A Gysel Power Divider/Combiner with Enhanced Power-Handling Capability

Abstract

:1. Introduction

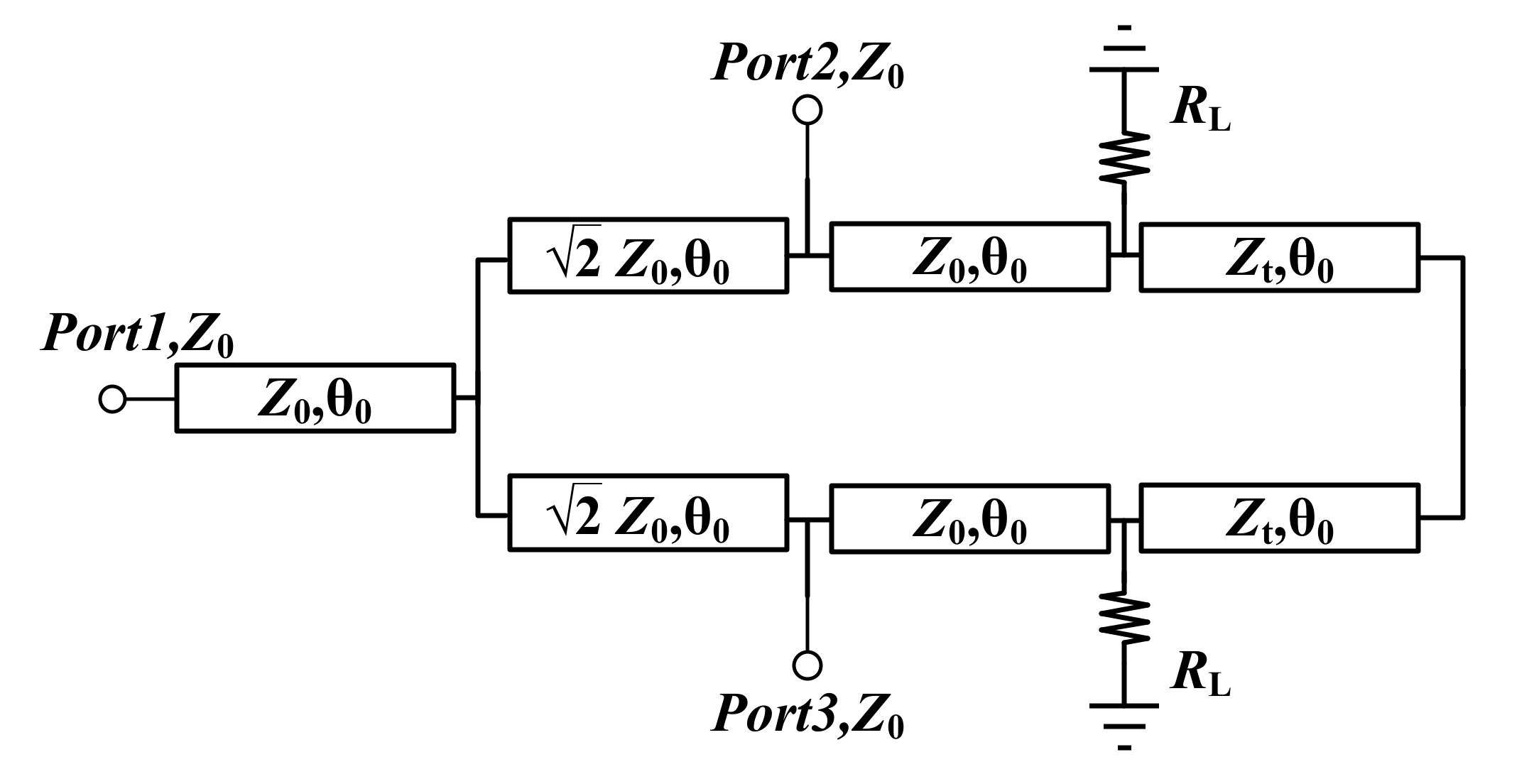

2. Design Theory and Circuit Structure

3. Implementation and Measurement

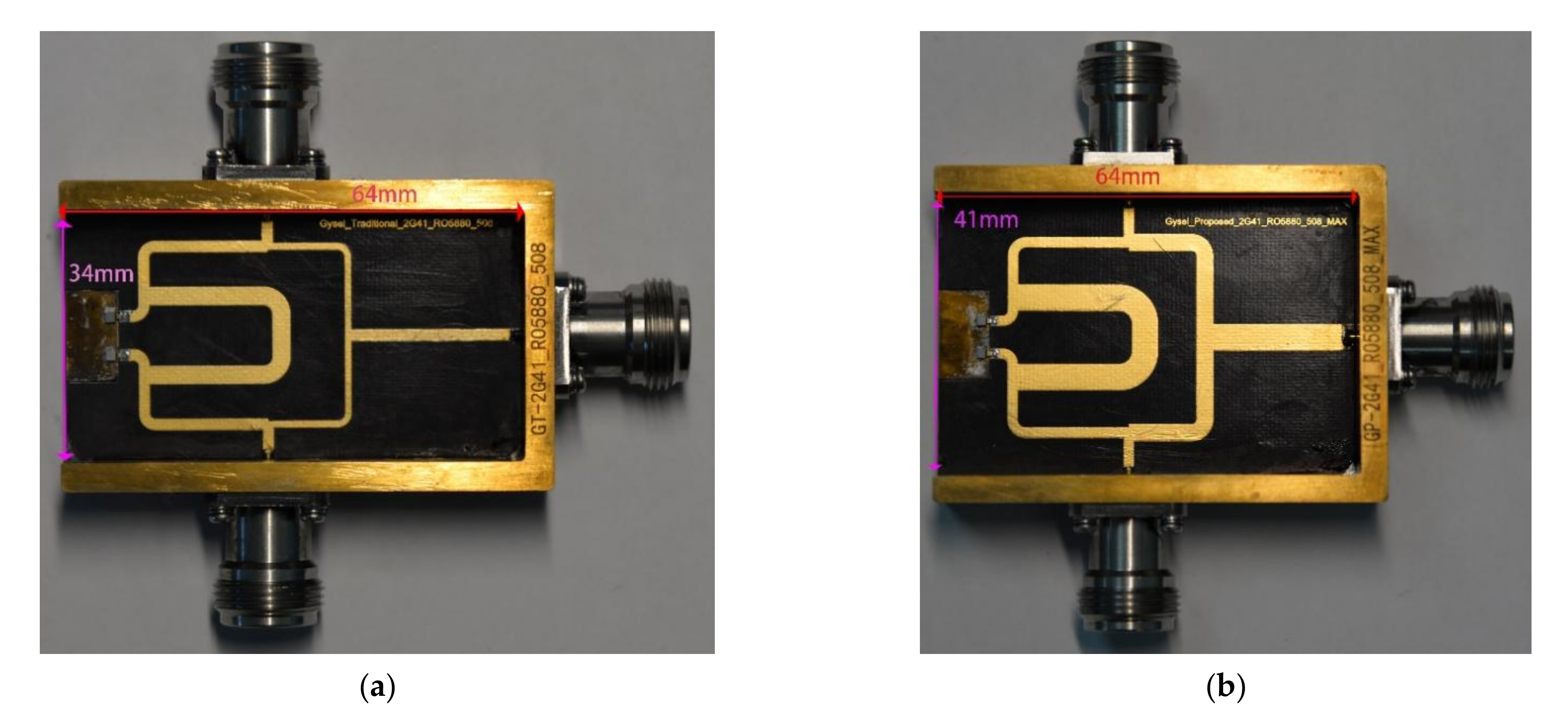

3.1. Prototypes for Traditional Gysel PCD and Proposed Gysel PCD

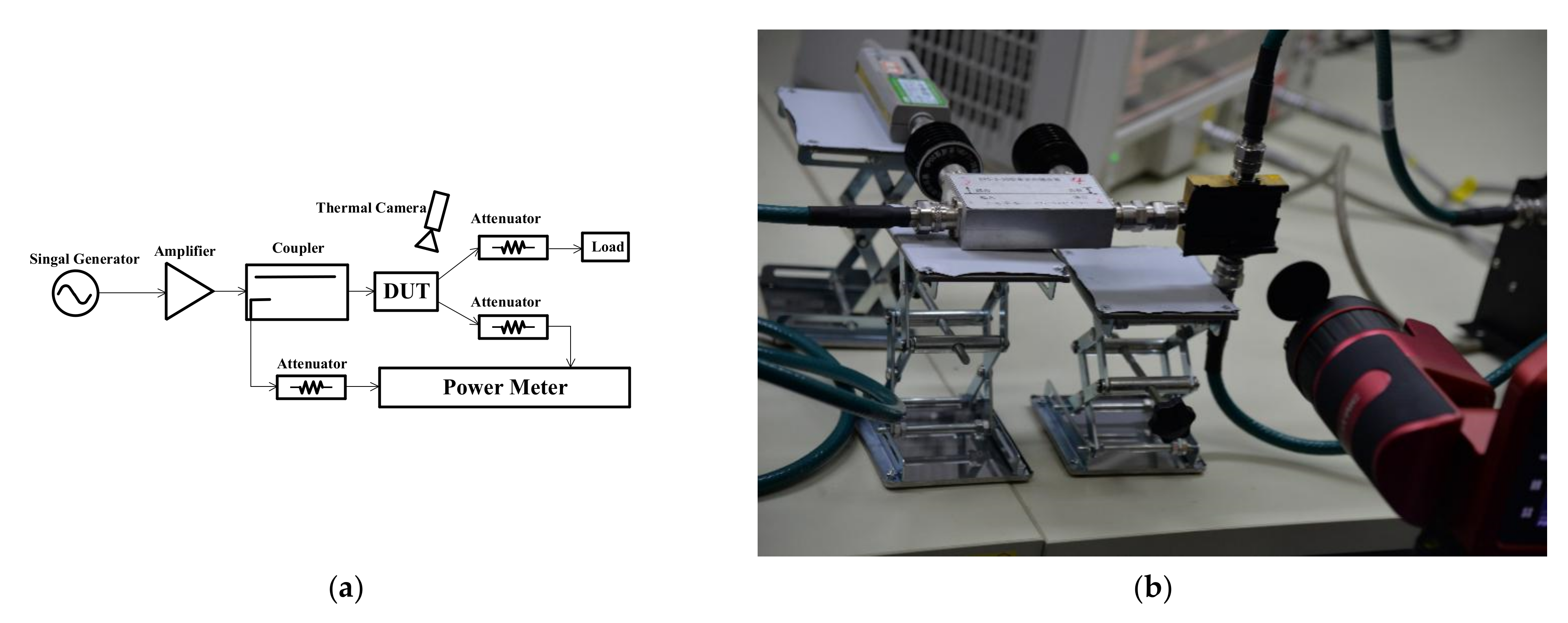

3.2. Thermal Characterization Measurement Experimental Results and Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gysel, U.H. A New N-Way Power Divider/Combiner Suitable for High-Power Applications. In Proceedings of the 1975 IEEE-MTT-S International Microwave Symposium, Palo Alto, CA, USA, 12–14 May 1975; pp. 116–118. [Google Scholar]

- Zhu, Z.; Wang, Z.; Fu, Y.; Fang, S.; Liu, H.; Chen, Z.N. Unlimited Power Division Ratio of Microstrip Balanced-to-Unbalanced Gysel-Type Arbitrary Power Divider. Electronics 2020, 9, 1124. [Google Scholar] [CrossRef]

- Shahi Gharehaghaji, H.; Shamsi, H. Design of Unequal Dual Band Gysel Power Divider With Isolation Bandwidth Improvement. IEEE Microw. Wirel. Compon. Lett. 2017, 27, 138–140. [Google Scholar] [CrossRef]

- He, J.; Luo, W.; Chen, S. A Gysel Power Divider with Enhanced Isolation Bandwidth. In Proceedings of the 2015 Asia-Pacific Microwave Conference (APMC), Nanjing, China, 6–9 December 2015; Volume 3, pp. 1–3. [Google Scholar]

- Lin, F.; Chu, Q.-X.; Gong, Z.; Lin, Z. Compact Broadband Gysel Power Divider with Arbitrary Power-Dividing Ratio Using Microstrip/Slotline Phase Inverter. IEEE Trans. Microw. Theory Tech. 2012, 60, 1226–1234. [Google Scholar] [CrossRef]

- Gupta, K.C.; Garg, R.; Bahl, I.; Bhartia, P. Microstrip Lines and Slotlines; Artech House: London, UK, 2013; p. 7. [Google Scholar]

- Bahl, I.J.; Gupta, K.C. Average Power-Handling Capability of Microstrip Lines. IEE J. Microw. Opt. Acoust. 1979, 3, 1. [Google Scholar] [CrossRef]

- Yin, W.Y.; Dong, X.T. Wideband Average Power Handling Capability of Coupled Microstrips on Polyimide and Polyimide∕GaAs Substrates. IEE Proc. Microw. Antennas Propag. 2004, 151, 385. [Google Scholar] [CrossRef]

- Yin, W.-Y.; Dong, X.; Gan, Y.B. Frequency-Dependent Maximum Average Power-Handling Capabilities of Single and Edge-Coupled Microstrip Lines on Low-Temperature Co-Fired Ceramic (LTCC) Substrates. Int. J. RF Microw. Comput. Aided Eng. 2006, 16, 103–117. [Google Scholar] [CrossRef]

- Wu, L.-S.; Zhou, X.-L.; Yin, W.-Y.; Tang, M.; Zhou, L. Characterization of Average Power Handling Capability of Bandpass Filters Using Planar Half-Wavelength Microstrip Resonators. IEEE Microw. Wirel. Compon. Lett. 2009, 19, 686–688. [Google Scholar] [CrossRef]

- Wu, L.-S.; Mao, J.; Yin, M.Y.; Tang, M. Average Power Handling Capability of Quarter-Wavelength Microstrip Stepped-Impedance Resonator Bandpass Filter. In Proceedings of the 2012 IEEE/MTT-S International Microwave Symposium Digest, IEEE, Montreal, QC, Canada, 17–22 June 2012; pp. 1–3. [Google Scholar]

- Yu, M. Power-Handling Capability for RF Filters. IEEE Microw. 2007, 8, 88–97. [Google Scholar] [CrossRef]

- Sanchez-Soriano, M.A.; Quere, Y.; Le Saux, V.; Quendo, C.; Cadiou, S. Average Power Handling Capability of Microstrip Passive Circuits Considering Metal Housing and Environment Conditions. IEEE Trans. Compon. Packag. Manuf. Technol. 2014, 4, 1624–1633. [Google Scholar] [CrossRef]

- Bahl, I.J. Average Power Handling Capability of Multilayer Microstrip Lines. Int. J. RF Microw. Comput. Aided Eng. 2001, 11, 385–395. [Google Scholar] [CrossRef]

- Yin, W.-Y.; Dong, X.T. Wide-Band Characterization of Average Power Handling Capabilities of Some Microstrip Interconnects on Polyimide and Polyimide/GaAs Substrates. IEEE Trans. Adv. Packag. 2005, 28, 328–336. [Google Scholar] [CrossRef]

- Yin, W.-Y.; Dong, X.T.; Mao, J.; Li, L.W. Average Power Handling Capability of Finite-Ground Thin-Film Microstrip Lines over Ultra-Wide Frequency Ranges. IEEE Microw. Wirel. Compon. Lett. 2005, 15, 715–717. [Google Scholar] [CrossRef]

- Yin, W.-Y.; Kang, K.; Mao, J.-F. Electromagnetic-Thermal Characterization of on On-Chip Coupled (A)Symmetrical Interconnects. IEEE Trans. Adv. Packag. 2007, 30, 851–863. [Google Scholar] [CrossRef]

- Fahmi, M.M.; Ruiz-Cruz, J.A.; Mansour, R.R. Compact Ridge Waveguide Gysel Combiners for High-Power Applications. IEEE Trans. Microw. Theory Tech. 2019, 67, 968–977. [Google Scholar] [CrossRef]

- Guan, J.; Zhang, L.; Sun, Z.; Leng, Y.; Peng, Y. Designing Power Divider by Combining Wilkinson and Gysel Structure. Electron. Lett. 2012, 48, 769. [Google Scholar] [CrossRef]

- Oraizi, H.; Sharifi, A.-R. Optimum Design of a Wideband Two-Way Gysel Power Divider With Source to Load Impedance Matching. IEEE Trans. Microw. Theory Tech. 2009, 57, 2238–2248. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, C.; He, T.; Fang, W.; Huang, W.; Fan, R.; Wang, L.; Zhang, Y.; Cao, Y. A Gysel Power Divider/Combiner with Enhanced Power-Handling Capability. Electronics 2022, 11, 2660. https://doi.org/10.3390/electronics11172660

Fu C, He T, Fang W, Huang W, Fan R, Wang L, Zhang Y, Cao Y. A Gysel Power Divider/Combiner with Enhanced Power-Handling Capability. Electronics. 2022; 11(17):2660. https://doi.org/10.3390/electronics11172660

Chicago/Turabian StyleFu, Chao, Tianwei He, Wenrao Fang, Wenhua Huang, Ruyu Fan, Lulu Wang, Yuchuan Zhang, and Yu Cao. 2022. "A Gysel Power Divider/Combiner with Enhanced Power-Handling Capability" Electronics 11, no. 17: 2660. https://doi.org/10.3390/electronics11172660

APA StyleFu, C., He, T., Fang, W., Huang, W., Fan, R., Wang, L., Zhang, Y., & Cao, Y. (2022). A Gysel Power Divider/Combiner with Enhanced Power-Handling Capability. Electronics, 11(17), 2660. https://doi.org/10.3390/electronics11172660