1. Introduction

In the traditional manufacturing process, processing [

1,

2] and assembly [

3,

4] are regarded as two independent stages. The current research on the problem mainly focuses on the processing stage, such as the flow shop scheduling environment [

5,

6] and the job-shop scheduling environment [

7,

8]. With the increase in the diversified demands of society, the orders of multiple varieties and small batches are gradually increasing. Driven by this diversified demand environment, a new production scheduling mode is needed to meet the needs of the people’s personalized customized products. In this way, integrated scheduling [

9] emerges as the times require, which unifies the machining process and assembly process of a product into a processing process, and maps complex products into a virtual processing operation tree. Since the linear processing constraints and assembly constraints among operations are considered at the same time, the integrated scheduling problem has important research significance and practical application value in shortening the product manufacturing cycle and improving the efficiency of the production system.

At present, researchers focus more on the integrated scheduling problem in the direction of simple products [

10,

11], but relatively less research on the complex product integrated scheduling problem with multi-layer tree structure. The comprehensive scheduling algorithm used in the research process is mainly divided into two categories: Heuristic rule algorithm and intelligent optimization algorithm. In the first type of comprehensive scheduling algorithm based on heuristic rules, there are different dispatching rules. In this type of algorithm, a series of algorithms based on the product process tree are proposed, and the problems involved include general product integrated scheduling [

12,

13], integrated scheduling with special process constraints [

14,

15], and special single workshop comprehensive scheduling problem of equipment [

16,

17], and comprehensive scheduling problem of distributed multi-workshop production environment [

18,

19,

20], etc. However, the above algorithms have certain defects. The first type of algorithm uses rule-based scheduling algorithms, which are more dependent on the processing structure of the product process, and it is difficult to adapt to the differences between different examples. Moreover, the scheduling scheme does not have diversity, and the quality of the solution cannot meet the needs very well. In the second type of algorithm, the solution to the comprehensive scheduling problem must first meet the complex priority constraints, so that the existing coding methods and evolutionary operators cannot achieve the expected results, and thus make this type of algorithm in the actual problem-solving process. restricted to a certain extent. While Wang et al. [

21] and Wang et al. [

22] proposed different solutions based on genetic algorithms, both of these two schemes cannot avoid the detection and repair of infeasible chromosomes generated by coding and genetic operators, making the calculation of the algorithm larger volume and lower operating efficiency. Zhao, Han and Wang [

23] proposed to realize the comprehensive scheduling of products by virtualizing the level of parts and coding according to the level of partition. The algorithm first sets different grades for the components of each part of the product, and then partitions them according to different grades, and then encodes the components according to different partitions. While this coding method can improve the initial solution to a certain extent, it is feasible, but this encoding method increases the constraints of the realization process of some processes, resulting in a reduction in the space of feasible solutions and an increase in the possibility of leaving the optimal solution. Shi and Zhao [

24] proposed a genetic algorithm solution based on constraint chain coding. The coding method designed ensures the feasibility and completeness of the initial solution space, but the crossover and mutation operations designed by it will produce an impossible solution, requiring additional detection and repair work. Lei, Guo and Song [

25] proposed a comprehensive scheduling algorithm based on the process relationship matrix table. The algorithm first establishes a process relationship matrix table for the product, and then designs the corresponding coding rules and evolution operators based on the table. Shi, Zhao and Meng [

26] proposed an algorithm that mixed the improved bottleneck equipment switching strategy and genetic algorithm, but it needs to perform different operations on different infeasible chromosomes to achieve the repair effect.

The flexible machine network integrated scheduling problem extends the traditional flexible integrated scheduling problem [

27,

28], that is, all kinds of machines providing processing services are no longer limited to the same physical location. Therefore, it is necessary to pay attention to the physical location of the process in practical applications and the transportation process between equipment resources. However, most of the equipment resources in the comprehensive scheduling problems studied by previous studies are geographically located in the same workshop or enterprise, and the designed algorithm ignores the process transportation between the equipment or includes the transportation time in the processing time. Such an assumption is not in line with the actual cloud manufacturing production environment and affects the final scheduling results. Therefore, in order to solve the problems faced by flexible equipment in network production scenarios, we propose a comprehensive scheduling solution for reverse-sequence equipment networks based on root node process sets that can meet real-time changes. Aiming at the priority processing constraints existing in complex products, combined with the reverse order scheduling method, a coding method that supports real-time changes based on the root node process set is given. In order to ensure that the population individuals conform to the corresponding rules during the evolution process, two available crossover and mutation operators are given, respectively.

2. Problem Description

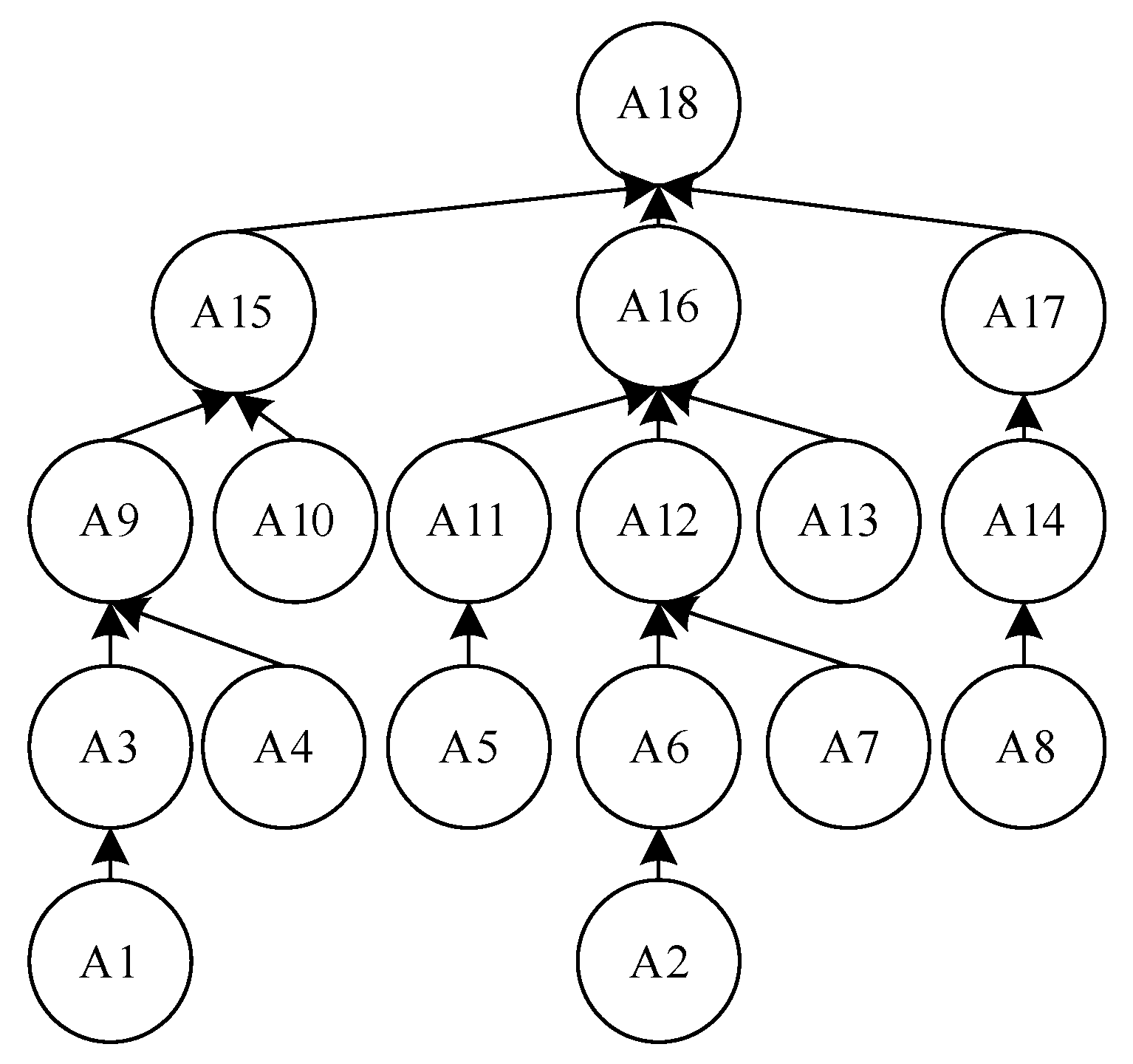

In general, the comprehensive scheduling problem of tree-structured complex products in the flexible equipment network production scenario can be understood as: A tree-structured complex product that contains n processes that can be completed and requires multiple interconnected processing equipment for collaborative production. For example,

Figure 1 shows the process of a product being processed into a finished product through multiple processes. Each process includes three different parts, which are the name of the process, the set of equipment to be used in the processing process, and the process required for the process. The transportation time between the devices in

Figure 1 is shown in

Table 1. The work of this paper is to reasonably arrange the scheduling sequence of each process and the corresponding processing equipment to reduce the time spent on product processing. Assuming that the selectable process set is

, the selectable equipment set of process

is

and

,

is the time it takes for process

to process products through equipment

is the transportation time between equipment

and

. The processing sequence between processes is executed according to the order specified by the constraint relationship set

it means that only Process

processing operation is completed,

can perform processing operation.

and

represent the processing start time and end time of

, respectively.

= 1 means that the process

is processed on the equipment

, otherwise it is 0;

= 1 means that the processes

and

are processed on the same equipment, and the process

is the immediate preceding process of the process

, that is, the process

starts processing after the processing of operation

is completed, otherwise it is 0.

The objective function

is constrained by conditions

Equation (1) shows how to make the product completion time the shortest. Equation (2) shows that no matter which process, can only be processed by certain equipment in . Equation (3) is the time required for process to process products. Equation (4) shows that any process must follow the prescribed order and the product to be processed in this process must reach the corresponding equipment before the product can be processed; Equation (5) is the time required for process to process the product. Equations (6) and (7) indicate that, if a device can perform two different processing procedures, the processing sequence will be carried out after the procedure. Equation (8) shows that the execution time of each process must conform to the actual scene.

3. Algorithm Design

The previous positive-sequence integrated scheduling algorithms all start scheduling from leaf nodes, which leads to the fact that when the scheduling algorithm was executed, the start processing time of a certain operation may be constrained by the completion time of multiple predecessor operations, and it is difficult to reasonably arrange these related operations, resulting in unsatisfactory scheduling results. Therefore, in this paper, we first adopt the framework of the genetic algorithm, learn from the method of reverse order scheduling to obtain the scheduling scheme with the optimal solution, and execute the final scheme according to the forward order scheme.

3.1. The Representation Method of Individual

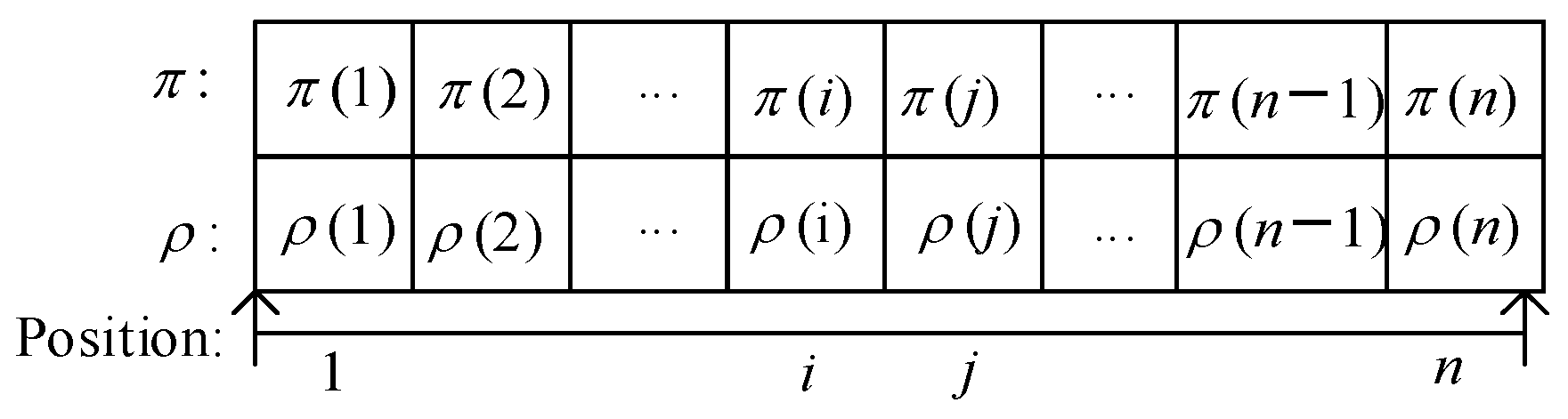

The pre-solved problems of the scheme proposed in this paper involves the sub-problem of operation arrangement and the sub-problem of machine selection. Therefore, in this paper, we apply the individual representation method to the double chain, that is, use the process chain and the equipment chain to jointly represent the individuals in the population, as shown in

Figure 2. For the sub-problem of operation arrangement, we use the operation chain

π to represent it, that is,

π(

i) means that the process

Oπ(i) is ranked in the

ith position of the process chain. For the sub-problem of machine selection, we use machine chain

ρ to represent it, that is,

ρ(

i) indicates that the operation

Oi is processed on the machine

ρ(

i).

3.2. Encoding

In this paper, we use the idea of reverse scheduling to pre-schedule the complex products. Therefore, for a tree that can display the product processing process, the root node indicates the beginning of scheduling, and the completion of all leaf nodes indicates that the product has been scheduled. Firstly, aiming at the sub-problem of operation scheduling, that is, the arrangement of each operation on the operation chain π, this paper proposes a real-time coding method using the process set on the root node. The coding process includes the following four sub-processes:

Step 1: Obtain the current root node operation set. Initially, the root node operation set has only one element, that is, the root node process;

Step 2: Obtain the current operation to be scheduled, that is, randomly select a root node from the current root node operation set for scheduling;

Step 3: Update the current root node process set, and add the processes in the child nodes of the currently selected process to the root node process set;

Step 4: Determine whether the process set of the root node is empty, if it is empty, it indicates that the process chain coding is completed, otherwise, skip to Step 1.

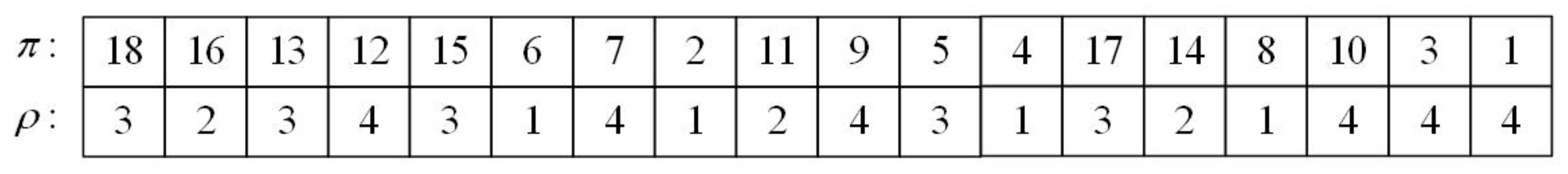

For the processing equipment corresponding to each process, this paper adopts the idea of roulette selection strategy. When a device takes less time to process a product, it is more likely to be used next. Through the above two steps, we can encode a complex product into a reasonable and feasible individual, and

Figure 3 is an example of encoding for the product shown in

Figure 1.

3.3. Decoding

For any individual in the population, this paper proposes a decoding method that applies the earliest possible start processing time to the decoding process to decode the individual into a specific scheduling scheme. Since the operation chain π specifies when the process should be scheduled, the machine chain

specifies the processing machine corresponding to the operation. Therefore, we obtain each operation in turn from left to right and obtain the corresponding machine. Therefore, we obtain each process in turn from left to right and obtain the processing equipment corresponding to the process. Then, in the order from the first idle time to the last idle time, each process is processed at the earliest in the corresponding equipment. The detailed decoding steps designed in this paper are as follows, and a specific example is shown in

Figure 4.

Step 1: Obtain the attribute information of operations, and set the pre-start processing time of the process to 0, where .

Step 2: Read a process gene in the process chain sequentially from left to right, set the process corresponding to this gene as , read the equipment chain to obtain the processing equipment corresponding to this process as , and the processing time as , is the migration time for transporting process Oi from its processing equipment to the processing equipment corresponding to Oj.

Step 3: Calculate the time when the actual processing operation of the operation Oi starts and the time when the processing operation ends. Find each idle time on the equipment in the order from the first idle time to the last idle time, that is, [, ], and then compare the idle time with the time required for the process to be executed, if , so that the actual start processing time of process , otherwise, continue to compare the next idle time with the time required for the process to be executed. If the process execution condition is not met until the last idle time, the process will be executed on the device after other processes are executed. At this time, , where is the time when the last process on the device ends. The time at which the execution of the actual machining operation of the operation ends.

Step 4: Reassign the pre-start processing time of the next process to be executed after process . Read the product process partial sequence relationship table to obtain the next process to be executed after the process . Assume that the next process to be executed after the currently acquired process Oi is Oj, then the pre-start execution time of the reassigned process Oj , where is the migration time for transporting process to the equipment corresponding to process Oj.

Step 5: Judge whether the reading of the chromosome is completed. If the reading is completed, the decoding process ends and the product processing process is completed; otherwise, skip to Step 2.

3.4. Selection Method

We use a tournament selection strategy to select two parent chromosomes that participate in evolution, and the individual with the smallest completion time is selected as the parent chromosome. At the same time, the elite retention strategy is applied in the algorithm, so that the optimal individual at this stage is directly selected into the next generation population.

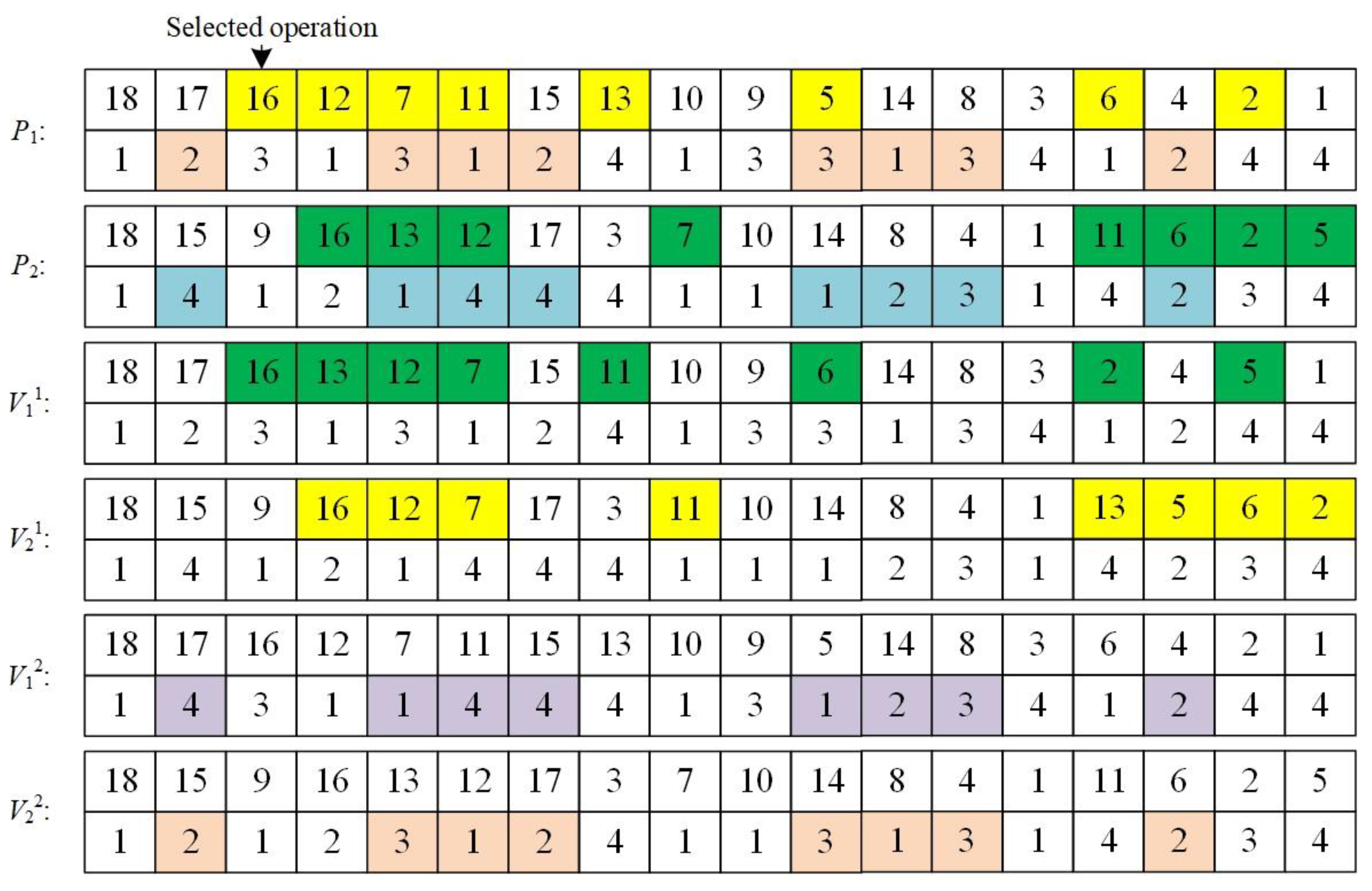

3.5. Crossover Method

In this paper, we adopt the crossover strategy of generating four-children, that is, generating four child chromosomes from two parent chromosomes. Based on position and operation, we give two crossover methods, namely the multi-child crossover method based on crossed row vector and the multi-child crossover method based on subtree. The algorithm randomly executes the above two crossover strategies during the execution process. If the number of chromosomes in the population reaches the individual maximum value, the crossover process is terminated. The detailed process of the implementation of the two crossover methods is as follows.

- (1)

Multi-child crossover method based on crossed row vectors

Step 1: Two parent chromosomes involved in evolution are generated by the selection strategy described in this paper, assuming that the selected parent chromosomes are P1, P2;

Step 2: Randomly generate a 0–1 sequence with the same length as the chromosome operation chain as the recombination marker, 0 indicates that the position is not recombined, and 1 means that the position is recombined;

Step 3: Generate child chromosomes from the parent chromosomes P1 and P2 respectively, and the specific generation method is as follows.

(a) Generation of child chromosome : The machine chain of the child chromosome is completely inherited from the machine chain of the parent chromosome P1, and in the process chain, how to arrange the process on which the recombination flag bit is 1 is specified by the parent chromosome P2, and the sequence of operations on the recombination flag bit 0 is exactly the same as that in the parent chromosome P1. The specific crossover method of the operations that needs to be recombined in the operation chain is: obtain the recombination gene sequence corresponding to the process corresponding to the position where the recombination flag bit is continuously 1, and the gene in the recombination sequence is placed in the gene corresponding to the position of the process chain in the child chromosome , and the placement order is specified by the parent chromosome P2. The recombination string corresponding to other continuous recombination markers is obtained in turn, and the recombination is carried out in the above way to generate the final individual.

(b) Generation of child chromosome : The machine chain in the child chromosome is completely inherited from the machine chain in the parent chromosome P2, and the ordering of the procedures with the operations on the recombination flag bit 1 in the operation chain is specified by the parent chromosome P1, and the recombination The sequence of the processes on the flag bit 0 is exactly the same as that in the parent chromosome P2. The specific recombination method of the operations that needs to be recombined in the process chain is: obtain the recombination gene sequence corresponding to the process corresponding to the position where the recombination flag bit is continuously 1, and the gene in the recombination sequence is placed in the gene corresponding to the position of the process chain in the child chromosome , and the placement order is specified by the parent chromosome P1. The recombination string corresponding to other continuous recombination markers is obtained in turn, and the recombination is carried out in the above way to generate the final individual.

(c) Generation of child chromosome : The operation chain in the child chromosome is completely inherited from the process chain in the parent chromosome P1, and the machines corresponding to the operations whose recombination flag is 1 in the machine chain is designated by the parent chromosome P2, the machine corresponding to the operation on which the recombination flag is 0 is exactly the same as that in the parent chromosome P1. The recombination process of the machine chain is as follows: The operations corresponding to the positions where the recombination flag is continuously 1 is obtained as the new recombination gene sequence, and the processing machine required for each operation in the recombination string in the child chromosome is specified by the parent chromosome P2, The recombination strings corresponding to the other consecutive recombination flags of 1 are sequentially obtained and recombined in the above manner to generate the final individual.

(d) Generation of child chromosome : The operation chain in the child chromosome is completely inherited from the operation chain in the parent chromosome P2, and the machine corresponding to the operation whose recombination flag is 1 in the machine chain is designated by the parent chromosome P1, the machine corresponding to the operation on which the recombination flag is 0 is exactly the same as that in the parent chromosome P2. The specific recombination method of the machine chain is as follows: The operation corresponding to the position where the recombination flag is continuously 1 is obtained as the new recombination gene sequence, and the processing machine required for each operation in the recombination string in the child chromosome is designated by the parent chromosome P1. The recombination strings corresponding to the other consecutive recombination flags of 1 are sequentially obtained and recombined in the above manner to generate the final individual.

Figure 5 shows four child chromosomes generated by the above steps for two randomly generated parent chromosomes.

- (2)

Multi-child crossover method based on subtree

Step 1: Two parent chromosomes involved in evolution are generated by the selection strategy described in this paper, assuming that the selected parent chromosomes are P1, P2.

Step 2: Randomly obtain all operations in a subtree as the current crossover operation string; Step 3: Generate child chromosomes from the parent chromosomes P1 and P2, respectively, and the specific generation method is as follows.

(a) Generation of child chromosome : The machine chain in the child chromosome is completely inherited from the machine chain in the parent chromosome P1. The sequence of each operation sequence of the crossover operation string in the operation chain is specified by the parent chromosome P2, and the sequence of the remaining operations is exactly the same as that in the parent chromosome P1.

(b) Generation of child chromosome : The machine chain in the child chromosome is completely inherited from the machine chain in the parent chromosome P2. The sequence of each operation sequence of the crossover operation string in the operation chain is specified by the parent chromosome P1, and the sequence of the remaining operations is exactly the same as that in the parent chromosome P2.

(c) Generation of child chromosome : The operation chain in the child chromosome is completely inherited from the parent chromosome P1. The machine corresponding to the process in the crossover operation string in the machine chain is designated by the parent chromosome P2, and the machine corresponding to the remaining operations is exactly the same as that in the parent chromosome P1.

(d) Generation of child chromosome : the operation chain in the child chromosome is completely inherited from the parent chromosome P2, the machine corresponding to the process in the crossover operation string in the machine chain is designated by the parent chromosome P1, and the machine corresponding to the remaining operation is exactly the same as that in the parent chromosome P2.

Figure 6 shows four child chromosomes generated by the above steps for two randomly generated parent chromosomes.

- (3)

Analysis of the crossover method

In the above two methods, part of the operation chain or machine chain of the individual offspring is designated by another parent chromosome. Since the individuals in the population are all legal chromosomes, that is, the scheduling order between operations satisfies the priority constraint relationship, and the corresponding processing machine is also legal processing machine, the individuals generated by the above two methods are also legal individuals.

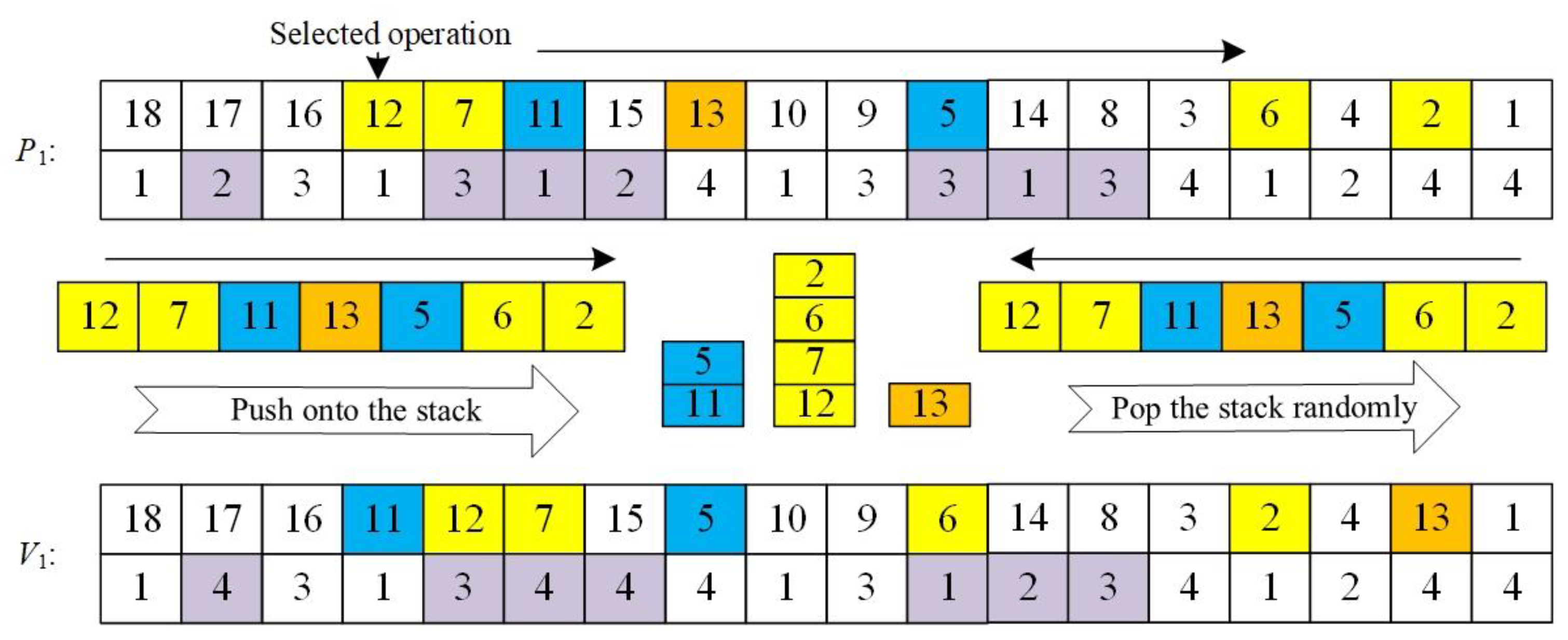

3.6. Mutation Method

- (1)

Chaotic mutation based on sibling operations

Step 1: Randomly select a process and its sibling operations, take each sibling operation as the bottom element of the stack, and add the descendant nodes of each sibling operation in the parent chromosome to its corresponding gene stack according to the order from front to back, so as to ensure that some processes in the same stack can be executed first under the influence of constraints, and the execution order of processes in different stacks will not be affected by constraints.

Step 2: Delete the selected operation and its corresponding processing machine in the parent chromosome.

Step 3: Randomly pop the top element of the stack and insert it into the last free position of the process chain in the child chromosome and re-determine which device should be processed for it according to the roulette selection strategy, repeat the above steps until all stacks are. If no element is present, it will no longer mutate.

An example of the encoding process of the encoding method introduced in this article is shown in

Figure 7, wherein operation

O12,

O11 and

O13 are sibling operations.

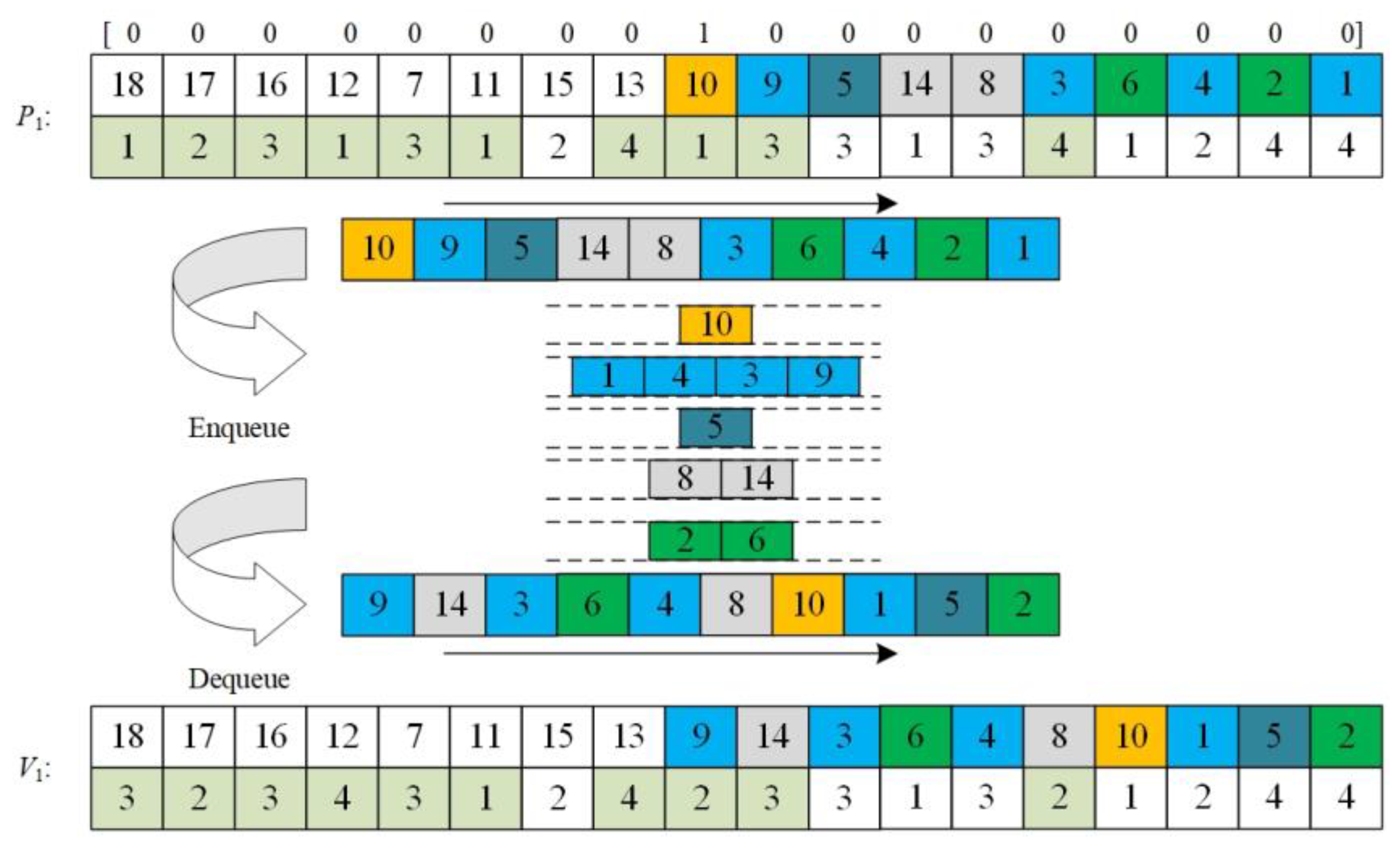

- (2)

Random mutation based on mutation row vector

Step 1: Randomly generate a mutation row vector, in which the elements are 0 or 1, and there is only one 1, which is used to identify the mutation position, and the operation sequence after the mutation position is the mutation gene sequence.

Step 2: Put the processes in the mutant gene sequence into different queues from front to back, so that the processes in the same queue are affected by the constraints, and the processes not in the same queue are not affected by the constraints.

Step 3: Randomly dequeue elements in different queues to generate mutated operation substrings and select the processing machine for them according to the roulette selection strategy. Repeat the above steps and specify that all queues are empty, and the mutation no longer takes place.

Figure 8 is the process of producing new individuals by the above mutation method.

- (3)

Analysis of the mutation method

In the above two mutation methods, the generation of the mutation string relies on stacks or queues, and the application of stacks or queues ensures that the operation of the final generated substrings satisfy the priority processing constraint relationship. Therefore, the two mutation methods designed in this paper will not produce infeasible individuals.

3.7. Local Search

This paper uses the local search method to increase the efficiency of the algorithm to retrieve the optimal solution better and faster. Specifically, to obtain the critical path corresponding to the optimal individual plan, first change the equipment corresponding to the process one by one in the order from the first process to the last process, then compare the advantages and disadvantages of the old and new scheduling plans, and finally retain the optimal plan as the latest scheme.

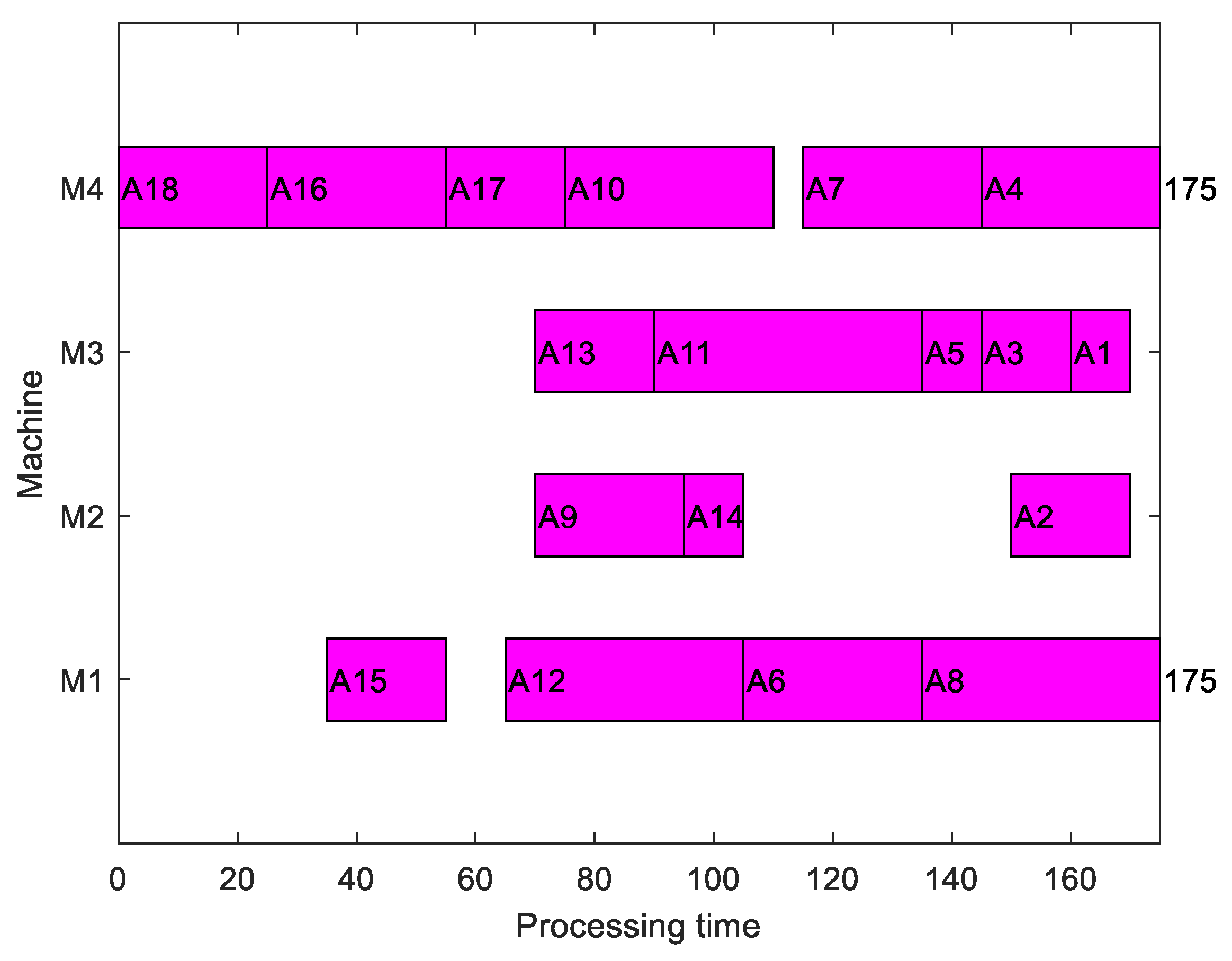

3.8. The Conversion Strategy Based on Completion Time Flipping

As the idea of reverse order scheduling is adopted in this paper, when an individual is decoded as a specific scheduling scheme, the generated Gantt chart is still in the form of reverse order. In order to obtain a positive sequence scheduling, we adopt the conversion strategy based on the completion time flipping [

29] that we previously proposed. When the proposed conversion strategy is used to convert the scheduling scheme shown in

Figure 4, the final positive scheduling scheme is shown in

Figure 9.

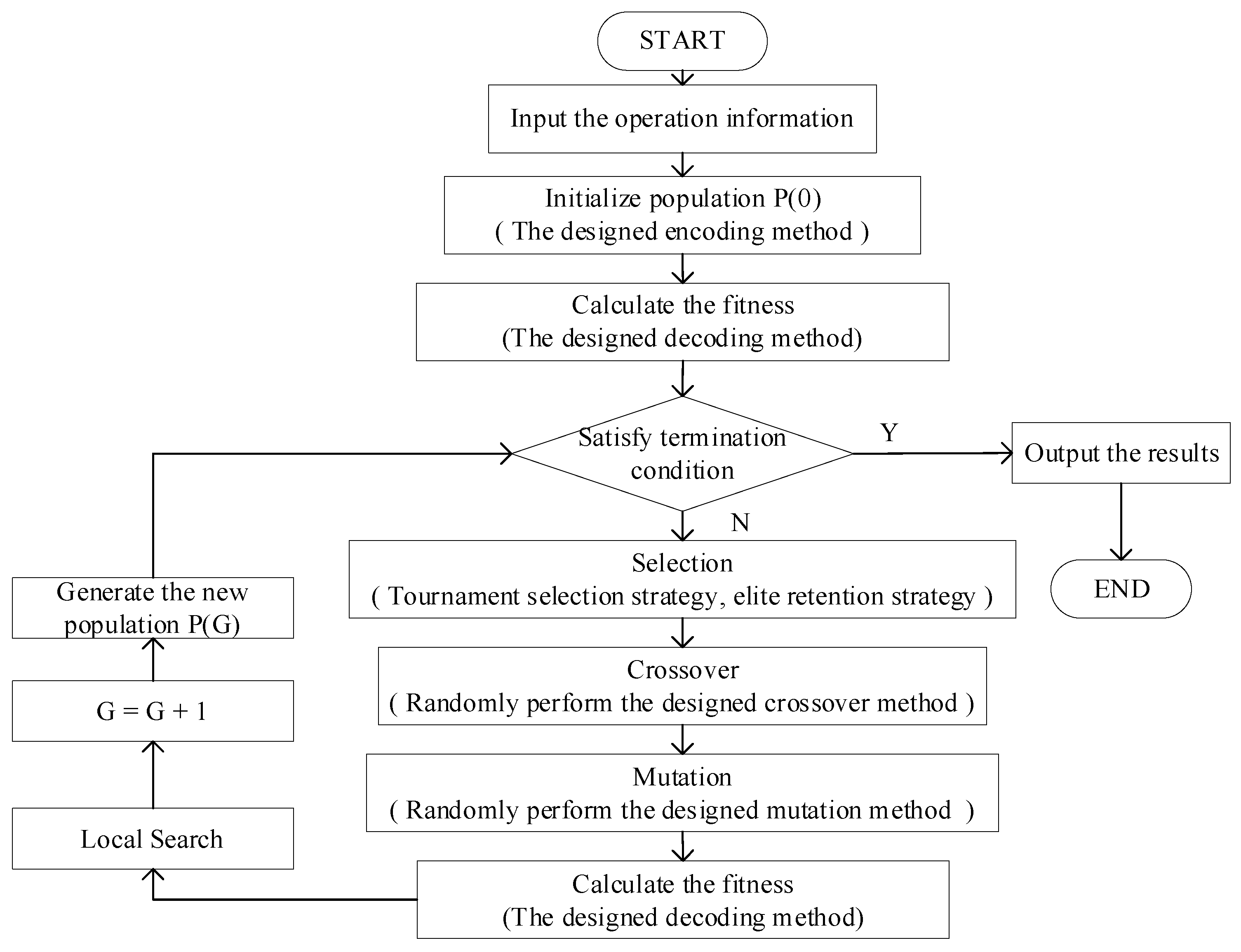

3.9. Algorithm Process

As shown in

Figure 10, the algorithm designed in this paper randomly performs crossover and mutation operations during operation. If the objective function value corresponding to the optimal individual of the population is not improved in consecutive

G generations, the algorithm terminates.