Abstract

Knowledge acquisition and reasoning are essential in intelligent welding decisions. However, the challenges of unstructured knowledge acquisition and weak knowledge linkage across phases limit the development of welding intelligence, especially in the integration of domain information engineering. This paper proposes a cognitive model combining image recognition and a knowledge graph. A CNN is used as the perception layer to obtain direct information. Automated logic rules based on a knowledge graph are described to enable information integration in the knowledge reasoning domain. In addition, a welding knowledge graph of the bogie frame was constructed based on entity and relationship recognition. CNN models with different network structures were compared and trained under supervised conditions. In the results, the InceptionV1 network obtained a high score (0.758 for the thickness relation, 0.642 for the groove form, 0.704 for the joint type, and 0.835 for the base material form). The proposed model showed positive performance in terms of accuracy, interpretation, knowledge coverage, scalability, and portability compared with several other methods. The model can effectively address the abovementioned limitations and is important for welding manufacturing with engineering information integration.

1. Introduction

Welding plays an important role in metal fabrication and is widely used in the manufacturing and construction industries. Ensuring welding quality and improving welding efficiency is crucial to enhancing welding production. With the development of information and intelligent technology in recent decades, intelligent manufacturing processes have attracted much attention [1,2,3,4]. The innovation of a welding production model based on digital information technology has significant economic and social implications. For example, the intelligent reasoning of welding processes [5,6] and the rapid detection of welding defects [7] have become essential tools supporting industrial manufacturing. At the same time, the requirement of manufacturing information and engineering integration (collaboration of resources and information at each production stage) presents new challenges for cooperation at all production stages, real-time and efficient information feedback, and applying knowledge for intelligent welding production.

Knowledge acquisition [8,9] and reasoning [10,11] are critical factors in intelligent welding. According to the type of knowledge, data can be classified as structured (traditional database structure data, e.g., welding base materials database), semi-structured (text data with a certain structure, e.g., welding process specifications), or unstructured (natural language description and multimedia data, e.g., welding joints should be designed based on stress level and safety level). Knowledge reasoning involves acquiring hitherto unknown knowledge from conditional knowledge based on inference mechanisms. The most commonly used inference mechanisms are case-based reasoning (CBR, search result case based on similarity calculation between case base and new case) [12,13], rule-based reasoning (RBR, reasoning decision results based on logical rules) [14], and model-based reasoning. CBR uses a standard case database as primary data and achieves the inference application of knowledge by matching similarity metrics. RBR is often employed as knowledge-based reasoning and decision making based on mathematical logic, with high interpretability. To solve the problem of complicated rulemaking, replacing rules with models is gradually being applied as knowledge reasoning. For example, Filipi et al. [15] used machine learning models for dielectric classification and tool selection in the industrial grinding process, with good results. Some researchers have also focused on multistrategy reasoning [16] and hybrid reasoning approaches [17,18] that synergize multiple reasoning mechanisms. However, most of these inference methods are based on structured data knowledge, and some complex and interconnected unstructured data are not easy to characterize with relational databases [19].

For unstructured knowledge, knowledge graph-based inference methods are considered due to their effective performance in the storage of interconnected and variable data. An increasing number of technologies and studies are concerned with knowledge graphs (semantic network of knowledge in the form of entities and relationships), covering biomedicine [20,21], geographical science [22], and information science [23]. However, only text knowledge weakens the ability of machines to describe the physical world [24]. Understanding knowledge and strengthening the connection between knowledge and the physical world is necessary for knowledge representation and reasoning. Leonardo et al. [25] discuss the understanding of knowledge from the perspective of knowledge origin and artificial intelligence. Sun et al. [26] propose a multimodal graph attention technique based on multimodal knowledge graph inferences to recommend certain information. Research on unstructured text and modal knowledge embedding [27,28] is gradually gaining ground, but research on welding manufacturing is still lacking.

Hence, we proposed a knowledge acquisition and reasoning model considering various knowledge forms and application scenarios. This model focuses on the integrated production requirements of welding manufacturing to realize its industrial application. We predict that the model has favorable generality, and is compatible with the multimodal knowledge of speech, light waves, currents, etc. In addition, the model can provide a reference for integrated production in manufacturing areas such as casting and punching. Our model has the following features compared with most other methods: (i) interconnected knowledge structure—the acquisition and reasoning of unstructured knowledge increase to achieve structured knowledge application; (ii) less limitations in terms of knowledge patterns—the acquisition and reasoning of unstructured knowledge increase to achieve structured knowledge application; and (iii) strong applicability—engineering information, integration-oriented design model that enables data interaction and knowledge linkage at all stages of welding and manufacturing. The model has strong engineering applicability.

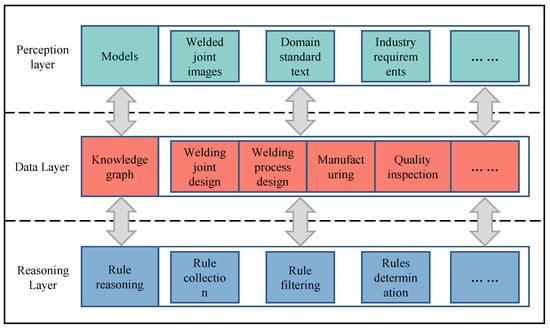

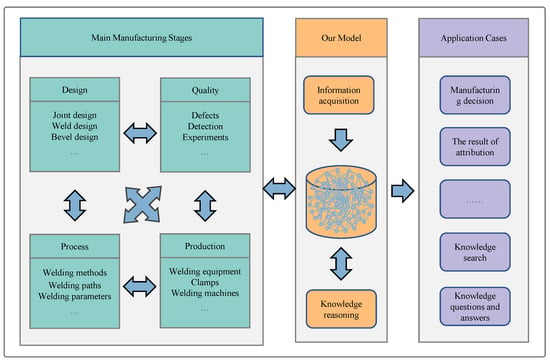

The model contains perception, data, and reasoning layers, as shown in Figure 1. A convolutional neural network (CNN) is an essential model in the perception layer for picture information acquisition. We used the knowledge graph of the welding manufacturing domain as the data layer and set the automatic rule inference mechanism based on the knowledge graph in the inference layer. The essential data related to welding manufacturing, such as design, process, production, and inspection, were collected to establish a domain knowledge graph. We annotated a large number of specialized vocabularies with the begin–inside–outside (BIO) method and completed the named entity identification (NER) task using the conditional random field (CRF) model. The relationship construction of the knowledge graph was achieved by combining bidirectional long short-term memory (Bi-LSTM) and manual calibration. In addition, we introduced the modal recognition model in the basic knowledge graph to support the acquisition of deep modal knowledge. The welded joint sketch was chosen as the data sample for unstructured knowledge acquisition because it contains crucial design information. The edge detection method is employed as a pre-processing method to obtain distinct gradient features, and thus, accurate information. Moreover, we analyzed CNN models in different structural states, such as InceptionV1 [29], MobileNet [30], and ResNet [31], VGG16 [32]. The optimal model for InceptionV1 was obtained, with a training accuracy of 0.814 and a validation accuracy of 0.735. Furthermore, we compared and analyzed CBR, RBR, and model-based CNNs, as well as our method, in terms of accuracy, interpretation, knowledge coverage, scalability, and portability with low, normal, and high indicators. We obtained results on unstructured knowledge acquisition and inference. These results show that the proposed model has excellent overall performance. The application for the integration of engineering information is also described in this paper. The main contributions of this paper are as follows:

Figure 1.

The model is divided into three layers: perception, data, and inference. The perceptual layer is based on intelligent perception models (CNN is employed as the perception layer model in this study). The data layer is based on knowledge graphs, while the inference layer is based on rule-based reasoning.

- The model with a CNN as the information-aware layer and a domain knowledge graph as the data center can produce deeply implicit knowledge acquisition (knowledge obtained from intuitive information through domain reasoning) and reasoning with certain cognitive abilities.

- The proposed model accomplishes the acquisition and reasoning of unstructured knowledge and provides a feasible solution for the integrated manufacturing of welding information.

- The design concept, which is based on a networked data structure considering a wide range of knowledge forms, enriches the driving model of intelligent systems.

The rest of this paper is organized as follows. Section 2 describes the construction of the information acquisition and reasoning model based on CNN and the knowledge graph. Section 3 implements the processing of the joint welding diagram and constructs the knowledge graph based on the welding manufacturing process. On this basis, the comparative training of information acquisition models is carried out. Section 4 presents the results of the comparison model, and analyzes the knowledge acquisition process of the welded joint sketch. In addition, engineering data acquisition and the reasoning model are verified, and engineering applications are described. In Section 5, corresponding conclusions are provided.

2. Methods and Models

2.1. Information Acquisition

In welding manufacturing, considerable knowledge is hidden in geometric and image information. This information usually needs to be addressed due to acquisition difficulties. In order to enrich knowledge acquisition, the feature extraction method is considered. CNN is one of the standard methods for feature extraction. It contains the input layer, convolutional layer, activation layer, pooling layer, and fully connected layer. Convolutional computation, a key element of CNN, extracts features from the input data using convolutional kernels. This method can effectively obtain the grid-like topology feature while reducing the amount of arithmetic data. The calculation formula is as follows:

where n_in is the number of input matrices, Xk represents the kth input matrix, Wk represents the kth sub-convolution kernel, s(i, j) is the value of the corresponding element of the input matrix, and b is the bias.

Feature transfer from the input to the output layer relies on a forward propagation algorithm, defining the current layer as l and the previous layer’s output as xl−1. The output layer data can be calculated using the current weight, bias, and activation function. The inter-layer calculation approach enables the calculation and training of the model via the continuous transfer of feature data from the original layer to the resulting output layer. The calculation formula is as follows:

Model training is a continuous iterative optimization process. In CNN computing, the smaller the difference, the greater the robustness of the model. The cost function, also known as the loss function, is used to evaluate the difference between the predicted and the actual values of the model. Thus, the squared cost function makes the model training efficient and directional. The training error for sample n can be expressed as Equation (3):

where M is the number of categories, yc is the variable (1 for correct; 0 for incorrect), and pc is the probability of a correct prediction.

2.2. Knowledge Graph Reasoning

Rule-based logic methods are often used for the reasoning of knowledge graphs, which have high accuracy and interpretability. With the addition of domain knowledge and increased data volume, the automatic acquisition of rules with high confidence from the knowledge graph becomes an essential concern for knowledge inference. Rule head and body are essential elements of rule inference, and the inference process is represented as Equation (4). If only atoms of the affirmative form exist in a rule, the rule is called Horn’s rule, as expressed in Equation (5) (each a represents an atom). Furthermore, we can express the relationship with the path rule, as shown in Equation (6).

where body+ denotes the set of atomic logical sums of the affirmative form and body− denotes the set of atomic logical sums of the negative form.

Each atom contains two variables, e, and all binary atoms form a path between entities.

To automatically acquire rules for achieving knowledge inference, support, confidence, and head coverage (HC) are employed to evaluate the rules. The support is the number of instances that meet the ruling body. The rule header and confidence generally represent the support ratio to the number of instances that meet the ruling body (Equation (7)). Most knowledge graphs are characterized by incompleteness. The r0(x, y′) is introduced as a confidence calculation condition to avoid judging the missing triples as incorrect. They count instances of entities satisfying the rule when the head entity connects entities other than y via the relation r0. The incompleteness of the knowledge graph is considered in the partial completeness assumption (PCA) confidence, which is also an important metric for evaluating the reasonableness of the rules. The mathematical expression is shown in Equation (8).

where support(rule) is the rule support, #body(rule) indicates the number of instances that meet the body of the rule, x is the head entity, y is the entity to which x is connected through the relation r0, and y′ represents entities other than y.

HC is the support and the number of instances that satisfy the rule head. The mathematical expression is shown in Equation (9), where #head(rule) denotes the number of instances that meet the rule head. In general, the higher the rule head coverage, the better the rules will be acquired.

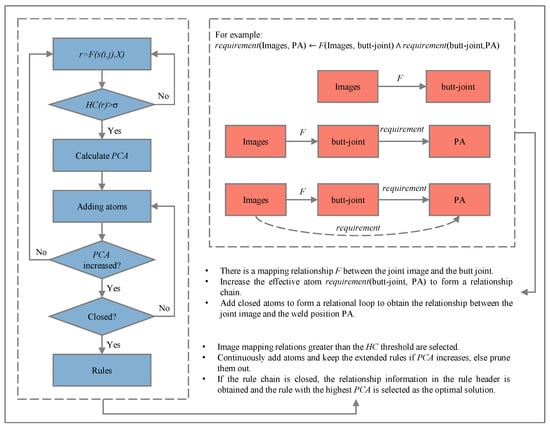

The AMIE (association rule mining under incomplete evidence) [33] method is often used to discover rules based on knowledge graphs. Rule extraction was achieved by continuously adding dangling, instantiated, or closing atoms. To achieve cross-stage knowledge acquisition and inference, we integrated CNN, AMIE, and a knowledge graph to build the driving model, which directly acquires hidden domain knowledge from the joint sketch. After defining the input image data i, j, the corresponding output s(i, j) is obtained according to Equation (1). The output–label correspondence mapping function is defined as F. The inference process and the example are shown in Figure 2.

Figure 2.

Inference process and example. The left side shows the depth inference process of image knowledge, while the right side shows the inference example.

2.3. Model Design

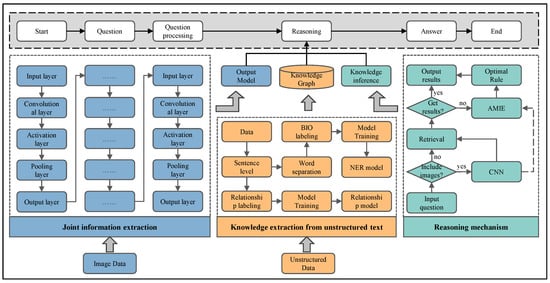

The model can also be summarized as “a data center with perception” or a data center in a knowledge graph based on actual welding production data. Unstructured data information is extracted via NER and relationship extraction models. This information is stored in a graph database through a triplet form. Image and geometric information can be collected using CNN models and mapped to entities in the knowledge graph as labels. For an engineering issue, unstructured problem information is reorganized into structured triads via semantic and image models. Expected results are inferred and obtained via the triad and knowledge graph. Regarding image inference, the approach of fusing CNN and AMIE is used for image knowledge acquisition. The overall process is illustrated in Figure 3.

Figure 3.

Overall process. The knowledge graph was built based on CNN, NER, and relationship extraction models. The fusing of AMIE and CNN is used to acquire knowledge related to engineering problems.

3. Experimental Section

3.1. Data Processing

The welded joint is an important information carrier for welding production. There is a large amount of design information, such as welding position, bevel form, weld type, base material type, plate thickness relationship, etc. The joint images are a standard welding instruction document in actual production. To further improve computational efficiency and retain the feature gradient information, we changed the joint images to grayscale, so that they were not strongly dependent on color. In addition, the weighted average method was employed for grayscale calculations. The mathematical expression is shown in Equation (10), where i and j represent the pixel point positions, R, G, and B represent three colors, and w1, w2, and w3 represent the corresponding weights.

Feature extraction is an effective means of acquiring image information. For joint images, geometric data, such as angle, length, width, and height, are clear feature points. Therefore, the Sobel operator is employed as an edge detection method for extracting image features and improving the information gradient. For a pixel, the horizontal and vertical grayscale can be calculated via its neighboring grayscale values, and we can obtain the pixel grayscale value using Equation (11). According to Equation (12), the gradient direction determines the boundary position when the gray value exceeds the threshold value.

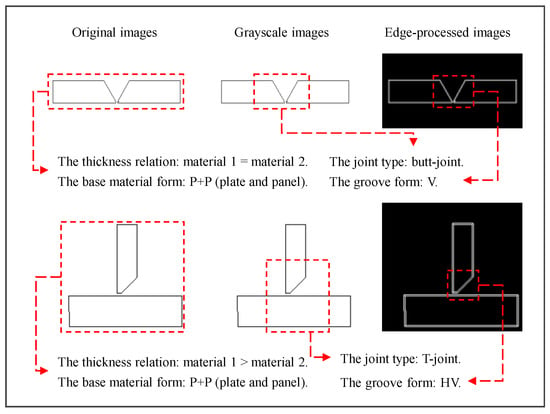

The processing results for a butt joint and a T-joint are shown in Figure 4. Possible feature areas are marked based on expert experience. Thickness relationships and parent material forms depend on the overall characteristics of the joint being marked in the original images. Features of the joint type are marked on the material joint in the grayscale images, including the groove and part of the base material shape. The edge-processed images indicate groove information, focusing on the base material connection, especially the groove geometry. Detailed information is provided in Figure 4.

Figure 4.

Pre-processing results and characterization. The original images are shown on the left, the middle images show the grayed-out images, and the right images show the edge detection results based on the Sobel operator.

3.2. Knowledge Graph Construction

Data form the basis for intelligent system reasoning and decision making. They can be divided into structured, semi-structured, and unstructured data. Structured and semi-structured data can be directly or indirectly used to construct knowledge graphs, but using unstructured data is challenging. Therefore, achieving knowledge extraction from unstructured documents is an essential concern of our study.

We collected numerous engineering documents that mainly focus on joint design, process design, and welding production to build an integrated engineering data system. In addition, entities involved in welding manufacturing were calibrated using the BIO method, and the engineering documents were organized into sentence-level data. Considering the large amount of data, we divided the data preparation task into two subtasks: NER and relationship extraction. The CRF model was employed to complete the NER subtask. Small batches of relations were manually labeled and trained using the Bi-LSTM model. Then, the trained model automatically transformed the unstructured data into a triad format. These data were then stored in the Neo4j graph database. Entities were divided into seven categories (Standard, Technology, Design, Department, Manufacture, Quality, and Experiment). Relationships were divided into five categories (belong_to, reference, requirement, based_on, applicable_to). The data are shown in Table 1.

Table 1.

Information about entities and relationships.

3.3. Model Training and Evaluation

The information acquisition of welded joint images requires multiple classification models because the images contain multiple classes of information, and each class contains multiple subclasses. We chose several vital pieces of information (thickness relation, groove form, joint type, base material form) in the joint image as research objects to train the corresponding model. Actual data on bogie welding fabrication for high-speed trains were collected to support the model training. In contrast to generic welding data, we only selected category objects in our experimental data to complete the classification training. For example, common groove forms include a, V, U, z, and J, but we only classified a, V, and HY in our study based on the data under specific conditions. Furthermore, if we suppose that two base materials are joined, the base material with the bevel is defined as base material 2, while the vertical base material is defined as base material 2 for non-beveled welds. A detailed description of the dataset is shown in Table 2.

Table 2.

Detailed data description.

The model training process included the following phases. (1) Data collection: the welding procedure specification documents, including the welding joint diagram and approval by the project, were collected. Then, the image in the file was automatically extracted as the initial data through the computer program. (2) Task division: we divided the information acquisition process into four classification tasks and trained the models separately for each task. (3) Data annotations: we selected the annotation team, which consisted of two annotators and a decision-maker. The annotators and the decision-maker had at least three to four years of welding learning experience. When there was disagreement in labeling, the disagreement was resolved by the decision-maker. (4) Dataset partitioning: due to the small amount of data, the dataset was divided into a training set and a test set, details of which are given in Table 3. (5) Model comparison training: CNN models under different networks, such as InceptionV1, MobileNet, ResNet, and VGG16, were employed to perform comparison tests in unsupervised conditions. In addition, we ran the program by using Python programming language (version 3.7) in the TensorFlow framework (version: 1.14.0) and the grid search method for parameter optimization.

Table 3.

Data allocation information.

In order to obtain depth knowledge of image information, we defined mapping templates as follows: “The A is B.” The categorical task and the corresponding category labels were static template constants (A) and dynamic variables (B). The label information obtained by the CNN was embedded into the semantic slot to form the complete template. Then, the link to the knowledge graph entities was achieved using Cypher query language transformation.

Accuracy is a commonly used evaluation metric which, in most cases, is a valid characterization of the quality of the model. We calculated the metric according to true positive (both true category and predicted category are positive examples, TP), false positive (true category is negative and predicted category is positive, FP), true negative (both true category and predicted category are negative, TN), false negative (true category is positive and predicted category is negative, FN). The calculation is shown in Equation (13).

4. Results Analysis

An appropriate joint information acquisition model is essential for knowledge acquisition and cross-stage reasoning. Four CNN network structures (InceptionV1, MobileNet, ResNet, and VGG16) were employed to train four classification tasks of welded joints (thickness relation, groove form joint type, and base material form) evaluated via test accuracy metrics. Details are provided in Table 4.

Table 4.

Comparison results of different CNN networks.

The results show that InceptionV1 positively impacts our data, with an accuracy of 0.758 for the thickness relation, 0.642 for the groove form, 0.704 for the joint type, and 0.835 for the base material form. The lower scores appear in the groove form category compared with the other categories. The geometric characteristics of the groove form are only in small areas and are not prominent enough concerning the overall characteristics of the welded joint. Enlarging local features, such as image cropping and labeling the region of interest (ROI), may improve model quality.

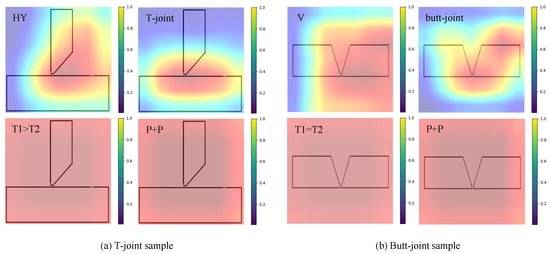

As shown in Figure 5, the prediction results are similar to the expert experience. The categories of thickness relation and base material form rely on overall features, while the categories of groove form and joint type focus on partial features, especially on the position of the linked base material. In addition, the gradient of the characteristics of the butt joint sample is not accurate enough, especially for predicting the groove form. This may be the reason for the relatively low accuracy of the groove form classification. Optimizing data samples, such as image cropping and labeling the region of interest (ROI), may improve model quality.

Figure 5.

Predicted heat map of welded joint sketch category: (a) is the sample result of the T-joint, and (b) is the sample result of the butt joint.

Actual production joint sketches were collected to confirm the feasibility of the model in cross-stage knowledge acquisition and reasoning. Intuitive joint information was automatically obtained based on the trained CNN model, while deep domain knowledge was discovered based on the inference of the knowledge graph. As an essential information carrier for welding design, the welded joint sketch strongly correlates with the welding process selection. Welding knowledge, such as preheat temperature, weld position, or assembly gap, are deeply hidden in the welded joint. We found this information using the proposed model. Detailed results are presented in Table 5.

Table 5.

Results for joint image knowledge acquisition.

In rail vehicle bogie welding, the welded joint’s preheating temperature is mainly developed based on the thickness and type of base material. Moreover, the preheating treatment is determined according to the thicker base material preheating temperature. In addition, the welding position selection requires consideration of both joint structure and welding difficulty. The assembly gap’s determination mainly considers the groove form, joint type, and other factors. As shown in Table 5, not only can we obtain visual design information from the joint design images, but knowledge of the welding process associated with the design is also found via our model. Then model exhibits high consistency with practical welding manufacturing knowledge.

5. Discussion

5.1. Qualitative Comparison with Other Methods

CBR, RBB, and model-based methods are widely applied for reasoning and decision making in the welding manufacturing process. However, a quantitative comparative analysis cannot be carried out due to uncertainty in terms of weights, thresholds, incomplete rules, and model quality. Hence, we used low, normal, and high fuzzy metrics to assess each method’s accuracy, interpretability, knowledge coverage, scalability, and portability. The detailed analysis is as follows, and the results are shown in Table 6.

Table 6.

Results of methods comparison.

For the CBR method, setting thresholds or weights based on case matching could only partially guarantee decision-making accuracy due to the inadequate references. To derive new cases, this method may not obtain satisfactory results due to the imperfection of the case base. In addition, although most of these methods only apply to structured knowledge acquisition and reasoning, they have good scalability and portability.

RBR methods are centered on mathematical logic with excellent interpretation and accuracy. However, the difficulty of knowledge representation and rule formulation leads to incomplete reasoning and expensive system construction. Furthermore, rule amendments or additions become challenging as knowledge grows and improves, resulting in weak scalability and portability.

The model-based inference approach relies on a high-quality model with reasonable accuracy, scalability, and portability. However, the model needs to be better interpreted because of its black-box nature.

Our approach integrates multiple factors that limit knowledge acquisition and reasoning, proposing a method structure centered on knowledge graphs with modal processing as a means of information acquisition. The dynamic logic inference method, based on a knowledge graph, can guarantee accuracy, and the expression process in terms of relational paths has strong interpretation. In addition, the method has superior performance in terms of knowledge coverage, scalability, and portability.

5.2. Engineering Applications

With the development of welding manufacturing information technology and automation, the knowledge of each production stage interacts more closely. Integrating knowledge feedback into the production cycle to improve production quality and efficiency is of significant concern. The process of bogie welding manufacturing includes joint design, process selection, welding production, and quality inspection. The joint design should consider the structure, weldability, relevant standards, etc., as well as the actual process and production conditions. Design conditions and actual production content are also necessary for selecting welding processes, except for domain knowledge. In addition, the welding and joining production process considers design and process information on the one hand, and production conditions and quality requirements on the other. Moreover, quality inspection is related to the other phases of the welding cycle. Therefore, bogie welding manufacturing is a complex, multistage information interaction process.

In welding manufacturing, complex information networks and extensive domain knowledge mean that information-integrated production requires a professional and interconnected data structure as well as extensive knowledge acquisition ability. Considering these characteristics, we designed an information engineering integration model for bogie welding manufacturing based on our model. The main stages and elements in manufacturing are enumerated, and they exist to transfer information to each other. Our model supports knowledge acquisition and reasoning for each stage and achieves information interaction and feedback between the stages. In addition, the model has applicability in manufacturing process support scenarios, such as knowledge retrieval, result attribution, and intelligent questions/answers. The design information is presented in Figure 6.

Figure 6.

Integrated welding design. The main manufacturing stages and contents are represented on the left side of the image. Our model includes information acquisition, knowledge graph, and knowledge inference in the middle. On the right side are several practical engineering application scenarios.

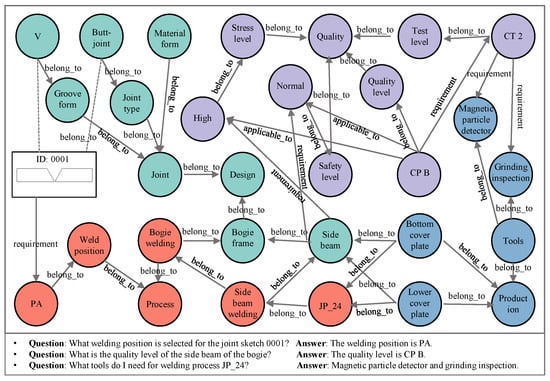

A process for bogie side beam welding is depicted in Figure 7 based on the proposed practical application model. The bottom and lower cover plate welding process involves the primary production stages (design, process, quality, and production). As shown in Figure 7, the knowledge graph is constructed using relationships that link entities. Joint sketch information is obtained and linked to the described knowledge graph. Several cross-stage, real-production questions are asked for intelligent question-and-answer applications, and the corresponding answers are obtained based on the constructed model. This detailed model and the information results are shown in Figure 7.

Figure 7.

Welding process of the bottom cover plate and lower cover plate. The knowledge graph of the two components, which contains information about the design, process, quality, and production stages, is described. The figure lists intelligent question-and-answer data based on the process graph.

The case design is based on the actual manufacturing process and is model-driven to achieve production information integration. Comprehensive knowledge coverage, low structural complexity, high portability, and extensive engineering applications are important features of the method. In addition, we conducted the experimental analysis with images only. We predict that the knowledge acquisition module can extract feature information, such as sound, current, and voltage, considering the structural characteristics. Therefore, the method is also highly scalable.

6. Conclusions

To address the challenges of limited access to welding depth knowledge and weak reasoning across production cycles, we designed a model driven by a knowledge graph as the data center, and a CNN as the perceptual layer. The aim of the model was to achieve cross-stage inference from modal information to depth knowledge. The domain knowledge graph about welded bogies was based on NER and relationship recognition subtasks. Additionally, the optimal perceptual model (InceptionV1: 0.758 for the thickness relation, 0.642 for the groove form, 0.704 for the joint type, and 0.835 for the base material form) was obtained with the welded joint images as data. Compared with traditional inference methods, our model shows comprehensive performance and can support the intelligent production of integrated welding and manufacturing.

The proposed model has comprehensive knowledge coverage, highly interconnected knowledge, and an extremely scalable structure. It effectively complements theoretical knowledge acquisition and reasoning systems. It is therefore significant for realizing engineering manufacturing in integrated welding information. Our research may inspire the development of cognitive intelligence in manufacturing.

Follow-up studies related to our method might be of interest. For example, (i) research patterns and content can be added to expand knowledge acquisition, and sound, light waves, and fabrication defects may be worth considering; (ii) intelligent systems based on the proposed method should be examined; and (iii) our model also applies to a cognitive intelligence system combined with physical sensors.

Author Contributions

K.G. and X.Y. proposed the idea and were the main contributors to writing the manuscript; Y.S. summarized the engineering problems and supported the description of the bogie manufacturing process; G.Y. provided technical support for the application and training of the algorithms involved in the model; X.Y. developed a feasible experimental protocol and reviewed the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the National Natural Science Foundation of China (Grant numbers: 51875072 and 52005071) and the Foundation for Overseas Talents Training Project in Liaoning Colleges and Universities (Grant number: 2018LNGXGJWPY-YB012).

Data Availability Statement

The data involved in this study are available upon reasonable request to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Yang, T.; Yi, X.; Lu, S.; Johansson, K.H.; Chai, T. Intelligent manufacturing for the process industry driven by industrial artificial intelligence. Engineering 2021, 7, 1193–1342. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, Q.; Liu, Y. Adaptive intelligent welding manufacturing. Weld. J. 2021, 100, 63–83. [Google Scholar] [CrossRef]

- Tsuzuki, M.; Silva, J.R.; Pereira, C.E. Special section on intelligent manufacturing systems. Mechatronics 2015, 31, 146. [Google Scholar] [CrossRef]

- Wu, J.; Xu, X.; Liao, X.; Li, Z.; Zhang, S.; Huang, Y. Intelligent Diagnosis Method of Data Center Precision Air Conditioning Fault Based on Knowledge Graph. Electronics 2023, 12, 498. [Google Scholar] [CrossRef]

- Zhang, Y.; Wei, Y.; Pu, J.; Yuan, X. Development and application of knowledge-based software for railcar frame welding process. Int. J. Adv. Manuf. Technol. 2021, 112, 273–284. [Google Scholar] [CrossRef]

- Jafarian, M.; Vahdat, S.E. A fuzzy multi-attribute approach to select the welding process at high pressure vessel manufacturing. J. Manuf. Process. 2011, 14, 250–256. [Google Scholar] [CrossRef]

- Sassi, P.; Tripicchio, P.; Avizzano, C.A. A smart monitoring system for automatic welding defect detection. IEEE Trans. Ind. Electron. 2019, 66, 9641–9650. [Google Scholar] [CrossRef]

- Parpola, P. Object-Oriented Knowledge Acquisition: Integrating Construction of and Reasoning in Object-Oriented Knowledge Bases; Aalto University Publication Series SCIENCE + TECHNOLOGY: Helsinki, Finland, 2015; p. 142. Available online: http://urn.fi/URN:ISBN:978-952-60-6461-1 (accessed on 5 January 2023).

- Yin, G.; Dang, Y.; Xu, Z. A Methodology for Problem-Driven Knowledge Acquisition and Its Application. International Symposium on Knowledge and Systems Sciences; Springer: Singapore, 2016. [Google Scholar] [CrossRef]

- Ali, R.; Afzal, M.; Sadiq, M.; Hussain, M.; Ali, T.; Lee, S.; Khattak, A.M. Knowledge-based reasoning and recommendation framework for intelligent decision making. Expert Syst. 2018, 35, e12242.1–e12242.23. [Google Scholar] [CrossRef]

- Seo, Y.; Sheen, D.; Kim, T. Block assembly planning in shipbuilding using case-based reasoning. Expert Syst. Appl. 2005, 32, 245–253. [Google Scholar] [CrossRef]

- Reyes, E.R.; Negny, S.; Robles, G.C.; Lann, J.M.L. Improvement of online adaptation knowledge acquisition and reuse in case-based reasoning: Application to process engineering design. Eng. Appl. Artif. Intell. 2015, 41, 1–16. [Google Scholar] [CrossRef]

- Shiu, S.; Pal, S.K. Case-based reasoning: Concepts, features and soft computing. Appl. Intell. 2004, 21, 233–238. [Google Scholar] [CrossRef]

- Wei, X.; Yuan, H.; Wang, H.; Chen, Y. Intelligent design for automotive interior trim structures based on knowledge rule-based reasoning. Int. J. Automot. Technol. 2020, 21, 1149–1167. [Google Scholar] [CrossRef]

- Filipi, B.; Junkar, M. Using inductive machine learning to support decision making in machining processes. Comput. Ind. 2000, 43, 31–41. [Google Scholar] [CrossRef]

- Ferilli, S. GEAR: A General Inference Engine for Automated MultiStrategy Reasoning. Electronics 2023, 12, 256. [Google Scholar] [CrossRef]

- Jiang, Z.; Jiang, Y.; Wang, Y.; Zhang, H.; Cao, H.; Tian, G. A hybrid approach of rough set and case-based reasoning to remanufacturing process planning. J. Intell. Manuf. 2017, 30, 19–32. [Google Scholar] [CrossRef]

- Li, S.; Zhang, H.; Yan, W.; Jiang, Z. A hybrid method of blockchain and case-based reasoning for remanufacturing process planning. J. Intell. Manuf. 2020, 32, 1389–1399. [Google Scholar] [CrossRef]

- Guo, L.; Yan, F.; Li, T.; Yang, T.; Lu, Y. An automatic method for constructing machining process knowledge base from knowledge graph. Robot. Comput. Integr. Manuf. 2022, 73, 102222. [Google Scholar] [CrossRef]

- Zeng, X.; Tu, X.; Liu, Y.; Fu, X.; Su, Y. Toward better drug discovery with knowledge graph. Curr. Opin. Struct. Biol. 2021, 72, 114–126. [Google Scholar] [CrossRef]

- Hussey, P.; Das, S.; Farrell, S.; Ledger, L.; Spencer, A. Title a knowledge graph to understand nursing big data: Case example for guidance. J. Nurs. Scholarsh. 2021, 53, 323–332. [Google Scholar] [CrossRef]

- Ma, X. Knowledge graph construction and application in geosciences: A review. Comput. Geosci. 2022, 161, 105082. [Google Scholar] [CrossRef]

- Wang, Q.; Mao, Z.; Wang, B.; Guo, L. Knowledge Graph Embedding: A Survey of Approaches and Applications. IEEE Trans. Knowl. Data Eng. 2017, 29, 2724–2743. [Google Scholar] [CrossRef]

- Zhu, X.; Li, Z.; Wang, X.; Jiang, X.; Sun, P.; Wang, X.; Xiao, Y.; Yuan, N.J. Multi-Modal Knowledge Graph Construction and Application: A Survey. IEEE Trans. Knowl. Data Eng. 2022, 34, 1–20. [Google Scholar] [CrossRef]

- Ranaldi, L.; Pucci, G. Knowing Knowledge: Epistemological Study of Knowledge in Transformers. Appl. Sci. 2023, 13, 677. [Google Scholar] [CrossRef]

- Sun, R.; Cao, X.; Zhao, Y.; Wan, J.; Zhou, K.; Zhang, F.; Wang, Z.; Zheng, K. Multi-modal Knowledge Graphs for Recommender Systems. In Proceedings of the 29th ACM International Conference on Information and Knowledge Management, Virtual, 19–23 October 2020. [Google Scholar] [CrossRef]

- Zhou, B.; Shen, X.; Lu, Y.; Li, X.; Hua, B.; Liu, T.; Bao, J. Semantic-Aware Event Link Reasoning Over Industrial Knowledge Graph Embedding Time Series Data. Int. J. Prod. Res. 2022, 60, 1–18. [Google Scholar] [CrossRef]

- Sahraoui, D.; Ning, H.; Tao, Z. STLF: Spatial-temporal-logical knowledge representation and object mapping framework. In Proceedings of the 2016 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Budapest, Hungary, 9–12 October 2016; pp. 001550–001554. [Google Scholar] [CrossRef]

- Szegedy, C.; Liu, W.; Jia, Y.; Sermanet, P.; Rabinovich, A. Going deeper with convolutions. In Proceedings of the 2015 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Boston, MA, USA, 7–12 June 2015; pp. 1–9. [Google Scholar] [CrossRef]

- Howard, A.G.; Zhu, M.; Chen, B.; Kalenichenko, D.; Wang, W.; Weyand, T.; Andreetto, M.; Adam, H. Mobilenets: Efficient convolutional neural networks for mobile vision applications. arXiv 2017, arXiv:1704.04861. [Google Scholar] [CrossRef]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 26 June–1 July 2016. [Google Scholar] [CrossRef]

- Simonyan, K.; Zisserman, A. Very deep convolutional networks for large-scale image recognition. arXiv 2014, arXiv:1409.1556v6. [Google Scholar] [CrossRef]

- Galárraga, L.A.; Teflioudi, C.; Hose, K.; Suchanek, F. AMIE: Association rule mining under incomplete evidence in ontological knowledge bases. In Proceedings of the 22nd International Conference on World Wide Web, New York, NY, USA, 13–17 May 2013. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).