Toward a Framework for Resource Efficiency Evaluation in Industry: Recommendations for Research and Innovation Projects

Abstract

:1. Introduction

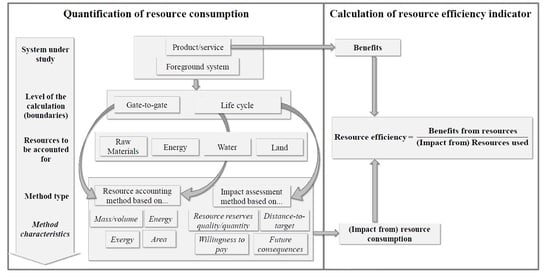

2. Methodological Approach

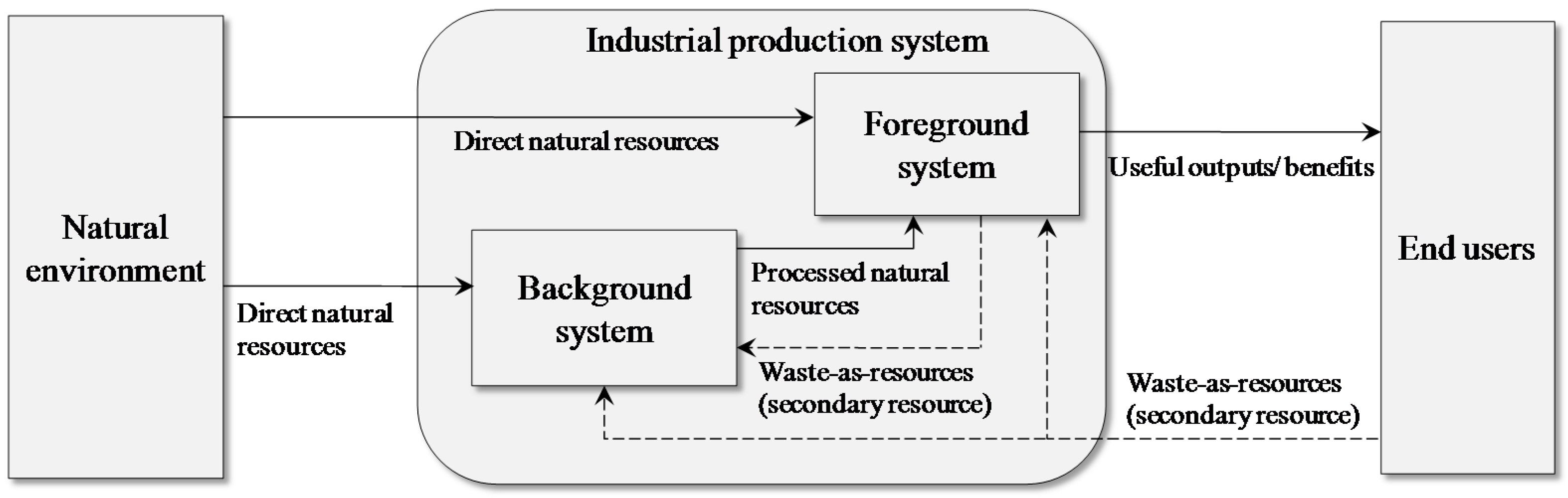

3. Setting the Framework

3.1. Definition of Resources

3.2. Definition of Resource Efficiency

3.3. Goal and Scope of the Calculation

3.4. Methods Available to Quantify Resources

- A physical accounting of resources: the quantity of resources consumed by the studied system is systematically accounted for based on a physical property (mass or volume, energy, exergy or area).

- An assessment of the impact from resource use: this is done by considering one of the following elements: the amount of resources available in the Earth’s crust, predefined targets, future consequences of resource extraction, or willingness-to-pay (WTP).

3.4.1. Resource Accounting Method

3.4.2. Impact Assessment Methods

- Methods based on the quantity/quality of reserves: these methods consider that the quantity and/or quality of resources available in the natural environment is decreasing and thus that the consumption of resources has an impact on resource availability. Some methods such as the Ore Requirement Indicator [55] or the Ore Grade Decrease methods [56] consider the decrease of ore grade as an indicator of resource availability in the natural environment, while other methods such as the ADP method [46] put the amount of resources consumed in perspective with the reserves remaining in the natural environment relative to those of a reference species (e.g., antimony in the ADP method). The last approach is most common in the literature because most associated methods were developed prior to other approaches and are available in most LCA software tools. Methods based on the quantity/quality of reserves are only able to account for non-renewable resources and are heavily discussed by the scientific community and the industry sector [57].

- Methods based on distance-to-target: these methods compare the quantity of resources consumed to previously defined targets. The most used distance-to-target LCA method is the Ecological Scarcity method [52], which puts the quantity of consumed resources in perspective with a critical flow of resources based on political targets or international policy.

- Methods based on willingness-to-pay: these methods estimate the amount of money people are ready to invest to restore damages caused to natural resources. The main LCA method that follows this approach in its weighting step is the EPS 2000 method [53].

- Methods based on future consequences: these methods consider the impact of current resource consumption on future parameters as a result of a decrease in the quality of ore in the natural environment. The most used parameters are the surplus energy (e.g., Impact 2002+ [48]) or surplus costs (e.g., ReCiPe Endpoint [41]; further developed by Vieira, et al. [58]) necessary to extract the same amount of resources in the future as today.

4. Points to Consider When Determining the Resource Efficiency Ratio’s Numerator and Denominator

4.1. Gate-to-Gate vs. Life Cycle Analysis

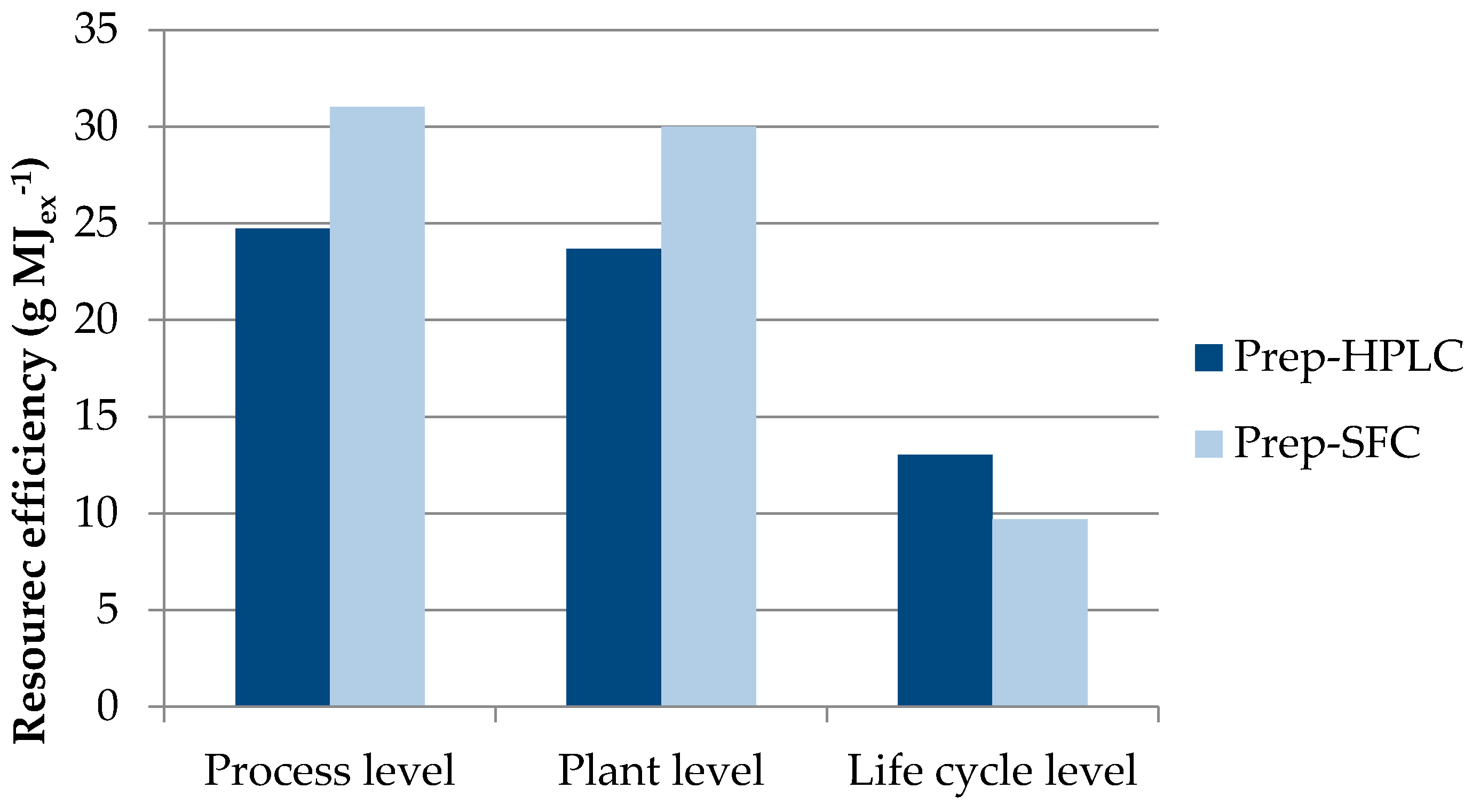

4.1.1. Resource efficiency of two chiral separation techniques

4.2. Accounting vs. Impact Assessment

4.3. Resource Coverage of Life Cycle-Based Methods

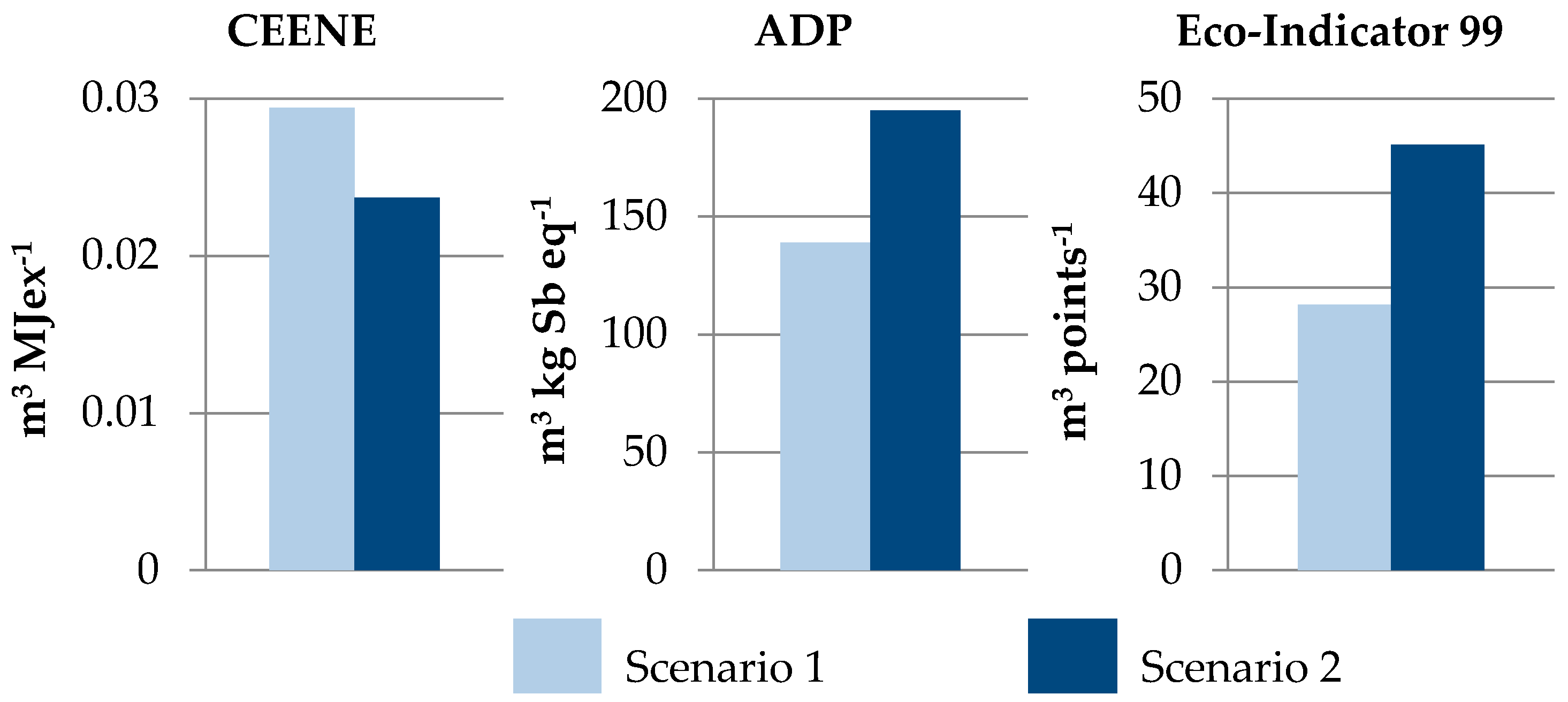

4.3.1. Case Study: Resource Efficiency of Two Valorization Pathways for Algae Grown in Wastewater

4.4. Entities Impacted by Resource Consumption

4.5. Functionality of the Output Products (Benefits)—How to Account for Recycling?

4.6. Criticality in the Evaluation of Resource Efficiency

4.7. Dealing with Data Availability and Representativeness

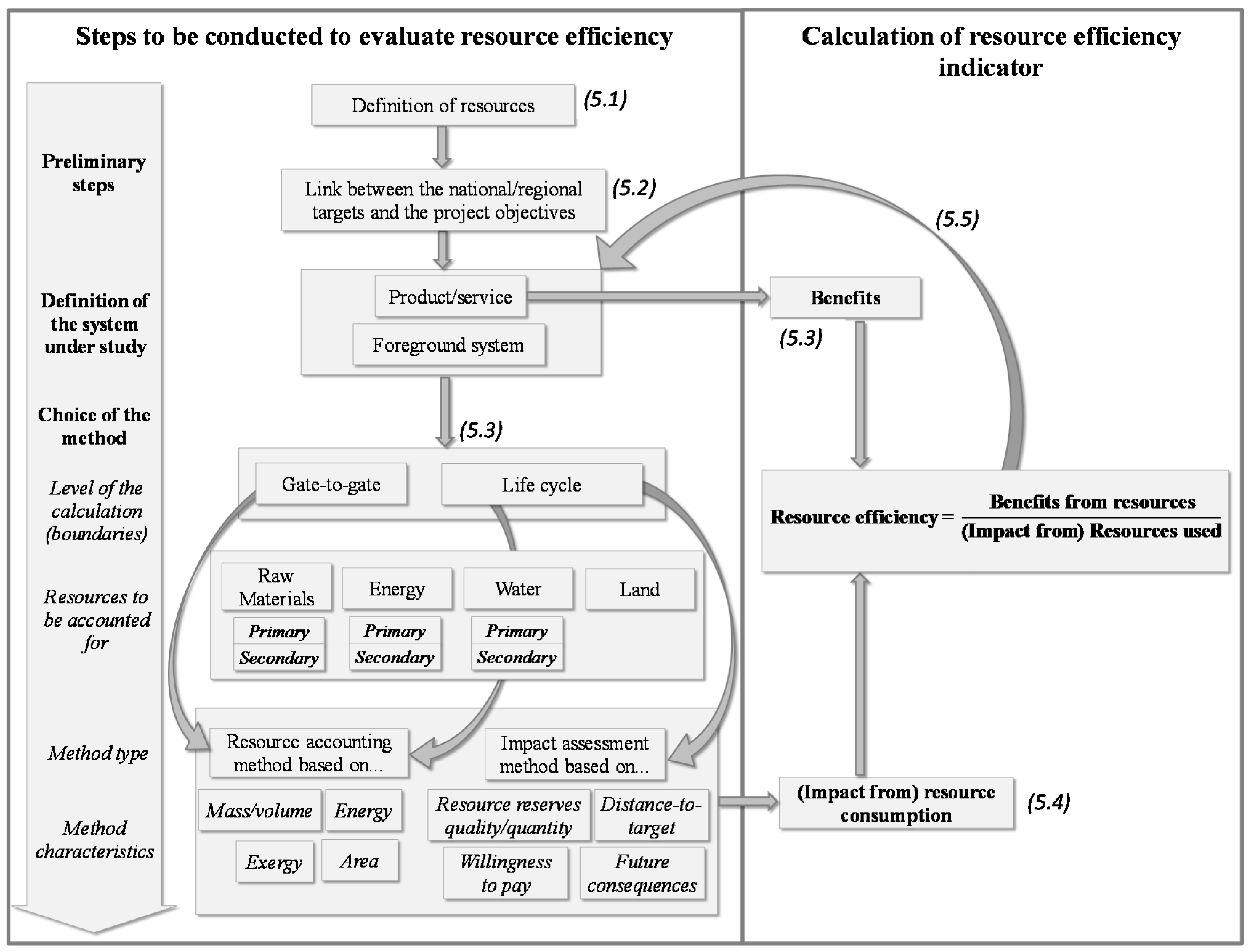

5. Paths Forward

5.1. Toward a More Consistent Vocabulary and Definitions

5.2. Linking Resource Efficiencies at the Micro- and Macro-Levels

5.3. Toward a More Informed Choice of the Numerator and Denominator of the Resource Efficiency Ratio

- To calculate the denominator, an LCA should be performed. If constraints concerning money, time or data availability are too high, a life cycle approach (i.e., not necessarily including quantification) should be followed, at least based on gate-to-gate data. A gate-to-gate analysis is a limited approach but can be very useful in the calculation of intermediary indicators in order to promote continuous process improvements and provide details about the studied process.

- One or several methods covering all resource categories should be selected. When dealing with abiotic renewable resources, a method that allows the presentation of results without considering these resources should also be considered.

- Only a gate-to-gate approach is able to consider waste as an input in the denominator. If an LC-based method is used to calculate the RE of a recycling process, the use of metrics other than those defined in the RE ratio here should be considered (e.g., RBR).

- An ideal assessment of RE and the impact of resource consumption that could be universally used in all research and innovation projects does not yet exist, and further research is needed [11]. Various methods exist and address different aspects of RE, such as specific resource properties or specific issues related to the impact of resource consumption. The limitations of each method should be kept in mind and accounted for as much as possible via a sensitivity analysis on key methodological choices. The challenges related to resource efficiency evaluation for specific process types or sectors could be discussed in each sector, as done by Ardashkin, et al. [87], who reviewed the approaches for RE evaluation followed in the foundry sector and discussed potential ways to improve this evaluation.

5.4. Aggregation vs. a Set of Individual Scores

5.5. Toward the Integration of Resource Efficiency Considerations during the Project Lifetime

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- United Nations Environment Programme (UNEP). UNEP’s Resource Efficiency Programme. Available online: http://www.unep.org/resourceefficiency/Home/UNEPsResourceEfficiencyProgramme/tabid/55552/Default.aspx (accessed on 29 April 2016).

- Bahn-Walkowiak, B.; Steger, S. Resource Targets in Europe and Worldwide: An Overview. Resources 2015, 4, 597–620. [Google Scholar] [CrossRef]

- European Commission (EC). A Resource-Efficient Europe—Flagship Initiative under the Europe 2020 Strategy; COM(2011) 21; European Commission: Brussels, Belgium, 2001. [Google Scholar]

- European Commission (EC). Roadmap to a Resource Efficient Europe; COM(2011) 571 Final; European Commission: Brussels, Belgium, 2011. [Google Scholar]

- European Commission (EC). Resource Efficiency Scoreboard Highlights 2014; European Commission: Brussels, Belgium, 2014. [Google Scholar]

- European Commission: European Union (EC). Europe 2020 Flagship Initiative—Innovation Union; COM(2010) 546 Final; European Commission: Brussels, Belgium, 2010. [Google Scholar]

- Sustainable Process Industry through Resource and Energy Efficiency (SPIRE). SPIRE Roadmap; A.SPIRE: Brussels, Belgium, 2013; Available online: https://www.spire2030.eu/uploads/Modules/Publications/spire-roadmap_december_2013_pbp.pdf (accessed on 18 October 2016).

- Bach, V.; Berger, M.; Henßler, M.; Kirchner, M.; Leiser, S.; Mohr, L.; Rother, E.; Ruhland, K.; Schneider, L.; Tikana, L.; et al. Integrated method to assess resource efficiency—ESSENZ. J. Clean. Prod. 2016, 137, 118–130. [Google Scholar] [CrossRef]

- BIO by Deloitte; CIRCE. Development and Definition of Key Resource Indicators; TOP-REF Deliverable 2.3; European Union: Brussels, Belgium, 2014; Available online: http://toprefproject.eu/?p=13681 (accessed on 9 January 2017).

- Huysman, S.; Sala, S.; Mancini, L.; Ardente, F.; Alvarenga, R.A.F.; De Meester, S.; Mathieux, F.; Dewulf, J. Toward a systematized framework for resource efficiency indicators. Resour. Conserv. Recycl. 2015, 95, 68–76. [Google Scholar] [CrossRef]

- Geldermann, J.; Kolbe, L.M.; Krause, A.; Mai, C.; Militz, H.; Osburg, V.S.; Schobel, A.; Schumann, M.; Toporowski, W.; Westphal, S. Improved resource efficiency and cascading utilisation of renewable materials. J. Clean Prod. 2016, 110, 1–8. [Google Scholar] [CrossRef]

- Berger, M.; Finkbeiner, M. Correlation analysis of life cycle impact assessment indicators measuring resource use. Int. J. Life Cycle Assess. 2010, 16, 74–81. [Google Scholar] [CrossRef]

- European Commission (EC). Directive 2010/75/EU on Industrial Emissions; Official Journal of the European Union: Brussels, Belgium, 2010. [Google Scholar]

- Europe Environment Agency (EEA). Impact of Selected Policy Measures on Europe’s Air Quality; Report No. EEA 8/2010; Europe Environment Agency: Copenhagen, Denmark, 2010. [Google Scholar]

- Udo de Haes, H.; Jolliet, O.; Finnveden, G.; Hauschild, M.; Krewitt, W.; Müller-Wenk, R. Best available practice regarding impact categories and category indicators in life cycle impact assessment. Int. J. Life Cycle Assess. 1999, 4, 167–174. [Google Scholar] [CrossRef]

- International Organization for Standardization (ISO). ISO 14040: Environmental Management—Life Cycle Assessment—Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- European Commission (EC). Eurostat. Available online: http://ec.europa.eu/eurostat/statistics-explained/index.php/Water_use_in_industry (accessed on 18 October 2016).

- Dewulf, J.; Bösch, M.E.; Meester, B.D.; Vorst, G.V.D.; Langenhove, H.V.; Hellweg, S.; Huijbregts, M.A.J. Cumulative Exergy Extraction from the Natural Environment (CEENE): A comprehensive Life Cycle Impact Assessment method for resource accounting. Environ. Sci. Technol. 2007, 41, 8477–8483. [Google Scholar] [CrossRef] [PubMed]

- Klinglmair, M.; Sala, S.; Brandao, M. Assessing resource depletion in LCA: A review of methods and methodological issues. Int. J. Life Cycle Assess. 2014, 19, 580–592. [Google Scholar] [CrossRef]

- Giljum, S.; Burger, E.; Hinterberger, F.; Lutter, S.; Bruckner, M. A comprehensive set of resource use indicators from the micro to the macro level. Resour. Conserv. Recycl. 2011, 55, 300–308. [Google Scholar] [CrossRef]

- Taelman, S.E.; Schaubroeck, T.; De Meester, S.; Boone, L.; Dewulf, J. Accounting for land use in life cycle assessment: The value of NPP as a proxy indicator to assess land use impacts on ecosystems. Sci. Total Environ. 2016, 550, 143–156. [Google Scholar] [CrossRef] [PubMed]

- EC-OREP. Eurostat. Available online: http://ec.europa.eu/environment/resource_efficiency/re_platform/index_en.htm (accessed on 18 October 2016).

- Debaveye, S.; De Soete, W.; De Meester, S.; Vandijck, D.; Heirman, B.; Kavanagh, S.; Dewulf, J. Human health benefits and burdens of a pharmaceutical treatment: Discussion of a conceptual integrated approach. Environ. Res. 2016, 144, 19–31. [Google Scholar] [CrossRef] [PubMed]

- Stylianou, K.S.; Heller, M.C.; Fulgoni, V.L.; Ernstoff, A.S.; Keoleian, G.A.; Jolliet, O. A life cycle assessment framework combining nutritional and environmental health impacts of diet: A case study on milk. Int. J. Life Cycle Assess. 2016, 21, 734–746. [Google Scholar] [CrossRef]

- Tukker, A.; Poliakov, E.; Heijungs, R.; Hawkins, T.; Neuwahl, F.; Rueda-Cantuche, J.M.; Giljum, S.; Moll, S.; Oosterhaven, J.; Bouwmeester, M. Towards a global multi-regional environmentally extended input-output database. Ecol. Econ. 2009, 68, 1928–1937. [Google Scholar] [CrossRef]

- Dietzenbacher, E.; Los, B.; Stehrer, R.; Timmer, M.; de Vries, G. The construction of world input-output tables in the WIOD project. Econ. Syst. Res. 2013, 25, 71–98. [Google Scholar] [CrossRef]

- Frischknecht, R.; Rebitzer, G. The ecoinvent database system: A comprehensive web-based LCA database. J. Clean. Prod. 2005, 13, 1337–1343. [Google Scholar] [CrossRef]

- Joint Research Center. The European Life Cycle Database. Available online: http://eplca.jrc.ec.europa.eu/?page_id=126 (accessed on 18 October 2016).

- GaBi Software, Software Solution; PE International: Stuttgart, Germany, 2013.

- Ekvall, T.; Assefa, G.; Björklund, A.; Eriksson, O.; Finnveden, G. What life-cycle assessment does and does not do in assessments of waste management. Waste Manag. 2007, 27, 989–996. [Google Scholar] [CrossRef] [PubMed]

- Oldfield, T.; Holden, N.M. An evaluation of upstream assumptions in food-waste life cycle assessments. In Proceedings of the 9th International Conference on Life Cycle Assessment in the Agri-Food Sector, San Francisco, CA, USA, 8–10 October 2014; pp. 926–933.

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A.; Ventura, A. LCA allocation procedure used as an incitative method for waste recycling: An application to mineral additions in concrete. Resour. Conserv. Recycl. 2010, 54, 1231–1240. [Google Scholar] [CrossRef]

- Weidema, B.P.; Bauer, C.; Hischier, R.; Mutel, C.; Nemecek, T.; Reinhard, J.; Vadenbo, C.O.; Wernet, G. Overview and Methodology. Data Quality Guideline for the Ecoinvent Database, version 3; Ecoinvent Report 1(v3); Swiss Centre for Life Cycle Inventories: St. Gallen, Switzerland, 2013. [Google Scholar]

- Heijungs, R.; Guinée, J.B.; Huppes, G. Impact Categories for Natural Resources and Land Use: Survey and Analysis of Existing and Proposed Methods in the Context of Environmental Life Cycle Assessment; CML: Leiden, The Netherlands, 1997. [Google Scholar]

- Zhong, S.; Geng, Y.; Liu, W.; Gao, C.; Chen, W. A bibliometric review on natural resource accounting during 1995–2014. J. Clean. Prod. 2016, 139, 122–132. [Google Scholar] [CrossRef]

- Swart, P.; Alvarenga, R.A.F.; Dewulf, J. Abiotic Resource Use. In LCA Compendium—The Complete World of Life Cycle Assessment; Klöpffer, W., Curran, M.A., Eds.; Springer: Dordrecht, The Netherlands, 2015; pp. 247–269. [Google Scholar]

- Dewulf, J.; Mancini, L.; Blengini, G.A.; Sala, S.; Latunussa, C.; Pennington, D. Toward an Overall Analytical Framework for the Integrated Sustainability Assessment of the Production and Supply of Raw Materials and Primary Energy Carriers. J. Ind. Ecol. 2015, 19, 963–977. [Google Scholar] [CrossRef]

- Alvarenga, R.A.F.; Dewulf, J.; Van Langenhove, H.; Huijbregts, M.J. Exergy-based accounting for land as a natural resource in life cycle assessment. Int. J. Life Cycle Assess. 2013, 18, 939–947. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Hellweg, S.; Frischknecht, R.; Hungerbühler, K.; Hendriks, A.J. Ecological footprint accounting in the life cycle assessment of products. Ecol. Econ. 2008, 64, 798–807. [Google Scholar] [CrossRef]

- Brunner, P.H.; Rechberger, H. Practical Handbook for Material Flow Analysis—Advanced Methods in Resource and Waste Management; Lewis Publishers: Boca Raston, FL, USA, 2003. [Google Scholar]

- Goedkoop, M.; Heijungs, R.; De Schryver, A.; Struijs, J.; van Zelm, R. ReCiPe 2008. A LCIA Method Which Comprises Harmonised Category Indicators at the Midpoint and the Endpoint Level; Report I: Characterisation; Ministerie van VROM: Den Haag, The Netherlands, 2009. [Google Scholar]

- Hauschild, M.Z.; Wenzel, H. Environmental Assessment of Products Volume 2: Scientific Background; Chapman & Hall/Kluwer Academic Publishers: London, UK; Hingham, MA, USA, 1998. [Google Scholar]

- Ritthoff, M.; Rohn, H.; Liedtke, C. Calculating MIPS. Resource Productivity of Products and Services; Wuppertal Institute for Climate, Environment and Energy: Wuppertal, Germany, 2002. [Google Scholar]

- Bullard, C.W.; Penner, P.S.; Pilati, D.A. Energy Analysis: Handbook for Combining Process and Input-Output Analysis; U.S. Energy Research and Development Administration: Springfield, IL, USA, 1976.

- Hischier, R.; Weidema, B.; Althaus, H.-J.; Doka, G.; Dones, R.; Frischknecht, R.; Hellweg, S.; Humbert, S.; Jungbluth, N.; Loerincik, Y.; et al. Implementation of Life Cycle Impact Assessment Methods; Final Report Ecoinvent V2.1; Swiss Centre for Life Cycle Inventories: St. Gallen, Switzerland, 2009; Volume 3. [Google Scholar]

- Guinée, J.B.; Heijungs, R. A proposal for the definition of resource equivalency factors for use in product life-cycle assessment. Environ. Toxicol. Chem. 1995, 14, 917–925. [Google Scholar] [CrossRef]

- Van Oers, L.; de Koning, A.; Guinée, J.B.; Huppes, G. Abiotic Resource Depletion in LCA; Leiden University: Leiden, The Netherlands, 2002. [Google Scholar]

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G.; Rosenbaum, R. IMPACT 2002+: A new life cycle impact assessment methodology. Int. J. Life Cycle Assess. 2003, 8, 324–330. [Google Scholar] [CrossRef]

- Szargut, J.; Morris, D.R.; Steward, F.R. Exergy Analysis of Thermal, Chemical, and Metallurgical Processes; Hemisphere Publishing: New York, NY, USA, 1987; p. 400. [Google Scholar]

- Bösch, M.; Hellweg, S.; Huijbregts, M.J.; Frischknecht, R. Applying cumulative exergy demand (CExD) indicators to the ecoinvent database. Int. J. Life Cycle Assess. 2007, 12, 181–190. [Google Scholar] [CrossRef]

- Global Footprint Network. Ecological Footprint Standards 2009; Global Footprint Network: Oakland, CA, USA, 2009. [Google Scholar]

- Frischknecht, R.; Büsser Knöpfel, S. Swiss Eco-Factors 2013 according to the Ecological Scarcity Method. Methodological Fundamentals and Their Application in Switzerland; Environmental Studies No. 1330; Federal Office for the Environment: Bern, Switzerland, 2013. [Google Scholar]

- Steen, B. A Systematic Approach to Environmental Priority Strategies in Product Development (EPS) Version 2000—General System Characteristics; CPM Report 1999:4; Centre for Environmental Assessment of Products and Material Systems: Göteborg, Sweden, 1999. [Google Scholar]

- Goedkoop, M.; Spriensma, R. The Eco-Indicator 99. A Damage Oriented Method for Life Cycle Impact Assessment, 3rd ed.; Methodology Report; Pré Consultants: Amersfoort, The Netherlands, 2000. [Google Scholar]

- Swart, P.; Dewulf, J. Quantifying the impacts of primary metal resource use in life cycle assessment based on recent mining data. Resour. Conserv. Recycl. 2013, 73, 180–187. [Google Scholar] [CrossRef]

- Vieira, M.; Goedkoop, M.J.; Storm, P.; Huijbregts, M.A.J. Ore Grade Decrease As Life Cycle Impact Indicator for Metal Scarcity: The Case of Copper. Environ. Sci. Technol. 2012, 46, 12772–12778. [Google Scholar] [CrossRef] [PubMed]

- Drielsma, J.A.; Russell-Vaccari, A.J.; Drnek, T.; Brady, T.; Weihed, P.; Mistry, M.; Simbor, L.P. Mineral resources in life cycle impact assessment-defining the path forward. Int. J. Life Cycle Assess. 2016, 21, 85–105. [Google Scholar] [CrossRef]

- Vieira, M.; Ponsioen, T.; Goedkoop, M.; Huijbregts, M. Surplus Cost Potential as a Life Cycle Impact Indicator for Metal Extraction. Resources 2016, 5. [Google Scholar] [CrossRef]

- United Nations Environment Programme (UNEP). Assessing the Environmental Impacts of Consumption and Production. Priority Products and Materials. A Report of the Working Group on the Environmental Impacts of Products and Materials to the International Panel for Sustainable Resource Management. 2010. Available online: http://www.unep.org/resourcepanel/Portals/24102/PDFs/PriorityProductsAndMaterials_Report.pdf (accessed on 9 January 2017).

- De Soete, W.; Dewulf, J.; Cappuyns, P.; Van der Vorst, G.; Heirman, B.; Aelterman, W.; Schoeters, K.; Van Langenhove, H. Exergetic sustainability assessment of batch versus continuous wet granulation based pharmaceutical tablet manufacturing: A cohesive analysis at three different levels. Green Chem. 2013, 15, 3039–3048. [Google Scholar] [CrossRef]

- Arena, U.; Di Gregorio, F.; Amorese, C.; Mastellone, M.L. A techno-economic comparison of fluidized bed gasification of two mixed plastic wastes. Waste Manag. 2011, 31, 1494–1504. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.J.; Hu, S.Y.; Chen, D.J.; Zhu, B. A case study of a phosphorus chemical firm’s application of resource efficiency and eco-efficiency in industrial metabolism under circular economy. J. Clean. Prod. 2015, 87, 839–849. [Google Scholar] [CrossRef]

- Van der Vorst, G.; Van Langenhove, H.; De Paep, F.; Aelterman, W.; Dingenen, J.; Dewulf, J. Exergetic life cycle analysis for the selection of chromatographic separation processes in the pharmaceutical industry: Preparative HPLC versus preparative SFC. Green Chem. 2009, 11, 1007–1012. [Google Scholar] [CrossRef]

- Finnveden, G.; Arushanyan, Y.; Brandão, M. Exergy as a Measure of Resource Use in Life Cycle Assessment and Other Sustainability Assessment Tools. Resources 2016, 5. [Google Scholar] [CrossRef]

- Vadenbo, C.; Rørbech, J.; Haupt, M.; Frischknecht, R. Abiotic resources: New impact assessment approaches in view of resource efficiency and resource criticality. In Proceedings of the 55th Discussion Forum on Life Cycle Assessment, Zurich, Switzerland, 11 April 2014; Springer: Berlin/Heidelberg, Germany, 2014; pp. 1686–1692. [Google Scholar]

- Sfez, S.; Van Den Hende, S.; Taelman, S.E.; De Meester, S.; Dewulf, J. Environmental sustainability assessment of a microalgae raceway pond treating aquaculture wastewater: From up-scaling to system integration. Bioresour. Technol. 2015, 190, 321–331. [Google Scholar] [CrossRef] [PubMed]

- Schneider, L.; Berger, M.; Finkbeiner, M. The anthropogenic stock extended abiotic depletion potential (AADP) as a new parameterisation to model the depletion of abiotic resources. Int. J. Life Cycle Assess. 2011, 16, 929–936. [Google Scholar] [CrossRef]

- Van Oers, L.; Guinee, J. The Abiotic Depletion Potential: Background, Updates, and Future. Resources 2016, 5. [Google Scholar] [CrossRef]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Dewulf, J.; Benini, L.; Mancini, L.; Sala, S.; Blengini, G.A.; Ardente, F.; Recchioni, M.; Maes, J.; Pant, R.; Pennington, D. Rethinking the Area of Protection “Natural Resources” in Life Cycle Assessment. Environ. Sci. Technol. 2015, 49, 5310–5317. [Google Scholar] [CrossRef] [PubMed]

- Al-Oqla, F.M.; Sapuan, S.M.; Ishak, M.R.; Nuraini, A.A. A Model for Evaluating and Determining the Most Appropriate Polymer Matrix Type for Natural Fiber Composites. Int. J. Polym. Anal. Charact. 2015, 20, 191–205. [Google Scholar] [CrossRef]

- European Commission (EC). Closing the Loop. An EU Action Plan for the Circular Economy; COM(2015) 614/2; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Ardente, F.; Mathieux, F. Identification and assessment of product’s measures to improve resource efficiency: The case-study of an Energy using Product. J. Clean. Prod. 2014, 83, 126–141. [Google Scholar] [CrossRef]

- Huysman, S.; Debaveye, S.; Schaubroeck, T.; Meester, S.D.; Ardente, F.; Mathieux, F.; Dewulf, J. The recyclability benefit rate of closed-loop and open-loop systems: A case study on plastic recycling in Flanders. Resour. Conserv. Recycl. 2015, 101, 53–60. [Google Scholar] [CrossRef]

- Allacker, K.; Mathieux, F.; Manfredi, S.; Pelletier, N.; De Camillis, C.; Ardente, F.; Pant, R. Allocation solutions for secondary material production and end of life recovery: Proposals for product policy initiatives. Resour. Conserv. Recycl. 2014, 88, 1–12. [Google Scholar] [CrossRef]

- European Commission (EC). Report on Critical Raw Materials for the EU. Report of the Ad Hoc Working Group on Defining Critical Raw Materials; European Union: Brussels, Belgium, 2014; Available online: http://mima.geus.dk/report-on-critical-raw-materials_en.pdf (accessed on 9 January 2017).

- Sonnemann, G.; Gemechu, E.D.; Adibi, N.; De Bruille, V.; Bulle, C. From a critical review to a conceptual framework for integrating the criticality of resources into Life Cycle Sustainability Assessment. J. Clean. Prod. 2015, 94, 20–34. [Google Scholar] [CrossRef]

- Virtual Desktop Infrastructure (VDI). Resource Efficiency—Evaluation of the Use of Raw Materials; VDI-Gesellschaft Energie und Umwelt: Düsseldorf, Germany, 2016; Available online: http://www.vdi.eu/nc/guidelines/entwurf_vdi_4800_blatt_2-ressourceneffizienz_bewertung_des_rohstoffaufwands_/ (accessed on 20 December 2015).

- Shibasaki, M.; Warburg, N.; Eyerer, P. Upscaling effect and Life Cycle Assessment. In Proceedings of the 13th CIRP International Conference on Life Cycle Engineering, Leuven, Belgium, 31 May–2 June 2006.

- Gavankar, S.; Suh, S.; Keller, A.A. The Role of Scale and Technology Maturity in Life Cycle Assessment of Emerging Technologies: A Case Study on Carbon Nanotubes. J. Ind. Ecol. 2015, 19, 51–60. [Google Scholar] [CrossRef]

- Taelman, S.E.; De Meester, S.; Roef, L.; Michiels, M.; Dewulf, J. The environmental sustainability of microalgae as feed for aquaculture: A life cycle perspective. Bioresour. Technol. 2013, 150, 513–522. [Google Scholar] [CrossRef] [PubMed]

- Kralisch, D.; Staffel, C.; Ott, D.; Bensaid, S.; Saracco, G.; Bellantoni, P.; Loeb, P. Process design accompanying life cycle management and risk analysis as a decision support tool for sustainable biodiesel production. Green Chem. 2013, 15, 463–477. [Google Scholar] [CrossRef]

- Weiss, M.; Junginger, H.M.; Patel, M.K. Learning Energy Efficiency: Experience Curves for Household Appliances and Space Heating, Cooling, and Lighting Technologies; Utrecht University: Utrecht, The Netherlands, 2008; Available online: http://dspace.library.uu.nl/handle/1874/32937 (accessed on 16 December 2016).

- Karali, N.; Park, W.Y.; McNeil, M.A. Using Learning Curves on Energy-Efficient Technologies to Estimate Future Energy Savings and Emission Reduction Potentials in the US Iron and Steel Industry; Ernest Orlando Lawrence Berkeley National Laboratory, International Energy Studies Group Energy Analysis and Environmental Impacts Division: Berkeley, CA, USA, 2015. Available online: https://eetd.lbl.gov/sites/all/files/lbnl-184179.pdf (accessed on 20 December 2016).

- Caduff, M.; Huijbregts, M.A.J.; Koehler, A.; Althaus, H.-J.; Hellweg, S. Scaling Relationships in Life Cycle Assessment. J. Ind. Ecol. 2014, 18, 393–406. [Google Scholar] [CrossRef]

- Rohn, H.; Pastewski, N.; Lettenmeier, M.; Wiesen, K.; Bienge, K. Resource efficiency potential of selected technologies, products and strategies. Sci. Total Environ. 2014, 473–474, 32–35. [Google Scholar] [CrossRef] [PubMed]

- Ardashkin, I.B.; Yakovlev, A.N.; Martyushev, N.V. Evaluation of the Resource Efficiency of Foundry Technologies: Methodological Aspect. In High Technology: Research and Applications; Bogdan, A., Martyushev, N., Eds.; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2014; Volume 1040, pp. 912–916. [Google Scholar]

- Hauschild, M.Z.; Jeswiet, J.; Alting, L. Design for Environment—Do We Get the Focus Right? CIRP Ann. Manuf. Technol. 2004, 53, 1–4. [Google Scholar] [CrossRef]

- Millet, D.; Bistagnino, L.; Lanzavecchia, C.; Camous, R.; Poldma, T. Does the potential of the use of LCA match the design team needs? J. Clean. Prod. 2007, 15, 335–346. [Google Scholar] [CrossRef]

- Ott, D.; Kralisch, D.; Dencic, I.; Hessel, V.; Laribi, Y.; Perrichon, P.D.; Berguerand, C.; Kiwi-Minsker, L.; Loeb, P. Life Cycle Analysis within Pharmaceutical Process Optimization and Intensification: Case Study of Active Pharmaceutical Ingredient Production. ChemSusChem 2014, 7, 3521–3533. [Google Scholar] [CrossRef] [PubMed]

- Kralisch, D.; Minkov, N.; Manent, A.; Rother, E.; Mohr, L.; Schowanek, D.; Sfez, S.; Lapkin, A.; Jones, M.; De Meester, S.; et al. Roadmap for Sustainability Assessment in European Process Industries; MEASURE Final Deliverable; Friedrich Schiller University Jena: Jena, Germany, 2016; Available online: https://www.spire2030.eu/measure/ (accessed on 9 January 2017).

- Baldassarri, C.; Mathieux, F.; Ardente, F.; Wehmann, C.; Deese, K. Integration of environmental aspects into R&D inter-organizational projects management: Application of a life cycle-based method to the development of innovative windows. J. Clean. Prod. 2016, 112, 3388–3401. [Google Scholar]

| Methods Based on... | Examples of Methods | Scope | Resource Classification | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Water | Land | Materials and Substances | Energy | ||||||||||

| Non-Renewable | Biotic Renewable | Non-Renewable | Abiotic Renewable | Biotic Renewable | |||||||||

| Gate-to-Gate | Life Cycle | Atmospheric Resources | Metals and Minerals | Biomass | Fossil Energy | Nuclear Energy | Flow Energy Resources | Biomass | |||||

| Accounting methods | Mass or volume | Material flow analysis (a) | X | X | X | X | X | X | X | ||||

| ReCiPe Midpoint—Water depletion (b) | X | X | |||||||||||

| EDIP 97/2003—renewable resources (c) | X | X 1 | X 1 | ||||||||||

| Material Input Per Service Unit (d) | X | X | X 2 | X | X | X 2 | |||||||

| Energy | Energy analysis (e) | X | X | X | X | X | X | ||||||

| CED/PED (f,g) | X | X 3 | X | X | X | X 3 | |||||||

| ADP—fossil fuels (h,i) | X | X | |||||||||||

| Impact 2002+—non-renewable energy (j) | X | X 4 | X | X | X 4 | ||||||||

| ReCiPe Midpoint—Fossil depletion (b) | X | X | |||||||||||

| Exergy | Exergy analysis (k) | X | X | X | X | X | X | X | X | X | |||

| CEENE (l) | X | X | (X) | X | X | X 4 | X | X | X | X 4 | |||

| CexD (m) | X | X | X | X | X 4 | X | X | X | X 4 | ||||

| Area | Direct land accounting | X | X | ||||||||||

| Ecological Footprint (n) | X | X | (X) | (X) | (X) | (X) | |||||||

| Impact assessment methods | Resource reserves quality/quantity | ADP (h,i) | X | X | X | ||||||||

| EDIP 97/2003—non-renewable resources (c) | X | X | X | X | |||||||||

| Distance to target | Ecological Scarcity (o) | X | X | (X) | X | X4 | X | X | X | X 4 | |||

| Willingness-to-pay | EPS2000—land occupation and abiotic stock resources (p) | X | X | X | X | X | |||||||

| Future consequences | Impact 2002+ (j) | X | X | ||||||||||

| Eco-Indicator 99 (q) | X | X | X | ||||||||||

| ReCiPe Endpoint—resources (b) | X | X | X | X | |||||||||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sfez, S.; Dewulf, J.; De Soete, W.; Schaubroeck, T.; Mathieux, F.; Kralisch, D.; De Meester, S. Toward a Framework for Resource Efficiency Evaluation in Industry: Recommendations for Research and Innovation Projects. Resources 2017, 6, 5. https://doi.org/10.3390/resources6010005

Sfez S, Dewulf J, De Soete W, Schaubroeck T, Mathieux F, Kralisch D, De Meester S. Toward a Framework for Resource Efficiency Evaluation in Industry: Recommendations for Research and Innovation Projects. Resources. 2017; 6(1):5. https://doi.org/10.3390/resources6010005

Chicago/Turabian StyleSfez, Sophie, Jo Dewulf, Wouter De Soete, Thomas Schaubroeck, Fabrice Mathieux, Dana Kralisch, and Steven De Meester. 2017. "Toward a Framework for Resource Efficiency Evaluation in Industry: Recommendations for Research and Innovation Projects" Resources 6, no. 1: 5. https://doi.org/10.3390/resources6010005

APA StyleSfez, S., Dewulf, J., De Soete, W., Schaubroeck, T., Mathieux, F., Kralisch, D., & De Meester, S. (2017). Toward a Framework for Resource Efficiency Evaluation in Industry: Recommendations for Research and Innovation Projects. Resources, 6(1), 5. https://doi.org/10.3390/resources6010005