Abstract

The use of rare earth elements in various technologies continues to grow despite some alternatives being found for particular uses. Given a history of ecological concerns about pollution from rare earth mines, particularly in China, there are growing social and environmental concerns about the growth of the mining and mineral processing in this sector. This is best exemplified by the recent social and environmental conflict surrounding the development of the Lynas Advanced Materials Plant (LAMP) in Kuantan, Malaysia which led to international activism and claims of environmental and social injustice. This paper analyses the structure of environmental and social conflicts surrounding rare earth minerals and opportunities for improving the social and environmental performance of the sector. Many of these elements are used for green technologies. Opportunities exist that offer a more circular supply chain following industrial ecological principles through which reuse and recycling of the materials can provide a means of mitigating social and environmental conflicts in this sector. In addition, public engagement processes that recognize community concerns about radiation, and transparent scientifically predicated decision-making through an appropriate governance structure within regulatory organizations are also presented.

Keywords:

rare earths; recycling; nuclear; environmental conflict; Lynas; Malaysia; Kuantan; Korea; green energy; industrial ecology 1. Introduction

The rare earths (RE) sector has come under intense public scrutiny in recent years because of a convergence of environmental narratives around natural resource extraction. First, there has been a growth of social movements around mining extraction more broadly which are predicated in resource nationalism as well as environmental activism. Second, there is a growing concern about any materials which have even a remote connection to radioactive pollution. Finally, a legacy of past projects has also played a role in further enhancing distrust between the community and the site developers of such projects.

Australian environmentalism around the rare earth sector has been amplified by these aforementioned factors and been linked particularly to the establishment of the Mount Weld mine, the concentrate of which is being shipped to Malaysia. There has been a pervasive movement in Malaysia against this project, which is partly a manifestation of distrust emanating from political tensions within the country between various ethnic groups and the transition towards pluralistic democracy. However, the case also highlights how activism around minerals has strong global linkages and claims of environmental injustice in shipping concentrate for processing to a developing country can be raised. This case highlights the need for a circular economy approach to material flows that would allow for trade of positive goods but minimize the need for export of environmentally harmful externalities. Recycling as a feature of such a circular economy deserves greater attention within the rare earths sector as well.

The Malaysian activism against this sector can be traced back to The Asian Rare Earth’s site which was operated by Mitsubishi at Bukit Merah 20 years ago. Leakage of radioactive materials from this site sensitized the country to rare earth environmental concerns which were exacerbated by mismanagement of various aspects of community relations at the site [1]. Although the claims of environmental health damage were initially upheld by the courts, and then eventually refuted by Malaysia’s highest court, the absence of a community engagement process led to immense public distrust of environmental regulation and enforcement.

Even though current rare earth mining and processing technologies are very different from the case in Bukit Merah, which involved old tailings with monazite from tin mining operations, there is a tendency to conflate the past and the present given the negative history of minimal engagement.

2. Rare Earths Mines

The mining process for RE varies depending on the kind of ore being processed and the range of accompanying elements which will also be extracted. For example, the world’s largest and best known RE mine in China, Bayan Obo, was originally discovered as an iron ore mine in 1927 and is also one of the world’s largest fluorite extraction sites [2]. The large footprint of mines such as Bayan Obo can clearly have major ecological impact and there is little doubt that environmental concerns have been real and present in this context and been documented. The reduced production by China on environmental grounds during the past three years triggered reduced export quotas which have been questioned by the United States, Japan and Europe deserves further research but there is little doubt that the scale of the operations in Bayan Obo needed environmental remediation.

An independent research article by the French Newspaper Le Monde which was subsequently published in The Guardian in 2012 documented through interviews with farmers and local residents of the town of Baotou that the scale of the mining had irrevocably changed the lifestyles of residents. In the village of Xinguang Sancun, farmers have abandoned fields and stopped planting anything but wheat and corn and the population has declined from 2000 to 300 within the past 10 years. A study by the municipal environmental protection agency showed that rare earth minerals were the source of their problems with increased pollution compounded with dozens of new factories and other industrial services [3]. The Chinese government has committed 4 billion Yuan ($600 million) to clean up the damage caused by the RE sector in this region. In 2012, Su Bo, the vice minister for industry and information technology noted publicly that the Chinese authorities were “absolutely not willing to sacrifice the environment in order to develop the RE industry” [4].

The Mountain Pass RE mine in California also faced environmental compliance cost challenges which led to its closure during the 1990s, allowing for the Chinese industry to flourish soon thereafter. However, the environmental issues at Mountain Pass involved leakage of a particular piping system used to carry wastewater to an evaporation system. A federal investigation found 60 spills—some unreported—occurred between 1984 and 1998, when the pipeline was shut down. In all, about 600,000 gallons of wastewater flowed onto the desert floor. The mine’s operator at the time was sued by the San Bernardino County district attorney and paid more than $1.4 million in fines and settlements. However, since then the current management of the company has changed the wastewater system completely and through new technologies tailings will be managed much closer to the mine site with a paste-tailings system to avoid piping of wastewater. A field visit by the author to the surrounding areas in January 2013 including interviews with various environmental regulators revealed general satisfaction with the processes being proposed for the site. There is thus far minimal environmental opposition to this site’s reopening.

Additional rare earth mining comes from ion-adsorbed clay deposits, which are particularly prevalent in Southern China and have a considerable environmental footprint in the province of Jiangxi. In 2010 there were 88 rare earth mineral producers in the province’s capital Ganzhou but according to a USGS study 90 percent of them ceased their operations because of weak prices. Jiangxi Province had a reserve of 2.3 Mt of the ion-adsorption RE [5]. An interesting development in this sector involves the Aluminum Corporation of China (Chinalco, Beijing, China) signing an agreement with the government of Jiangxi Province to allow the company to consolidate the local nonferrous metals producers to take shares of Jiangxi Rare Earth and Rare Metals Tungsten Group Co. Ltd. Involvement of a much larger company with multinational reach will likely provide greater environmental and social scrutiny of the ion-adsorbed clays sector of RE as well.

The Mount Weld mine in Western Australia, which is the source of the concentrate for the LAMP facility in Malaysia, is clearly of a lower impact than Bayan Obo, Mountain Pass and indeed adsorbed clay deposits, given the small footprint of the mine itself and the remoteness of the location. The kind of ore being mined (rare earth phosphates: carbonatite, monazite) may have higher thorium content than bastnasite ore from the Chinese or American mines but still far below radiation concerns that may emanate from high grade uranium operations. Communicating the ecological differences between the various types of mine sites is essential to ensuring that the social perception of the respective mines is not conflated. However, the connection between mining and the processing steps and the generation of various kinds of waste, including mildly radioactive thorium needs to be addressed.

3. Processing

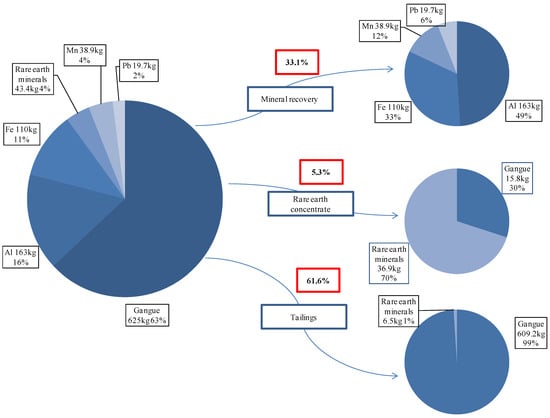

The processing of RE elements is a complex process and often involves multiple facilities. As with other metals, a combination of solvent extraction and flotation processes, coupled with some electrolytic processes may be used. Minimal research has been done on the environmental accounting of rare earth processing in terms of recovery. Hardly any empirical data is available on energy usage of the processing. Figure 1 provides one empirical analysis conducted by a postgraduate student at University College London of a mine in China [6].

Figure 1.

Environmental Accounting Analysis of the Maoniuping Mine China delineating how the ore can be disaggregated into various useful and “waste” materials [6]. REE = Rare Earth Elements.

The amount of gangue (i.e., the waste material mixed with the wanted material in an ore deposit) produced and much of the concern around pollution emanates from public perception of this waste material. There is contention as to the classification of this material as “waste” since it has been argued by the industry that given the thorium content, the material could be used at a later date for extracting usable products. The categorization of this material as a non-waste has regulatory compliance implications since waste management requires an immediate disposal plan whereas potentially useful material can be stored with more flexible compliance mechanisms.

Each ore has a slightly different waste profile and the processing technologies and materials are proprietary at a detailed level. However, for compliance purposes the basic wastes produced are generally known. Thus in the case of the LAMP facility in Malaysia, the process will produce some wastewater and spent chemicals which will go through a wastewater treatment facility before discharge; gypsum; magnesium-content gypsum and iron phosphor-gypsum (with thorium content).

The final product to be shipped to refiners would be rare earth oxides which would need further processing before being available for manufacturing.

4. Manufacturing

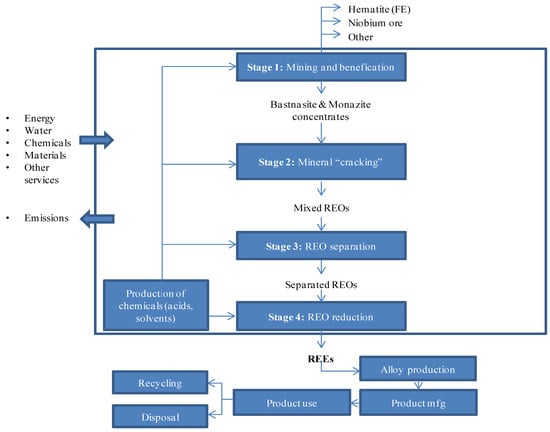

After initial processing to extract RE, there is a specialized chemical refiners sector that produces specific metals which can be used by fabricators for products such as magnets and phosphors. Much of the processing techniques are similar but with a higher levels of extraction precision in smaller units. A lifecycle diagram of a typical RE operation is provided in Figure 2 which highlights the particular environmental nodes which could be socially consequential.

Figure 2.

Lifecycle analysis boundary for the production of rare earth element products [7]. REO = Rare Earth Oxides *; REOH = Rare Earth Hydroxide.

5. Recycling

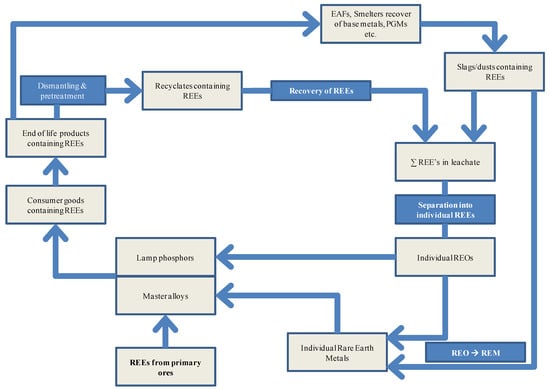

Recycling of RE is still quite limited and was calculated in 2011 to be around 1 per cent of supply. Binnemans et al. [8] have done an exhaustive review of the various recycling pathways for RE and their potentials. There is little doubt that recycled RE could reduce the ecological footprint of mining but the cost of extraction from products in which RE get embedded makes recovery less competitive. Figure 3 presents the closed-loop prospect for RE products from which the extraction could be undertaken.

Figure 3.

Recycling prospects for RE and opportunities for environmental efficiency [8]. Acronyms: REE = Rare Earth Elements; EAF = Electric Arc Furnaces; REO = Rare Earth Oxides.

However, the potential for further developing this sector remains uncertain since there is also a competing strategy by some RE users to seek alternatives to the materials themselves and hence research and development has been divided between recycling proponents and substitute proponents.

6. Monitoring

Given the complexity of RE supply from mines to markets and the potential for a “cradle to cradle” circular economy approach, the sector requires a deliberate and detailed monitoring system which should be adaptive to technological changes. Monitoring protocols for complex industrial processes are often a key means of assuaging social concerns. In particular, the following four areas deserve prioritization for monitoring and enforcement.

6.1. Radiation

Rare earth elements themselves have some radioactive isotopes that need to be monitored based on the ore grade. With several decades of experience of monitoring pitchblende ore for uranium mines, there is potential for good lesson-drawing on radiation monitoring from the uranium mining sector. In particular, the high grade Athabascan uranium deposits in Saskatchewan, Canada deserve attention for comparative protocols on monitoring.

Often, the major concern regarding radiation emanates from the processing of the ore which can lead to thorium production. Since the major decay process for thorium involves alpha particle emissions, it is important to have a particular monitoring plan around alpha-emitting sources. Alpha emissions do not travel far but can cause more cellular damage, particularly when inhaled. There is a vast amount of literature on monitoring alpha emissions from radon—a naturally occurring radioactive gas which has caused major public health concerns for indoor air pollution in the basements of North American homes.

6.2. Environmental (Air, Water, Soil)

Environmental monitoring of RE facilities is similar to most large industrial operations. The use of complex organic and inorganic reagents in processing requires diligence in the wastewater treatment system working and having secondary containment in case of failure (such containment is provided in the LAMP facility) and the same is true of the new Molycorp expansion at Mountain Pass, California. Given the history of pipe leakage at the site in the past, far more stringent environmental monitoring has been instated.

Much of the monitoring for environmental harm is undertaken at the refinery level. As noted in a US Environmental Protection Agency report in 2011: “Extracting the ore from the Earth represents only a small portion of rare earth element production. Refining rare earth element bearing minerals into marketable products constitutes the major aspect of rare earth element production” [9].

Carbonate rare earth minerals provide a natural buffer against hyperacidity that may come from various acidic leaching processes in refinement. However, excessive carbonate presence can also lead to alkalinity and therefore pH monitoring of treated effluent is essential.

6.3. Safety

Monitoring of safety considerations at RE sites follows protocols similar to other industrial establishment in which solvent extraction, electrolytic processes and infrastructure for piping of high intensity chemicals are used. Safety at sites is largely dependent on regulatory compliance and enforcement and rare earth processing sites can occur in close proximity to human habitation as long as there is stringent safety enforcement. French company Rhodia’s RE processing site in La Rochelle, France is a fine example of such a site which is located in a small, closely-knit town with a strong tourist economy and yet because of stringent safety standards there has been no palpable public opposition or any serious safety-related incident. The plant is subject to environmental surveillance by the Installations Classées pour la Protection de l‘Environnement (ICPE) that has immense experience with monitoring of safety at sites with radiation concerns, given France’s major dependence on nuclear power. Safety standards from this site in particular are worth considering as blueprint for protocols at other rare earth refinement facilities.

6.4. Health

Much of the public health concerns around RE emanate from concerns around thorium-containing wastes as a source of radiation. The epidemiological evidence of the impact of RE mining is still somewhat limited since much of the processing in China has not been undertaken with publicly available monitoring. The only detailed study of RE health-related toxicity was carried out in the early 1990s by Hirano and Suzuki [10] and provides data similar to that of heavy metals toxicity concerns. The data on thorium health impacts is also very limited and any negative health impacts monitored are constrained by the fact that sample size in many cases has been too small to make any statistically significant causation [11]. Ongoing health monitoring must remain an important part of the overall community engagement plan for the LAMP site, particularly since so much of the environmental conflict has emanated from perceptions of what constitutes an “acceptable dose” of radiation. The public health data can render such arguments redundant if effectively demonstrated that there is no longitudinal health impact over a statistically significant sample size around the plant.

7. Public Engagement

Because rare earth mining and processing has been predominantly taking place in China for the past two decades, the public engagement experience on this sector is relatively limited. The Mountain Pass mine in California is located in a relatively isolated area and although Las Vegas is only 70 miles away and the pit is itself within a mile of a major interstate highway, the physical location of the mine is hidden behind a mountain range. There has been very limited public interest on broad engagement beyond the environmental and social impact assessment on that project’s reopening.

Given the lack of history of engagement, the Kuantan site for the LAMP facility had limited precedent to go by in designing an effective public engagement process. There was an underestimation of the level of resistance from residents and the awakening of fervent environmentalism. In any project where a foreign company is locating a complex industrial site remotely from the source of the mine, there can be some degree of suspicion that comes from what environmental scholars have traditionally called “The NIMBY Syndrome—‘Not in my Back Yard’”. This was clearly the case with the Kuantan site where the perception of the site being located in Malaysia far from the Australian mine raised suspicions among activists which were initially not adequately addressed. For example, there was spread of misinformation about the site not being permitted in Australia for environmental reasons.

However, a proactive policy of public engagement was initially not followed in the case of the LAMP Kuantan site. Indeed, with RE sites, the importance of public engagement has now become more acute because the wider public has started to associate RE with nuclear residues following greater Malaysian activism and their alliances with European and Japanese anti-nuclear groups. Some lessons regarding how to approach public engagement in this particularly polarized context can be learned from the Republic of Korea.

Korea’s Approach to Nuclear Power

An example of how public engagement around an environmentally charged development, similar to the RE mining, has been undertaken at a national level comes from the Republic of Korea’s experience with nuclear power development. Given the high degree of industrialization in Korea and the rapid rise of affluence, there has been concern about environmental fall-out and its impact on quality of life. While recognizing the need for stable energy sources, Koreans showed trepidation with the development of nuclear power. Valentine and Sovacool [12] have documented how the social ethos around nuclear development of South Korea evolved with reference to their history of conflict and their familiarity with experiences in Japan.

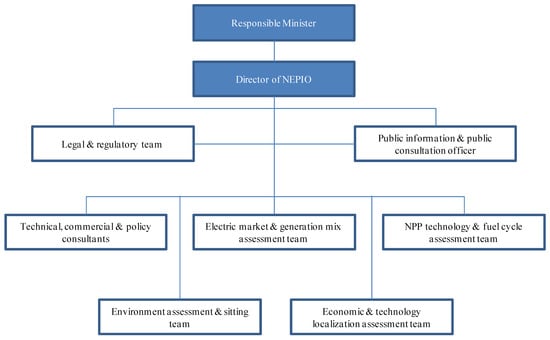

The government’s approach to public engagement and the organizational issues which they covered in this approach have been studied in detail by Choi et al. [13]. Figure 4 provides a schematic of the organizational structure of government communication in the country around 2007 which was suggested through International Atomic Energy Agency (IAEA) guidelines in response to growing environmental resistance to siting of nuclear waste sites in the country.

Figure 4.

Structure of Korean Nuclear Energy Program Implementation organization [13].

After the Japanese tsunami and the ensuing disaster at the Fukushima nuclear plant, Korean public sentiment towards the operating 23 nuclear power plants has deteriorated. An investigation found nuclear plants were using components with faked safety certificates which led to the dismissal of Kim Kyun-seop, the head of state-run Korea Hydro & Nuclear Power Company.

President Park Geun-hye has said that it “would review the role of nuclear power to reflect “social acceptability” in its energy plan due by the end of 2013”. The Korean government had planned to build more reactors to cope with electricity demand it forecast to surge almost 60 per cent by the year 2027 but surveys show nuclear power is becoming increasingly unpopular. Sixty-three per cent of respondents to a March 2013 survey by pollster Hangil Research said they consider domestic reactors “unsafe”, compared with 54 per cent in a poll conducted a year earlier by the non-profit Korean Federation for Environmental Movement [14].

Given the previous sound record of the Korean government managing public engagement in this sector, it will be an important case to follow of how the current discontent on nuclear power and siting of power plants is managed by the government as a means of drawing lessons for countries like Malaysia.

8. Conclusions

The social component of sustainability can be defined as those components relating to the physical and psychological well-being of humans within society. In this case we include both the individual and social network elements which could be separated, for example under a “five capitals” approach (i.e., manufactured, financial, social, human and natural capitals). Recently, socio-environmental issues of the health impacts of rare earth processing (from both radioactive and non-radioactive contamination) in areas of China have been raised as a major concern. The question of whether sites that have been contaminated by RE mineral processing can be adequately rehabilitated to allow for other uses post-mining from a social sustainability perspective is linked to perceptions of health risks and the technical ability to rehabilitate contaminated sites. The potential for such impacts has also been one of the key drivers behind protests at the Lynas Corporation plant in Malaysia, partially fueled by the negative experiences that a previous RE processing site on the peninsula.

Social resistance to RE mining also stems from arguments about environmental justice and how processing sites are often more difficult to get permitted in developed countries and hence lead to their location in developing countries. Indeed, environmental regulation was one key reason for the closure of RE operation in the USA. Much of the resistance to the Lynas plant in Malaysia questioned whether the company’s choice to situate the site in Malaysia was for purely economic factors or because social resistance in Australia would have been far too great. Assuaging such perceptions of differentiated standards and environmental justice concerns will be central in preventing escalation of socio-environmental conflict.

On the other hand, there can be a social argument made for RE development as a contribution towards developing a “green economy”. The Malaysian industrial park in Kuantan has made this case in their branding of the initiative as part of a national planning effort towards sustainability. Social perceptions of risk at the site level thus need to be balanced with broader national trajectory towards sustainable technology development in determining the social sustainability of the RE sector. Furthermore, recycling and service sector opportunities for this sector have much potential for development as technologies improve for micro-retrieval of the metals. There is likely to be less social resistance as efforts towards a circular economy for RE develops alongside their green economic uses in products.

Acknowledgments

Support for this article was provided by the Academy of Sciences, Malaysia. Special thanks to Gillian Cornish and Artem Golev for research support provided for this article.

Conflicts of Interest

The author declares no conflict of interest.

References

- Ichihara, M.; Harding, A. Human rights, the environment and radioactive waste: A study of the Asian rare earth case in Malaysia. Rev. Eur. Community Int. Environ. Law 1995, 4, 1–14. [Google Scholar] [CrossRef]

- Zhongxin, Y.; Ge, B.; Chenyu, W.; Zhongqin, Z.; Xianjiang, Y. Geological features and genesis of the Bayan Obo REE ore deposit, Inner Mongolia, China. Appl. Geochem. 1992, 7, 429–442. [Google Scholar] [CrossRef]

- Rare-earth Mining in China Comes at a Heavy Cost for Local Villages. The Guardian. 7 August 2012. Available online: http://www.theguardian.com/environment/2012/aug/07/china-rare-earth-village-pollution (accessed on 18 December 2013).

- Cai, P.; Wilkins, G. China Cites Environment to Justify Grip on Rare Earths. The Sydney Morning Herald. 21 June 2012. Available online: http://www.smh.com.au/business/china-cites-environment-to-justify-grip-on-rare-earths-20120620-20omc.html (accessed on 16 December 2013).

- Tse, P.-K. China’s Rare-Earth Industry: U.S. Geological Survey Open-File Report 2011–1042. Available online: http://pubs.usgs.gov/of/2011/1042 (accessed on 18 December 2013).

- Bourakima, A. Production of Rare Earth Oxides: Assessment of the Environmental Impact of Two Rare Earth Mines. University College of London: London, UK, 2011. Available online: http://www-research.cege.ucl.ac.uk/Posters/2011PosterFair/33_Bouorakima_Alandji.pdf (accessed on 18 December 2013).

- Tharumarajah, R.; Koltun, P. Cradle to Gate Assessment of Environmental Impact of Rare Earth Metals. In 7th Australian Conference on Life Cycle Assessment, Melbourne, Australia, 9–10 March 2011; CSIRO, Ed.; Australian Life Cycle Assessment Society Melbourne: Victoria, Australia, 2011; p. 5. [Google Scholar]

- Binnemans, K.; Jones, P.T.; Blanpain, B.; Van Gerven, T.; Yang, Y.; Walton, A.; Buchert, M. Recycling of rare earths: A critical review. J. Clean. Prod. 2013, 51, 1–22. [Google Scholar]

- Paul, J.; Campbell, G. Investigating Rare Earth Element Mine Development in EPA Region 8 and Potential Environmental Impacts; United States Environmental Protection Agency: Washington, DC, USA, 2011; p. 11. [Google Scholar]

- Hirano, S.; Suzuki, K.T. Exposure, metabolism, and toxicity of rare earths and related compounds. Environ. Health Perspect. 1996, 104, 85–95. [Google Scholar]

- Najem, G.R.; Voyce, L.K. Health effects of a thorium waste disposal site. Am. J. Public Health 1990, 80, 478–480. [Google Scholar] [CrossRef]

- Valentine, S.V.; Sovacool, B.K. The socio-political economy of nuclear power development in Japan and South Korea. Energy Policy 2010, 38, 7971–7979. [Google Scholar]

- Choi, S.; Jun, E.; Hwang, I.; Starz, A.; Mazour, T.; Chang, S.; Burkart, A.R. Fourteen lessons learned from the successful nuclear power program of the Republic of Korea. Energy Policy 2009, 37, 5494–5508. [Google Scholar]

- Nuclear Power Turns off South Koreans after Fukushima. South China Morning Post. 10 August 2013. Available online: http://www.scmp.com/news/asia/article/1295684/nuclear-power-turns-south-koreans (accessed on 18 December 2013).

© 2014 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).