Abstract

Currently, hydrogen is mainly produced through steam reforming of natural gas. However, this conventional process involves environmental and energy security concerns. This has led to the development of alternative technologies for (potentially) green hydrogen production. In this work, the environmental and energy performance of biohydrogen produced in Europe via steam reforming of glycerol and bio-oil is evaluated from a life-cycle perspective, and contrasted with that of conventional hydrogen from steam methane reforming. Glycerol as a by-product from the production of rapeseed biodiesel and bio-oil from the fast pyrolysis of poplar biomass are considered. The processing plants are simulated in Aspen Plus® to provide inventory data for the life cycle assessment. The environmental impact potentials evaluated include abiotic depletion, global warming, ozone layer depletion, photochemical oxidant formation, land competition, acidification and eutrophication. Furthermore, the cumulative (total and non-renewable) energy demand is calculated, as well as the corresponding renewability scores and life-cycle energy balances and efficiencies of the biohydrogen products. In addition to quantitative evidence of the (expected) relevance of the feedstock and impact categories considered, results show that poplar-derived bio-oil could be a suitable feedstock for steam reforming, in contrast to first-generation bioglycerol.

1. Introduction

Currently, hydrogen is mostly used for the production of methanol and ammonia in the refining industry. Nevertheless, the shortage of fossil fuel reserves, the increasing fuel prices and the pollution caused by the growing global energy demand make hydrogen an attractive product for energy purposes [1]. Thus, the role of hydrogen as an energy carrier is attracting much interest in quest of a future sustainable energy system [2]. However, the environmental performance of hydrogen-production systems highly depends on the type of primary energy and conversion technology used. Steam methane reforming (SMR) is the most common process for hydrogen production at present. Since the raw material used in this process is natural gas, significant greenhouse gas emissions and other environmental and energy security concerns are associated with this process.

Within this context, alternative systems for hydrogen production are required [3]. Among the technological options for “green” hydrogen production [4], the steam reforming (SR) of bioproducts might be a clean and renewable option for hydrogen production [5]. For instance, bioglycerol [6,7,8] and bio-oil [9,10] have been proposed in the scientific literature to be used for hydrogen production via SR.

A comprehensive evaluation of the different systems for hydrogen production should be carried out in order to check their suitability according to sustainability criteria. Life Cycle Assessment (LCA) is a standardised methodology to assess the environmental aspects and potential impacts associated with a product system [11,12]. The LCA methodology has already proven to be a useful tool for the evaluation of hydrogen energy systems [13,14,15]. The present article aims to complement previous studies on the life-cycle performance of hydrogen-production systems by addressing the LCA of biohydrogen fuels produced in Europe via steam reforming of glycerol (GSR) and bio-oil (BSR).

2. Method: Definition of the Case Studies

2.1. Goal and Scope

The goal of this work is to evaluate the life-cycle (environmental and energy) performance of biohydrogen produced through the steam reforming of either glycerol (GSR-H2) or bio-oil (BSR-H2). A subsequent objective is to compare the life-cycle profile of these biofuels with that of conventional (i.e., fossil-derived) hydrogen produced via SMR (SMR-H2).

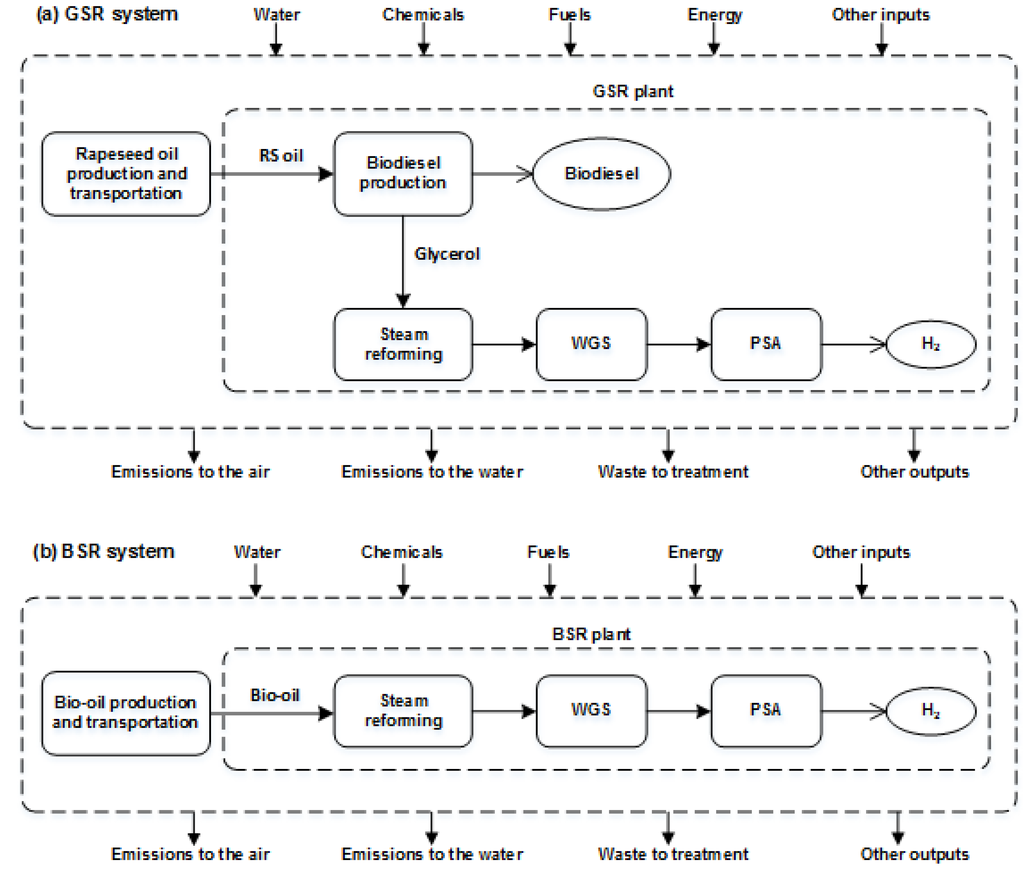

The LCA methodology was used to evaluate the performance of the different hydrogen-production systems following a cradle-to-gate approach [11,12]. Figure 1 shows a general flowchart of the SR-based systems for biohydrogen production. The functional unit (FU) of the study is 1 kg of hydrogen produced in the SR plants (99.9 vol. % purity, at plant). Capital goods were excluded from the study.

Figure 1.

General flowchart of the SR-based systems for biohydrogen production: (a) GSR system; (b) BSR system.

2.1.1. GSR System

Glycerol as a by-product from the production of biodiesel via the transesterification of rapeseed (RS) oil in Europe was considered. Transesterification involves the reaction of the vegetable oil (made up mainly of triglycerides) with an alcohol (usually methanol) in the presence of an alkali catalyst to produce a mixture of fatty-acid esters (biodiesel) and glycerol [16]. RS was selected as the feedstock for biodiesel production since it is one of the most common choices in Europe for this energy purpose.

The following stages were taken into account within the GSR system: vegetable oil production and transportation, biodiesel (and glycerol) production, bioglycerol steam reforming, water gas shift (WGS) process, and hydrogen purification through pressure swing adsorption (PSA).

In the processing plant, RS oil is compressed and heated before being fed to the transesterification reactor together with methanol (6:1 alcohol-to-oil molar ratio) and sodium hydroxide (catalyst; 1:100 sodium hydroxide-to-oil mass ratio), which are previously mixed [17,18]. The transesterification reactor operates at 60 °C and 4 bar. The product stream from the reactor contains mainly biodiesel and glycerol, and also methanol and sodium hydroxide. This stream is sent to a vacuum distillation column in which methanol is recovered with 94% purity at the top of the column and recycled to the transesterification reactor. The stream from the bottom of the column is washed with water in order to separate glycerol and sodium hydroxide from biodiesel. The resultant biodiesel stream is fed to another vacuum distillation column to separate the remaining methanol, water and unreacted oil from the biodiesel, achieving a biodiesel purity of 99.7%. The glycerol stream, together with phosphoric acid, is introduced in a neutralisation reactor in order to remove the catalyst (sodium hydroxide), thus producing sodium phosphate, which is removed later in a gravity separator [17]. Waste streams (residual oil and sodium phosphate) are sent to landfilling.

The glycerol by-product (55% moisture content) is processed in the GSR section of the plant. Glycerol purification is not considered since GSR requires a steam-to-carbon molar ratio of 3 [19]. In this section, glycerol is compressed and mixed with water to achieve the desired steam-to-carbon ratio. The resulting stream is heated and introduced in the SR reactor, which operates at 860 °C and 25 bar and uses a commercial Ni-based catalyst [19]. Steam reforming is an endothermic process in which the hydrocarbon feedstock reacts with steam producing a syngas made up mainly of H2, CO, CO2, and CH4 [20]. The heat required by the reforming process is satisfied by the combustion of a fuel in a combustor chamber that surrounds the reformer. The syngas produced is cooled down and introduced in a high-temperature shift-reactor with the aim of increasing the amount of hydrogen. Finally, the output stream is cooled and sent to a PSA unit where H2 with 99.9 vol. % purity is obtained (85% efficiency, 40 °C and 25 bar) [21]. The PSA off-gas, together with natural gas, is used as the fuel of the combustion chamber that surrounds the reformer. Catalysts are replaced every three years (conservative assumption). The GSR section of the plant operates at similar conditions to those reported in Susmozas et al. [22] for conventional SMR, with slight differences in the SR reactor temperature (850 °C for SMR) and the final H2 pressure (22 bar for SMR). Hence, key differences between the SR sections of GSR and SMR are limited to those directly linked to the different feedstock state and composition.

2.1.2. BSR System

Bio-oil from the fast pyrolysis of short-rotation poplar biomass cultivated in Europe was considered [23]. Biomass pyrolysis consists in the thermal decomposition of biomass in the absence of oxygen to produce bio-oil, char and gas. Similarly to the definition of the GSR system, the stages taken into account in the LCA of the BSR system included: bio-oil production and transportation, bio-oil steam reforming, WGS process, and hydrogen purification through PSA.

The bio-oil feedstock used in this study was based on that produced in the pyrolysis plant presented in Peters et al. [23,24]. Poplar biomass (50% moisture) is dried to 7% moisture and milled to achieve a particle size below 3 mm. Thereafter, biomass is introduced in a circulating fluidised bed (CFB) fast pyrolysis reactor producing bio-oil, char, and gas. The pyrolysis reactor is fluidised with recirculated gases and operates at 520 °C and atmospheric pressure. The bio-oil produced is recovered through separation, quenching and condensation processes [23,24]. The gases and a fraction of the produced char are burnt in a gas and char combustor in order to provide the heat required by the pyrolysis reactor and the biomass dryer. Finally, the bio-oil is transported to the BSR plant. In the BSR plant, bio-oil is processed to hydrogen through steam reforming as described above for the GSR section (Section 2.1.1).

2.2. Data Acquisition

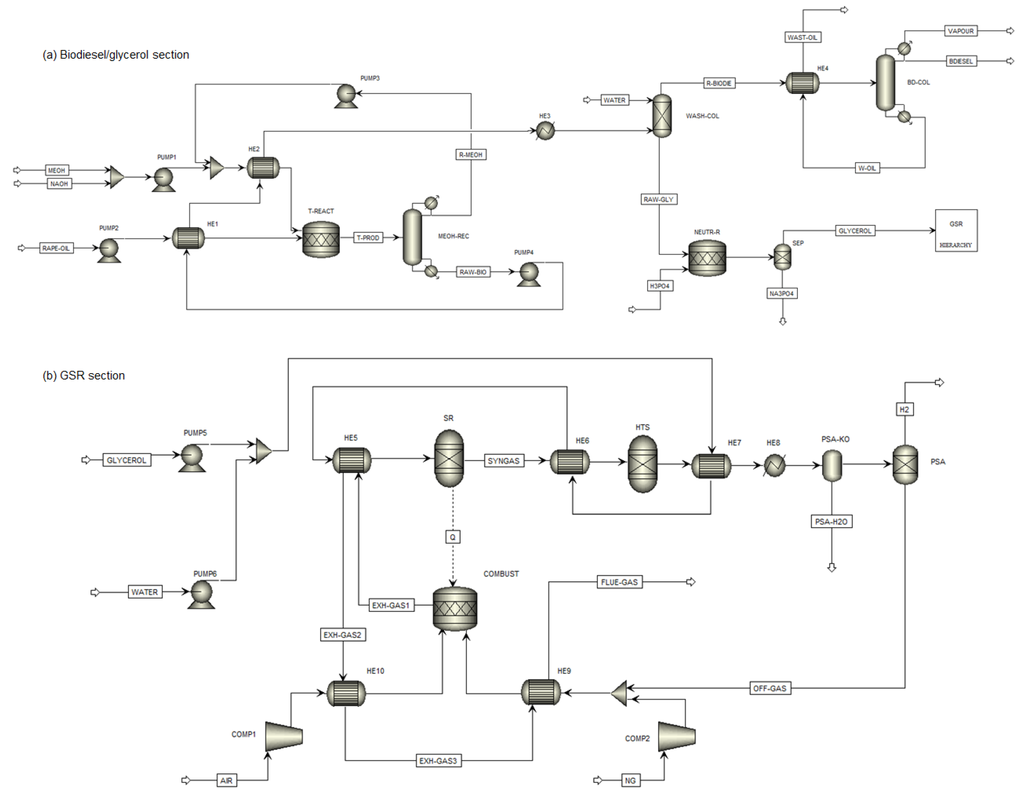

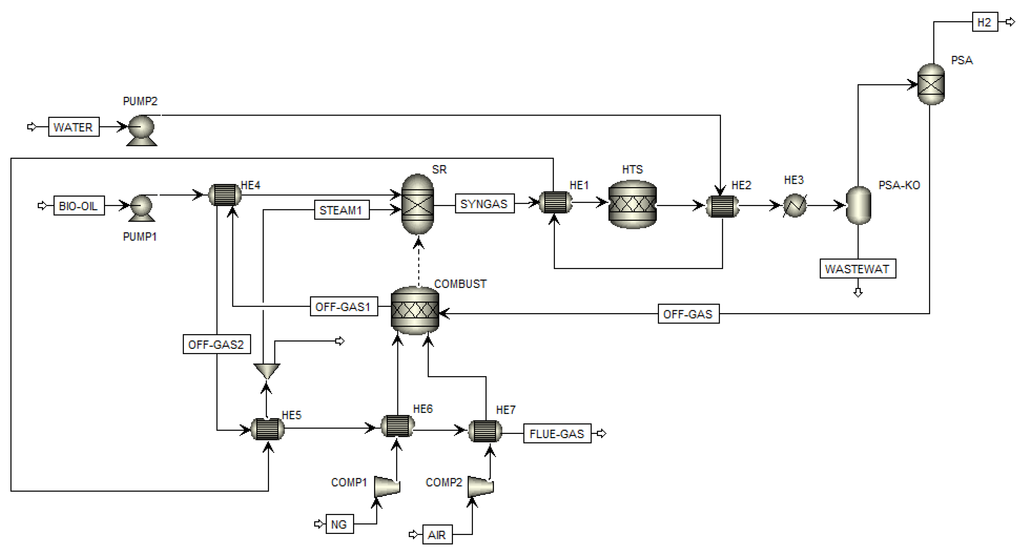

The processing plants defined in Section 2.1 were simulated in Aspen Plus® [25] to provide reliable inventory data for the LCA study. Figure 2 and Figure 3 show the simulation diagrams of the GSR and BSR plants, respectively.

Figure 2.

Simulation diagram of the GSR plant: (a) biodiesel/glycerol production; (b) reforming section.

The GSR plant embeds not only hydrogen production from bioglycerol (Figure 2b), but also biodiesel and glycerol production from RS oil (Figure 2a). For simulation purposes, RS oil was defined as triolein (main triglyceride of RS oil) [26]. The transesterification reactor and the neutralisation reactor were modelled with RStoic blocks, assuming 95% RS oil conversion and 100% NaOH conversion, respectively [17]. Vacuum distillation columns for methanol recovery and biodiesel purification were simulated with RadFrac blocks.

The BSR plant involves hydrogen production from bio-oil. The simulation of the BSR plant (Figure 3) is very similar to that of the reforming section of the GSR plant (Figure 2b). In both cases, the reformer and the WGS reactor were modelled with RGibbs blocks that calculate the product composition using the Gibbs free energy minimisation method [6]. The PSA unit was simulated by means of a separator block with 85% hydrogen recovery. Finally, the combustion chamber that provides the heat required by the reforming process was modelled with an RStoic block.

Figure 3.

Simulation diagram of the BSR plant.

Power requirements of the GSR and BSR plants were calculated using the simulation software. The whole GSR plant was found to require 15.29 kWh per tonne of RS oil, while the power usage of the BSR plant amounted to 85.81 kWh per tonne of bio-oil. These values refer to the whole plants (no allocation). The requirements directly related to SR operation at 25 bar (i.e., those of the pumps for water and glycerol/bio-oil feedstock) contributed a relatively small share to the total power requirements of the GSR and BSR plants (contribution percentages of 3.03% and 3.64%, respectively).

Data for bio-oil production were also based on process simulation in Aspen Plus® according to specific literature on the fast pyrolysis of poplar biomass cultivated in Europe [23,24]. On the other hand, inventory data for RS oil production in Europe [27] and background processes for chemicals [28], energy carriers [29] and waste management [30] were retrieved from the ecoinvent database.

3. Results and Discussion

3.1. Process Simulation as a Source of Inventory Data

Based on the results obtained through process simulation in Aspen Plus®, Table 1 presents a selection of the main inventory data of the GSR and BSR systems. It should be noted that data in Table 1 refer only to the hydrogen product. In the case of the GSR plant (from RS oil to hydrogen), because the biodiesel-production section produces not only biodiesel but also bioglycerol, an allocation approach based on the energy content of both product streams was applied in order to distribute the inventory data (and subsequent impacts) of this section between biodiesel (allocation factor: 0.9575) and bioglycerol (allocation factor: 0.0425). In this way, the impacts linked to the biodiesel product were not transferred to the hydrogen product. In the case of the BSR plant (from bio-oil to hydrogen), no allocation approach was applied since only H2 is produced.

Data in Table 1 are valid for the specific case studies described in Section 2.1. In this sense, since data come from process simulation, they should be understood as specific values for the hypothetical GSR and BSR systems under study. The usefulness of this information lies in the fact that it enables the preliminary assessment of energy systems not yet implemented at the industrial scale, anticipating potential technical and sustainability issues.

Table 1.

Main inventory data of the GSR and BSR systems (values for 1 kg of hydrogen).

| Inputs | GSR-H2 | BSR-H2 |

| From the technosphere | ||

| Feedstock (kg)a | 4.05 | 7.86 |

| Feedstock transportation (t·km) | 0.32 | 0.62 |

| Methanol (kg) | 0.40 | - |

| Sodium hydroxide (kg) | 4.68 × 10−3 | - |

| Phosphoric acid (kg) | 3.83 × 10−3 | - |

| Water (kg) | 20.64 | 20.59 |

| Natural gas (kg CH4) | 0.32 | 1.04 |

| SR catalyst (kg) | 1.12 × 10−5 | 9.70 × 10−6 |

| WGS catalyst (kg) | 7.71 × 10−5 | 1.71 × 10−4 |

| Heat (MJ) | 9.79 | - |

| Electricity (kWh) | 0.49 | 0.67 |

| From the environment | ||

| Air (kg) | 20.11 | 35.27 |

| Outputs | GSR-H2 | BSR-H2 |

| Product | ||

| Hydrogen (kg) | 1.00 | 1.00 |

| Waste | ||

| Waste to landfill (kg) | 0.43 | 1.81 × 10−4 |

| Wastewater (kg) | 11.76 | 10.97 |

| Emissions to the air | ||

| CO2 (kg) | 13.72 | 16.59 |

Note: a “Feedstock” means RS oil for GSR-H2 and bio-oil for BSR-H2.

3.2. Environmental Characterisation and Life-Cycle Energy Balances

The life-cycle inventories of the GSR and BSR systems were implemented into SimaPro 8 [31]. A set of nine impact potentials (widely used for the characterisation of energy systems) were evaluated: global warming (GWP), abiotic depletion (ADP), ozone layer depletion (ODP), photochemical oxidant formation (POFP), land competition (LC), acidification (AP), eutrophication (EP), cumulative non-renewable energy demand (CEDnr), and total cumulative energy demand (CEDt). GWP was evaluated taking into account the 100-year characterisation factors defined by the Intergovernmental Panel on Climate Change (IPCC) [32]. The CML method was used to evaluate ADP, ODP, POFP, LC, AP, and EP [33]. Finally, the two CED indicators were quantified according to VDI guidelines [34]. The characterisation results calculated for the biohydrogen fuels (GSR-H2 and BSR-H2) are shown in Table 2. Furthermore, a comparison of the life-cycle profiles of GSR-H2 and BSR-H2 as alternatives to SMR-H2 is presented later in Section 3.3.

Table 2.

Life-cycle profiles of GSR-H2 and BSR-H2 (values for 1 kg of hydrogen).

| Impact Category | GSR-H2 | BSR-H2 |

|---|---|---|

| GWP (kg CO2 eq) | 12.65 | 3.79 |

| ADP (kg Sb eq) | 5.69 × 10−2 | 4.13 × 10−2 |

| ODP (kg CFC-11 eq) | 8.90 × 10−7 | 5.54 × 10−7 |

| POFP (kg C2H4 eq) | 5.16 × 10−3 | 6.00 × 10−4 |

| LC (m2a) | 21.17 | 7.73 |

| AP (kg SO2 eq) | 6.51 × 10−2 | 1.56 × 10−2 |

| EP (kg PO43− eq) | 5.26 × 10−2 | 3.20 × 10−3 |

| CEDnr (MJ) | 127.33 | 89.34 |

| CEDt (MJ) | 344.67 | 466.31 |

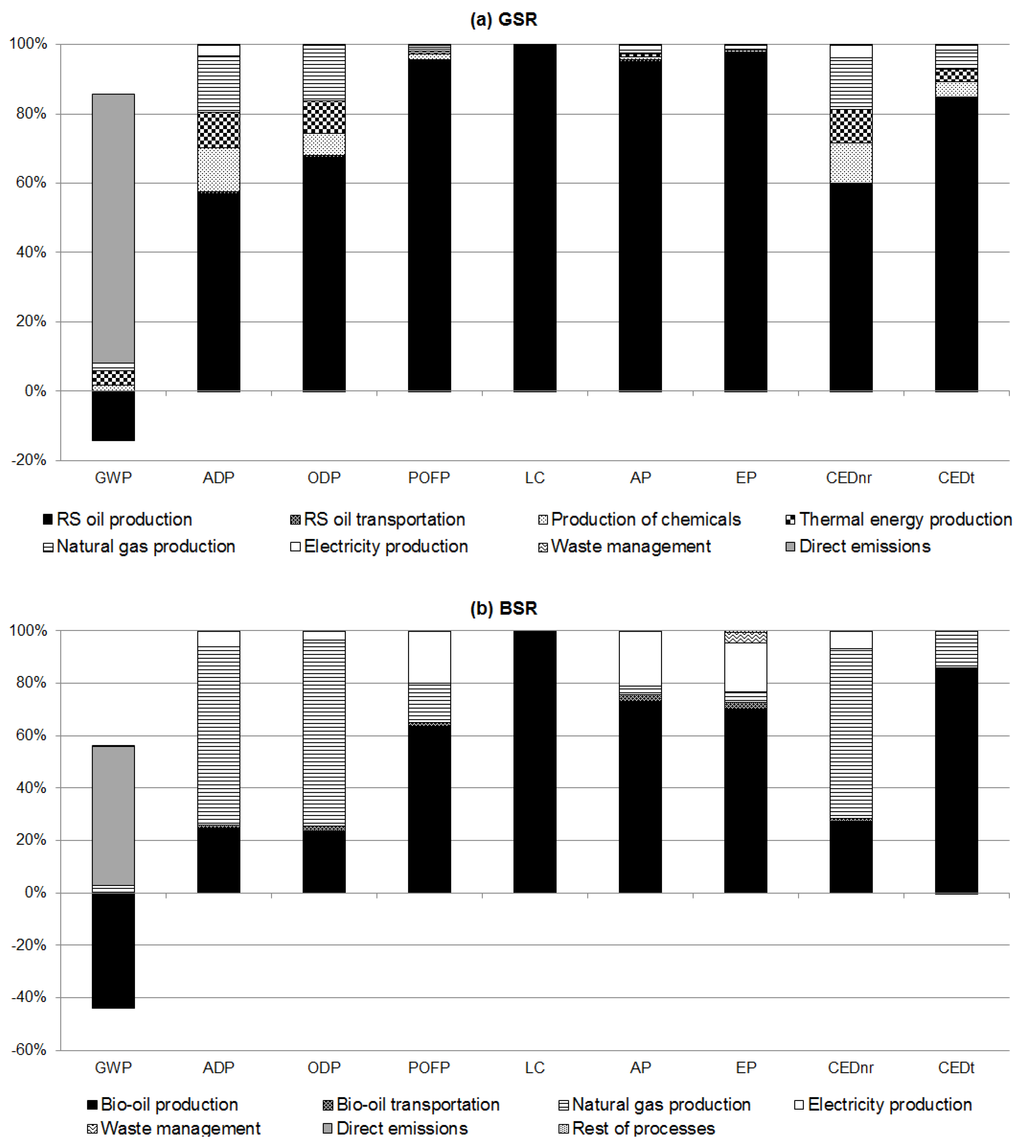

Figure 4 facilitates the identification of the main processes responsible for the potential impacts of the evaluated biohydrogen fuels. In the case of GSR-H2 (Figure 4a), RS oil production was found to dominate all impact categories (except for GWP), with contribution percentages ranging from 57% (for ADP) to 100% (for LC). This is mainly due to the high inputs (land, energy and fertilisers) required in RS plantations [27]. Hence, the selection of the biogenic feedstock for biodiesel production highly influences the results reported for GSR-H2. It should be noted that CO2 fixation during biomass growth leads to a favourable GWP result for RS oil (negative percentage in Figure 4a), being this impact category dominated by direct CO2 emissions from the processing plant. Finally, the production of chemicals (mainly methanol production), the generation of the thermal energy required by the distillation of biodiesel, and the production of natural gas to meet the heat demand of the SR process also accounted for significant contributions to ADP, CEDnr, CEDt, and ODP.

In the case of BSR-H2 (Figure 4b), bio-oil production was found to dominate LC, CEDt, AP, EP, and POFP, with contribution percentages ranging from 64% (for POFP) to 100% (for LC). This is linked not only to poplar biomass cultivation but also to the electricity demand of both biomass pre-treatment and fast pyrolysis [23,24]. As also seen for GSR-H2, CO2 absorption during biomass growth results in a favourable GWP value for the biogenic feedstock (negative percentage in Figure 4b), being this impact category dominated by direct CO2 emissions from the processing plant. ODP, ADP, and CEDnr were found to be mainly associated with natural gas production to satisfy the heat demand of the BSR plant. Electricity production to meet the electricity demand of the BSR plant also accounted for significant contributions to several impact categories, in particular to AP, POFP, and EP.

The life-cycle energy balance of GSR-H2 and BSR-H2 was calculated as the difference between the potential energy output (119.96 MJ·kg−1, according to the lower heating value of hydrogen) and the corresponding CEDnr indicators in Table 2. A positive balance is desired, as it means that the energy output exceeds the cumulative non-renewable (fossil and nuclear) energy demand of the product [22]. Life-cycle energy balances of −7.37 MJ·kg−1 and +30.62 MJ·kg−1 were calculated for GSR-H2 and BSR-H2, respectively. These balances indicate a favourable life-cycle energy performance of BSR-H2 (unlike GSR-H2). The life-cycle energy performance of these hydrogen biofuels is discussed further in Section 3.3.

Figure 4.

Process contribution to the impacts of (a) GSR-H2 and (b) BSR-H2.

3.3. Comparison of the Life-Cycle Performance

In this section, the life-cycle performances of GSR-H2 and BSR-H2 are compared both to one another and to that of conventional SMR-H2. The life-cycle profile of SMR-H2 was calculated through the implementation in SimaPro of the inventory data reported by Susmozas et al. [22] for a conventional SMR system (data obtained mainly by process simulation). This conventional SMR system involves feedstock (i.e., natural gas) production and transportation, steam reforming, WGS in a high-temperature shift-reactor, and hydrogen purification in a PSA unit [22].

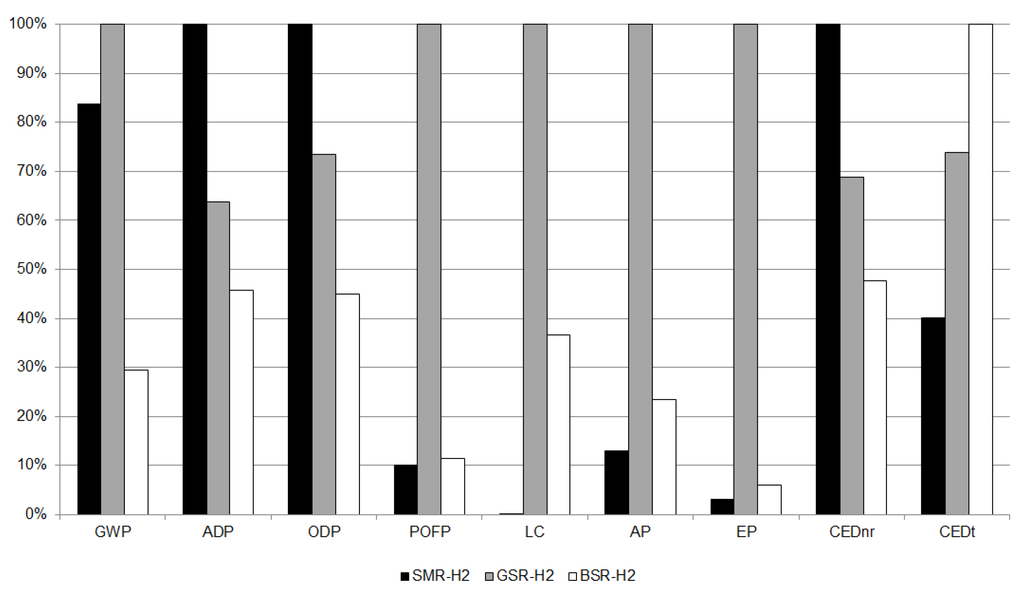

Figure 5 shows the comparison of the life-cycle profiles of GSR-H2, BSR-H2 and SMR-H2. As it can be observed in Figure 5, the suitability of a specific hydrogen fuel highly depends on the impact category taken into account. For instance, BSR-H2 shows the best results in terms of GWP, ADP, CEDnr, and ODP, but it performs worse than SMR-H2 in terms of LC, CEDt, EP, POFP, and AP.

Figure 5.

Comparison of the life-cycle profiles of GSR-H2, BSR-H2 and SMR-H2.

Regarding GSR-H2 (Figure 5), it shows better results than SMR-H2 in terms of ADP, CEDnr, and ODP. However, GSR-H2 shows the worst behaviour in terms of LC, EP, POFP, AP, and GWP. More favourable results would be obtained for GSR-H2 by selecting a more eco-friendly feedstock for biodiesel/glycerol production. For instance, the use of glycerol coming from the esterification-transesterification of waste vegetable oils is expected to result in a better life-cycle profile of GSR-H2 [35].

The fact that the CEDnr indicator of both biohydrogen fuels (GSR-H2 and BSR-H2) is lower than that of SMR-H2 implies that the latter accounts for a worse life-cycle energy balance. Nevertheless, in order to complete the discussion on the life-cycle energy performance of the hydrogen fuels under study, their life-cycle energy efficiencies were also estimated. These efficiencies were calculated by dividing the potential energy output (119.96 MJ per kg of hydrogen in all cases) with the CEDt indicator [22]. In contrast to the CEDnr indicator (which only includes the fossil and nuclear energy demand), the CEDt indicator takes into account not only the non-renewable energy demand but also the renewable energy demand. CEDt indicators of 344.67 MJ, 466.31 MJ, and 186.81 MJ (per kg of hydrogen) were computed for GSR-H2, BSR-H2, and SMR-H2, respectively. Hence, SMR-H2 (64.21%) was found to show higher life-cycle energy efficiency than both GSR-H2 (34.80%) and BSR-H2 (25.73%). Finally, the renewability scores of the three hydrogen fuels were estimated as an additional indicator of their life-cycle performance [14,22]. These scores were calculated by dividing the cumulative renewable energy demand with the CEDt indicator. As expected, the renewability of BSR-H2 (80.84%) and GSR-H2 (63.05%) was found to be much higher than that of SMR-H2 (0.92%).

A robust comparison with SMR-H2 was possible because inventory data for conventional hydrogen production were retrieved from an LCA study with a methodological framework consistent with that of GSR-H2 and BSR-H2 [22]. For the same reason, a robust comparison with hydrogen produced through indirect gasification of poplar biomass is also possible [22]. In this respect, hydrogen from biomass gasification is generally associated with a better life-cycle performance than hydrogen from biofuel reforming (especially in terms of GWP and ADP), but at the expense of a low life-cycle energy efficiency (<20%, which means a high consumption of biomass feedstock). Comparison with other hydrogen energy systems is subject to consistency concerns owing to methodological discrepancies. Nevertheless, taking into account results from LCA studies covering a wider set of hydrogen energy systems [15,36], hydrogen from biofuel reforming seems to bring about a better life-cycle performance than hydrogen from fossil-based methods (coal gasification and steam reforming, partial oxidation or autothermal reforming of natural gas) in terms of GWP and ADP, while performing potentially worse than hydrogen produced through other renewable methods such as water electrolysis using wind or solar power. Regarding the selection of a suitable feedstock for biofuel reforming, bio-oil from the fast pyrolysis of poplar biomass might be a better option than first-generation bioethanol, but the use of biomethane in reforming systems might lead to a more favourable life-cycle performance [36].

4. Conclusions

LCA proved to be a useful methodology to evaluate the performance of hydrogen produced via biofuel steam reforming in Europe. From a life-cycle perspective, the environmental and energy performance of hydrogen from biofuel reforming was found to be highly dependent on the biogenic feedstock selected. This choice, along with the selection of the impact categories to be taken into account, determines the suitability of a specific hydrogen fuel as a green alternative to conventional hydrogen from steam methane reforming.

The LCA of hydrogen produced through biofuel reforming provided not only quantitative evidence of the (expected) relevance of the feedstock and impact categories considered, but also specific results for two well-defined case studies. In this respect, bio-oil from the fast pyrolysis of poplar biomass is seen as a potentially suitable feedstock for steam reforming (but with the need for reduced biomass demands), in contrast to glycerol from biodiesel production via rapeseed oil transesterification. Thus, the use of a renewable resource does not necessarily guarantee an appropriate life-cycle performance of a hydrogen-production system. In this sense, LCA studies help support decision-making processes oriented towards sustainability.

Acknowledgments

The authors would like to thank Jens F. Peters for valuable scientific exchange.

Conflicts of Interest

The authors declare no conflict of interest.

Acronyms and Abbreviations

| ADP | abiotic depletion impact potential |

| AP | acidification impact potential |

| BSR | bio-oil steam reforming |

| BSR-H2 | hydrogen produced through bio-oil steam reforming |

| CED | cumulative energy demand |

| CEDnr | cumulative non-renewable energy demand |

| CEDt | total cumulative energy demand |

| CFB | circulating fluidised bed |

| CML | Institute of Environmental Sciences of Leiden University |

| EP | eutrophication impact potential |

| FU | functional unit |

| GSR | glycerol steam reforming |

| GSR-H2 | hydrogen produced through glycerol steam reforming |

| GWP | global warming impact potential |

| IPCC | Intergovernmental Panel on Climate Change |

| LC | land competition |

| LCA | life cycle assessment |

| ODP | ozone layer depletion impact potential |

| POFP | photochemical oxidant formation impact potential |

| PSA | pressure swing adsorption |

| RS | rapeseed |

| SMR | steam methane reforming |

| SMR-H2 | hydrogen produced through steam methane reforming |

| SR | steam reforming |

| VDI | Verein Deutscher Ingenieure |

| WGS | water gas shift |

References

- International Energy Agency. World Energy Outlook 2012; OECD/IEA: Paris, France, 2013. [Google Scholar]

- Dutta, S. A review on production, storage of hydrogen and its utilization as an energy resource. J. Ind. Eng. Chem. 2014, 20, 1148–1156. [Google Scholar]

- Chaubey, R.; Sahu, S.; James, O.O.; Maity, S. A review on development of industrial processes and emerging techniques for production of hydrogen from renewable and sustainable sources. Renew. Sustain. Energy Rev. 2013, 23, 443–462. [Google Scholar]

- Dincer, I. Green methods for hydrogen production. Int. J. Hydrog. Energy 2012, 37, 1954–1971. [Google Scholar] [CrossRef]

- Blasi, A.; Fiorenza, G.; Freda, C.; Calabrò, V. Steam reforming of biofuels for the production of hydrogen-rich gas. In Membranes for Clean and Renewable Power Applications; Gugliuzza, A., Basile, A., Eds.; Woodhead Publishing: Cambridge, UK, 2014; pp. 145–181. [Google Scholar]

- Rossi, C.C.R.S.; Alonso, C.G.; Antunes, O.A.C.; Guirardello, R.; Cardozo-Filho, L. Thermodynamic analysis of steam reforming of ethanol and glycerine for hydrogen production. Int. J. Hydrog. Energy 2009, 34, 323–332. [Google Scholar] [CrossRef]

- Iriondo, A.; Barrio, V.L.; El Doukkali, M.; Cambra, J.F.; Güemez, M.B.; Requies, J.; Arias, P.L.; Sánchez-Sánchez, M.C.; Navarro, R.; Fierro, J.L.G. Biohydrogen production by gas phase reforming of glycerine and ethanol mixtures. Int. J. Hydrog Energy 2012, 37, 2028–2036. [Google Scholar] [CrossRef]

- Dou, B.; Song, Y.; Wang, C.; Chen, H.; Xu, Y. Hydrogen production from catalytic steam reforming of biodiesel byproduct glycerol: Issues and challenges. Renew. Sustain. Energy Rev. 2014, 30, 950–960. [Google Scholar] [CrossRef]

- Trane, R.; Dahl, S.; Skjøth-Rasmussen, M.S.; Jensen, A.D. Catalytic steam reforming of bio-oil. Int. J. Hydrog. Energy 2012, 37, 6447–6472. [Google Scholar] [CrossRef]

- Remón, J.; Broust, F.; Valette, J.; Chhiti, Y.; Alava, I.; Fernandez-Akarregi, A.R.; Arauzo, J.; Garcia, L. Production of a hydrogen-rich gas from fast pyrolysis bio-oils: Comparison between homogeneous and catalytic steam reforming routes. Int. J. Hydrog. Energy 2014, 39, 171–182. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO 14040:2006 Environmental Management—Life Cycle Assessment—Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- International Organization for Standardization. ISO 14044:2006 Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Smitkova, M.; Janíček, F.; Riccardi, J. Life cycle analysis of processes for hydrogen production. Int. J. Hydrog. Energy 2011, 36, 7844–7851. [Google Scholar] [CrossRef]

- Dufour, J.; Serrano, D.P.; Gálvez, J.L.; González, A.; Soria, E.; Fierro, J.L.G. Life cycle assessment of alternatives for hydrogen production from renewable and fossil sources. Int. J. Hydrog. Energy 2012, 37, 1173–1183. [Google Scholar] [CrossRef]

- Cetinkaya, E.; Dincer, I.; Naterer, G.F. Life cycle assessment of various hydrogen production methods. Int. J. Hydrog. Energy 2012, 37, 2071–2080. [Google Scholar] [CrossRef]

- Leung, D.Y.C.; Wu, X.; Leung, M.K.H. A review on biodiesel production using catalyzed transesterification. Appl. Energy 2010, 87, 1083–1095. [Google Scholar] [CrossRef]

- Morais, S.; Mata, T.M.; Martins, A.A.; Pinto, G.A.; Costa, C.A.V. Simulation and life cycle assessment of process design alternatives for biodiesel production from waste vegetable oils. J. Cleaner. Prod. 2010, 18, 1251–1259. [Google Scholar] [CrossRef]

- Kaewcharoensombat, U.; Prommetta, K.; Srinophakun, T. Life cycle assessment of biodiesel production from jatropha. J. Taiwan Inst. Chem. Eng. 2011, 42, 454–462. [Google Scholar] [CrossRef]

- Tindall, B.M.; King, D.L. Designing steam reformers for hydrogen production. Hydrocarb. Process. 1994, 73, 69–75. [Google Scholar]

- Sun, S.; Yan, W.; Sun, P.; Chen, J. Thermodynamic analysis of ethanol reforming for hydrogen production. Energy 2012, 44, 911–924. [Google Scholar] [CrossRef]

- Long, R.; Picioccio, K.; Zagoria, A. Optimising hydrogen production and use. PTQ 2011, Q3, 1–12. [Google Scholar]

- Susmozas, A.; Iribarren, D.; Dufour, J. Life-cycle performance of indirect biomass gasification as a green alternative to steam methane reforming for hydrogen production. Int. J. Hydrog. Energy 2013, 38, 9961–9972. [Google Scholar] [CrossRef]

- Peters, J.F.; Iribarren, D.; Dufour, J. Life cycle assessment of pyrolysis oil applications. Biomass Convers. Biorefin. 2015, 5, 1–19. [Google Scholar] [CrossRef]

- Peters, J.F.; Iribarren, D.; Dufour, J. Simulation and life cycle assessment of biofuel production via fast pyrolysis and hydroupgrading. Fuel 2015, 139, 441–456. [Google Scholar] [CrossRef]

- Aspen Plus®. Available online: http://www.aspentech.com/products/aspen-plus.aspx (accessed on 1 April 2015).

- Vlysidis, A.; Binns, M.; Webb, C.; Theodoropoulos, C. A techno-economic analysis of biodiesel biorefineries: Assessment of integrated designs for the co-production of fuels and chemicals. Energy 2011, 36, 4671–4683. [Google Scholar] [CrossRef]

- Jungbluth, N.; Chudacoff, M.; Dauriat, A.; Dinkel, F.; Doka, G.; Faist-Emmenegger, M.; Gnansounou, E.; Kljun, N.; Schleiss, K.; Spielmann, M.; et al. Life Cycle Inventories of Bioenergy; Ecoinvent Report No. 17; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2007. [Google Scholar]

- Althaus, H.J.; Chudacoff, M.; Hischier, R.; Jungbluth, N.; Osses, M.; Primas, A. Life Cycle Inventories of Chemicals; Ecoinvent Report No. 8; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2007. [Google Scholar]

- Dones, R.; Bauer, C.; Bolliger, R.; Burger, B.; Faist-Emmenegger, M.; Frischknecht, R.; Heck, T.; Jungbluth, N.; Röder, A.; Tuchschmid, A. Life Cycle Inventories of Energy Systems: Results for Current Systems in Switzerland and other UCTE Countries; Ecoinvent Report No. 5; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2007. [Google Scholar]

- Doka, G. Life Cycle Inventories of Waste Treatment Services; Ecoinvent Report No. 13; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2009. [Google Scholar]

- Goedkoop, M.; Oele, M.; Leijting, J.; Ponsioen, T.; Meijer, E. Introduction to LCA with SimaPro; PRé Consultants: Amersfoort, The Netherlands, 2013. [Google Scholar]

- Myhre, G.; Shindell, D.; Bréon, F.M.; Collins, W.; Fuglestvedt, J.; Huang, J.; Koch, D.; Lamarque, J.F.; Lee, D.; Mendoza, B.; et al. Anthropogenic and natural radiative forcing. In Climate Change 2013: The Physical Science Basis—Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Stocker, T.F., Qin, D., Plattner, G.K., Tignor, M., Allen, S.K., Boschung, J., Nauels, A., Xia, Y., Bex, V., Midgley, P.M., Eds.; Cambridge University Press: Cambridge, UK, 2013; pp. 659–740. [Google Scholar]

- Guinée, J.B.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; de Koning, A.; van Oers, L.; Wegener-Sleeswijk, A.; Suh, S.; Udo de Haes, H.A.; et al. Life Cycle Assessment—An Operational Guide to the ISO Standards; Centre of Environmental Science: Leiden, The Netherlands, 2001. [Google Scholar]

- Verein Deutscher Ingenieure. VDI Guideline 4600: Cumulative Energy Demand (KEA)—Terms, Definitions, Methods of Calculation; VDI: Düsseldorf, Germany, 2012. [Google Scholar]

- Dufour, J.; Iribarren, D. Life cycle assessment of biodiesel production from free fatty acid-rich wastes. Renew. Energy 2012, 38, 155–162. [Google Scholar] [CrossRef]

- Hajjaji, N.; Pons, M.N.; Renaudin, V.; Houas, A. Comparative life cycle assessment of eight alternatives for hydrogen production from renewable and fossil feedstock. J. Clean. Prod. 2013, 44, 177–189. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).