Abstract

Despite the serious threat of global warming caused by carbon emissions, commercial refrigeration systems that generate cooling are unable to adjust their usage time. Therefore, it is essential to enhance the energy efficiency of refrigeration systems themselves. Recently developed refrigeration systems offer improved energy consumption efficiency as they utilize inverter-type outdoor units that can communicate with indoor units. However, traditional legacy refrigeration systems still suffer from poor energy efficiency because the existing indoor units cannot communicate with inverter-type outdoor units. Hence, this paper introduces a heuristic energy efficiency improvement algorithm for commercial refrigeration systems using legacy indoor units when an inverter-type outdoor unit is installed. In particular, to reduce the computational complexity of the process of selecting the optimal temperature difference and target low-pressure variables that can enhance energy efficiency, the algorithm employs the Monte Carlo method. Finally, the performance of the proposed heuristic energy efficiency improvement algorithm was evaluated in a laboratory environment to confirm its applicability.

1. Introduction

Recently, the United Nations announced that the global average temperature from June to August 2023 was 16.77 °C, the highest recorded since the beginning of meteorological observations in 1940, and further warned that the era of global warming is over and the era of global degradation has arrived. Phoenix, Arizona, in the western United States, has set a record the same year for the longest period of extreme heat with temperatures exceeding 43 °C for 31 consecutive days, and China’s San Baohyang broke its all-time high temperature of 52.2 °C. With climate change becoming increasingly evident given these temperature extremes, countries around the world are working together to achieve carbon neutrality by reducing carbon emissions, the main culprit in global degradation [1,2]. Carbon neutrality means that carbon dioxide absorption is balanced with carbon dioxide emissions generated by companies or individuals, making actual carbon dioxide emissions “zero”. To this end, 195 countries participated in the 2015 United Nations Climate Change Conference to try to reduce carbon emissions through the Paris Agreement. Representative ways to reduce carbon include reducing carbon emissions and reducing the consumption of goods and energy made from carbon resources, such as fossil fuels [3,4,5,6,7].

Global companies with high carbon emissions are making efforts to reduce their emissions by installing carbon reduction devices or purchasing carbon emission allowances from other companies [8]. Apart from the efforts of high-carbon-emitting companies, there is a need to produce goods and energy with lower carbon emissions and consume them more efficiently [9]. In particular, not consuming energy at all and improving energy efficiency are important. Not consuming energy requires certain choices in this era of extreme climate change. In general, increasing energy efficiency may be more realistic in working toward reduced energy use.

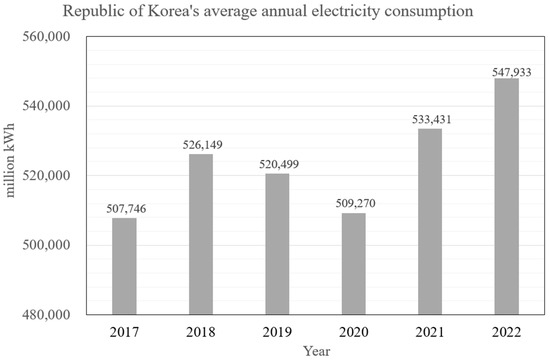

During the coronavirus 2019 (COVID-19) pandemic, electric energy usage decreased worldwide but now appears to be on the rise again [10]. According to data from the Korea Electric Power Corporation (KEPCO), as shown in Figure 1, South Korea’s electricity usage increased by 4.74%, from 509,270 million kWh in 2020 to 533,431 million kWh in 2021, and then by 2.72% to 547,933 million kWh in 2022. This annual average electricity usage growth rate significantly surpasses that from 2017 to 2022 (1.57%). The increased electricity usage since the COVID-19 pandemic is primarily due to coal-fired power plants, which emit a substantial amount of carbon, as opposed to carbon-neutral alternative energy sources. Thus, efforts to reduce the use of electrical energy by increasing alternative energy production are urgently needed.

Figure 1.

Republic of Korea’s average annual electricity consumption.

Devices that generate heat using electricity, such as heating systems in office buildings, can reduce electricity usage through adjustment of their operating hours based on the situation. In contrast, devices that generate cold air, such as air conditioners and refrigerators, have limitations in terms of reducing electricity usage through adjustment of their operating hours. The recent climate conditions (i.e., frequent abnormally high temperatures) make it difficult to reduce refrigeration system usage because of the risk of spoilage of food stored in refrigerators. For a refrigeration system that generates cold air, usage time cannot be adjusted, unlike a device that generates heat; thus, it is necessary to increase the energy efficiency of the refrigeration system itself. Recently developed refrigeration systems offer improved energy consumption efficiency by using an inverter-type outdoor unit that can transmit and receive information from the indoor unit through communication. However, existing refrigeration systems still have low energy efficiency issues due to the lack of communication with the indoor unit, even if a new inverter-type outdoor unit is installed. Numerous studies are underway to improve the energy efficiency of integrated systems, including commercial refrigeration systems.

Chiou et al. introduced a fuzzy temperature control method for multi-unit room air conditioners to improve energy efficiency [11]; however, the energy efficiency of refrigeration systems was not addressed. Jasmin et al. (2013) investigated domestic refrigerators’ energy consumption [12]; the operating condition variables (ambient temperature, thermostat setting position, and heat load) that affect the energy consumption of refrigerators were evaluated; their results revealed differences in the absence of information on the indoor unit. Ali et al. (2020) studied the single-phase induction motor drive of a refrigerator compressor [13]; they developed an algorithm to improve the energy efficiency of cooling systems through modeling and analysis of commercial refrigeration systems. Kassai et al. (2019) considered optimizing the energy consumption of direct-current refrigerators used in commercial freezers [14]; they concluded that 62.4% in energy savings could be achieved by using a proportional-integral-derivative controller. However, the indoor unit was not addressed. Antonio et al. (2020) sought to reduce energy costs by introducing a photovoltaic self-consumption system to industrial refrigeration [15]; despite the potential reduction in power consumption through self-consumption of energy, their approach was limited by the requirement for additional devices for implementation in conventional commercial refrigeration systems.

Here, we developed an algorithm to increase the energy efficiency of refrigeration systems that use an inverter-type outdoor unit that does not communicate with the indoor unit of an old refrigeration system. In particular, the algorithm uses the Monte Carlo method to reduce the calculations required when selecting the optimal set temperature difference and target low-pressure variable. Finally, the performance of the proposed heuristic energy efficiency improvement algorithm was evaluated in a laboratory environment to confirm its applicability.

2. Commercial Refrigeration Systems

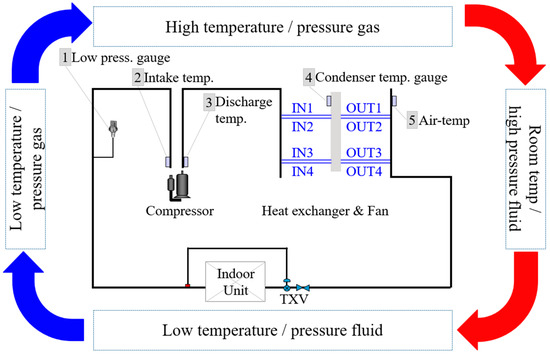

In general, refrigeration systems have the same temperature control method but are divided into indoor and commercial refrigeration systems depending on the space and purpose of installation. A commercial refrigeration system, consisting of an indoor unit that absorbs heat and lowers the temperature and an outdoor unit that emits the absorbed heat, controls the temperature inside a commercial refrigerator [16]. The temperature of a commercial refrigeration system is controlled via changes in the state of the refrigerant using an evaporator, a condenser, and a compressor. The refrigerant lowers the internal temperature of a commercial refrigerator due to the latent heat it absorbs when it evaporates while passing through the evaporator. As the refrigerant passes through the condenser, it loses heat and remains in a high-temperature, high-pressure gaseous state. The high-temperature, high-pressure refrigerant gas that passes through the compressor also passes through the condenser, releases latent heat to the outdoors, and finally passes through the expansion valve before being transferred back to the evaporator.

Here, we assumed that the indoor unit is installed with an expansion valve through which the refrigerant flows in and performs the function of internal storage, while the outdoor unit releases the latent heat of the refrigerant through the process of evaporation–compression–condensation. Commercial refrigeration systems often have large capacities or consist of multiple built-in systems; as such, they are installed with separate indoor and outdoor units.

Figure 2 shows the structure of the operation cycle of a typical commercial refrigeration system. First, when a commercial refrigeration system is running, the thermostatic expansion value (TXV) system of the indoor unit opens, allowing the refrigerant to flow in from the outdoor unit. When the current temperature of the indoor unit reaches the temperature set in the indoor unit, the TXV system closes and the outdoor unit stops operating. The pressure of the refrigerant coming out of the indoor unit is measured at the position of sensor 1 (a low-pressure gauge sensor), and the compressor operates and moves to the outdoor unit. The temperature of the refrigerant moving to the outdoor unit is confirmed using the temperature difference between sensor number 4 (the condenser temperature gauge sensor) and sensor number 5 (the air temperature sensor). Sensor number 2 (the intake temperature sensor) and sensor number 3 (the discharge temperature sensor) are used to analyze the direct correlation between the indoor and outdoor units by measuring the intake temperature of the refrigerant.

Figure 2.

Refrigeration system operation sequence.

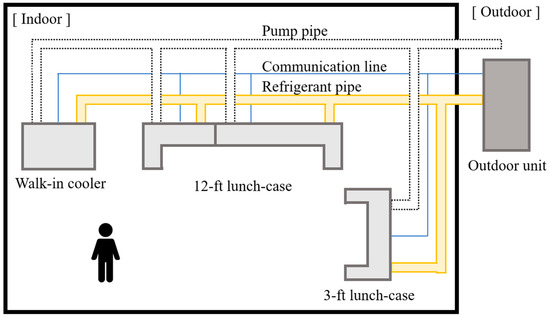

In a commercial refrigeration system, the outdoor unit, which releases the absorbed latent heat to the outside, also performs important functions. In contrast to the indoor unit, which absorbs heat and lowers the temperature, the outdoor unit is controlled by stopping the operation of the outdoor unit when the indoor unit reaches the set target temperature, and by receiving status information from the indoor unit through communication and comparing it to the target temperature to stop the operation. The method of operating according to the target temperature without information about the indoor unit involves repetition of the operation for a certain period of time depending on the power status (on/off). In particular, when the refrigeration load of the indoor unit fluctuates, considerable energy is consumed through intermittent operation, in which the outdoor unit repeats the operation over very short time periods. On the other hand, the method of receiving and controlling the status information of the indoor unit based on communication shows excellent control performance by reaching the target temperature relatively quickly. Outdoor units that receive and control information from indoor units through communication are classified as inverter-type outdoor units and are used in many commercial refrigeration systems. Compared to existing outdoor units, inverter-type outdoor units can control the temperature in proportion to the refrigeration load of the indoor unit. Moreover, the time to reach the target temperature is short, so it has excellent energy consumption efficiency. Figure 3 shows the structure of a typical commercial refrigeration system. In commercial refrigeration systems, multiple indoor units are often installed with one outdoor unit, and information from the indoor units is shared with the outdoor unit through communication. Additionally, multiple indoor units exchange refrigerant through a refrigerant pipe and discharge generated water through a pump pipe.

Figure 3.

Typical commercial refrigeration system configuration.

This new commercial refrigeration system shows excellent energy consumption efficiency because it uses an inverter-type outdoor unit that receives and controls information from the indoor unit through communication. Contrarily, when using older commercial refrigeration systems, energy consumption efficiency is relatively low. Older commercial built-in systems use an inverter-type outdoor unit that can receive information from the indoor unit via communication when the outdoor unit, which has a relatively high probability of failure, breaks down. However, older indoor units, which are relatively expensive and do not break down frequently, cannot transmit information through communication, so although an inverter-type outdoor unit is installed, no improvement in energy consumption efficiency can be expected. Replacing an expensive indoor unit with a new model because you cannot expect it to improve energy consumption efficiency is not an appropriate method from an energy-saving perspective. Therefore, an inverter-type outdoor driving algorithm that can improve energy efficiency even without information about the existing old indoor unit is needed.

3. Heuristic Energy Efficiency Improvement Algorithm

A commercial refrigeration system uses multiple indoor units to communicate and provide information to an inverter-type outdoor unit and operates using temperature difference (TDj), current low pressure (LPi), and outside air temperature as variables. The set temperature difference refers to the difference between the temperature set by the indoor unit and the temperature inside the indoor unit. The larger the set temperature difference, the faster the operating frequency of the inverter-type outdoor unit. Low pressure refers to the pressure measured at the gas valve at the evaporator outlet in the indoor unit, and is the standard for an inverter-type outdoor unit to perform its on/off operation. Outdoor temperature is a factor that affects the release of latent heat from the refrigerant in the condenser of the inverter-type outdoor unit and also has a seasonal effect. In other words, the energy efficiency of an inverter-type outdoor unit in an environment where it cannot receive information from the indoor unit can be improved if the final set temperature difference (TD) and the final target low pressure (LP) are properly established.

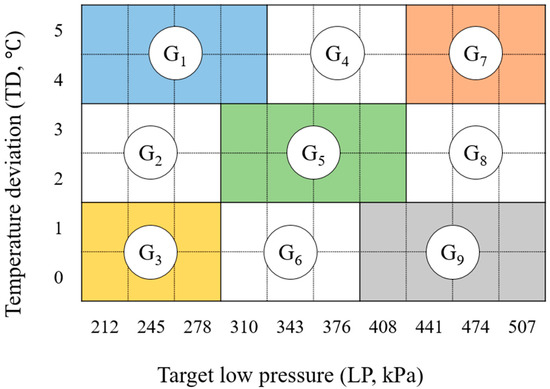

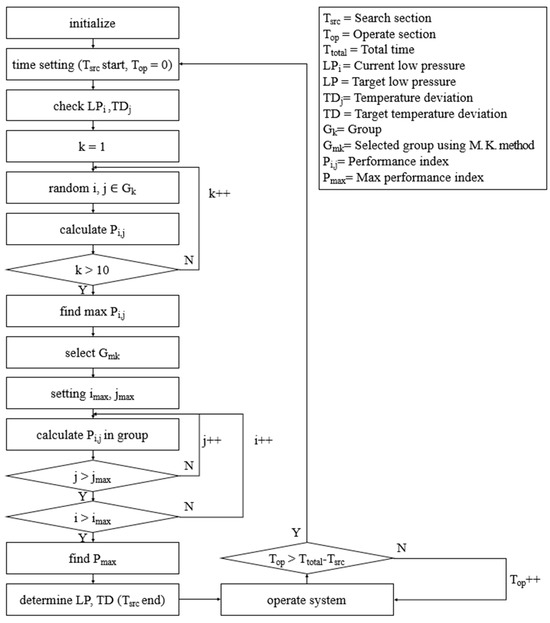

The proposed energy efficiency improvement algorithm divides the operation of the inverter-type outdoor unit into search and operation sections and changes the set temperature difference and target low pressure in the search section to determine the values that achieve the highest performance. Once the set temperature difference and target low pressure are determined, the inverter-type outdoor unit operates at that value during the operation section. Based on expert consultation with commercial refrigeration system manufacturers, the temperature, as shown in Figure 4, is divided into six levels (0–5 °C), and the target pressure is divided into 10 levels (spanning 212–507 kPa). In our proposed approach, the Monte Carlo method was employed, effectively dividing the process into nine segments to reduce the computational workload.

Figure 4.

Control section setting considering TD and LP.

Figure 5 shows the heuristic energy efficiency improvement algorithm for a commercial refrigeration system without indoor unit information. First, the search section (Tsrc) and operation section (Top) of the inverter-type outdoor unit are set to 0, and the set temperature difference (TDj) and current low pressure (LPi) are checked. The most important factors for an inverter-type outdoor unit without information from the indoor unit to operate energy efficiently are the set temperature difference (TDj) and current low pressure (LPi). The set temperature difference is an arbitrary value between 0 and 5 °C. The target low pressure is set to 1 of 10 values measured from an inverter-type outdoor unit. The target low-pressure stage is a requirement of the company that supported the research service and is the stage at which the inverter-type outdoor unit normally operates. The Monte Carlo method is then used to calculate the performance index value (Pi,j) of any coordinate of the first to ninth groups (Gk). The reason for selecting the nine random groups was also determined by the requirements of the companies to which they applied. The group with the highest performance index value (Pmax) is selected. Here, the performance index can be calculated as follows:

where Wk and Hk represent the power consumption and heat absorption in the k-th operation, respectively, and Wk+1 and Hk+1 represent the power consumption and heat absorption in the k+1-th operation, respectively, for comparison. α refers to the coefficient that determines the ratio of power consumption and heat absorption and is set to 0.3 in this study. The α value of 0.3 was selected as the most optimized value through several trials and errors. The first performance index value (P1,1) is set to 1 because there is no comparison target. The performance index value (Pi,j) then changes in the second operation. A performance index value > 1 indicates better performance. The highest performance index value (Pmax) represents the group with the best performance. Power consumption and heat absorption were calculated with reference to [16].

Figure 5.

Heuristic energy efficiency improvement algorithm flowchart.

Once the group with the highest performance index value is selected, the coordinate value with the highest performance index value in the selected group is identified. The search section ends when the highest performance index value (Pmax) is selected within the selected group. Next, the inverter-type outdoor unit operates during the operation section with the selected target temperature difference and target low-pressure value. If the operation section time of the inverter-type outdoor unit exceeds the value obtained by subtracting the search section time from the total operation time, the inverter-type outdoor unit initializes the search section time again and the process is repeated. The process stops when the user-set operation section ends.

4. Performance Evaluation

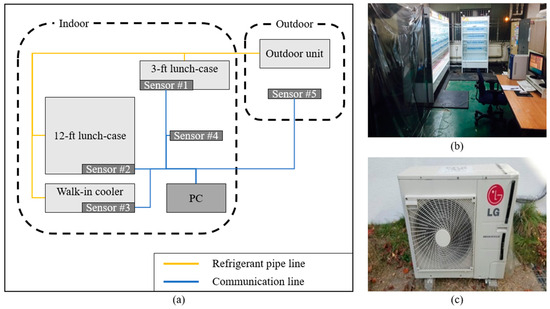

The performance evaluation of our proposed energy efficiency improvement algorithm for a commercial refrigeration system without indoor unit information was conducted in a laboratory-scale environment consisting of three indoor units and one inverter-type outdoor unit, as shown in Figure 6a. The indoor unit consisted of a 3 ft lunch case, a 12 ft lunch case, and a walk-in cooler (Figure 6b). One inverter-type outdoor unit was equipped with L company’s (Seoul, Republic of Korea) 5 HP LSC-V0990A9 inverter condensing units (CDUs), as shown in Figure 6c. Temperature sensors that measure indoor temperature were installed at the top of the 3 ft and 12 ft lunch cases and at the top of the walk-in cooler. The LGMV program provided by L Company was used to monitor the commercial refrigeration system’s performance evaluation environment, and information such as set temperature, set temperature difference, target low pressure, and power consumption was collected and stored in real time.

Figure 6.

Commercial refrigeration system experimental test-bed structure. (a) Schematic diagram of the entire commercial refrigeration system. (b) Experimental environment for indoor unit (3 ft lunch case, 12 ft lunch case, walk-in cooler). (c) Experimental environment for outdoor unit (5 HP LSC-V0990A9).

The experiment was conducted at the end of August in a laboratory at Pusan National University (Busan, Republic of Korea), and performance was evaluated continuously over a 3-day period, starting and ending at 1 PM. The average outdoor temperature for the 3-day experiment ranged from 31.1° ± 0.42° to 23.1° ± 0.46°, and the average humidity was 71.6 ± 0.12%. The average indoor temperature was 24.2° ± 0.29°, and humidity was 77.7 ± 0.46%. There was no change in weather, such as rain, during the three days that the experiment was conducted. The experiment was conducted three times. In the first experiment, power consumption was measured in an experimental environment, in which the inverter-type outdoor unit was operated for 24 h in a random manner set by the manufacturer, without information about the indoor unit. In the second experiment, the power consumption was measured while the inverter-type outdoor unit to which the proposed algorithm was applied was operated for 24 h according to the algorithm, without information from the indoor unit. In the second experiment, the performance index values were calculated for all coordinates and consumption was measured while operating for 24 h according to the selected set temperature difference and target low pressure. The third experiment was conducted to confirm the performance of the Monte Carlo method in the proposed algorithm. The Monte Carlo method is set randomly every time the inverter-type outdoor unit operates, and it determines the set temperature difference and target low pressure according to the set area.

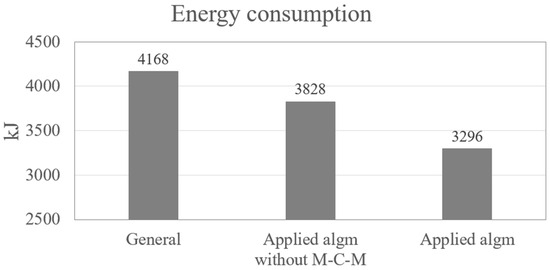

Figure 7 shows the performance evaluation results of the proposed heuristic energy efficiency improvement algorithm. In the absence of information about the indoor unit, it was confirmed that the inverter-type outdoor unit operated 24 h a day in a random manner set by the manufacturer, with an average energy consumption of 4168 KJ per hour. It was also confirmed that the inverter-type outdoor unit to which the proposed algorithm was applied in the absence of indoor unit information operated 24 h a day according to the algorithm and consumed an average of 3296 KJ per hour. Furthermore, the inverter-type outdoor unit to which the proposed algorithm was applied exhibited reduced power consumption (by 26.5%) compared to the inverter-type outdoor unit that normally operated without indoor unit information. This is because the inverter-type outdoor unit to which the proposed algorithm is applied finds the optimal set temperature difference and target low pressure through the search period. This occurs even without indoor unit information; thus, power consumption is lower than that of a general inverter-type outdoor unit. On the one hand, an inverter-type outdoor unit without indoor information to which the algorithm is not applied cannot know the set temperature difference and target low pressure, so it operates at the time set to operate by the user and stops at the time set to stop. In this inverter-type outdoor unit driving method, energy efficiency is determined by user operation, and energy efficiency may vary greatly depending on the user. On the other hand, the inverter-type outdoor unit to which the algorithm proposed in this paper is applied has little variation in energy efficiency depending on the user, and power consumption will be reduced due to improved energy efficiency.

Figure 7.

Experimental results of heuristic energy efficiency improvement algorithm without indoor information.

In the proposed algorithm without information on the indoor unit, it was confirmed that the inverter-type outdoor unit that did not use the Monte Carlo method operated for 24 h, and the average energy consumption was 3828 KJ per hour. In comparison, the inverter-type outdoor unit to which the proposed algorithm was applied consumed an average of 3296 KJ per hour when operated 24 h a day. Thus, by applying the algorithm including the Monte Carlo method, the energy consumption of the inverter-type outdoor unit was reduced by 11.6% compared to the algorithm excluding the Monte Carlo method. Applying the algorithm using the Monte Carlo method consumed more energy because the inverter-type outdoor unit operated more during the process of finding the optimal set temperature difference and target low pressure. On the other hand, the algorithm that does not apply the Monte Carlo method caused the inverter-type outdoor unit to operate more and consume more power during the calculation process to find the optimal set temperature difference and target low pressure. In particular, algorithms that apply the Monte Carlo method may consume less power because the computational process of finding the optimal set temperature difference and target low pressure can be significantly reduced. In other words, it was confirmed that the method of finding the set temperature difference and target low pressure in the absence of indoor unit information, and the method of reducing the calculation requirements to find the set temperature difference and target low pressure using the Monte Carlo approach, can reduce the power consumption of inverter-type outdoor units.

5. Conclusions

This paper introduces a heuristic energy efficiency improvement algorithm for commercial refrigeration systems when installing an inverter-type outdoor unit that does not communicate with the indoor unit of old refrigeration systems. In particular, the algorithm for increasing energy efficiency proposed in this paper uses the Monte Carlo method to improve energy efficiency by reducing the number of calculations when selecting the optimal set temperature difference and target low pressure. Based on our performance evaluation of the heuristic energy efficiency improvement algorithm, we conclude the following:

First, a commercial refrigeration system using an inverter-type outdoor unit that can receive information from the indoor unit has higher energy efficiency compared to existing refrigeration systems. It was confirmed that the inverter-type outdoor unit shows superior energy efficiency because it controls the refrigerant based on information on the indoor heat load through communication with the indoor unit.

Second, the algorithm optimizes the set temperature difference and target low pressure, resulting in an improvement in the energy efficiency of the commercial refrigeration system that could not receive information from the indoor unit. The inverter-type outdoor unit to which the proposed algorithm was applied exhibited reduced power consumption (by 26.5%) compared to the inverter-type outdoor unit that normally operated without indoor unit information.

Third, application of the proposed algorithm provided excellent energy efficiency, even though information about the indoor unit could not be obtained because it set the set temperature difference and target low pressure for optimal performance while reducing the calculation speed using the Monte Carlo method. Notably, because the performance of the proposed algorithm was evaluated in a laboratory environment rather than a perfectly controlled chamber, the reliability of the evaluation results is limited. By applying the algorithm including the Monte Carlo method, the energy consumption of the inverter-type outdoor unit was reduced by 11.6% compared to the algorithm excluding the Monte Carlo method.

More research is needed to identify evaluation items that can more accurately determine the variable values of the proposed algorithm. Lastly, additional research is needed to more effectively segment variable values. Finally, in order to apply the proposed method to a commercial refrigeration system, research is needed on the process of verifying performance in an environment similar to the actual environment, along with additional verification of the performance of inverter-type outdoor units according to changes in external conditions and environment.

Author Contributions

Conceptualization and methodology, S.L.; software and validation, J.-H.K. and S.-G.M.; formal analysis and investigation, J.-H.K. and S.-G.M.; resources, J.-H.K. and J.-K.L.; data curation, J.-H.K. and H.-J.K.; writing—original draft preparation, J.-H.K., H.-J.K. and M.-H.K.; writing—review and editing, J.-H.K. and M.-H.K.; supervision, S.L.; project administration and funding acquisition, S.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by a National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (No. 2020R1A6A6018584).

Data Availability Statement

The datasets used and/or analyzed during the current study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The company had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

References

- Chou, K.T.; Walther, D.; Liou, H.M. The conundrums of sustainability: Carbon emissions and electricity consumption in the electronics and petrochemical industries in Taiwan. Sustainability 2019, 11, 5664. [Google Scholar] [CrossRef]

- Cui, K.; Wu, G.; Du, Y.; An, X.; Wang, Z. The coupling effects of freeze-thaw cycles and salinization due to snowfall on the rammed earth used in historical freeze-thaw cycles relics in northwest China. Cold Reg. Sci. Technol. 2019, 160, 288–299. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, Q.; Liu, L.; Wu, Y.; Liu, H.; Gu, Z.; Zhu, C. A review of low and zero carbon fuel technologies: Achieving ship carbon reduction targets. Sustain. Energy Technol. Assess. 2022, 54, 102762. [Google Scholar] [CrossRef]

- Li, K.; Ma, M.; Xiang, X.; Feng, W.; Ma, Z.; Cai, W.; Ma, X. Carbon reduction in commercial building operations: A provincial retrospection in China. Appl. Energy 2022, 306, 118098. [Google Scholar] [CrossRef]

- Wei, Y.; Chen, Z. New Insights on Environmentally Friendly Materials. Appl. Sci. 2023, 13, 10806. [Google Scholar] [CrossRef]

- Xu, G.; Zang, L.; Schwarz, P.; Yang, H. Achieving China’s carbon neutrality goal by economic growth rate adjustment and low-carbon energy structure. Energy Policy 2023, 183, 113817. [Google Scholar] [CrossRef]

- Fu, J.X.; Tang, G.H.; Zhao, R.J.; Hwang, W.S. Carbon reduction programs and key technologies in global steel industry. J. Iron Steel Res. Int. 2014, 21, 275–281. [Google Scholar] [CrossRef]

- Decanio, S.J. The political economy of global carbon emissions reductions. Ecol. Econ. 2009, 68, 915–924. [Google Scholar] [CrossRef]

- Arora, V.; Mahla, S.K.; Leekha, R.S.; Dhir, A.; Lee, K.; Ko, H. Intervention of Artificial Neural Network with an Improved Activation Function to Predict the Performance and Emission Characteristics of a Biogas Powered Dual Fuel Engine. Electronics 2021, 10, 584. [Google Scholar] [CrossRef]

- Kang, H.; An, J.; Kim, H.; Ji, C.; Hong, T.; Lee, S. Changes in energy consumption according to building use type under COVID-19 pandemic in South Korea. Renew. Sustain. Energy Rev. 2021, 148, 111294. [Google Scholar] [CrossRef] [PubMed]

- Chiou, C.B.; Chiou, C.H.; Chu, C.M.; Lin, S.L. The application of fuzzy control on energy saving for multi-unit room air-conditioners. Appl. Therm. Eng. 2009, 29, 310–316. [Google Scholar] [CrossRef]

- Geppert, J.; Stamminger, R. Analysis of effecting factors on domestic refrigerators’ energy consumption in use. Energy Convers. Manag. 2013, 76, 794–800. [Google Scholar] [CrossRef]

- Önceler, A.A.; Taşkin, S. Modeling and analysis of single-phase induction motor drive for variable capacity control of a refrigerator compressor. Sigma J. Eng. Nat. Sci. 2020, 38, 1509–1526. [Google Scholar]

- Kassai, M.; Kajtar, L.; Nyers, J. Experimental optimization of energy consumption for direct current refrigerator by PID controller tuning and comparison with ON/OFF refrigerator. Therm. Sci. 2019, 23 Pt B, 941–952. [Google Scholar] [CrossRef]

- Martínez-Calahorro, A.J.; Jiménez-Castillo, G.; Rus-Casas, C.; Gómez-Vidal, P.; Muñoz-Rodríguez, F.J. Photovoltaic self-consumption in industrial cooling and refrigeration. Electronics 2020, 9, 2204. [Google Scholar] [CrossRef]

- Lee, J.-K.; Lee, S. Selection of inverter frequency for commercial refrigerators without indoor information. Int. J. Precis. Eng. Manuf. 2017, 18, 1189–1194. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).