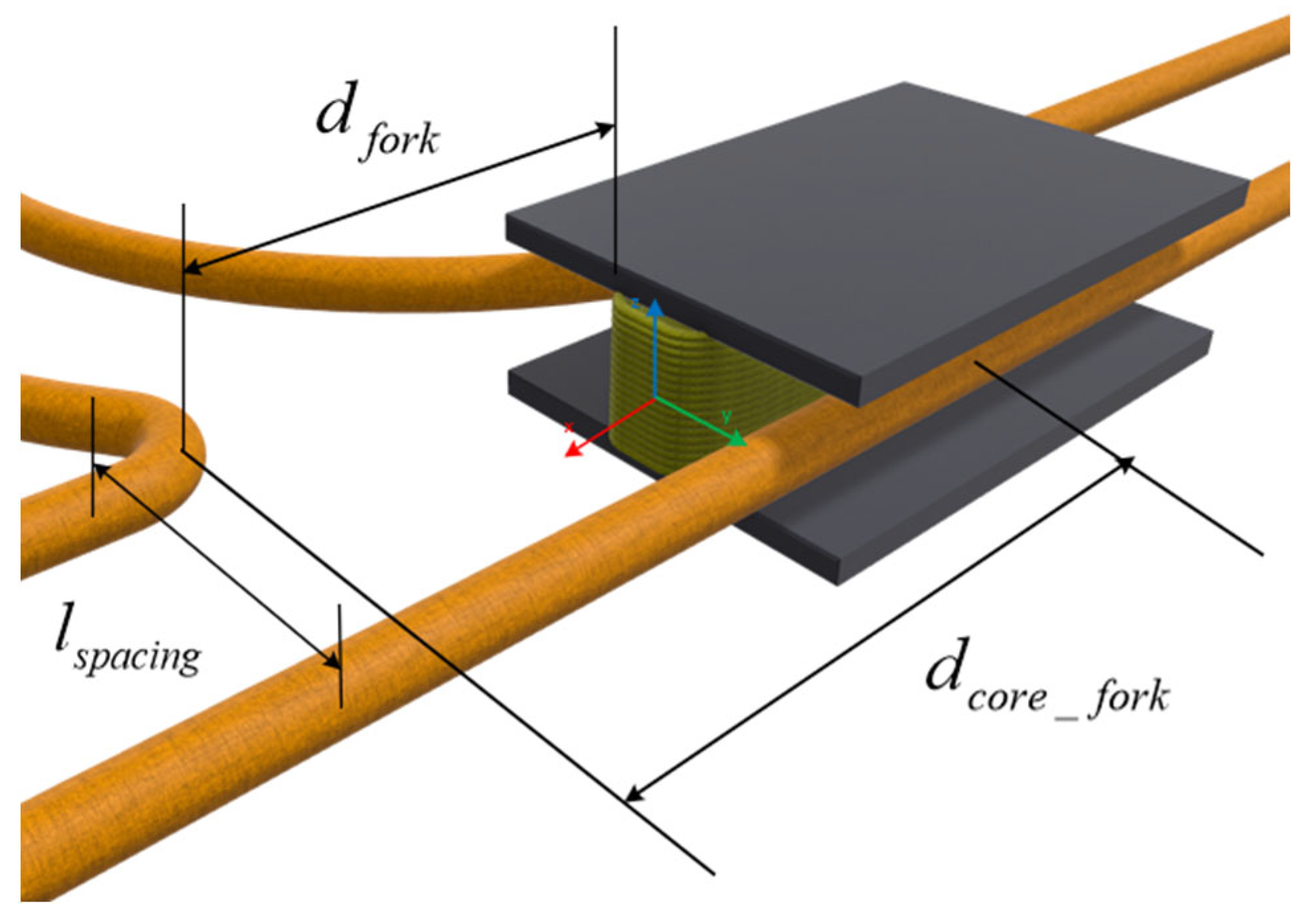

3.2. Turnout Track Running

4. Power Loss and Design Process Analysis

4.1. Analysis of Ferrite Heat and Power Loss

4.2. Analysis of Design Process

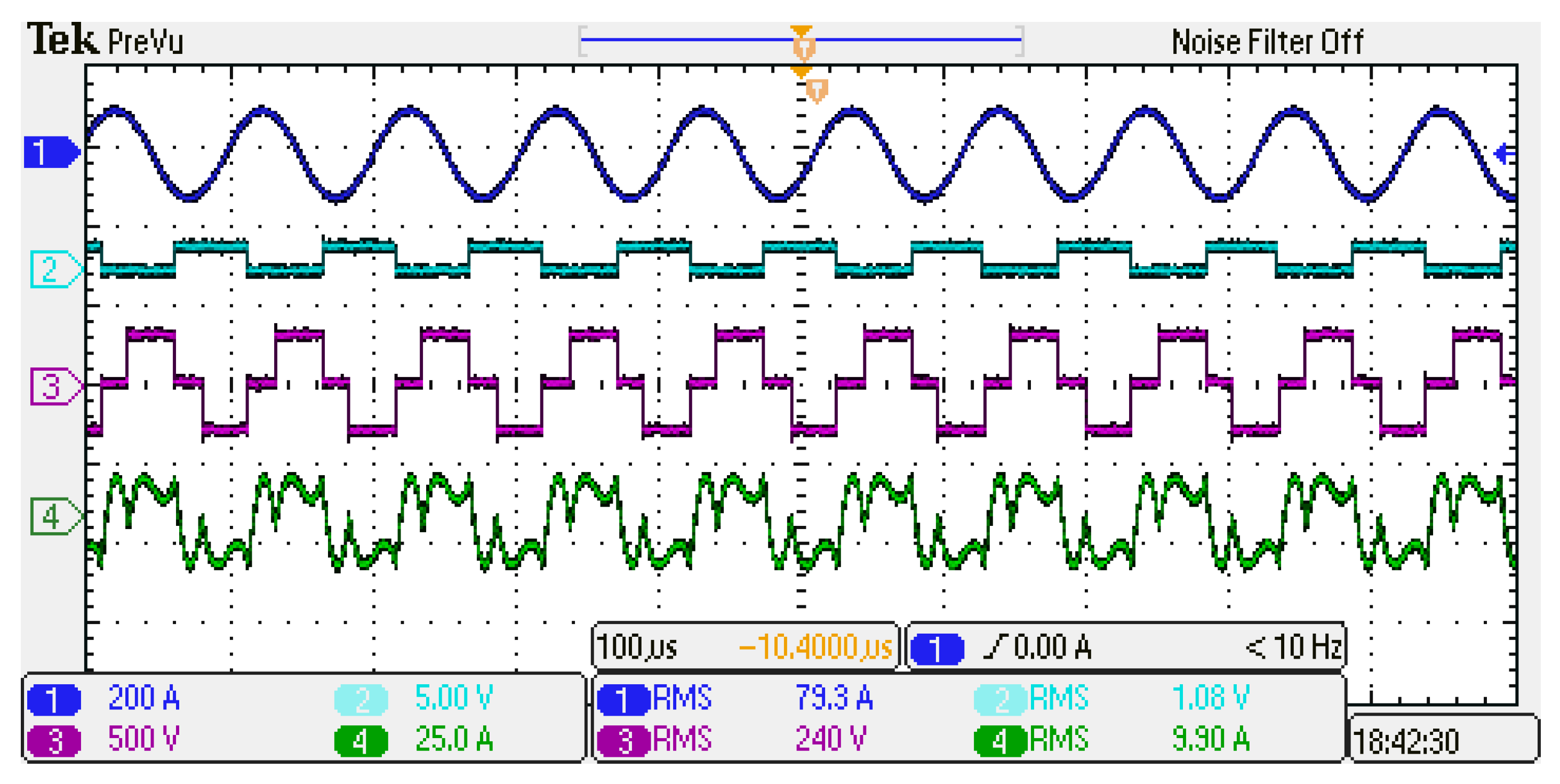

5. Experimental Verification

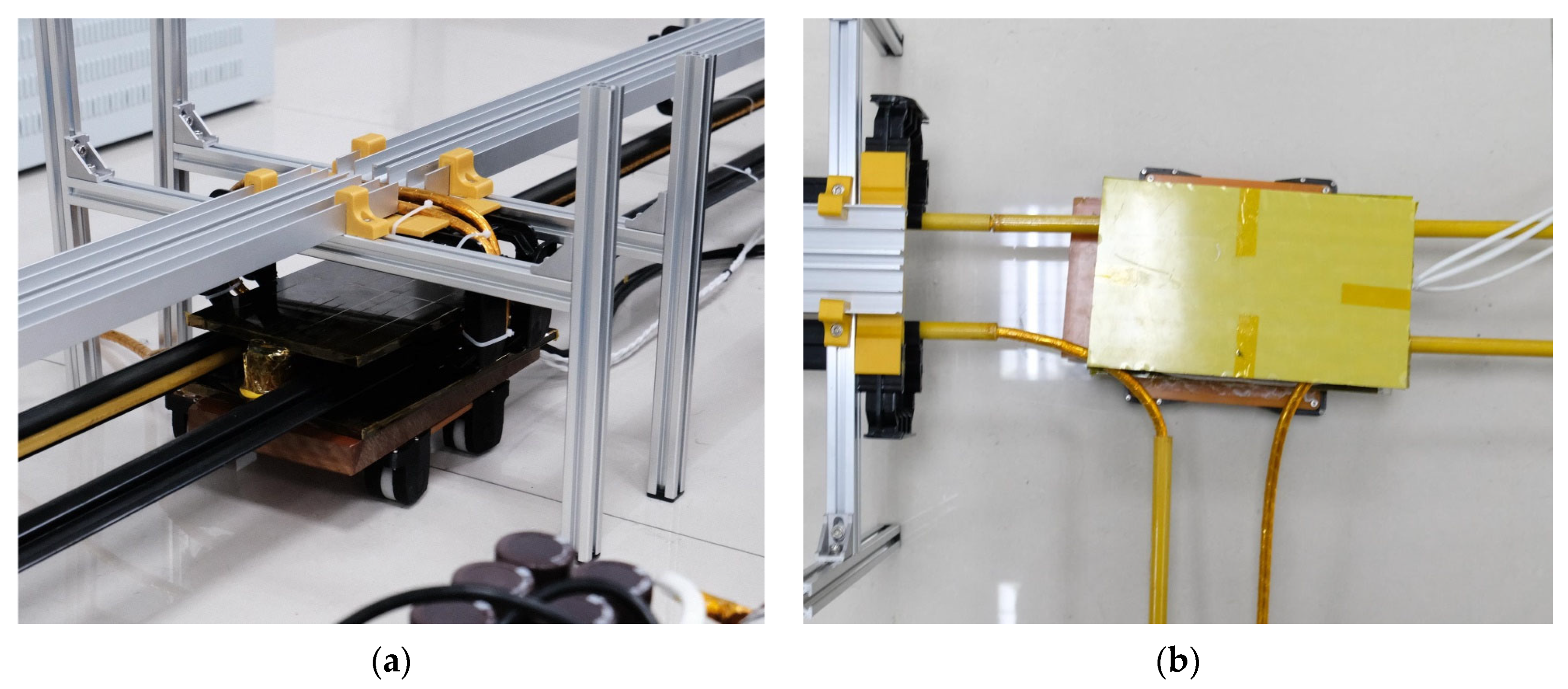

5.1. Design of H-Type Pickup and Rx Circuit

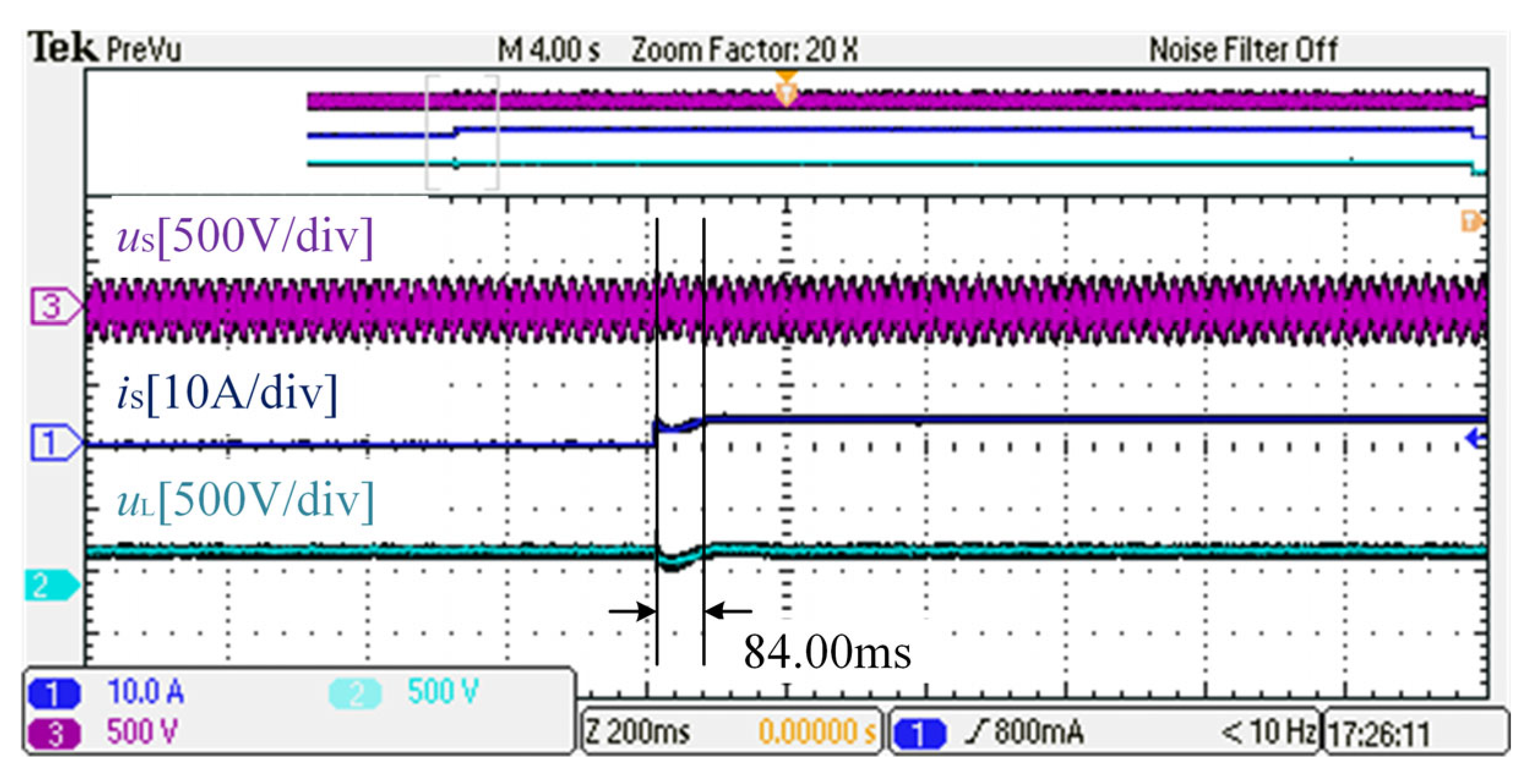

5.2. Experimental and Comparative Analyses

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Symbol | Meaning | Symbol | Meaning |

| Lspacing | Tx track spacing | Lt2 | Length of upper plates of magnetic core |

| dfork | Fork spacing | Lt1 | Width of the upper plates of the core |

| hdoor | The height of the door structure | Tm1 | Newel column width |

| ldoor | The width of the door structure | Tt1 | Thickness of the upper plates of the core |

| ddoor | Track spacing at cross-track | Td1 | Width of the lower plates of the core |

| ltrack_door | Door structure width excluding track spacing | Ld1 | Thickness of the lower plates of the core |

| hm | Center column height | Ld2 | Length of lower plates of magnetic core |

References

- Zhou, L.; Liu, S.; Li, Y.; Mai, R.; Li, Y.; Fu, L.; Qi, L. Efficiency Optimization of LCC-S Compensated Multiple-Receiver Bidirectional WPT System for Stackers in Automated Storage and Retrieval Systems. IEEE Trans. Power Electron. 2022, 37, 15693–15705. [Google Scholar] [CrossRef]

- Lee, E.S.; Kim, M.Y.; Kang, S.M.; Han, S.H. Segmented IPT Coil Design for Continuous Multiple Charging of an Electrified Monorail System. IEEE Trans. Power Electron. 2022, 37, 3636–3649. [Google Scholar] [CrossRef]

- Wang, H.; Cheng, K.W.E.; Li, X.; Hu, J. A Special Magnetic Coupler Structure for Three-Coil Wireless Power Transfer: Analysis, Design, and Experimental Verification. IEEE Trans. Magn. 2021, 57, 8002108. [Google Scholar] [CrossRef]

- Tavakoli, R.; Pantic, Z. Analysis, Design, and Demonstration of a 25-kW Dynamic Wireless Charging System for Roadway Electric Vehicles. IEEE J. Emerg. Sel. Top. Power Electron. 2018, 6, 1378–1393. [Google Scholar] [CrossRef]

- Mahesh, A.; Chokkalingam, B.; Mihet-Popa, L. Inductive wireless power transfer charging for electric vehicles–A review. IEEE Access 2021, 9, 137667–137713. [Google Scholar] [CrossRef]

- Lee, S.-H.; Lee, B.-S.; Lee, J.-H. A New Design Methodology for a 300-kW, Low Flux Density, Large Air Gap, Online Wireless Power Transfer System. IEEE Trans. Ind. Appl. 2016, 52, 4234–4242. [Google Scholar] [CrossRef]

- Barmada, S.; Musolino, A.; Zhu, J.; Yang, S. A Novel Coil Architecture for Interoperability and Tolerance to Misalignment in Electric Vehicle WPT. IEEE Trans. Magn. 2023, 59, 8600205. [Google Scholar] [CrossRef]

- Song, B.; Cui, S.; Li, Y.; Zhu, C. A Fast and General Method to Calculate Mutual Inductance for EV Dynamic Wireless Charging System. IEEE Trans. Power Electron. 2021, 36, 2696–2709. [Google Scholar] [CrossRef]

- Beh, H.Z.; Neath, M.; Boys, J.T.; Covic, G.A. An Alternative IPT Pickup Controller for Material Handling Using a Current Doubler. IEEE Trans. Power Electron. 2018, 33, 10135–10147. [Google Scholar] [CrossRef]

- Pearce, M.G.S.; Covic, G.A.; Boys, J.T. Reduced Ferrite Double D Pad for Roadway IPT Applications. IEEE Trans. Power Electron. 2021, 36, 5055–5068. [Google Scholar] [CrossRef]

- Chakibanda, V.; Komanapalli, V.L.N. Optimization in Magnetic Coupler Design for Inductively Coupled Wireless Charging of Electric Vehicle: A Review. Arab. J. Sci. Eng. 2023, 48, 14257–14294. [Google Scholar] [CrossRef]

- Zeng, H.; Liu, Z.; Hou, Y.; Hei, T.; Zhou, B. Optimization of Magnetic Core Structure for Wireless Charging Coupler. IEEE Trans. Magn. 2017, 53, 8000804. [Google Scholar] [CrossRef]

- Kim, D.; Lee, S. Propulsion and Control of Microrobot Using a Multi-Selective Wireless Power Transfer Coil. IEEE Trans. Magn. 2023, 59, 8000806. [Google Scholar] [CrossRef]

- Han, W.; Chau, K.T.; Jiang, C.; Liu, W.; Lam, W.H. Design and Analysis of Quasi-Omnidirectional Dynamic Wireless Power Transfer for Fly-and-Charge. IEEE Trans. Magn. 2019, 55, 8001709. [Google Scholar] [CrossRef]

- Shin, J.; Shin, S.; Kim, Y.; Ahn, S.; Lee, S.; Jung, G.; Jeon, S.-J.; Cho, D.-H. Design and Implementation of Shaped Magnetic-Resonance-Based Wireless Power Transfer System for Roadway-Powered Moving Electric Vehicles. IEEE Trans. Ind. Electron. 2014, 61, 1179–1192. [Google Scholar] [CrossRef]

- Choi, S.Y.; Jeong, S.Y.; Gu, B.W.; Lim, G.C.; Ultraslim, C.T.R. S-Type Power Supply Rails for Roadway-Powered Electric Vehicles. IEEE Trans. Power Electron. 2015, 30, 6456–6468. [Google Scholar] [CrossRef]

- Huh, J.; Lee, S.W.; Lee, W.Y.; Cho, G.H.; Rim, C.T. Narrow-Width Inductive Power Transfer System for Online Electrical Vehicles. IEEE Trans. Power Electron. 2011, 26, 3666–3679. [Google Scholar] [CrossRef]

- Zhang, Q.; Song, S.; Dong, S.; Zhu, C. Receiver-Side-Oriented Simulator for Dynamic Wireless Charging System with I-Type Transmitter and Multiphase Receiver. IEEE Trans. Ind. Electron. 2021, 68, 3906–3916. [Google Scholar] [CrossRef]

- Boys, J.T.; Covic, G.A. The Inductive Power Transfer Story at the University of Auckland. IEEE Circuits Syst. Mag. 2015, 15, 6–27. [Google Scholar] [CrossRef]

- Hwang, I.; Jang, Y.J.; Choi, H. Overhead shuttle design for a flat panel display production line considering the contactless power supply capacity. Comput. Ind. Eng. 2018, 126, 232–242. [Google Scholar] [CrossRef]

- Hong, S.; Hwang, I.; Jang, Y.J. Practical Q-Learning-Based Route-Guidance and Vehicle Assignment for OHT Systems in Semiconductor Fabs. IEEE Trans. Semicond. Manuf. 2022, 35, 385–396. [Google Scholar] [CrossRef]

- Wang, J.; Sun, W.; Cai, S.; Guo, Y.; Liu, Z. Cross-Rail Voltage Stabilization Control Strategy for Multi-Transmitter Contactless Power System. In Proceedings of the 2023 International Conference on Power System Technology (PowerCon), Jinan, China, 21–22 September 2023; pp. 1–6. [Google Scholar]

- Chen, Y.; Chen, K.; Zheng, S.; Yuan, L.; Zhao, Z. Analytical Modeling Method for Inductance of Planar Magnetic Coupler in Wireless Power Transfer. Proc. Chin. Soc. Electr. Eng. 2023, 43, 1504–1517. [Google Scholar]

- Zhang, X.; Hao, C.; Dou, R.; Liu, S.; Zhao, L.; Zhang, P.; Yang, Q. Ferrite Pads Gap Thermal-Magnetic Evaluation and Mitigation for 11.1 kW Wireless Power Transfer. IEEE Trans. Magn. 2023, 59, 8600806. [Google Scholar] [CrossRef]

- Li, Z.; Han, W.; Xin, Z.; Liu, Q.; Chen, J.; Loh, P.C. A Review of Magnetic Core Materials, Core Loss Modeling and Measurements in High-Power High-Frequency Transformers. CPSS Trans. Power Electron. Appl. 2022, 7, 359–373. [Google Scholar] [CrossRef]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| f | 9.7 kHz | Rp | 0.022 Ω |

| Uin | 240 V | Ls1 | 1243.2 μH |

| Lf | 45.6 μH | Ls2 | 1182.1 μH |

| Cf | 5.9 μF | Cs | 0.0565 μF |

| Lp | 65.6 μH | Rs | 0.76 Ω |

| Cp | 13.56 μF | RL | 60 Ω |

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Lspacing | 65 mm | Lt2 | 220 mm |

| dfork | 65 mm | Lt1 | 150 mm |

| hdoor | 30 mm | Tm1 | 15 mm |

| ldoor | 221 mm | Tt1 | 10 mm |

| ddoor | 20 mm | Td1 | 10 mm |

| ltrack_door | 78 mm | Ld1 | 160 mm |

| hm | 40 mm | Ld2 | 220 mm |

| H-Type | S-Type | E-Type | Flat E-Type | |

|---|---|---|---|---|

| Transfer capability | Relatively high | High | Relatively high | Moderate |

| Operational flexibility | High | Low | Low | High |

| Power level | Moderate | Moderate | High | High |

| Commercialization capacity | High | Low | High | High |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Hou, Y.; Shi, Z.; Sun, Q.; Guo, Y.; Cai, S.; Liu, Z. Design and Analysis of an H-Type Pickup for Multi-Segment Wireless Power Transfer Systems. Electronics 2024, 13, 1125. https://doi.org/10.3390/electronics13061125

Wang J, Hou Y, Shi Z, Sun Q, Guo Y, Cai S, Liu Z. Design and Analysis of an H-Type Pickup for Multi-Segment Wireless Power Transfer Systems. Electronics. 2024; 13(6):1125. https://doi.org/10.3390/electronics13061125

Chicago/Turabian StyleWang, Jintao, Yanjin Hou, Zhuoqun Shi, Qianfang Sun, Yanhua Guo, Shengkun Cai, and Zhizhen Liu. 2024. "Design and Analysis of an H-Type Pickup for Multi-Segment Wireless Power Transfer Systems" Electronics 13, no. 6: 1125. https://doi.org/10.3390/electronics13061125

APA StyleWang, J., Hou, Y., Shi, Z., Sun, Q., Guo, Y., Cai, S., & Liu, Z. (2024). Design and Analysis of an H-Type Pickup for Multi-Segment Wireless Power Transfer Systems. Electronics, 13(6), 1125. https://doi.org/10.3390/electronics13061125